Electromagnetic permanent magnet combined driving apparatus

A driving device and permanent magnet technology, applied in electromechanical devices, power devices inside switches, circuits, etc., can solve problems such as inability to move as a whole, poor transient performance of actions, and hidden dangers of fatigue failure, so as to achieve simple overall mechanism and fast opening and closing action , The effect of high driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

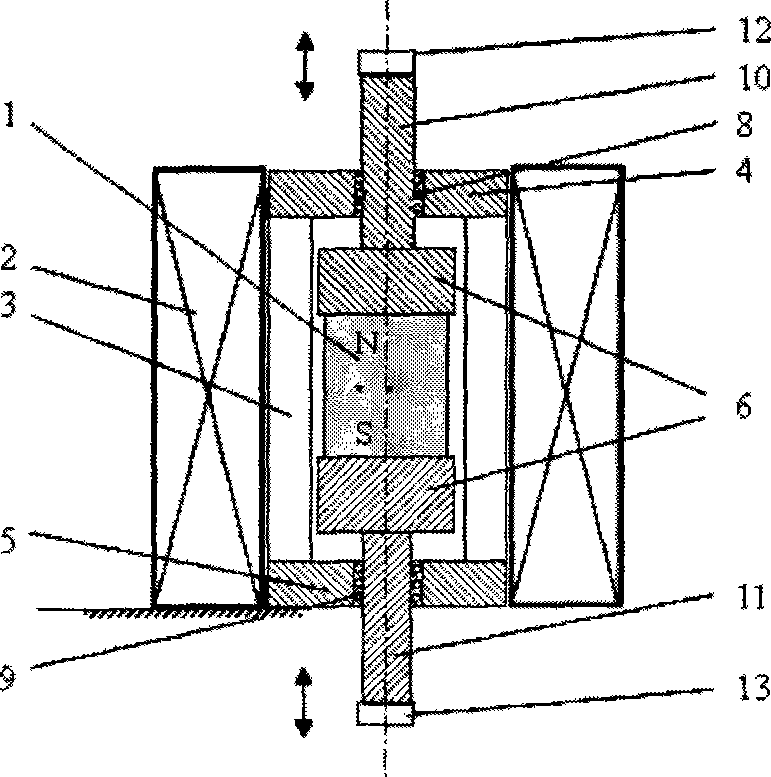

[0033] Such as figure 1 As shown, this embodiment includes: a permanent magnet moving body, an electromagnetic coil 2, a sleeve, an upper magnetically permeable cover 4, a lower magnetically permeable cover 5, an upper force output rod 10, and a lower force output rod 11, wherein the sleeve is a non- The magnetically conductive rigid frame 3, the permanent magnet mobile body is composed of a permanent magnet 1 sandwiched between two ferromagnetic bodies 6, the permanent magnet 1 and the ferromagnetic body 6 are fixedly connected, and the permanent magnetic mobile body is placed on a rigid upper guide In the space formed by the fixed connection of the magnetic cover 4, the lower magnetically conductive cover 5 and the non-magnetically conductive rigid frame 3, the two ends of the permanent magnet moving body are respectively fixedly connected with the upper force output rod 10 and the lower force output rod 11, and the upper force output The rod 10 and the lower force output ro...

