Patents

Literature

83results about How to "Tensile stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

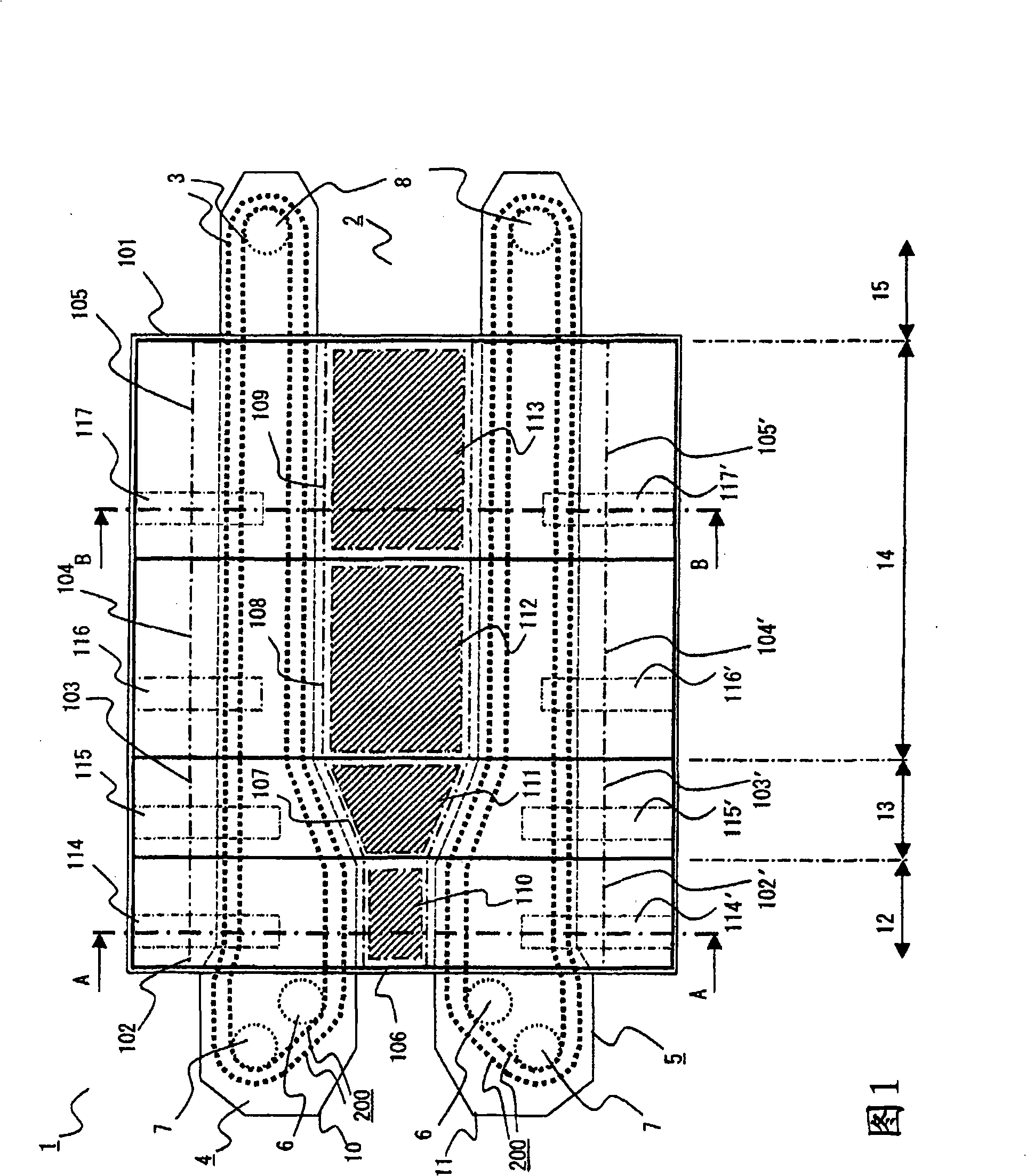

Stretcher for sheet-like substance

The present invention provides a drawing machine of flake capable of improving the reliability and quality of the flake. The drawing machine of flake has annular link device pair; the annular link device pair is correspondingly installed at two ends on width direction of the thermoplastic flake and leads a plurality of equal-length links along the roughly closed route on the horizontal plane; the plurality of equal-length links are connected with each other; on one hand, the equal-length links extend like a curved ruler, and on the other hand, hold each end part of the flake; the annular link device pair transports the flake to the outlet from the inlet, synchronously stretches the flake, then returns to the inlet side so as to move; wherein, in the space of transporting the flake, the stretching area for stretching the flack has heater which is installed on the upper part of the flake and radiates heat to the flake, and parts which are formed by the thermal conductivity parts heated by receiving the heat from the heater and installed on the lower part of the flake.

Owner:JAPAN STEEL WORKS LTD

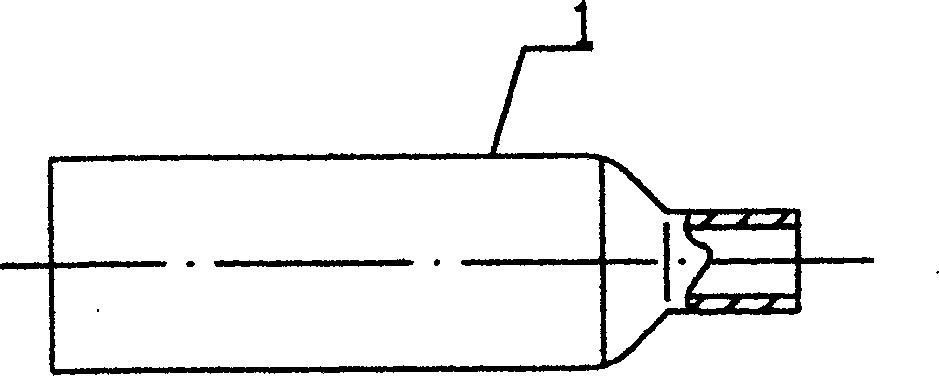

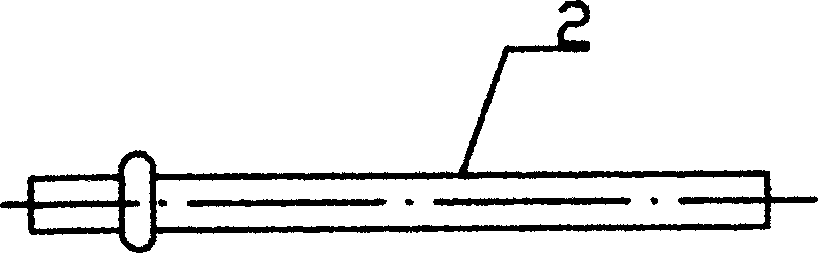

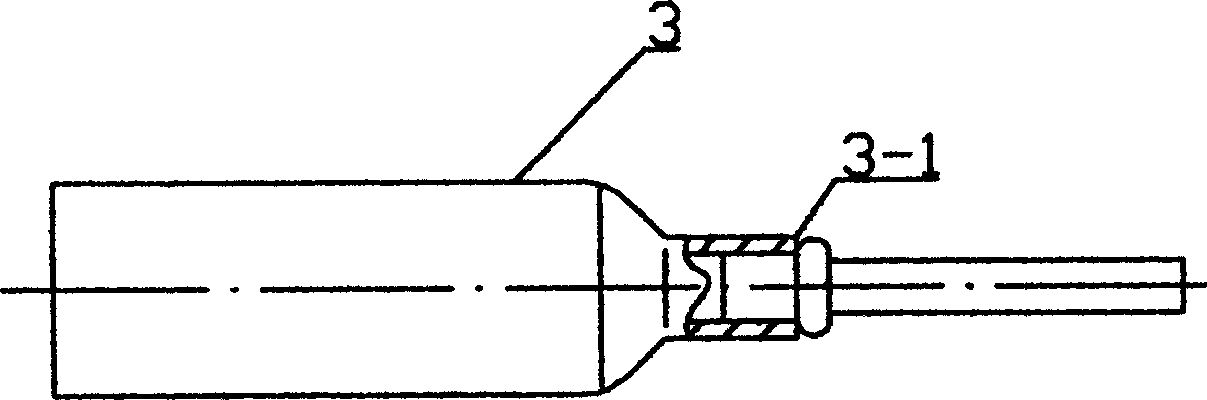

Method and apparatus for manufacturing reducing pipe

InactiveCN1528542ASleek appearanceIncrease productivityDrawing diesEngine componentsControl systemThin walled

The invention relates variable aperture tube making method and device, including tube end rotary forging and draw stretching. It first forges one end of the tube on the rotary forger into a smaller-aperture technical tube, which makes the stretching mould through to be clamped by the clamping module; using a hydraulic control system to drive clamping base and clamping module; inserting core rod with mould head in the copper tube to stretch by the stretching mould. It includes rotary forger and draw-stretching device. The clamping module, the stretching mould and the core rod makes up a stretching process line. The position of the core rod is adjustable and the stretching effect is good. The hydraulic control system is installed with travel switch to control stretching travel. It is applied to the control of thin-wall small-aperture copper tube and widely applied to cryogen pipeline in refrigerating industry.

Owner:广州冠华金属精工制造有限公司

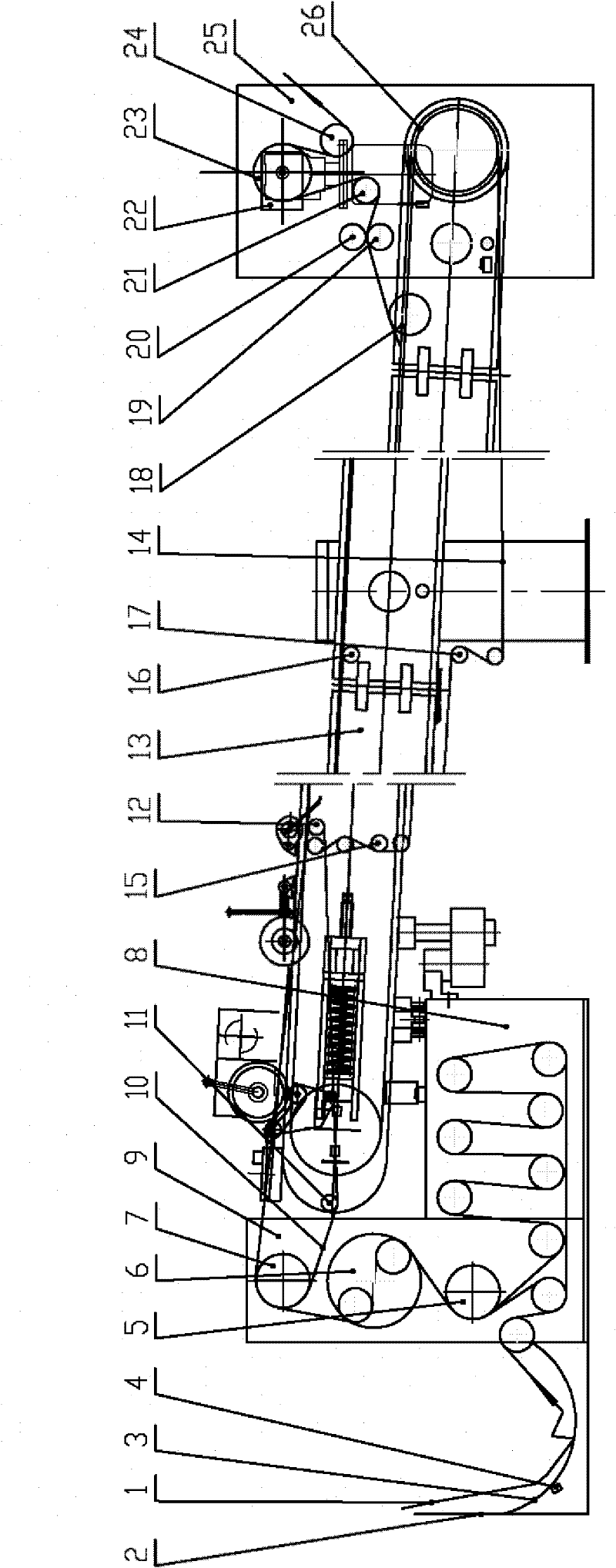

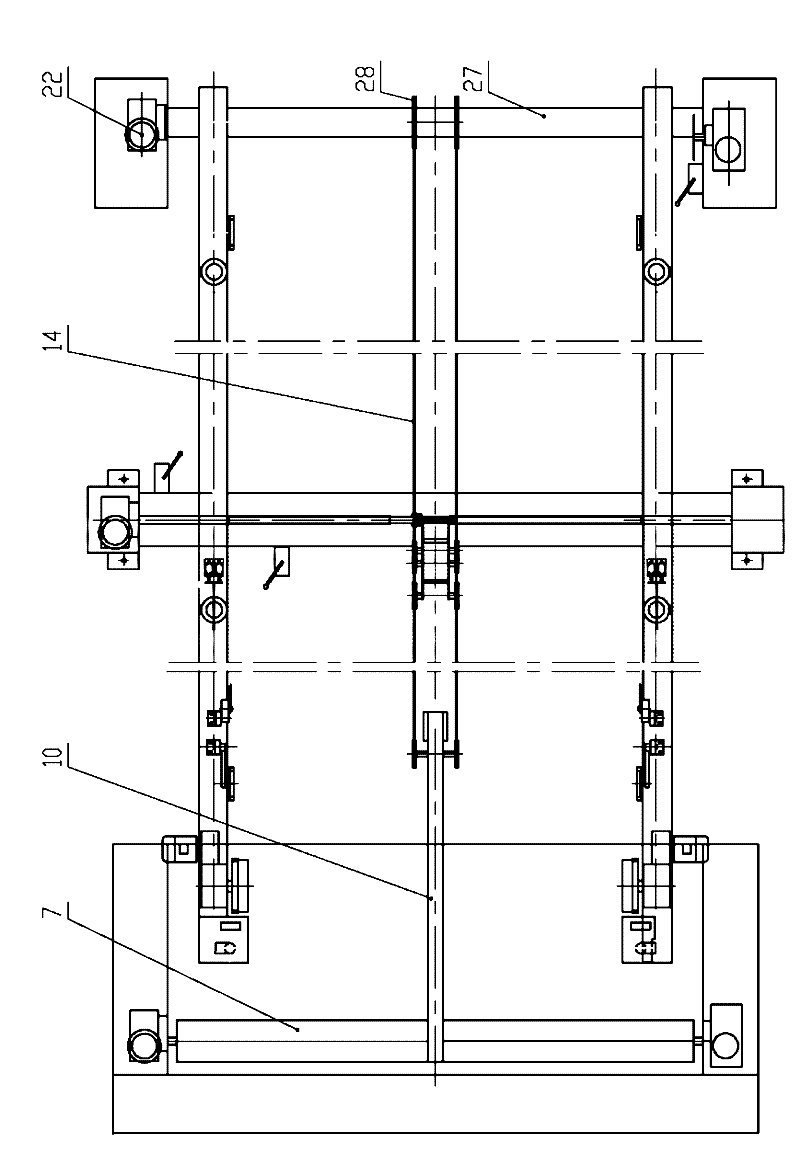

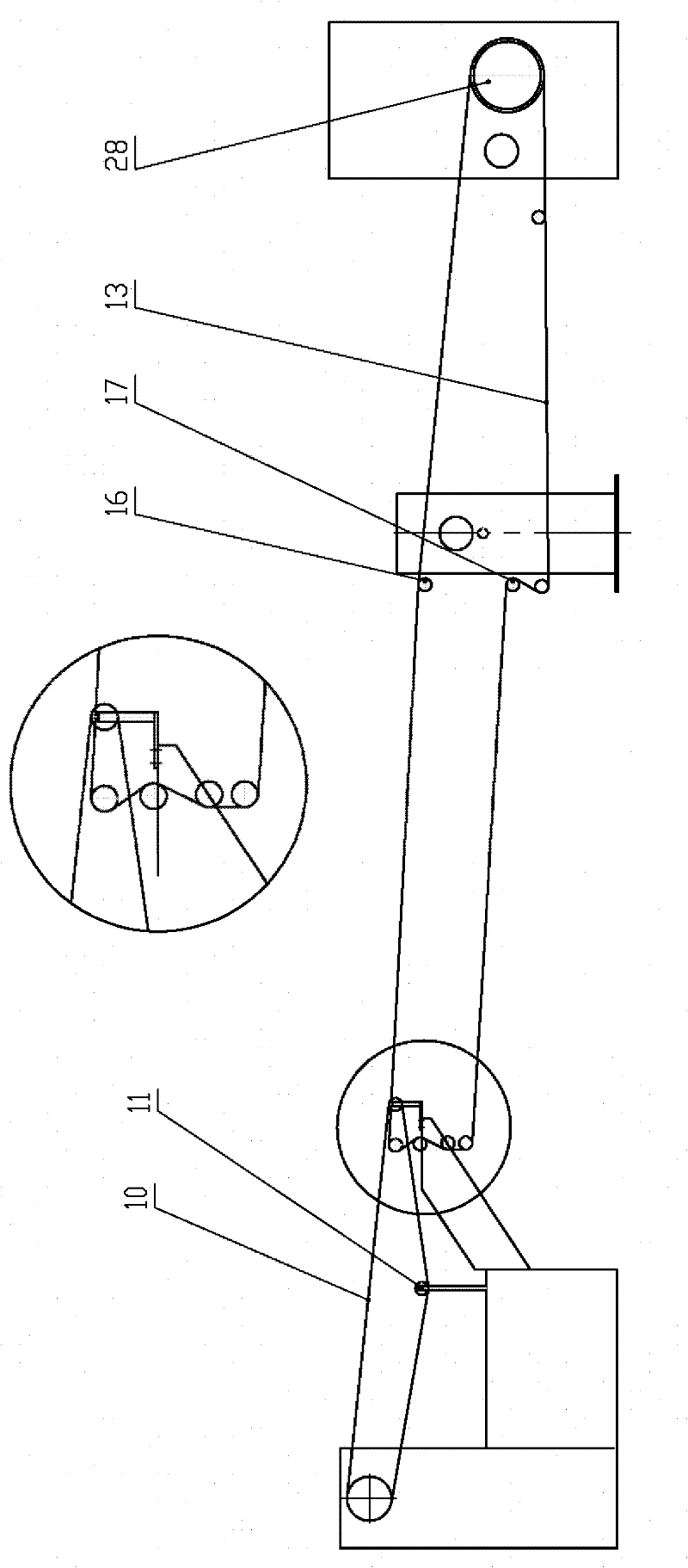

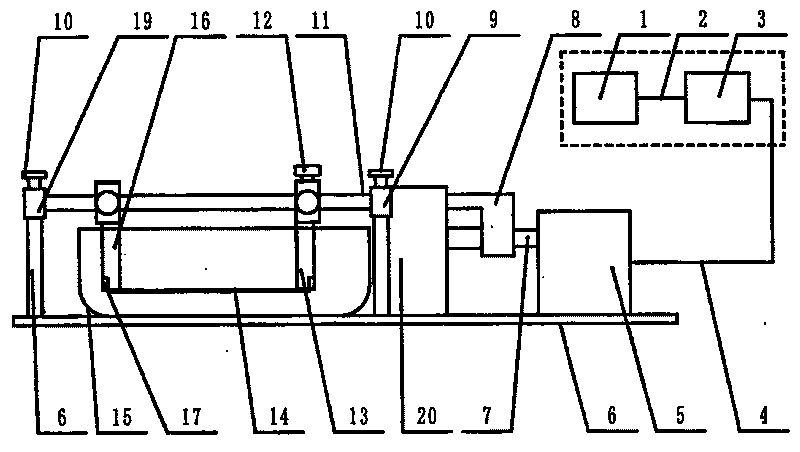

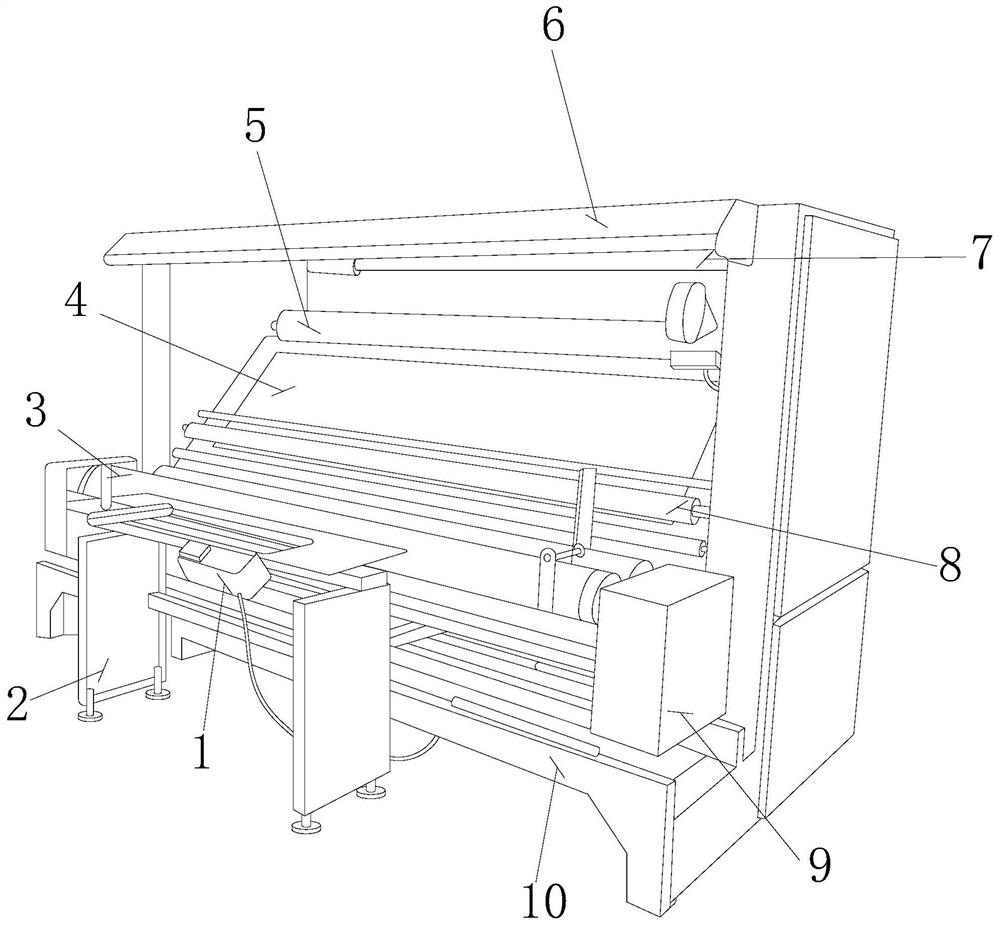

Vertical guide rail automatic cloth conveying device for transfer printing machine

ActiveCN102248758AWeft neatUniform distribution of squeeze liquidTransfer printingEngineeringDrive motor

The invention discloses a vertical guide rail automatic cloth conveying device for a transfer printing machine. The device comprises a cloth storage device, a headstock box, a cloth conveying device and a tailstock box, wherein a weft adjustment device and an overfeed device are arranged in the headstock box; the cloth conveying device consists of a vertical guide rail cloth flatly-conveying system and a fabric carrying device; an active pin miss device, an active cloth feeding device and two sets of tension detection devices are arranged in the tailstock box; the weft adjustment device is positioned on the rear lower side of the headstock box; the overfeed device is positioned in the middle of the headstock box and consists of an upper overfeed device, a lower overfeed device and a widthexpansion device; the vertical guide rail cloth flatly-conveying system comprises a vertical guide rail and a pin plate conveying chain and is used for supporting the two sides of a fabric; the fabric carrying device consists of a cloth carrying flat belt part and a rope-shaped cloth carrying belt part and is used for supporting the middle part of the fabric; the active pin miss device consists of an active pin miss wheel and an active pin miss roller and is used for stripping the fabric from the pin plate; the active cloth feeding device consists of an active cloth feeding roller, a drive motor and a speed reducer; and each set of tension detection device consists of a tension sensor and a tension roller.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

