Patents

Literature

133results about How to "Fast opening and closing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

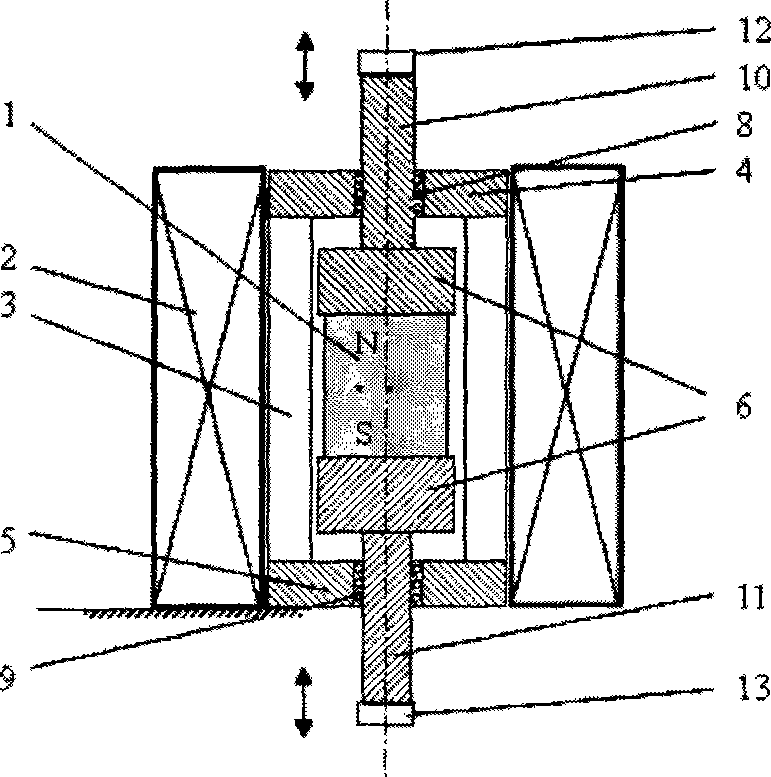

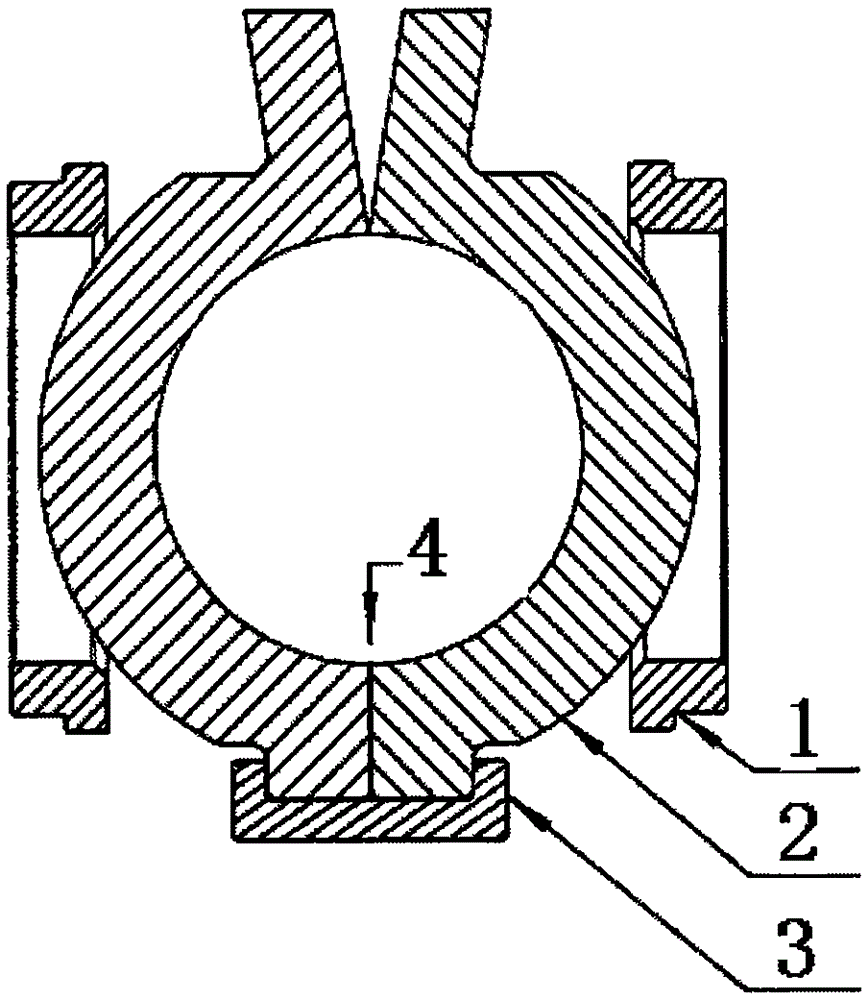

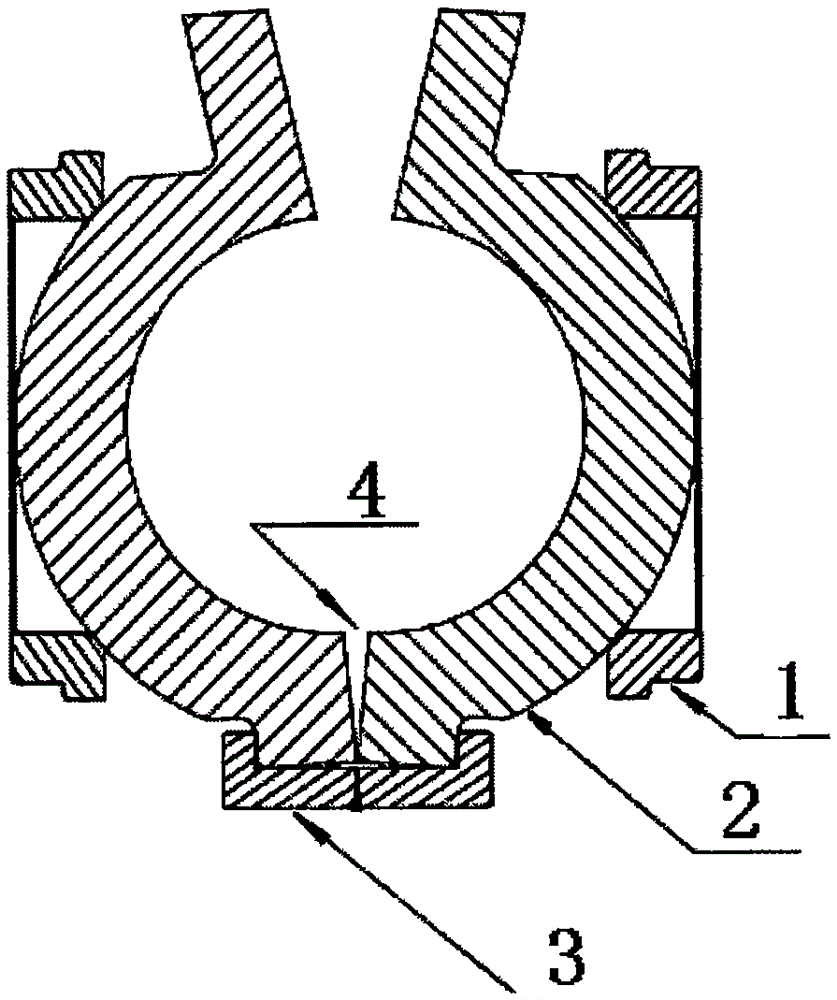

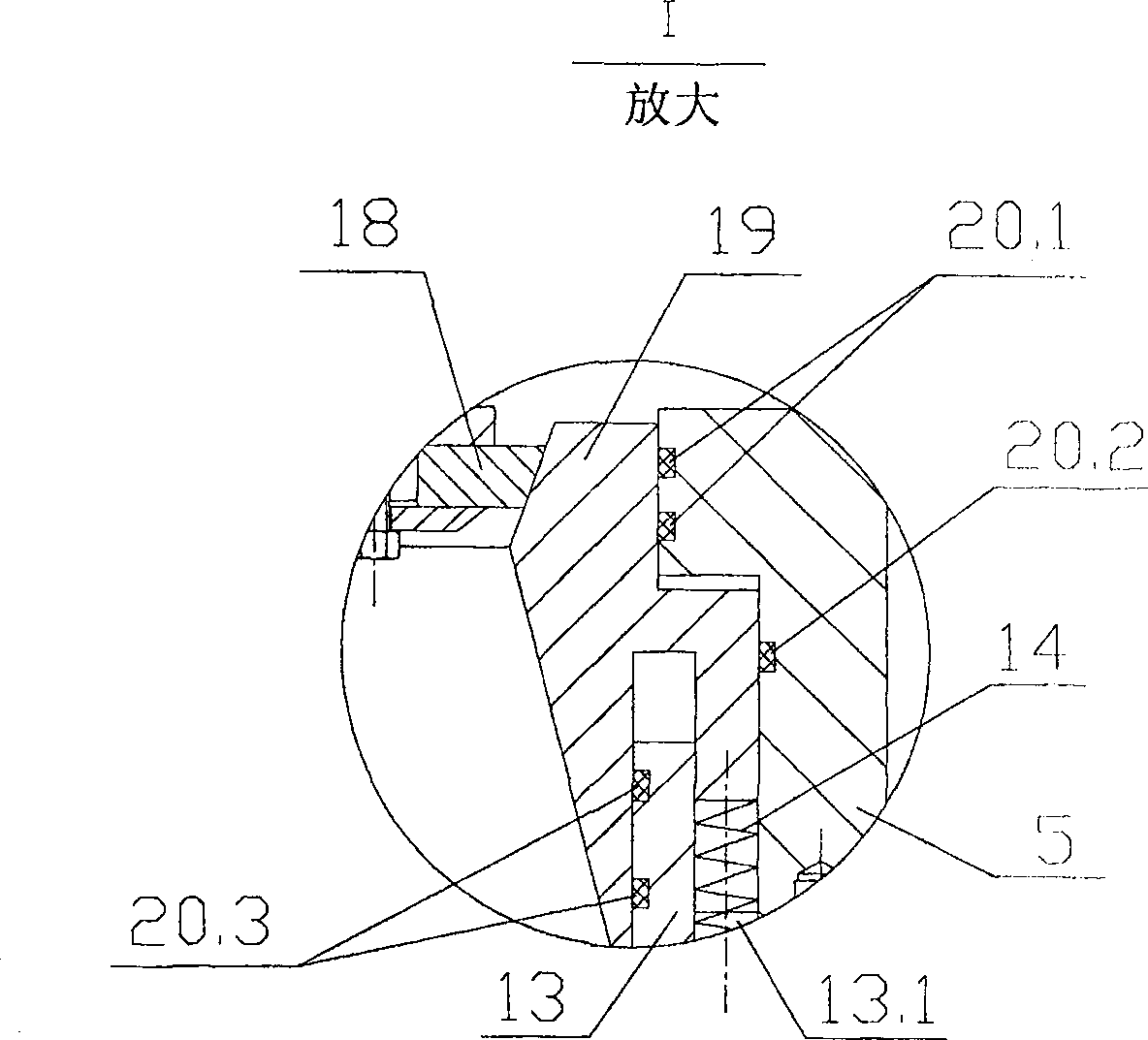

Electromagnetic permanent magnet combined driving apparatus

InactiveCN101425733AStable opening and closingFast opening and closingSwitch power arrangementsHigh-tension/heavy-dress switchesEngineeringElectromagnetic coil

The invention relates to an electromagnetic permanent composite driving switch and an impact mechanism, comprising a permanent-magnet moving body, an electromagnetic coil, a sleeve, an upper magnetic conductive cover, a lower magnetic conductive cover, an upper force output bar and a lower force output bar, wherein the permanent-magnet moving body is arranged in a space formed by the upper magnetic conductive cover, the lower magnetic conductive cover and the sleeve which are fixedly connected, the permanent-magnet moving body is also arranged inside the electromagnetic coil, the spacing between the upper magnetic conductive cover and the lower magnetic conductive cover is more than the length of the permanent-magnet moving body, the upper and the lower ends of the permanent-magnet moving body are respectively and fixedly connected with the upper force output bar and the lower force output bar, the upper force output bar and the lower force output bar respectively penetrate through through holes in the middle of the upper magnetic conductive cover and the lower magnetic conductive cover, the permanent-magnet moving body is a single permanent magnet and a permanent ferromagnetic composite body, and the permanent ferromagnetic composite body is formed by a permanent magnet and a ferromagnet which are fixedly connected. The invention has the advantages that the overall structure is simple, the instantaneous suction without partial vibration can be formed, the opening and the closing are stable, the opening and closing actions are quick and accurate without fluctuation, and the power failure stability retention at the opening or the closing position can be realized.

