Anti-impact protection structure for box type beams of hull

A technology of protective structure and box girder, applied in the direction of hull, hull frame, hull parts, etc., to achieve the effect of improving strength, high utilization rate and good anti-explosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

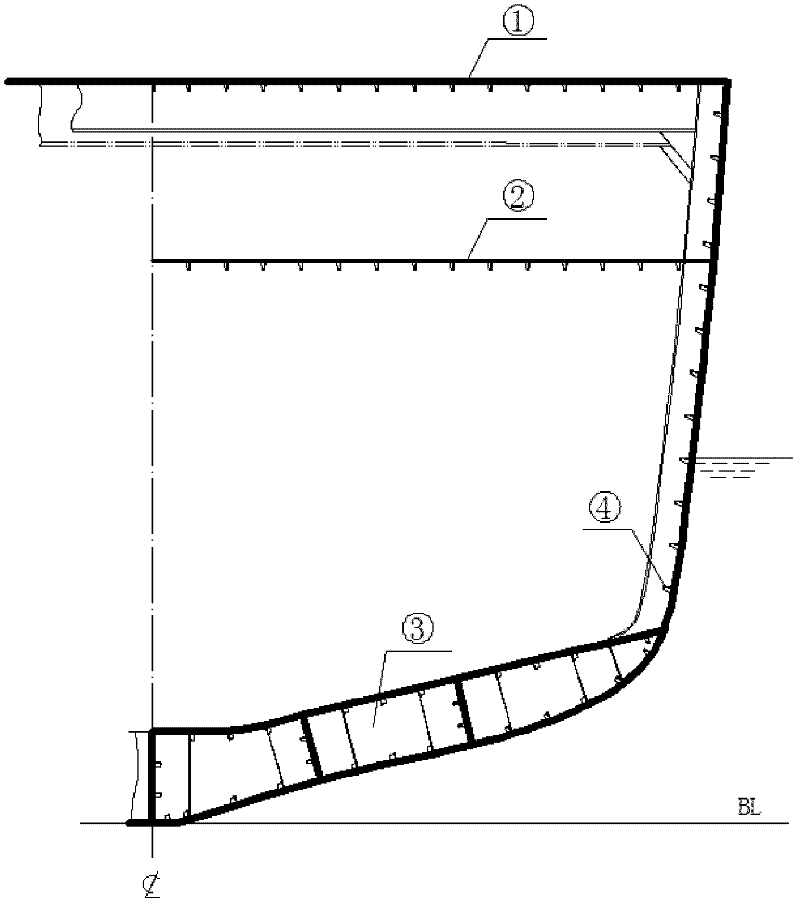

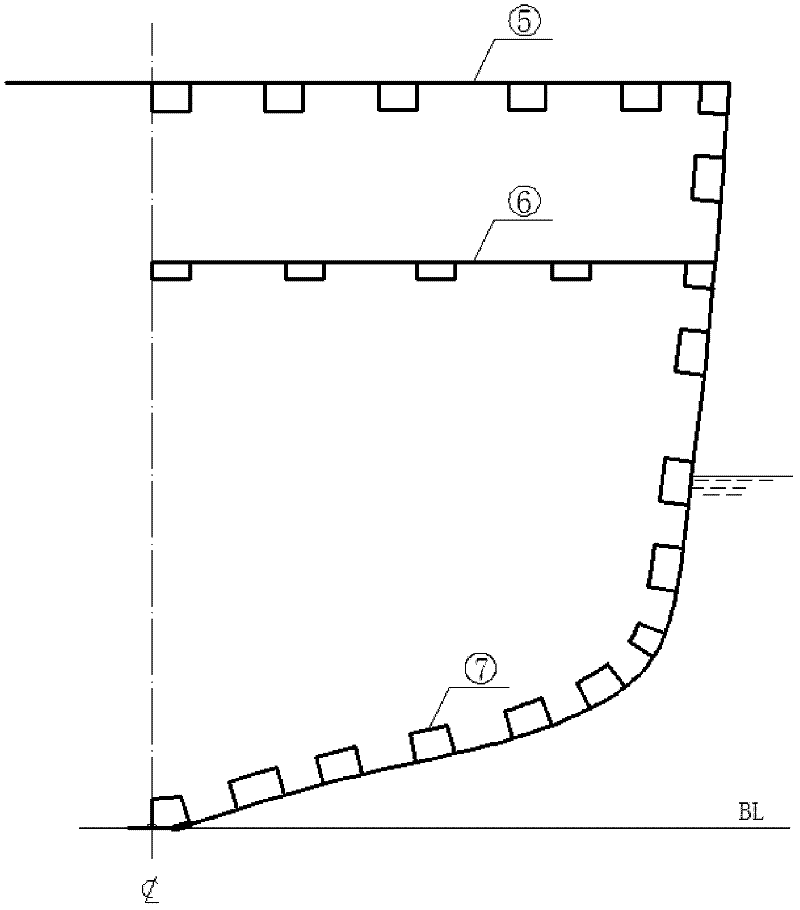

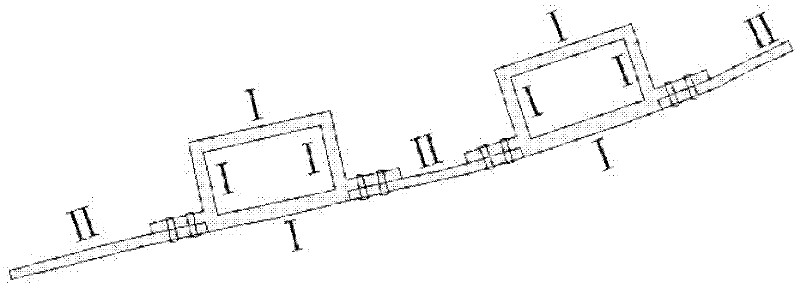

[0045] Here, a small ship with bulbous flat steel as the longitudinal reinforcement member is taken as an example, such as figure 1 As shown, the box girder structure is improved, and the improvement is as follows figure 2 As shown, to improve the anti-knock and anti-shock performance of the ship, the specific implementation is as follows:

[0046] 1. Calculate the cross-sectional area of the original ship

[0047] Draw the cross-sectional view of the hull according to the calculation software, and calculate the cross-sectional area including the longitudinal reinforcement members. If you are designing a new ship, you can skip this step if you are not improving the ship type.

[0048] 2. Determine the thickness and quantity of the box girder

[0049] According to the calculated cross-sectional area of the original ship, the plate thickness of the box girder is allocated without exceeding this area, and the number of box girders and the plate thickness of the composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com