Ultra-thick high temperature-resistant steel for pressure vessel and preparation method thereof

ActiveCN102094150AProportion design is reasonableIncrease productivityTemperature control deviceMetal rolling arrangementsChemical compositionMetallurgy

The invention relates to an ultra-thick high temperature-resistant steel for a pressure vessel and a preparation method thereof. After smelting and refining, the steel is subjected to continuous casting, hot rolling, normalizing and tempering. The steel comprises the following controlled chemical components in percentage by mass: 0.08-0.15% of C, 0.15-0.40% of Si, 0.40-0.70% of Mn, 0.90-1.20% of Cr, 0.15-0.30% of V, 0.25-0.35% of Mo, at most 0.025% of P, at most 0.010% of S and the balance of Fe and inevitable inclusions. The preparation method provided by the invention comprises the steps of smelting, heating, rough rolling, finish rolling, normalizing and tempering. The invention has the characteristics of appropriate design and proportion of the chemical components, simple manufacturing process, large thickness dimension (80mm), good heat resistance, stable product performance and the like.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

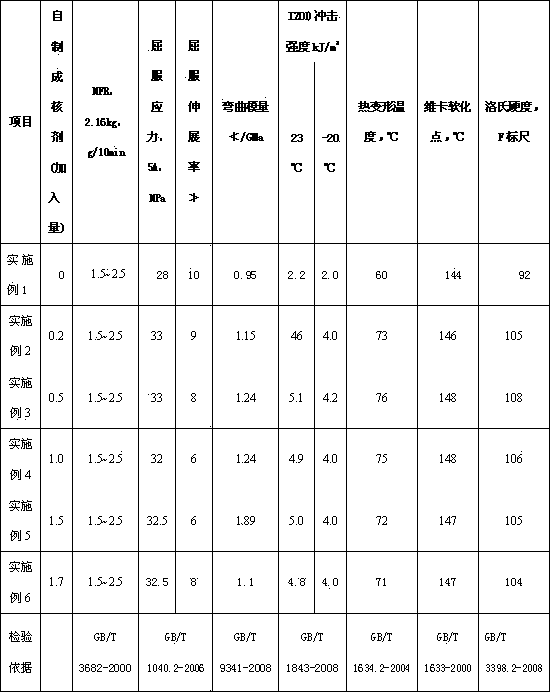

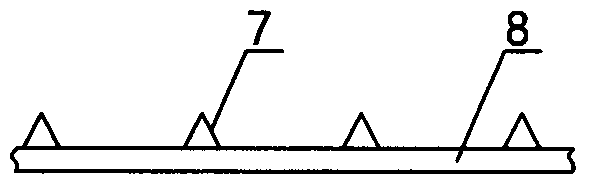

High-performance modified polypropylene and processing method for two-way stretch geogrid special material

The invention discloses high-performance polypropylene prepared from methods of self-producing a nucleating agent and synthesizing an antioxidant. The high-performance polypropylene is used for processing a two-way stretch geogrid special material; a beta crystalline hexagonal honeycomb-shaped stable product is produced through a double-screw extruder under process conditions of a preset rotating speed, temperature and the like, and the product is excellent in performances including stable tensile strength, high compressive strength, high yield extensibility and the like. The method disclosed by the invention optimizes raw material proportion, so that the prepared grid special material is completely consistent with or better than national and industrial standards and shows strong economy and practicability.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

