Liquid crystal display panel structure and manufacturing method thereof

A technology of liquid crystal display and manufacturing method, which is applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems of uneven cell thickness around the liquid crystal display panel, unable to maintain a proper gap between glass substrates, and glass spacers gathering together, etc. Achieve the effect of improving display quality, good support strength and conductivity, good support strength and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

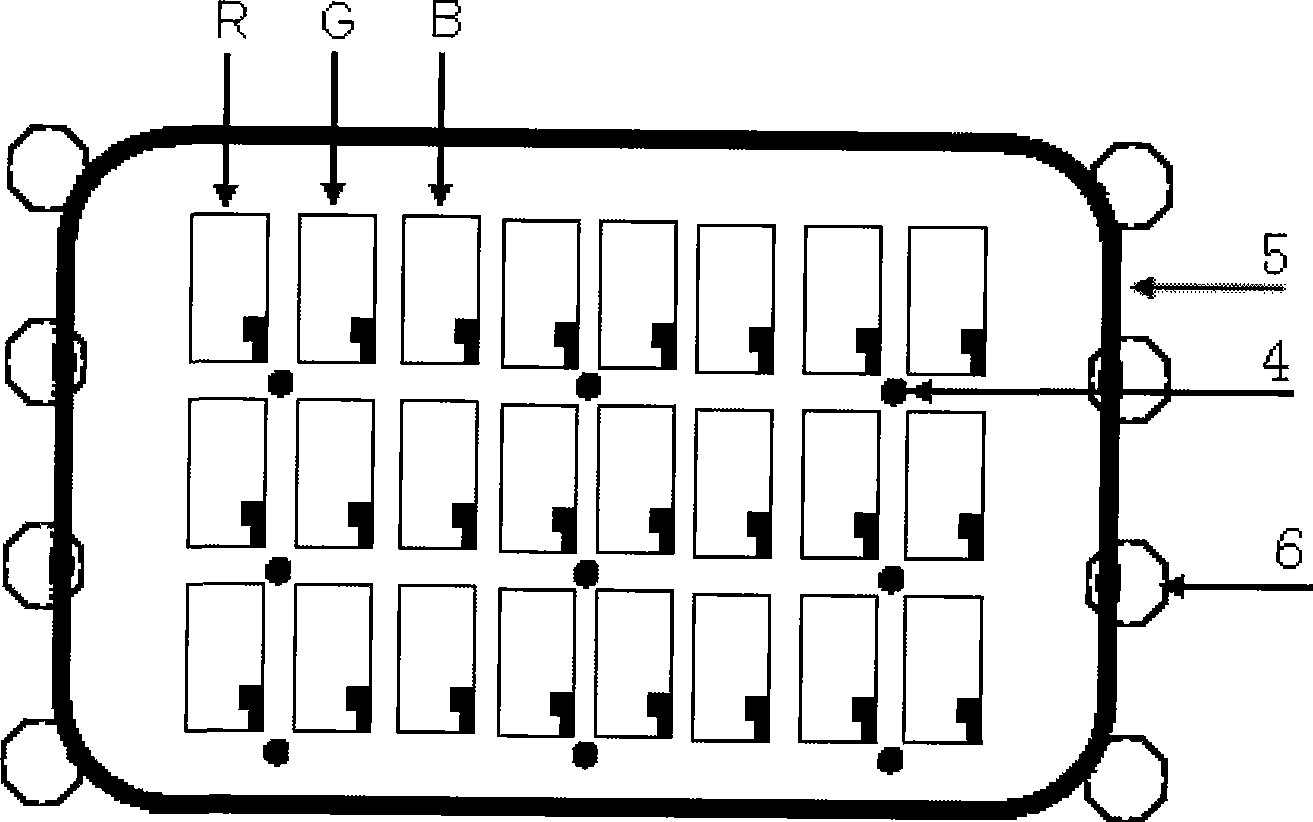

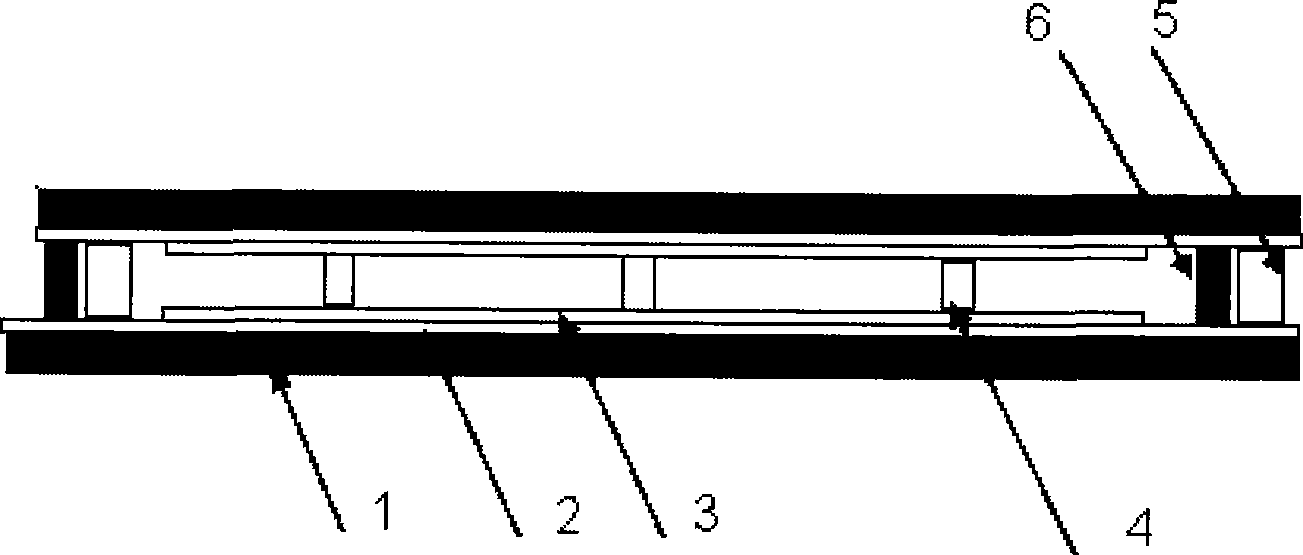

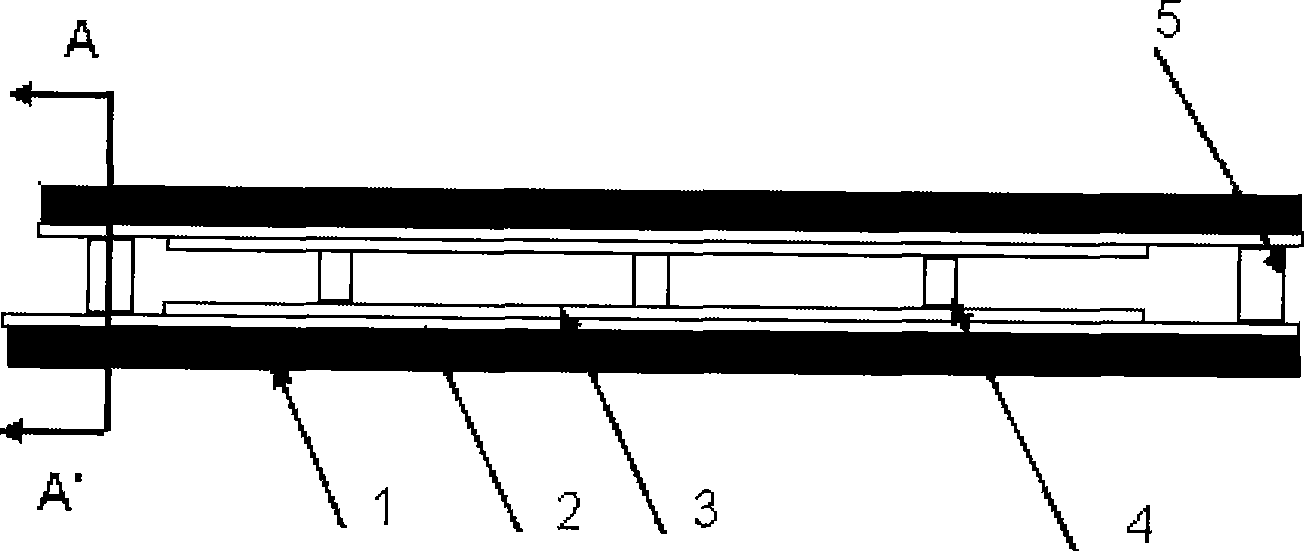

[0034] In order to solve the problem of poor display quality of the liquid crystal display panel in the prior art, the present invention provides a liquid crystal display panel. Such as Figure 5 , Figure 6 As shown, the liquid crystal display panel includes: a color filter substrate and an array substrate disposed opposite to each other, support spacers 4 are evenly distributed in the display area on the side of the color filter substrate opposite to the array substrate, and the color filter substrate is opposite to the array substrate. The edge of one side is bonded to the edge of the array substrate opposite to the color filter substrate through the sealant 5 to form a closed area, and the closed area is filled with liquid crystals.

[0035] In order to provide good support strength and electrical conductivity between the color filter substrate and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com