Mould locking device for bottle blowing machine

A machine locking and mold locking technology, applied in the field of mold locking devices of blow molding machines, can solve the problems of low energy consumption, large mold locking pressure, long mold locking stroke, etc., and achieves high work efficiency, low energy consumption, and opening and closing speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

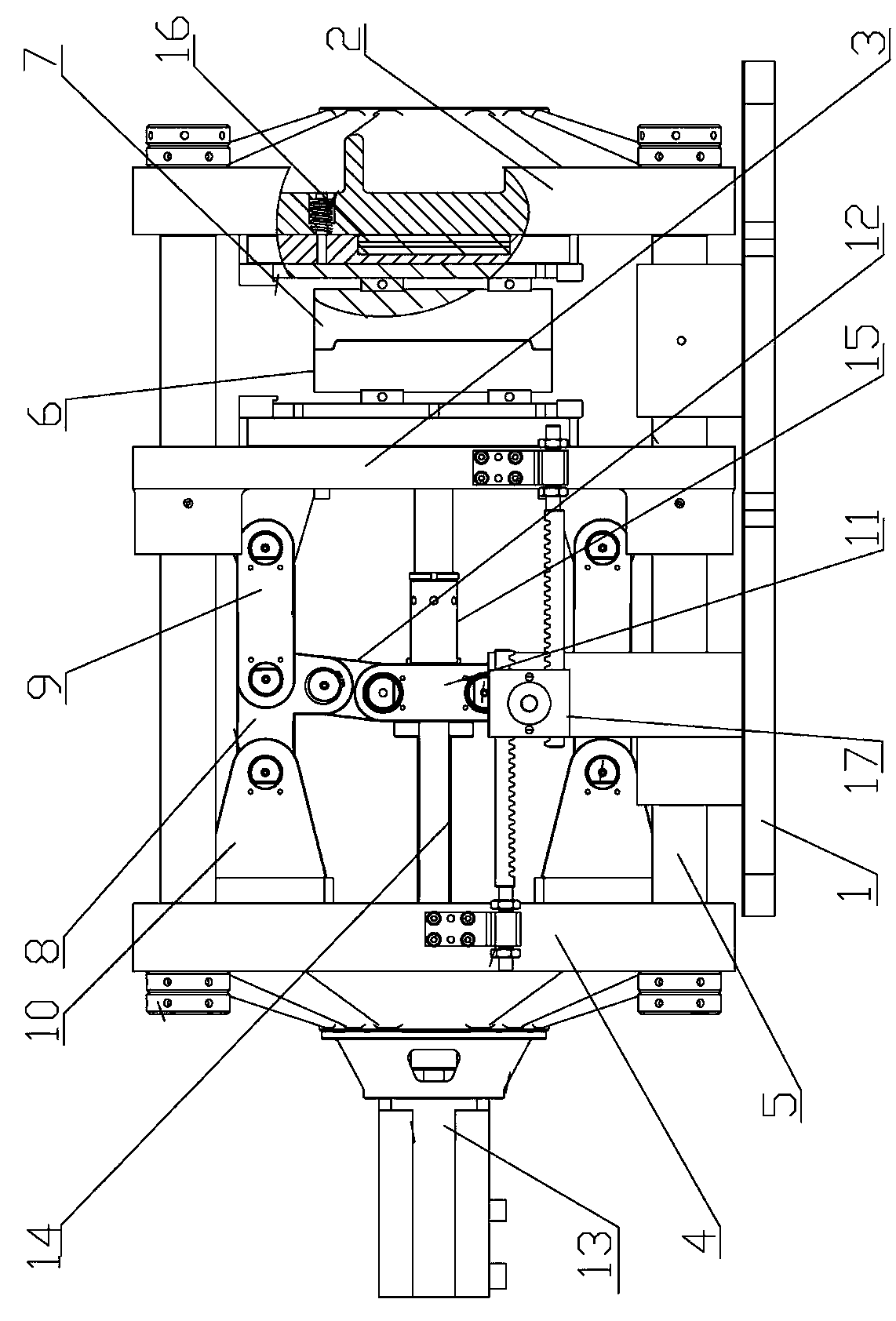

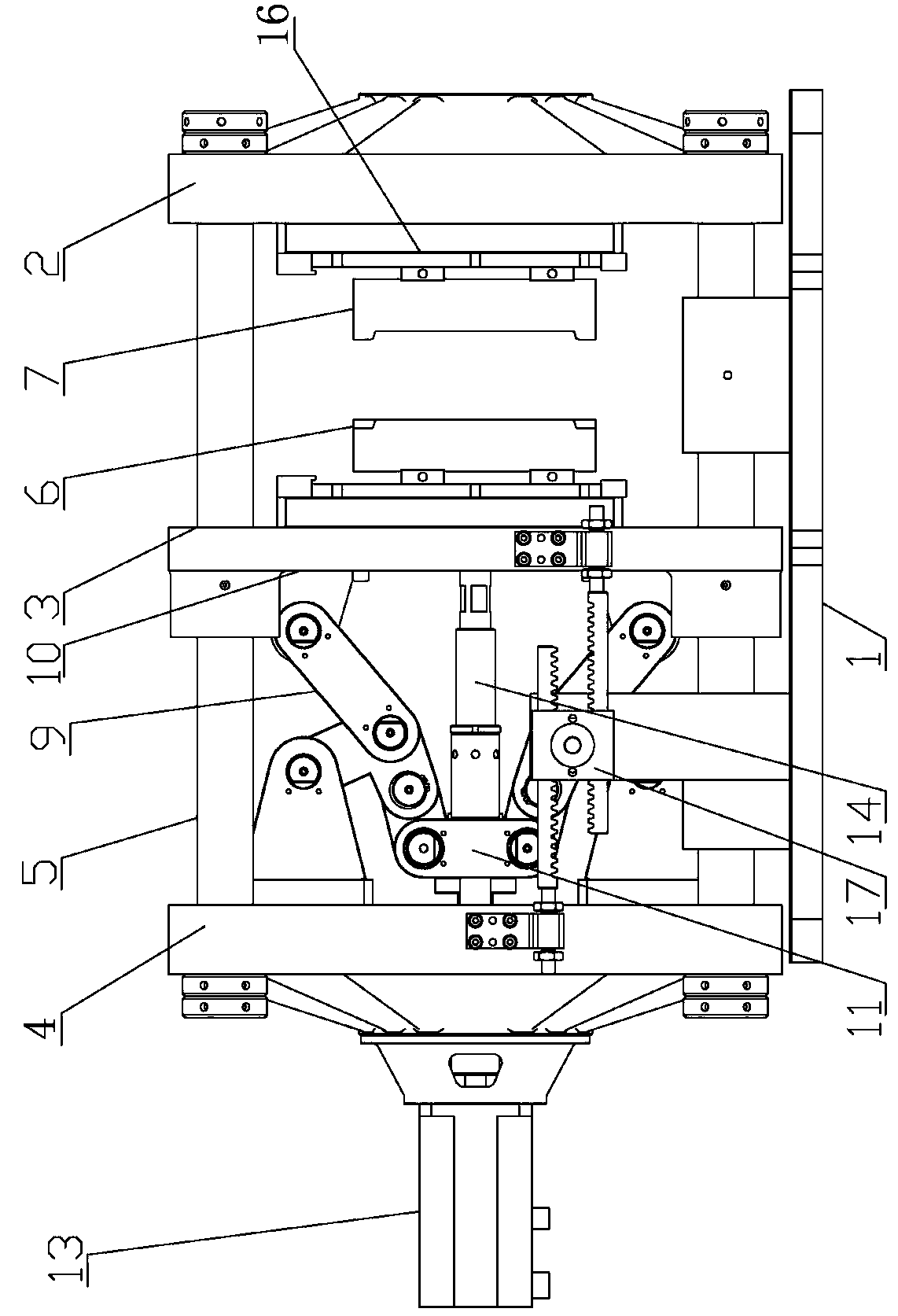

[0017] Hereinafter, the present invention will be further explained in detail with reference to the drawings. A mold clamping device for a bottle blowing machine includes a mold base 1, a front mold 2, a middle mold 3, a rear mold 4, and a guide post 5 that penetrates between the mold bases. The middle mold 3 is installed The left mold 6, the right mold 7 is installed on the front mold 2, the middle mold 3 and the rear mold 4 are symmetrically distributed and hinged hinged mold clamping mechanism, characterized in that: the right mold 7 and the front mold 2 A clamping and pressing mechanism 16 is installed between.

[0018] The clamping and pressing mechanism 16 is a flat piston cylinder.

[0019] The flat piston cylinder of the clamping and pressing mechanism 16 is a pneumatic cylinder.

[0020] The flat piston cylinder of the clamping and pressing mechanism 16 is a hydraulic cylinder.

[0021] The articulated mold clamping mechanism is connected to the connecting block 10 by two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com