Automatic-preheating cold-water-avoiding water heater

A water heater and zero cold water technology, which is applied in the field of automatic preheating zero cold water water heaters, to achieve the effect of saving pipe laying costs and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the water heater is a gas water heater. Those skilled in the art can predict that the pipeline structure of the present invention is also suitable for other types of water heaters (such as electric water heaters). The arrows in the drawings indicate the direction of water flow.

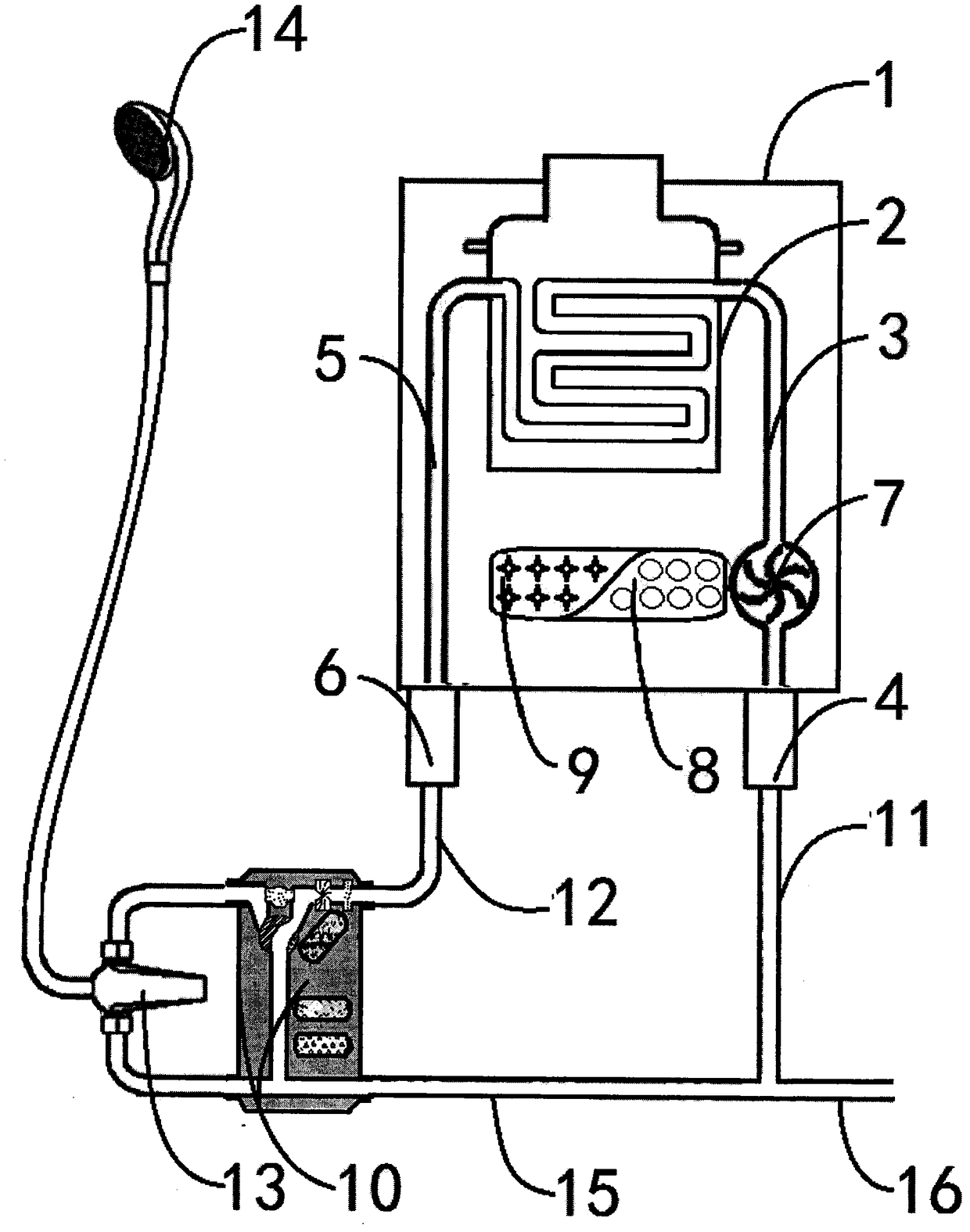

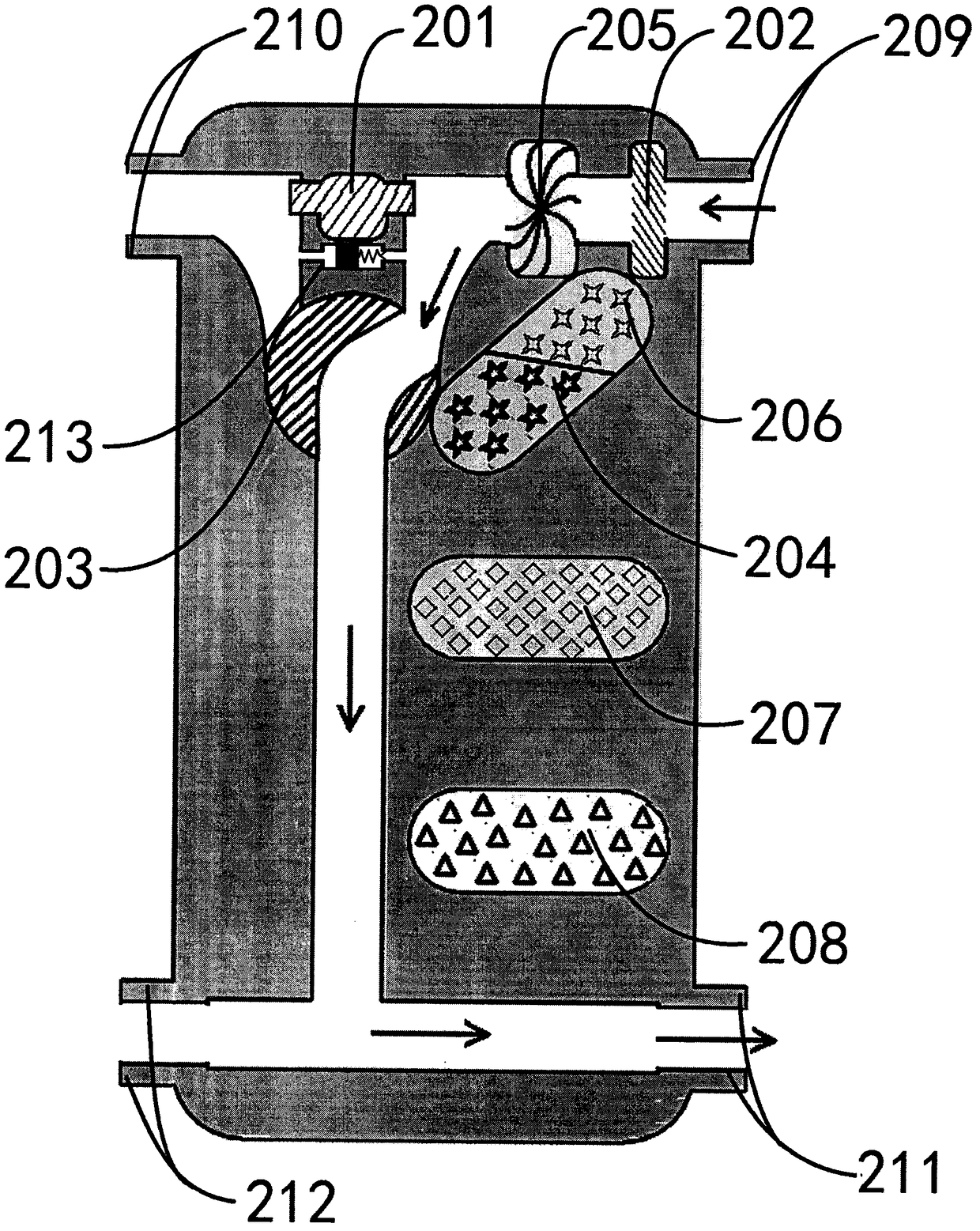

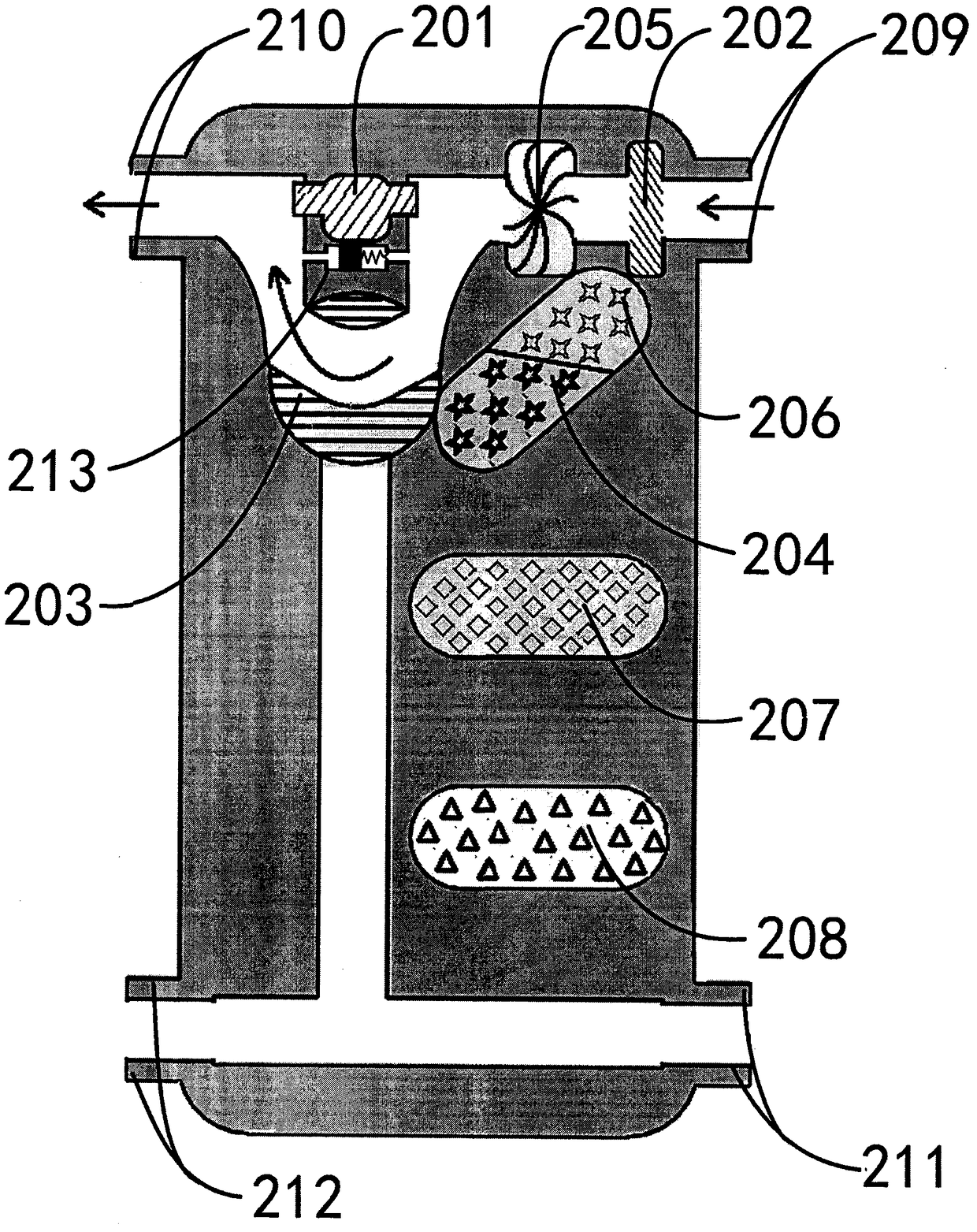

[0026] Such as figure 1 , 2 As shown in and 3, a zero-cold water heater capable of automatically preheating includes a water heater body (1), a heat exchange device (2), an internal water inlet pipeline (3), a water inlet joint (4), and an internal water outlet pipeline (5 ), a water outlet joint (6), a preheating circulation pump (7), a circulation pump controller (8), a wireless signal receiver (9) and a water outlet terminal controller (10), and