Owner:SHANGHAI JIAO TONG UNIV

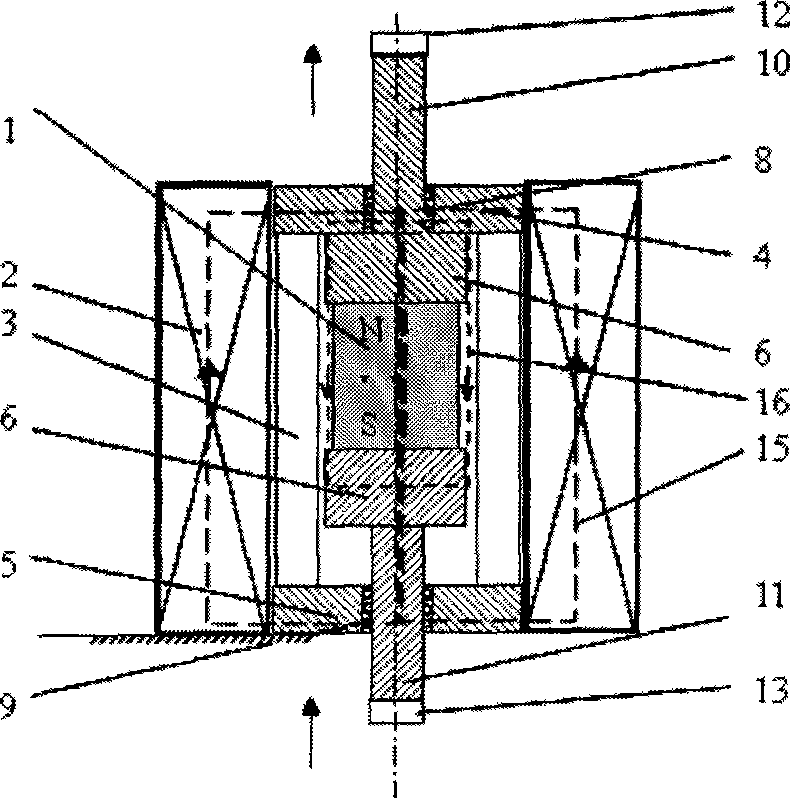

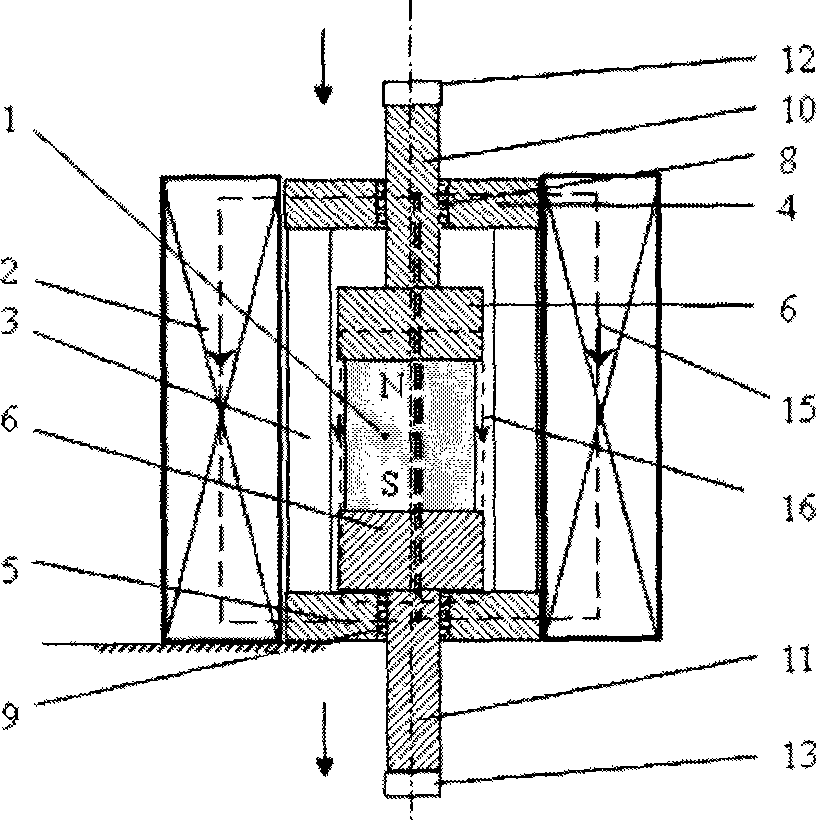

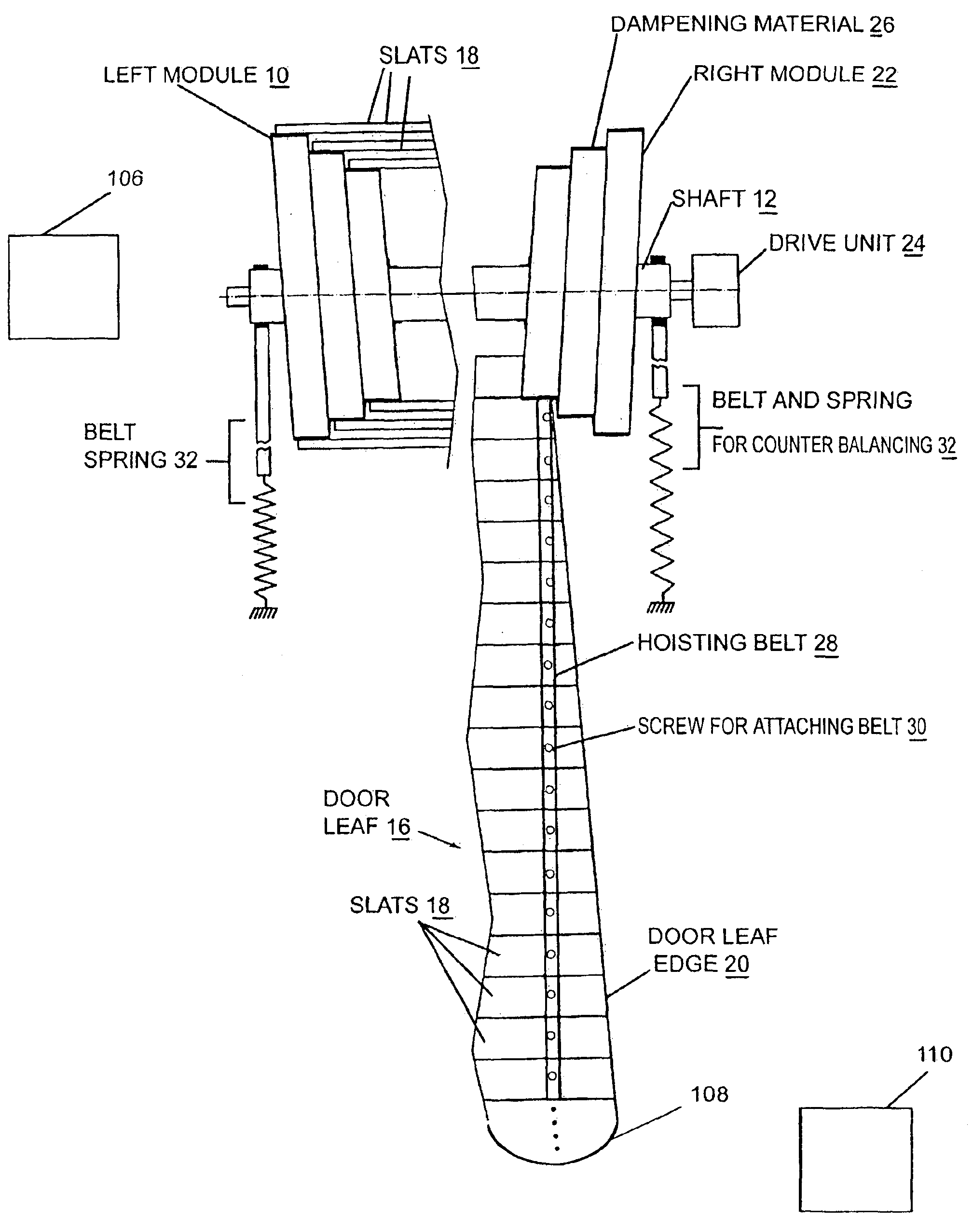

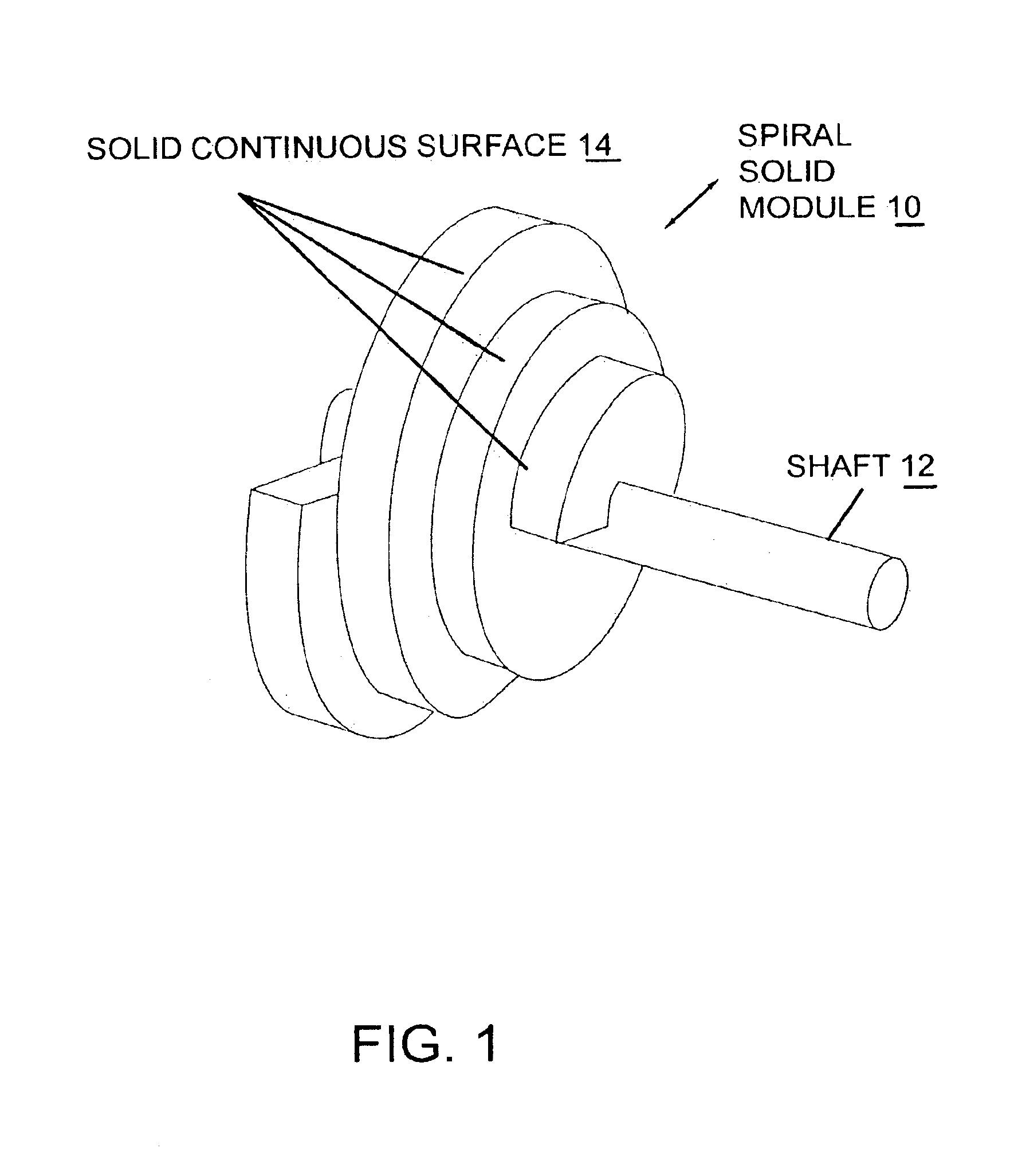

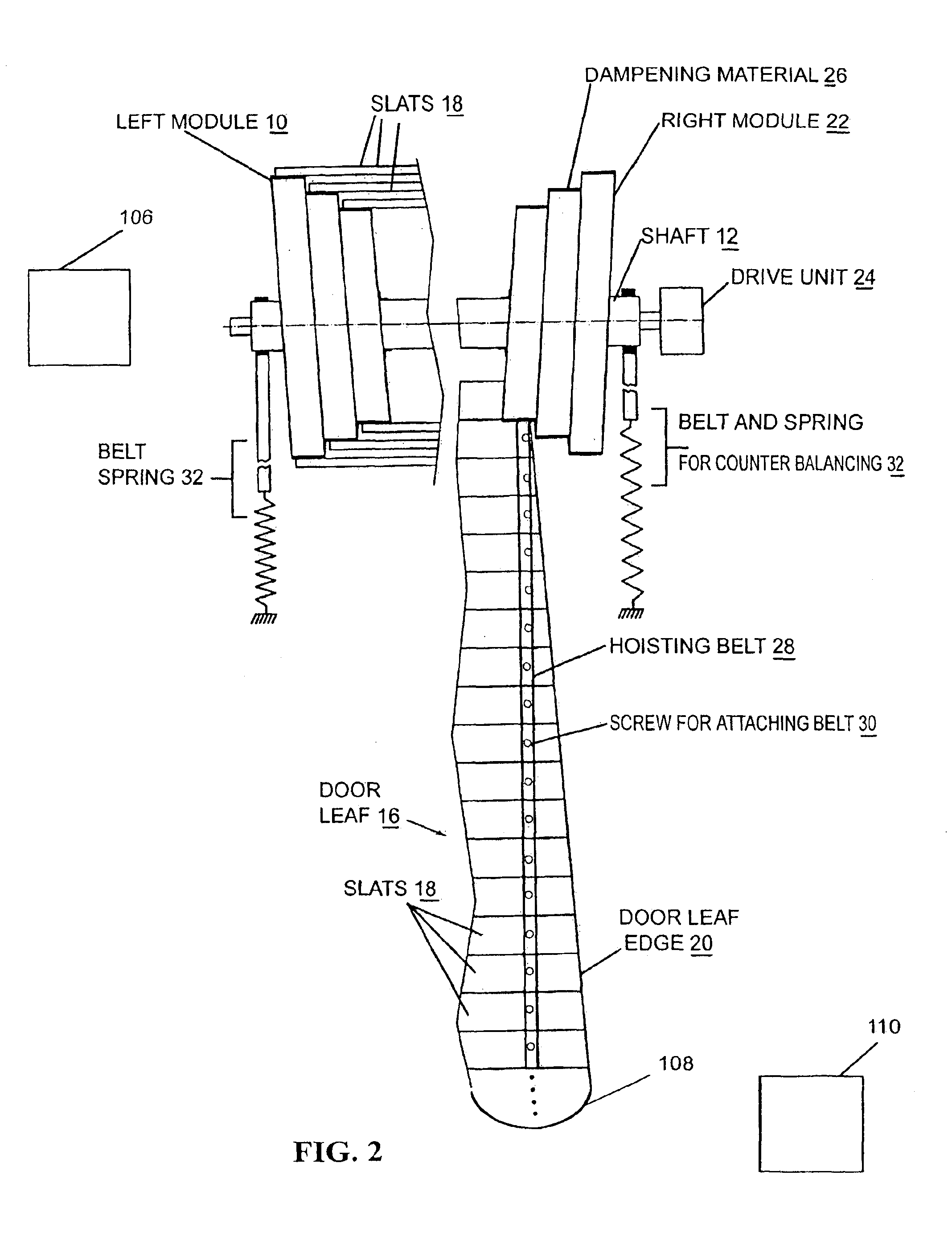

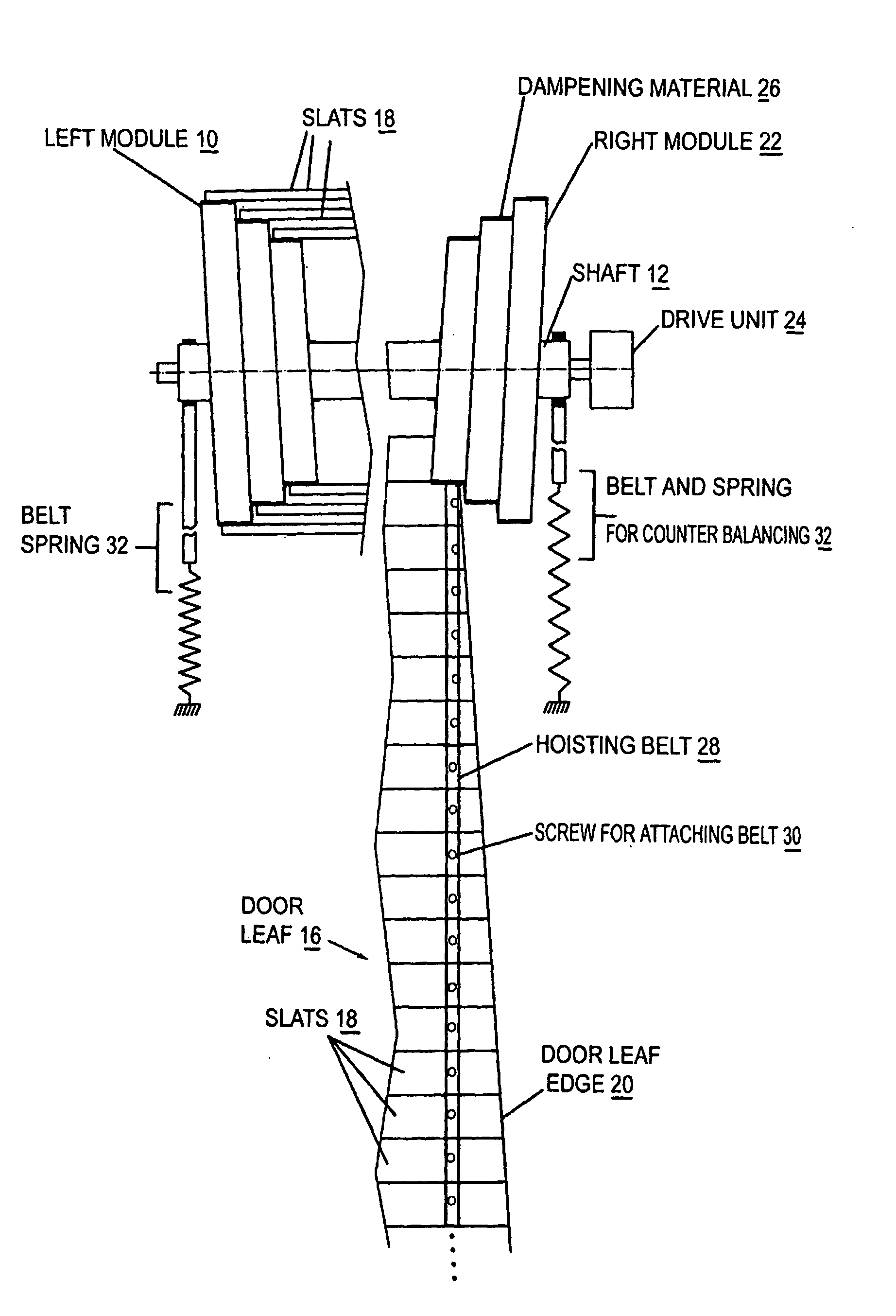

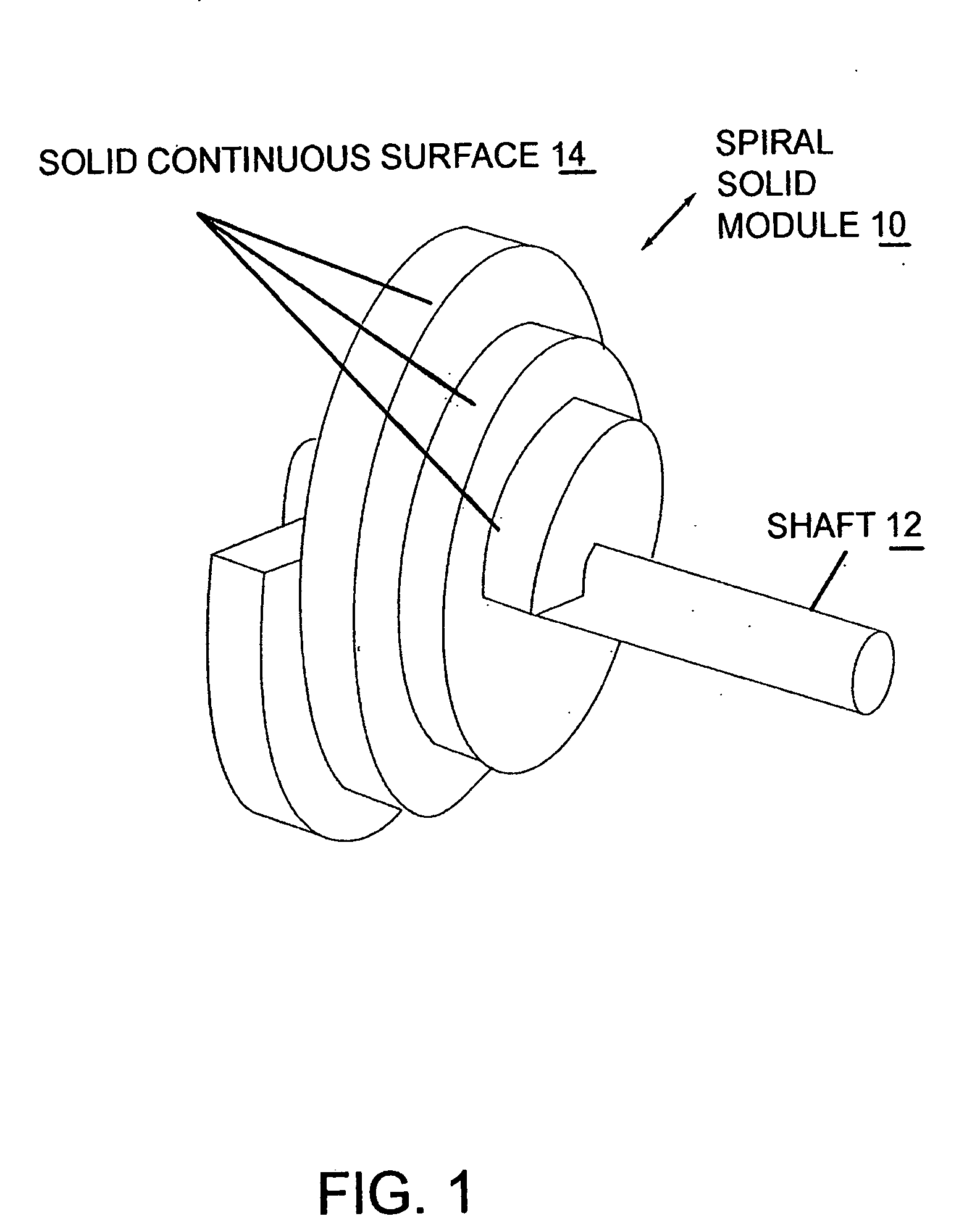

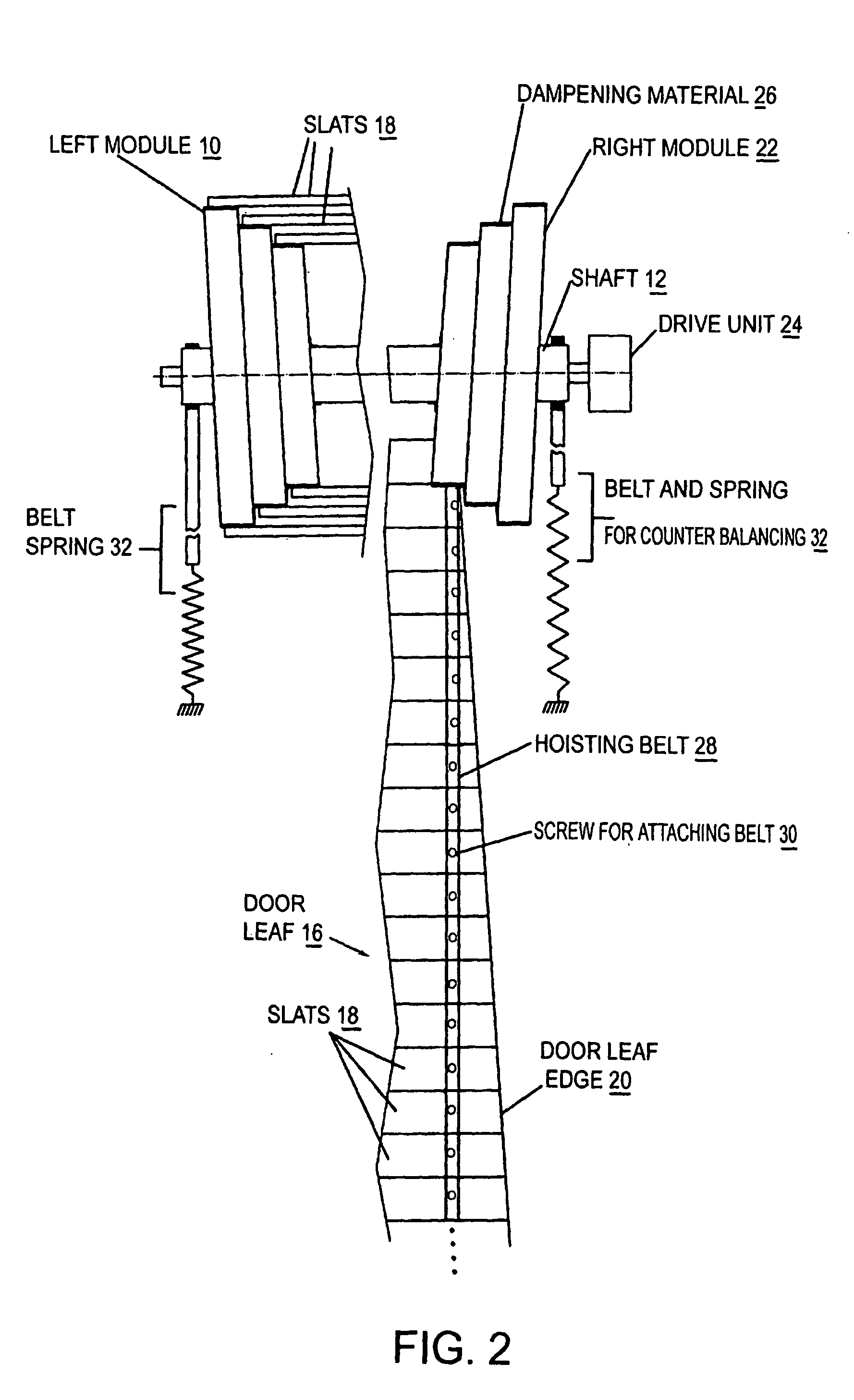

Rollup door with rollable door leaf

InactiveUS6883577B2Noise minimizationMinimizing wearScreensShutters/ movable grillesEngineeringMechanical engineering

A rollup door comprising a door leaf of increasing width from top to bottom and having a narrower part on the top and a wider part on the bottom, and flexibility in the rolling direction; channels for guiding the door; and two modules for rolling and unrolling the door leaf so that a number of leaf layers do not come in contact. The modules are situated on each side of the door, have the same center axes and are successive radially enlarged so that on opening and closing of the door, the narrower and wider parts of the leaf engage the smaller and larger parts respectively of the modules.

