Machine for automatically charging gunpowder into firecrackers

An automatic charging machine and firecracker technology, which is applied to fireworks, offensive equipment, weapon types, etc., can solve the problems of low measurement accuracy of loaded gunpowder, affecting the quality of firecrackers, low production efficiency, etc., to reduce human damage and compact structure. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

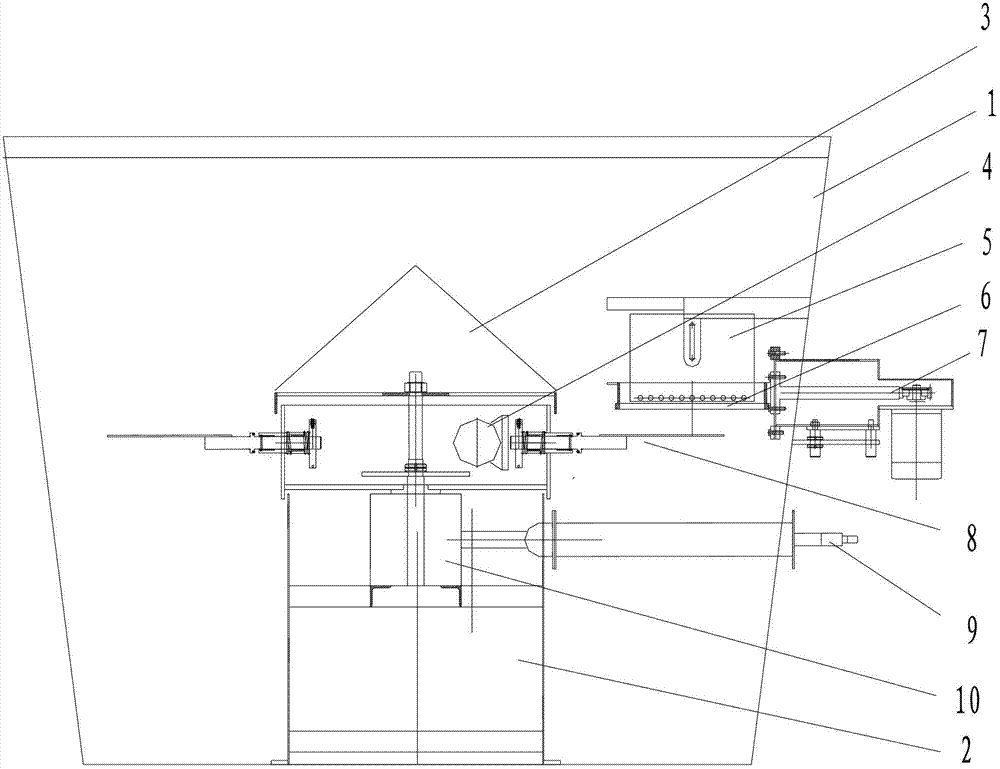

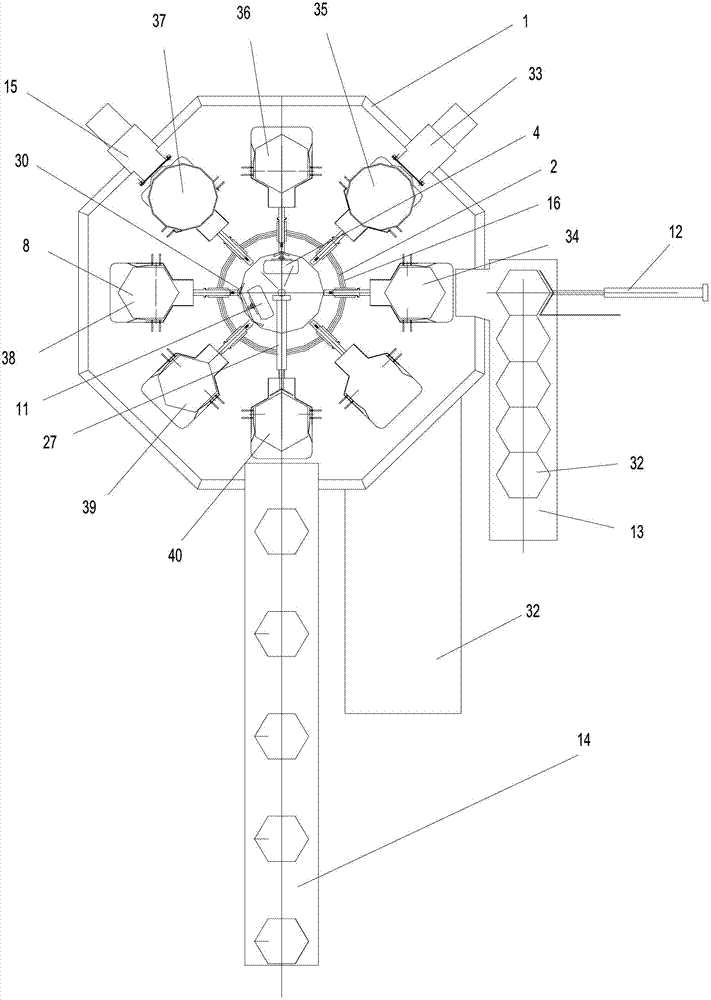

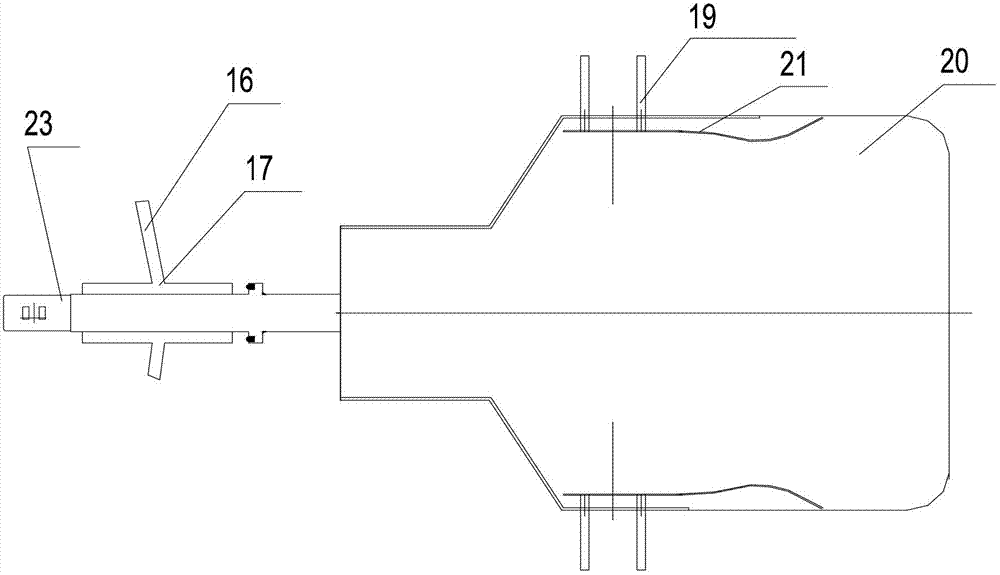

[0026] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , the frame 2 is provided with a precision divider or a sheave clearance mechanism 10, the input end of the precision divider or the sheave clearance mechanism 10 is connected with a power input shaft 9, and the output end of the precision divider or the sheave clearance mechanism 10 is connected There is a turntable 16, the frame 2 is provided with a dust cover 3 covering the turntable 16, eight workpiece pallet units 8 are arranged on the outer circumference of the turntable 16, and the structure of each workpiece pallet unit 8 is that the base 17 is installed on the On the turntable 16, a rotating shaft 23 is provided in the base 17, and one end of the rotating shaft 23 is provided with a workpiece tray 20, and an adjusting screw 19 is used on both sides of the workpiece tray 20 to be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com