the water outlet terminal controller (10) includes Pressure difference sensor (201), temperature sensor (202), three-way valve (203), switch control motor (204), water flow power generation device (205), power storage device (206...

Embodiment 2

[0028] Such as figure 1 , 2 As shown in and 3, a zero-cold water heater that can automatically preheat, the temperature sensor (202), the three-way valve (203) and the switch control motor (204) together form a temperature control switch, and the information processing unit (207) according to the temperature The real-time water temperature detected by the sensor (202) controls the working state of the three-way valve (203) through the switch control motor (204). The information processing unit (207) can process the pressure difference signal detected by the pressure difference sensor (201), and finally control it through the wireless signal transmitter (208), the wireless signal receiver (9) and the circulation pump controller (10) Opening and closing of preheating circulation pump (7). The water flow power generation device (205) can generate electric energy and store it in the power storage device (206), which is a pressure difference sensor (201), a temperature sensor (20...

Embodiment 3

[0030] Such as figure 1 , 2 As shown in and 3, a zero-cold water heater that can automatically preheat, the preheating circulation pump (7) includes an on state and an off state, and the on and off of the preheating process is realized through the above two state transitions, the on state and the off state The state transition process is as follows:

[0031] 1. Water heater preheating is automatically turned on: when the user starts to use water, the water mixing valve (13) is opened. At this time, the pressure difference sensor (201) detects an obvious pressure difference, and the rear sensor transmits the pressure difference signal to the information processing unit (207). After the difference signal is processed, it is transmitted to the wireless signal receiver (9) through the wireless signal transmitter (208), and finally the pressure difference information generates a preheating circulating pump (7) start command in the circulating pump controller (8), preheating After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com