Owner:ASSA ABLOY ENTRANCE SYST

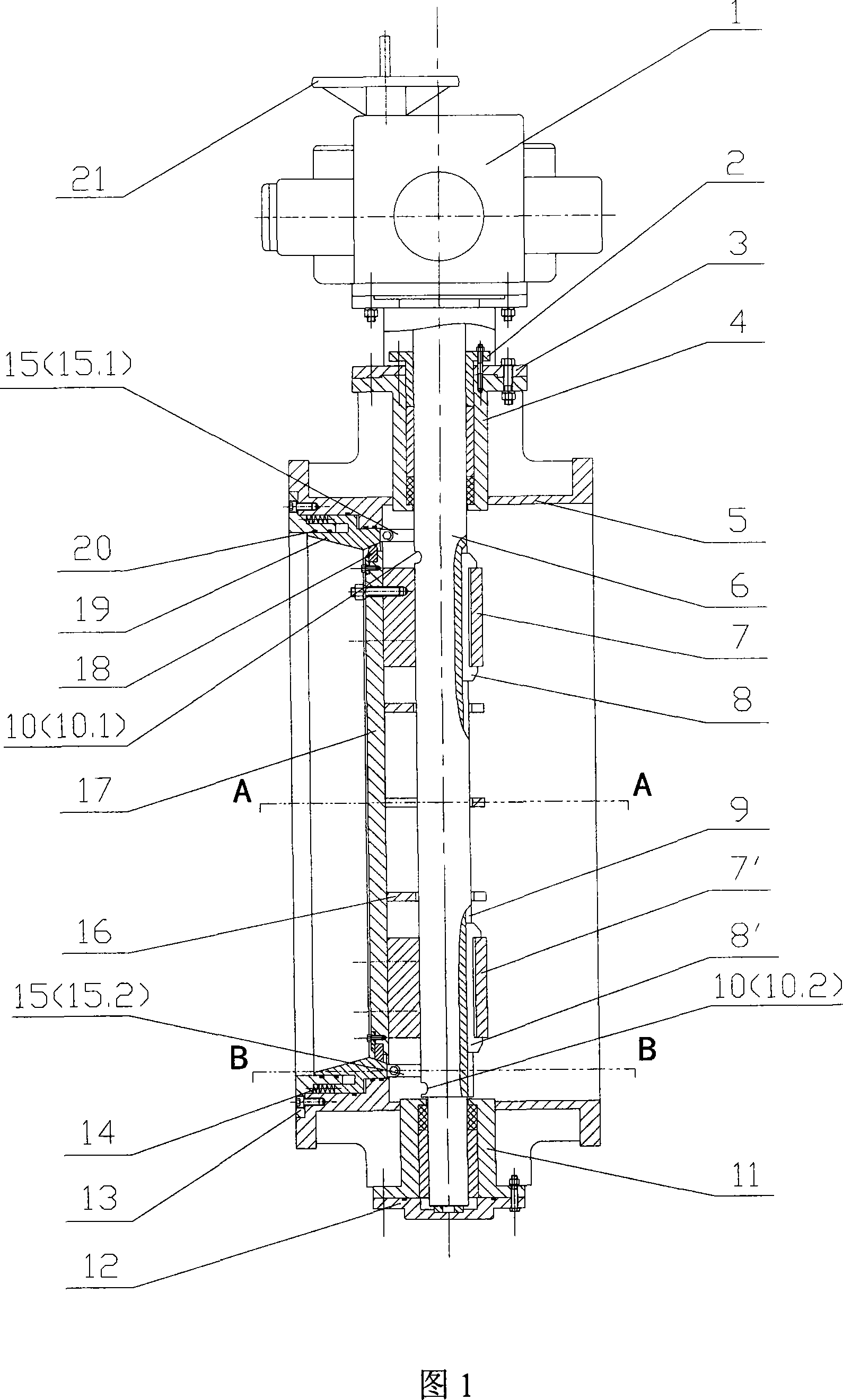

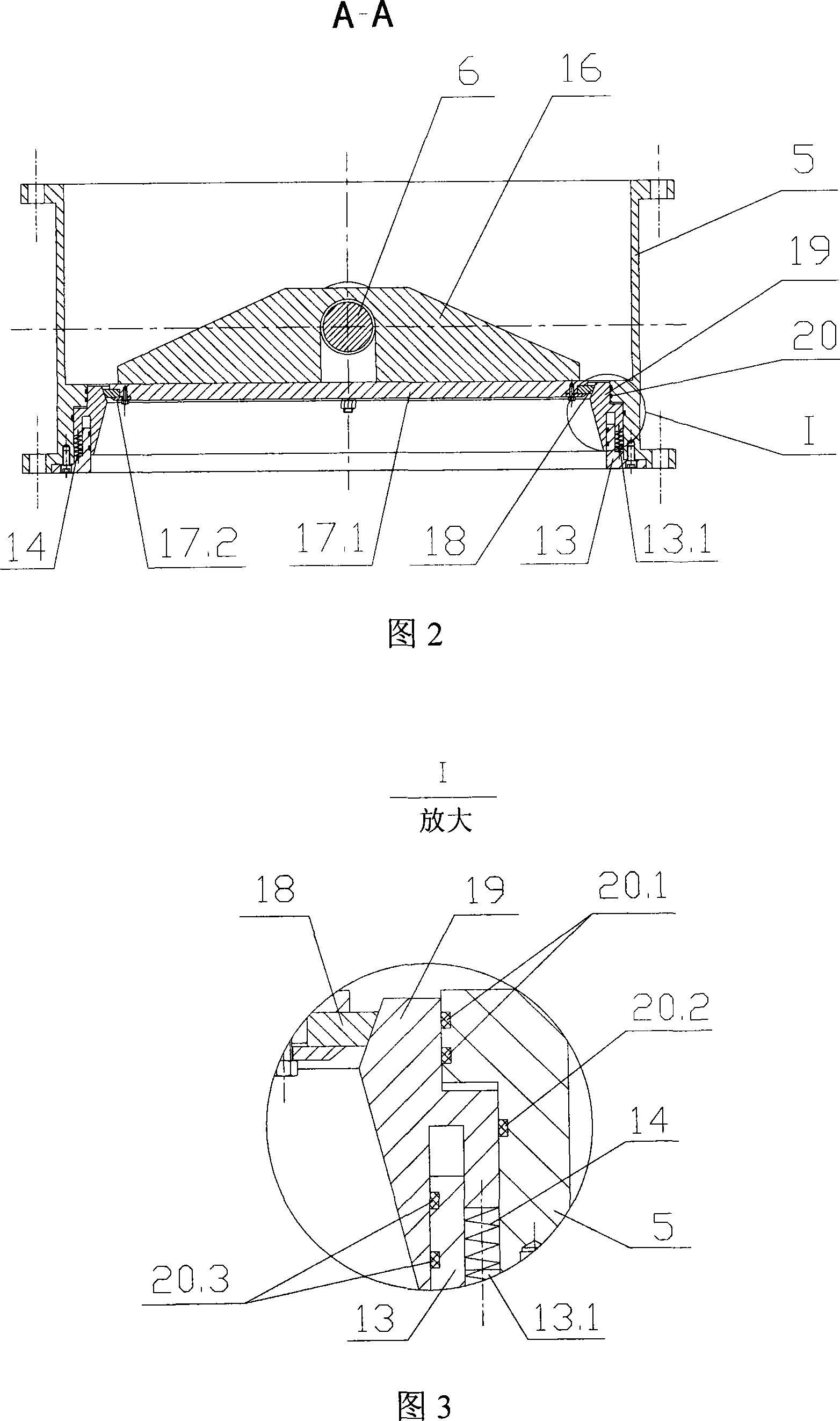

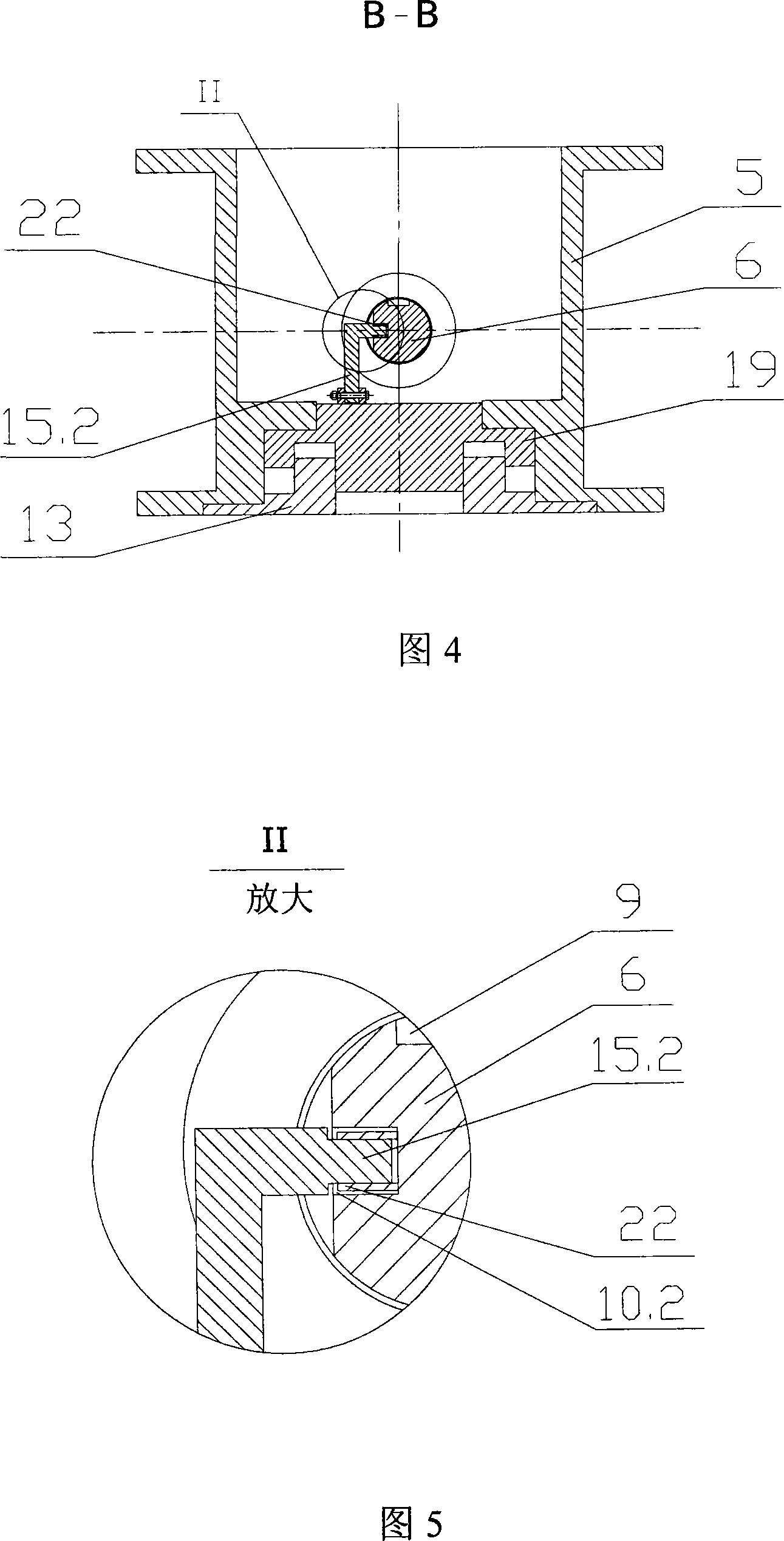

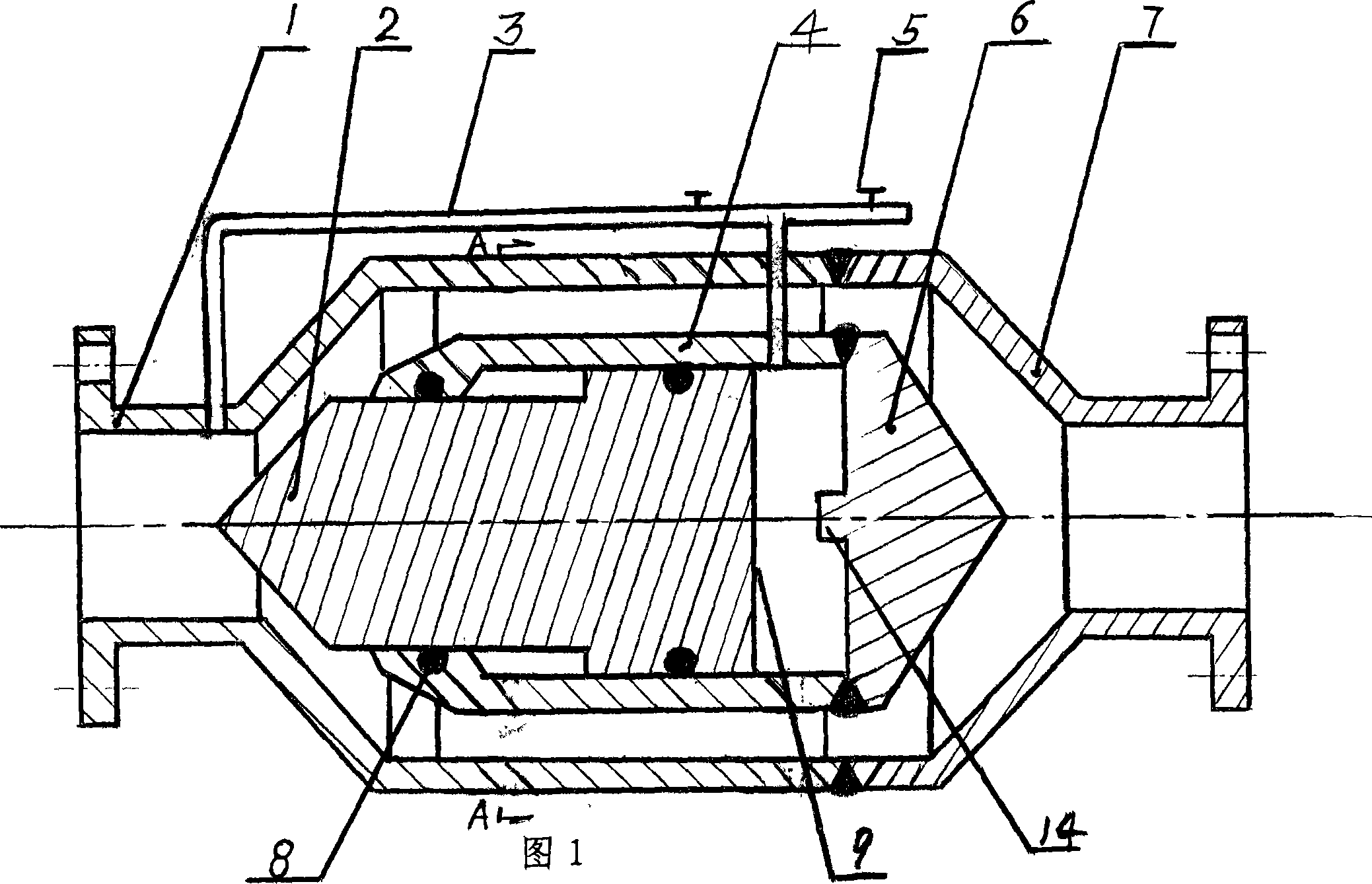

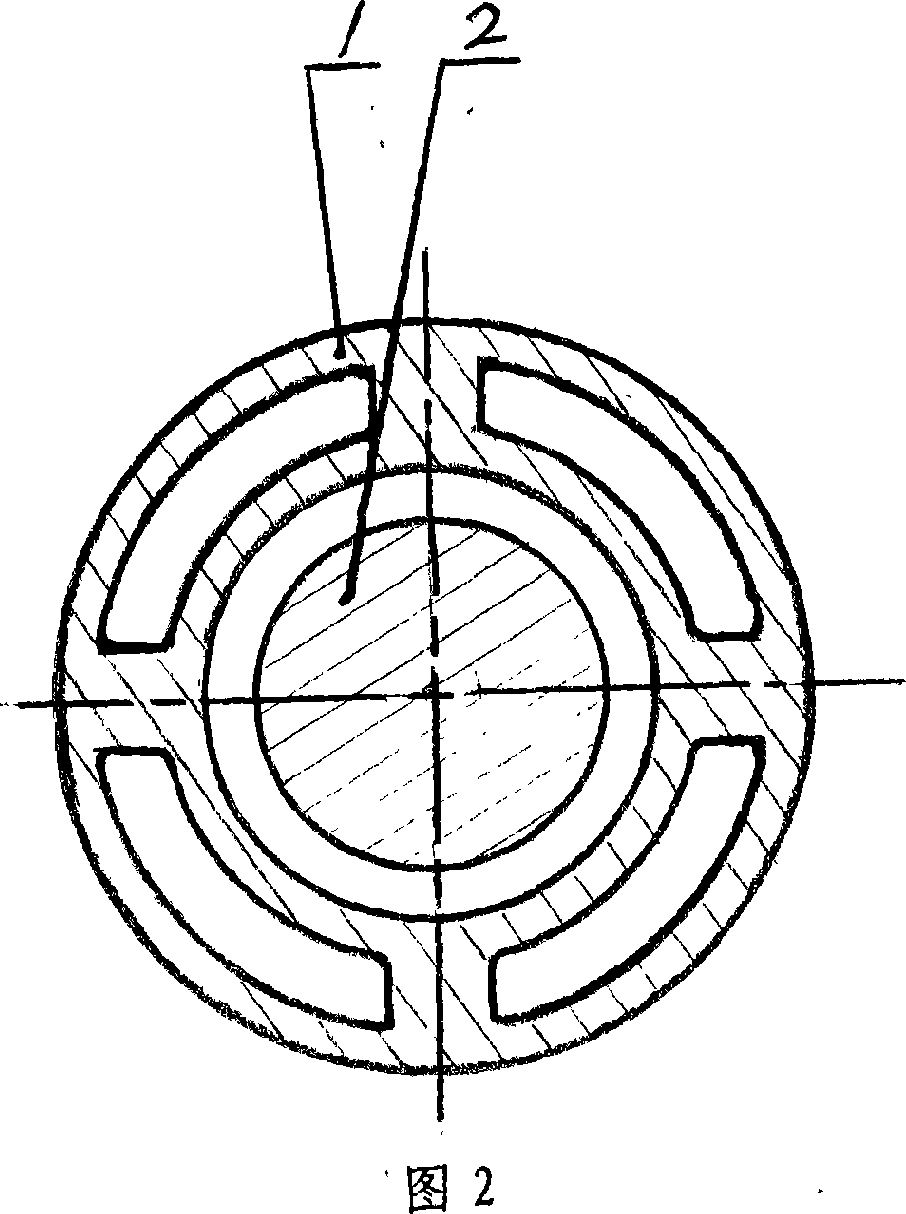

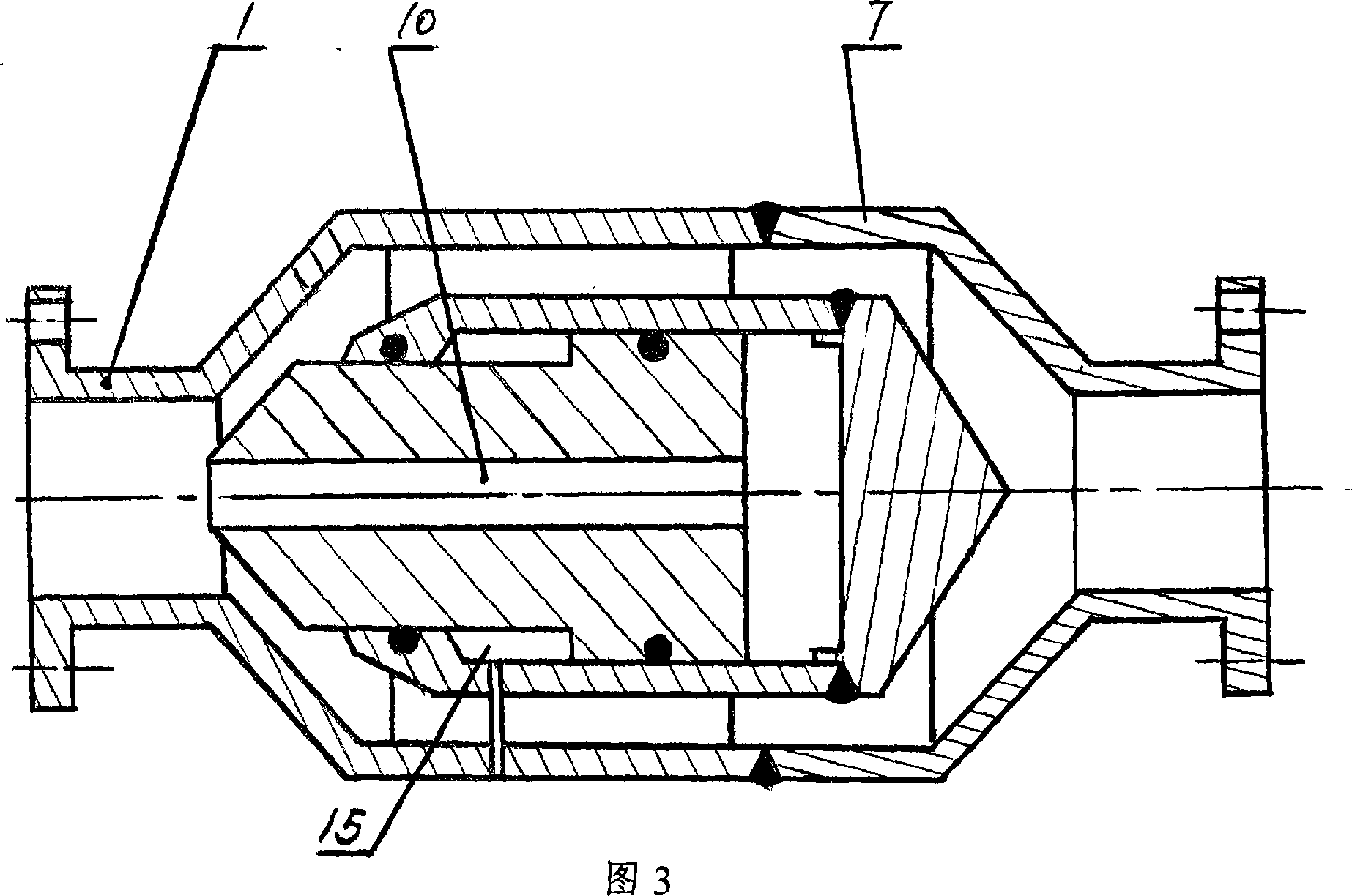

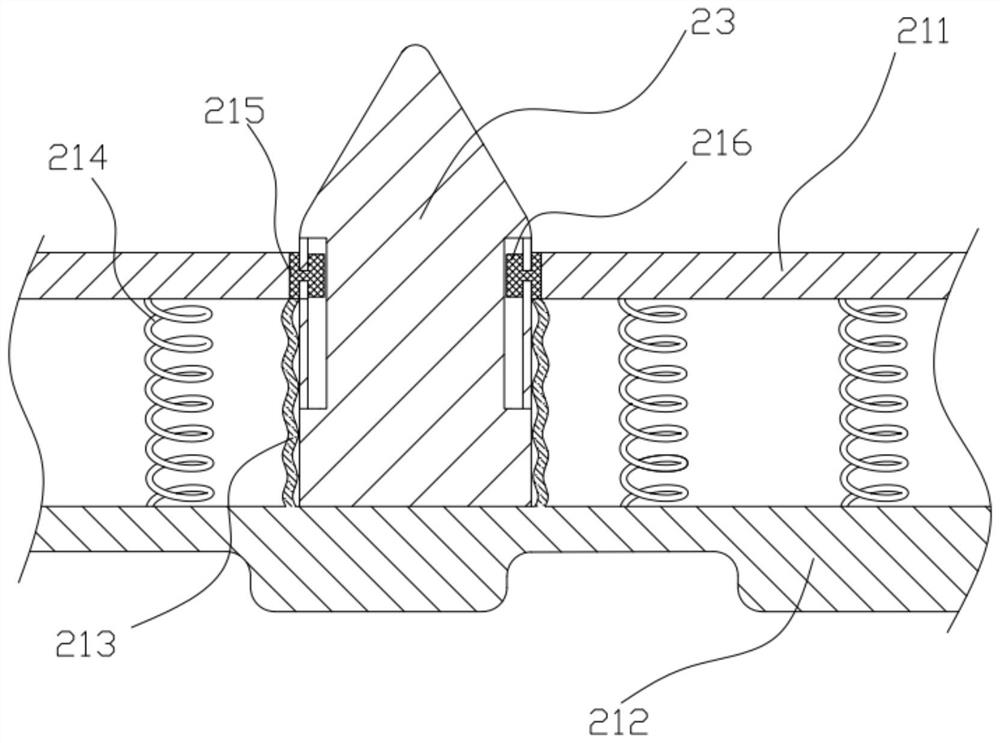

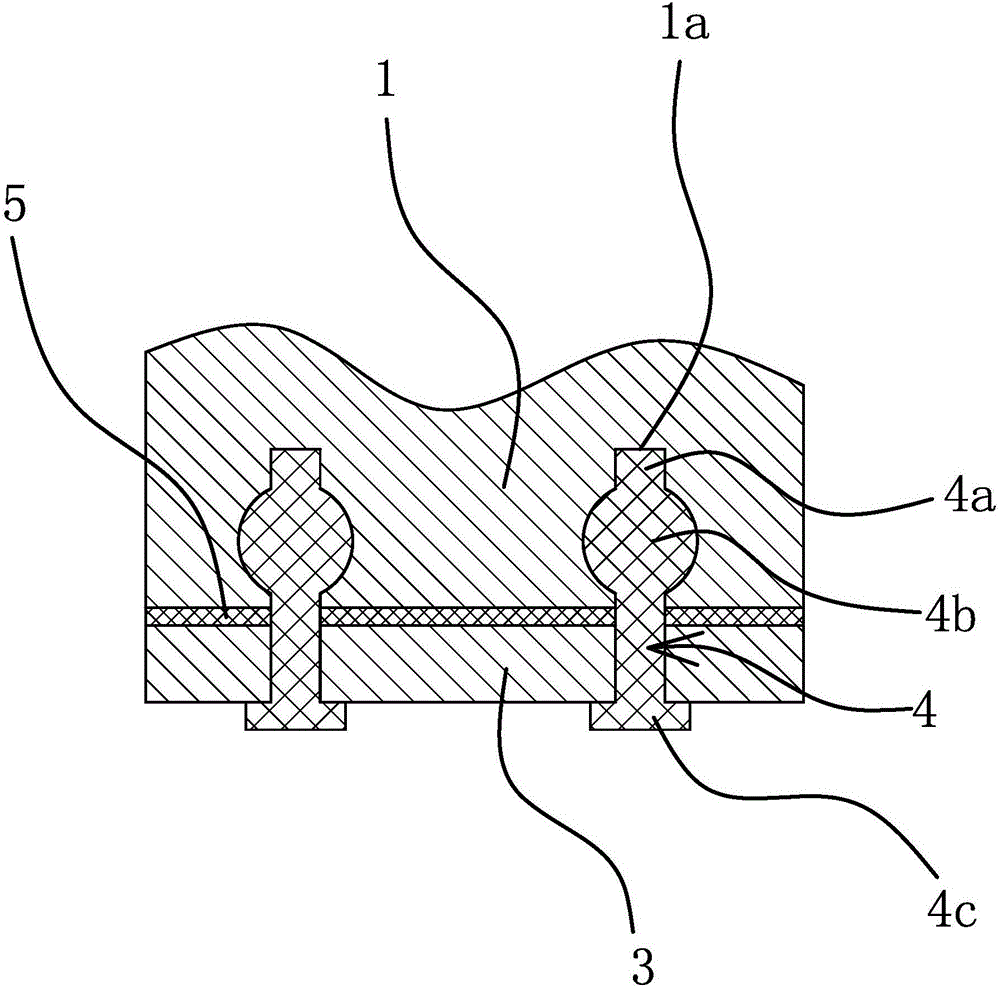

Non-abrasion hard-sealing butterfly valve

The invention relates to a non-loss hard seal butterfly valve which consists of a valve body, a valve rod, a butterfly plate and a valve seat. The invention is characterized in that the valve seat can be a movable valve seat which can axially move along the inner wall of the valve body; one side of the valve body is provided with a lateral body; seal rings are arranged both between the valve seat and the valve body, between the valve seat and the lateral body; a seal component is fixed on a butterfly plate frame; moving fit clearances are reserved between an inner side surface and an outer side surface of the valve seat, between the valve body and the lateral body; a spring is arranged between an outer end surface of the valve seat and the lateral body, an inner end surface of the valve seat is connected with the valve rod through a push rod; an inner end surface of the lateral body is provided with a spring; an upper end and a lower end of the valve rod are respectively provided with a curved slot; an upper curved slot and a lower curved slot are respectively formed by a skewed slot and an arc slot; the middle part of the valve rod is also provided with a long keyway, and an upper sliding key and a lower sliding key which are respectively fixed on an upper connecting seat and a lower connecting seat, and the upper connecting seat and the lower connecting seat are respectively fixed on the butterfly plate; the push rod consists of an upper push rod and a lower push rod, one end of the upper push rod and one end of the lower push rod are both provided with a roller, one end of the lower push rod is embedded in the lower curved slot and capable of sliding, while the other end of the lower push rod is hinged with the inner end surface of the movable valve seat; the upper push rod and the lower push rod are symmetrically arranged; a uni-eccentric structure is formed between a butterfly plate rotating axis and a seal pair plane.

Owner:HEBEI UNIV OF TECH

Rollup door with rollable door leaf

InactiveUS20050115688A1Facilitate rapid opening/closingAvoid direct contactScreensShutters/ movable grillesEngineeringMechanical engineering

A rollup door comprising a door leaf of increasing width from top to bottom and having a narrower part on the top and a wider part on the bottom, and flexibility in the rolling direction; channels for guiding the door; and two modules for rolling and unrolling the door leaf so that a number of leaf layers do not come in contact. The modules are situated on each side of the door, have the same center axes and are successive radially enlarged so that on opening and closing of the door, the narrower and wider parts of the leaf engage the smaller and larger parts respectively of the modules.

Owner:FREDE FRIEDHELM

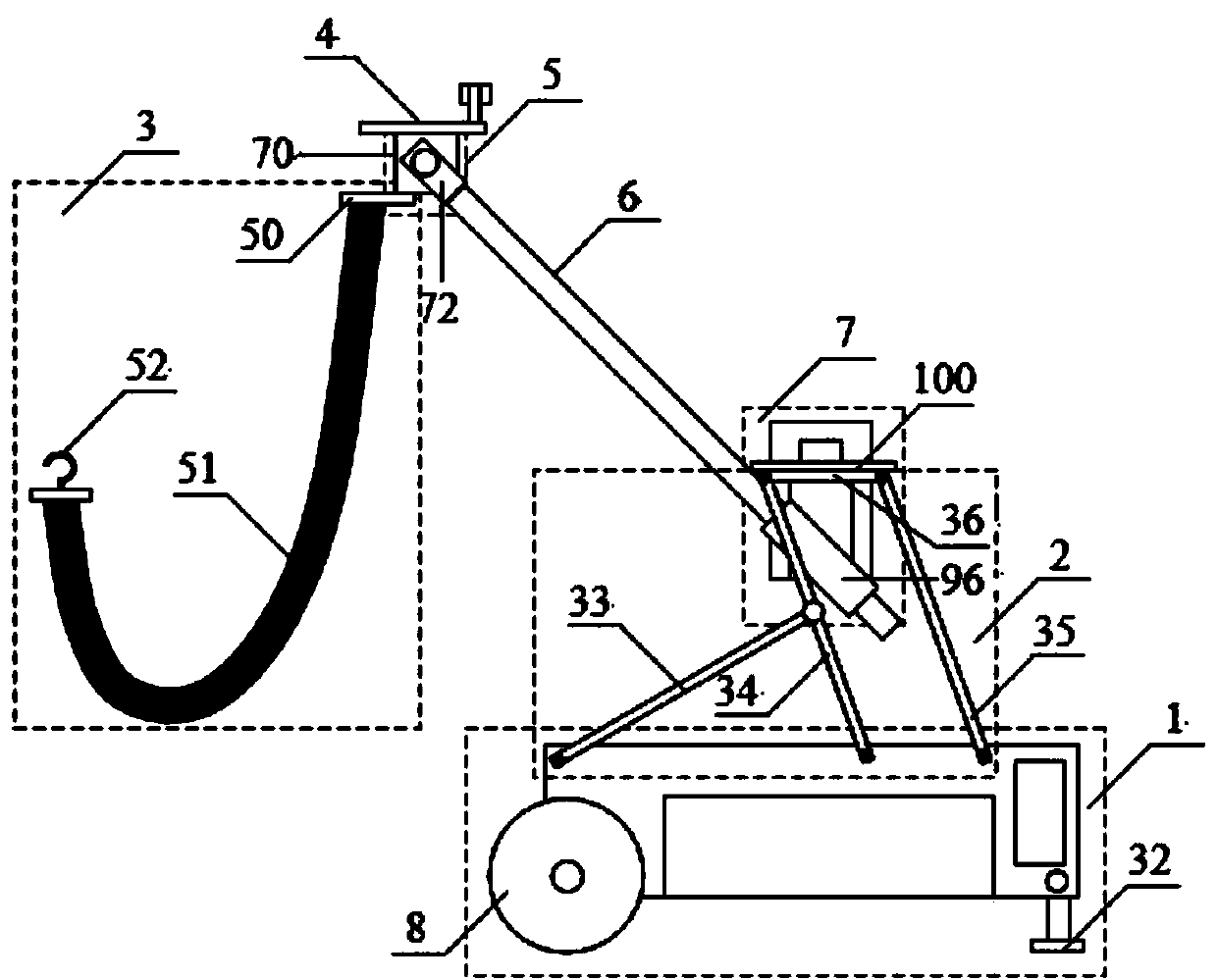

Agricultural high fruit picking device

The invention discloses an agricultural high fruit picking device comprising a two wheel trolley. A lifting mechanism is movably connected to the upper portion of the two wheel trolley and is movably connected to a console; the console is movably connected to one end of a telescopic arm, the other end of the telescopic arm is movably connected to a balance mechanism, the top of the balance mechanism is connected to a shearing arm, and the bottom of the balance mechanism is connected to an accommodating bag. According to the device, the two wheel trolley replaces of a power transport vehicle to be adaptive to poor driving condition of an orchard; the telescopic arm replaces of a mechanical arm with multiple freedom degrees, weight is decreased, structure and control of the arm are simplified, and the moving space of the arm is saved; the suspended soft bag replaces of a fixed fruit conveying channel, the fruit conveying distance is shortened, and fruit damage is reduced; the device is more adaptive to the application for the orchard.

Owner:XI'AN POLYTECHNIC UNIVERSITY

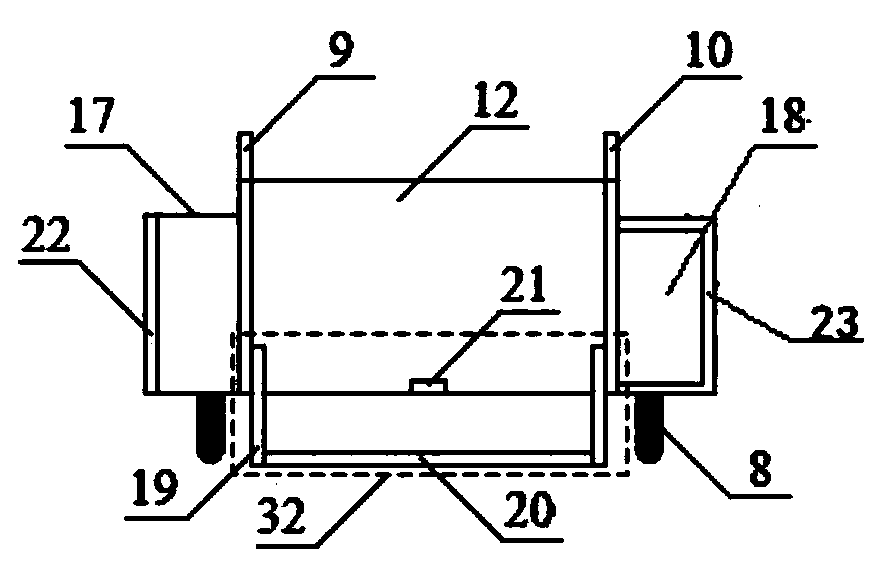

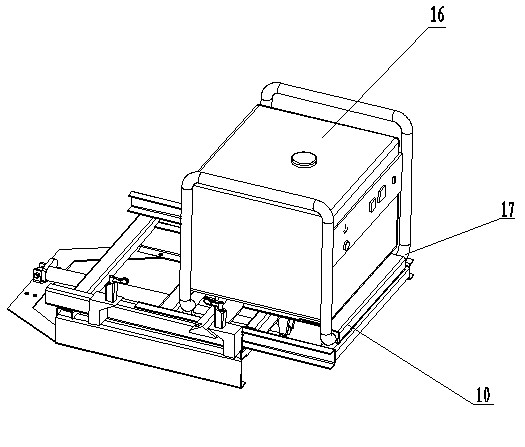

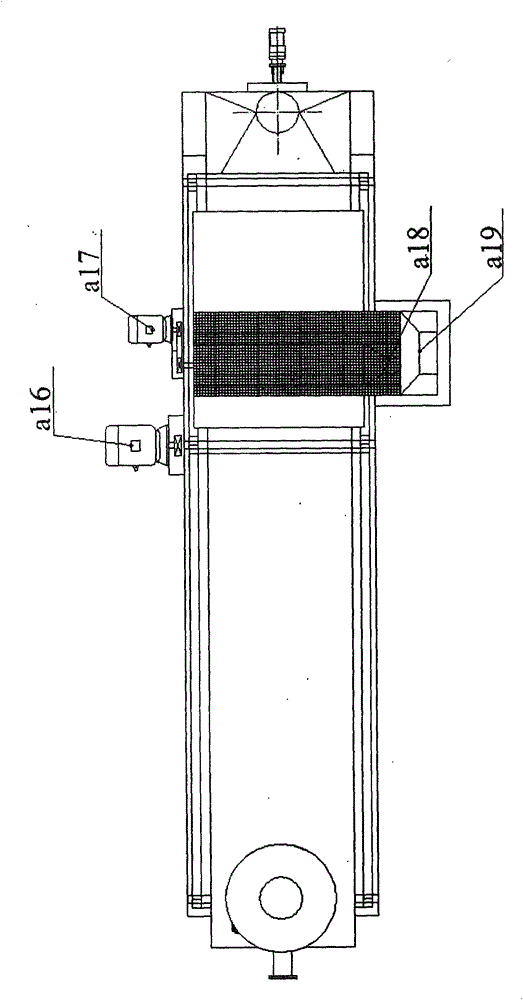

Electric push-pull type vehicle-mounted generator bracket

InactiveCN102222999ARealize automatic push and pullRetain manual operation functionSupports/enclosures/casingsPush and pullPush pull

The invention discloses an electric push-pull type vehicle-mounted generator bracket. Front ends of two side beams of a lower bracket are connected with push rod fixing plates; two sliding chutes are correspondingly arranged above the two side beams of the lower bracket; an upper bracket is mounted in the two sliding chutes; the upper bracket slides in the two sliding chutes back and forth; an electric push rod is arranged between each push rod fixing plates and the upper bracket; one end of the electric push rod is hinged with a support on the push rod fixing plate, and the other end of the electric push rod is hinged with a support fixed below the bracket; a groove-shaped limiting bar of which the notch faces forward is fixed above the rear end of the upper bracket; the upper bracket is provided with a generator fixing plate; two sides of the generator fixing plate are connected with upper bracket fixing blocks; the two upper bracket fixing blocks are lapped on the two sides of the upper bracket; the upper bracket fixing blocks move back and forth along the sliding chutes with the upper bracket; and the upper bracket fixing blocks are limited back and forth by front and rear fixing blocks arranged on the outer sides of the two sliding chutes. Labor is saved to push and pull the bracket; and a generator is reliably fixed and convenient to assemble and disassemble.

Owner:CHONGQING JINGUAN AUTOMOBILE MFR

Positioning jacking-out device for stamping die and working method of positioning jacking-out device

InactiveCN108097832AEasy to fixPrecise positioningMetal-working feeding devicesPositioning devicesAutomatic controlEngineering

The invention discloses a positioning jacking-out device for a stamping die, and relates to the technical field of stamping dies. The positioning jacking-out device comprises a box. The bottom of theinner wall of the box is fixedly connected with a hydraulic rod. The top end of the hydraulic rod is fixedly connected with a mounting plate. The bottom of the inner wall of the box is fixedly connected with an electromotor. An output shaft of the electromotor is fixedly connected with a first conical gear. The two sides of the first conical gear are engaged with second conical gears. The axes ofthe two second conical gears are fixedly connected with lead screw shafts. The surfaces of the lead screw shafts are connected with moving plates in a threaded mode. The bottoms of the moving plates are slidably connected with sliding rails. The positioning jacking-out device for the stamping die and a working method of the positioning jacking-out device have a novel positioning structure and mode, opening and closing are automatically controlled, using is very convenient, the positioning effect is good, damage does not occur easily, jacking out of the die is not affected, the opening and closing speed is high, and the production efficiency of the die is greatly increased.

Owner:ZHONGSHAN RNICE COMML ELECTRIC CO LTD

Pressure control valve

InactiveCN101067454ASimple structureEasy to operateOperating means/releasing devices for valvesFluid pressure controlEngineeringHollow form

The invention provides a pressure controlling valve which the two ends have the inlet or outlet of the fluid. The front valve is connected to the back valve to form the valve. The front valve is connected with the valve barrel canister which is connected with the cover to form the valve barrel. The valve barrel canister is connected with the valve core which is combined with the interface of the front valve. The valve barrel hollow formed by the valve barrel cover and the valve core bearing surface is connected with the inner hollow of the valve by the leading channel. The valve has the simple structure and is not easy to leak, has long using life.

