Flexible pipe filling end sealing machine

A tail sealing machine and hose technology, applied in packaging machines, packaging sealing/fastening, packaging, etc., can solve the problems of affecting production efficiency, poor continuity, limiting the reciprocating speed of connecting blocks, etc., and achieve fast forward and reverse switching, The effect of fast response and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

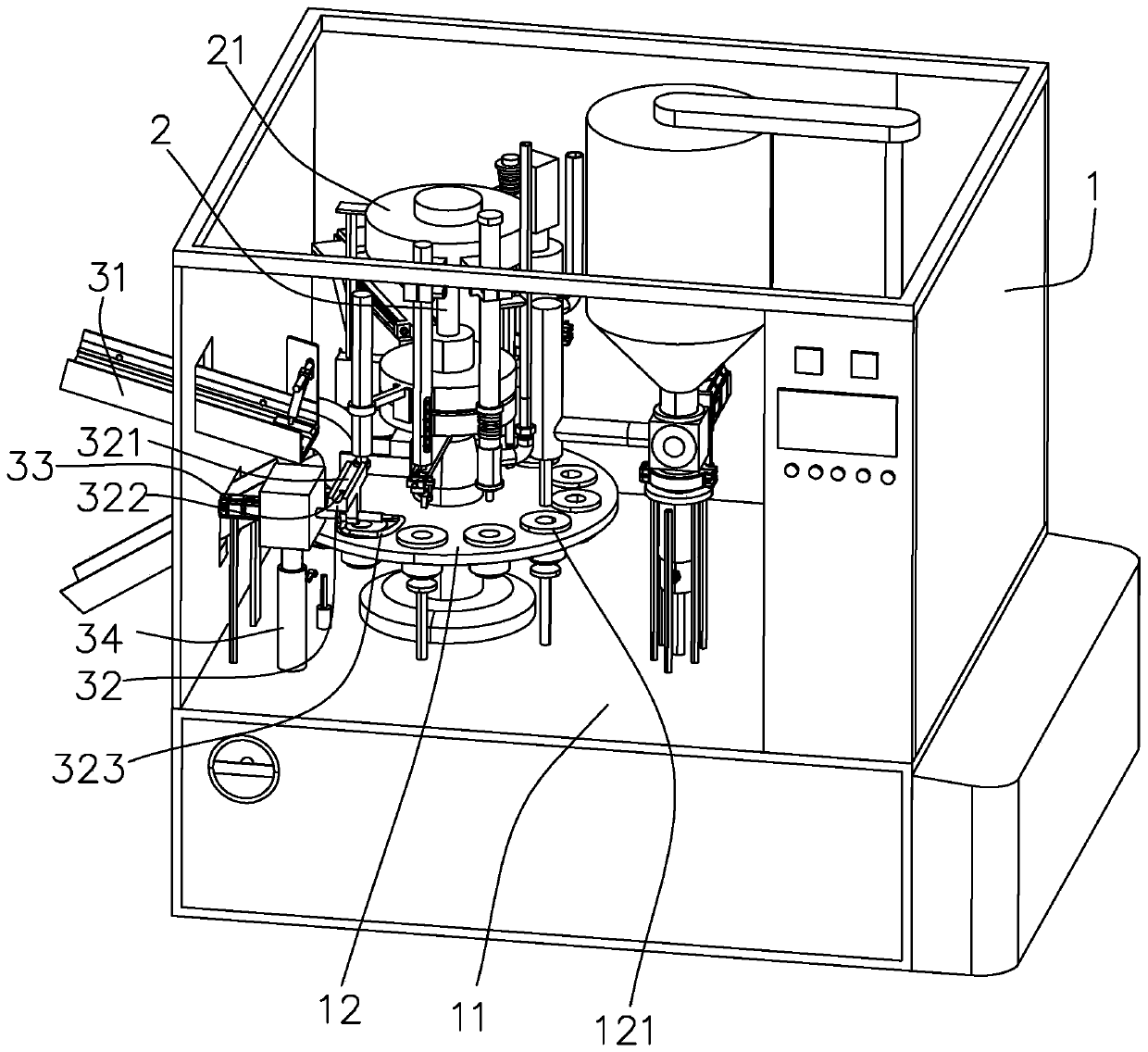

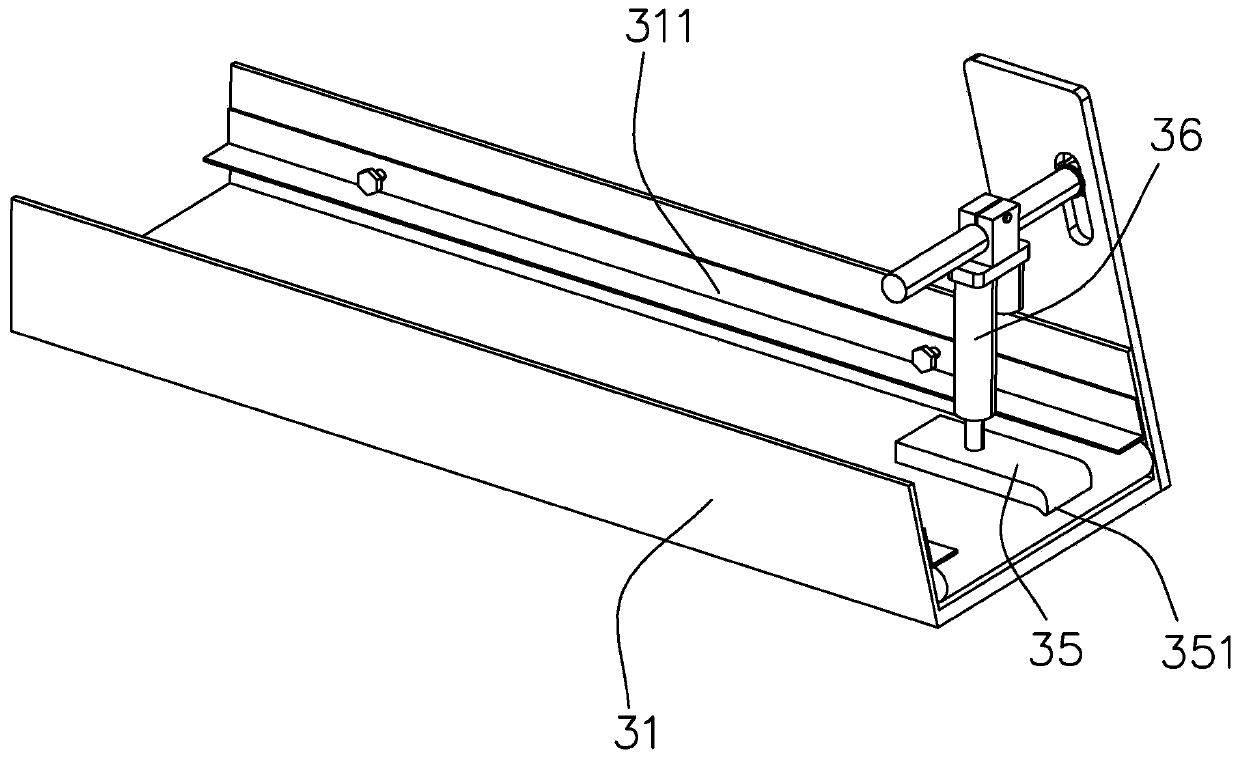