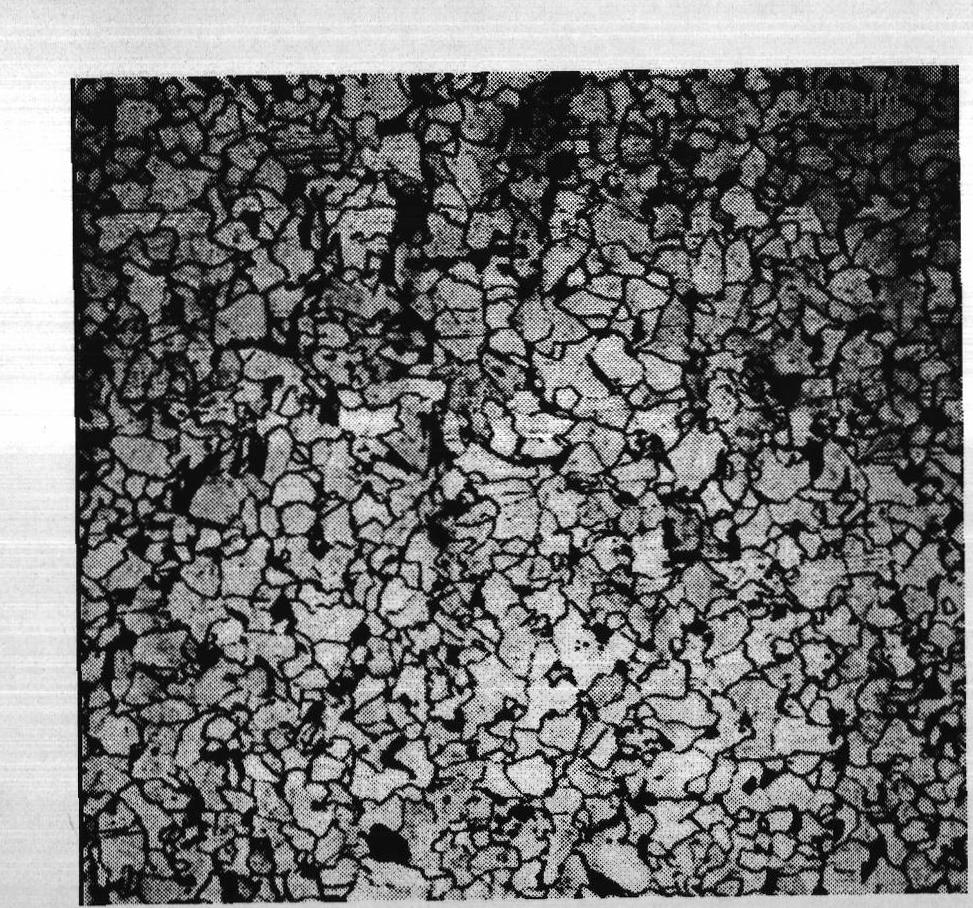

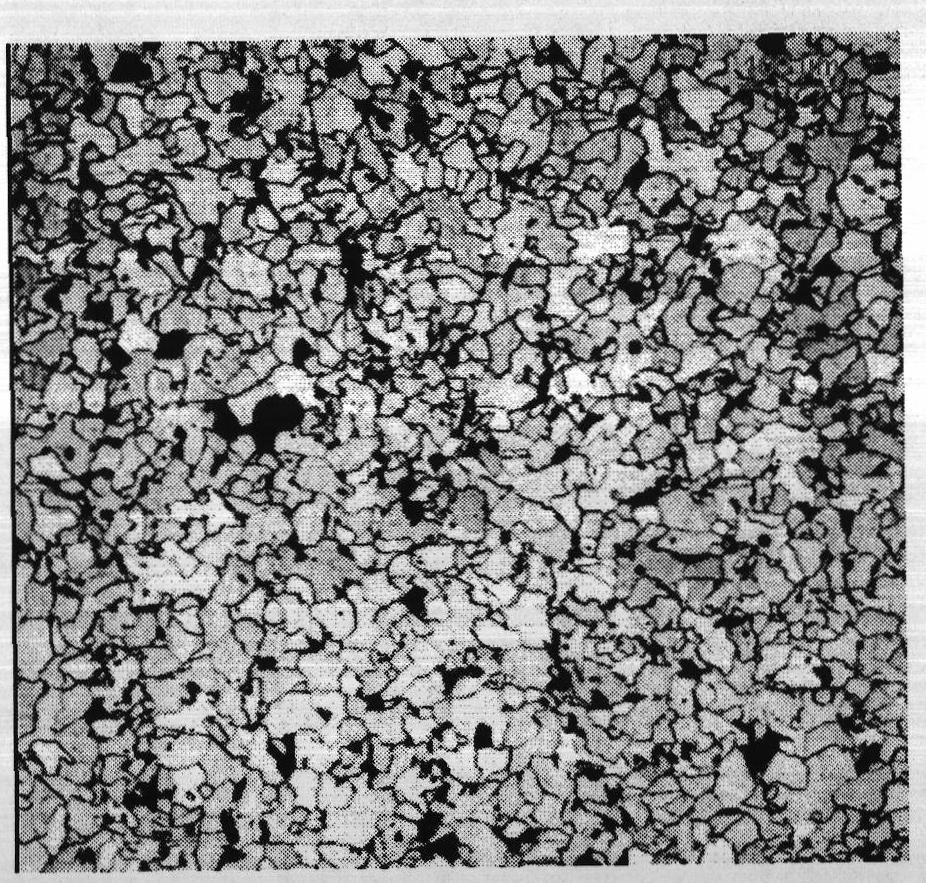

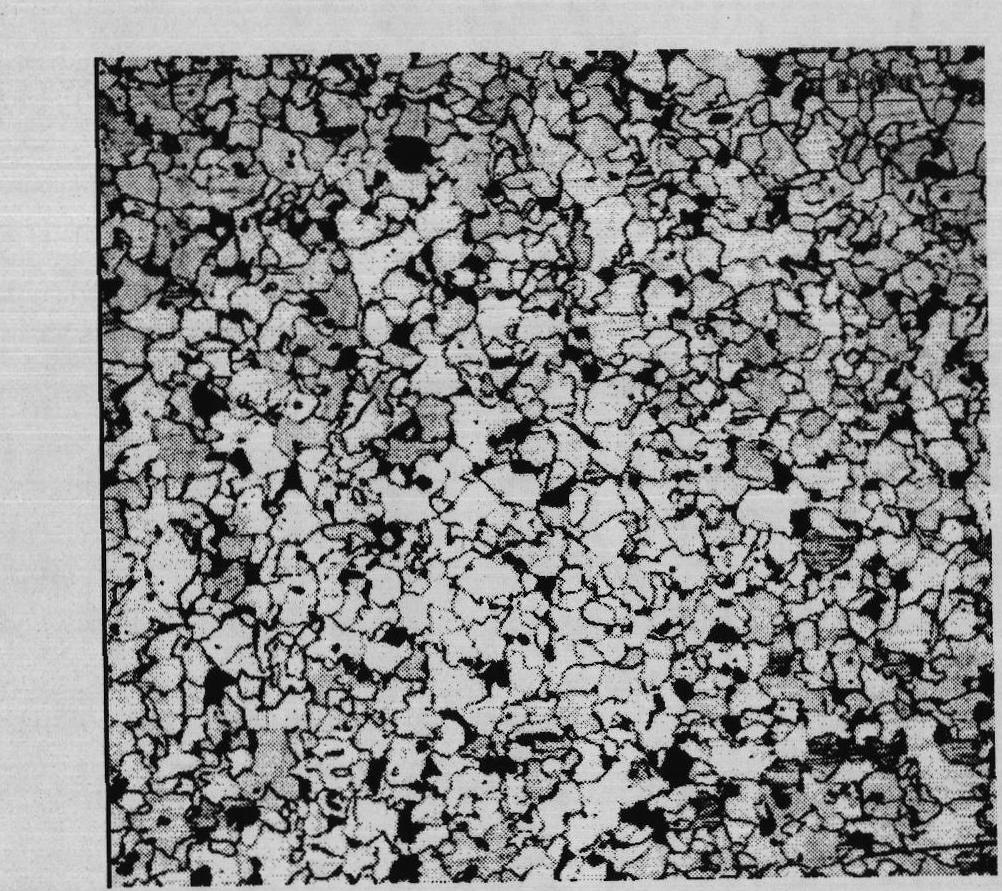

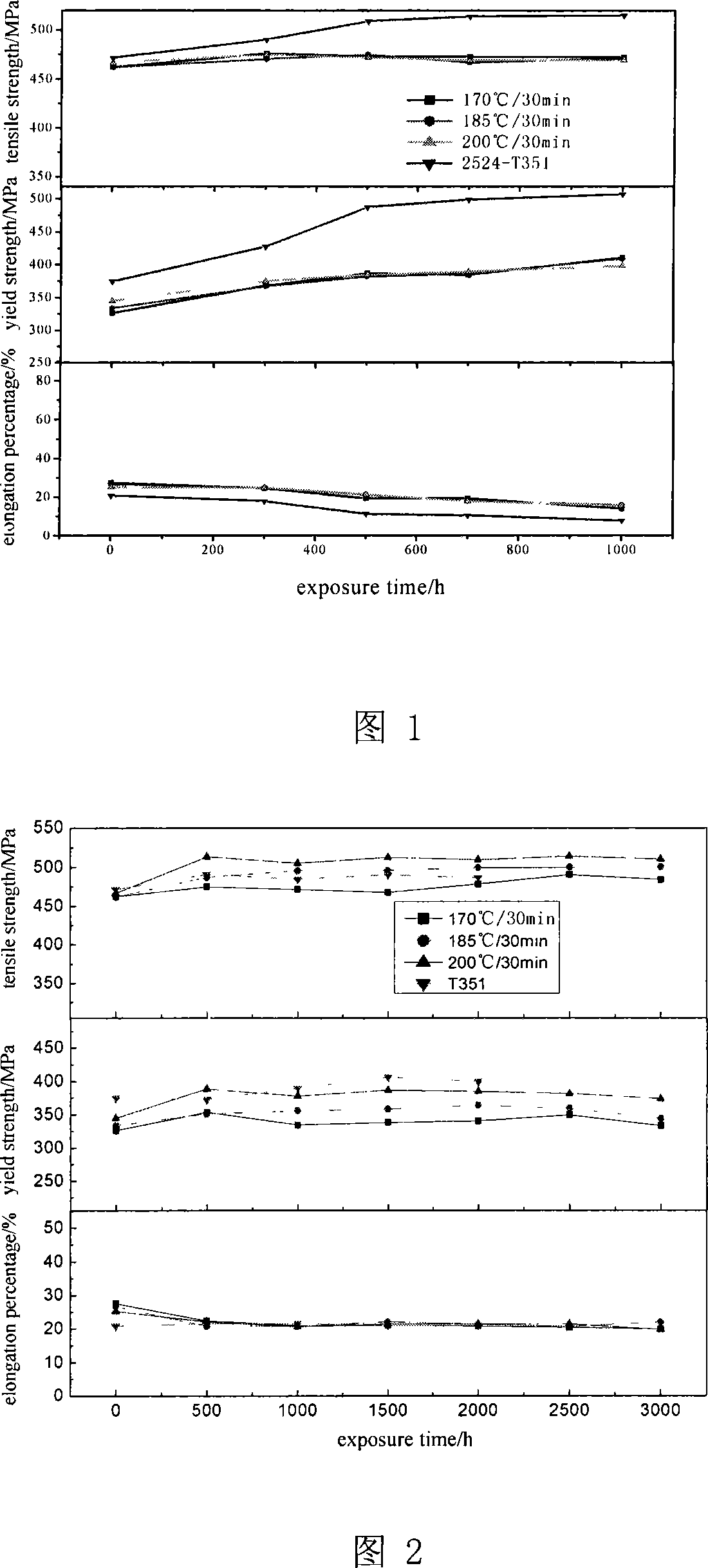

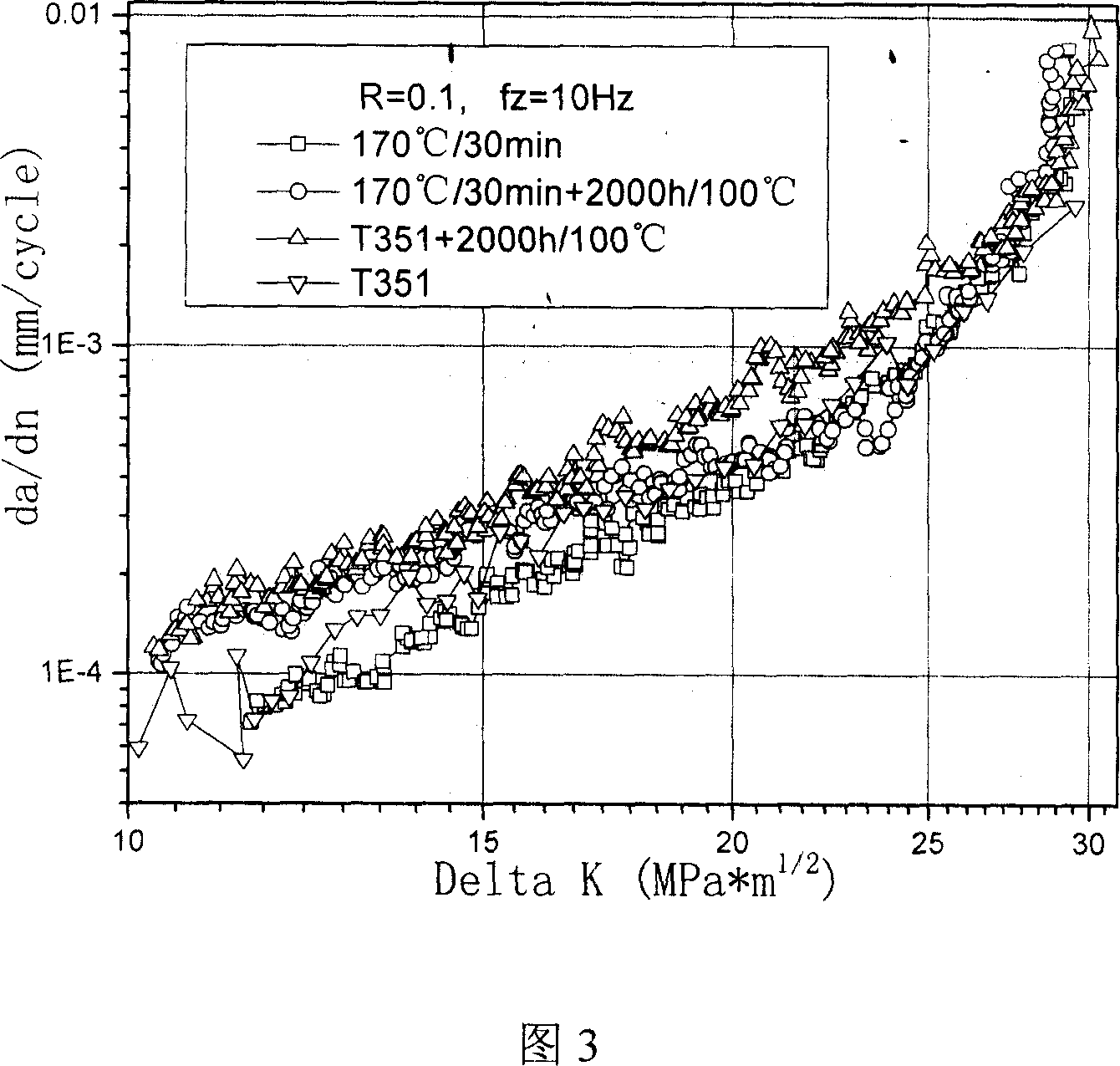

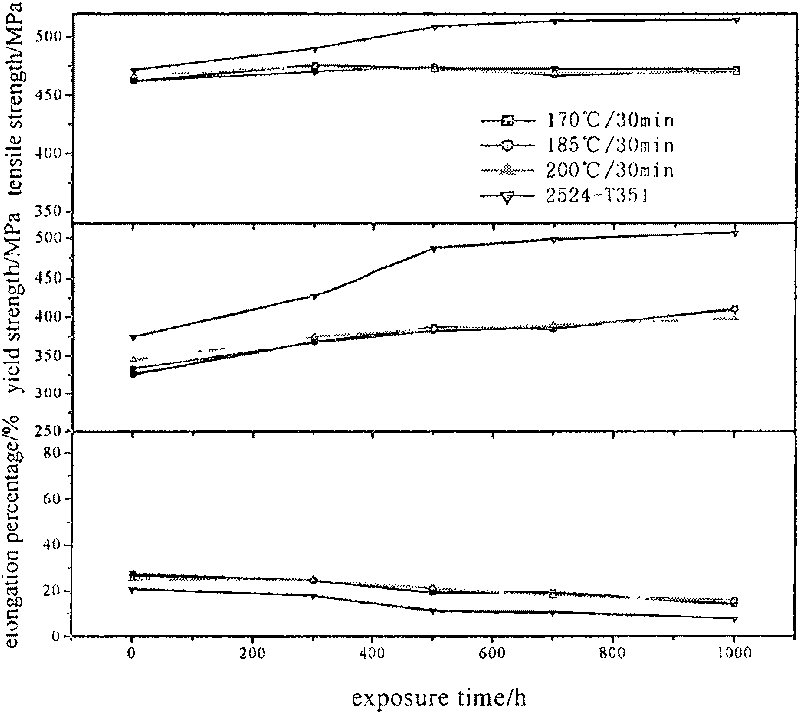

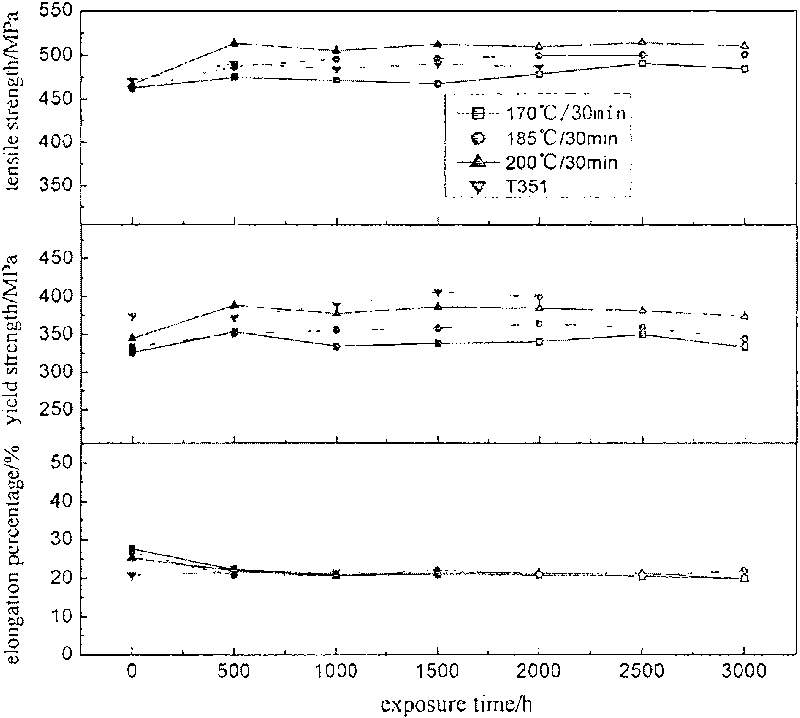

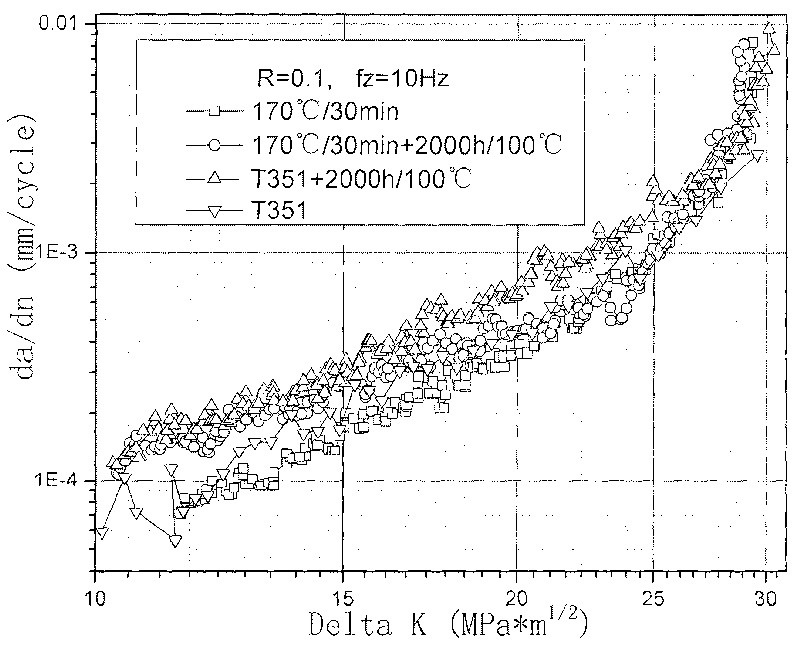

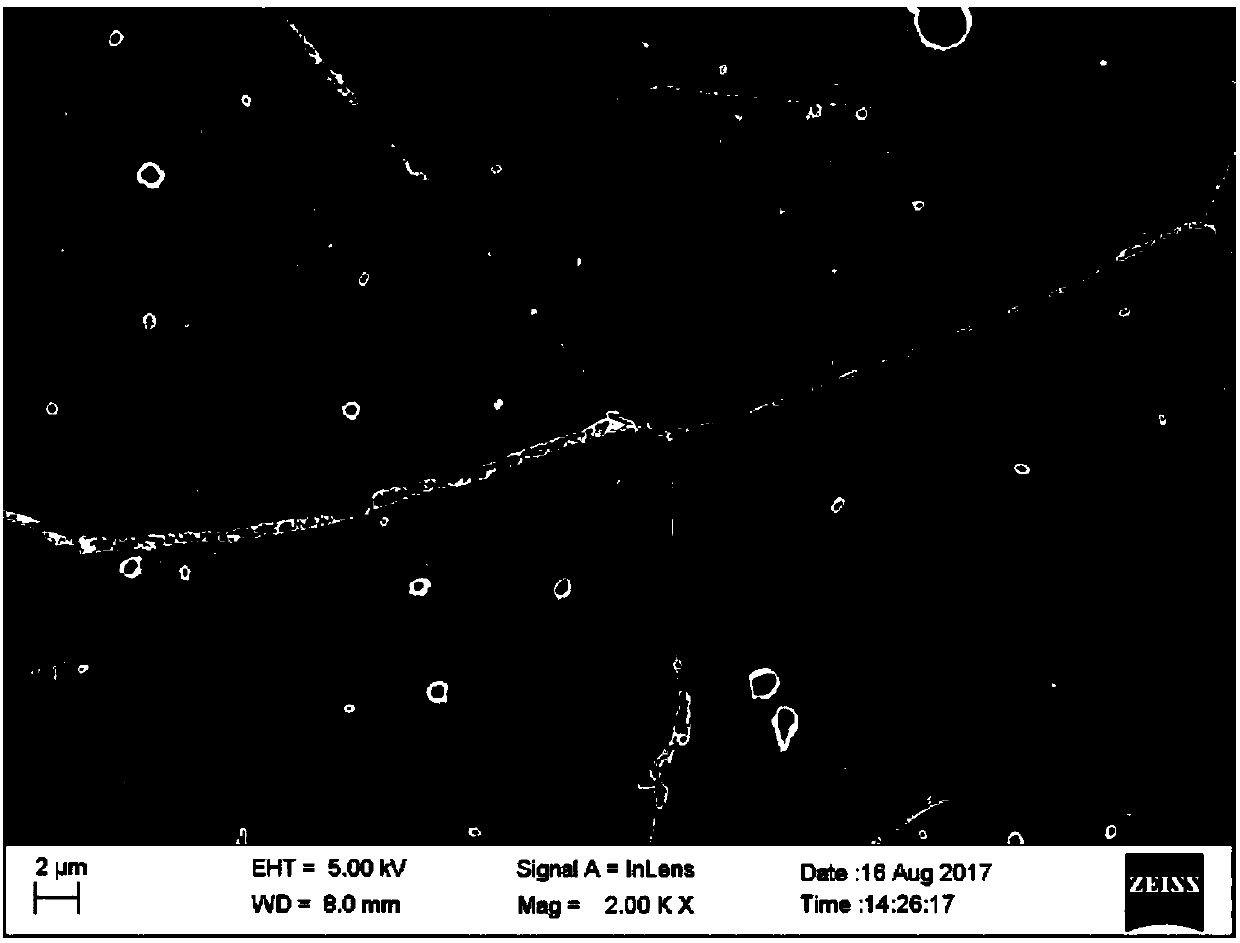

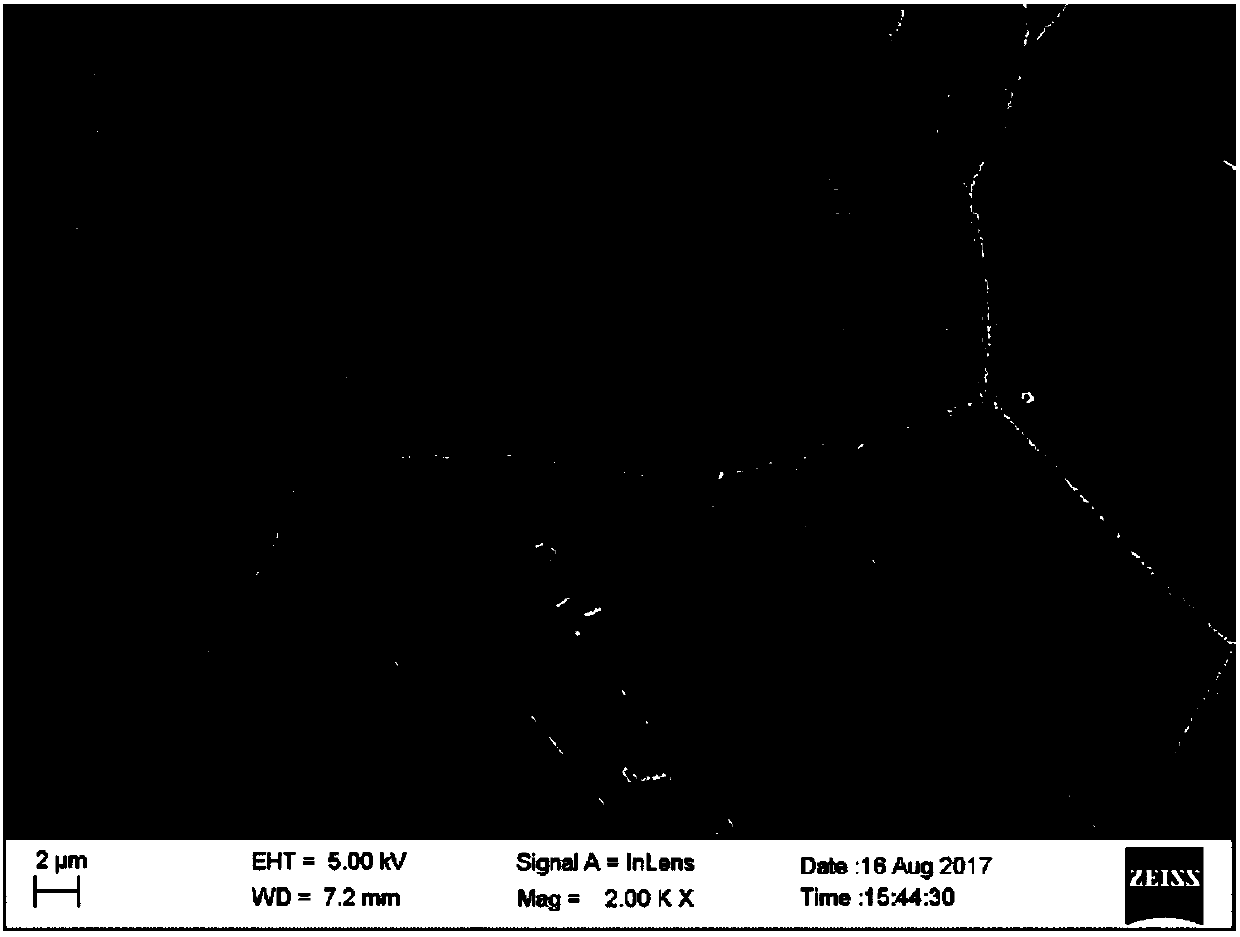

Treatment method for providing aluminum alloy with high thermal stability anti-fatigue microstructure

The present invention discloses one heat treating process for aluminum alloy to obtain anitfatigue microstructure with high heat stability. The treating process for aluminum alloy plate includes the first solution treatment at 490-500 deg.c, and the subsequent artificial ageing treatment at 170-200 deg.c for 20-60 min. The heat treating process makes the Al-Cu-Mg alloy obtain reinforcing GPB structure in relatively large size, excellent antifatigue performance, delayed degradation of the antifatigue performance and anitfatigue microstructure with high heat stability.

Owner:CENT SOUTH UNIV

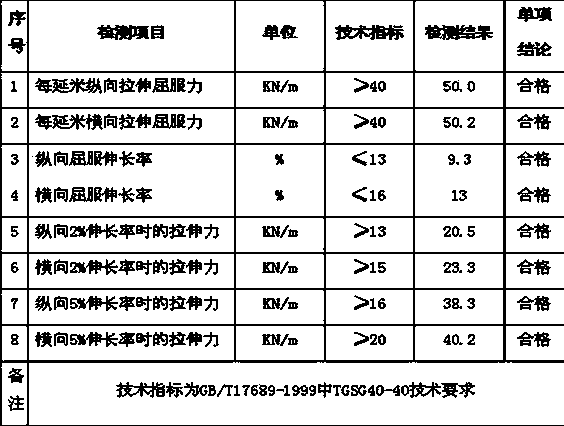

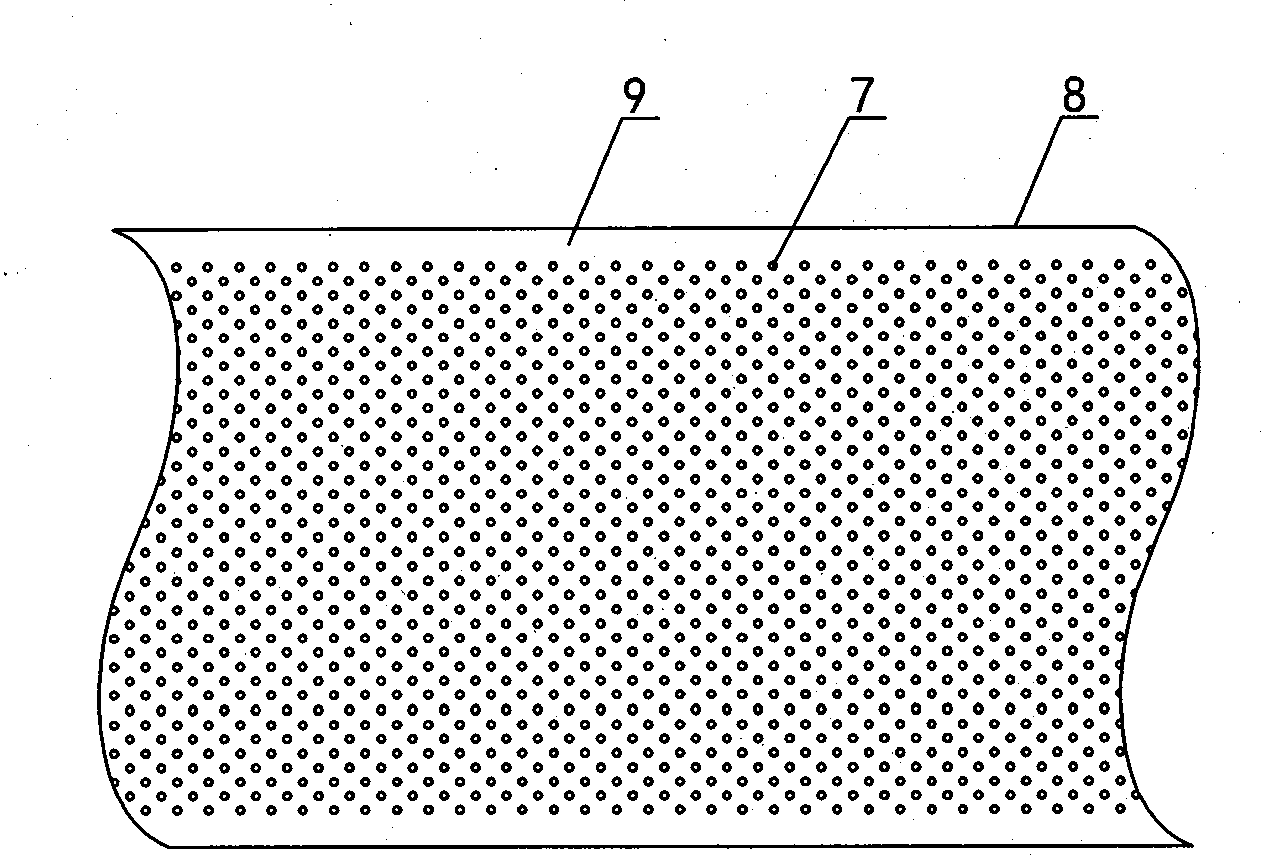

High-intensity damage-free type flexible roughened surface geomembrane and producing method thereof

InactiveCN102912782AGood flexibilityHigh tensile strengthSoil preservationUltraviolet lightsEngineering

The invention discloses a high-intensity damage-free type flexible roughened surface geomembrane and a producing method of the high-intensity damage-free type flexible roughened surface geomembrane, belonging to the field of production of a geomembrane. The high-intensity damage-free type flexible roughened surface geomembrane comprises a geomembrane body. The high-intensity damage-free type flexible roughened surface geomembrane is characterized in that the geomembrane body is in a monolayer calendaring membrane structure; and taper convex points are calendered on the upper surface and / or the lower surface of the membrane body. The main raw materials of the geomembrane comprise ethylene-alpha olefin copolymer, high-intensity polyethylene, high-pressure low-intensity polyethylene, antioxygen, ultraviolet light absorber and carbon black. Compared with the prior art, the high-intensity damage-free type flexible roughened surface geomembrane disclosed by the invention has the characteristics of simplicity in production technique, excellent performance index, and the like, can be widely applied to a railway anti-shock layer, a refuse landfill, a tunnel, a reservoir, a canal, a sewage treatment tank, a landscape lake and other environment-friendly anti-seepage projects, and has very good popularizing and applying values.

