Automatic lossless dismounting recovery method and automatic lossless dismounting recovery device of discarded printed circuit board

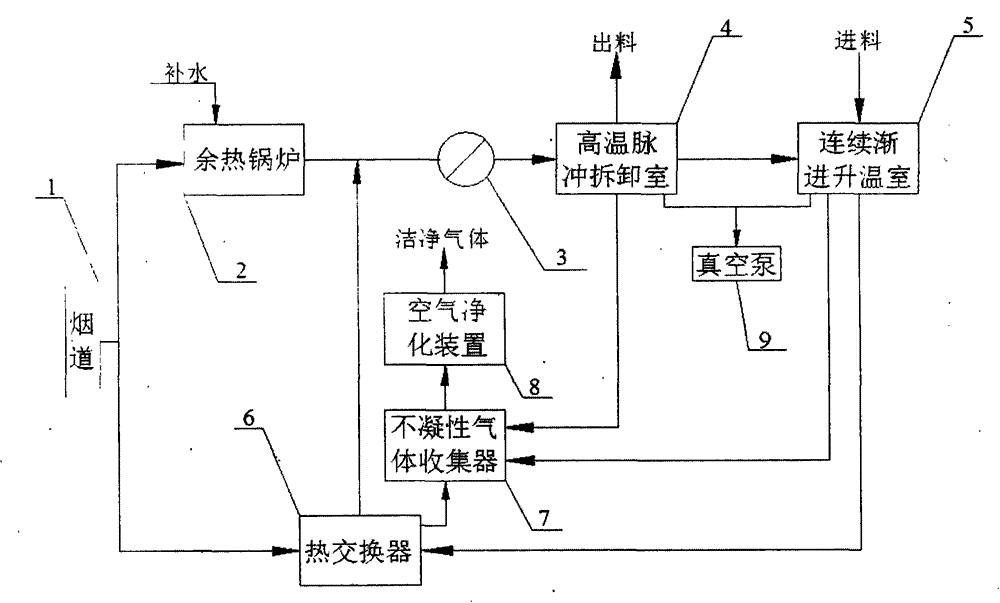

A technology for a printed circuit board and a recycling method is applied in the field of comprehensive utilization of electronic waste resources, which can solve the problems of increasing the loss of low-grade superheated steam, leakage of low-grade steam, and inability to achieve sealing, and achieve harmless automatic disassembly. The effect of separation, reduction of processing frequency, reduction of thermal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with specific embodiments.

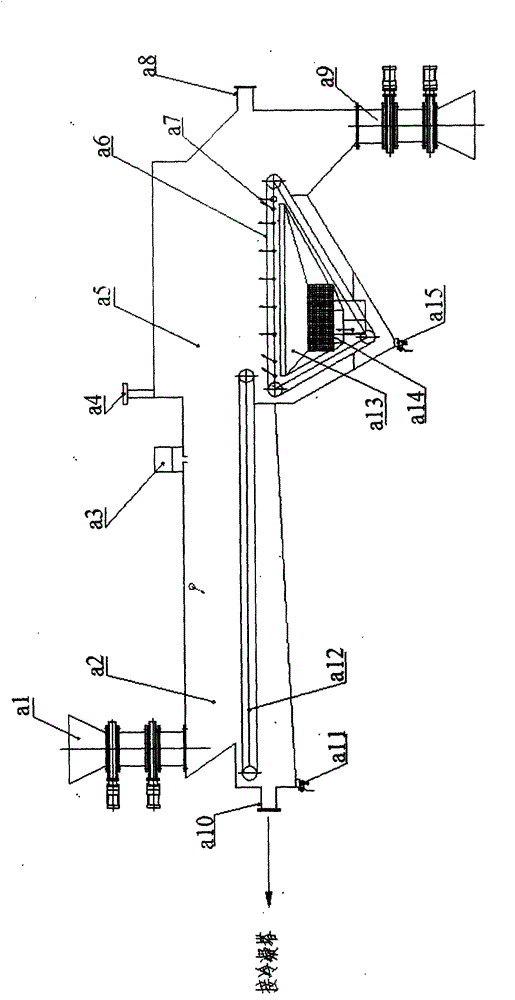

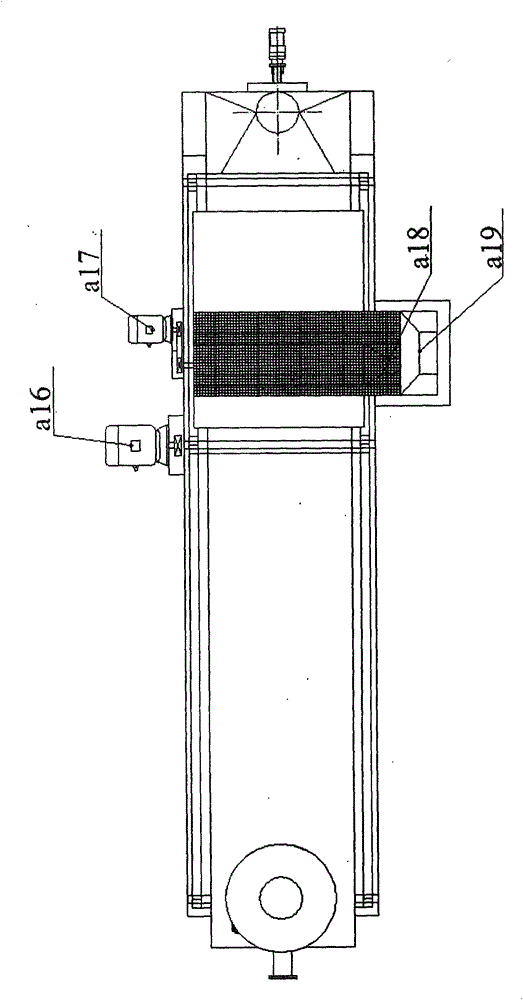

[0037] The invention improves the use of industrial waste heat to dismantle waste printed circuit boards, especially improves the industrial waste heat utilization method and the structural setting of the feed port and discharge port of the waste print circuit board automatic disassembly and recovery equipment, greatly improving the The working efficiency of the equipment is reduced, and the energy consumption of the equipment is reduced.

[0038] It should be noted that the waste printed circuit board mentioned in the present invention is a circuit board that has been used in electronic and electrical equipment, and then discarded together with the electronic and electrical equipment or in the production of circuit boards or production of circuit boards or production of electronic and electrical equipment. Waste circuit boards that appear during the equipment process.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com