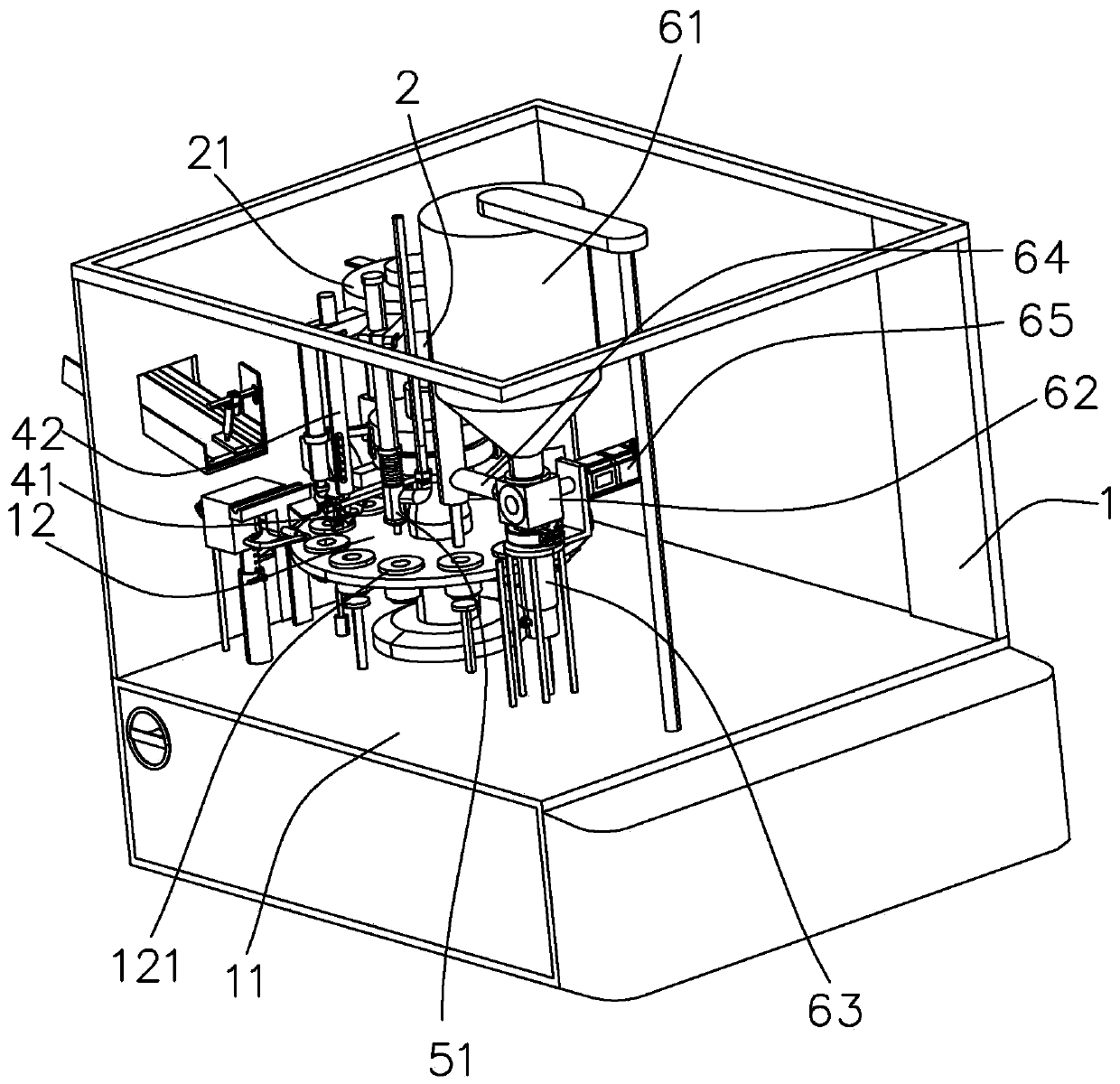

[0037] A high-speed hose filling and sealing machine, such as figure 1As shown, a frame 1 is included, and the frame 1 is provided with an upper pipe mechanism, a positioning mechanism, a dust removal mechanism, a filling mechanism, a heating mechanism, a clamping mechanism and an ejection mechanism. The frame 1 includes a workbench 11 on which a turntable 12 is rotatably connected. The turntable 12 is provided with a plurality of tube cups 121 in the circumferential direction, an upper pipe mechanism, a positioning mechanism, a dust removal mechanism, a filling mechanism, a heating mechanism, a clamping mechanism and a The outlet mechanism is arranged in sequence in the circumferential direction and corresponds to the tube cup 121. The tube cup 121 transports the hose, and the hose is sequentially processed through various processes until it is discharged.

[0038] Such as figure 1 As shown, the center of the turntable 12 is provided with a through hole and is vertically sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com