Engaged structure for telescopic gate sheet

A technology of retractable doors and door pieces, applied in the direction of gates/doors, etc., can solve the problems of high cost, inconvenient installation, and no linkage of the door body, and achieve the effect of low manufacturing cost, simple structure, and stable opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

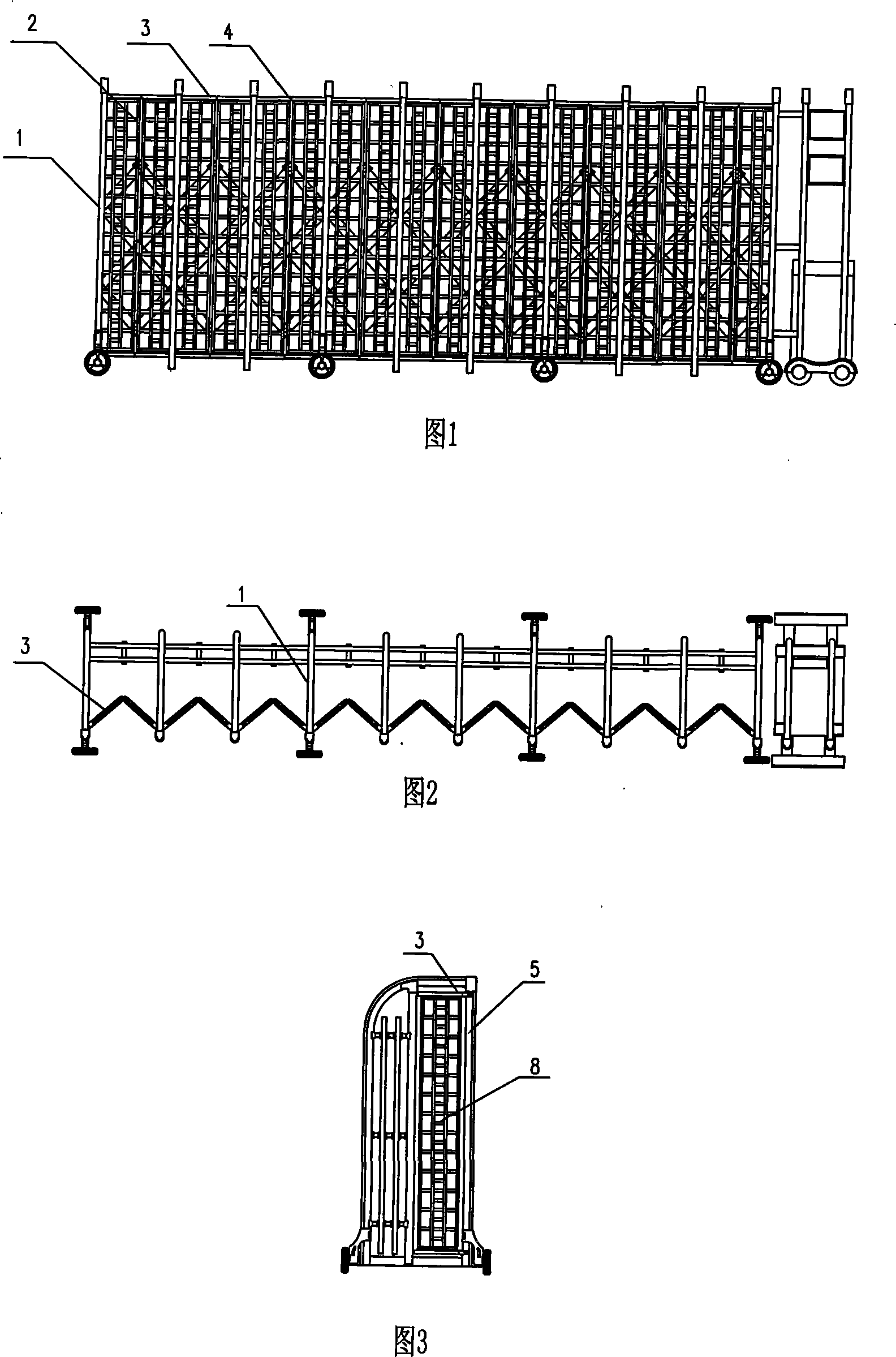

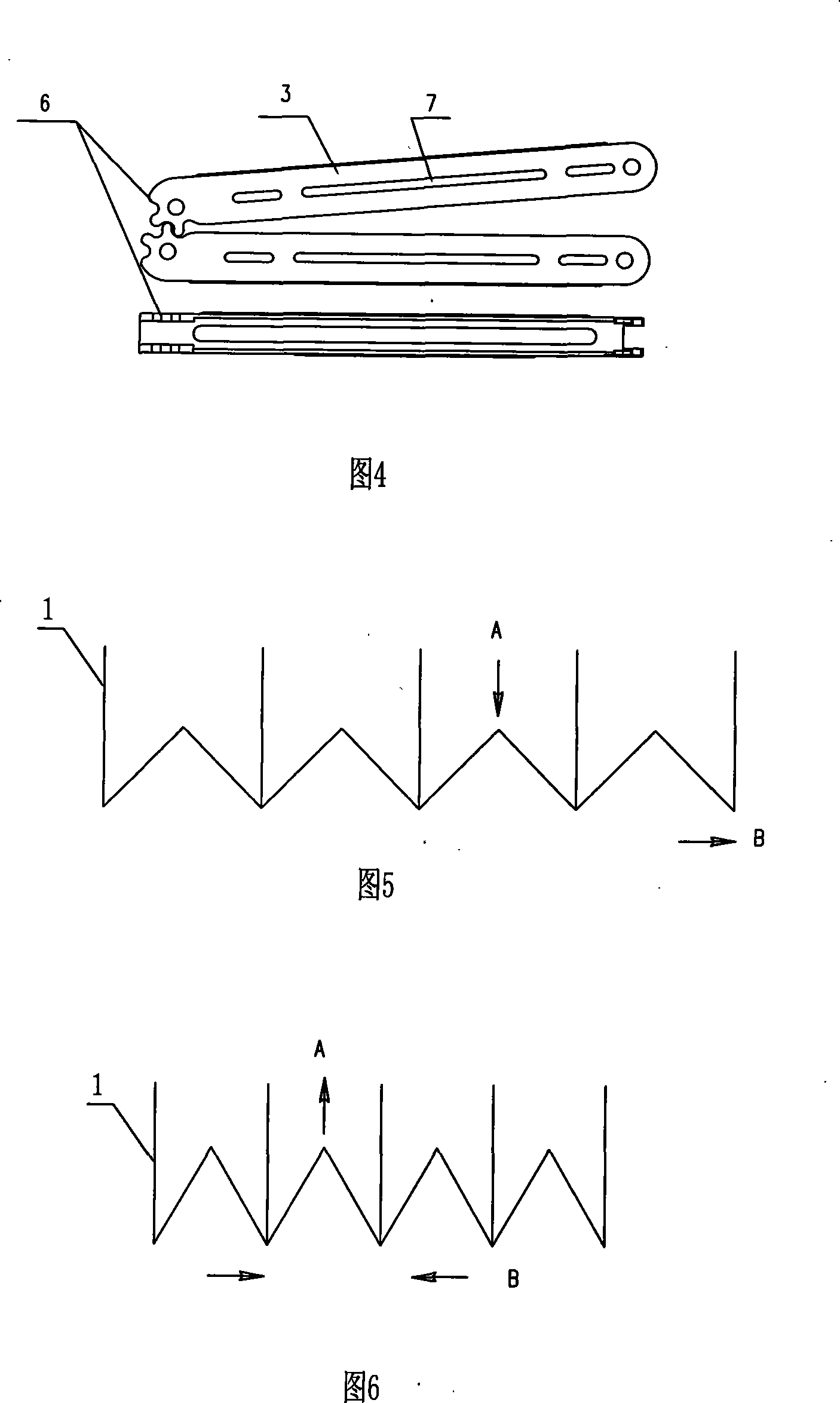

[0017] As shown in Figures 1 to 6, a telescopic door leaf engagement linkage structure of the present invention includes several door sheets 2 arranged in a telescopic door frame body 1, and the door sheets 2 are connected with transverse connecting rods 3, and the transverse connecting rods The two ends of 3 are respectively hinged with movable column 4 and door body column 5, telescopic door frame body 1 is mainly made up of door body column 5; Gear 6 is arranged, and the gears 6 of the transverse connecting rods 3 of two adjacent door sheets are engaged with each other, and the transverse connecting rods 3 of adjacent two door sheets 2 are connected as a whole by movable columns 4 . In this embodiment, the moving direction A of the rack and the moving direction B of the door sheet are perpendicular to each other, so as to realize the opening or closing of the retractable door. Axial ribs 7 are arranged on the transverse connecting rod 3 to improve the strength of the rod bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com