Owner:山东天海新材料工程有限公司

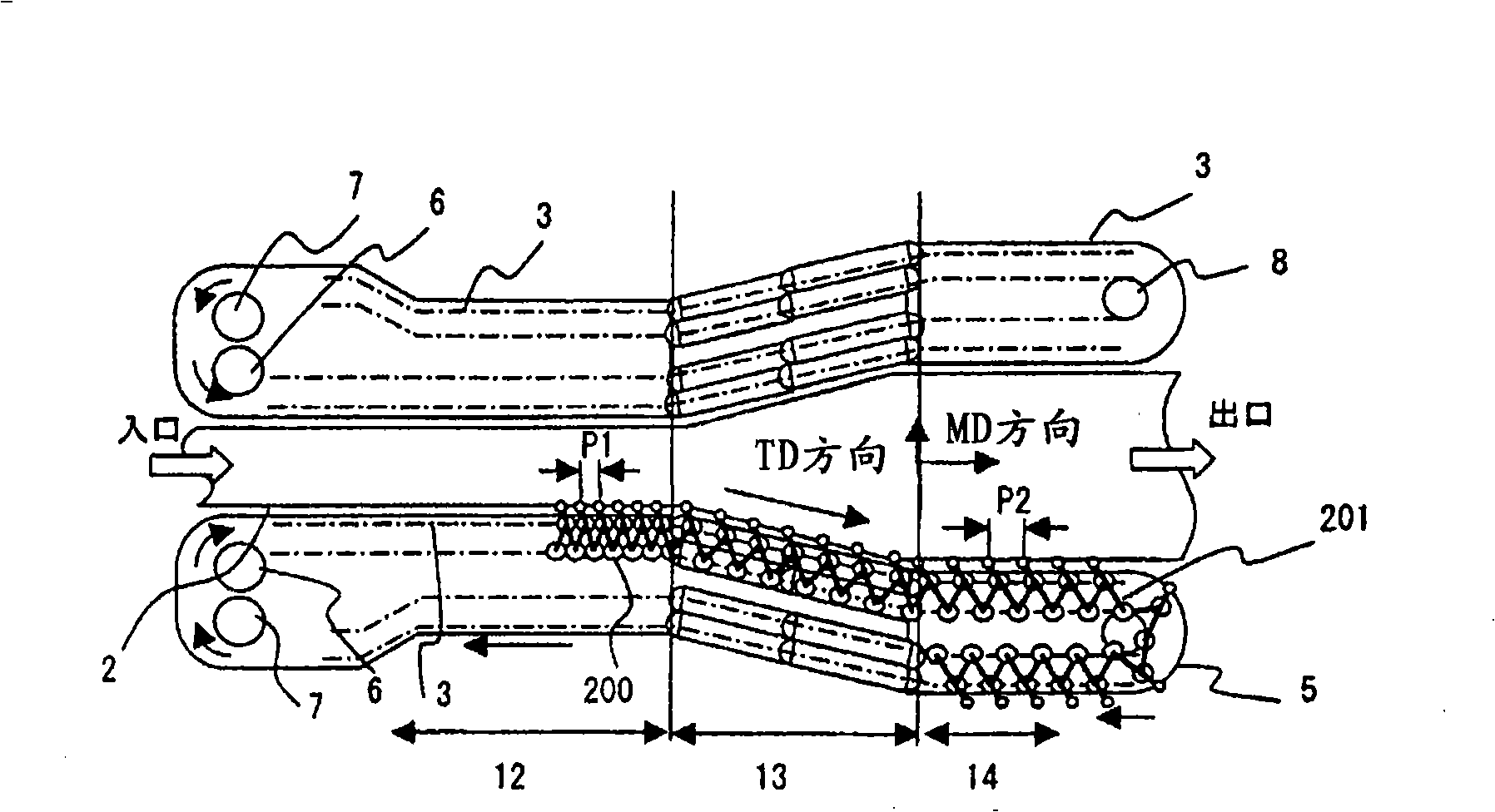

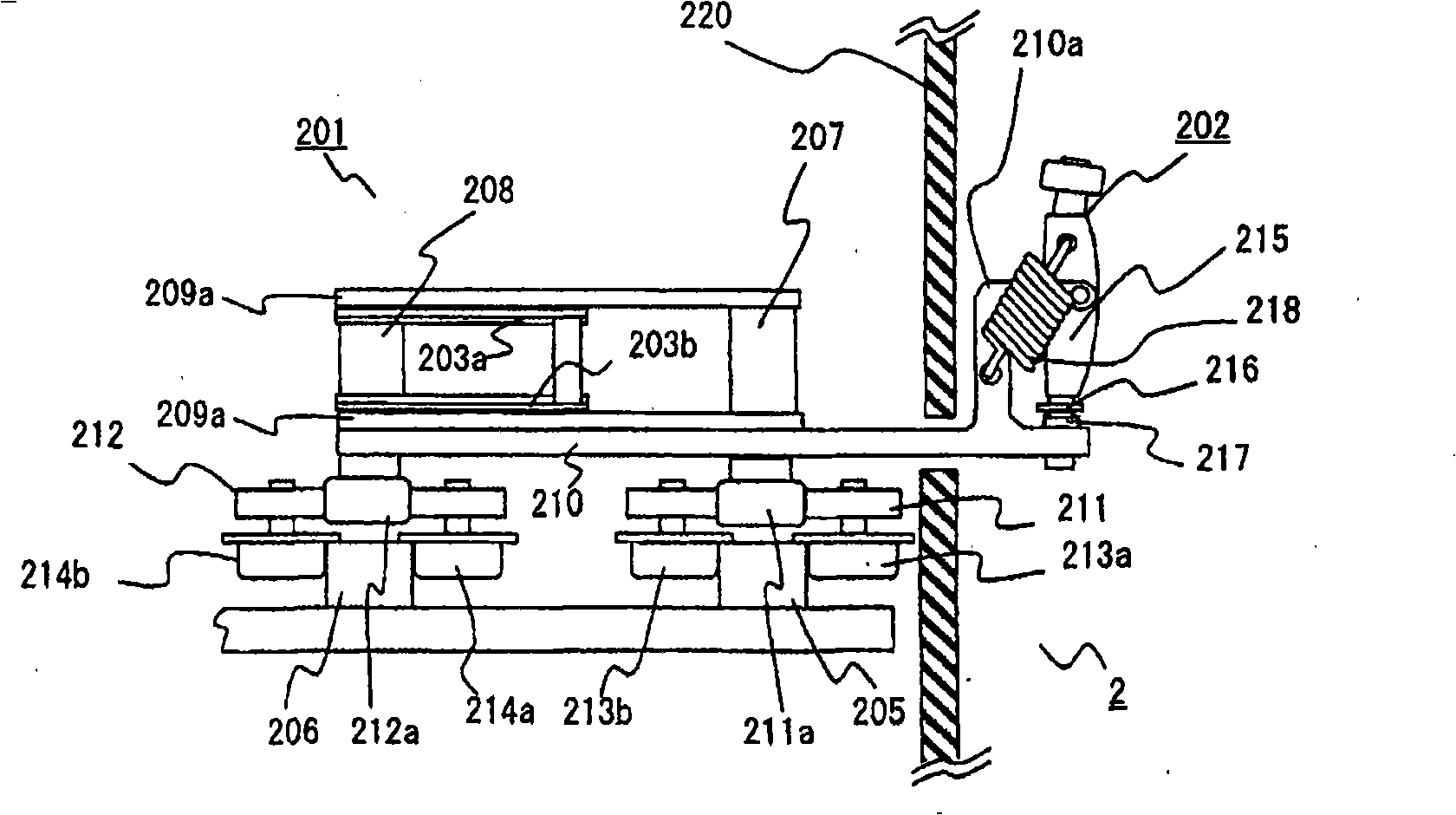

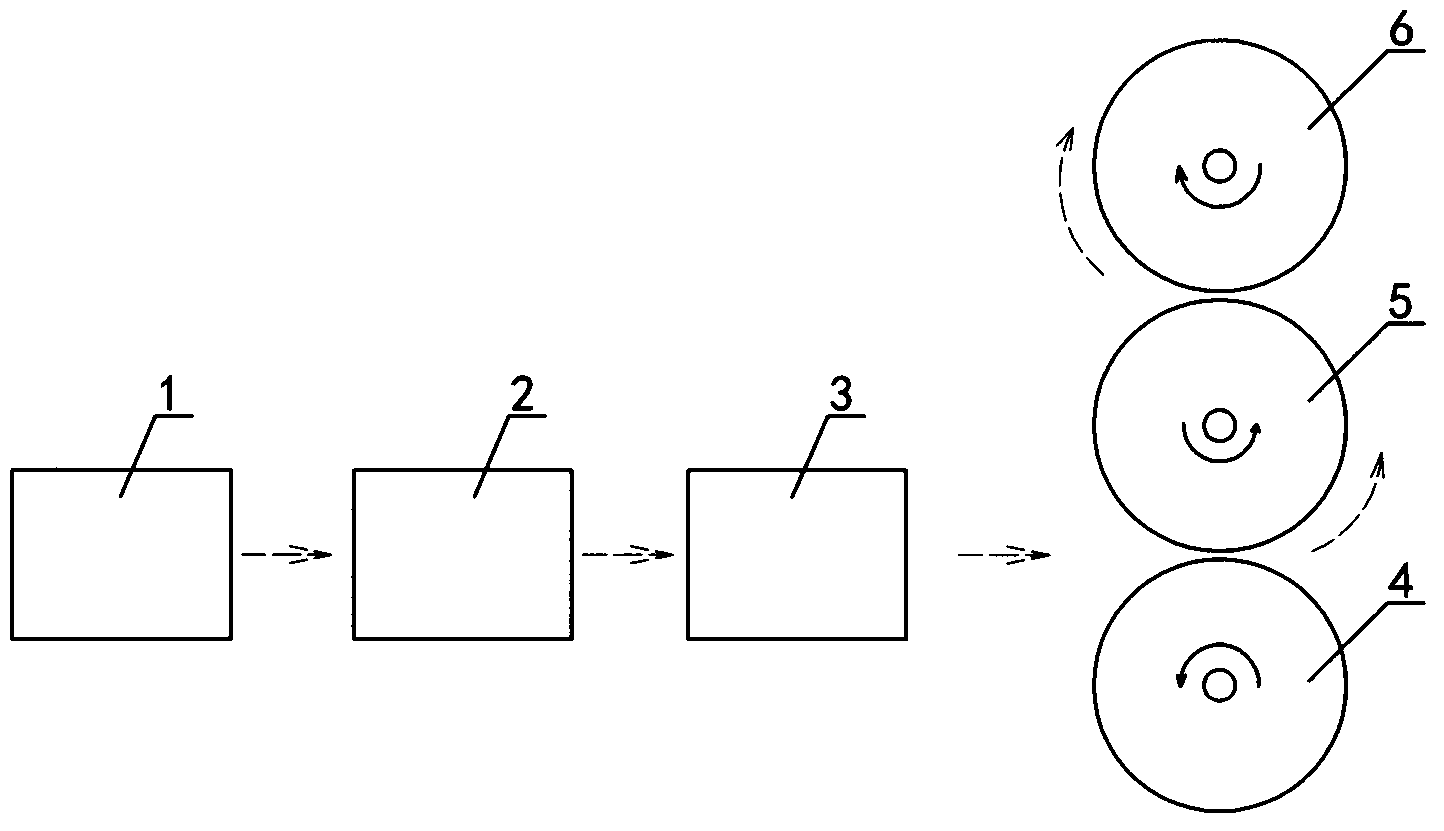

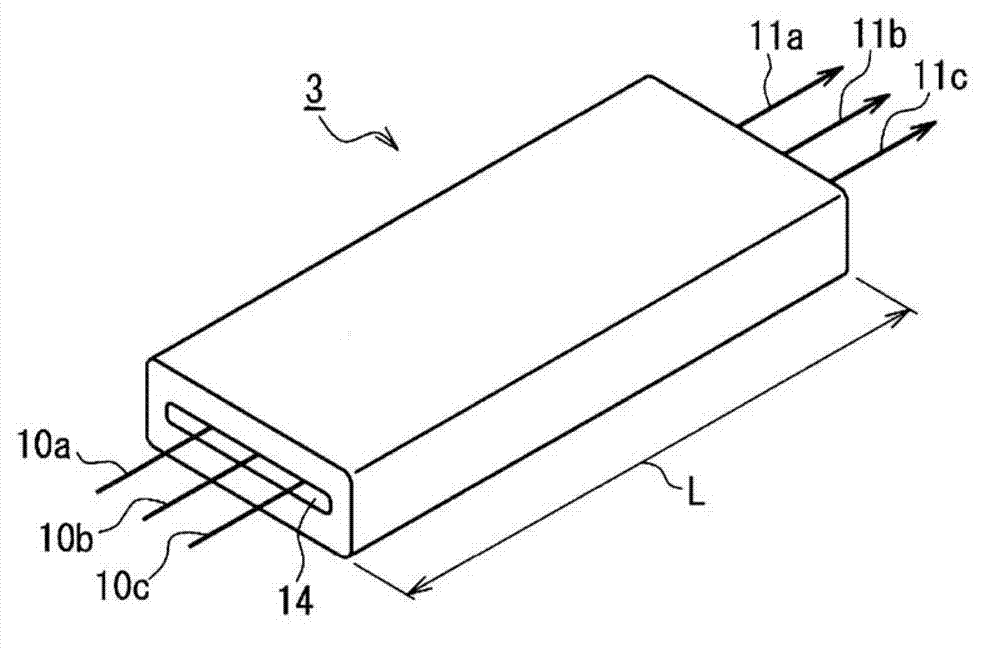

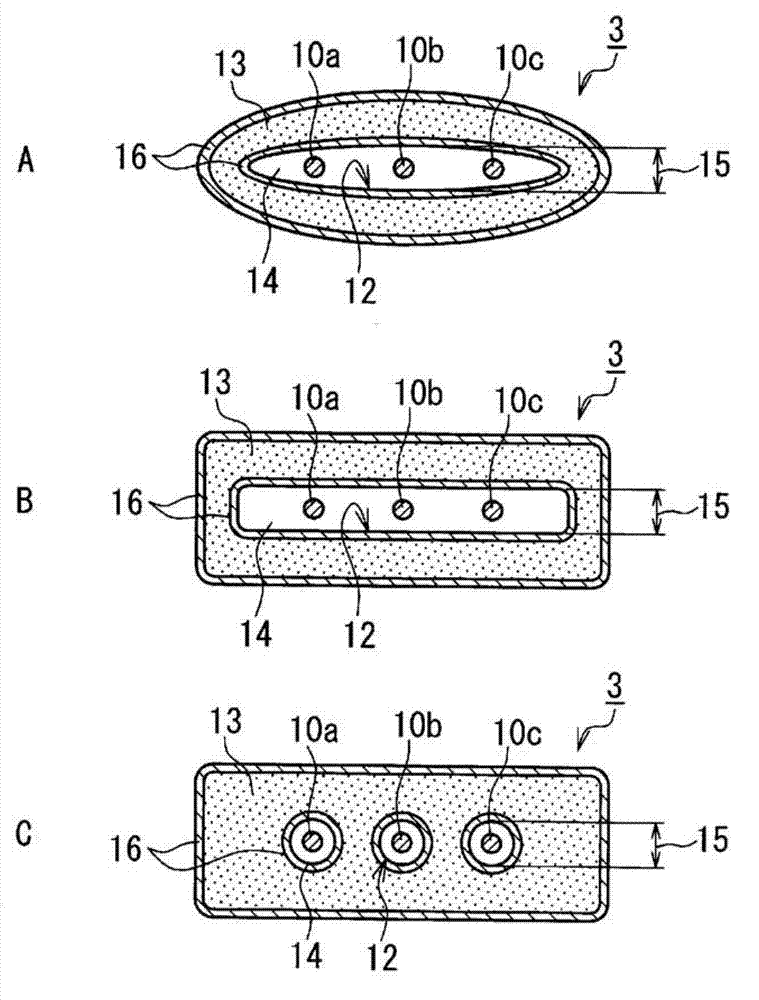

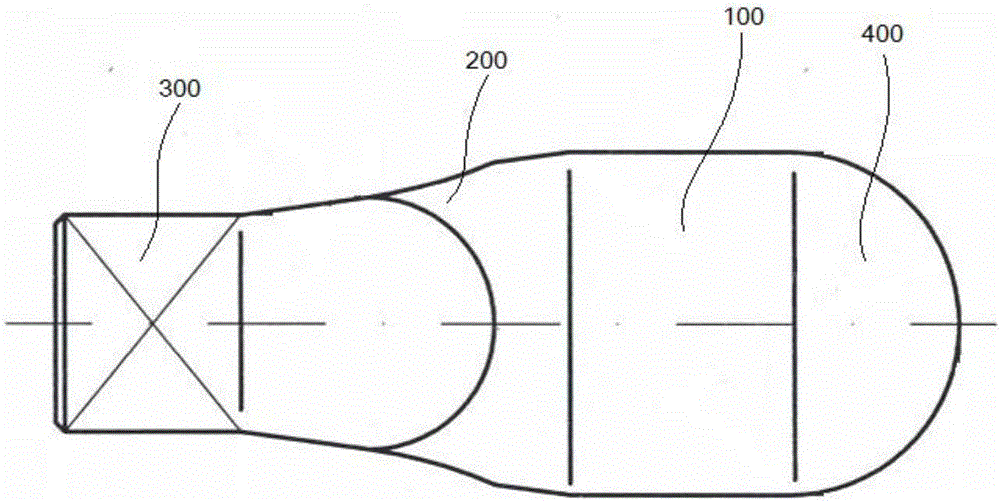

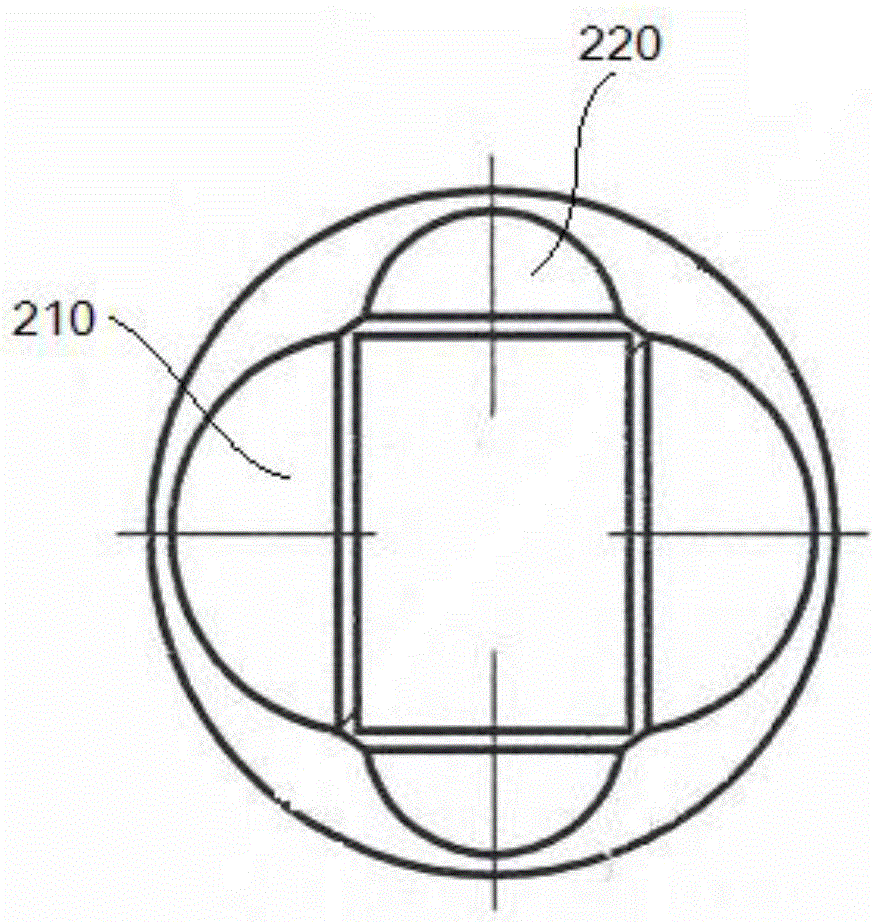

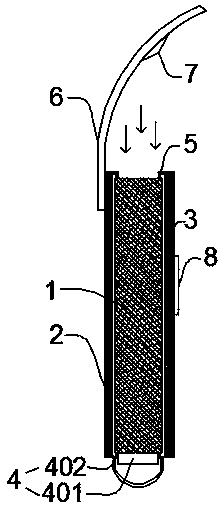

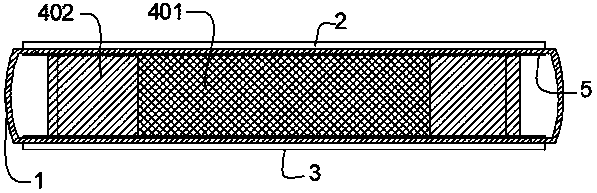

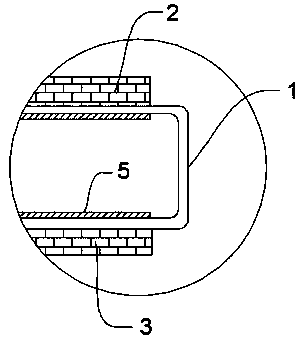

Super-high-molecular-weight polyolefin yarn, method for producing same, and drawing device

InactiveCN103097596ASmall coefficient of variationImprove uniformitySuture equipmentsFilament/thread formingYarnContact free

When determined as the maximum peak temperature under conditions of a temperature elevation speed of 20 C / minute by a differential scanning calorimeter (DSC), the melting point of a drawn super-high-molecular-weight polyolefin yarn of the present invention is higher than the melting point of the yarn before drawing. In a production method of the present invention, a passage opening (14) for yarn is hollow, a drawing tank (3) in which hot liquid circulates is disposed in a drawing zone in a jacket part (13), and the yarn is heated and drawn while being passed, contact-free, through the passage opening (14). A drawing device of the present invention comprises means (1) for feeding yarn, the drawing tank (3) for heating and drawing yarn, and means (5) for reeling in the drawn yarn, and the yarn passage opening (14) of the drawing tank (3) is hollow and the hot liquid circulates in the jacket part (13). A drawing method and a drawing device are therefore provided with which it is possible to draw, with stability even at a high draw ratio, super-high-molecular-weight, high-strength polyolefin yarn, and yarn obtained by the drawing method is also provided.