Owner:池严围

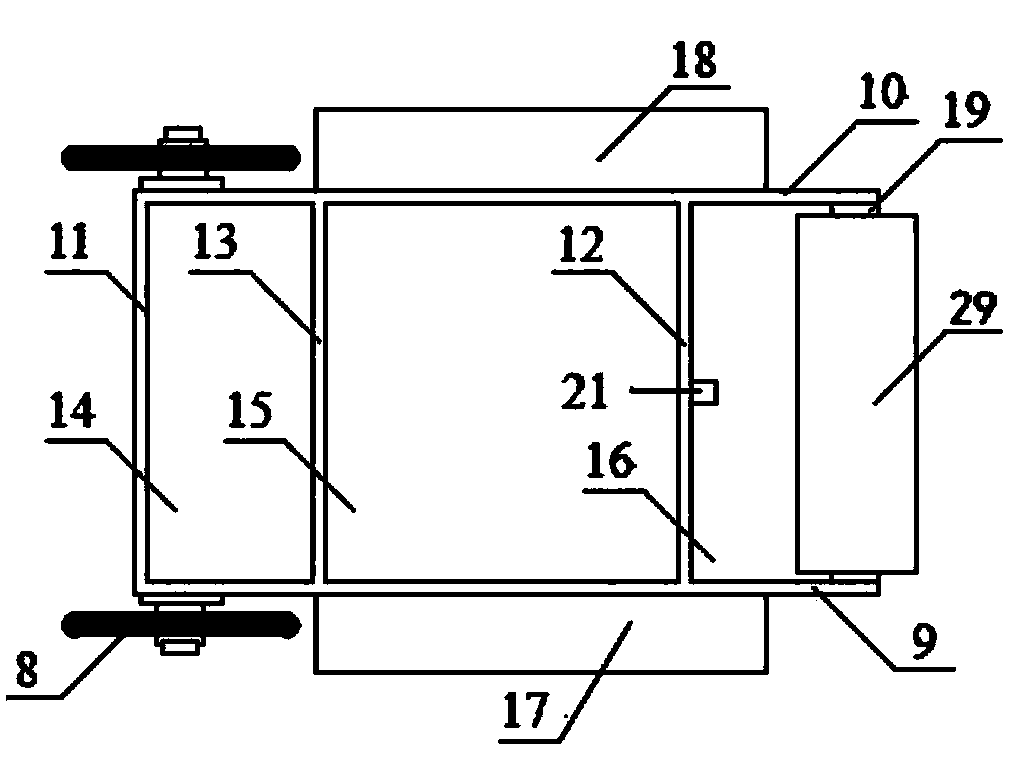

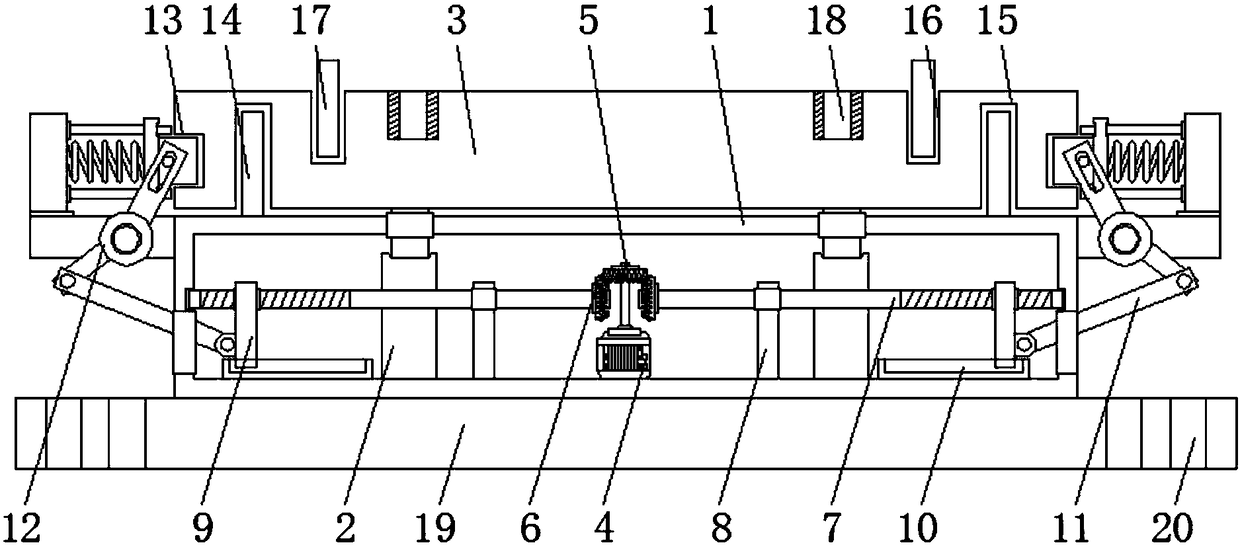

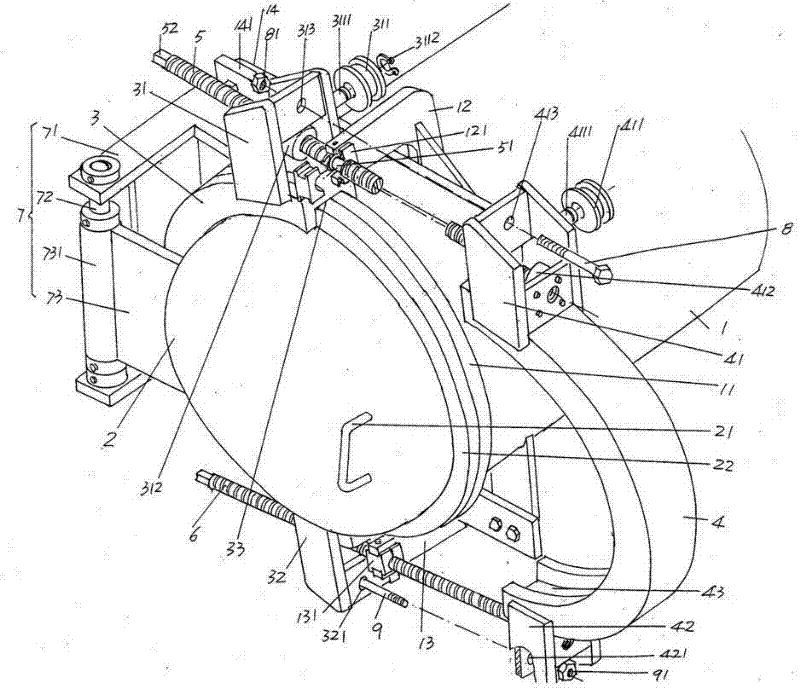

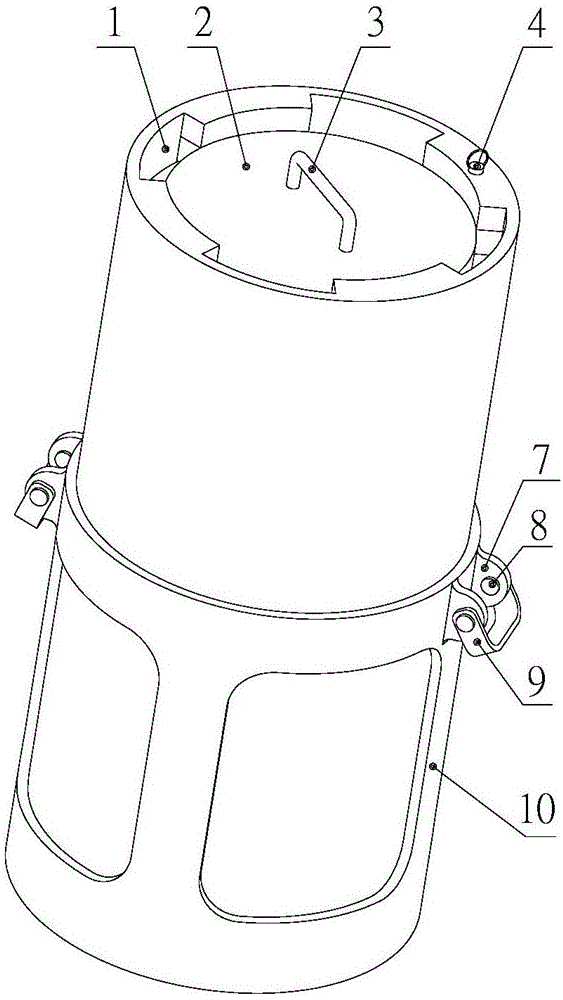

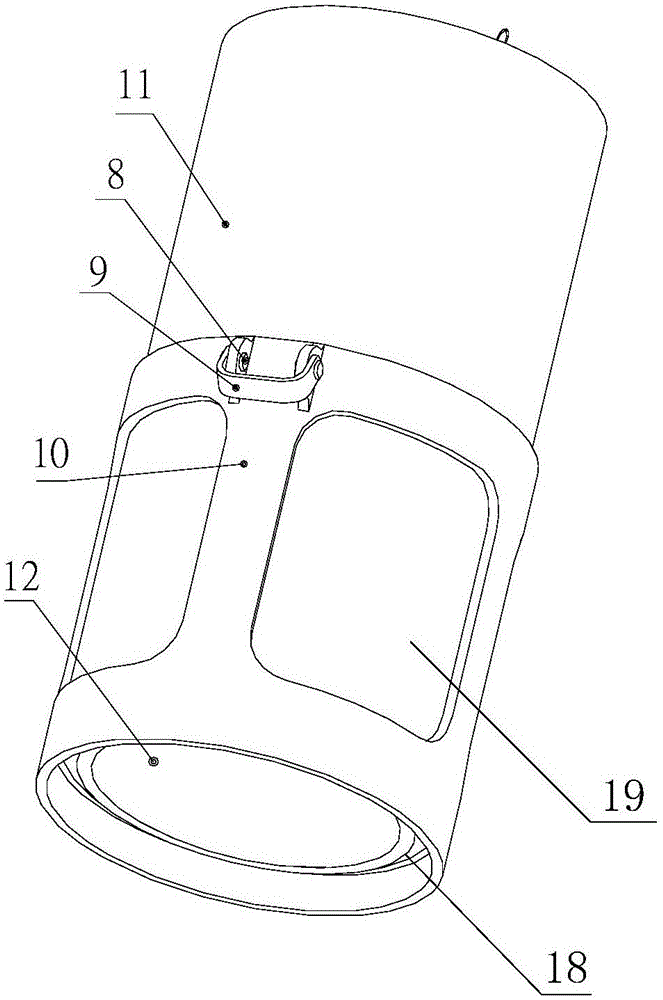

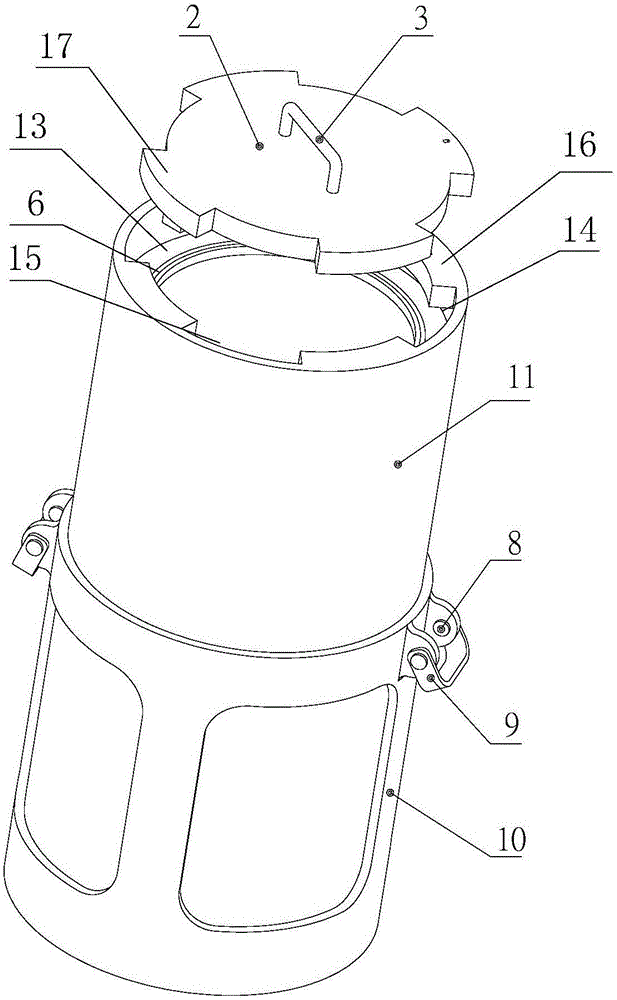

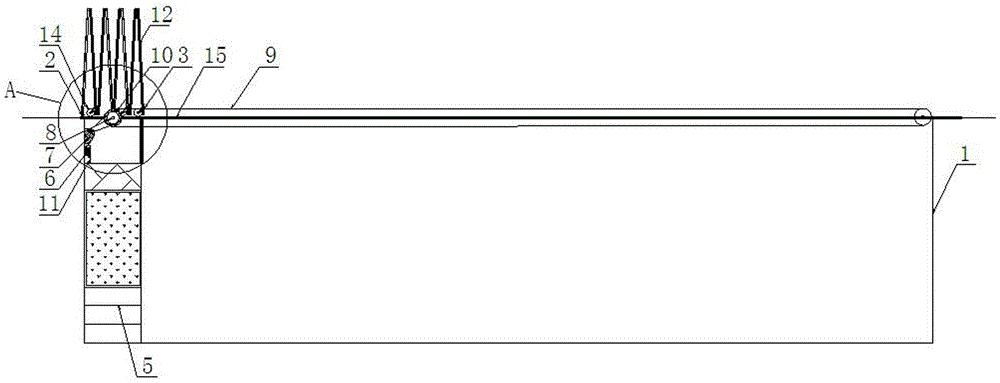

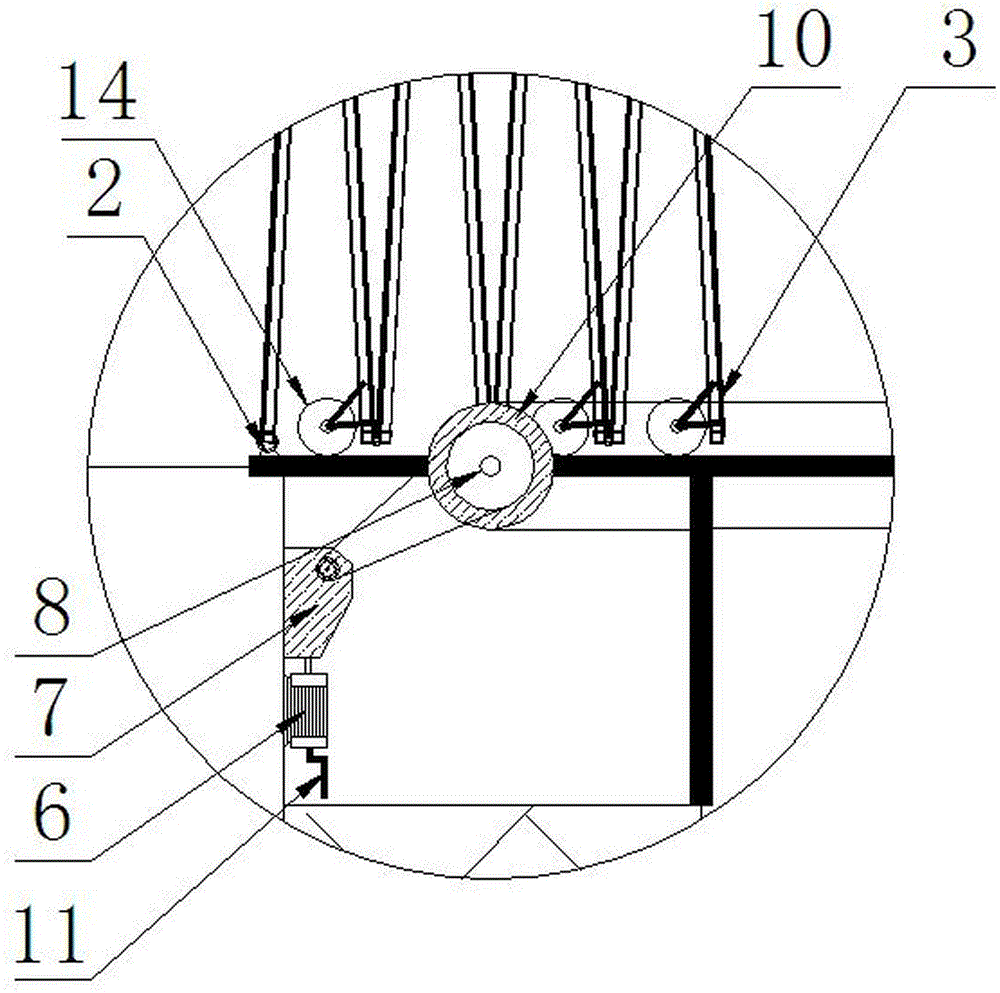

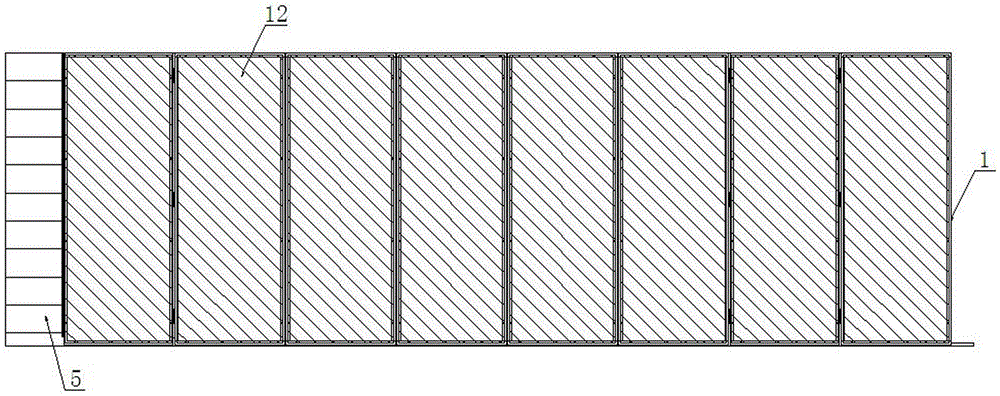

Quick opening and closing mechanism for horizontal type pressure container

InactiveCN102563067AImprove securityFast opening and closingPressure vesselsControl engineeringControl theory

The invention discloses a quick opening and closing mechanism for a horizontal type pressure container, and belongs to the technical field of pressure containers. The horizontal type pressure container comprises a barrel body and a cover; the quick opening and closing mechanism comprises a first clamping hoop and a second clamping hoop which are semicircular, a first bidirectional screw, a second bidirectional screw and a cover pivoting supporting device, wherein a first locking seat is fixed at one end of the first clamping hoop, and a second locking seat is fixed at the other end of the first clamping hoop; a third locking seat is fixed at one end of the second clamping hoop, and a fourth locking seat is fixed at the other end of the second clamping hoop; the first locking seat is matched with the third locking seat, and the second locking seat is matched with the fourth locking seat; one end of the first bidirectional screw is connected to the first locking seat in a rotatable manner, and the other end of the first bidirectional screw is connected to the second locking seat in a rotatable manner; one end of the second bidirectional screw is connected to the third locking seat in a rotatable manner, and the other end of the second bidirectional screw is connected to the fourth locking seat in a rotatable manner; and the cover pivoting supporting device is arranged on the barrel body and pivoted with a cover. The invention has the advantages that: the quick opening and closing mechanism is prevented from being limited by the space, has high opening and closing speed, has a whole simplified structure, is favorable for manufacturing and mounting and convenient to use, and improves the safety by avoiding a phenomenon that the cover is opened mistakenly.

Owner:CHANGSHU NO 2 CHEM ENG EQUIP PLANT

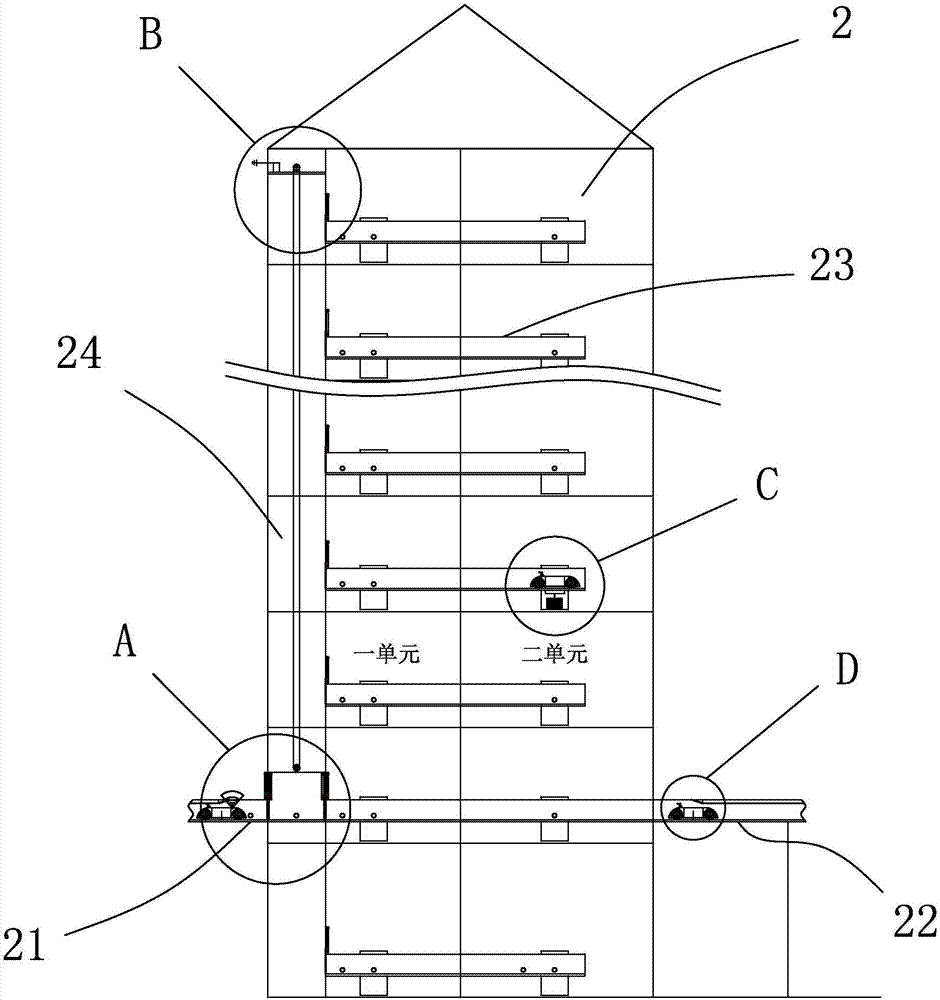

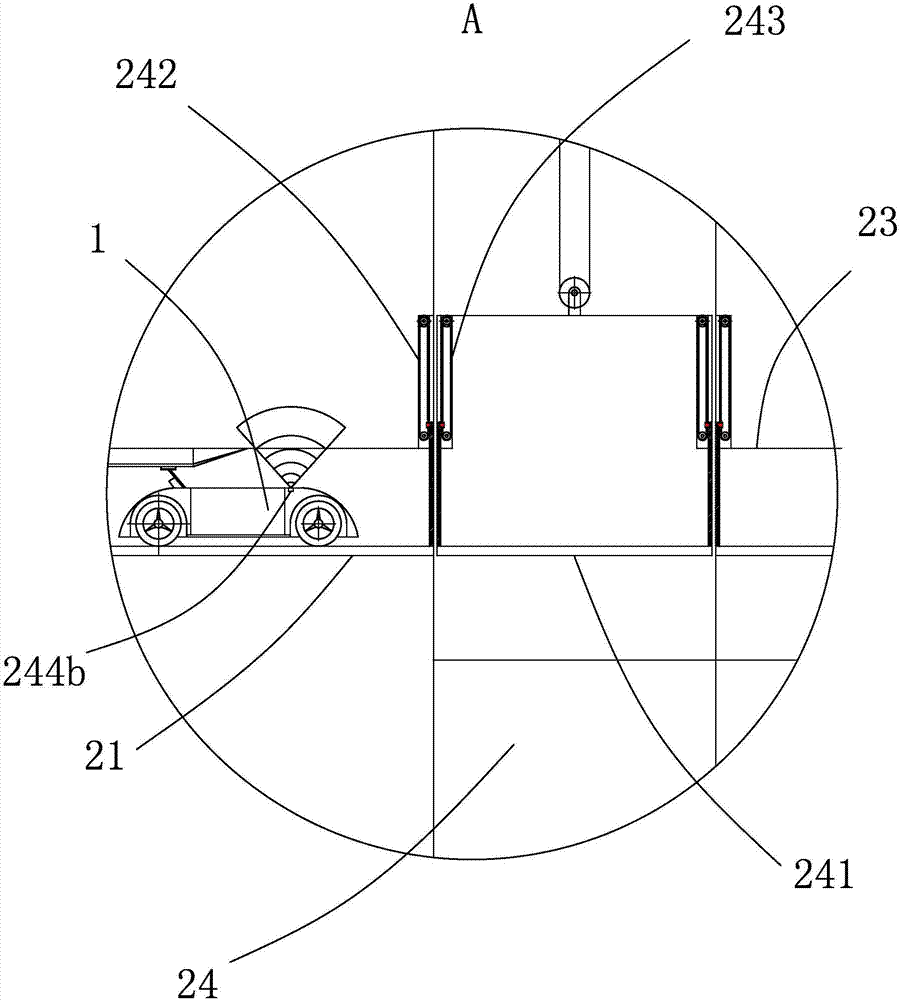

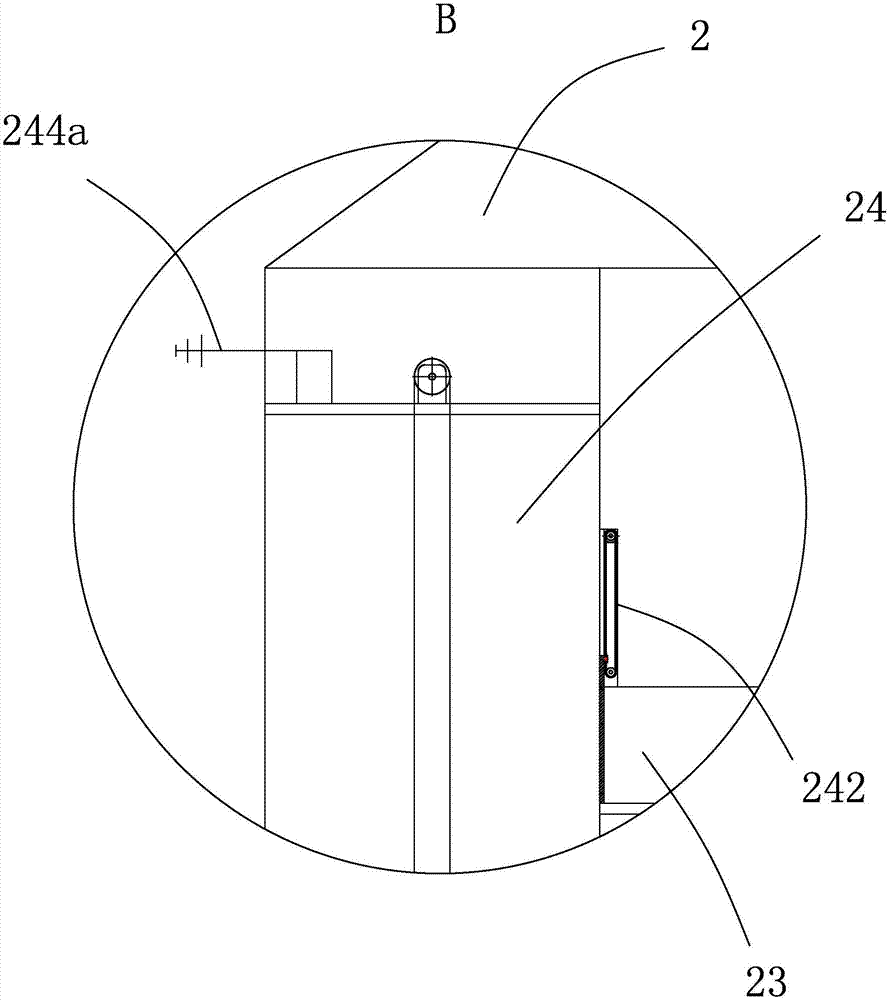

Delivery system for high-rise building

The invention discloses a delivery system for a high-rise building. The delivery system comprises an automatic delivery cart, a multi-storey building main body and a control module, wherein an elevator shaft is arranged in the building main body; a lifting device capable of feeding the automatic delivery cart to each storey is arranged in the elevator shaft; the lifting device comprises a lifting table; a pull-in channel and a pull-out channel are arranged on the building main body; the pull-in channel communicates with the elevator shaft; each storey of the building main body is connected with a loading and unloading channel which communicates with the elevator shaft; the pull-out channel communicates with one loading and unloading channel; and the control module is separately in communication connection with the automatic delivery cart and the lifting device. According to the delivery system for the high-rise building provided by the invention, even people who live in the high-rise building also can easily receive and deliver goods, so that the delivering process and the receiving process of goods are more convenient, economical and safer, and therefore, a great deal of manpower and material resources are saved.