Embodiment 2

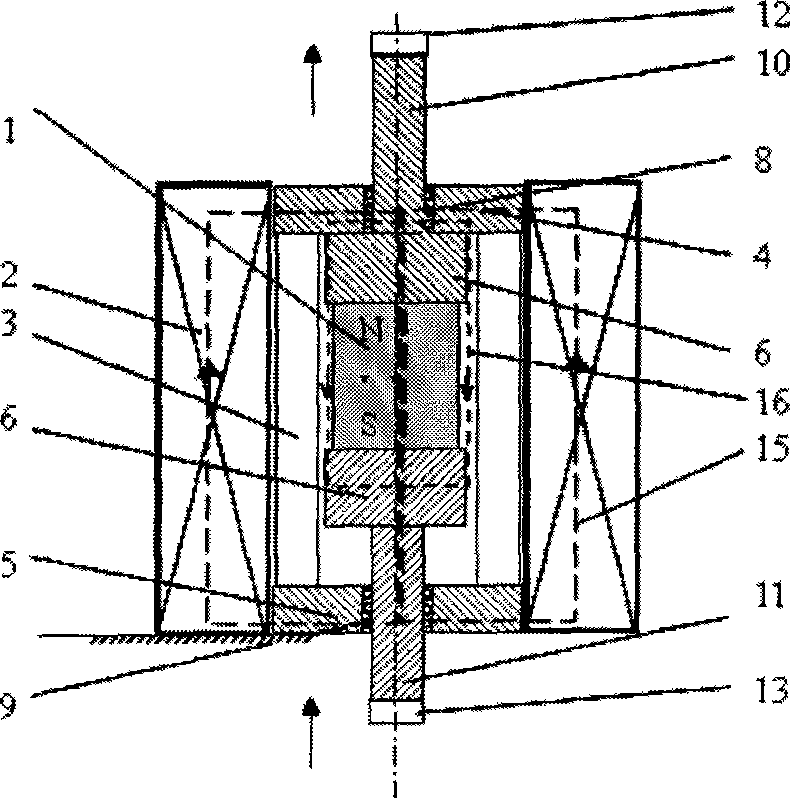

[0041] Such as Figure 4 As shown, this embodiment includes: a permanent magnet moving body, an electromagnetic coil 2, a sleeve, an upper magnetically permeable cover 4, a lower magnetically permeable cover 5, an upper bearing 8, an upper bearing 9, an upper force output rod 10, and a lower force output rod 11. The upper block 12 and the lower block 13, wherein: the sleeve is a non-magnetic rigid frame 3, the permanent magnetic moving body is composed of a ferromagnet 6 and a permanent magnet 1, and the ferromagnet 6 is used as the central body, and the outer side is covered with a tubular permanent magnet. The magnet 1, the permanent magnet 1 and the ferromagnet 6 are fixedly connected, the outer end faces of the permanent magnet moving body are fixedly connected with the upper force output rod 10 and the lower force output rod 11 respectively, and the permanent magnet moving body is placed on a rigid upper guide In the space formed by the fixed connection of the magnetic co...

Embodiment 3

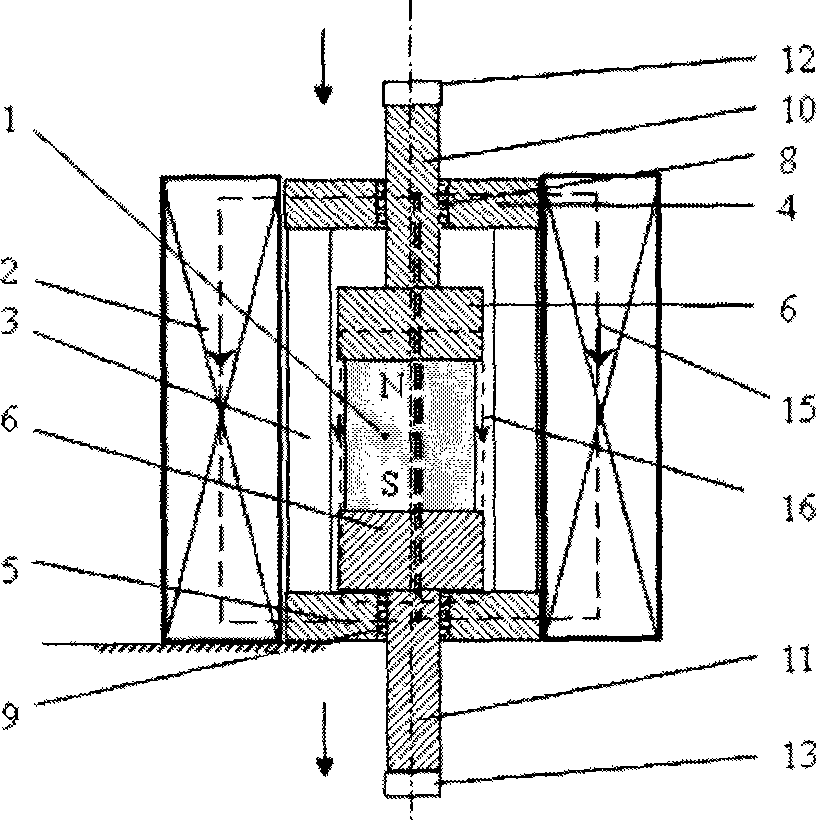

[0049] Such as Figure 7 As shown, this embodiment includes: a permanent magnet moving body, an electromagnetic coil 2, a sleeve, an upper magnetically permeable cover 4, a lower magnetically permeable cover 5, an upper bearing 8, a lower bearing 9, an upper force output rod 10, and a lower force output rod 11, wherein: the sleeve is a ferromagnetic rigid outer shell 17, the permanent magnetic moving body is composed of a ferromagnet 6 and a permanent magnet 1, the ferromagnet 6 is used as a central body, and the outer side is covered with a tubular permanent magnet 1, permanent magnet 1 and ferromagnet 6 The outer end faces of the permanent magnet mobile body are fixedly connected with the upper force output rod 10 and the lower force output rod 11 respectively, and the permanent magnet mobile body is placed on a rigid upper magnetic cover 4, a lower magnetic cover 5 and In the space formed by the fixed connection of the rigid non-magnetic sleeve 3, the upper force output rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com