Owner:GOSEN CO LTD

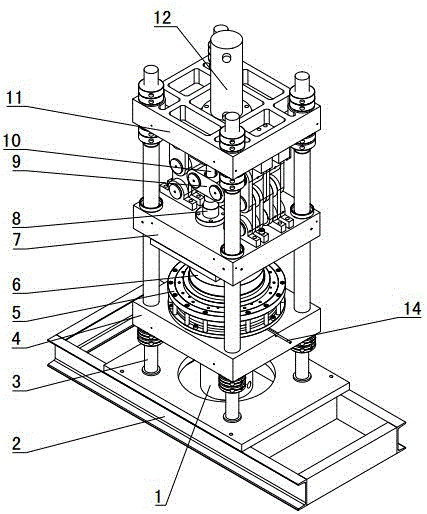

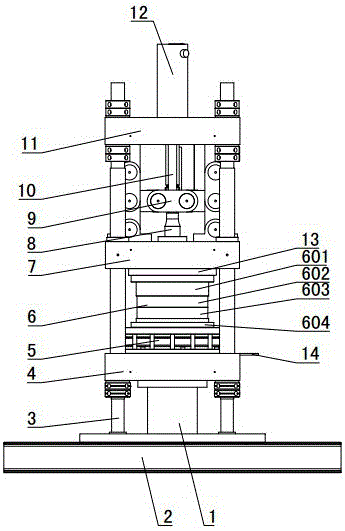

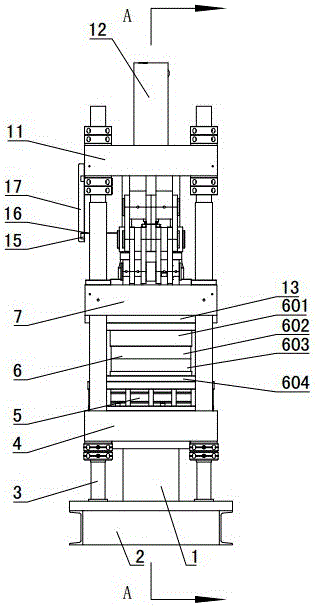

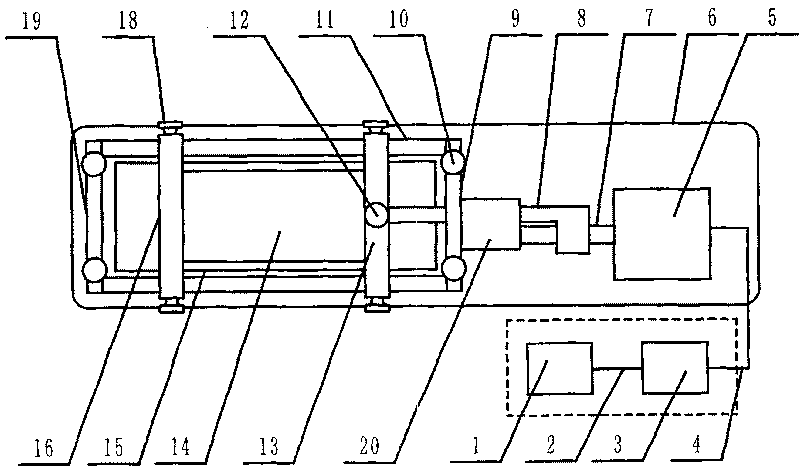

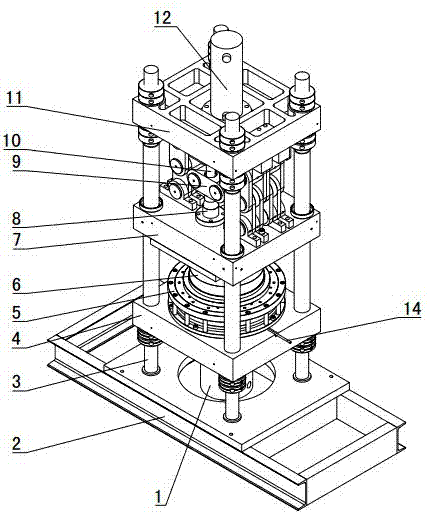

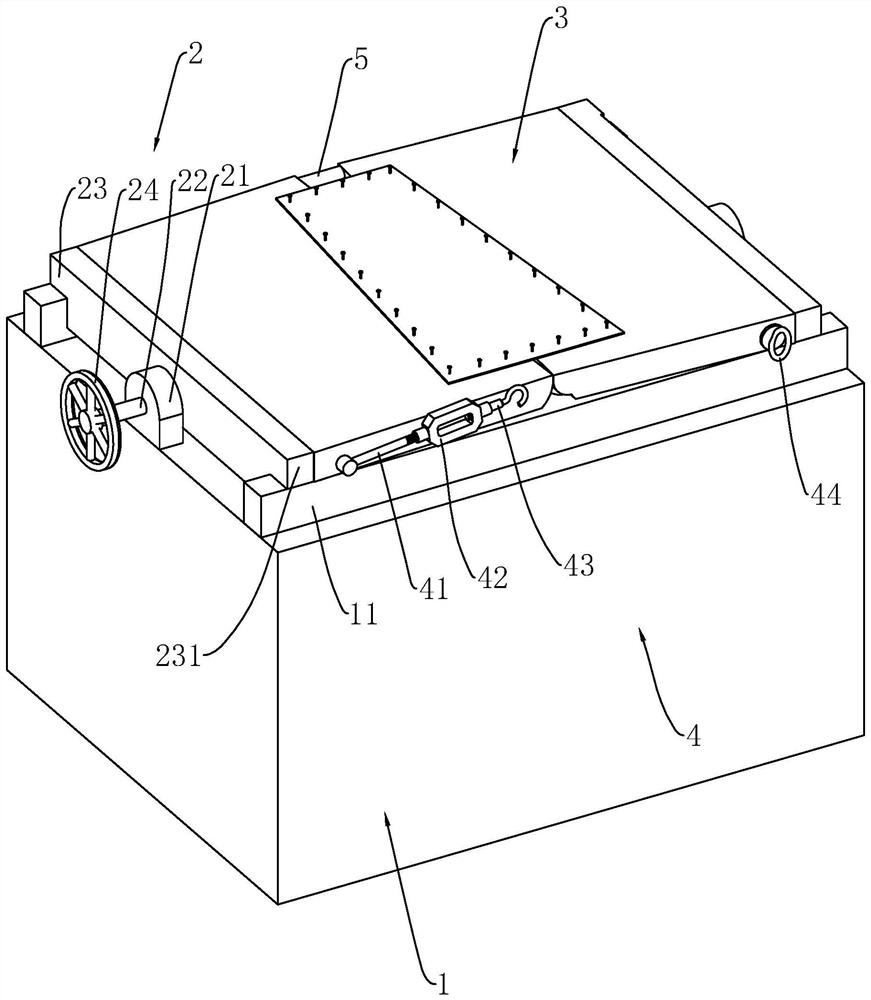

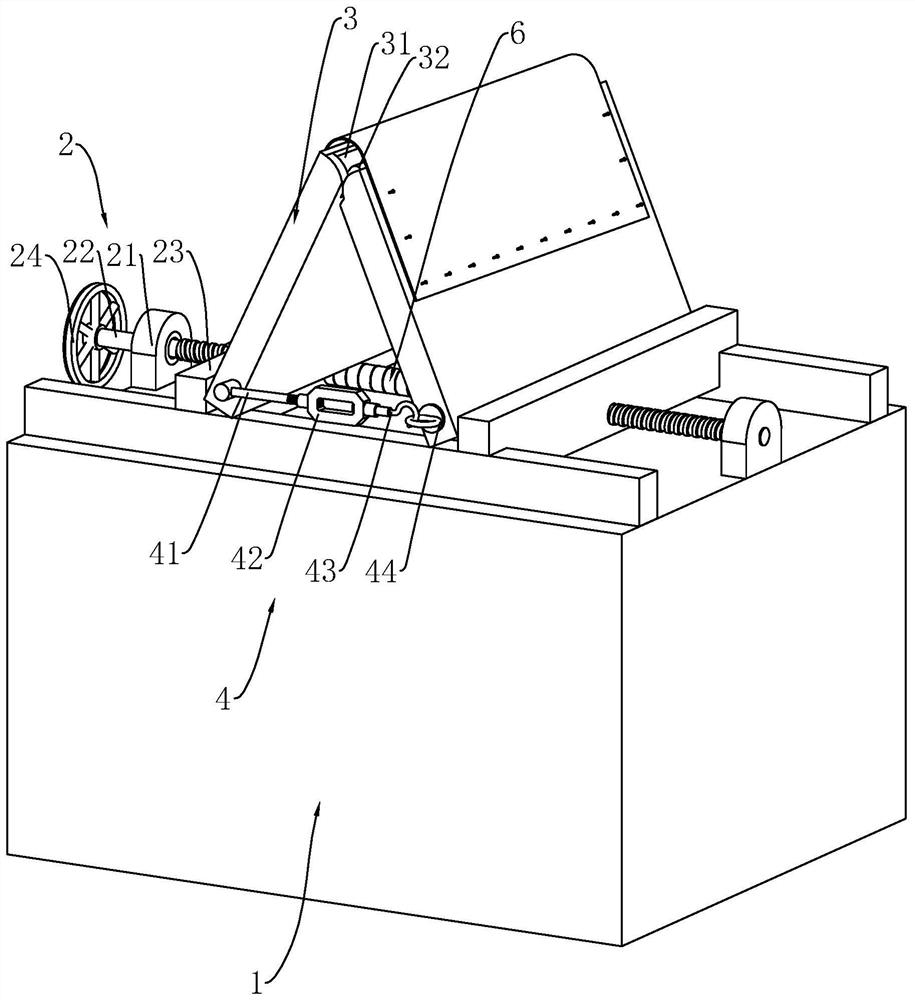

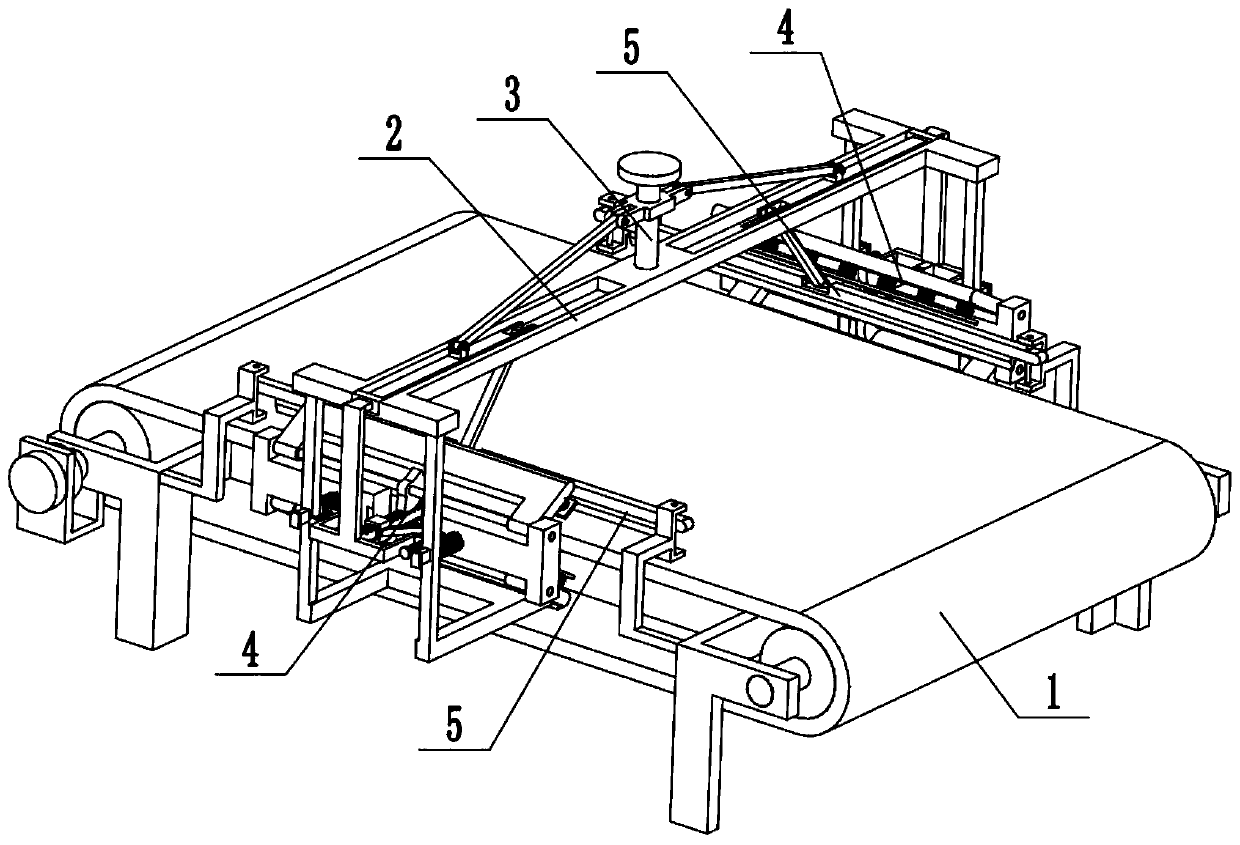

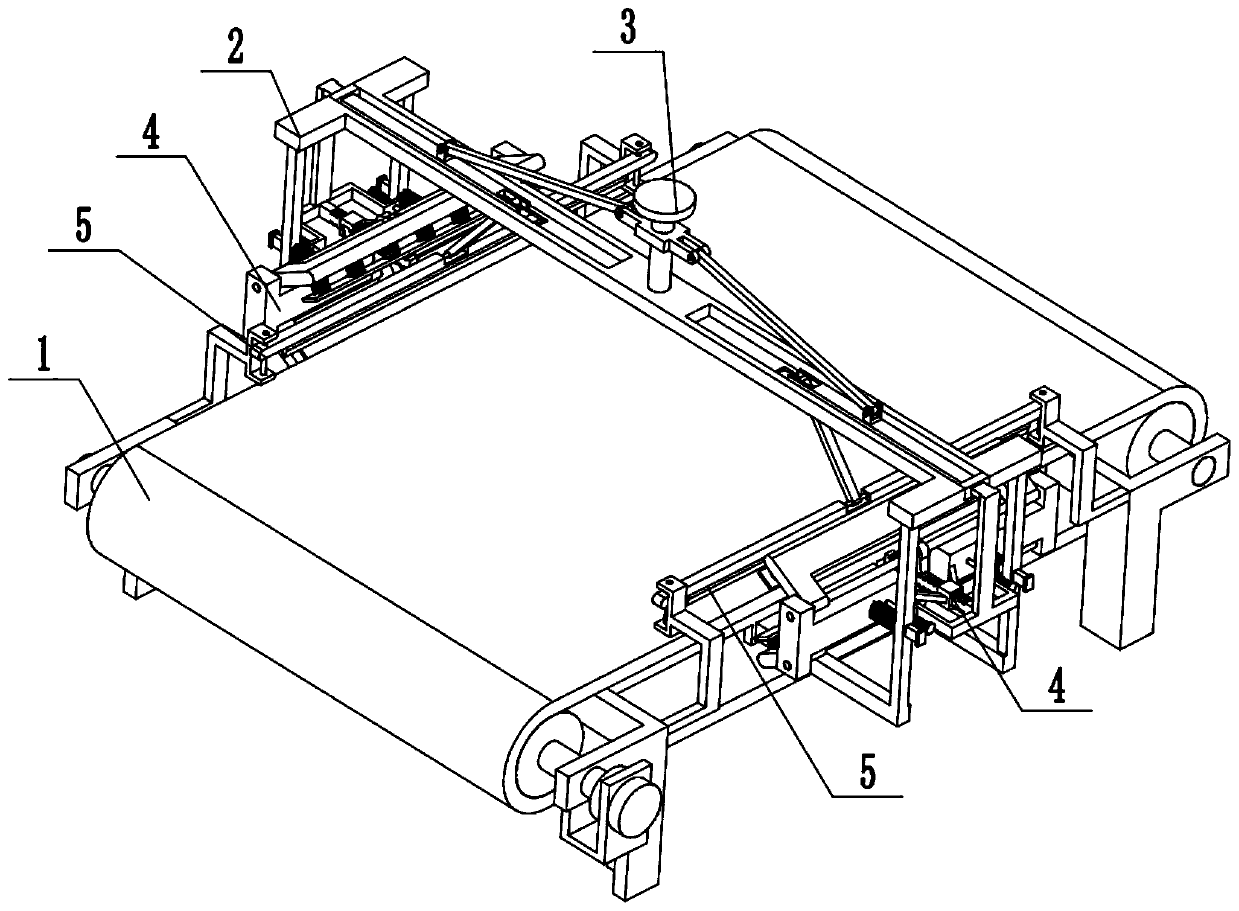

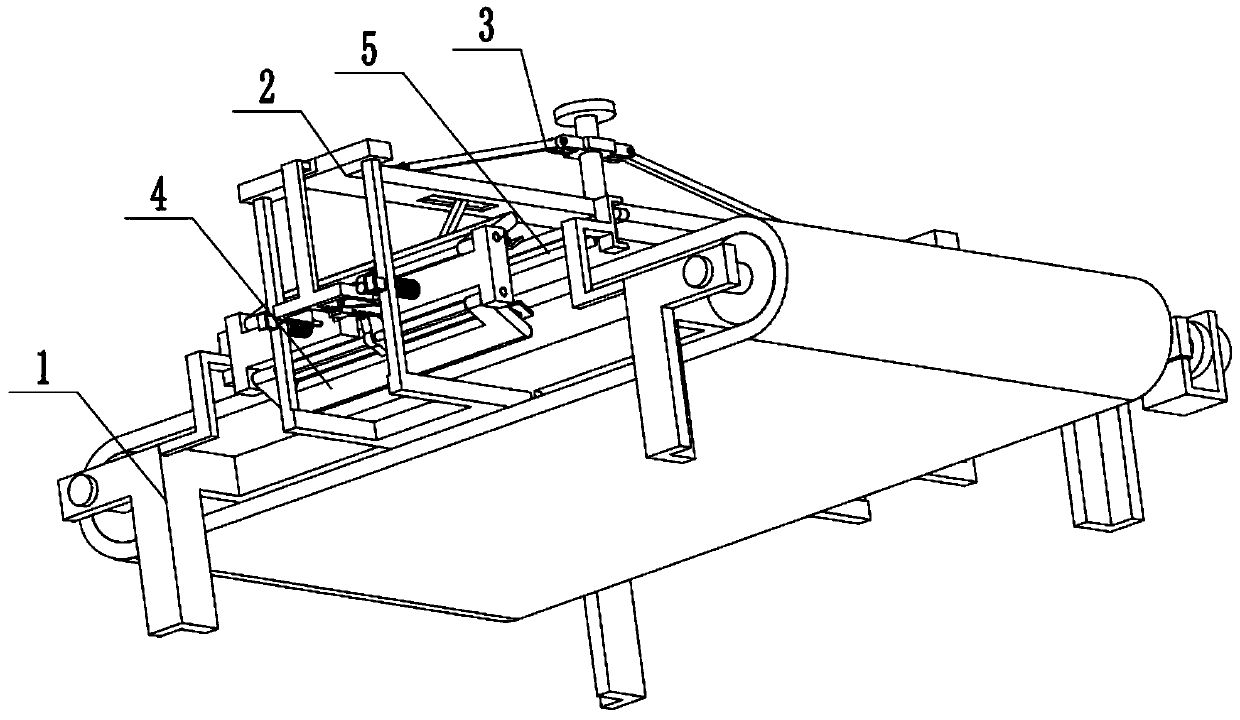

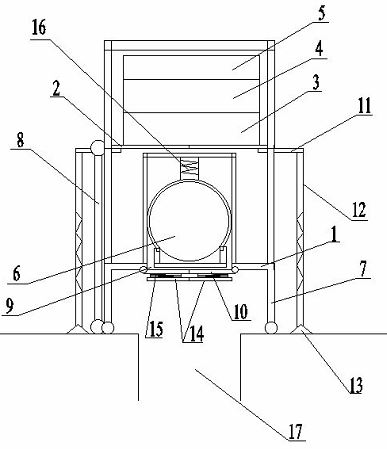

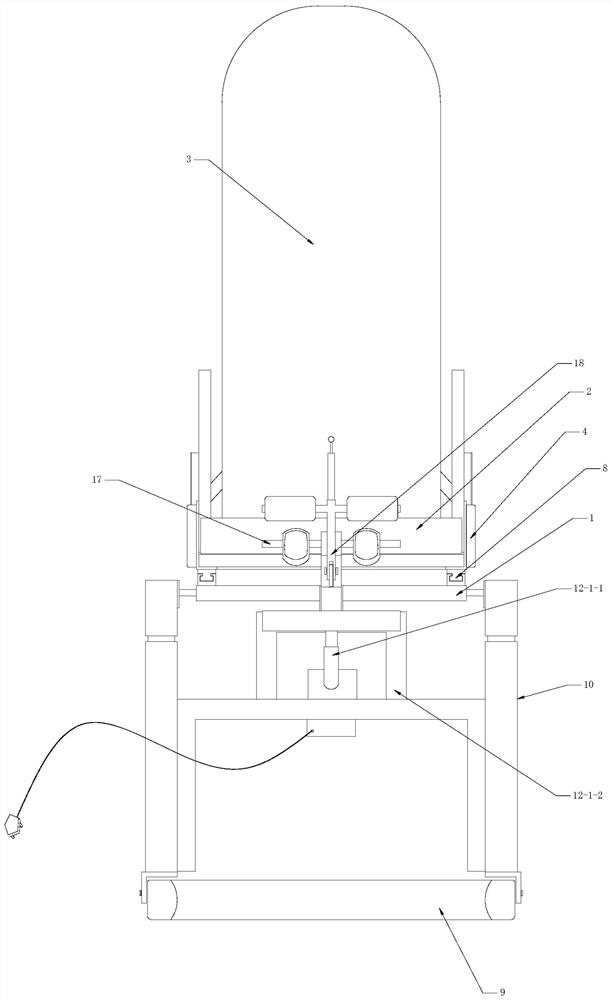

Muitlaxial tension test machine

InactiveCN105043862ATensile stabilityGuaranteed uniformityMaterial strength using tensile/compressive forcesMotor driveEngineering

The invention relates to a muitlaxial tension test machine, which includes a mounting bench, a supporting part arranged thereon, an object board arranged on the supporting part, a plurality of fixed pulleys which are disposed uniformly and are arranged on the object board, a laser extensometer arranged on the mounting bench towards the object board, a connecting board fixedly connected to the mounting bench, a motor and a ball screw rod member arranged on the connecting board, a moving disk arranged on a force sensor, and a lifting mechanism which passes through the mounting bench and is fixedly connected to a screw rod in the ball screw rod member, a force sensor, a plurality of holding members arranged uniformly on the object board and steel ropes. The motor drives a nut in the ball screw rod member to rotate. The screw rod is fixedly connected to force sensor. The steel ropes are winded on the fixed pulleys and is connected to the moving disk and the holding members. The screw rod is driven by the motor to be reduced and applies a down-drawing force on the moving disk through the force sensor, so that the holding members are pulled correspondingly through the steel ropes, thereby achieving stable tension in multiple directions on a thin material. Because the moving disk applies tension on the holding members at the same time, force uniformity on thin material is ensured.

Owner:GOTECH TESTING MACHINES DONGGUAN

Pot stretcher

Owner:山东多星电器有限公司

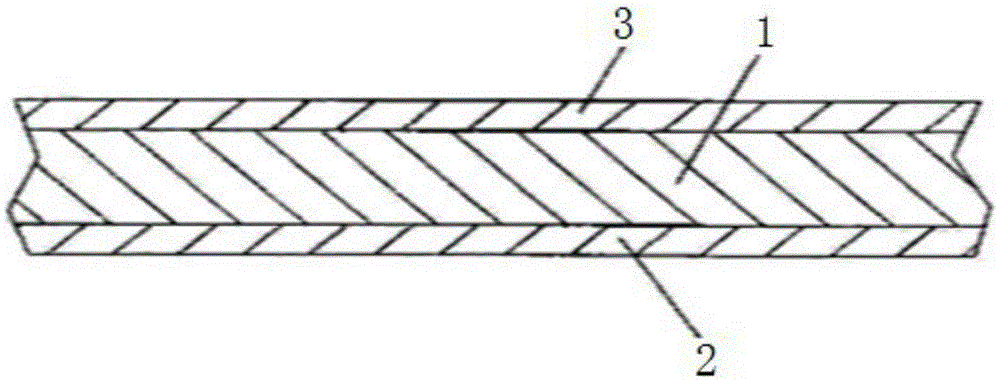

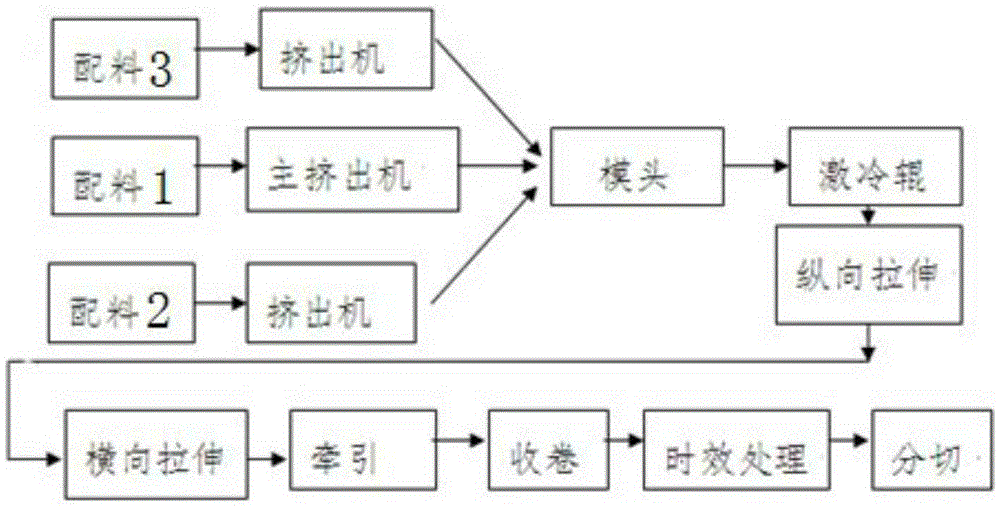

Double-sided corona cover light membrane

InactiveCN105415842ALow staticAvoid stickingFlexible coversWrappersPhysical chemistryMembrane surface

The present invention discloses a double-sided corona cover light membrane. The membrane comprises a core layer located between a corona side printing surface layer and a composite layer. A preparation method of the double-sided corona cover light membrane comprises the following steps: adding raw materials corresponding to the core layer, the corona side printing surface layer and the composite layer into corresponding high-speed mixers respectively, after being uniformly mixed, feeding the raw material of the core layer into a main extruder, feeding the raw material of the corona side printing surface layer and the raw material of the composite layer into corresponding auxiliary extruders, heating up heating zones of the main extruder and the auxiliary extruders, and integrating, longitudinally stretching and transversely stretching by a screw extruder to obtain the product. According to the double-sided corona cover light membrane, electric resistance of the surface of a printing membrane is reduced to be below 10 to the 21th power omega by adding an anti-static agent, and static electricity of the membrane is reduced; the problem that the printing membrane is adhered to other substances is solved by adding a release agent; and by corona treatment of 32 dynes at a membrane traction position, chemical bonds of plastic molecules are broken and degraded, roughness and surface area of the membrane surface are increased, and coloring ability of the membrane is improved during printing in a later stage.

Owner:GETTEL GRP TONGCHENG PLASTIC IND

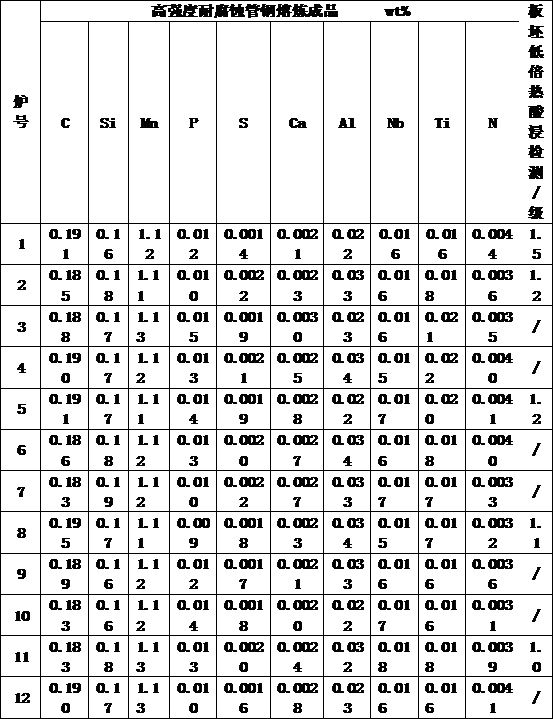

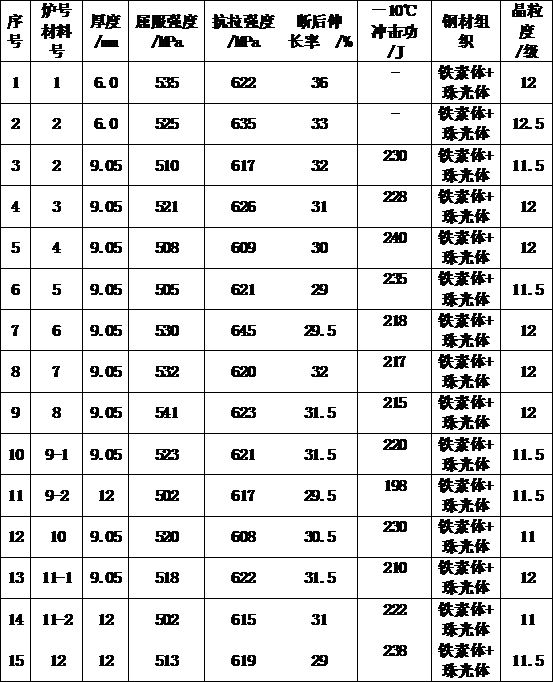

Production method of hot-rolled plate coil used for high-strength corrosion-resistant pipe steel

ActiveCN113512684ATensile stabilitySmall fluctuationProcess efficiency improvementAqueous corrosionProduct inspection

The invention discloses a production method of a hot-rolled plate coil used for high-strength corrosion-resistant pipe steel. The hot-rolled plate coil used for the high-strength corrosion-resistant pipe steel comprises the following components: 0.18 to 0.21 wt% of C, 0.10 to 0.20 wt% of Si, 1.15 to 1.25 wt% of Mn, less than or equal to 0.015 wt% of P, less than or equal to 0.0025 wt% of S, 0.015 to 0.20 wt% of Nb, 0.015 to 0.25 wt% of Ti, 0.015 to 0.035 wt% of Al, less than or equal to 0.0045 wt% of N and the balance impurities. The material production technology comprises the steps of molten iron desulphurization pretreatment, top-bottom combined blowing converter blowing, LF refining, RH vacuum treatment, slab continuous casting, slab cleaning, slab entering a furnace and reheating, controlled rolling and cooling, coiling, steel coil finished product inspection and performance detection. The method is developed aiming at various problems of high-strength steel used for petroleum casing pipes in the current market, the high-strength corrosion-resistant pipe steel is steel used for oil casing pipes, gas casing pipes and geothermal water pipes, and the steel is resistant to corrosion of H2S, CO2, Cl<-> and the like, resistant to water corrosion and good in comprehensive performance.

Owner:XINJIANG BAYI IRON & STEEL

Manufacturing method for low-shrinkage high-strength PET industrial yarn

The invention relates to a manufacturing method of low-shrinkage and high-strength polyester industrial yarn. The process flow is high-viscosity molten polyester raw material—measurement—spraying—cooling—oiling—stretching—heat setting—winding; the polyester slices used are It is a high-viscosity chip obtained by solid-phase viscosification. The cooling process includes four parts: slow cooling, pre-cooling, windless zone cooling and blowing cooling. The pre-cooling adopts the method of active outer ring sequential pre-cooling. The hot air is conveyed through the active outer ring sequencer to cool the filaments. Through the introduction of the pre-cooling device, not only the disturbance of the tow caused by the downward movement of the fiber solidification point is reduced, the deviation rate of the linear density of the tow is controlled, but also the orientation and crystallization of the primary fibers are reduced, and the deviation rate of the linear density is ≤ 1.5%, breaking strength > 7.5cN / dtex, polyester industrial yarn with dry heat shrinkage rate of 1.8±0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