Owner:金勇

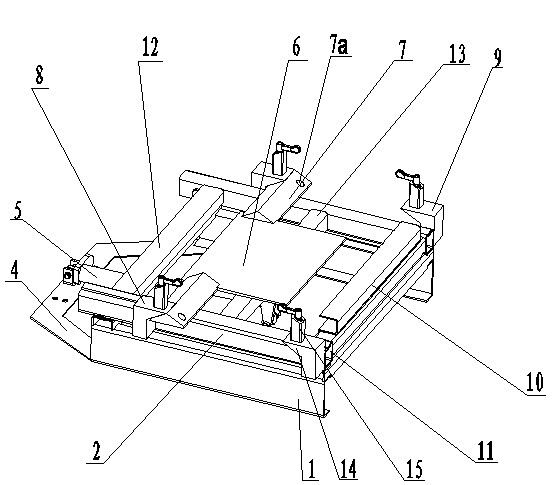

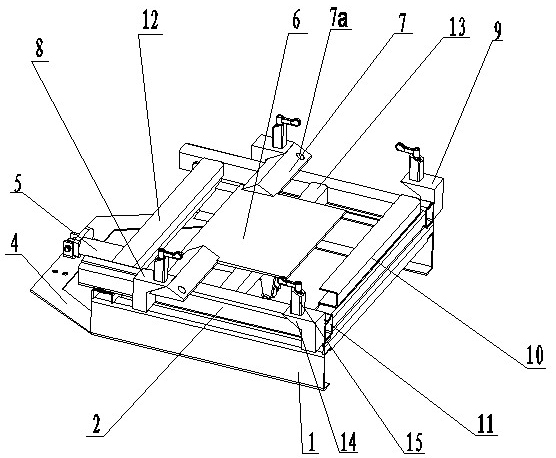

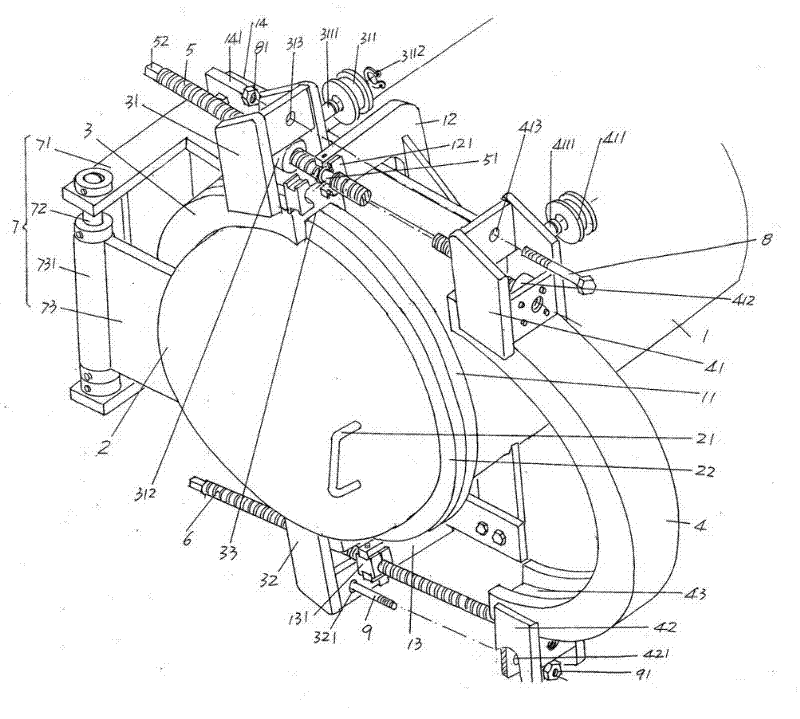

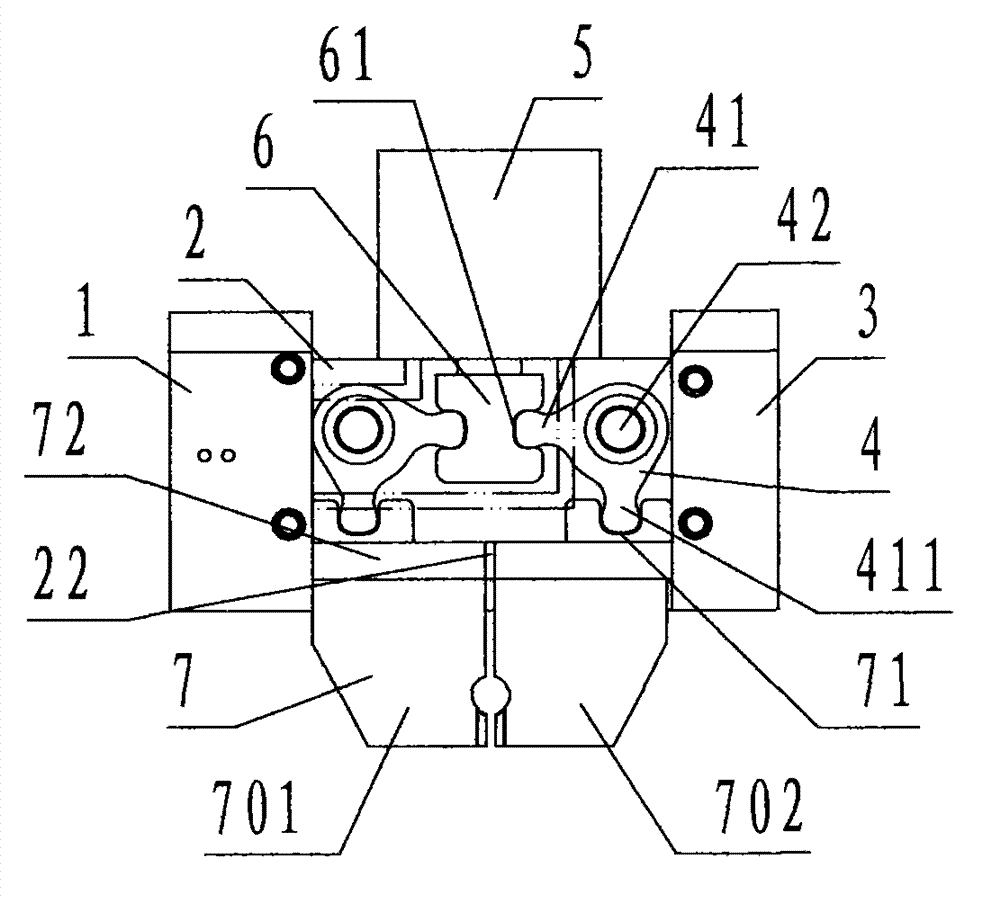

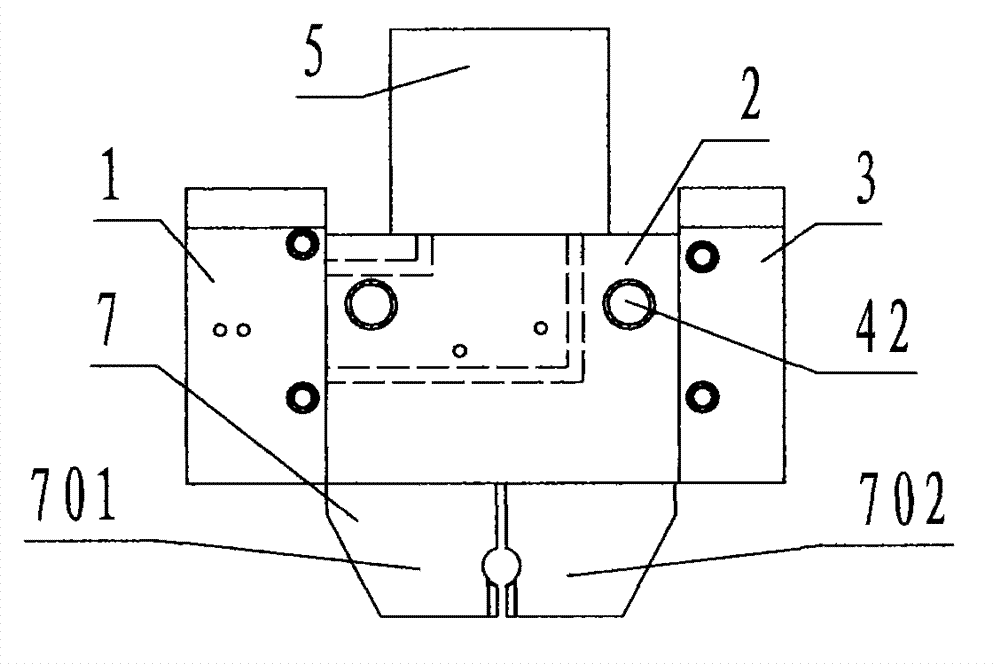

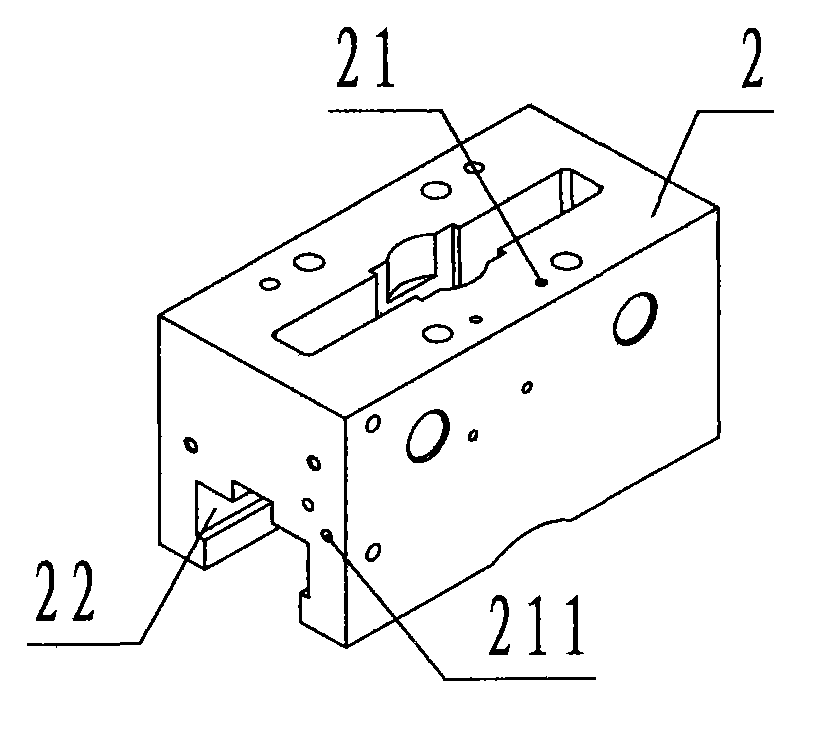

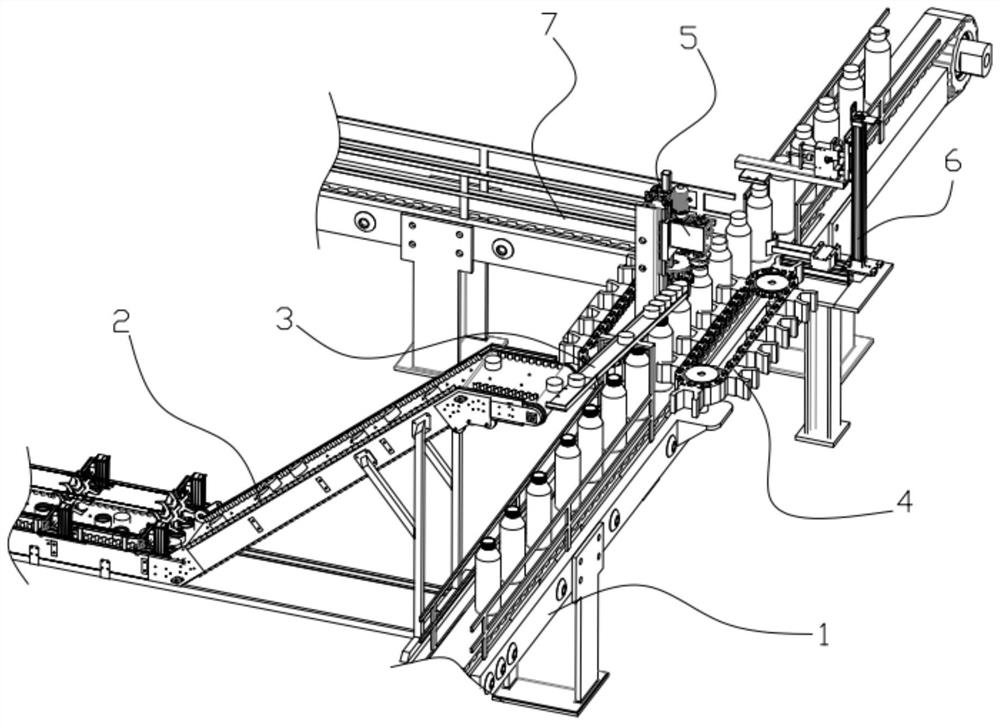

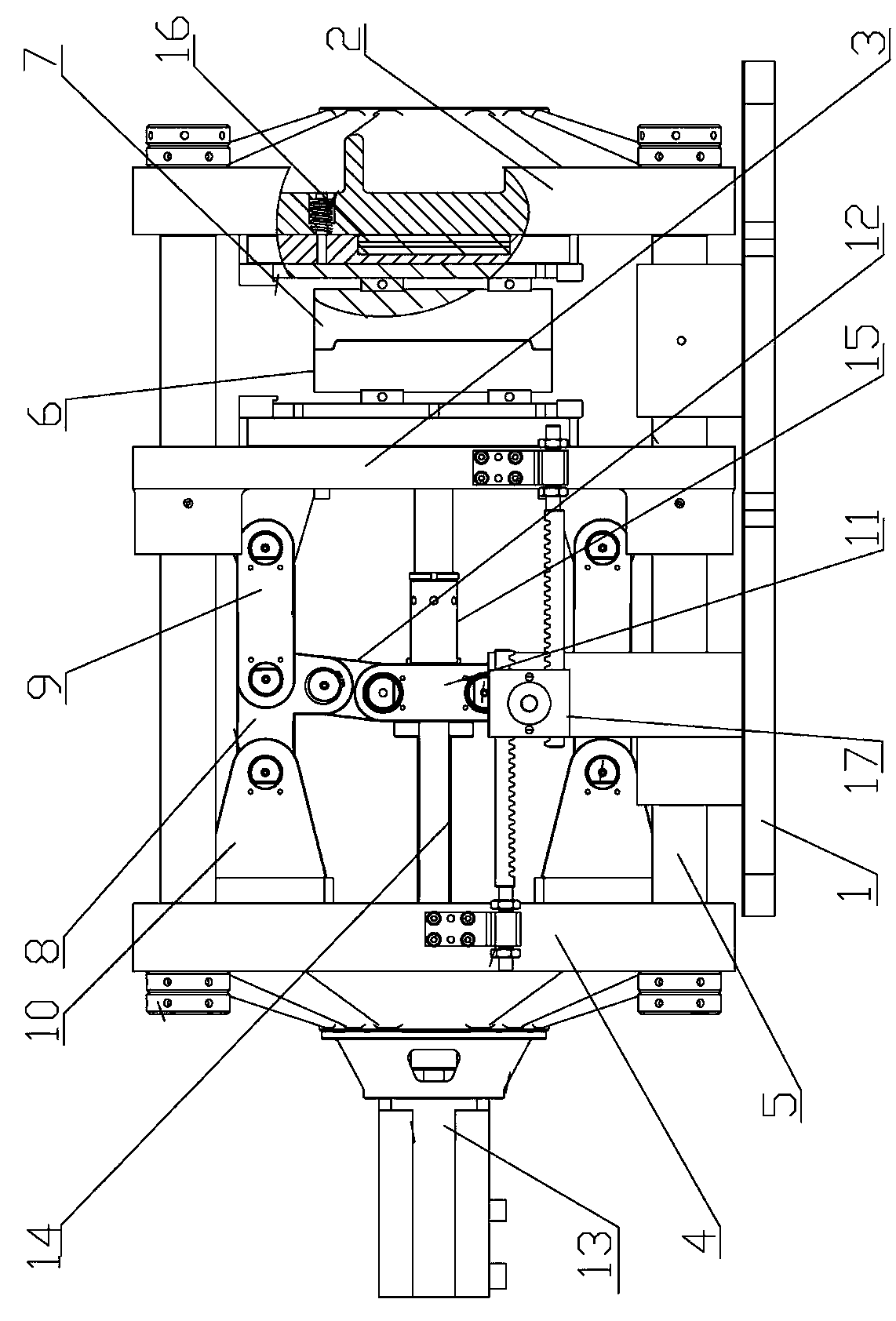

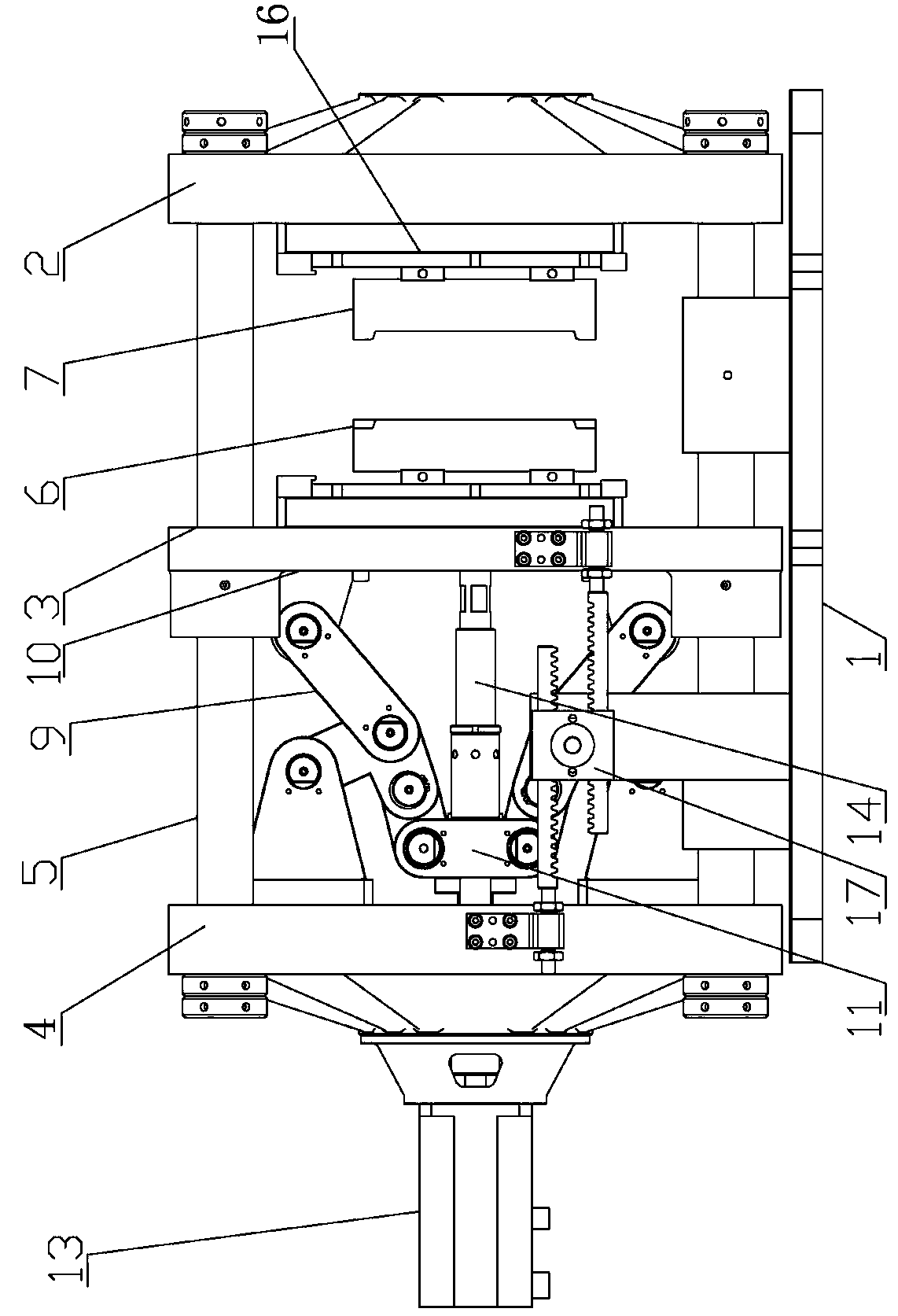

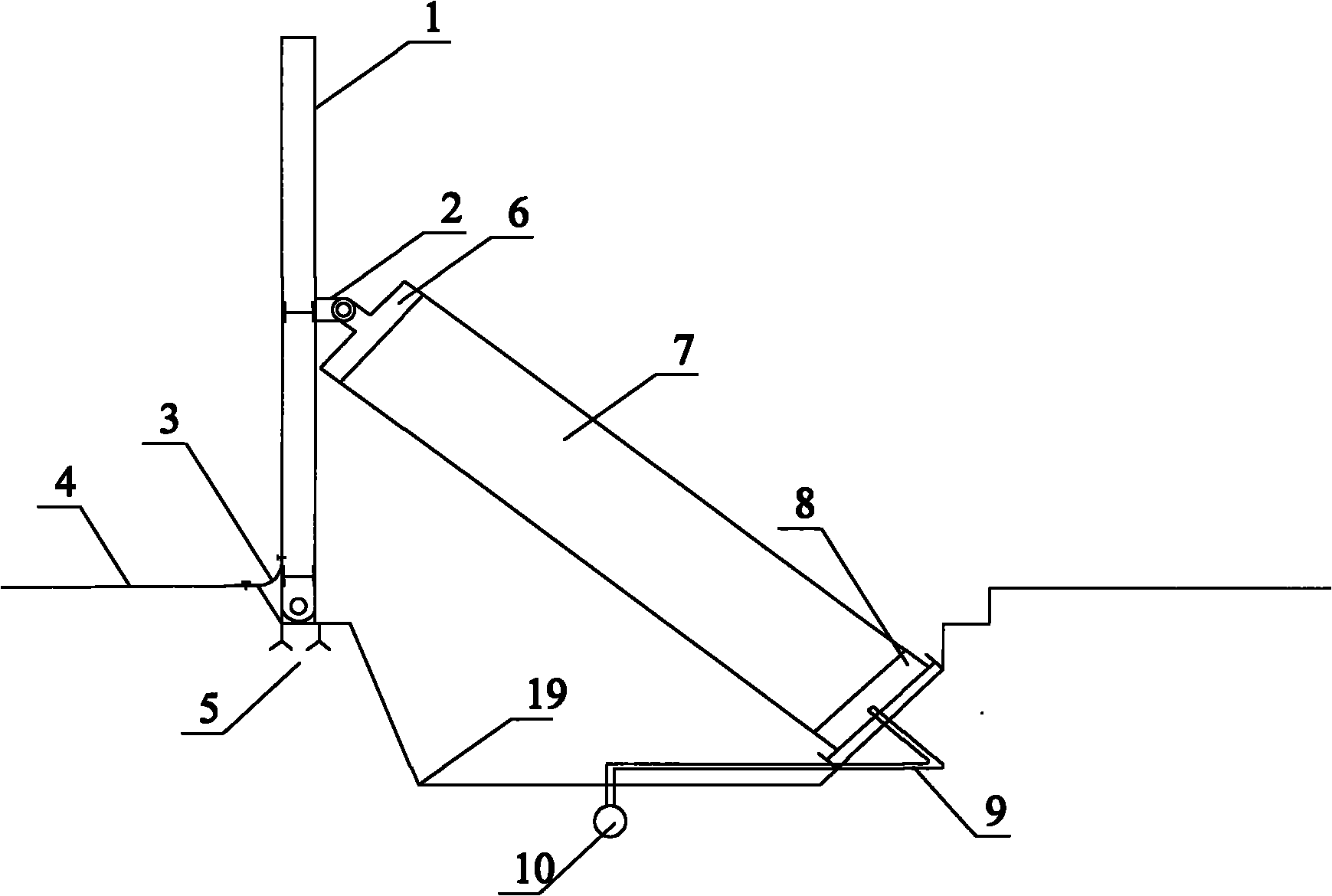

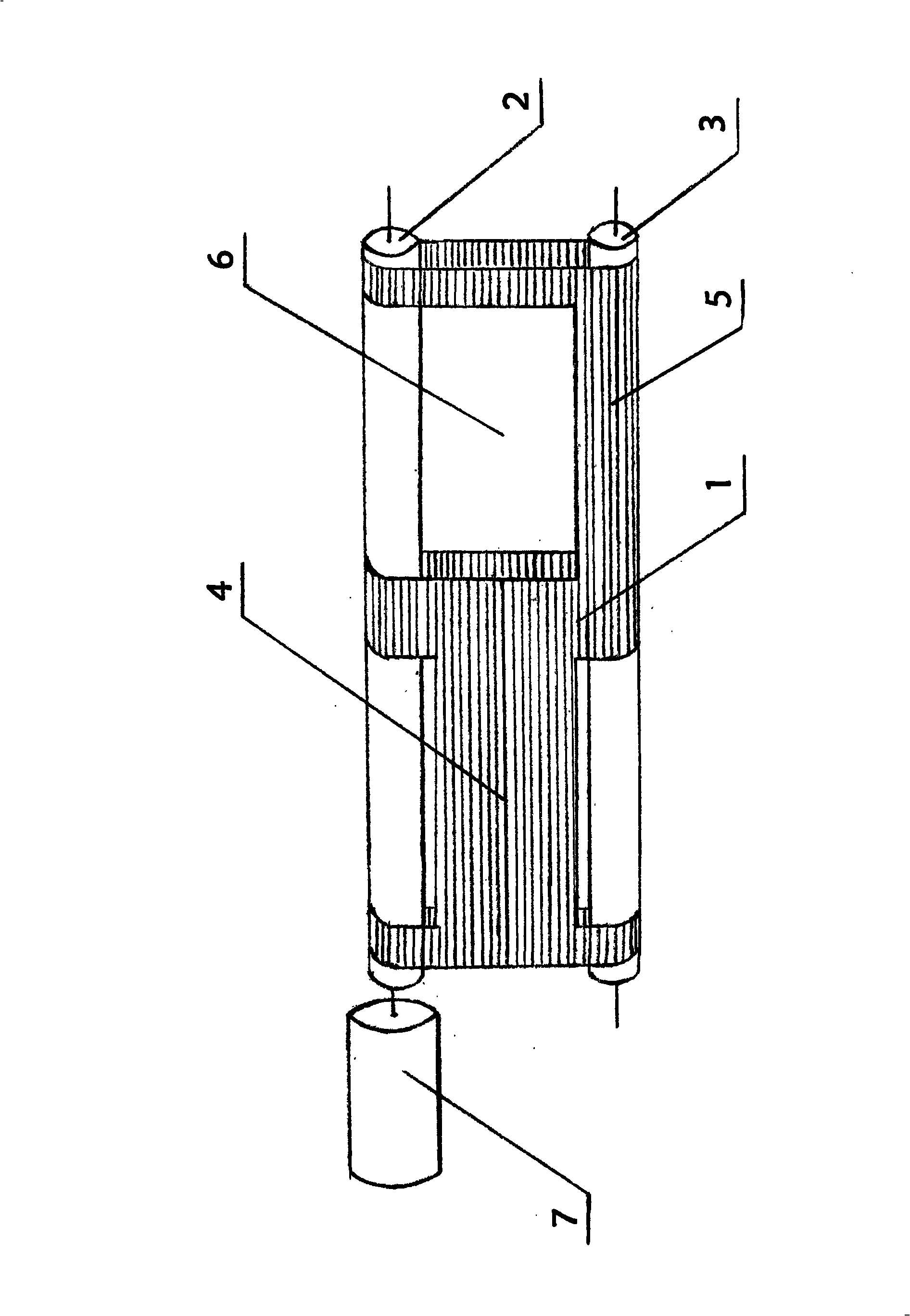

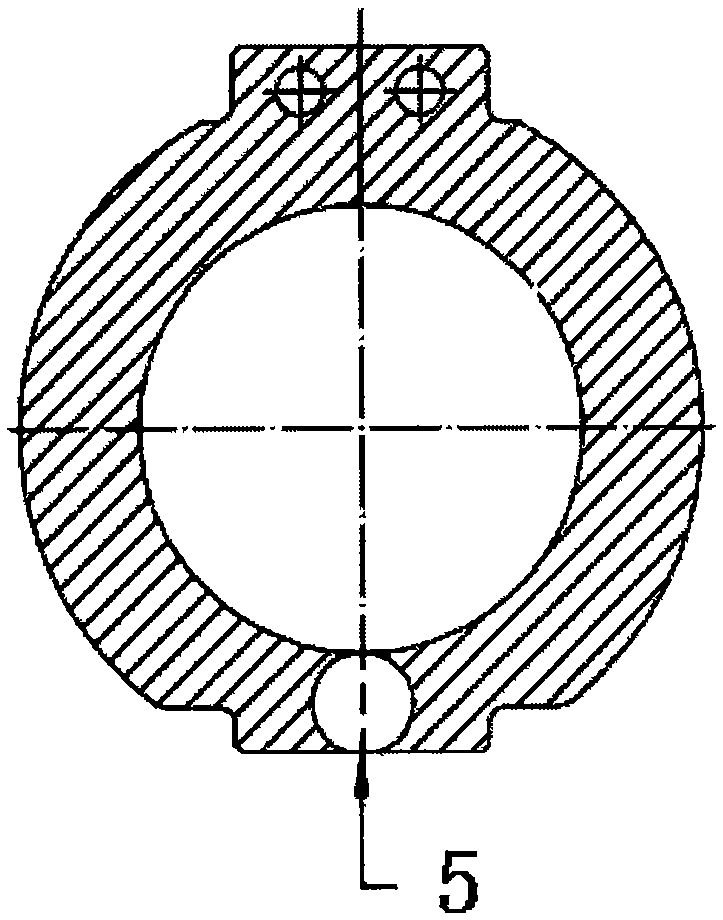

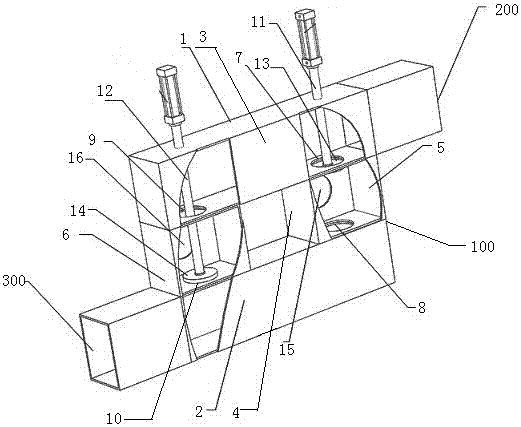

Hydraulic self-centering fast clamping device

ActiveCN102886703AImprove reliabilitySelf centeringPositioning apparatusMetal-working holdersNumerical controlDevice form

The invention discloses a hydraulic self-centering fast clamping device which comprises an oil path end plate (1), an oil path bridge plate (2), an end plate (3), a rotary shifting fork (4), an oil cylinder (5), a driving joint (6) and a clamp (7). When the clamping device formed by the components is applied, the device is fixed on a fourth shaft which rotatably works in a numerical control center. The oil cylinder is connected with an oil distributer of the fourth shaft of the numerical control center through built-in oil paths in the oil path bridge plate and the oil path end plate, and is controlled by a computer of the numerical control center. The oil cylinder drives the clamp to open and close quickly to clamp a dissembling workpiece through the driving joint and the rotary shifting fork for three-dimensional five-shaft cutting processing, the deficiencies of large strength, low efficiency and poor clamping precision are overcome in the prior art. The clamping device is connected with the fourth shaft of the numerical control center and is driven hydraulically to open and close, so that the work intensity is reduced, the disassembling efficiency is improved, and the clamping precision is improved for clamping and disassembling work pieces.

Owner:NINGBO SONGYING AUTOMOBILE PARTS

Anti-explosion container

ActiveCN106225608AGood explosion resistanceFast opening and closingAmmunition storageDesign technologyFlange

The invention discloses an anti-explosion container which mainly comprises a container body, a quick-opening end cover and a peripheral support. The container body mainly comprises a shell, an end flange and an ellipsoidal seal head, the end flange and the ellipsoidal seal head are respectively welded at two ends of the shell, and a concave clamp groove is formed in the flange by means of machining. The peripheral support sleeves the container body, so that a skirt support can be provided for the container, and the anti-explosion performance of the container body can be reinforced. Lugs are welded on the peripheral support, lifting handles are hinged to the lugs by dowels, and the container with the lugs is convenient to carry. The anti-explosion container with peripheral support reinforcement design technologies has the advantages of high anti-explosion equivalence, light weight, convenience in carrying and the like.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

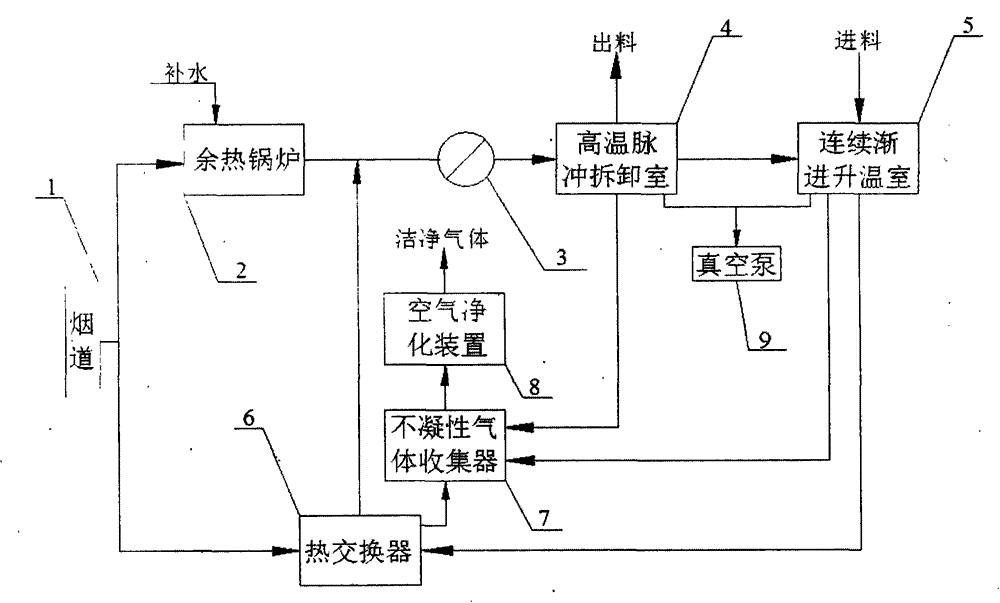

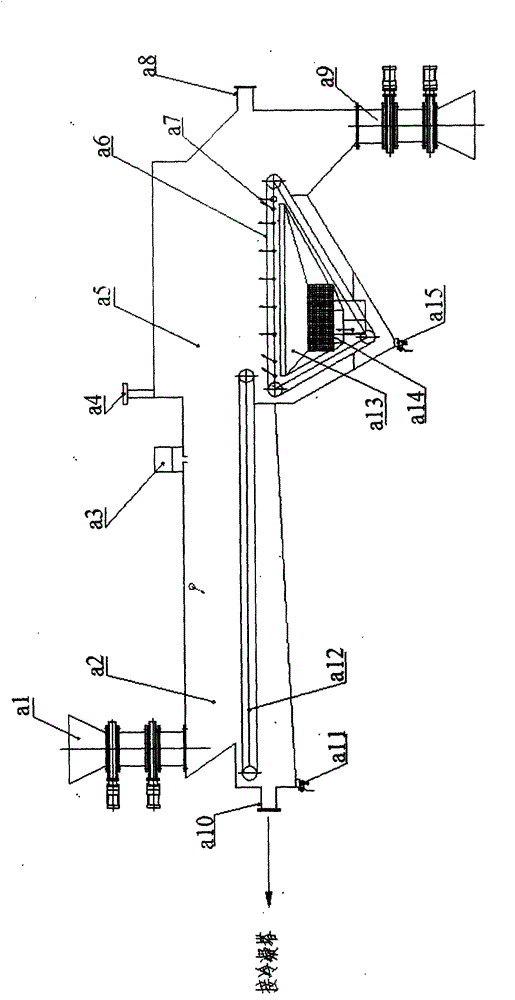

Automatic lossless dismounting recovery method and automatic lossless dismounting recovery device of discarded printed circuit board

InactiveCN103599921ASave resourcesReduce heat pollutionSolid waste disposalElectronic waste recyclingRecovery methodLower grade

The invention discloses an automatic lossless dismounting recovery method and an automatic lossless dismounting recovery device of a discarded printed circuit board. The method is characterized by comprising the following steps of preparing low-grade overheat vapor by using industrial waste heat through a waste heat boiler, and heating and pulse blowing the discarded printed circuit board at high temperature so as to realize the automatic lossless dismounting of electronic elements and devices on the discarded printed circuit board; guiding the overheat vapor after the working into a heat exchanger, reheating the overheat vapor after the working through the heat exchanger by utilizing the industrial waste heat as a heat source, and recycling the overheat vapor. By adopting the automatic lossless dismounting recovery method and the device, not only can the energy be greatly saved, but also the heat pollution caused by the industrial waste heat can be effectively reduced, the secondary pollution to the environment caused by dismounting the discarded printed circuit board at the high temperature can be avoided, the energy can be reasonably reused, and not only can the national policy of energy conservation and emission reduction be satisfied, but also a positive effect on protecting the environment can be realized.

Owner:SOUTHWEAT UNIV OF SCI & TECH

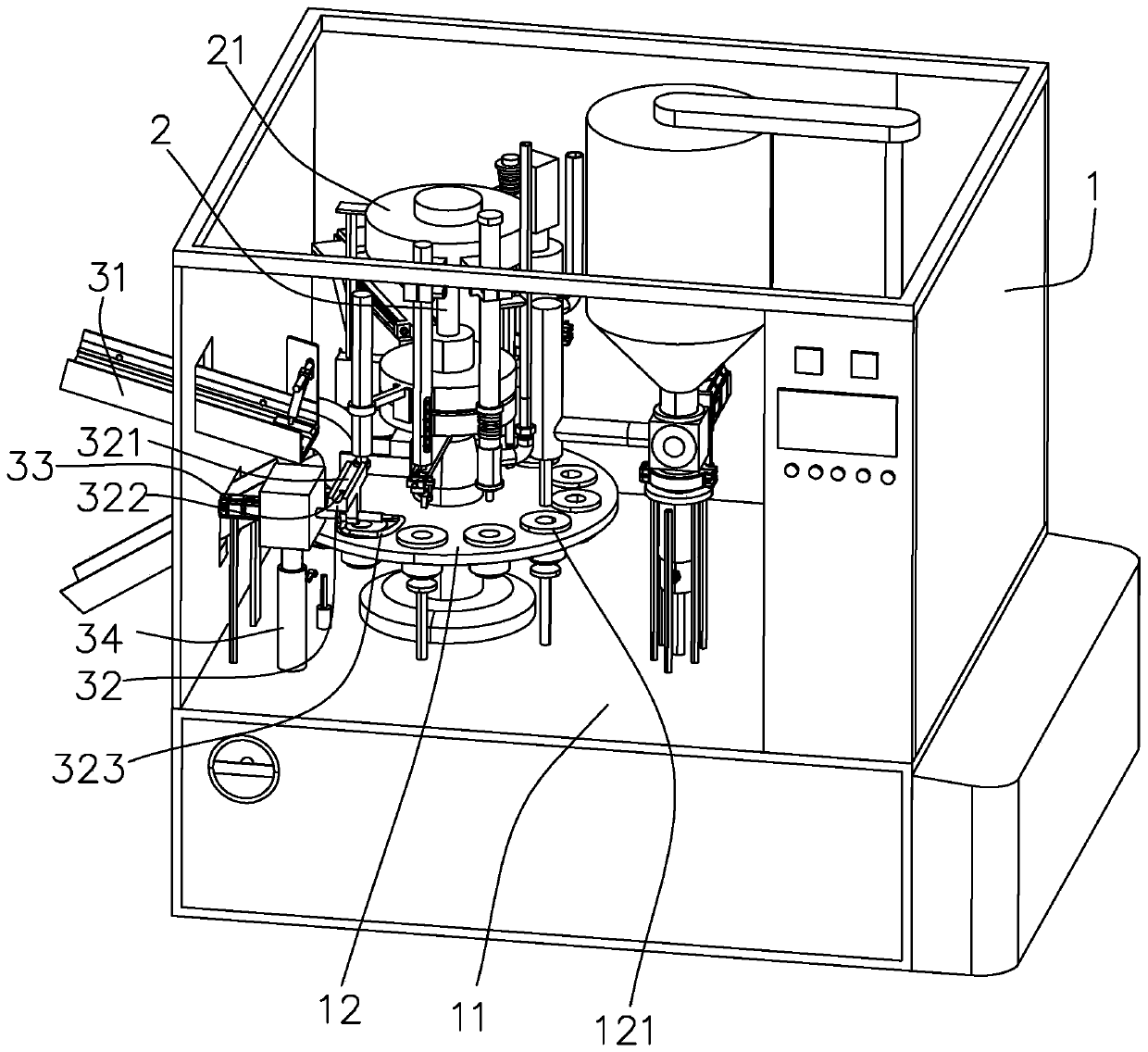

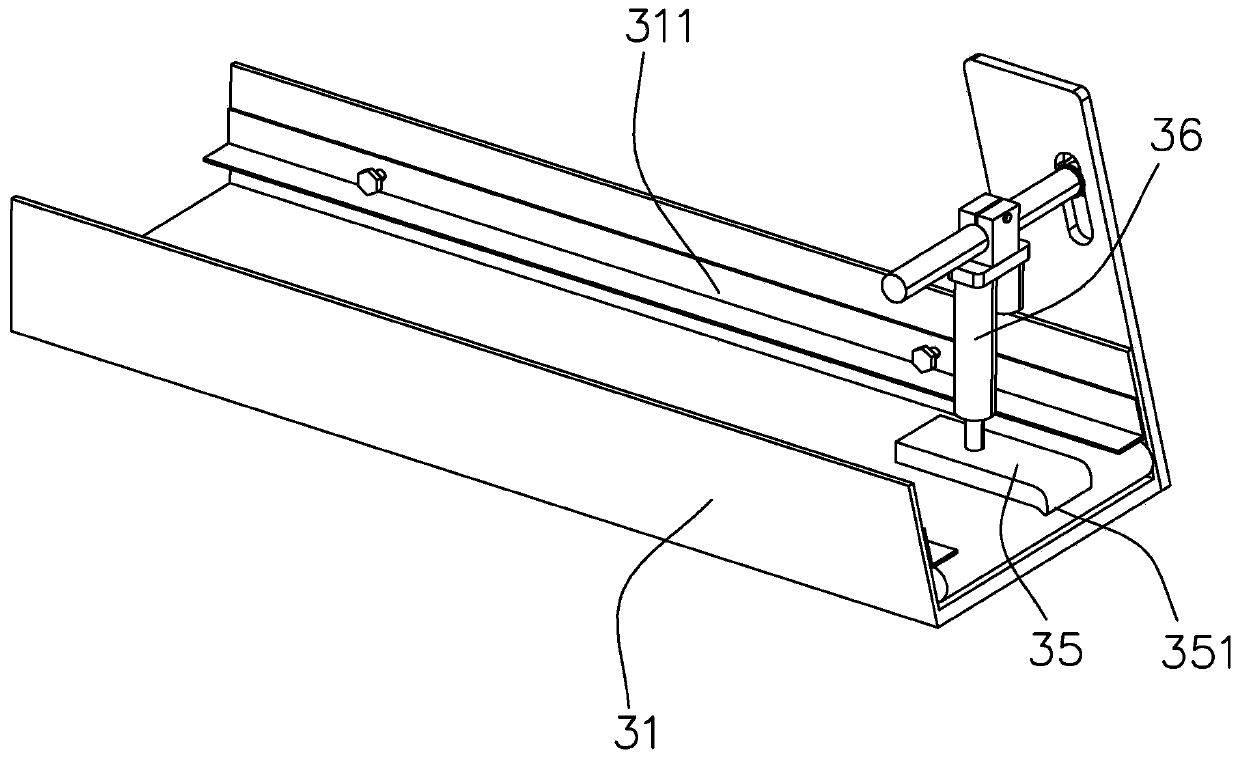

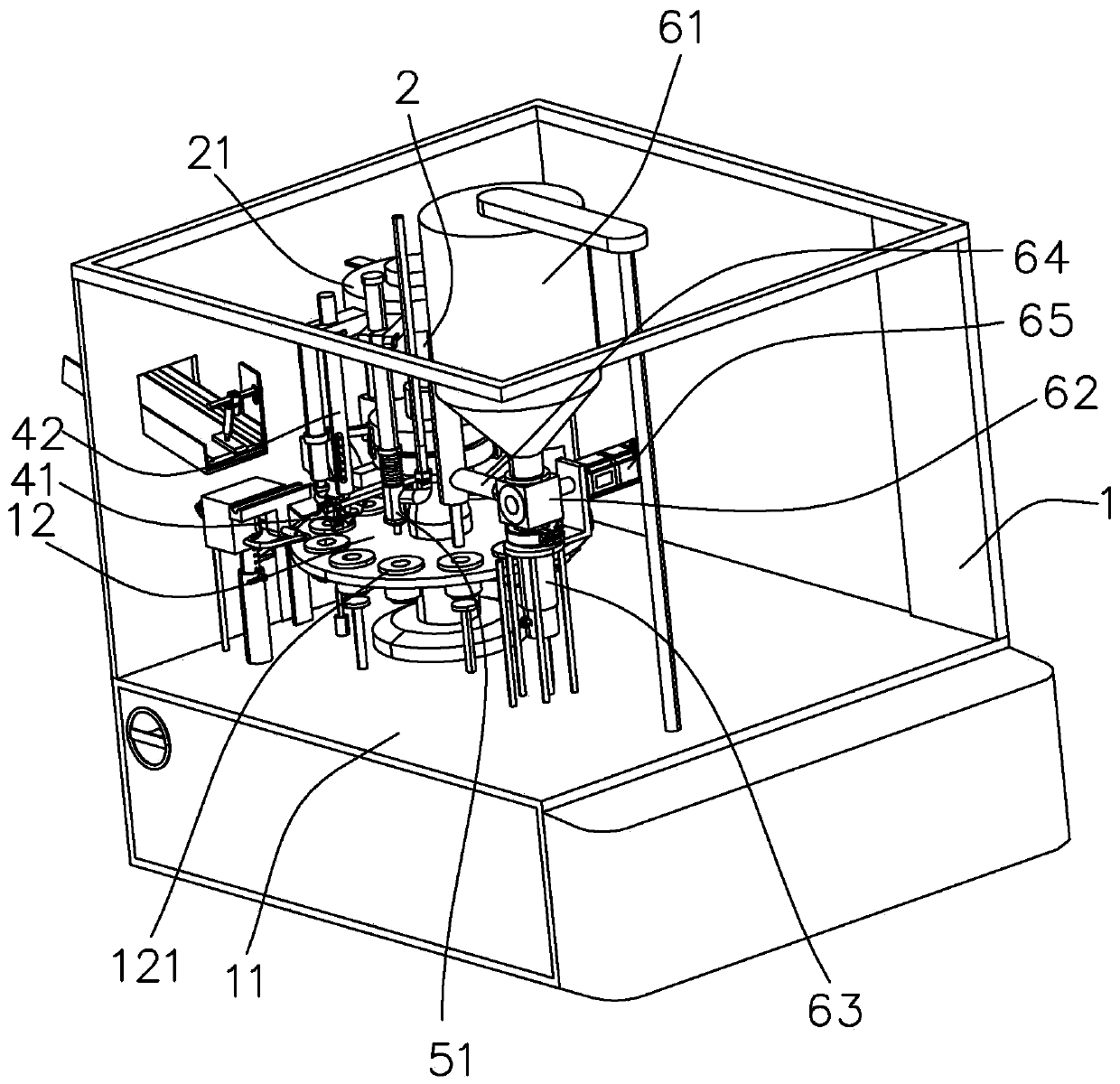

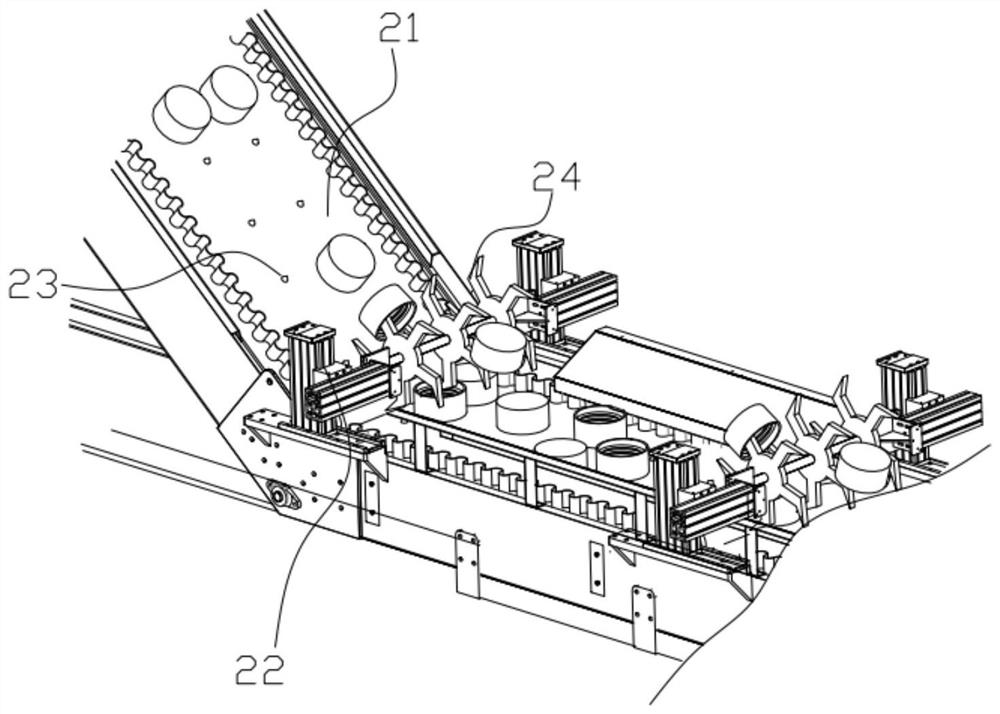

Flexible pipe filling end sealing machine

ActiveCN111056094AQuick responseFast forward and reverse switchingWrapper twisting/gatheringPackaging protectionUniversal jointElectric machinery

