Hydraulic self-centering fast clamping device

A clamping device and self-centering technology, applied in positioning device, clamping, support and other directions, can solve the problems of inaccurate centering of workpieces, high work intensity, low loading and unloading efficiency, etc., to improve loading and unloading efficiency, The effect of reducing work intensity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

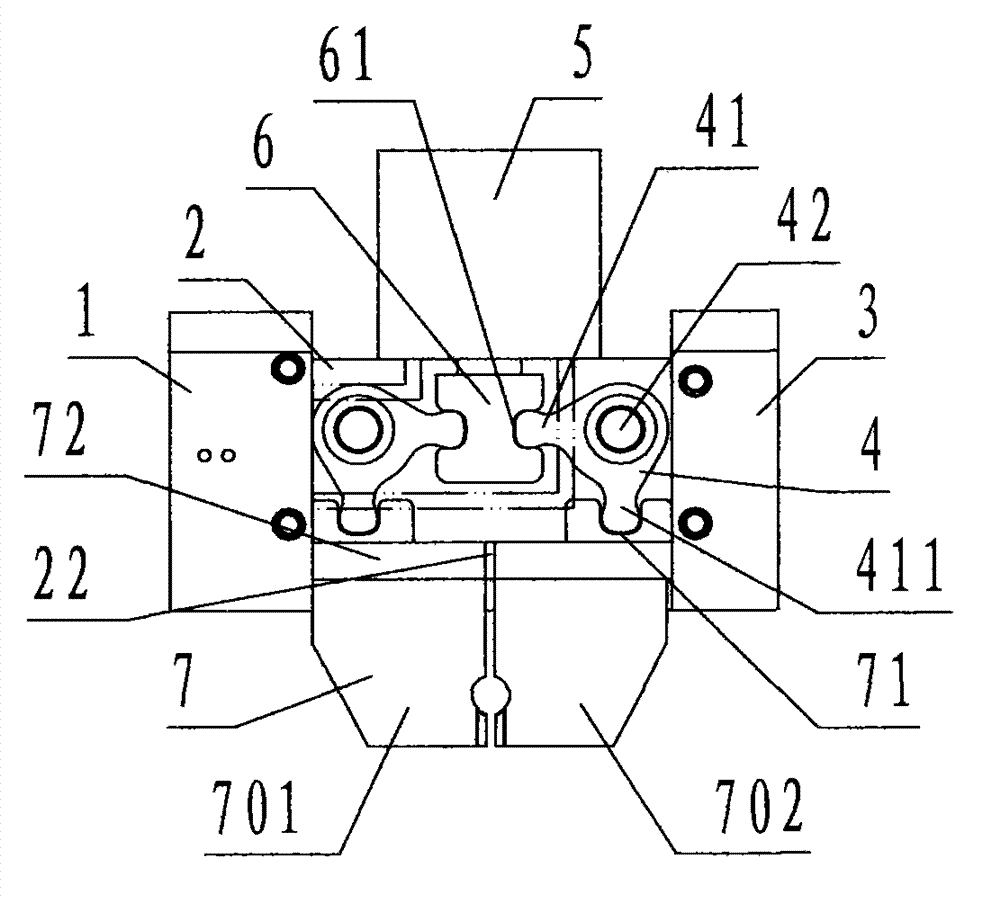

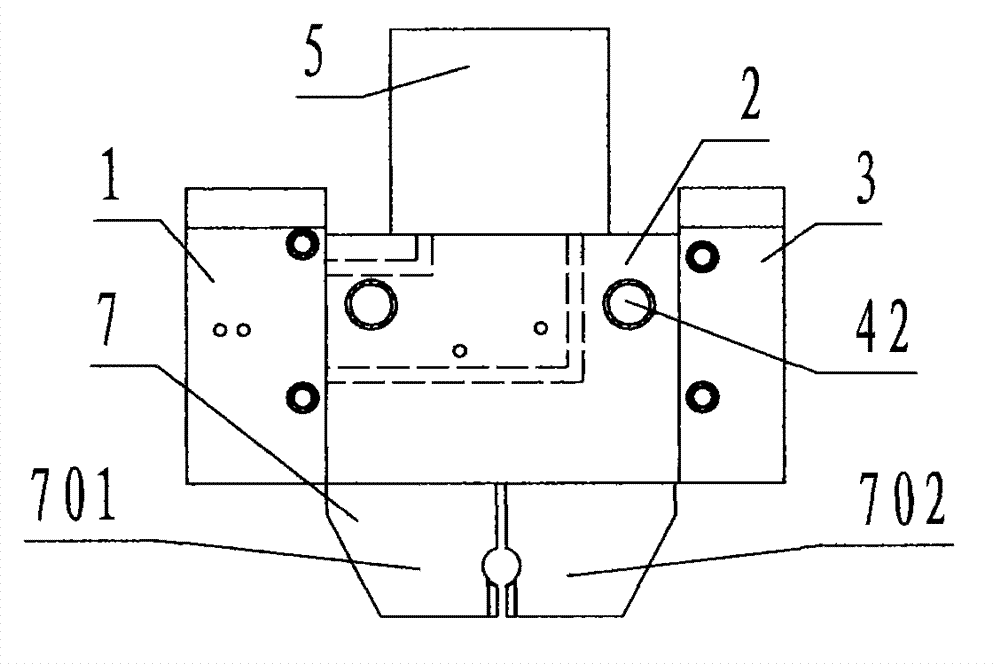

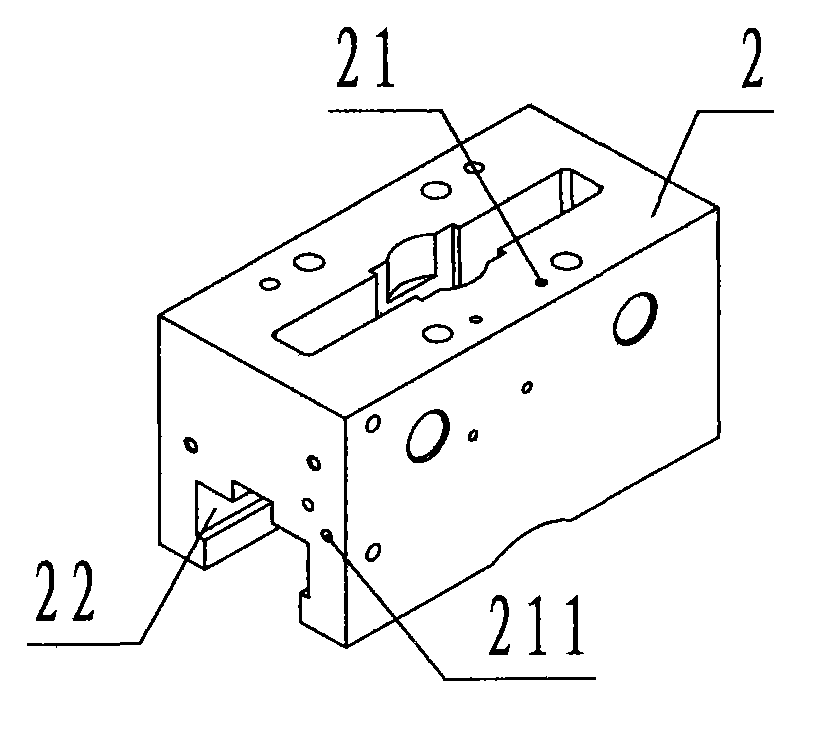

[0025] refer to Figure 1 ~ Figure 3 , a hydraulic self-centering fast clamping device of the present invention, comprising an oil circuit end plate 1, an oil circuit bridge plate 2, an end plate 3, a rotating shift fork 4, an oil cylinder 5, a driving joint 6, and a clamp 7, wherein: The oil passage end plate 1 described above is a rectangular block steel member; the right side of the oil passage end plate 1 is provided with a slot for fixing and inserting the left side of the oil bridge plate 2, which is called the right slot, and the inside of the oil passage end plate 1 There are two oil passages, and the two oil passages are provided with two A interfaces for respectively connecting with the two bridge oil passages of the oil bridge 2 in the bridge plate slot; the two oil passages On the left side of the oil passage end plate 1, there are two B interfaces for connecting with the oil distributor of the fourth axis of the CNC machining center; the center of the left side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com