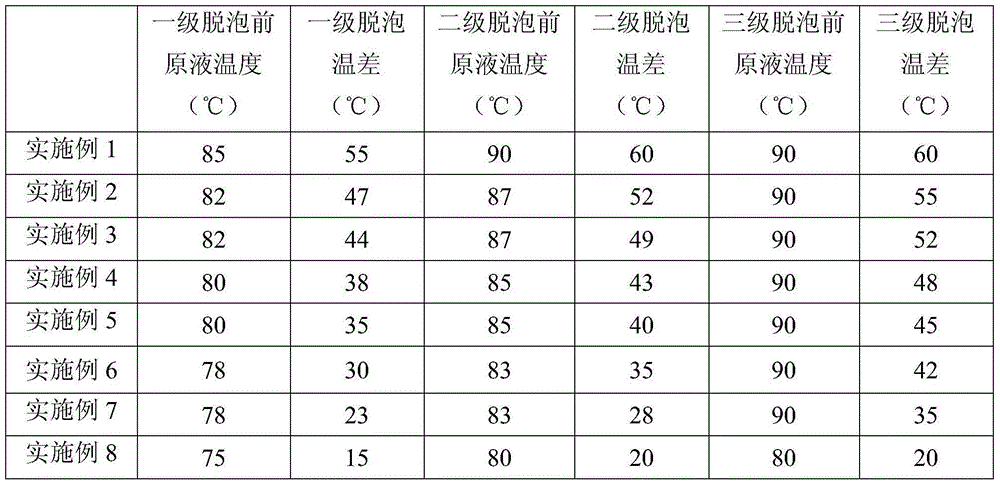

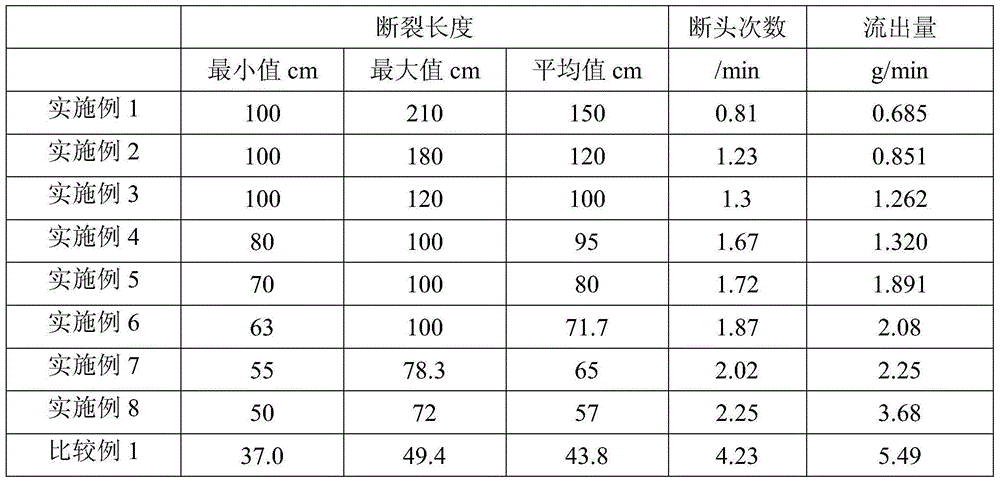

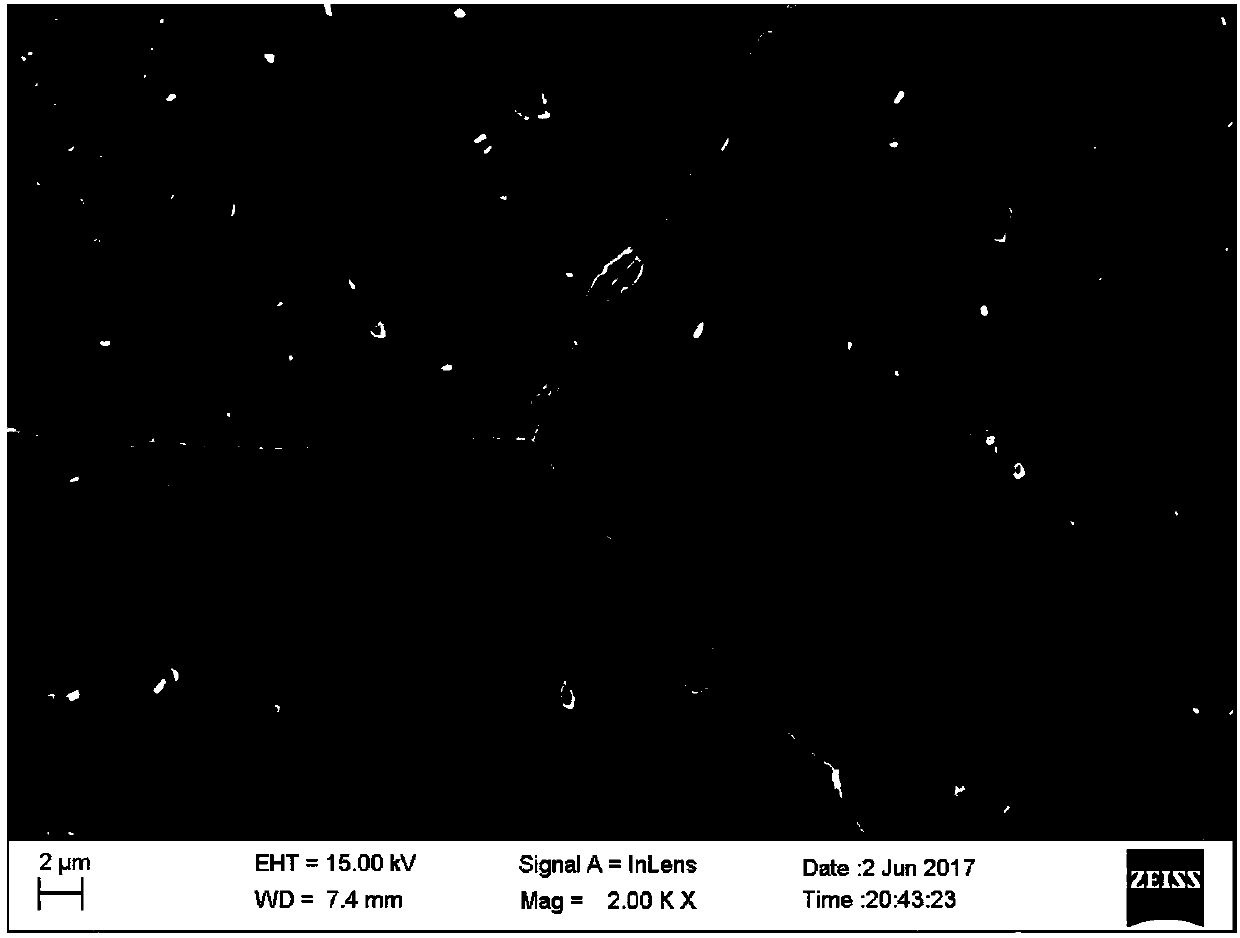

Method for preparing carbon fiber precursor by employing sodium thiocyanate through dry and wet spinning process

ActiveCN105525388ARealize industrial applicationIncrease concentrationFibre chemical featuresSpinning solutions preparationFiberSodium sulfocyanate

The invention discloses a method for preparing carbon fiber precursor by employing sodium thiocyanate through a dry and wet spinning process. The method comprises the following steps: taking a sodium sulfocyanate aqueous solution as a solvent for polymerization to obtain a polymerization stock solution, passing the polymerization stock solution through a first demonomerization tower for removing an unreacted monomer in the polymerization stock solution, then preheating the material to the temperature of 75-85 DEG C and introducing the material into a second demonomerization tower, and wherein content of a residual monomer is controlled at less than or equal to 0.1%, preheating the demonomerized polymerization stock solution to the temperature of 70-95 DEG C, defoaming the polymerization stock solution under a pressure reduction state and then dehydrating, then performing multistage cyclic preheating, defoaming and dehydrating to obtain the high-density (high solid content) spinning stock solution which satisfies the dry and wet spinning requirements, and spinning to obtain the carbon fiber precursor. The method is simple, the obtained carbon fiber precursor has good wire drawing capability, nozzle stretching is stable, breakage rate is little, precursor dispersion is little, and intensity is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

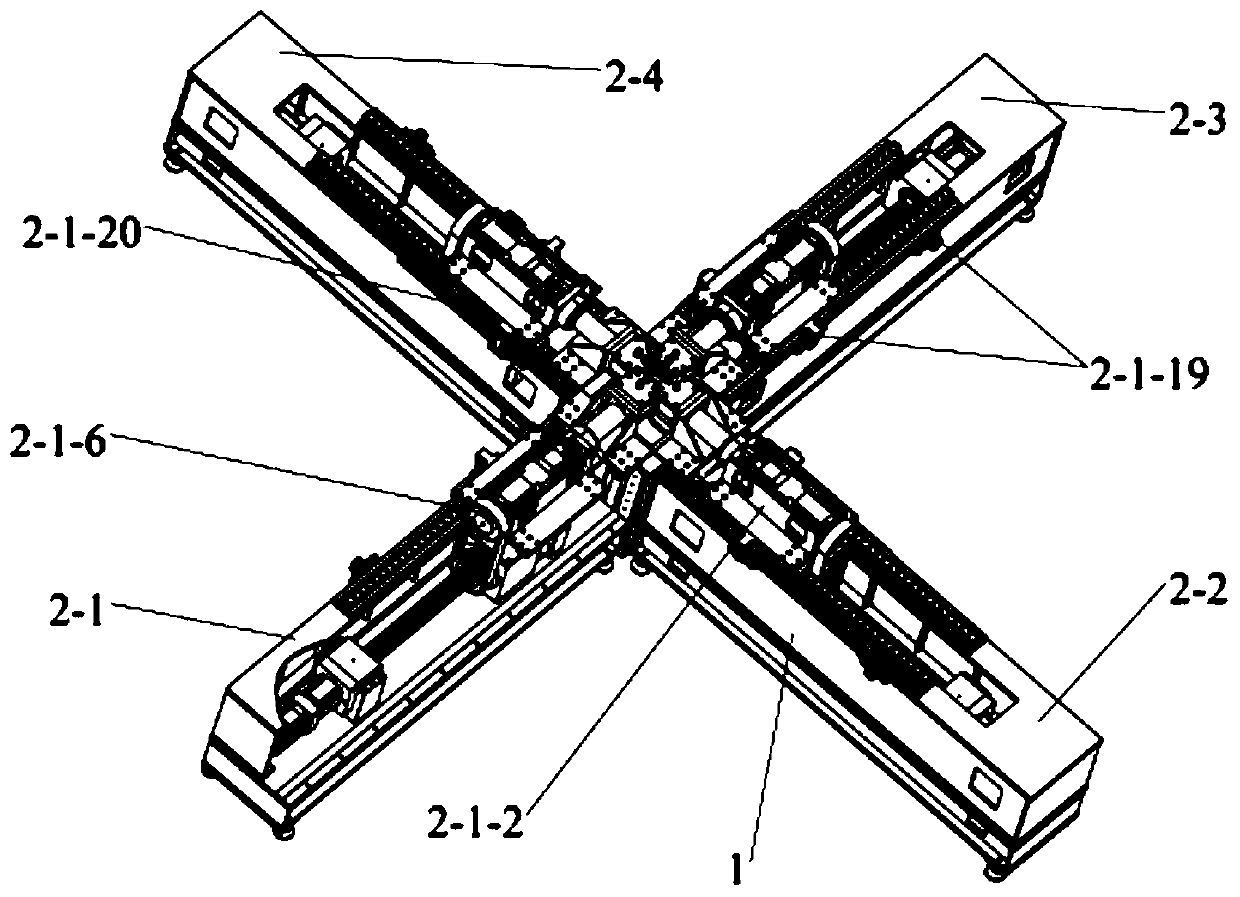

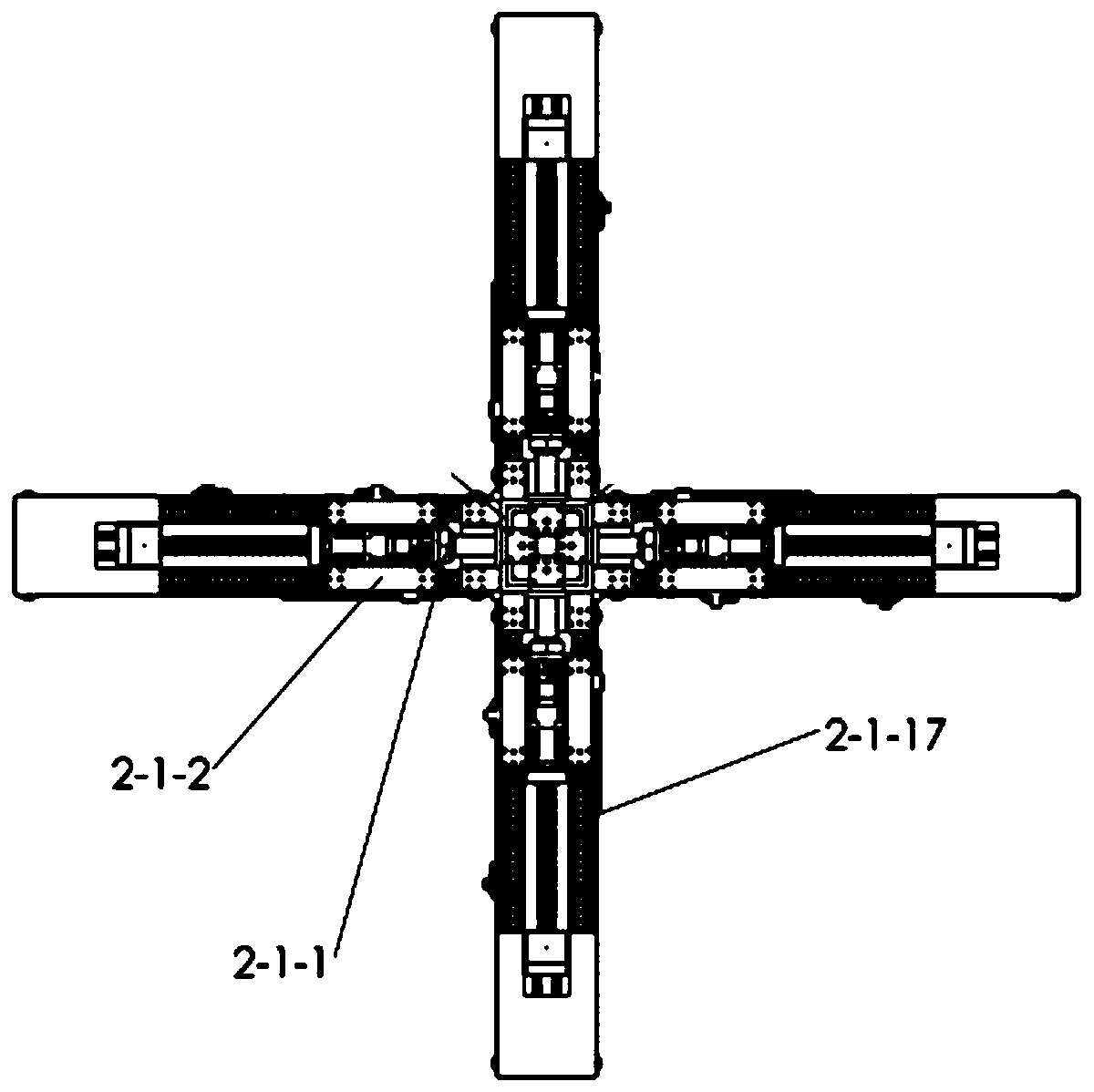

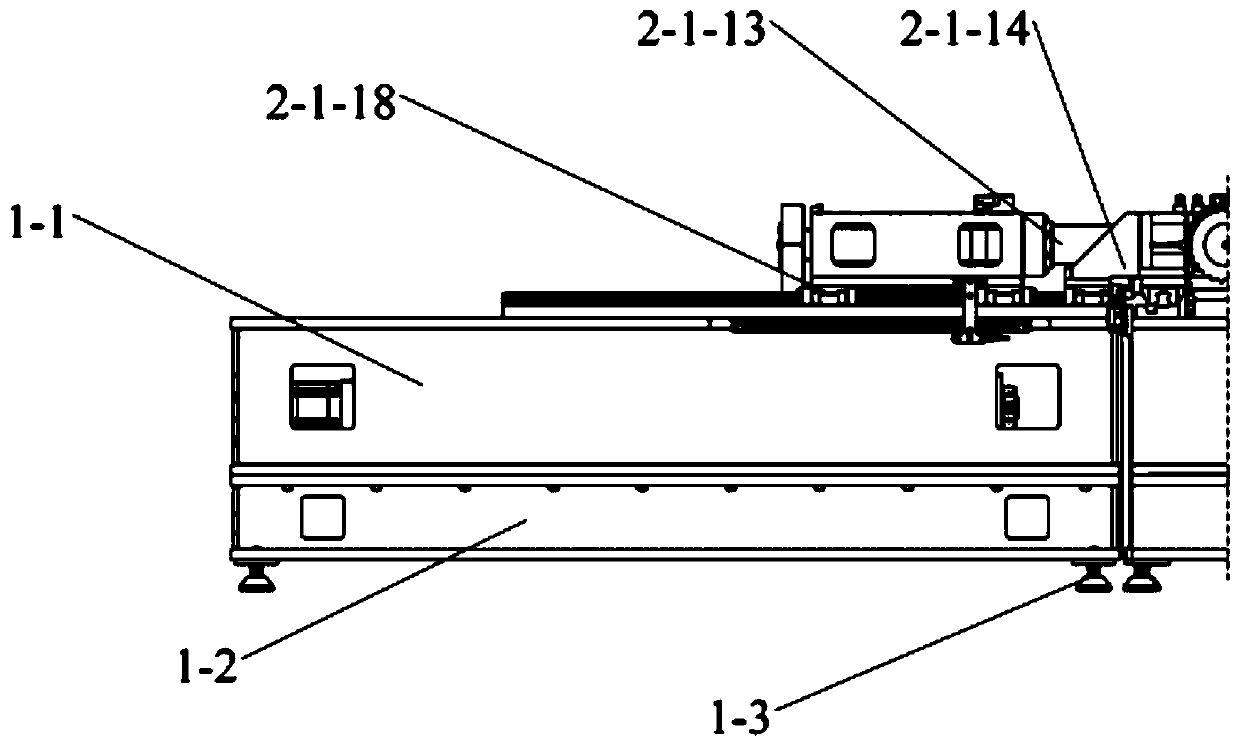

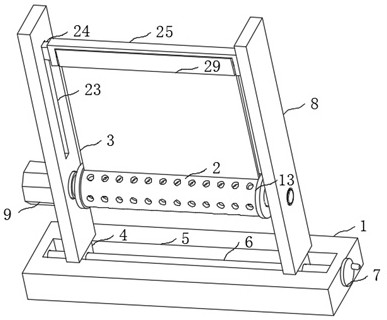

Two-way tension device with large-range adjustable tension rate and two-way tension method

PendingCN111337348ACompact structureStretch at low speedMaterial strength using tensile/compressive forcesPhysicsEngineering

The invention relates to the field of tension test machines, and discloses a two-way tension device with a large-range adjustable tension rate and a two-way tension method. The two-way tension devicecomprises a base, four tension mechanisms are arranged on the base, and each tension mechanism comprises a lead screw module, a tension module and a roller linear guide rail pair; the lead screw module is connected with the tension module, and the roller linear guide rail pair is connected with the tension module and the lead screw module. Each tension mechanism is provided with a tension and pressure sensor; two of the four tension mechanisms are oppositely arranged in the x direction, the other two tension mechanisms of the four tension mechanisms are oppositely arranged in the y direction,and the four tension mechanisms are arranged on the base in a crossed mode. The two-way tension testing machine is compact in structure, the uniaxial feeding speed is controlled through the two servomotors, the nut rotating type ball screw pair is matched, the tension rates in different ranges are achieved, and compared with a traditional two-way tension testing machine, the two-way tension testmachine has the advantages that the tension rates can be adjusted in a large range, tension is stable, and the control precision is higher.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

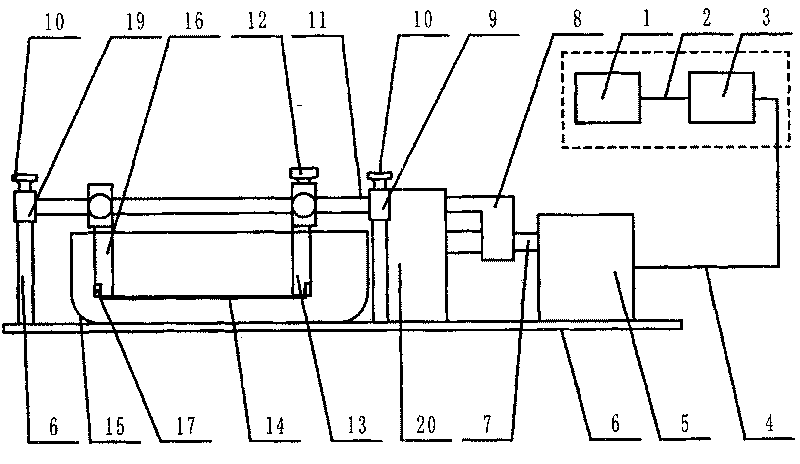

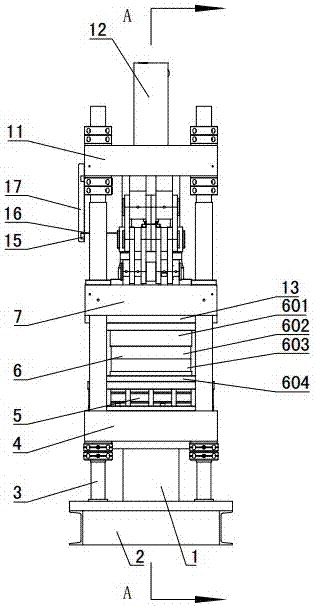

Cell tensile loader

InactiveCN1932510BTensile stabilityEven by forceMicrobiological testing/measurementStrength propertiesCell mechanicsBiomechanics

A kind of cell pulls to stretch to add to carry device, involve a medical science experiment instrument in of the cell mechanics add to carry device. The invention mainly includes a machine, motive system and spreads to move system and pulls to stretch sport part. Motive system mainly from controller, actuator, tread to constitute into the electrical engineering; Spread to move the system main grenadine and pull pole composing; Pull to stretch sport part mainly from glide a support, fix support, direction pole, pioneer pole piece and behind lead a pole piece composing. Because the invention has and pull and stretch process to the cell steady, the cell is subjected to dint even, the ability accurate control pulls and stretches range and frequency, pulling and stretching distance can the convenience regulates within the scope of 0~60 mm, can make under same condition of the experiment have good consistency etc. characteristics, so the invention can used to a medical science experiment the cell mechanics of the instrument and add and carry device extensively, is the ideal which carries on mechanics incitement and responds to a research to the living creature organization and the cellin the biomechanics and add and carry device.

Owner:CHONGQING UNIV

A pot body stretching machine

Owner:山东多星电器有限公司

Treatment method for providing aluminum alloy with high thermal stability anti-fatigue microstructure

InactiveCN101082115BLow fatigue crack growth rateTensile stabilitySolution treatmentThermal stability

The present invention discloses one heat treating process for aluminum alloy to obtain anitfatigue microstructure with high heat stability. The treating process for aluminum alloy plate includes the first solution treatment at 490-500 deg.c, and the subsequent artificial ageing treatment at 170-200 deg.c for 20-60 min. The heat treating process makes the Al-Cu-Mg alloy obtain reinforcing GPB structure in relatively large size, excellent antifatigue performance, delayed degradation of the antifatigue performance and anitfatigue microstructure with high heat stability.

Owner:CENT SOUTH UNIV

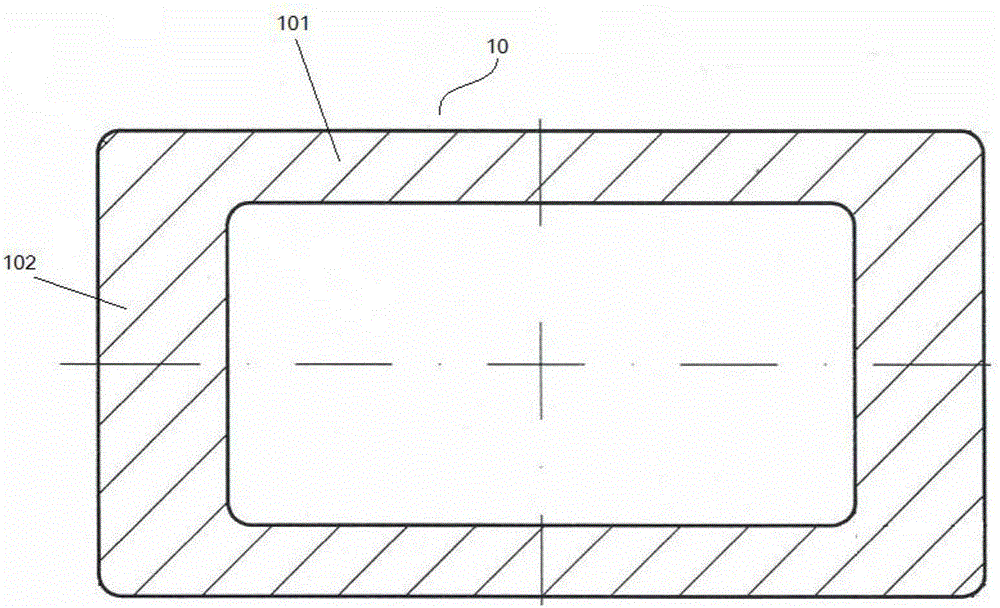

Rectangular hollow copper wire coil tube with unequal wall thicknesses

InactiveCN106130226ATensile stabilityWon't escapeManufacturing dynamo-electric machinesWindings conductor shape/form/constructionCopper wireCooling effect

The invention proposes a rectangular hollow copper wire coil tube with unequal wall thicknesses. The rectangular hollow copper wire coil tube with unequal wall thicknesses comprises a hollow tube, wherein the hollow tube has a rectangular cross section, and the thickness of a tube wall of a long edge of the hollow tube is different from the thickness of a tube wall of a short edge of the hollow tube. The rectangular hollow copper wire coil tube with unequal wall thicknesses, proposed according to the embodiment of the invention, is made of a moving core head used for the rectangular hollow copper wire coil tube with unequal wall thicknesses, an ultra-long wire copper tube can be obtained, a product has the characteristics of high size precision, smooth inner and outer surfaces, high voltage resistance, long length, large size and the like, a cooling effect can be improved, the smooth inner hole surface is difficult to get scaling, the working condition of a large-size machine set can be improved, and the service lifetime of the large-size machine set is prolonged.