The invention relates to the technical field of end sealing machines, and discloses a flexible pipe filling end sealing machine. The flexible pipe filling end sealing machine comprises a rack, whereinthe rack comprises a workbench; the workbench is provided with a rotary disk and a clamping mechanism; a sliding rail is in sliding connection with a first clamping claw and a second clamping claw; the first clamping claw is set into an n shape and comprises a control end and a clamping end; the second clamping claw just faces the clamping end; the upper end of a driving connecting rod is positioned between the control end and the second clamping claw; a control lever is rotatably connected in the sliding rail; the upper end of the driving connecting rod is hinged to the control lever througha bulb universal joint; and two ends of the control lever are independently abutted against the control end and the second clamping claw. Through the arrangement of a driving motor, the movement of the first clamping claw and the movement of the second clamping claw are both controlled through the driving motor, a response speed of the motor is high, positive and negative rotation can be quicklyswitched so as to control the first clamping claw and the second clamping claw to be quickly opened and closed, a flexible pipe is subjected to clamping and end sealing, and production efficiency is high.

Owner:烟台开发区创佳制药机械有限公司

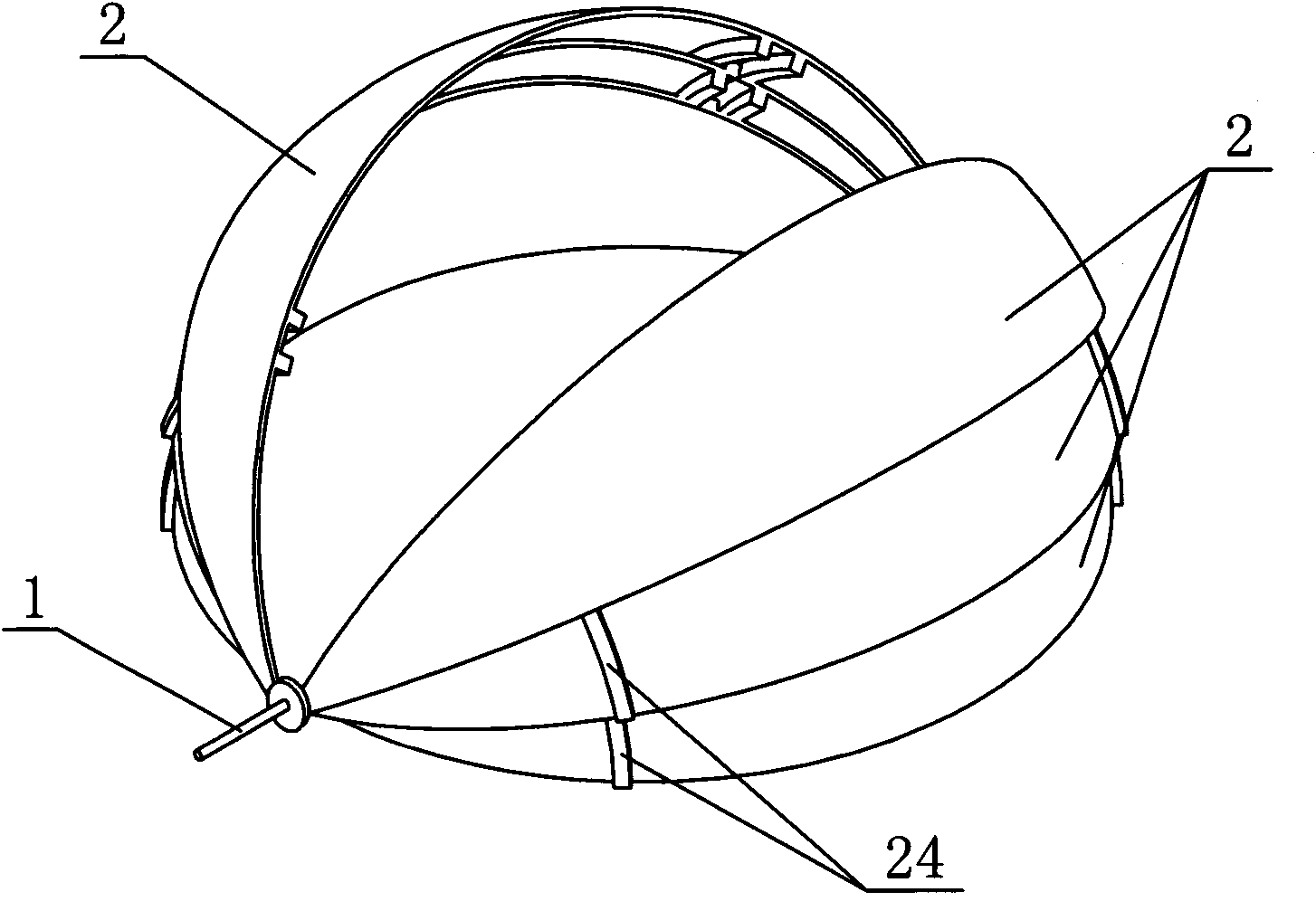

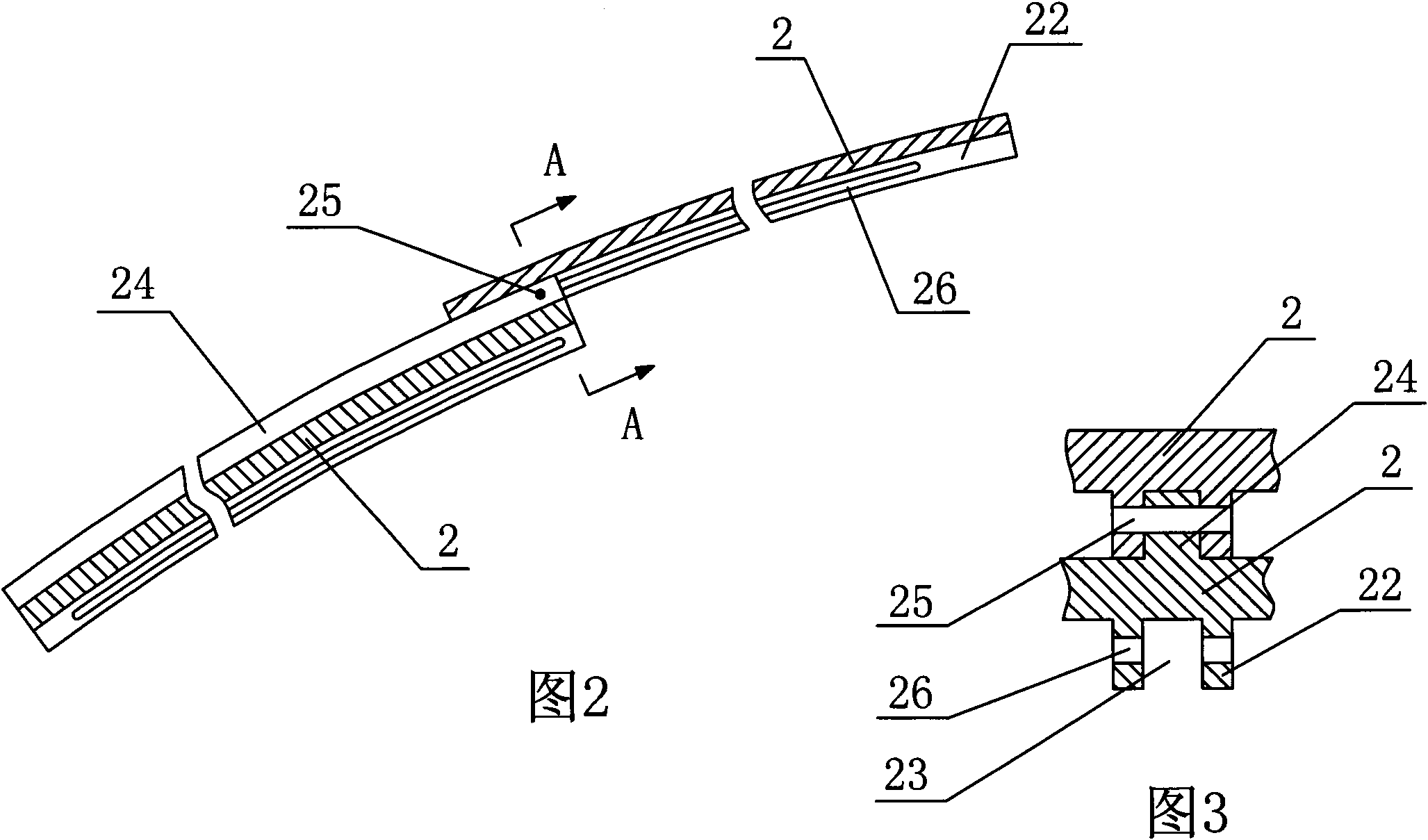

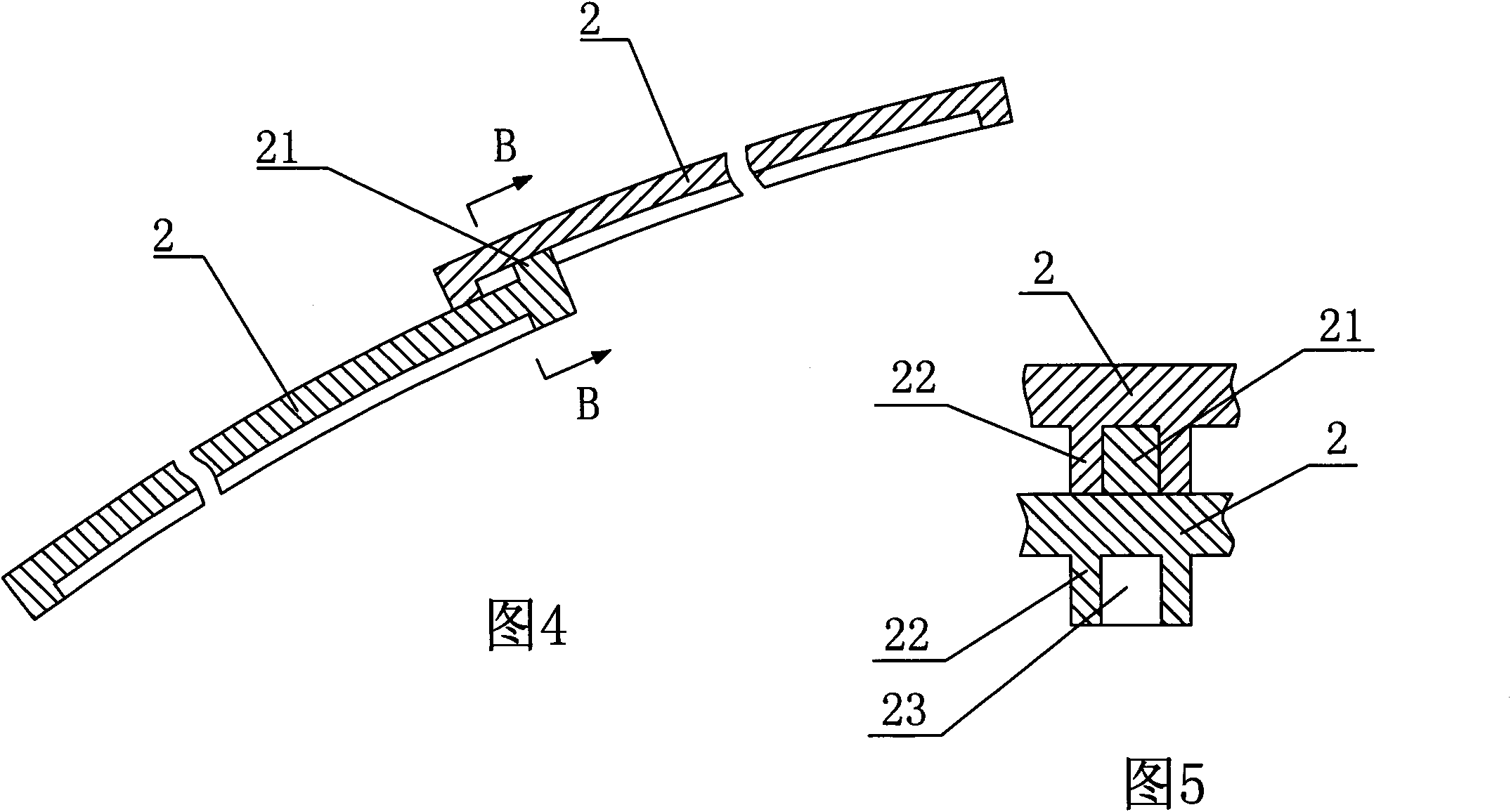

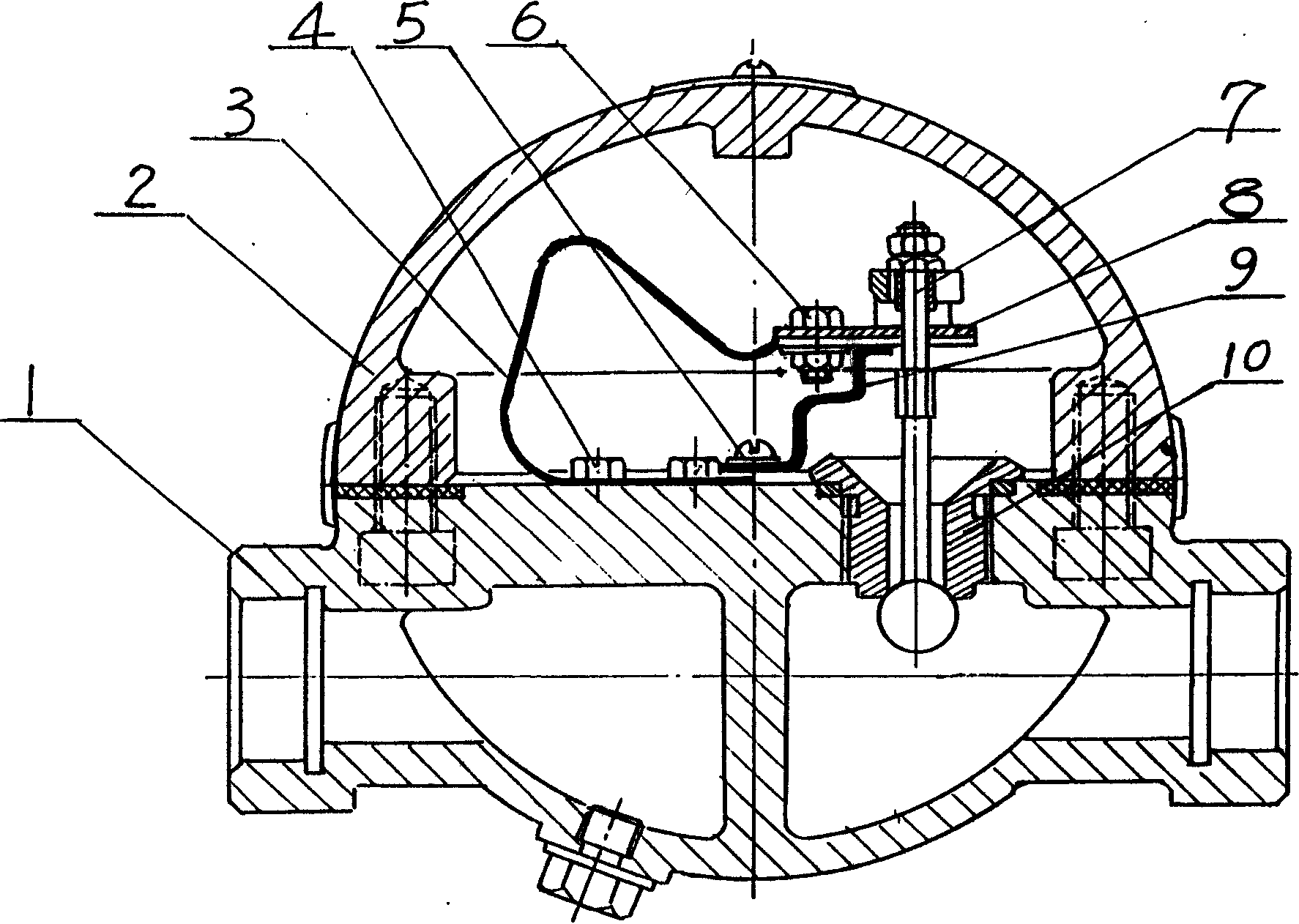

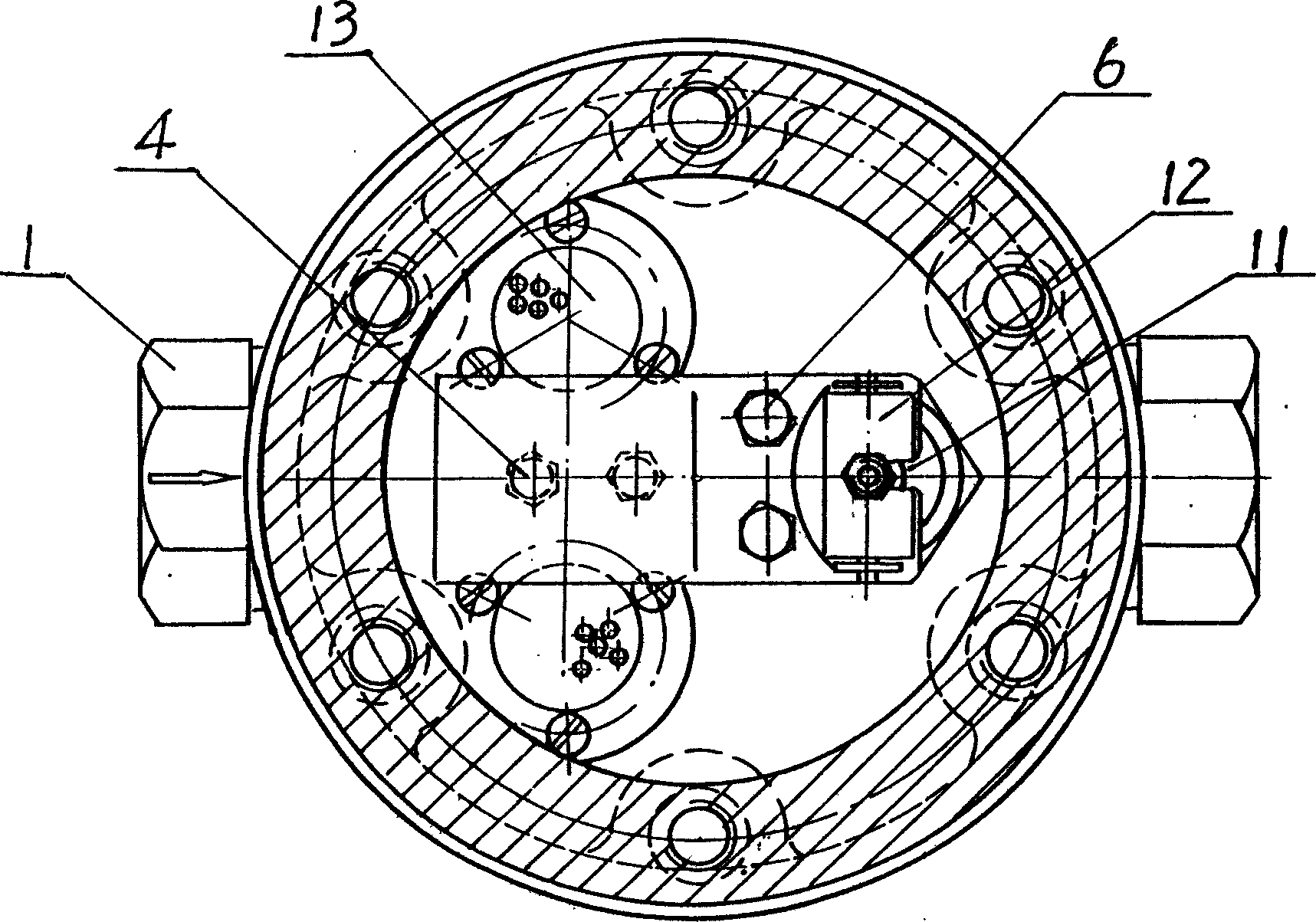

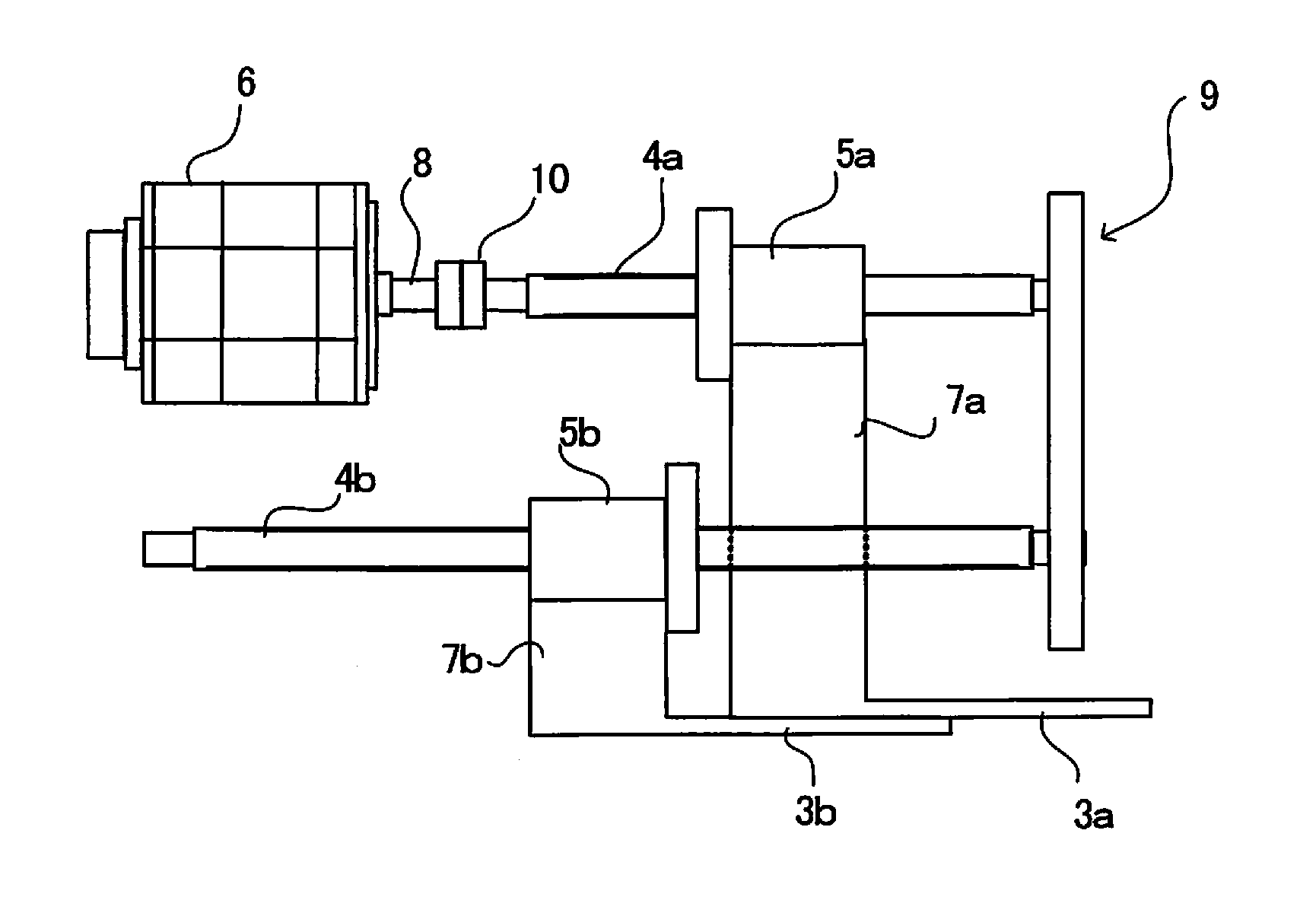

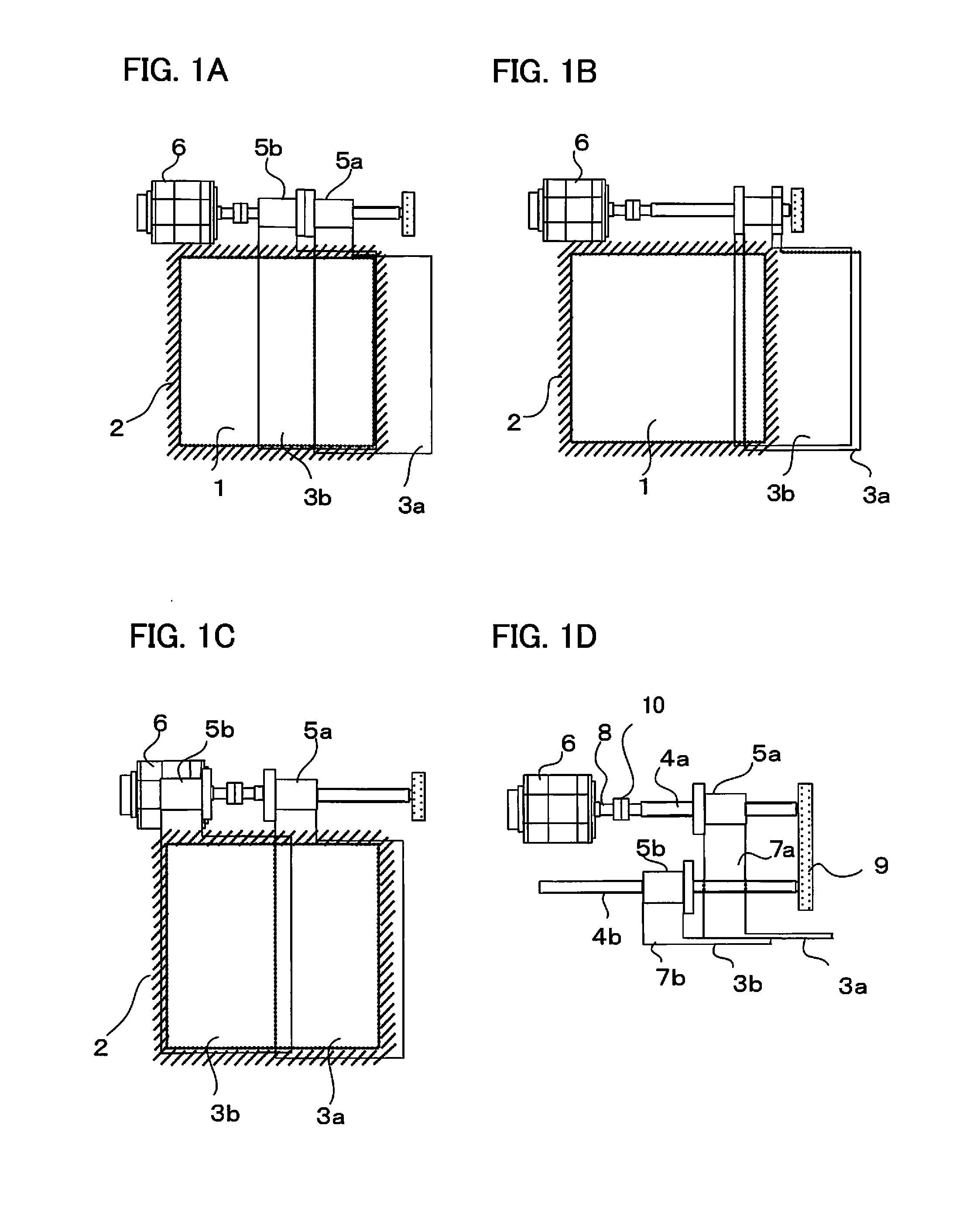

Spherical door and bidirectional synchronous opening and closing driving device for same

InactiveCN101936115AOpening and closingFlexiblePower-operated mechanismWing arrangementsEngineeringMechanical engineering

Owner:NINGBO UNIV

Automatic cap screwing mechanism for cosmetic bottle

InactiveCN111661797AImprove efficiencyImprove general purposeThreaded caps applicationConveyorsEngineeringBottle cap

The invention discloses an automatic cap screwing mechanism for a cosmetic bottle. The automatic cap screwing mechanism for the cosmetic bottle comprises a conveying device, a cap arranging device, aclamping device and a cap screwing device, the conveying device conveys cosmetic bottles to move in equipment, the cap arranging device can arrange output bottle caps to be in a state that cap openings face downwards and move the bottle caps to a bottle cap sliding way connected with the output ends of the bottle caps, the bottle cap sliding way sequentially hangs and takes away the cosmetic bottles passing through the tail ends of the bottle cap sliding way, the clamping device clamps and fixes the cosmetic bottles on the conveying device and moves the cosmetic bottles to the position under acap screwing ring of the cap screwing device, the cap screwing device can screw the bottle caps on the cosmetic bottles, a detection device is further arranged at the rear end of the cap screwing device, and unqualified cosmetic bottles are moved into a defective product conveying belt by the detection device. Compared with the prior art, the automatic cap screwing mechanism for the cosmetic bottle is wide in application range and capable of achieving automatic work in the whole process, improving work efficiency and reducing labor intensity.

