Wet spraying machine of concrete drier

A concrete spraying machine and concrete technology, which is applied in earthwork drilling, shaft lining, tunnel lining, etc., to achieve the effects of increasing sealing performance, reducing dust generation, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

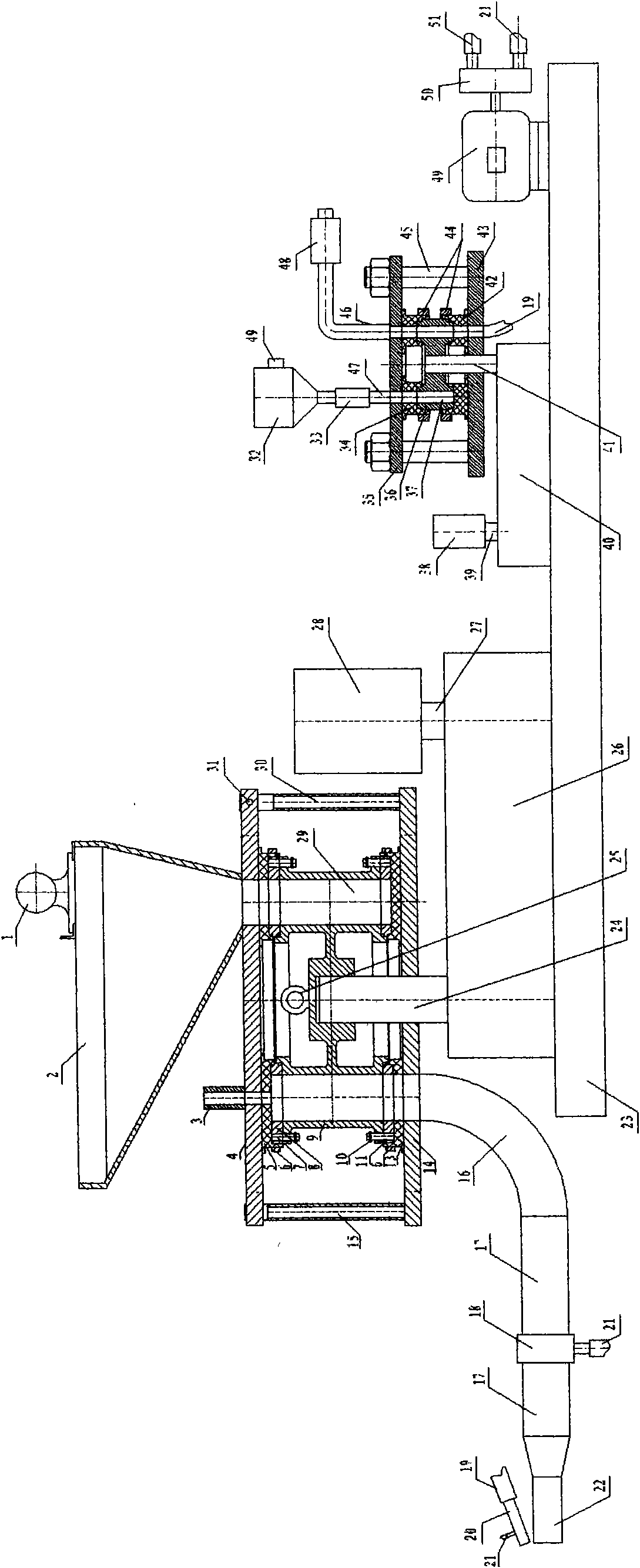

[0029] figure 1 It is a schematic diagram of the structure of the concrete dry material wet spraying machine

