Non-abrasion hard-sealing butterfly valve

A hard-sealed, non-abrasive technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems that the valve drive cannot be used in both manual and electric forms at the same time, the sealing problem of butterfly valves has not been completely solved, and the sealing effect is difficult to guarantee. The effects of various driving methods, reduced types of driving devices and actuators, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and drawings, but it does not limit the claims of the present invention.

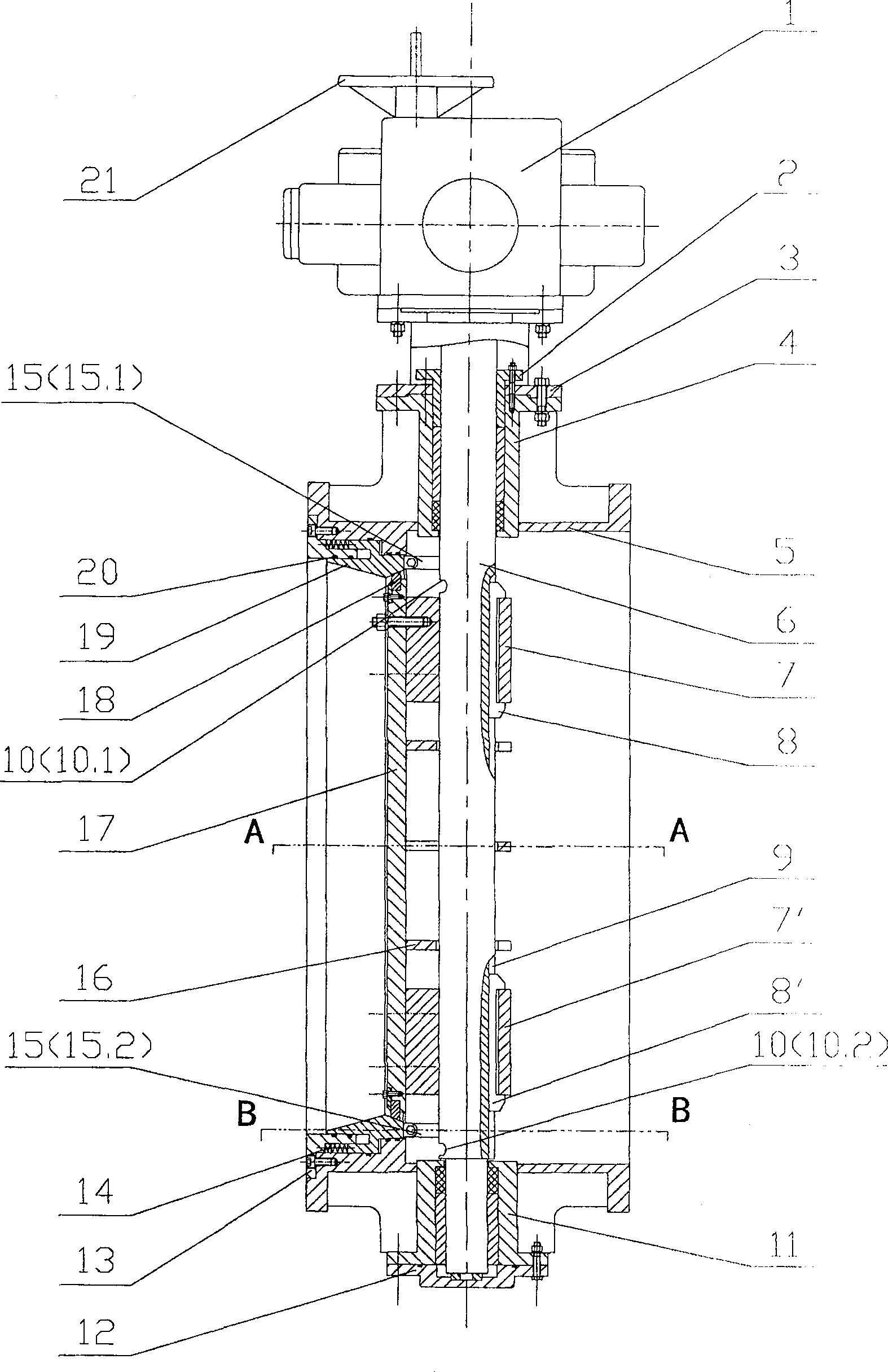

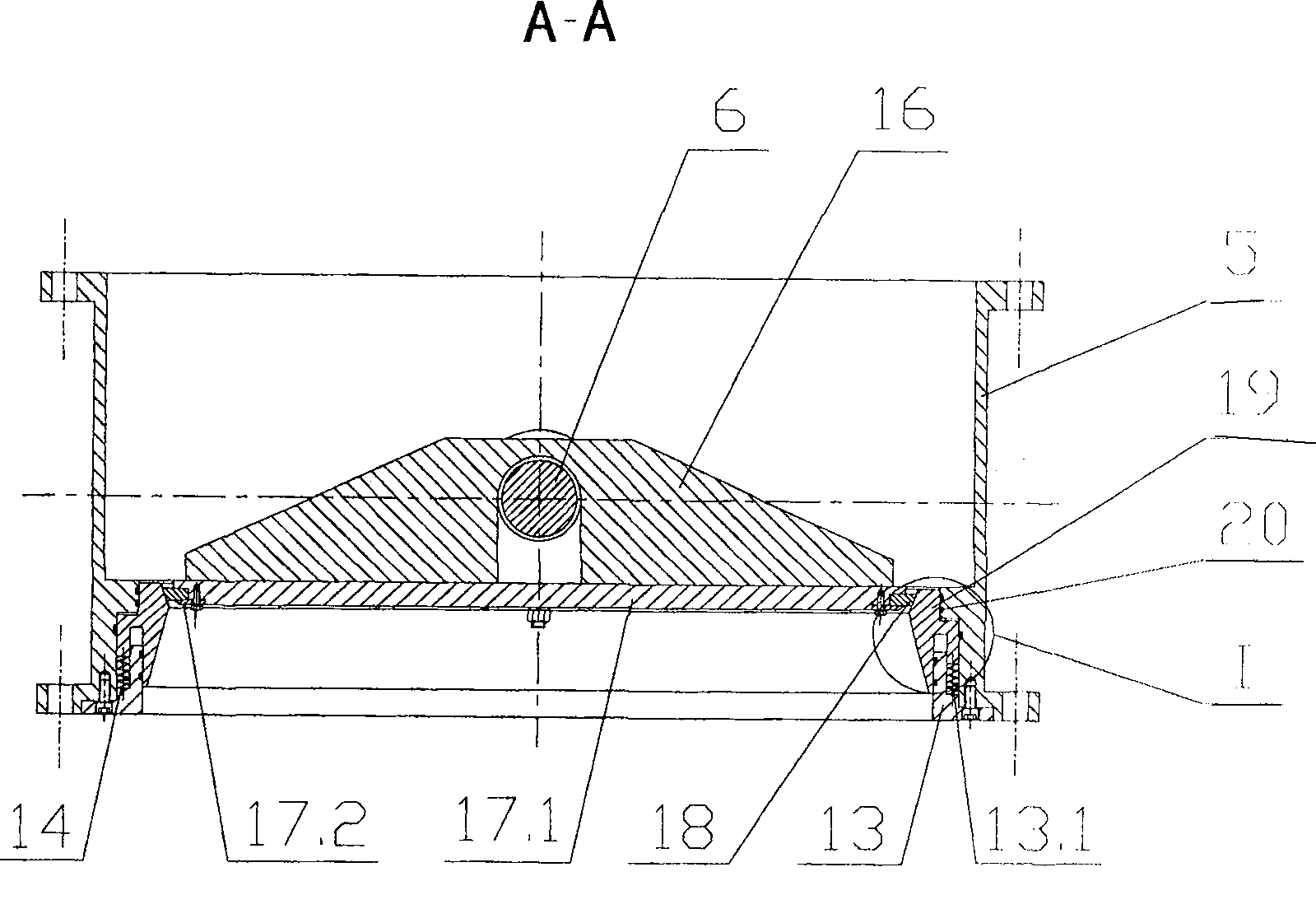

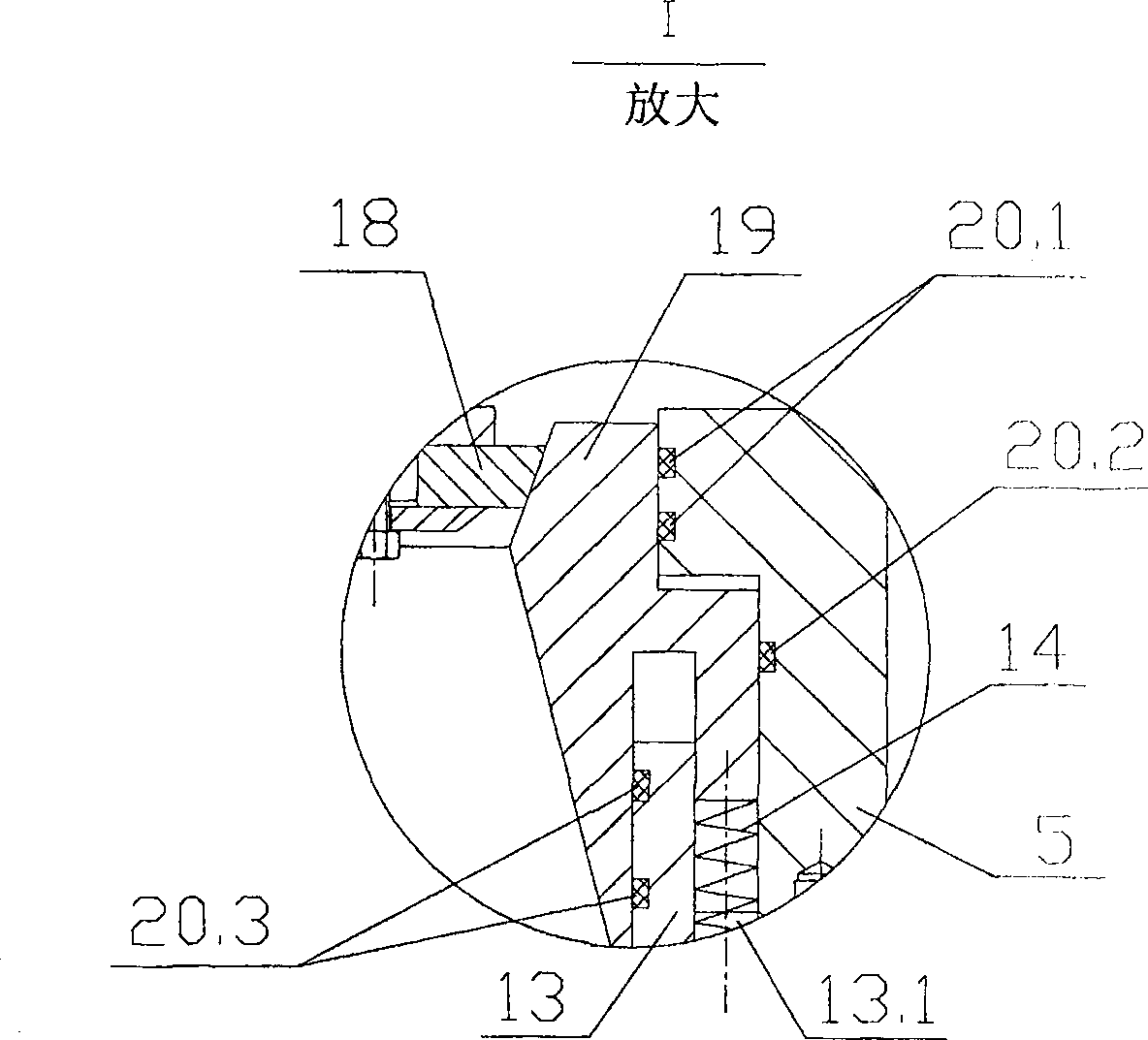

[0019] A wear-free hard-sealed butterfly valve designed by the present invention (hereinafter referred to as butterfly valve, see the Figure 1-8 ) The embodiment includes a valve body 5, a valve stem 6, a butterfly plate 17, and a valve seat 19, characterized in that the valve seat 19 is a movable valve seat with an annular structure that can move axially along the inner wall of the valve body 5. 19. Set in the valve body 5, when moving axially, the sealing surface of the movable valve seat 19 is perpendicular to the central axis of the butterfly plate 17, and cooperates with the sealing member 18 installed on the edge of the butterfly plate 17 to form the butterfly valve The sealing pair; a side body 13 is fastened on one side of the valve body 5 by screws; a sealing ring 20 is installed between the movable va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com