Owner:SUZHOU XINPAITE INFORMATION TECH CO LTD

Double-locking trap

The invention relates to a double-lock drainage valve, the cavity formed by the valve and the shell has a valve core, valve base and a flat compound metal plate which is heat-variable deformation, 'C' type compound metal plate and supporting plate, the sealed surface of the valve core and the base is arranged at the lower part of the valve base, the 'C' type compound metal plate is fixed on the valve, the upper side of the 'C' type compound metal plate is connected to the flat compound metal plate directly, the supporting plate is arranged on the lower part of the flat compound metal and acts supporting effect. The flat compound metal plate and the valve core are connected together with shifting yoke mode. When the temperature in the cavity changes, the 'C' type plate and the flat compound metal plate shift the valve core to move up and down, thus control the valve to be opened or closed. The invention has a large lock force, the volume of the valve is small.

Owner:周杰仁

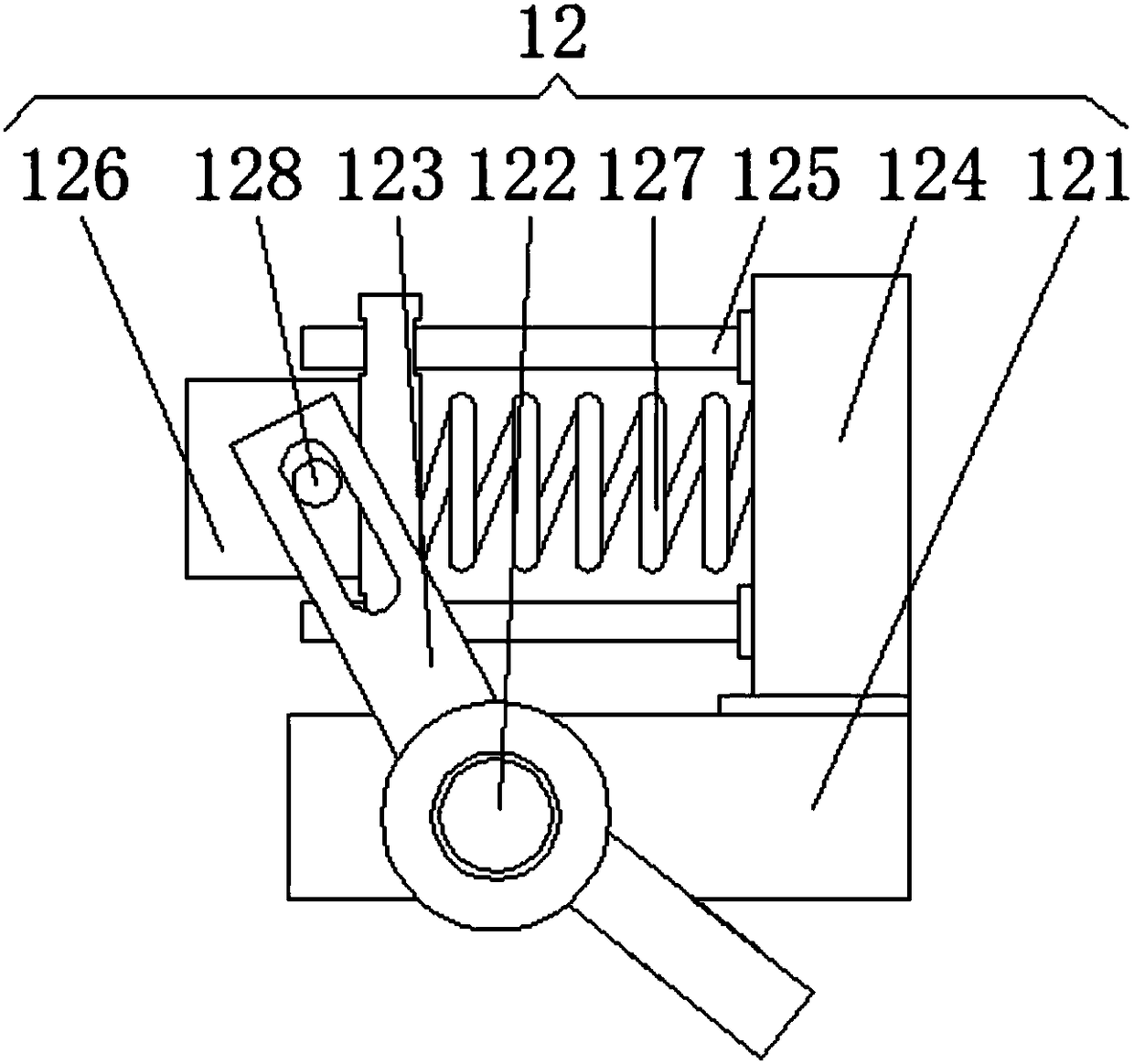

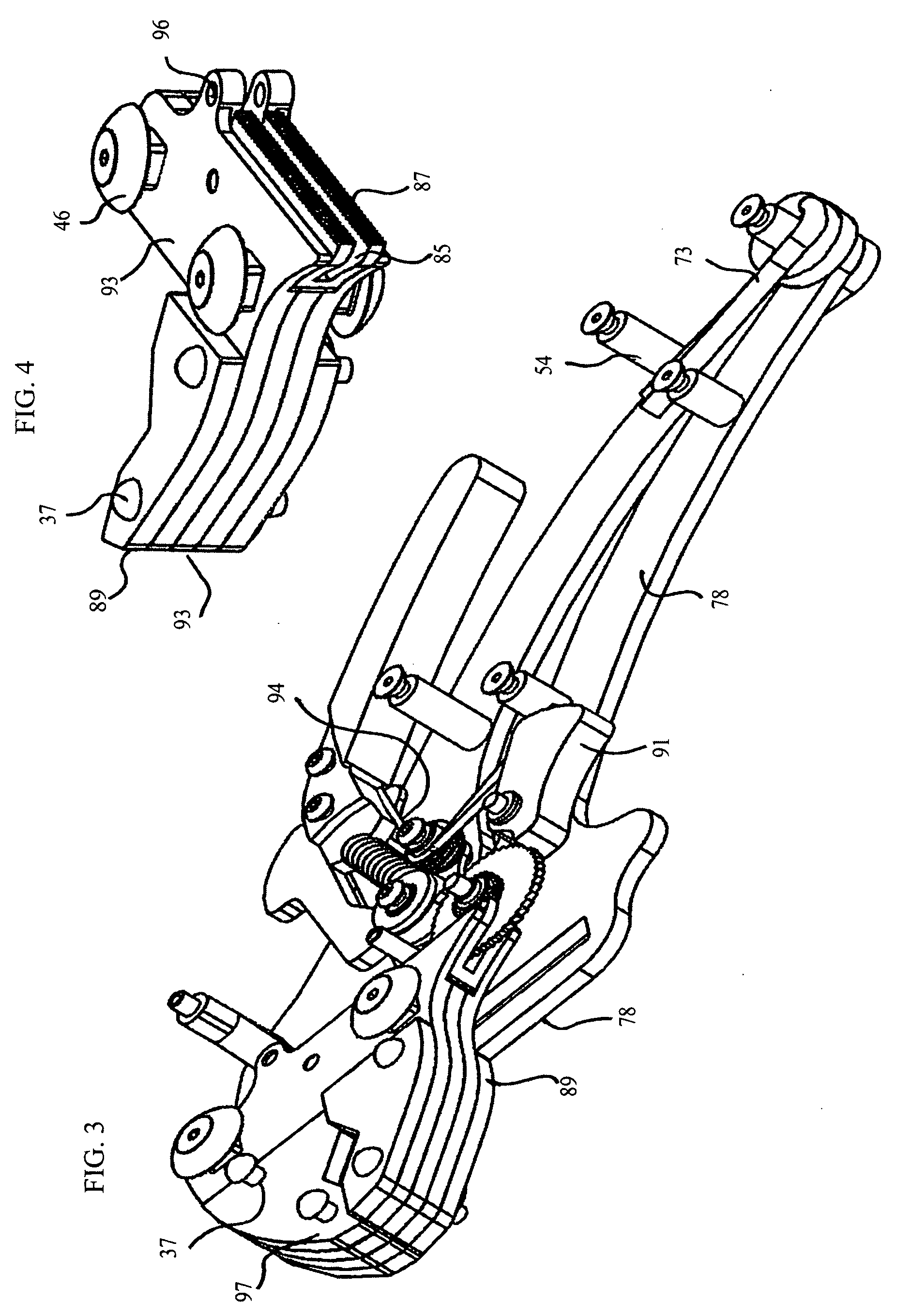

Mould locking device for bottle blowing machine

A mould locking device for a bottle blowing machine comprises a mould frame base, a front mould plate, a middle mould plate, a rear mould plate and a guide column, wherein the front mould plate, the middle mould plate and the rear mould plate are arranged on the mould frame base, the guide column penetrates through all mould plates, a left mould is positioned on the middle mould plate, a right mould is arranged on the front mould plate, and a hinged mould locking mechanism is symmetrically distributed and movably hinged between the middle mould plate and the rear mould plate. The mould locking device is characterized in that a flat piston cylinder is installed between the right mould and the front mould plate. The hinged mould locking mechanism is formed by two hinge rods which are movably hinged with a connection rod A and a connection block, the two hinge rods are movably hinged through a carriage, and a servo motor driving roller lead screw is in screw connection with a nut on the carriage. The mould locking device has the advantages of using an ordinary air cylinder or a hydraulic oil cylinder or even the servo motor push lever principle to open and close a mould so as to be quick in opening and closing speed and small in energy consumption; and individually using a mould locking air cylinder with large cylinder diameter and short stroke to lock the mould so as to be large in mould locking force, high in work efficiency and the like.

Owner:GUANGDONG LESHAN INTELLIGENT EQUIP CORP LTD

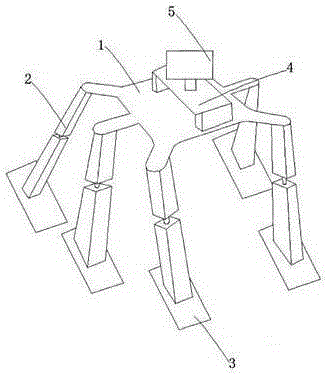

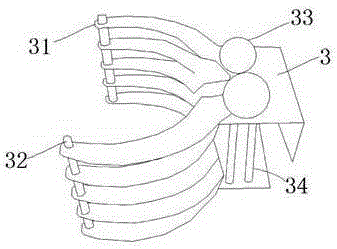

Mobile climbing type image acquisition detection robot

The invention discloses a mobile climbing type image acquisition detection robot. The mobile climbing type image acquisition detection robot comprises a bearing chassis, mechanical arms and a total controller, wherein a supporting base is arranged on the upper surface of the bearing chassis; a video camera is arranged at the top of the supporting base; mechanical arm supporting frames are arranged at the periphery of the bearing chassis; the mechanical arms are fixedly arranged on the end parts of the mechanical arm supporting frames; mechanical claws are arranged at the tail ends of the mechanical arms; and each mechanical claw comprises mechanical branched claws, collecting columns, gears and supporting columns. The mobile climbing type image acquisition detection robot adopts six-feet design and a mechanical claw structure, has the functions of the functions of the existing robot and realizes a true climbing robot by virtue of the grabbing capabilities of the six mechanical claws, can climb vertical steps, can stop on a vertical structure object by virtue of a grabbing force and facilitates effective work of image acquisition equipment and a detector on the robot; and the robot chassis is provided with caterpillar tracks capable of moving on muddy ground conveniently.

Owner:董艳华

Pressure test pit

InactiveCN105605401ARealize automatic openingAchieve closureEngineering safety devicesArchitectural engineeringStructural engineering

Owner:SICHUAN NAUTILUS IND EQUIP OPERATION MANAGEMENT CO LTD

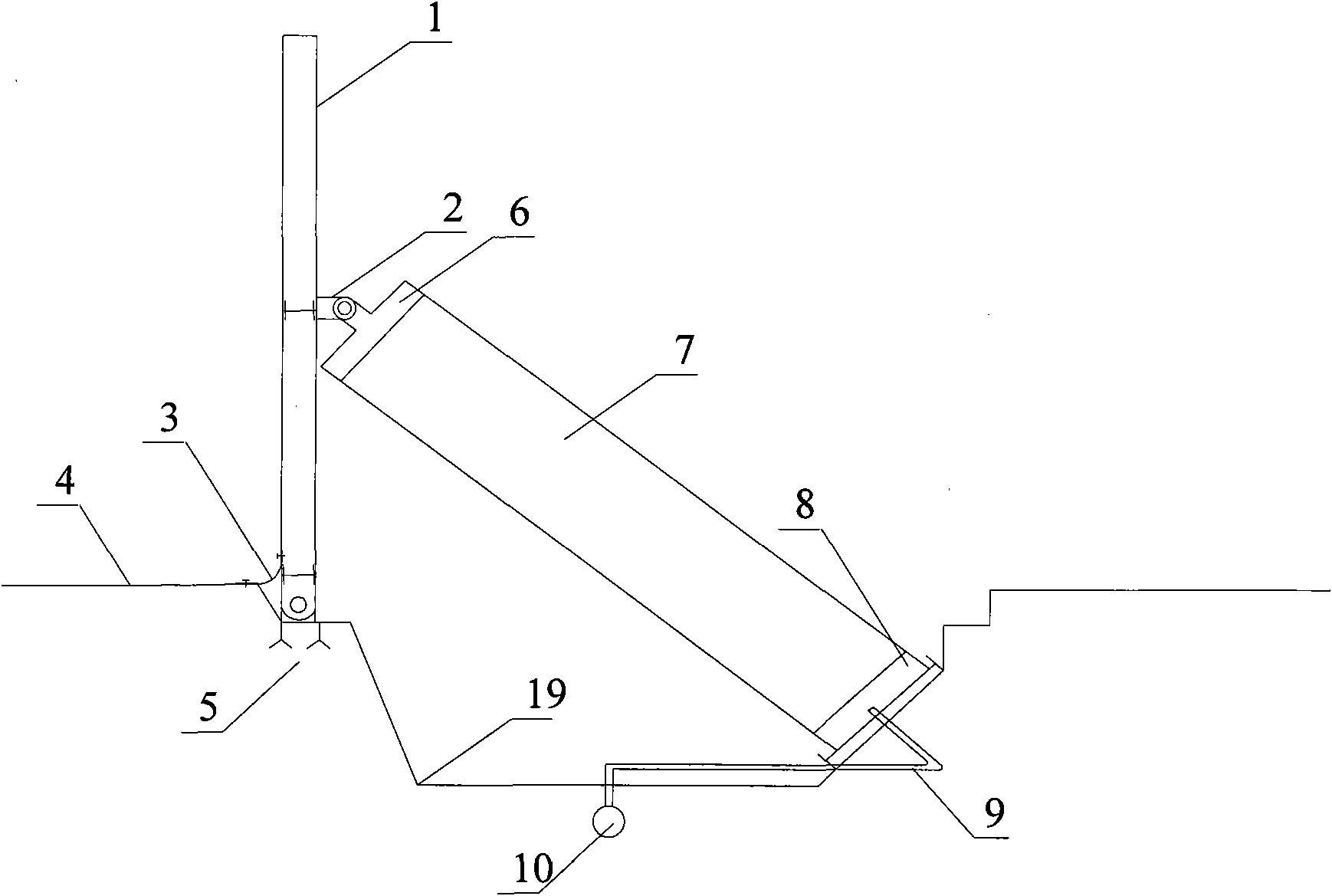

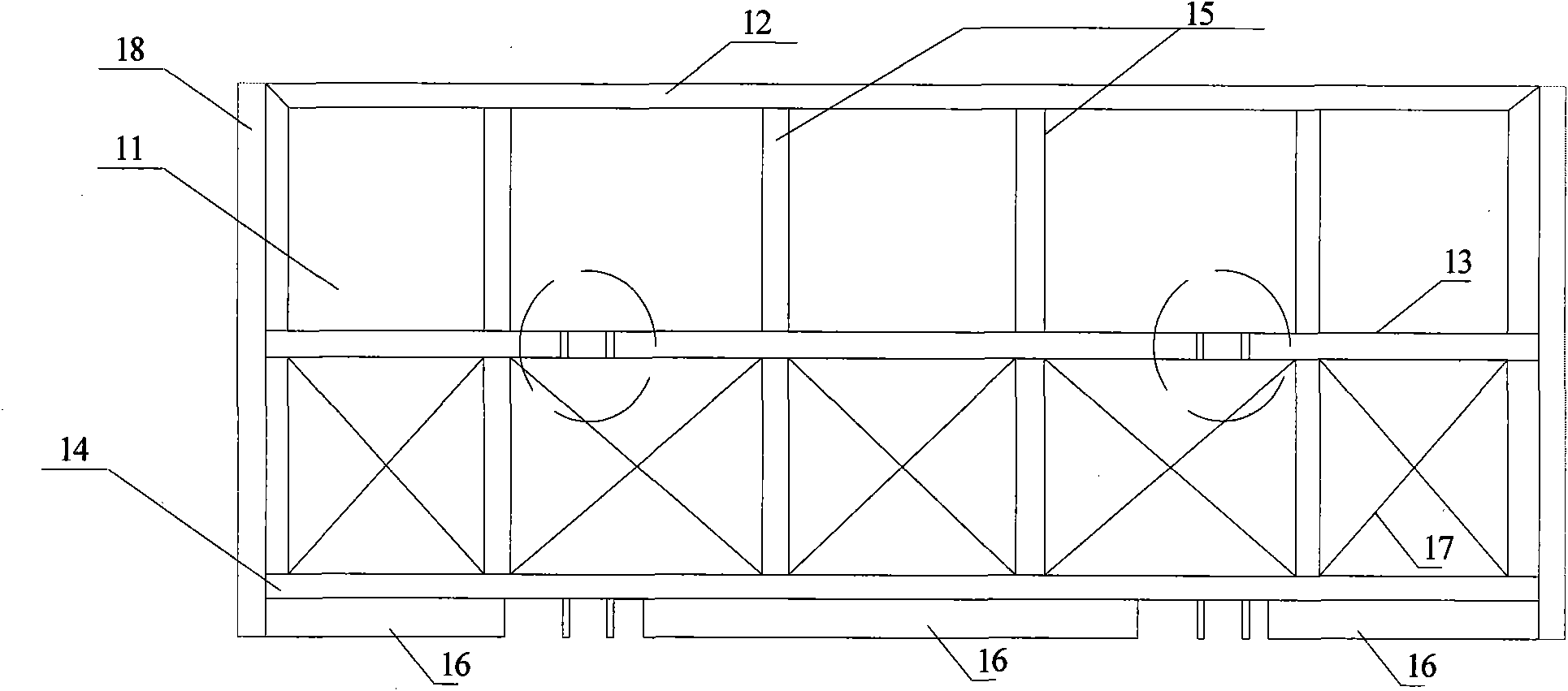

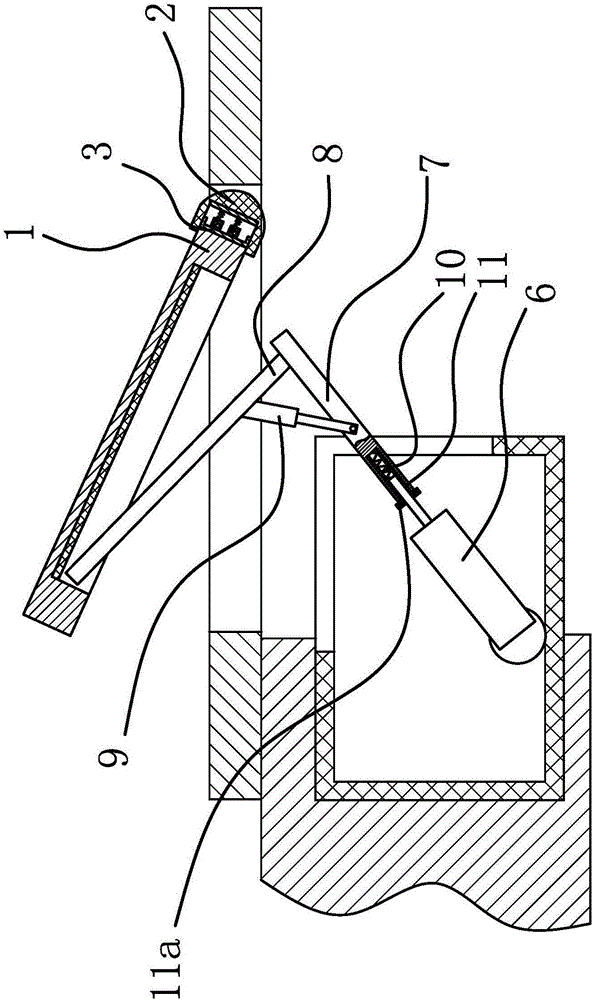

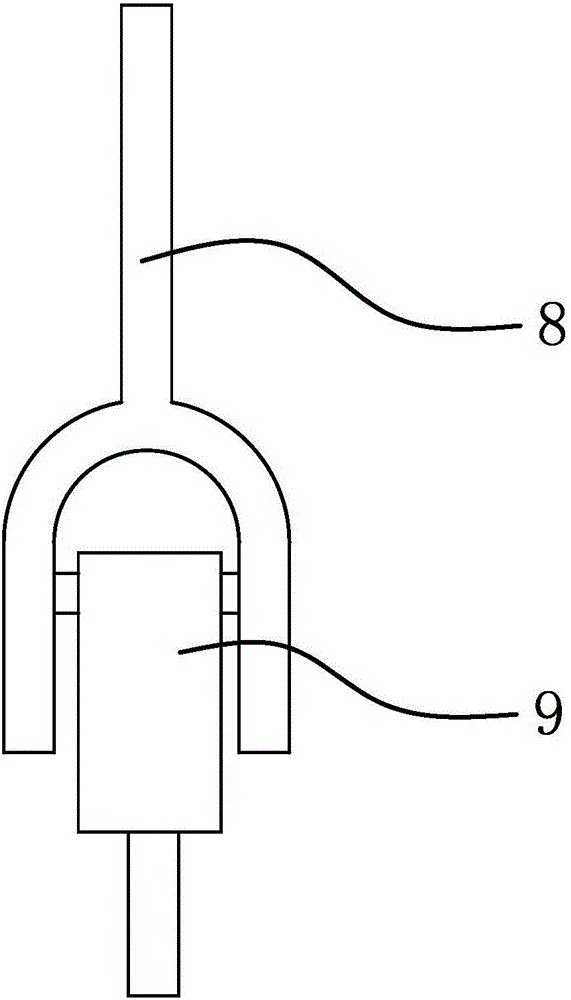

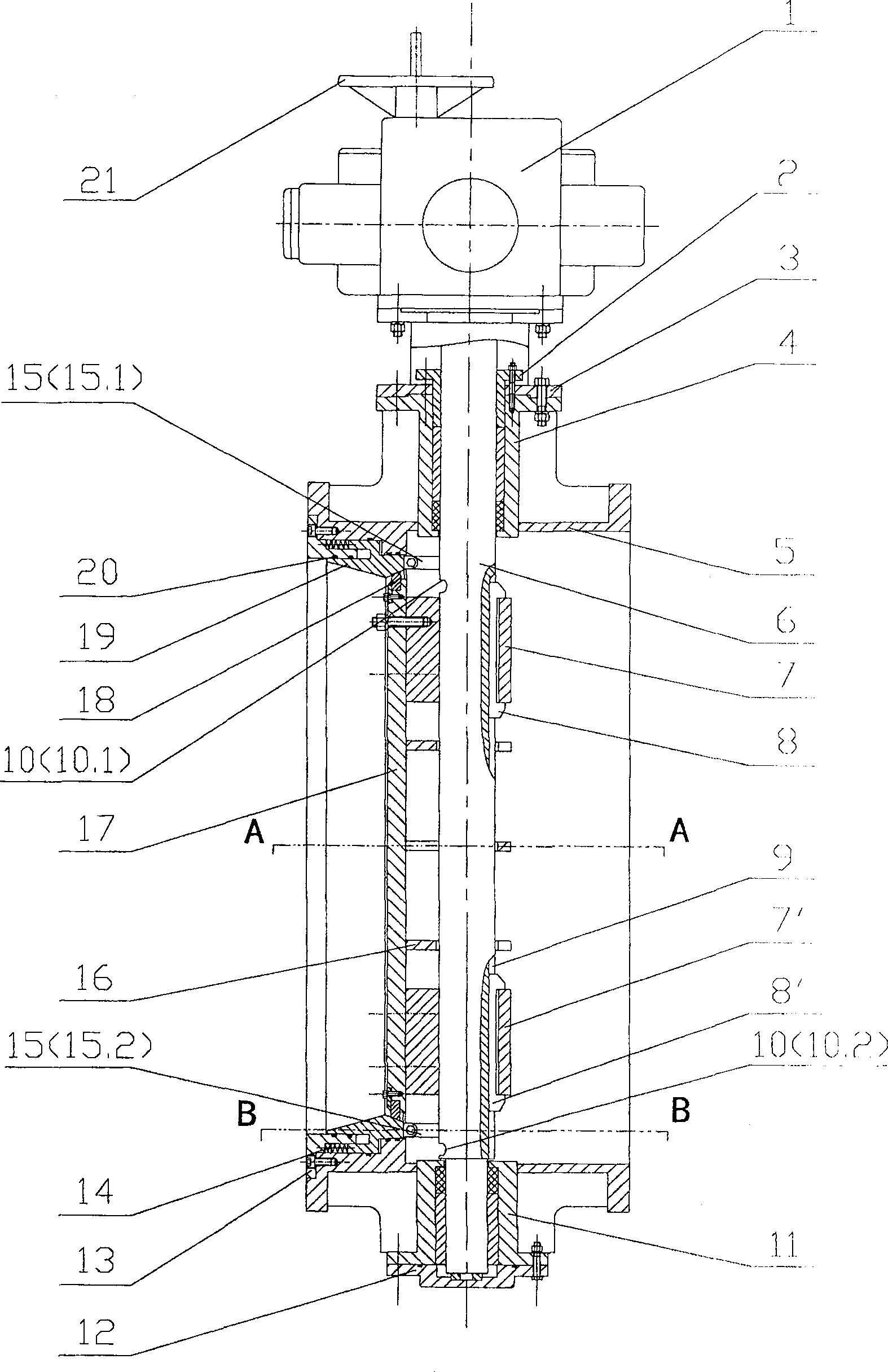

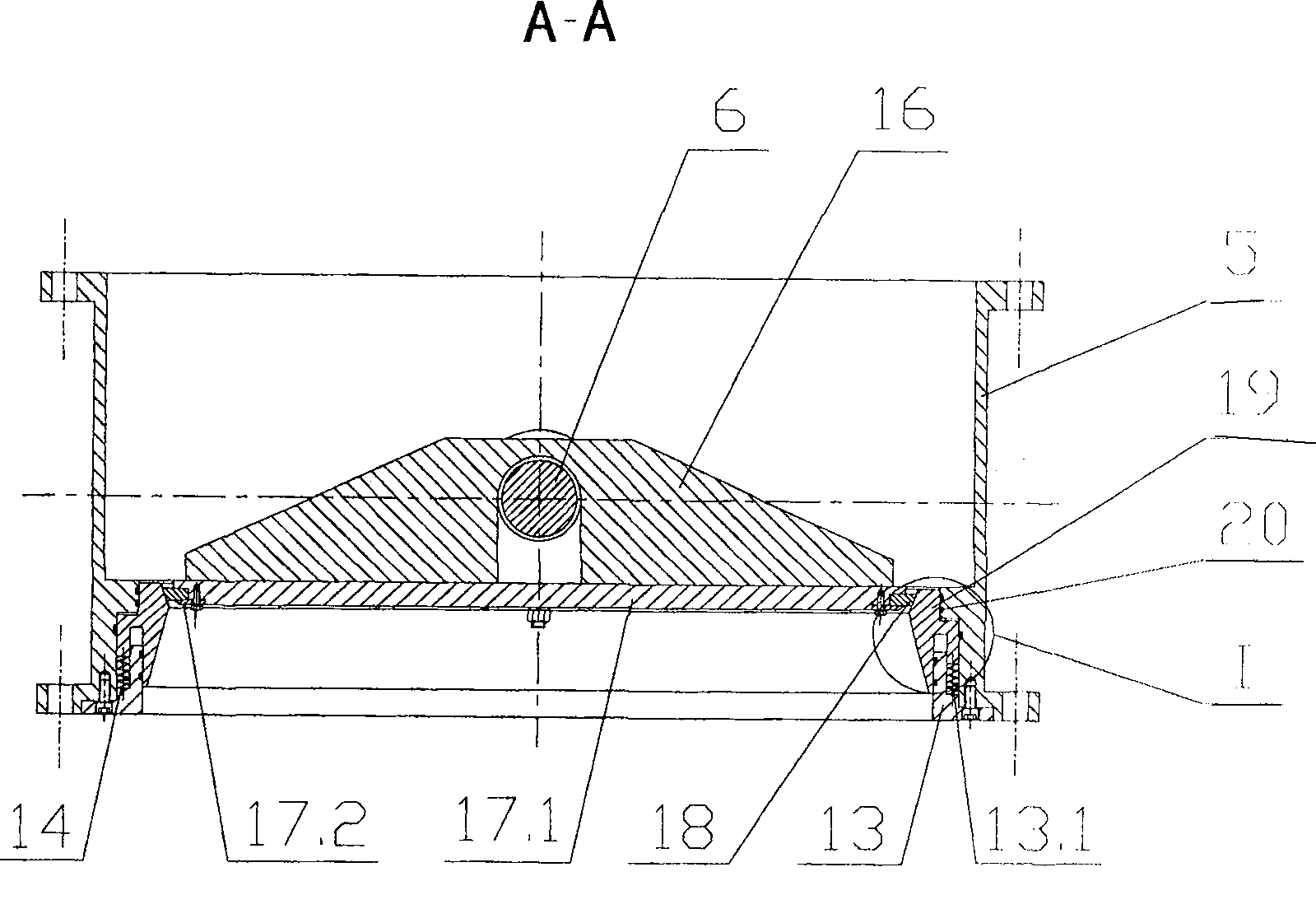

Flexible interlink steel gate and support opening/closing device thereof

The invention provides a flexible interlink steel gate and a support opening / closing device thereof, which belongs to the technical field of hydraulic engineering. The flexible interlink steel gate mainly comprises a flat plate steel gate (1), a gate support hinge (2), a cylindrical rubber bag communicated (7) with a water supply / drainage system, a flange (6) at the upper part of the rubber bag, a connecting piece (8) at the lower part of the rubber bag, a bottom water stop (3), a side water stop (18), a door interlink, and the like. The steel gate is made of a steel panel and a light structural steel beam grid system through welding, adjacent gates can be connected through the water stops and the interlink fasteners, and one gate is connected with a bottom plate pre-embedded part (5) through a hinge, and is controlled to be opened or closed through the expansion and the retraction of the rubber bag which is filled with water or discharges water. The invention has the advantages that less central piers are used, water is not blocked, the gate has a light and thin body and can be controlled to be opened or closed by a person, the water filled and discharge amount is small, the cost of construction is low, and the use is convenient, so that the flexible interlink steel gate and the support opening / closing device thereof can be widely applied in mountainous area watercourses and small hydro-electric power plants.