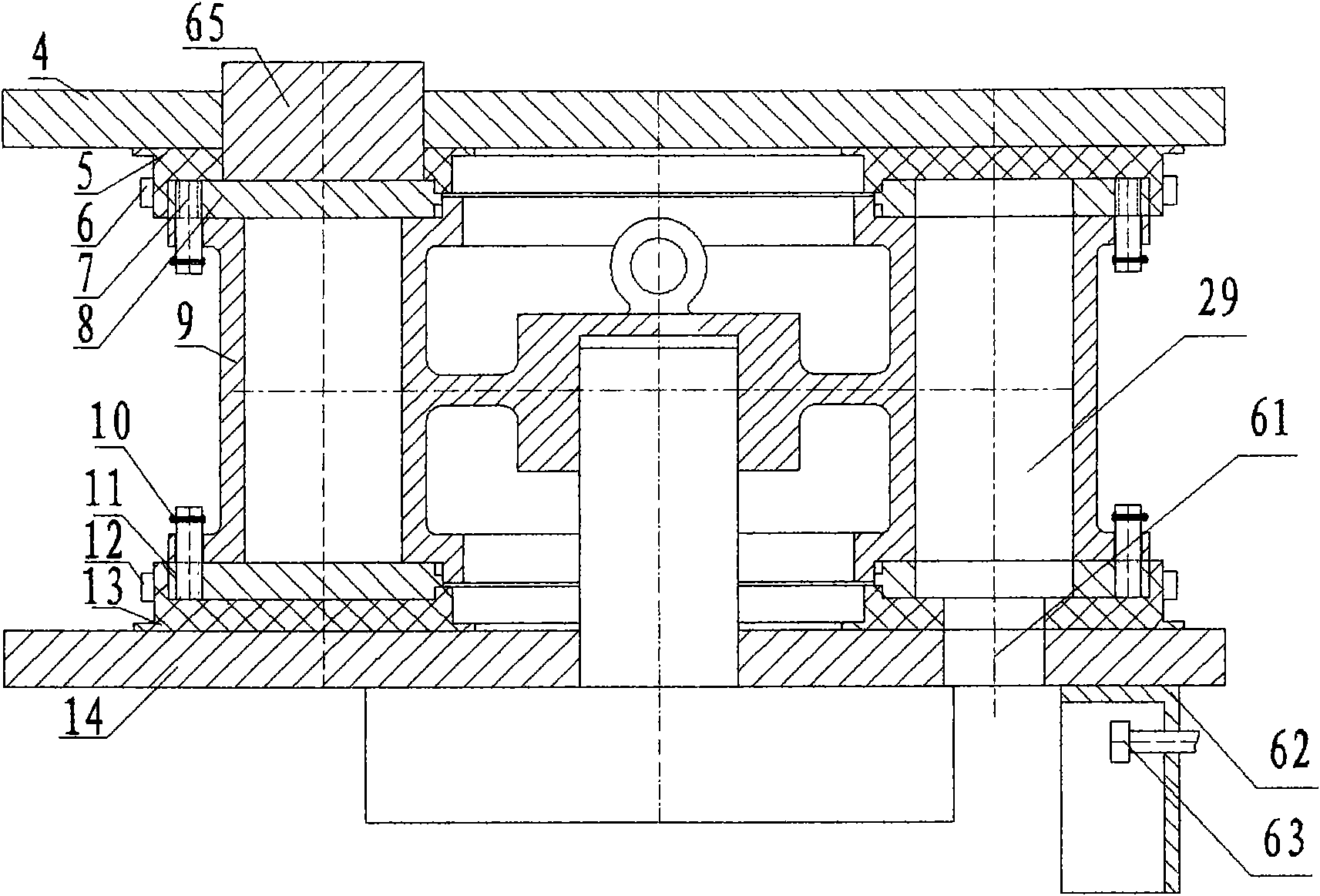

[0030] figure 2 It is a schematic diagram of the structure of the residual air hole dust removal box of the sprayer in the concrete dry material wet spraying machine

