Pressure control valve

A pressure control and valve technology, applied in the direction of fluid pressure control, non-electric variable control, control/regulation system, etc., can solve the problems of large operating torque, slow opening and closing speed, short service life, etc., and achieve simple and reasonable structure, opening and closing The effect of fast closing speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

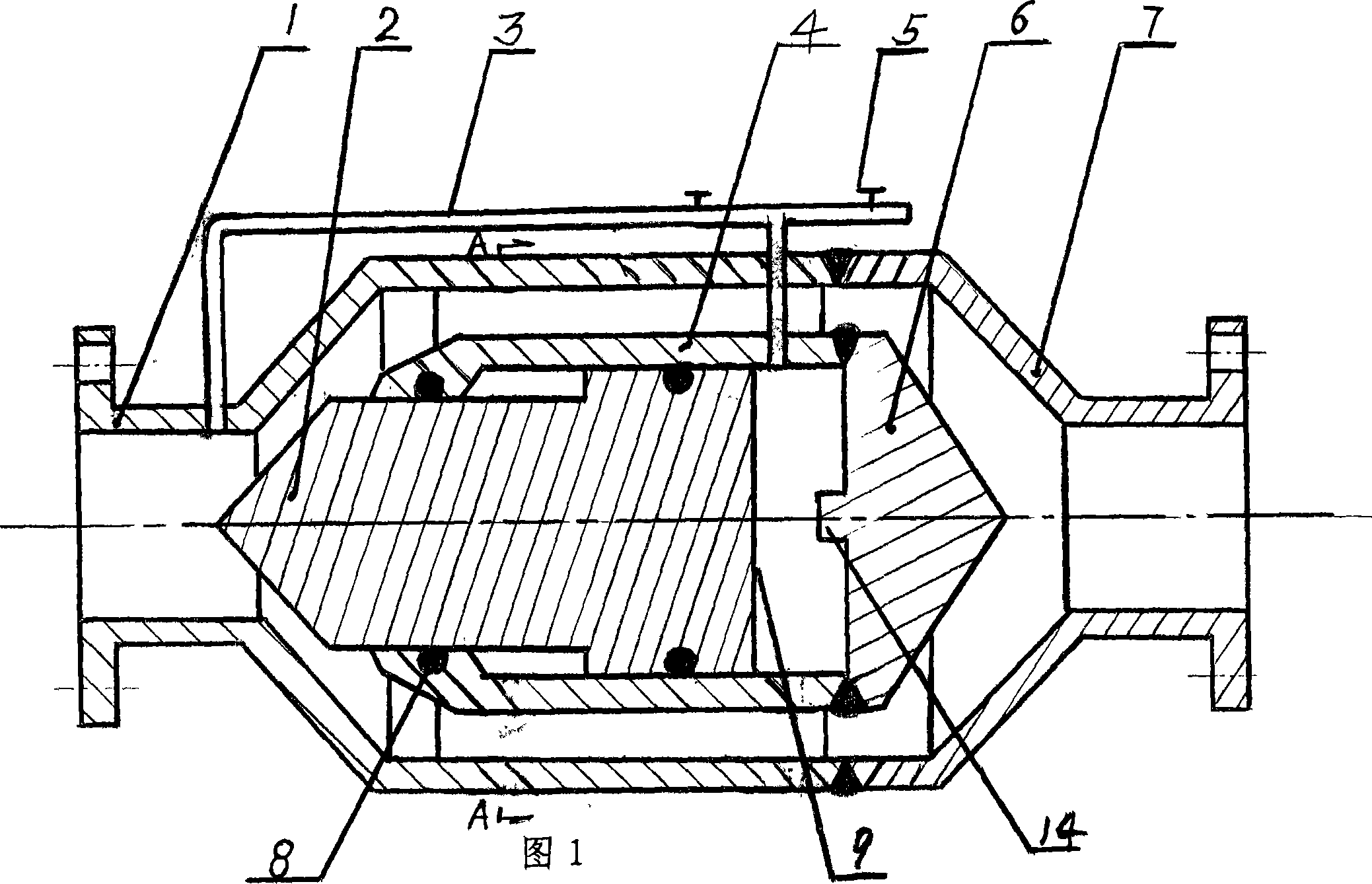

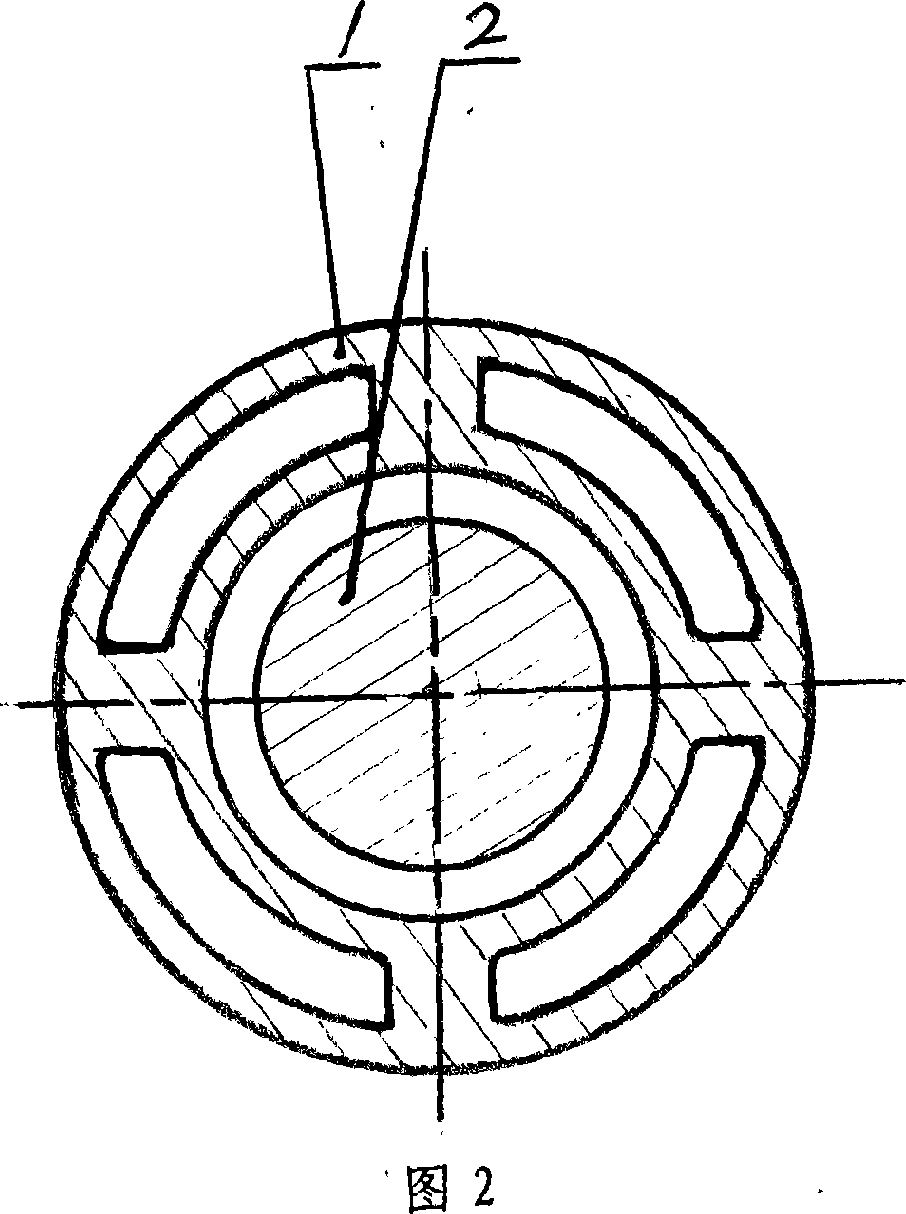

[0018] Referring to the accompanying drawings 1 and 2, it is an external diversion passage type pressure control valve. The two ends of the pressure control valve have inlets or outlets respectively. The front valve body 1 is welded to the rear valve body 7 to form the valve body. The front valve body 1 The valve chamber is connected to the valve cylinder 4 through four connecting beams, and the valve cylinder 4 is welded to the valve cylinder cover 6 to form a valve cylinder. The valve cylinder 4 is slidingly connected to the valve core 2, and its valve core is "T" shape. The structure of the junction between the slider, the spool and the front valve body 1 is a cone spool, and the spool and the matching surface of the front valve body are combined to control the opening and closing and the fluid flow rate, and the matching surface adopts a face seal. A sealing body 8 is inlaid on the connection surface between the valve core 2 and the valve cylinder 4 , and the inner surface ...

