Rollup door with rollable door leaf

a technology of industrial doors and door leaf, which is applied in the direction of door/window protective devices, shutters/movable grilles, constructions, etc., can solve the problems of visible marks on the lamella surface, increased wear and noise, and flexible door leaf with sensitive materials such as pvc, etc., to facilitate the rapid opening/closing of the door, reduce the noise level, and reduce the effect of noise and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

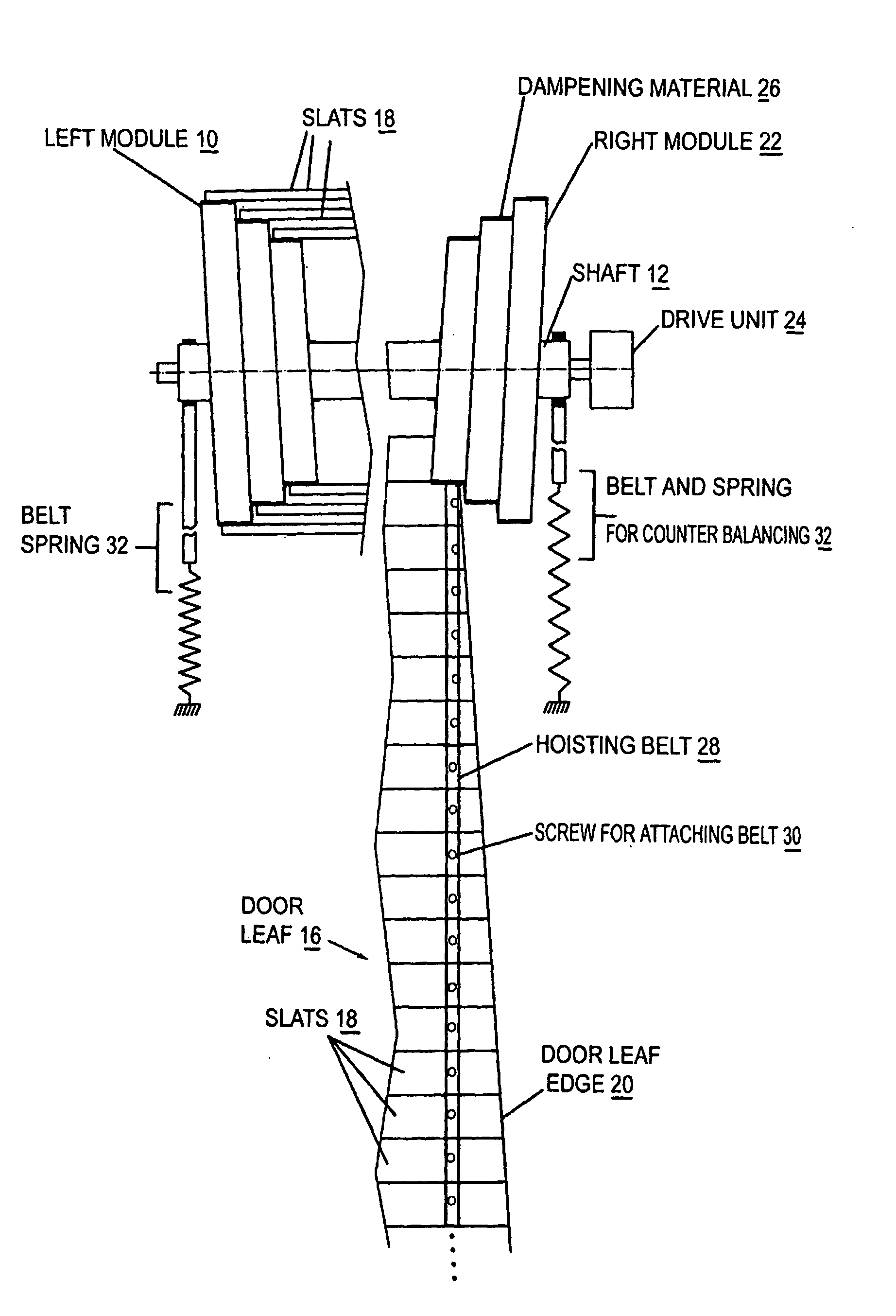

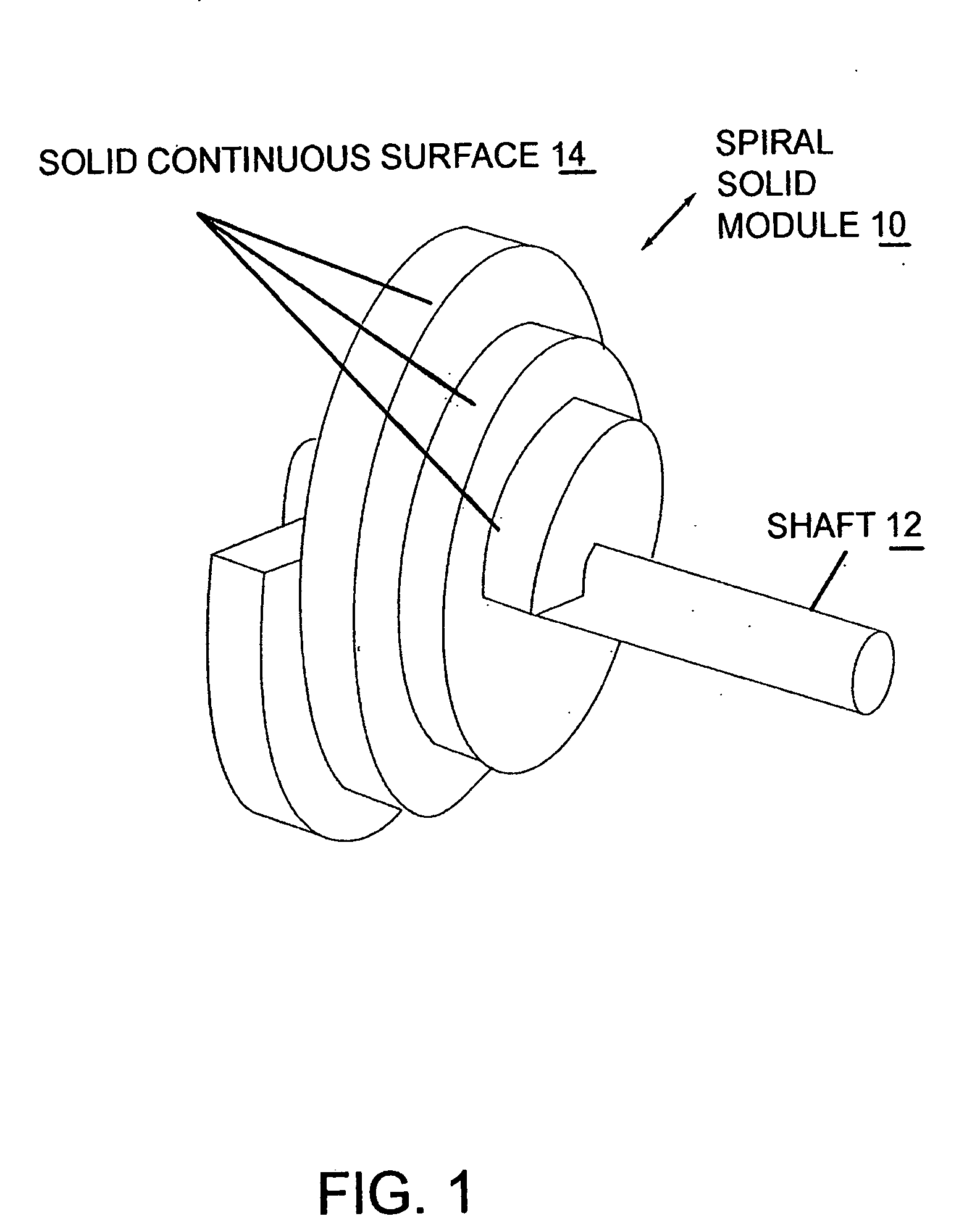

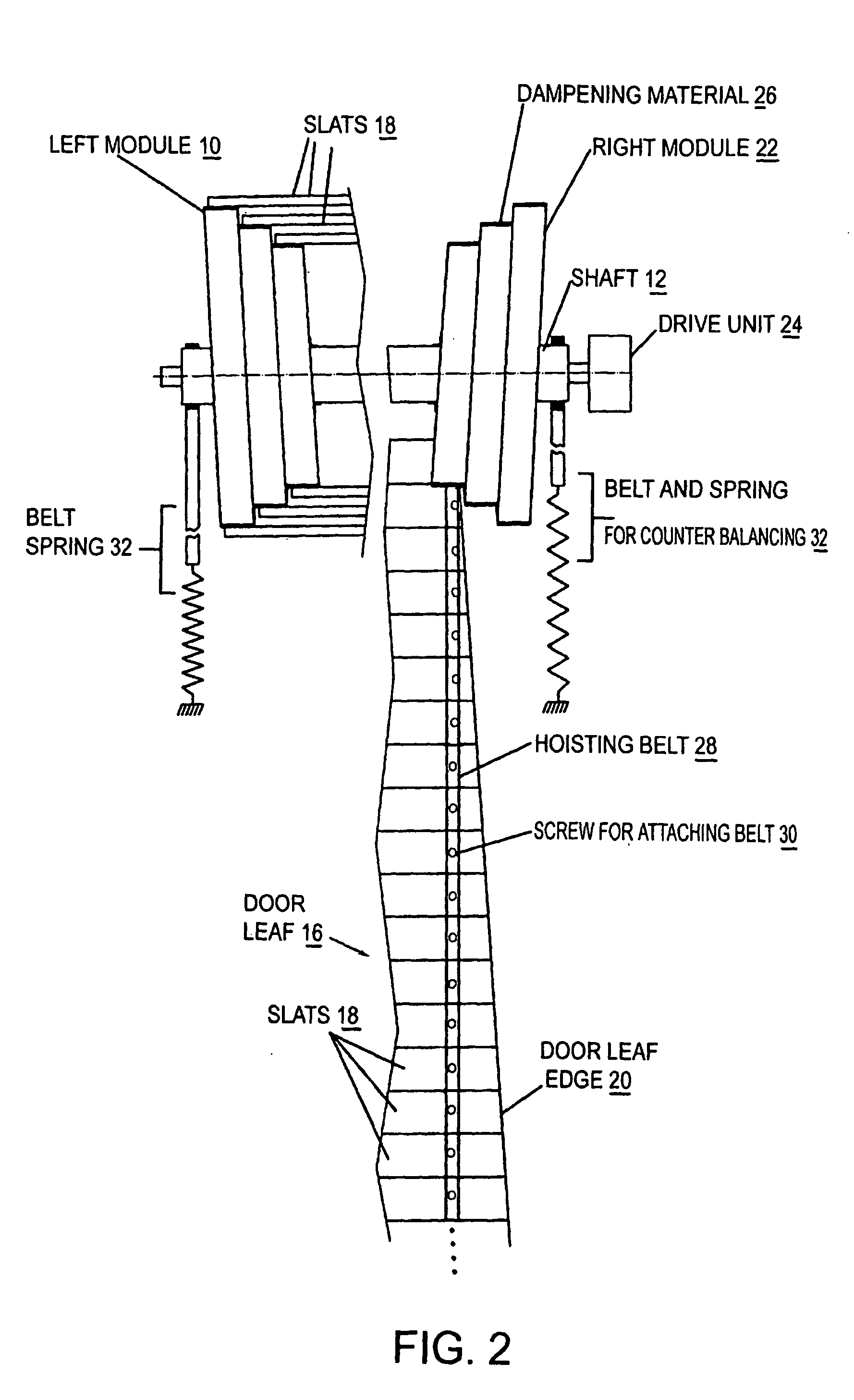

[0022] the rollup door according to the present invention will now be described with reference to FIGS. 1-4. FIG. 1 is a perspective view of a module 10 mounted on a shaft 12 and used in rolling and unrolling the door. Alternatively, the shaft 12 itself could