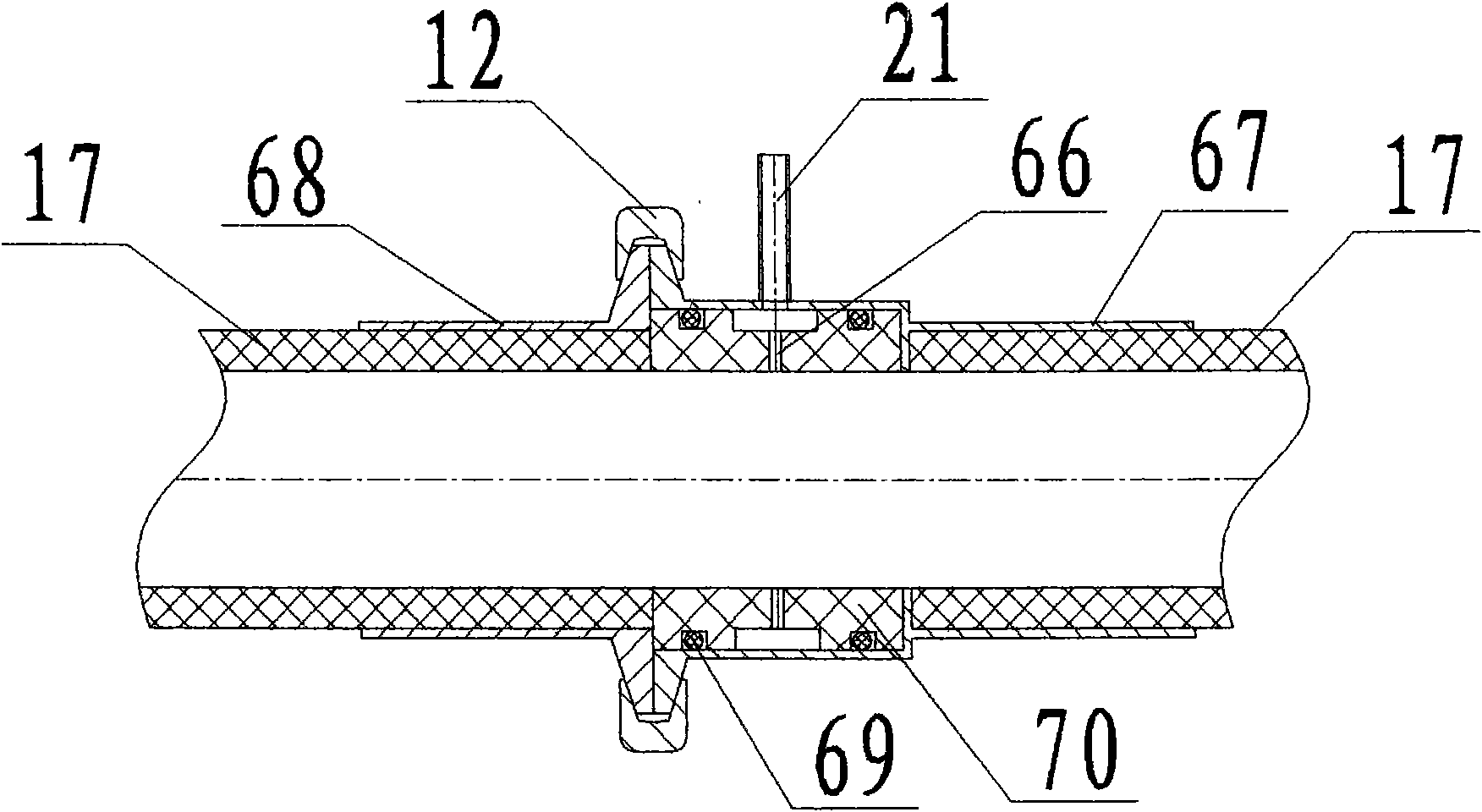

[0031] image 3 It is a schematic diagram of the structure of the water ring in the middle of the concrete delivery hose in the concrete dry material wet spraying machine

[0032] Figure 4 It is a schematic diagram of the structure of the rotor lifting mechanism, the large pressure plate and the hopper turning in the concrete dry material wet spraying machine

[0033] Figure 5 It is a schematic cross-sectional structure diagram of the rubber friction plate of the sprayer and the powder accelerator additive in the concrete wet spraying unit

[0034] Figure 6 It is a schematic diagram of the left end structure of the feeding port of the upper rubber friction plate and the large pressure plate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com