Embodiment 2

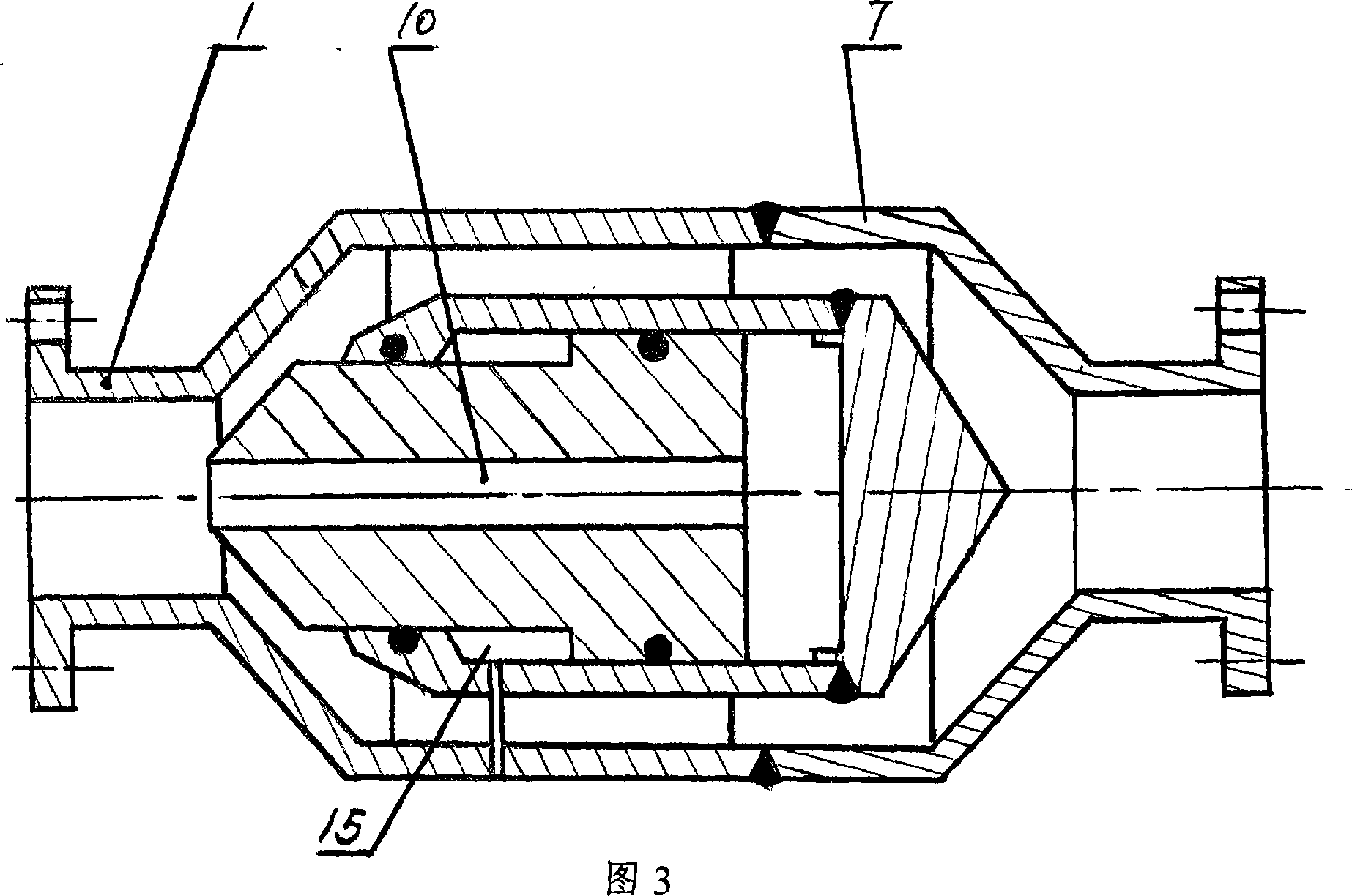

[0020] Referring to accompanying drawing 3, it is an internal diversion passage type pressure control valve, the difference from Embodiment 1 is that the valve cylinder cavity formed between the valve cylinder cover 6 and the pressure bearing surface of the valve core 2 is guided by the internal guide of the valve core 2. The flow passage 10 communicates with the flow cavity at one end of the valve body, and there is a flow pressure control ring cavity 15 between the valve core 2 and the inner wall of the valve cylinder 4, and the cavity is connected with a fluid pressure source through the flow guide path to realize the control valve opening and closing and balance.

Embodiment 3

[0022] Referring to accompanying drawing 4, it is a pressure control valve with a straight cylindrical slider type spool, and the difference from Embodiment 1 is that the spool is a straight cylindrical slider type spool 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com