Pressure test pit

A pit cover and anti-extrusion technology, used in mechanical equipment, engineering safety devices, etc., can solve problems such as non-compliance with safety production specifications, equipment parts falling off impact force, and equipment loss in test pits, so as to reduce the risk of pressure testing and increase The effect of large rigid strength and saving pressure test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

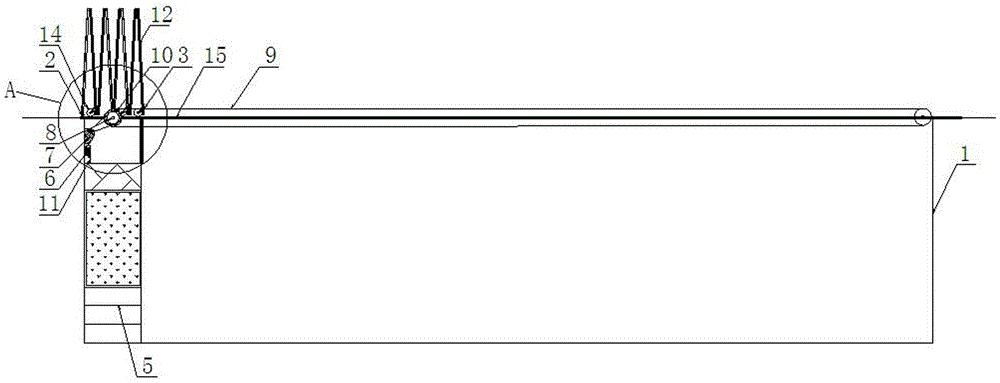

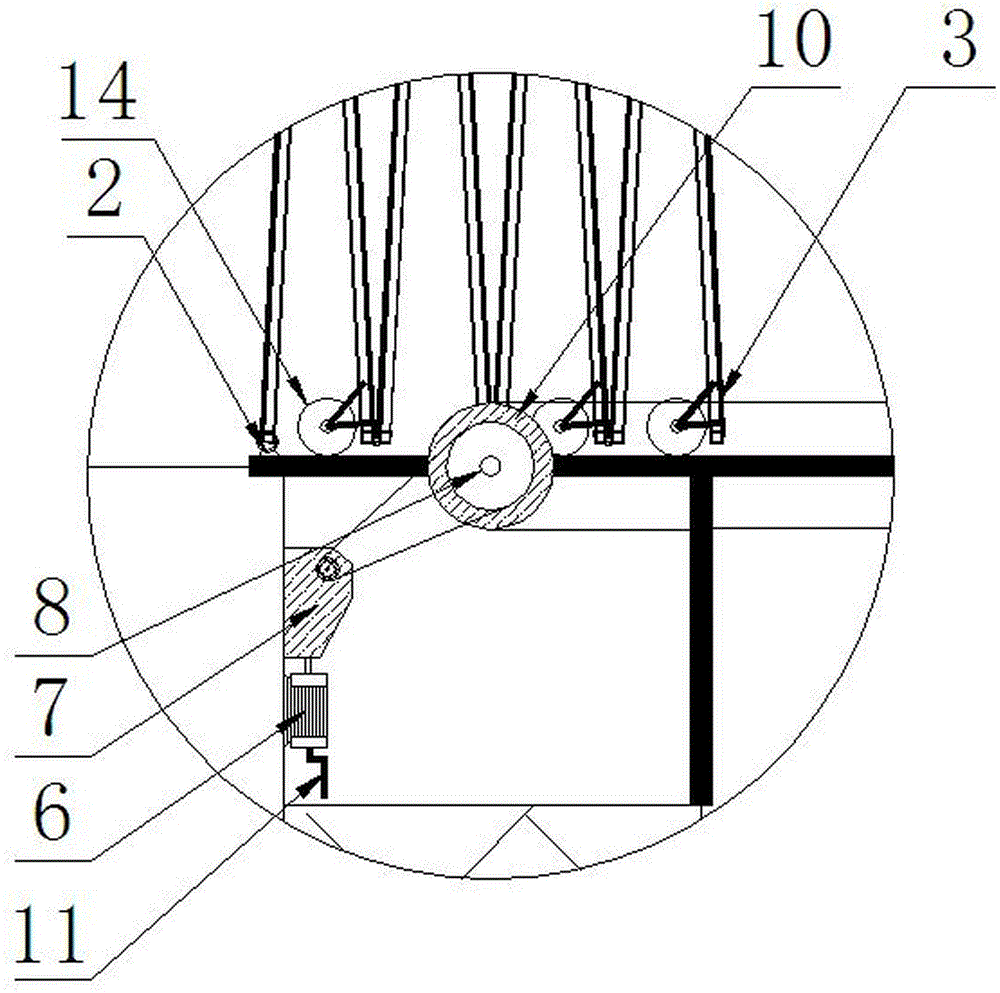

[0038] A pressure test pit, comprising a pit body 1, a foldable pit cover and a pit cover drive mechanism, the foldable pit cover is slidably arranged above the pit body 1, the foldable pit cover includes a positioning end 2 and a driving end 3, The positioning end 2 of the foldable pit cover is movably connected to the end of the pit body 1, and the driving end 3 of the foldable pit cover is movably connected with the pit cover driving mechanism.

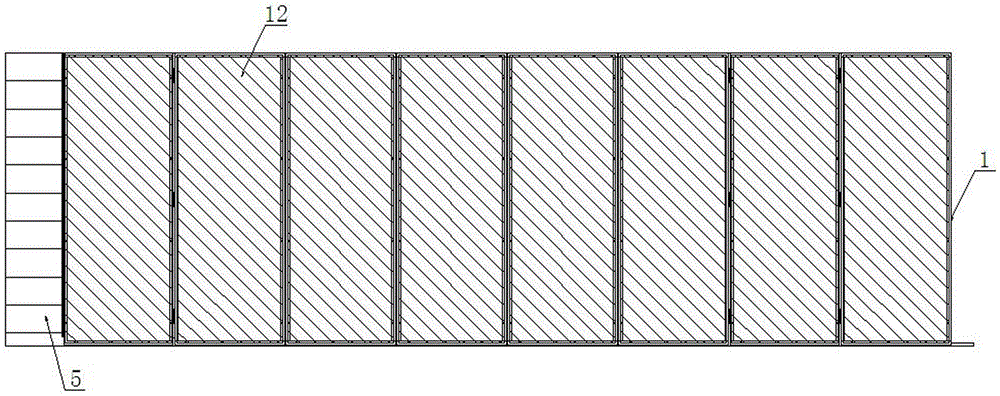

[0039] In this embodiment, the foldable pit cover includes a plurality of cover plates 12 that are movably connected in sequence. Connect them with pins, and fill the frame with cover plates 12 of equal size. The cover plates 12 are Kablon PC endurance boards, and the two adjacent cover plates 12 are connected by hinges.

[0040] In this embodiment, the pit cover driving mechanism includes a motor 6, a reducer 7, two linkage shafts 8 and two chains 9, and the two linkage shafts 8 are respectively rotated and arranged at both ends o...

Embodiment 2

[0045] A pressure test pit, comprising a pit body 1, a foldable pit cover and a pit cover drive mechanism, the foldable pit cover is slidably arranged above the pit body 1, the foldable pit cover includes a positioning end 2 and a driving end 3, The positioning end 2 of the foldable pit cover is movably connected to the end of the pit body 1, and the driving end 3 of the foldable pit cover is movably connected to the pit cover driving mechanism.