Owner:上海飞轮有色新材料股份有限公司

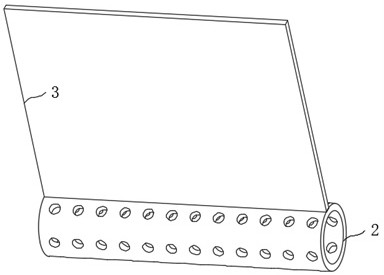

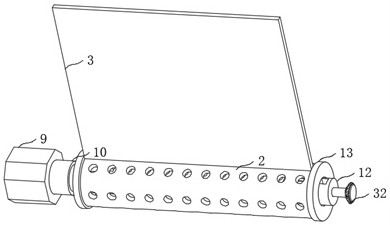

A fur stretching device

InactiveCN110628961BTensile stabilityGuaranteed stabilityLeather stretching/tensioningSkins/hides/leather/fur manufacturing apparatusStructural engineeringMechanical engineering

The invention relates to a fur stretching device, which comprises a supporting platform, a clamping assembly, a nail plate and a positioning piece; the supporting platform is placed on the ground, and two sliding rails are arranged on both sides of the upper surface of the supporting platform; the clamping assembly It is set on the supporting table and is located between two slide rails. The clamping assembly includes a clamping block, which is slidably connected with the slide rails; there are two pegboards, placed horizontally on the slide rails, and the fur is fixed on the pegboards , the side of the nail plate close to each other is set as an arc surface; the clamping block can push the two nail plates to move towards each other, so that the junction of the nail plates is arched upwards, and the fur is stretched, and the two nail plates form a V shape structure, with the opening facing downward; the positioning piece is arranged at the opening of the V-shaped structure formed by the two nail plates, and the positioning piece connects the lower ends of the two nail plates to limit their positions. The invention can stretch the fur, and keep the fur in a stable tension state for a long period of time, and the problem of slack is not easy to occur.

Owner:北京束兰国际服装有限责任公司

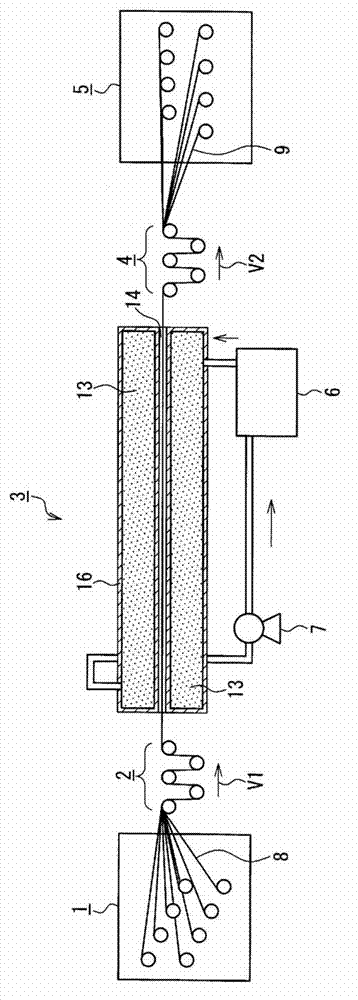

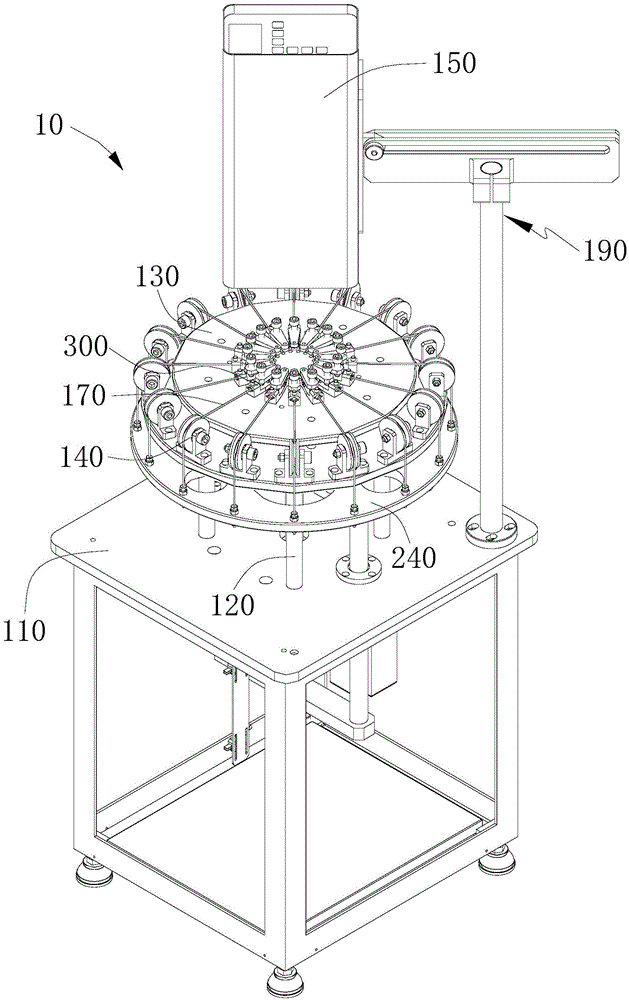

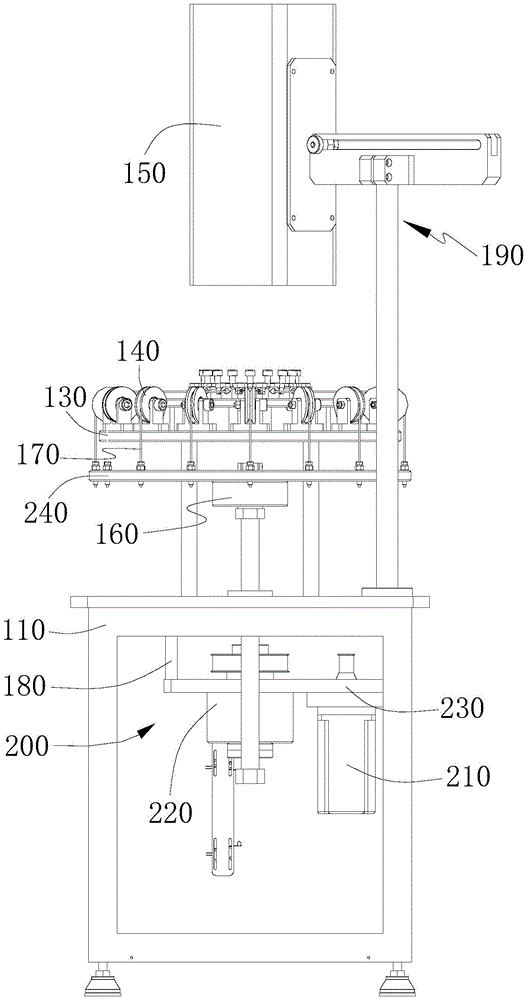

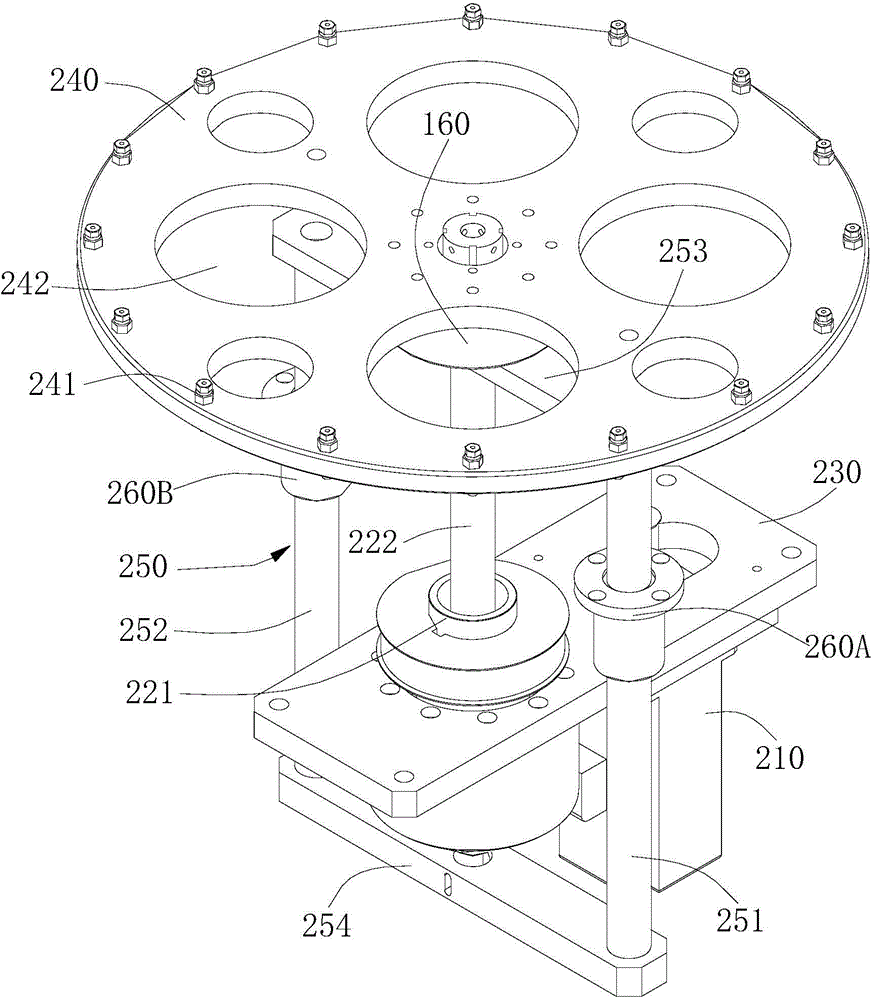

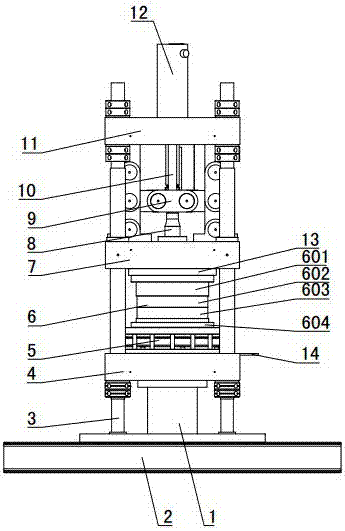

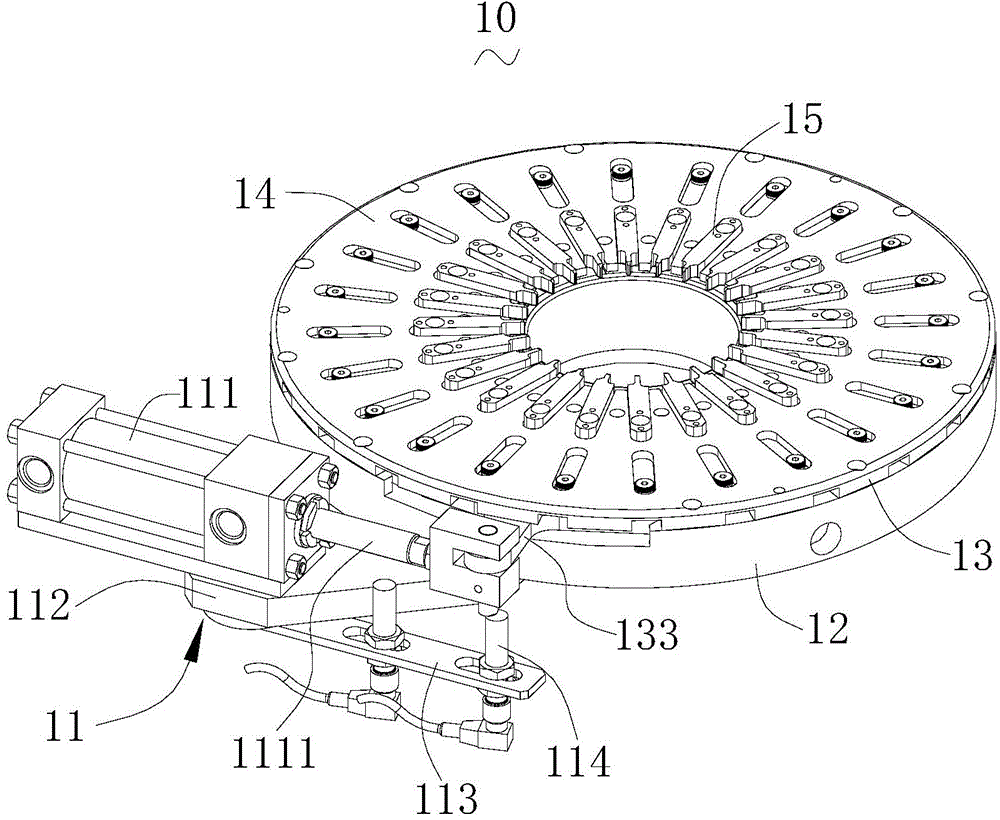

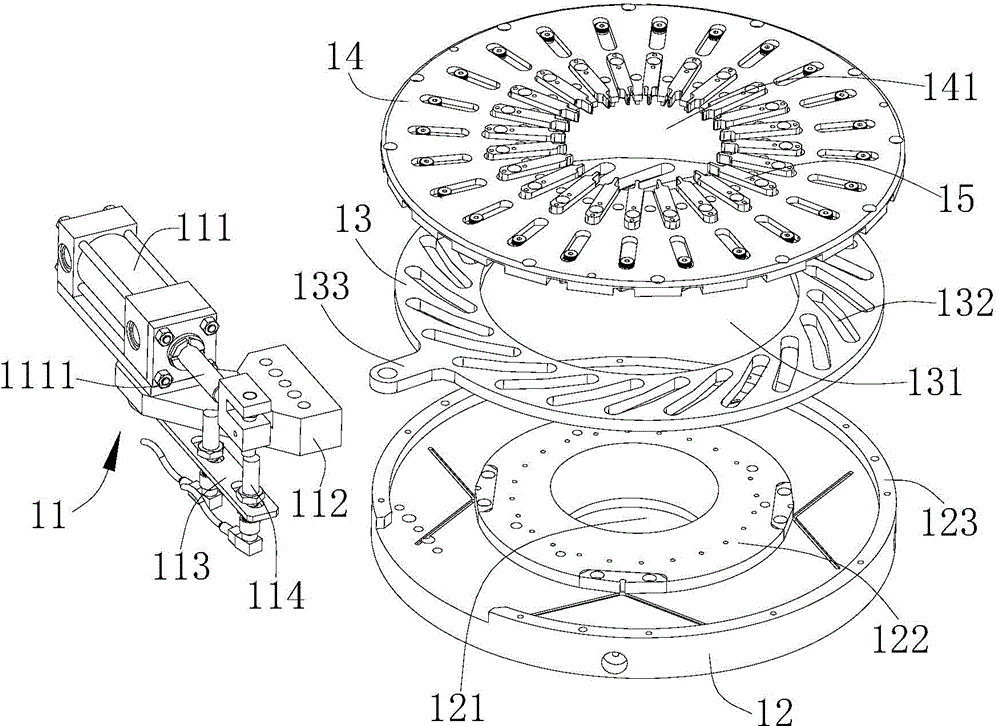

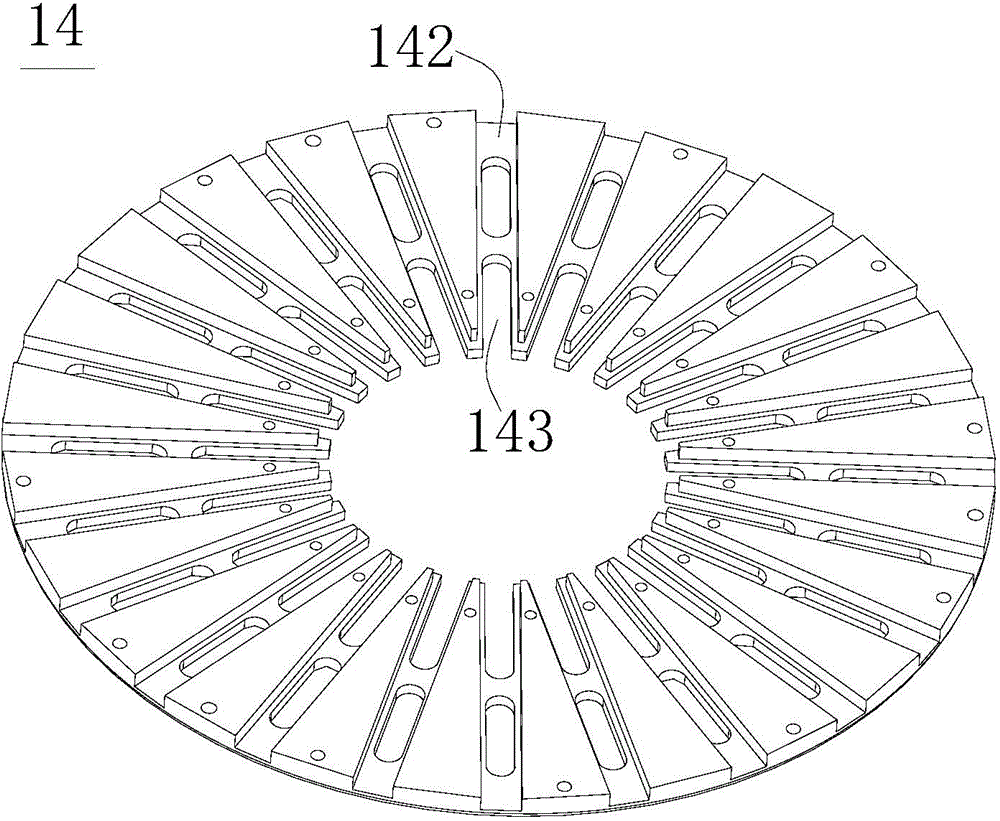

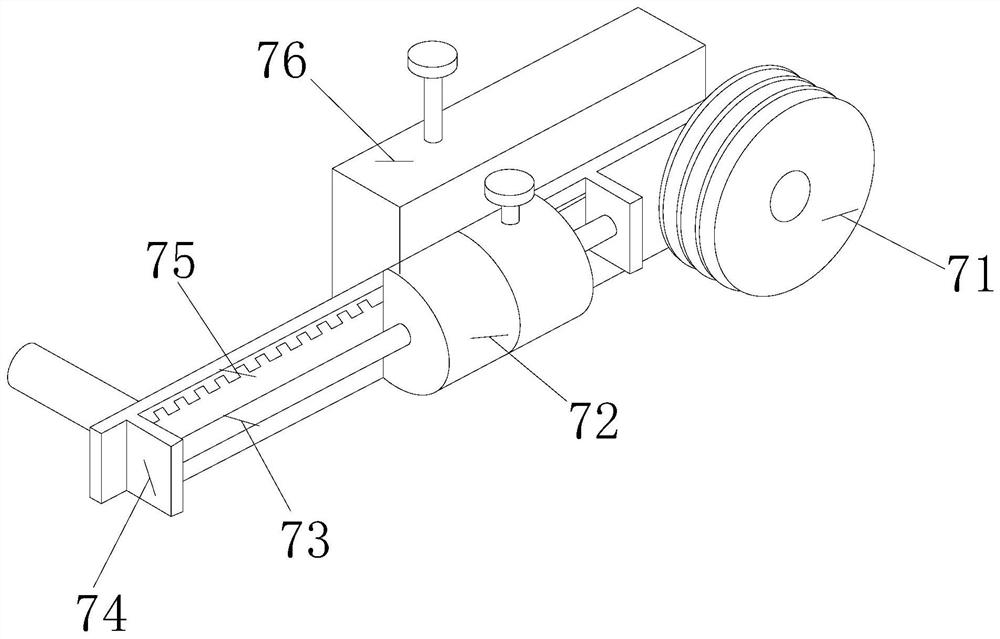

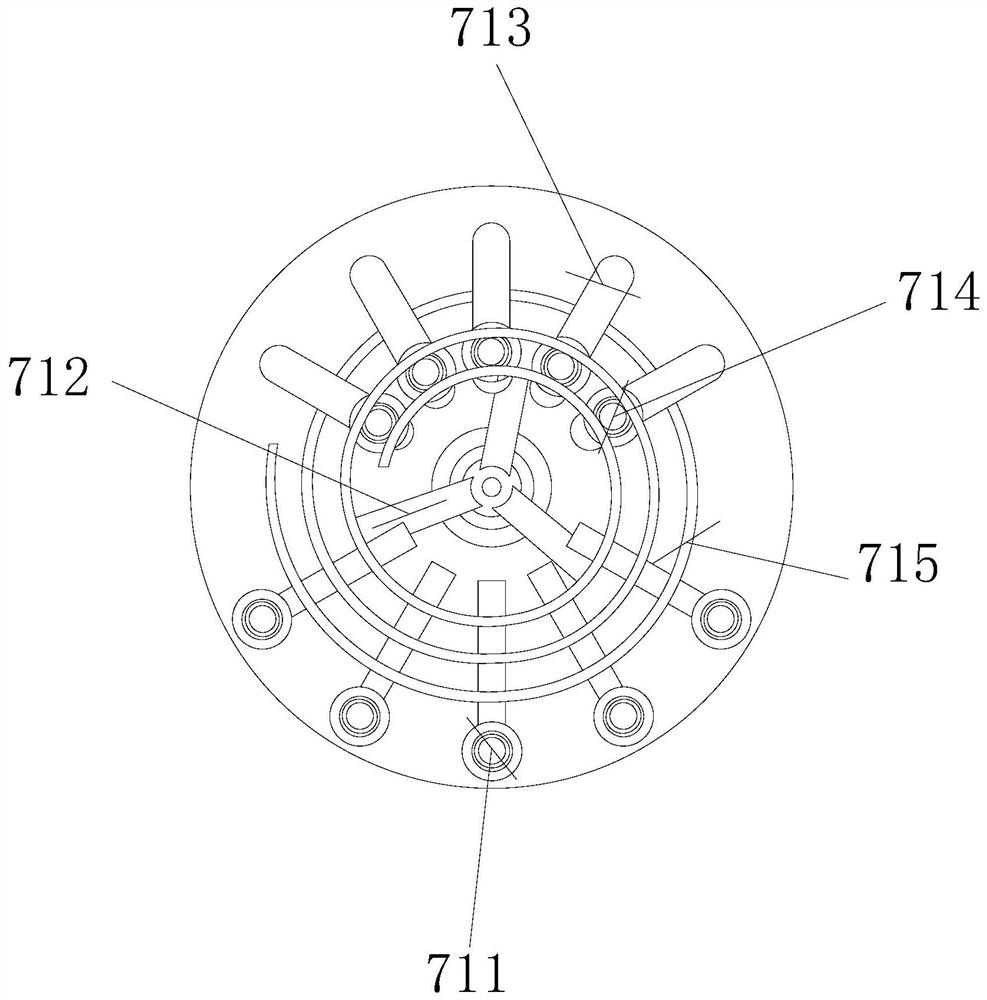

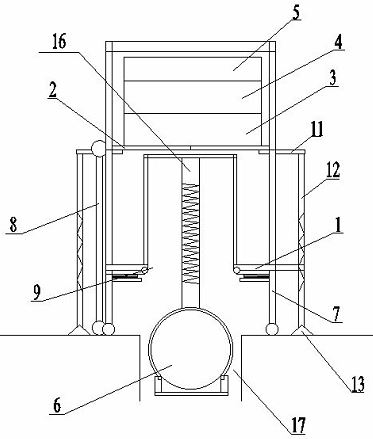

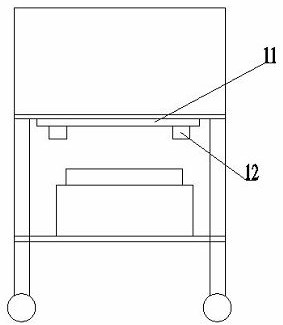

Multi-directional tensile testing machine for thin material of LED decorative lighting

ActiveCN104931347AEven by forceImprove accuracyMaterial strength using tensile/compressive forcesEngineeringTensile testing

The invention relates to a multi-directional tensile testing machine for thin material of LED decorative lighting. The multi-directional tensile testing machine comprises a driving mechanism, as well as a guide disc and a support part fixedly connected with each other, force application parts and a rotating disc arranged between the support part and the guide disc in a rotary manner, wherein a placement hole, a through hole and an accommodating hole communicated with each other are formed in the support part, rotating disc and guide disc respectively; multiple guide holes are formed in the rotating disc clockwise and radially around the axis of the rotating disc; multiple sliding grooves are formed in the guide disc radially around the axis of the guide disc; the force application parts comprise braces and sliding blocks connected with the braces in a rotary manner; the sliding blocks are arranged in the guide holes in a sliding manner; the braces are arranged in the sliding grooves in a sliding manner; the driving mechanism is in drive connection with the rotating disc. The driving mechanism drives the rotating disc to rotate to further drive the sliding blocks to slide along the guide holes, so that the braces slide along the sliding grooves, stable tension in multiple directions is performed on the thin material connected with the multiple braces, force applied to the thin material in multiple directions is balanced, and the accuracy for a tensile test to the thin material is improved.