have the shape of a module (not shown). In the present embodiment, the module 10 has an outer shape of a conical spiral with a solid continuous surface 14. Advantageously, module 10 is successively radially enlarged, and includes smaller and larger parts of increasing diameter. The module 10 will be further described in reference to FIG. 2.

[0023]FIG. 2 is an internal view of the door in the closed position (see right portion of FIG. 2), and in the open position (see left portion of FIG. 2). The right portion of FIG. 2 shows a door blade, or door leaf 16, in a closed position covering a door opening. In most door applications the door is operated vertically as shown in FIG. 2, but horizontal or angled operation of the door is al...

second embodiment

[0029] the invention is now described with reference to FIGS. 5-7. FIG. 5 is an internal view of the door in the closed position (see right portion of FIG. 5), and in the open position (see left portion of FIG. 5). According to the present embodiment, door leaf 40 comprises layers 42, 44, 46 of stepwise increasing width from top to bottom. Note that each layer comprises slats of equal width. Also with this embodiment, each of the two modules is a package of thin-walled parallel disks. For simplicity, the disk package comprising disks 50, 52, 54 on the right side of the door will be described. Distance elements 56 are provided, for example, to stiffen up the disc package. The distance element 56 between the smallest and middle disks 50, 52 may also serve as a fixing point 64 for the attachment of the hoisting belt 66. In addition, the distance elements 56 also facilitate guiding the door leaf 40.

[0030] As the door is raised, each respective layer 42, 44, 46 is rolled up on the respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com