Owner:HEBEI AGRICULTURAL UNIV.

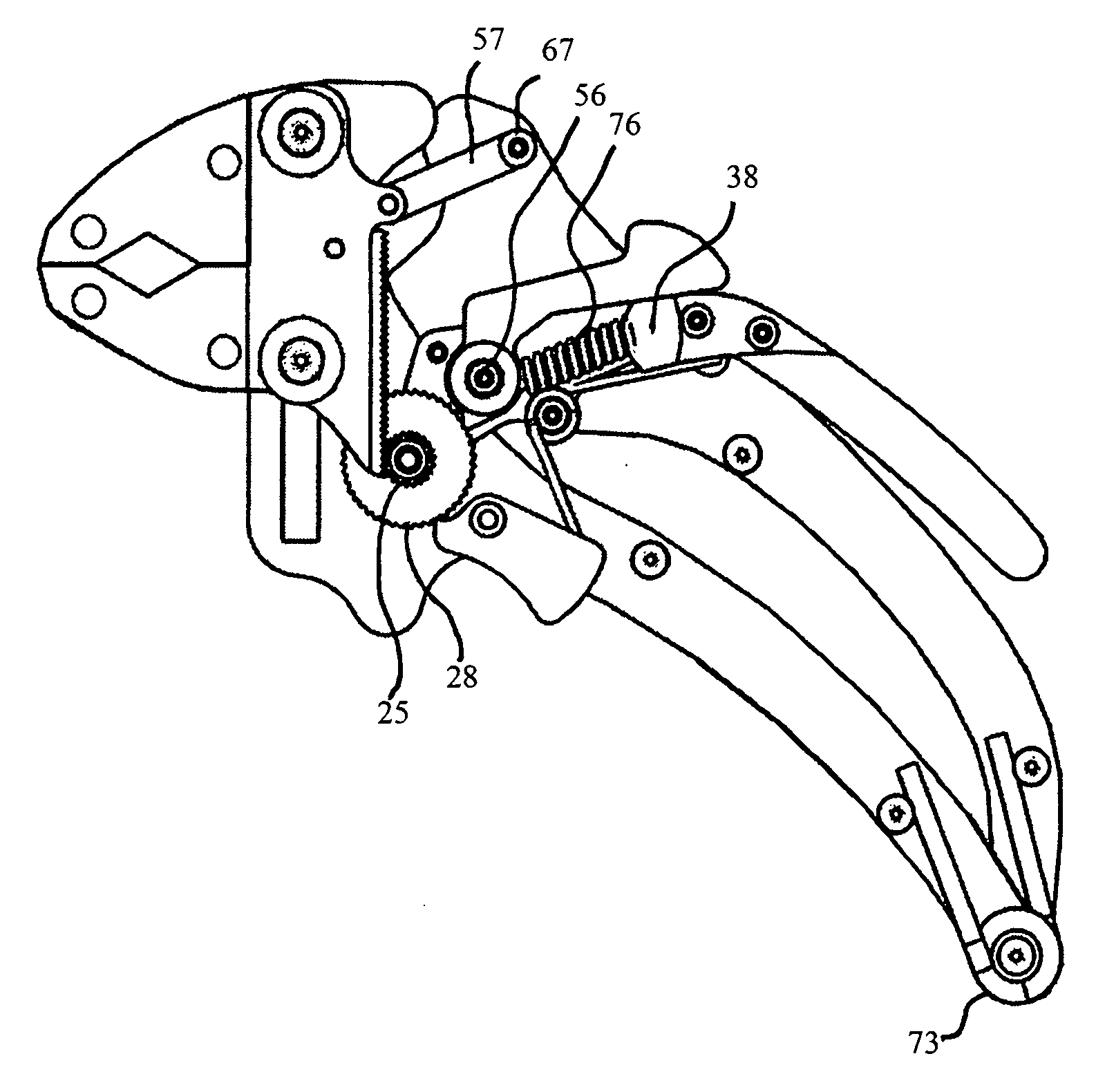

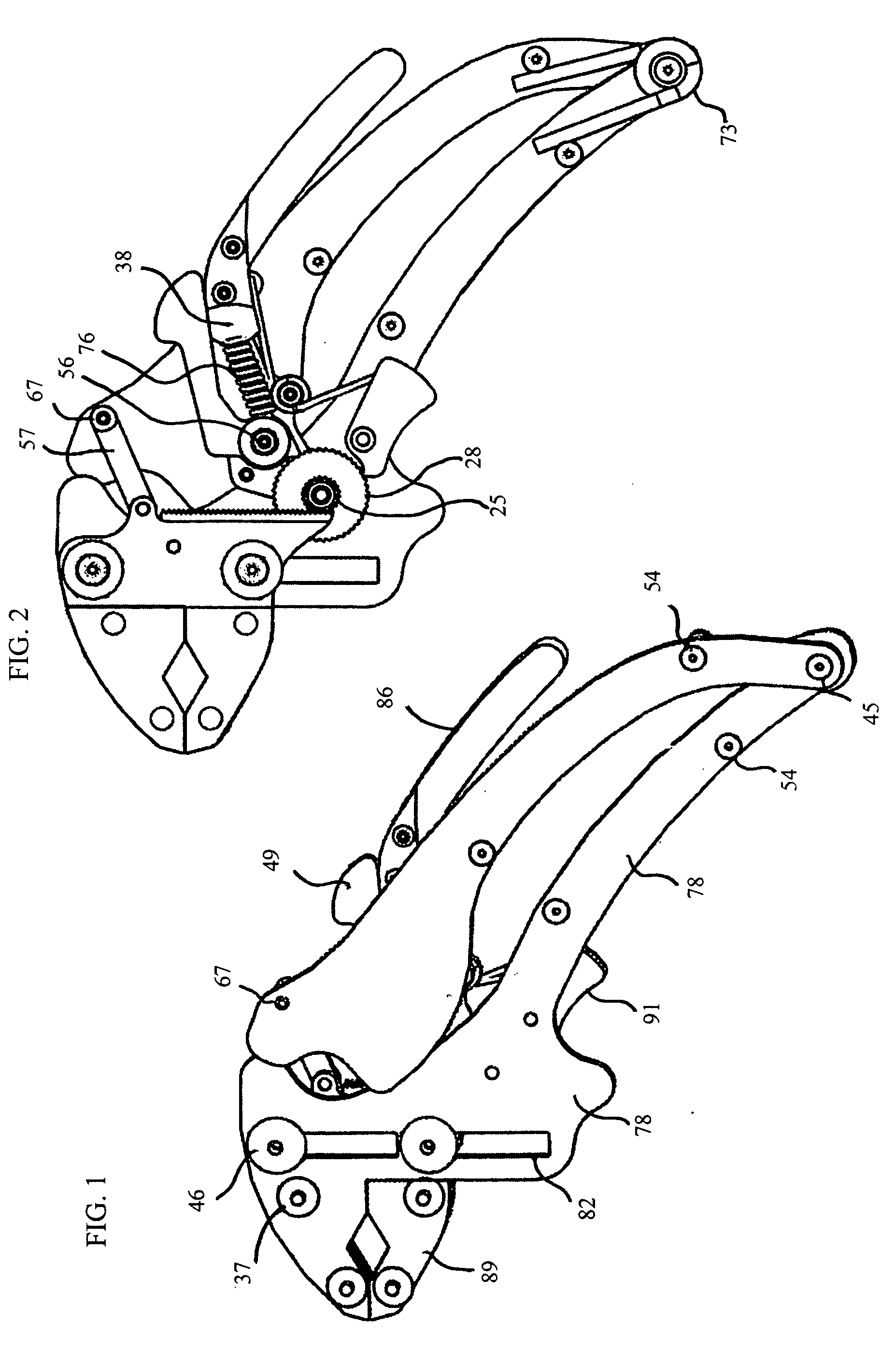

Release auto-grip locking tool

InactiveUS20100192735A1Maximizes single handed ease of useImprove ease of usePliersEngineeringHigh security

Owner:KELLY ARA DON

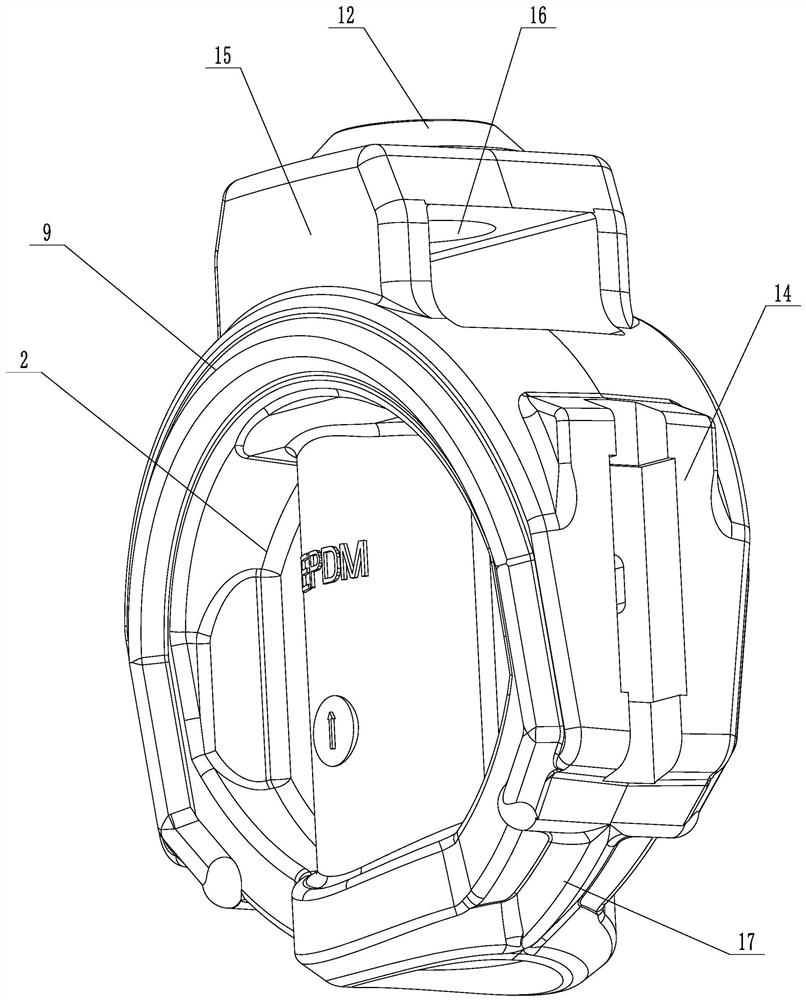

Rotary belt type stereo glasses

InactiveCN101261370AImprove clarityViewing comfortNon-optical adjunctsStereoscopic photographyComputer graphics (images)High definition

The invention relates to a rotating-belt type stereo glass belonging to the optical field, which is characterized in that, a stereoscopic television and a stereoscopic movie watched through the invention have extremely high definition; two opaque parts used for view occlusion are vertically arranged in interlaced distribution on the belt of the rotating-belt type stereo glass; the alternative occlusion of the opaque parts on the belt to the eyes is synchronous with the changes of television images or movie images; when two telefilms or movies simultaneously shot by two video cameras or cameras are played alternatively, the television images or movie images shot for the left eye enters the left eye, and the television images or movie images shot for the right eye enters the right eye; therefore, the stereoscopic television or the stereoscopic movie with high definition can be seen through the invention.

Owner:韩晓刚

Manufacturing method of combined ball clack for high-pressure double-valve-seat track ball valve

The invention provides a manufacturing method of a combined ball clack for a high-pressure double-valve-seat track ball valve. Ball clack bodies and a rolling shaft are of a matched structure, a gap is formed in the center connection position, and normal movement of the combined ball clack is guaranteed. According to the manufacturing method, firstly a cylindrical through hole is machined in the lower end of a center shaft of a whole valve ball body; secondly, the ball body is symmetrically divided into the left ball clack body and the right ball clack body; thirdly, the rolling shaft is machined according to the diameter of the cylindrical through hole; fourthly, the rolling shaft is put into the cylindrical through hole between the two ball clack bodies; and fifthly, the combined ball clack is formed. The combined ball clack is flexible to open and close, high in opening / closing speed and convenient to operate, and meanwhile the problem of dirt deposition at the center connection position of the ball clack is solved.

Owner:ZHEJIANG PETROCHEMICAL VALVE CO LTD

Drive component in automobile sunroof

The invention provides a drive component in an automobile sunroof and belongs to the technical field of machinery. The drive component in the automobile sunroof comprises a main oil cylinder, a first connecting rod, a second connecting rod and an auxiliary oil cylinder, wherein a cylinder body of the main oil cylinder is hinged to an automobile, a piston rod of the main oil cylinder is fixedly connected with the inner end of the first connecting rod circumferentially, the first connecting rod is capable of translating axially relatively to the piston rod, the outer end of the first connecting rod is hinged to the inner end of the second connecting rod, the outer end of the second connecting rod is used for being connected with the sunroof, a cylinder body of the auxiliary oil cylinder is hinged to the second connecting rod, and a piston rod of the auxiliary oil cylinder is hinged to the first connecting rod. The drive component in the automobile sunroof solves the problem that the sunroof is slow to open and close in the prior art, and is capable of increasing sunroof opening and closing speed.

Owner:绍兴职业技术学院

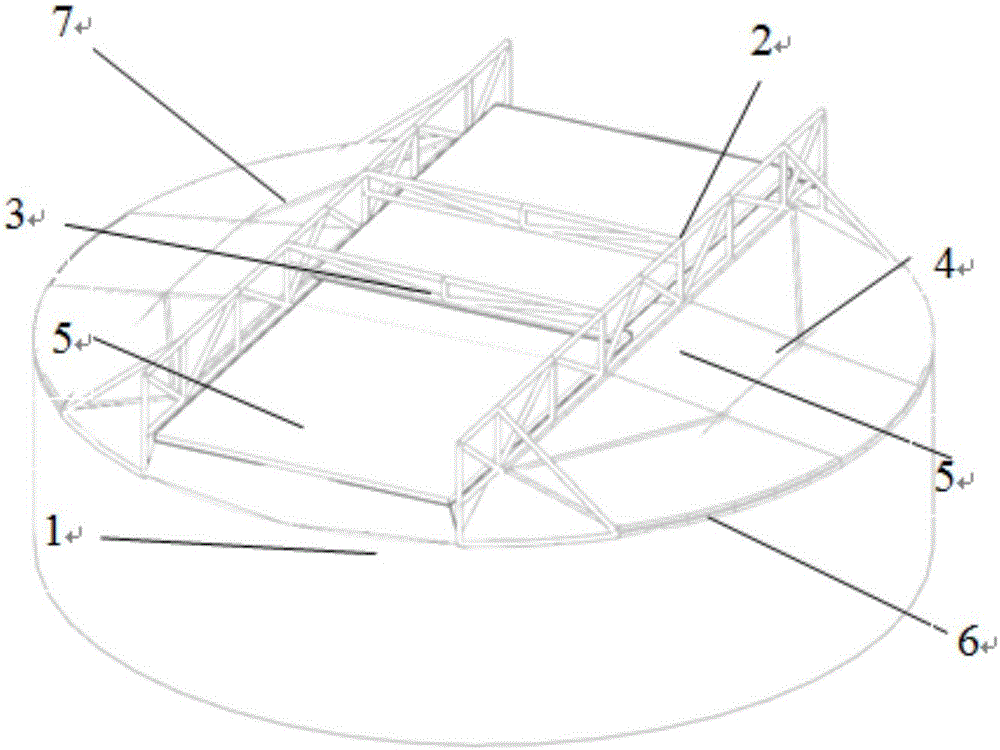

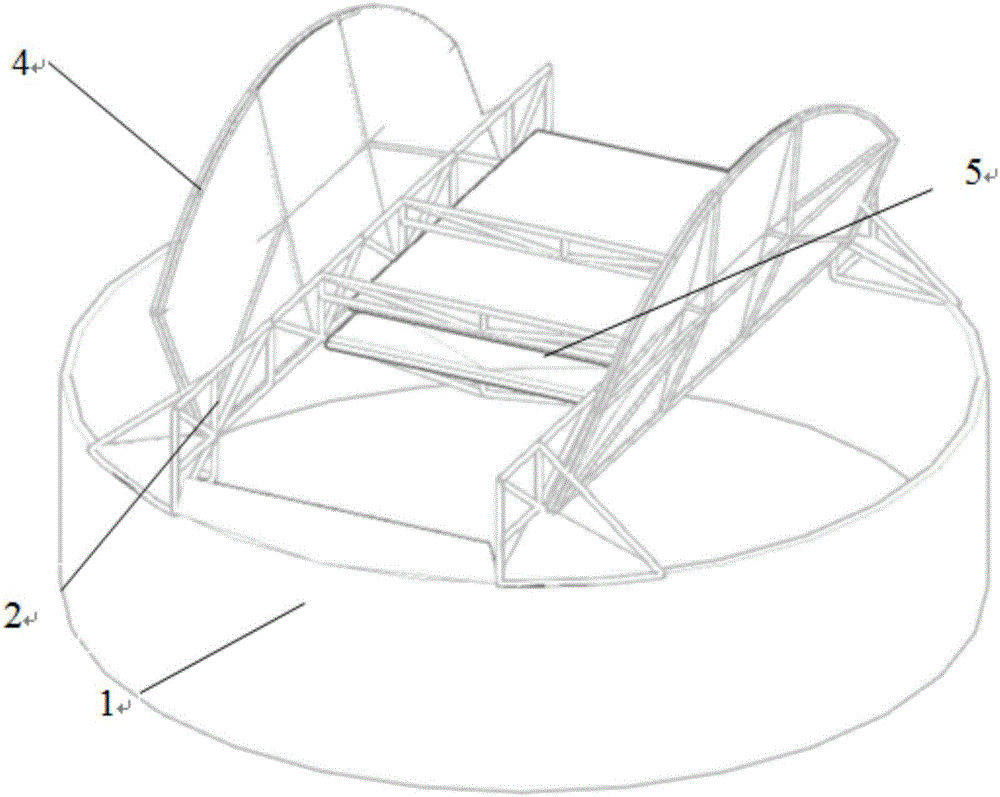

Turnover sliding combined type roofing structure capable of being opened and closed

PendingCN106437000ASimple structureImprove applicabilityBuilding roofsStructural engineeringEngineering

The invention provides a turnover sliding combined type roofing structure capable of being opened and closed. The structure comprises main beams, a main beam bracket, a support, a turnover structure and a sliding structure, wherein the main beams stretch across a building; the main beam bracket stretches across the main beams; the support is used for supporting the main beams; the turnover structure is arranged on the support; and the sliding structure is arranged on the support in a sliding way. A vehicle body sealing plate provided by the invention is simple in structure and high in applicability, and can be directly arranged on a steel safe shell cylinder body. Large-area opening or closing can be realized through automation, the requirements on building lighting, rain and snow resistance and wind resistance can be met, the lifting operation requirement of a reactor building can be met, and the structure can be conveniently mounted and dismounted for reuse.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Organic waste gas-smoke channel switching equipment and channel switching method

PendingCN107420919AImprove sealingSolution to short lifeIncinerator apparatusEnvironmental engineeringMechanical engineering

The invention discloses organic waste gas-smoke channel switching equipment and a channel switching method. The equipment and the method are applied to a double-chamber RTO waste gas treatment system in the field of organic waste gas treatment. The switching equipment is connected with an air inlet chamber, an air outlet chamber and an RTO equipment body, and comprises an upper gas channel, a lower gas channel and a vertical channel, the vertical channel is divided by a separating plate into two parts, the two vertical channel parts comprise an upper channel opening and a lower channel opening, hydraulic valves are arranged between the upper gas channel and the two vertical channel parts, the bottoms of valve rods are connected with a baffle, and the baffle is located between the upper channel opening and the lower channel opening; and a vent opening is formed in one side of the vertical channel. According to the switching method, motion position changes of the two valve rods are switched to achieve switching of smoke and waste gas flowing directions of the RTO equipment. The system switching speed is high, the thrust force of the hydraulic valves is large, the overall structure is compact, the floor space of the RTO equipment is greatly reduced, installation is convenient, the closed achieving manner of the baffle and the channel is metal sealing, the sealing effect is good, and the service life is as long as million times.

Owner:南京艾尔普特环保科技有限公司

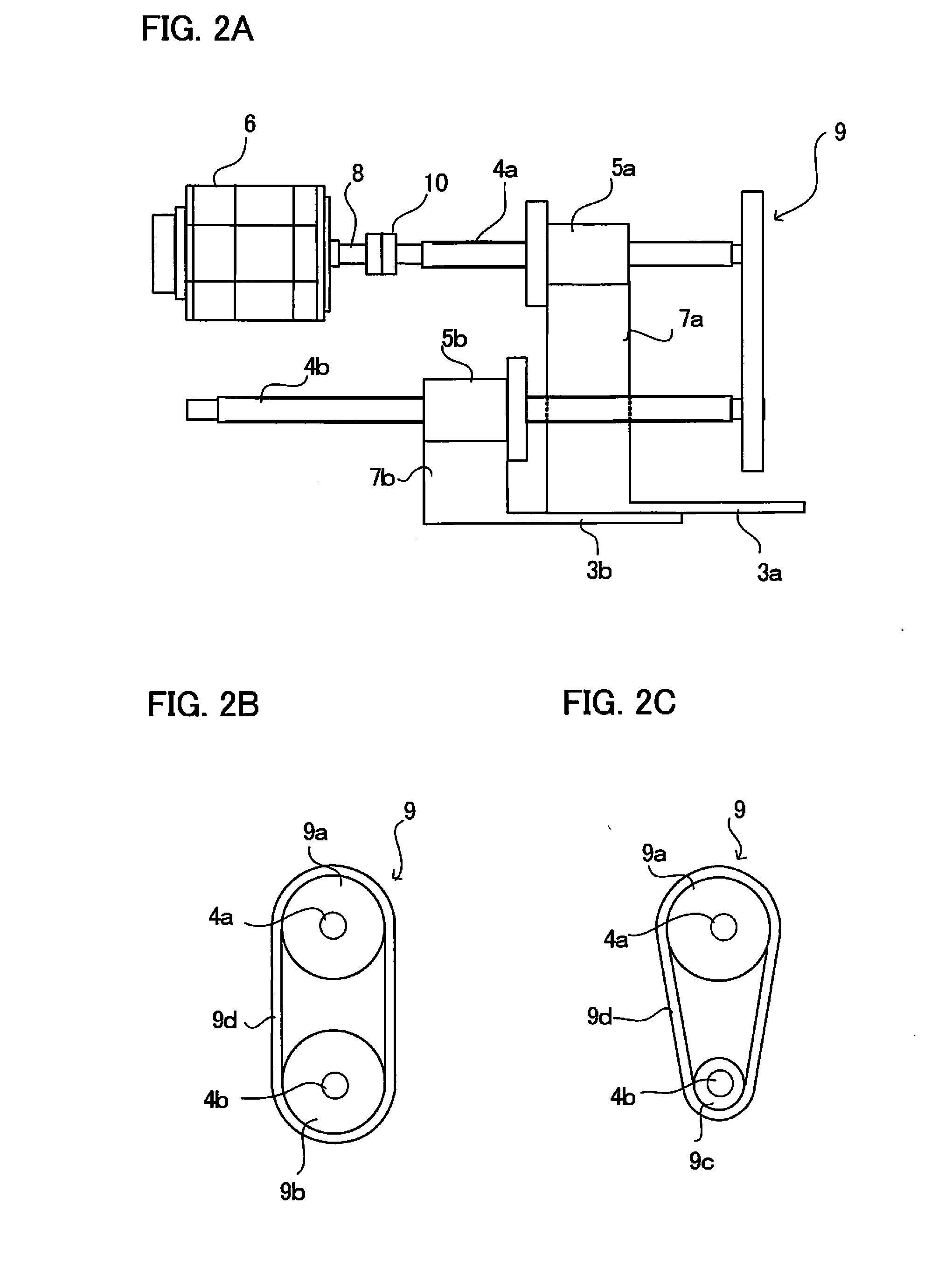

Slide door of machine tool

InactiveUS20160024834A1Open fastClose fastPower-operated mechanismWing arrangementsBall screwScrew thread

A slide door of a machine tool which slide door is constituted by first and second doors for opening and closing, in a sliding manner, an opening of the machine tool includes: a first nut fixed to the first door; a first ball screw engaged threadedly to the first nut; a second ball screw placed in parallel with the first ball screw; a second nut engaged threadedly to the second ball screw and fixed to the second door is fixed thereto; and a motor for driving the first and second ball screws via a power transmission mechanism.

Owner:FANUC LTD

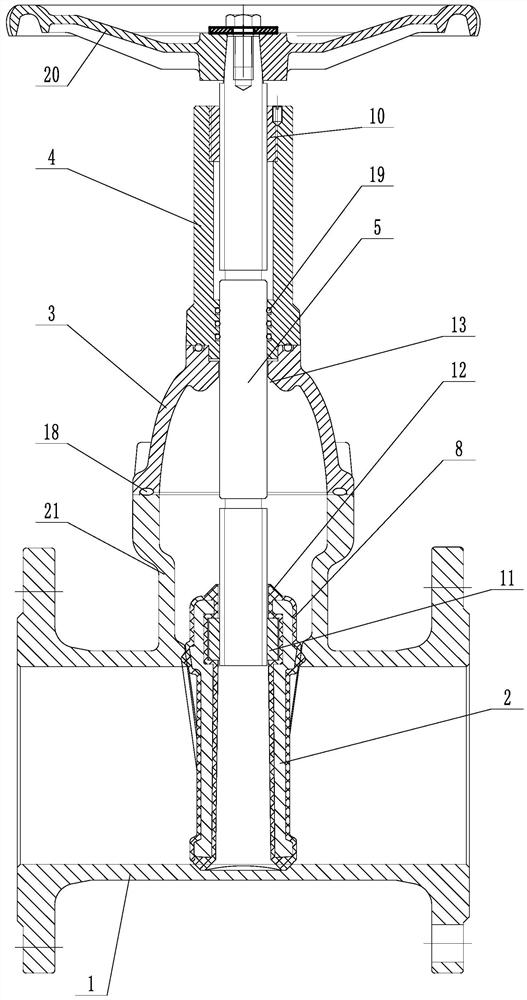

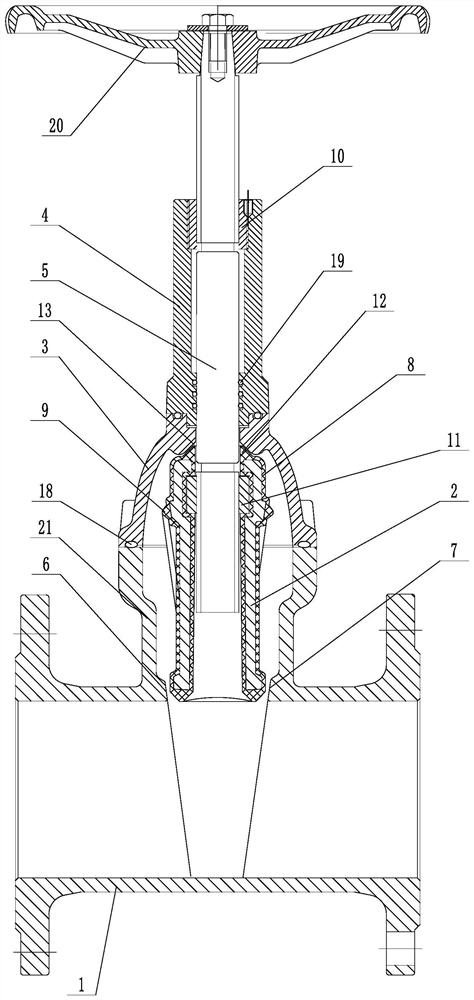

High-performance gate valve

ActiveCN112483672AOvercome the shortcomings of poor sealing performance and slow opening and closing speedFast opening and closingSpindle sealingsOperating means/releasing devices for valvesEngineeringGate valve

The invention discloses a high-performance gate valve and aims to overcome the defects that an existing gate valve is poor in sealing performance and low in opening and closing speed. The gate valve comprises a valve body, a gate plate, a valve deck and a support, wherein the gate plate is installed in the valve body in a matched mode, the valve deck is connected between the valve body and the support, a valve rod is connected to the gate plate, a left sealing face and a right sealing face are arranged in the valve body and correspond to the position of the gate plate, the outer surface of thegate plate is coated with a sealing layer, and sealing protrusions are arranged on the two sides of the gate plate. The two sealing protrusions are respectively attached and sealed with the left sealing face and the right sealing face. A support nut is installed on the support, a gate plate nut is installed on the gate plate, the thread turning direction of the support nut is opposite to that ofthe gate plate nut, and the support nut and the gate plate nut are both in threaded connection with the valve rod. The high-performance gate valve is good in sealing performance and high in opening and closing speed.

Owner:HANGZHOU CHUNJIANG VALVE

Non-abrasion hard-sealing butterfly valve

The invention relates to a wear-free hard-sealed butterfly valve, which includes a valve body, a valve rod, a butterfly plate and a valve seat, and is characterized in that the valve seat is a movable valve seat that can move axially along the inner wall of the valve body; one side of the valve body There is a side body; a sealing ring is installed between the valve seat, the valve body and the side body; the seal is fastened on the butterfly plate frame; there is a moving fit gap between the inner and outer sides of the valve seat and the valve body and the side body , there is a spring between the outer end surface of the valve seat and the side body, and the inner end surface is connected with the valve stem through a push rod; There is a long keyway in the middle of the valve stem, and there are upper and lower keys respectively fixed on the upper and lower connecting seats, and the upper and lower connecting seats are respectively fastened on the butterfly plate; the push rod It includes upper and lower push rods, one end of which is equipped with a roller, one end of the lower push rod is embedded in the lower curved groove, and can slide, and the other end is hinged with the inner end surface of the movable valve seat; the upper push rod and the lower push rod are installed symmetrically ; There is a single eccentric structure between the disc rotation axis and the sealing plane.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com