Craft beer filling and capping machine

A technology of capping machine and beer, which is applied in bottling machines, packaging, synchronizing devices, etc., can solve the problem of high oxygen increase, and achieve the effects of simple flow channels, stable opening and closing, and reliable filling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

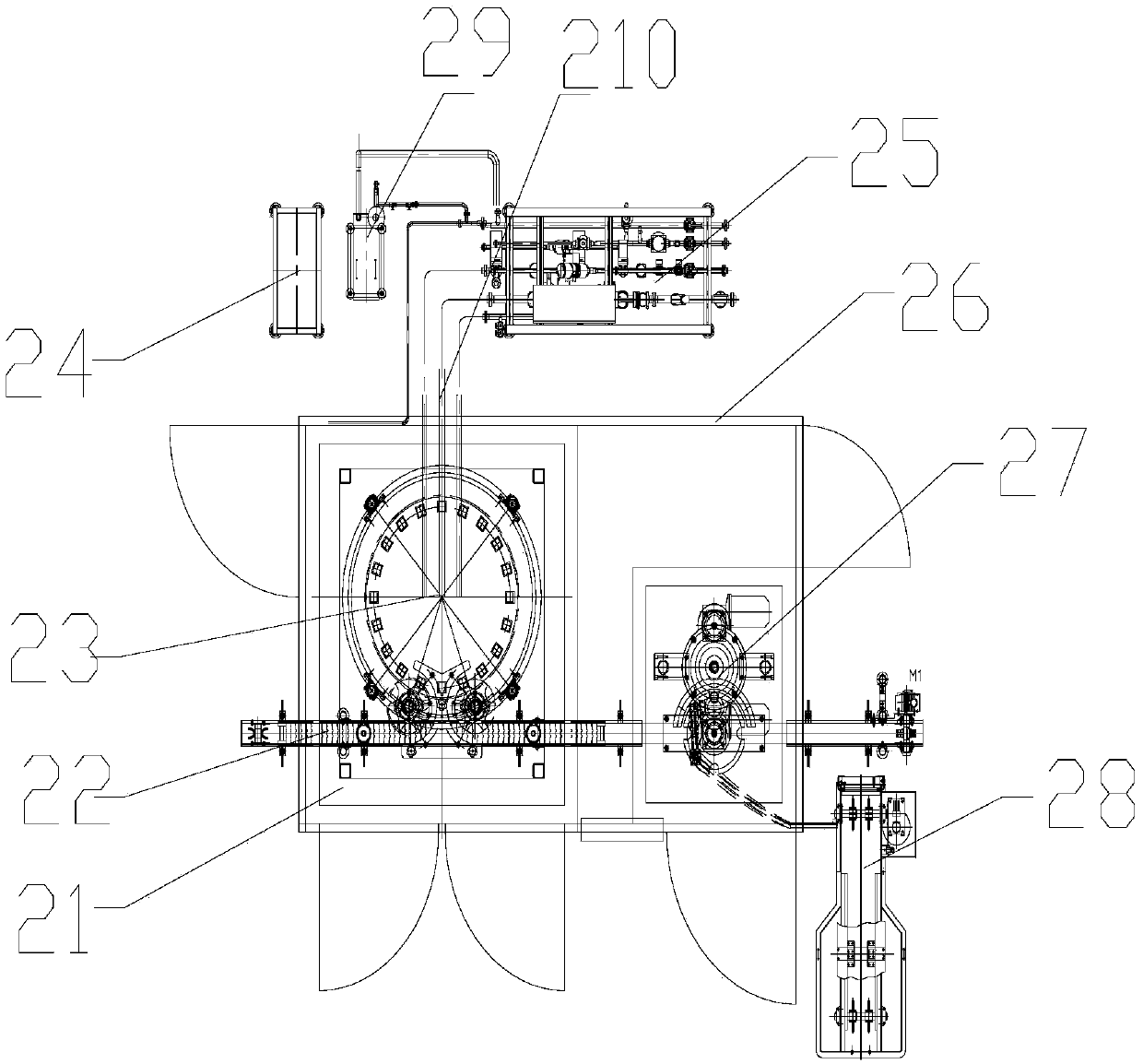

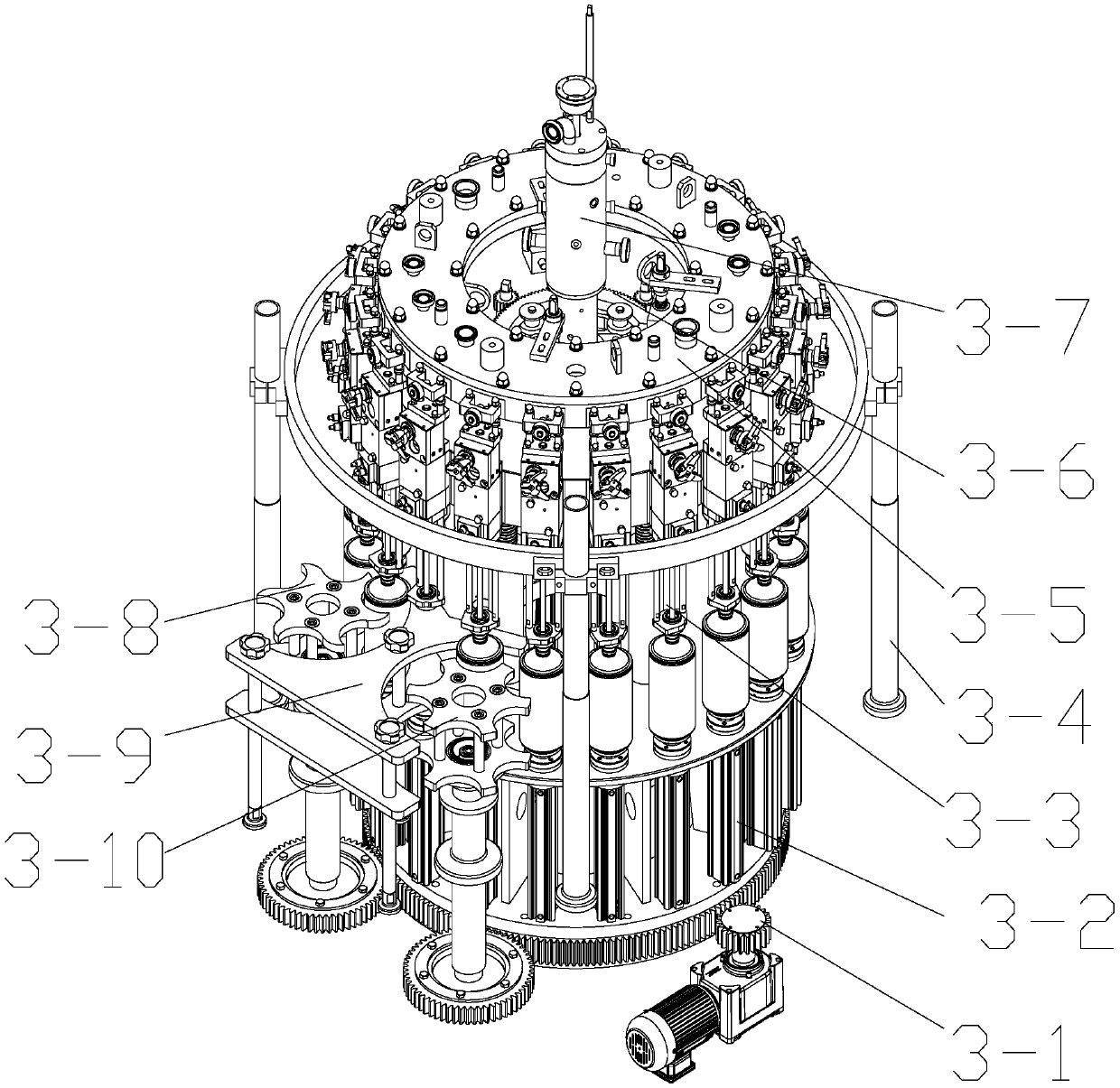

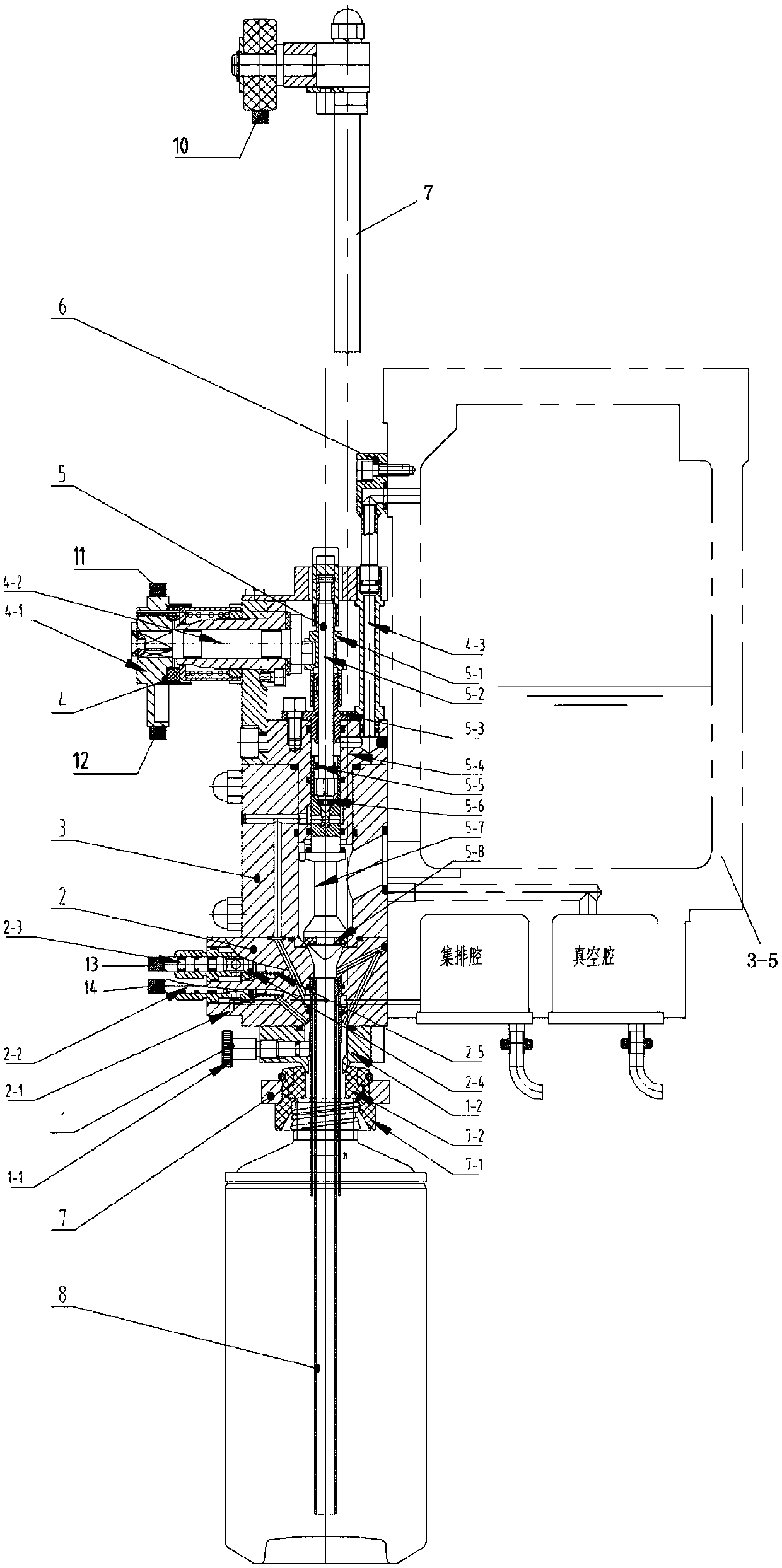

[0044] Such as Figure 1-2 , a craft beer filling and capping machine, including a workbench 21, a filling mechanism 23 and a capping mechanism 27 are arranged on the workbench 21, and a filling mechanism 23 for conveying empty wine bottles to the workbench 21 is provided. And the conveying mechanism 22 that is used to convey the wine bottle that has been filled to the capping mechanism 27, the filling mechanism 23 includes the mounting frame that rotates relative to the workbench 21, and several long tube filling valves 3 are fixed along the circumferential direction on the mounting frame -3, a rotating table 3-2 for carrying beer bottles is installed below the installation frame, and a guide plate mechanism 3-9 is provided between the conveying mechanism 22 and the rotating table 3-2, which is used to guide the beer bottles from the conveying mechanism 22 to the The bottle-feeding dial 3-8 of the rotary table 3-2 and the bottle-feeding dial 3-10 for exporting beer bottles fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com