Anti-knock rubber O-ring material and preparation method thereof

An O-ring and rubber technology is applied in the field of anti-knock rubber O-ring materials and its preparation, which can solve the problems of easy foaming of rubber O-rings, loss of sealing performance of products, cracks in rubber sections, etc., and achieve good anti-knock performance. , high hardness, small compression deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

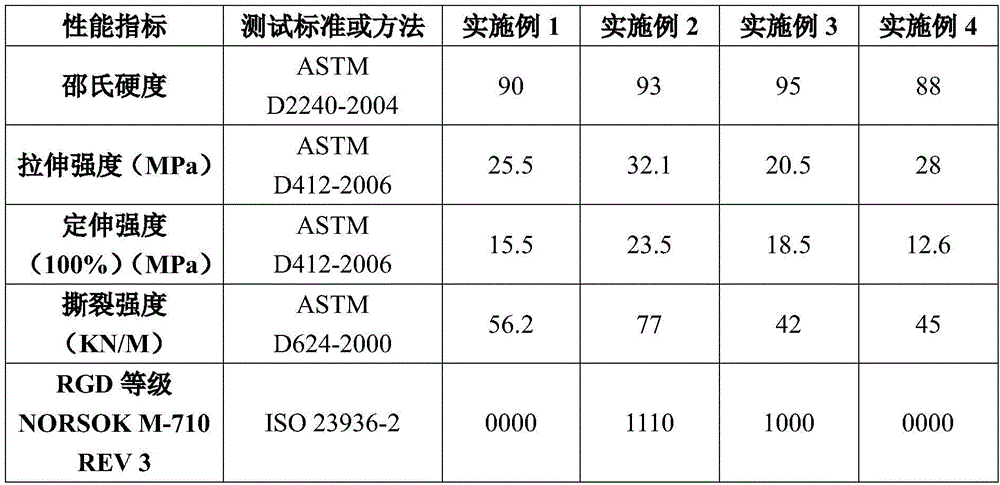

Examples

Embodiment 1

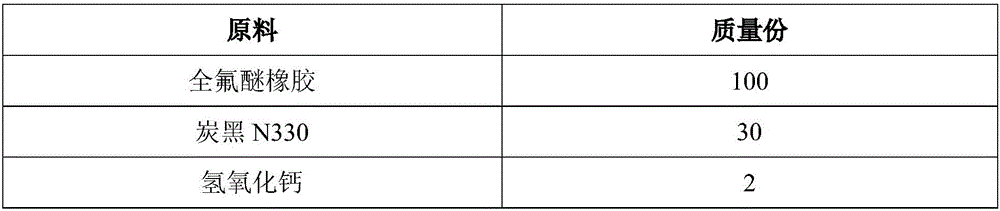

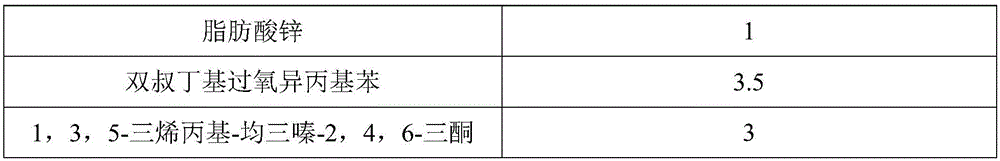

[0048] The raw material composition of an antiknock rubber O-ring material is shown in Table 1:

[0049] Table 1 The raw material composition table of a kind of antiknock rubber O-ring material

[0050] raw material

Embodiment 2

[0052] The raw material composition of an antiknock rubber O-ring material is shown in Table 2:

[0053] Table 2 The raw material composition table of a kind of antiknock rubber O-ring material

[0054] raw material

Embodiment 3

[0056] The raw material composition of an antiknock rubber O-ring material is shown in Table 3:

[0057] Table 3 The raw material composition of a kind of antiknock rubber O-ring material

[0058] raw material

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com