[0046] In this embodiment, the foldable pit cover includes a plurality of cover plates 12 that are movably connected in turn, and the cover plates 12 are provided with an anti-extrusion portion 13, and the anti-extrusion portion 13 has the characteristics of cushioning and anti-extrusion. It is made of soft materials, such as rubber, foam, etc., and the anti-extrusion portion 13 is hemispherical, square or circular. The anti-extrusion parts 13 on any two adjacent cover plates 12 on the multiple cover plates 12 are symmetrical, and wh...

Embodiment 3

[0048] A pressure test pit, comprising a pit body 1, a foldable pit cover and a pit cover drive mechanism, the pit body 1 is fixedly provided with a partition wall 16 for dividing the pit body 1 into two pit chambers 4, the foldable There are two sets of pit covers and pit cover drive mechanisms. The two sets of foldable pit covers are respectively slidably arranged above the two pit chambers 4, and the positioning ends 2 of the two sets of foldable pit covers are respectively located at both ends of the pit body 1. The two sets of pit cover driving mechanisms are respectively connected with the driving ends 3 of the two sets of foldable pit covers. Wherein, the two pit chambers 4 are independent of each other, and can be pressure tested at the same time, or one of them can be tested independently, and the foldable pit covers on the two pit chambers 4 are unfolded and folded in opposite directions.

[0049] In this embodiment, the two pit chambers 4 are provided with stairs 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com