Owner:DONGGUAN WENYU IND

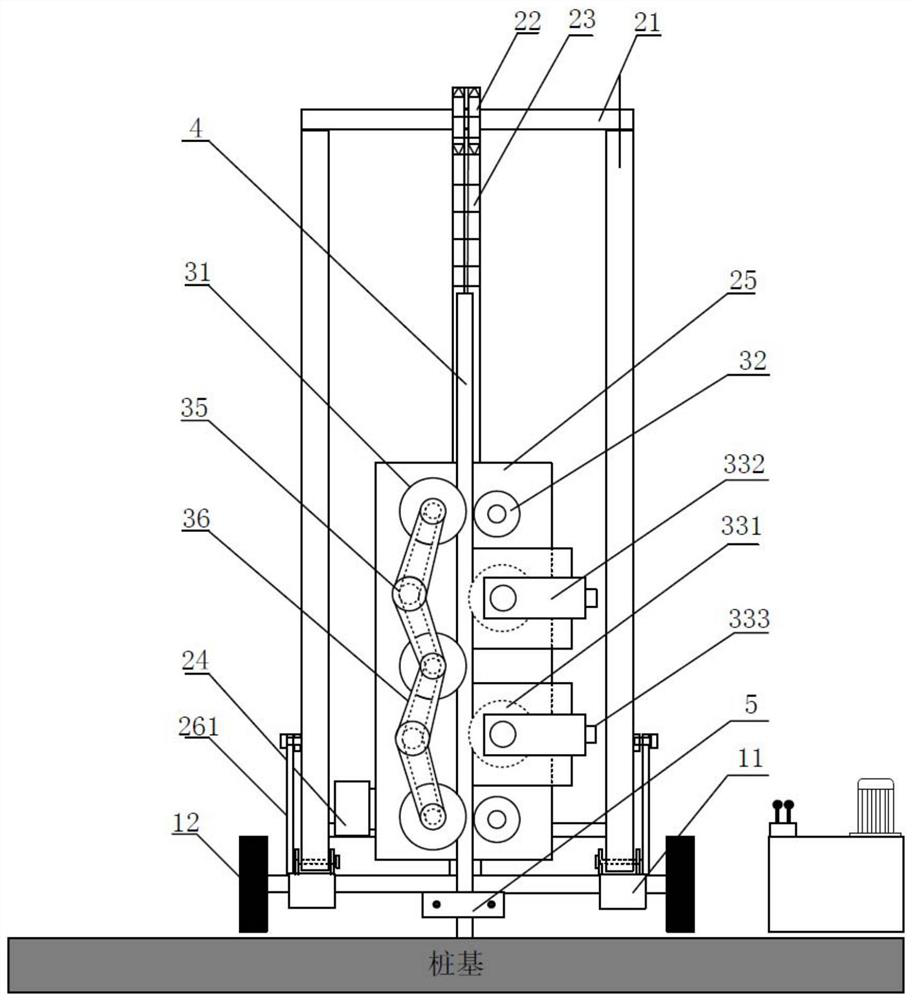

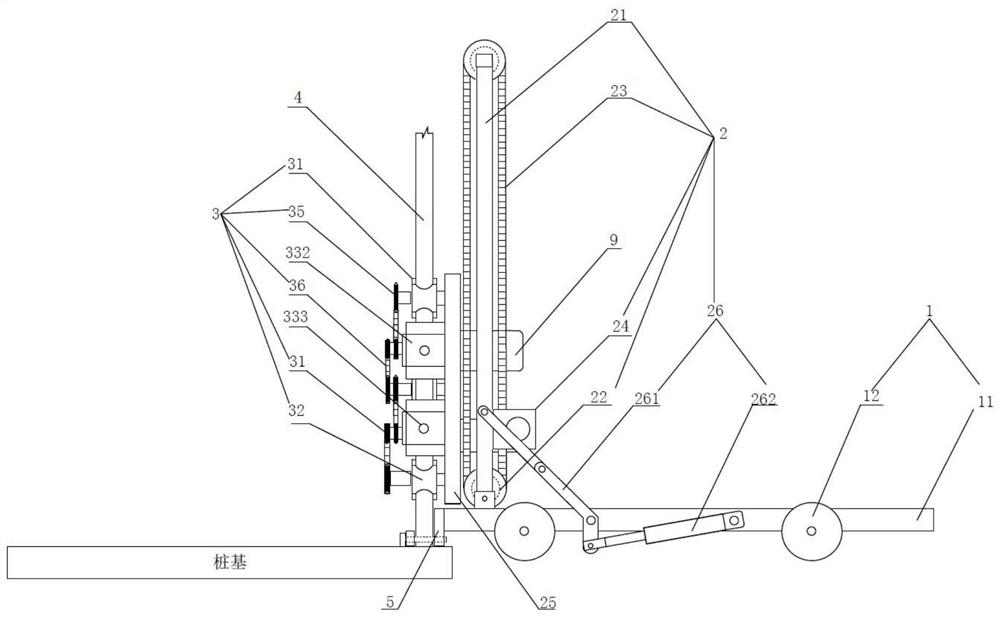

Movable pile head steel bar automatic straightening device

The invention discloses a movable pile head steel bar automatic straightening device. The movable pile head steel bar automatic straightening device comprises a walking mechanism, a traction mechanism and a positioning straightening mechanism; the walking mechanism is arranged at the bottom and used for driving the traction mechanism and the positioning straightening mechanism to move; the traction mechanism is arranged on the walking mechanism; the traction mechanism is used for adjusting the traction angle according to needs and is driven to move up and down along the traction mechanism; and the positioning straightening mechanism is connected with the traction mechanism, arranged on a pile head steel bar to be straightened in an embracing mode and used for straightening the pile head steel bar. The movable pile head steel bar automatic straightening device has the advantages that the design structure is reasonable, traction and stretching are stable, double power drive is achieved, the safety performance is high, the movement is more convenient and rapid due to the adoption of a movable support, cooperation of other hoisting equipment is not needed during operation, the traction mechanism is used for adjusting and straightening, and self-driving power is also used for adjusting and straightening due to the adoption of hydraulic driving during adjustment, the operation speed is high, the stability performance is high, high in practicability and suitable for popularization and application, the safety coefficient of construction operation is high, the working efficiency is greatly improved, and the quality requirement and the safety requirement are met.

Owner:NO 3 ENG LIMITED OF CR20G

Flexible cigarette carton turnover box with variable space

ActiveCN110116856AEasy to adjust the volumeIncrease coefficient of frictionPackage recyclingVariable capacity containersCartonEngineering

The invention discloses a flexible cigarette carton turnover box with a variable space. The flexible cigarette carton turnover box comprises a box body, and the upper part of the box body is providedwith an opening and is hollow; the side wall of the box body is provided with an opening and a tension belt, so that the side wall of the box body is formed through the tension belt; the front wall ofthe box body is provided with a first molding plate, and the rear wall of the box body is provided with a second molding plate; the bottom of the box body is provided with an opening and a support net structure comprising a bottom net and an anti-falling net, and the bottom net is arranged at the opening position; the anti-falling net is arranged at the interspace position between the bottom netand the tension belt, and a cigarette carton is supported through the bottom net when the anti-falling net is in contact with the bottom of the cigarette carton; and it is expected that the problems that the number of the cigarette cartons in the turnover box is changed to a certain extent, the cigarette cartons are liable to move in the turnover box, and consequently the distribution arrangementis not benefited are solved.

Owner:SICHUAN GUANGHAN JINHUA PLASTIC PACKAGING

Intelligent numerical-control textile device for non-woven fabric

InactiveCN111807143ATensile stabilityImprove quality and efficiencyFilament handlingTextile fiberYarn

The invention discloses an intelligent numerical-control textile device for non-woven fabric. The structure of the intelligent numerical-control textile device for the non-woven fabric comprises a controller, a supporting device, a fabric coiling rod, a manufacturing platform, a thread conveying roller, a yarn guiding frame, a tensioning device, a roller, an air blowing device and a machine body.When the intelligent numerical-control textile device for the non-woven fabric is in use after being improved, separating rotating rods convey short textile fiber into a guide pipe, moving wheels rotate, the tension of the short textile fiber is controlled, a clamping hoop is buckled with a buckle block through telescopic rods, so that a thread guiding groove is fixed to a certain tension, it is guaranteed that the stretching force of the short textile fiber during paying-off is stable, and the textile quality and efficiency are improved; suction tubes assist an air suction element to suck inbatting, an air draft piece and dust suction pieces suck the batting into shells, clearing brush pieces brush the batting to filter nets in a unified manner, the batting is machined and processed through the filtering nets, a large amount of batting and dust are separated and stored in dust storage cavities, so that the physical health of work personnel in a production workshop is protected, and the service life of the intelligent numerical-control textile device for the non-woven fabric is prolonged.

Owner:陈晓瑜

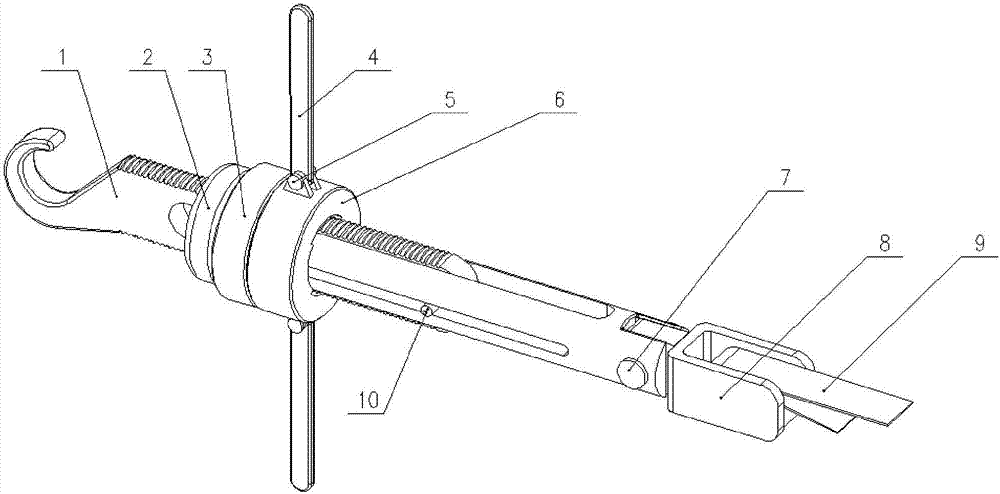

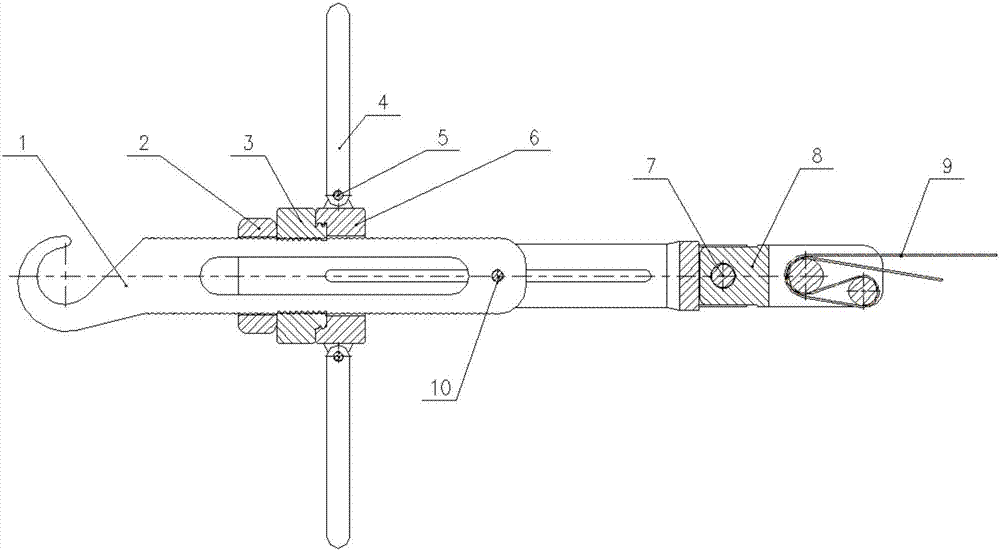

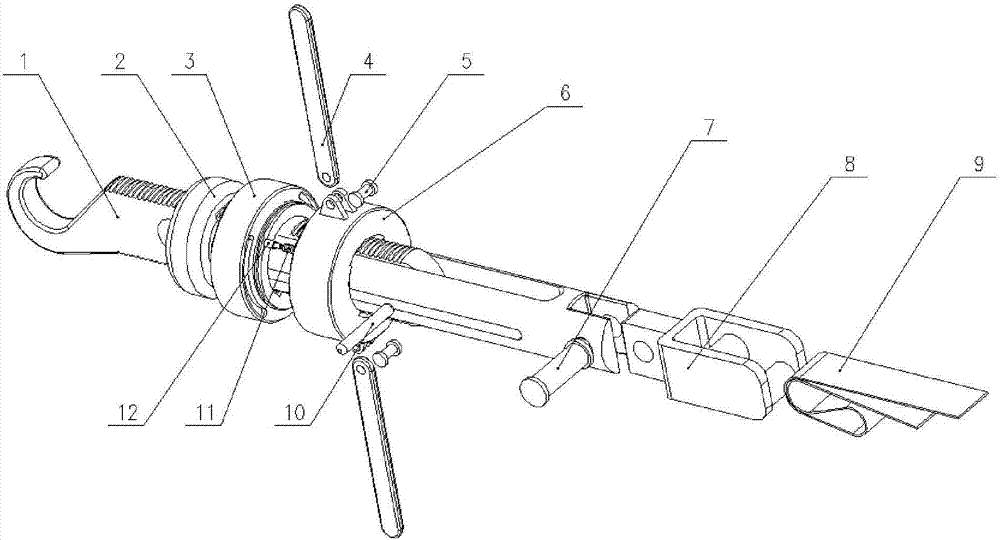

Fast mooring and releasing adjuster

ActiveCN107963008ATensile stabilityShrinkage stableAccommodation for deck loadsLoad securingFiberScrew thread

The present invention provides a fast mooring and releasing adjuster. The fast mooring and releasing adjuster comprises a rectangular threaded hook rod (1), a traction rod sleeve (2), a first tensionnut (3), a second tension nut (6), a bearing pin shaft (7), a fiber belt buckle (8), a fiber belt (9), an anti-off rod (10), a spring (11) and a shifting rod (12); the fast mooring and releasing adjuster is characterized in that the rear end of the rectangular threaded hook rod (1) is in a hook shape and used for hanging and connecting a lug ring on a mooring rope, and the traction rod sleeve (2)is composed of a sleeve ring, a traction fork and a fiber belt buckle connecting fork lug; and the first tension nut (3) and the second tension nut (6) are provided with two opposite adjusting inner threads which are matched with an external thread of the rectangular threaded hook rod (1), and the fiber belt buckle (8) is provided with a connecting plate which is hinged to the fiber belt buckle connecting fork lug of the traction rod sleeve (2) through the bearing pin shaft (7). The fast mooring and releasing adjuster is simple in structure, small in weight, low in cost and large in bearing capacity, and can realize fast mooring fixing and rapid releasing of moving objects.

Owner:SHANGHAI MARINE EQUIP RES INST

Greenhouse film stretching device

ActiveCN111037899APrevent tear damageEliminates the need to pick and place multiple filmsFlat articlesArticle deliveryThin membraneMechanical engineering

The invention discloses a greenhouse film stretching device and belongs to the technical field of film processing. The device comprises a film conveying mechanism, a supporting frame assembly, a stretching adjusting mechanism, grabbing mechanisms and edge cutting mechanisms. According to the greenhouse film stretching device of the invention, a film clamping mode is adopted, so that the phenomenonthat a film is unevenly pulled and stressed during stretching is avoided, the film is prevented from being damaged due to stress concentration; and the unstretched edge part of the film can be automatically cut off after the film is stretched. The supporting frame assembly is arranged on the film conveying mechanism. The stretching adjusting mechanism is connected with the supporting frame assembly in a matched mode. The number of the grabbing mechanisms is two. The two grabbing mechanisms are symmetrically arranged on the supporting frame assembly. The two grabbing mechanisms are both connected with the stretching adjusting mechanism. The number of edge cutting mechanisms is two. The two edge cutting mechanisms are symmetrically arranged on the film conveying mechanism. The two edge cutting mechanisms are both connected with the stretching adjusting mechanism in a matched mode. The stretching adjusting mechanism drives the two grabbing mechanisms to clamp a film, and meanwhile the stretching adjusting mechanism drives the two edge cutting mechanisms to cut the film.

Owner:恩施市来发塑料有限公司

Heat treatment technology for improving ageing impact toughness of austenitic heatproof steel for preparing boiler pipes

The invention discloses a heat treatment technology for improving the ageing impact toughness of austenitic heatproof steel for preparing boiler pipes. The technology comprises the following steps: atfirst, subjecting austenitic heatproof steel to a solid solution treatment at a solid solution temperature, cooling the solid solution temperature to 600 to 700 DEG C at a speed of 1-5 DEG C / min, andfinally cooling to the room temperature, wherein the austenitic heatproof steel is HR3C alloy in a delivery state. On the premise that the tensile performance of alloy is not reduced, a simple heat treatment technology is adopted to improve the impact toughness of alloy after long time ageing, and the safety coefficient of HR3C alloy during the operation period of a power station boiler is increased.

Owner:XIAN THERMAL POWER RES INST CO LTD

Intelligent hogging moment tensioning device for bottom die

PendingCN114108482AImprove handling suitabilityImprove stabilityBridge erection/assemblyElectrical connectionHogging

The invention relates to an intelligent hogging moment tensioning device for a bottom die, in particular to an intelligent hogging moment tensioning device for a bottom die, which comprises an expandable mounting frame, and a power supply and a motor are arranged on the mounting frame. The power source and the motor are both electrically connected with the central controller, a tensioning jack capable of ascending and descending is arranged between the mounting frame and the base, a movable foot and a telescopic fixed foot are arranged below the base, a working opening is formed in the base, and an automatic working door is arranged on the working opening. In the first working state, the working door is opened, the tensioning jack penetrates through the working door to move downwards, in the second working state, the working door is closed, the tensioning jack is placed on the working door, and the tensioning jack is arranged in the device, so that the overall tensioning effect can be guaranteed in the operation process of the bridge bottom die, meanwhile, the tensioning stability of the mounting frame is guaranteed, and the service life of the mounting frame is prolonged. And under the action of the fixing feet, the tensioning effect is guaranteed to the maximum extent.

Owner:SICHUAN EAST SPRING MACHINERY EQUIP MFG CO LTD

Reverse osmosis membrane rolling device

ActiveCN113385040AEasy to disassemble and operateReduce the difficulty of operationReverse osmosisElectric machineryEngineering

The invention discloses a reverse osmosis membrane rolling device which comprises a base and a membrane fixedly mounted on a rolling cylinder, two mounting rods are mounted on the base through a moving mechanism, a driving motor is fixedly mounted on one of the mounting rods, the output end of the driving motor is fixedly connected with a driving rod, the driving rod is rotationally connected with the corresponding mounting rod, the other mounting rod is rotationally connected with a rotating rod, fixing rods are fixedly mounted at the ends, close to each other, of the rotating rod and the driving rod, moving rings are slidably connected to the two fixing rods, and fixing mechanisms matched with the rolling cylinder are arranged on the two fixing rods. The device has the advantages that the winding cylinder is simple and convenient to disassemble and assemble on the device, the operation difficulty can be effectively reduced, and the production efficiency is improved to a certain extent; meanwhile, the overall tension of the membrane can be kept stable in the rolling process so that the use effect of the rolled reverse osmosis membrane is ensured.

Owner:JIANGSU BANGTEC ENVIRONMENTAL SCI TECH CO LTD

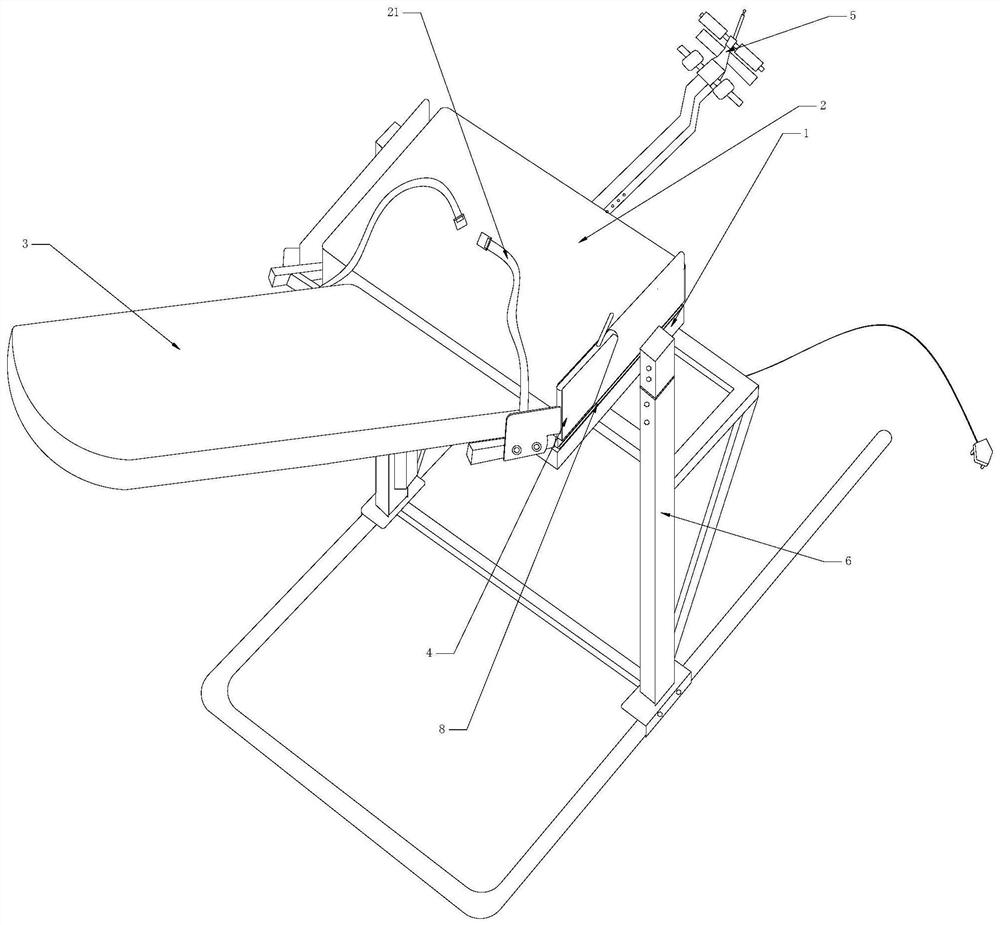

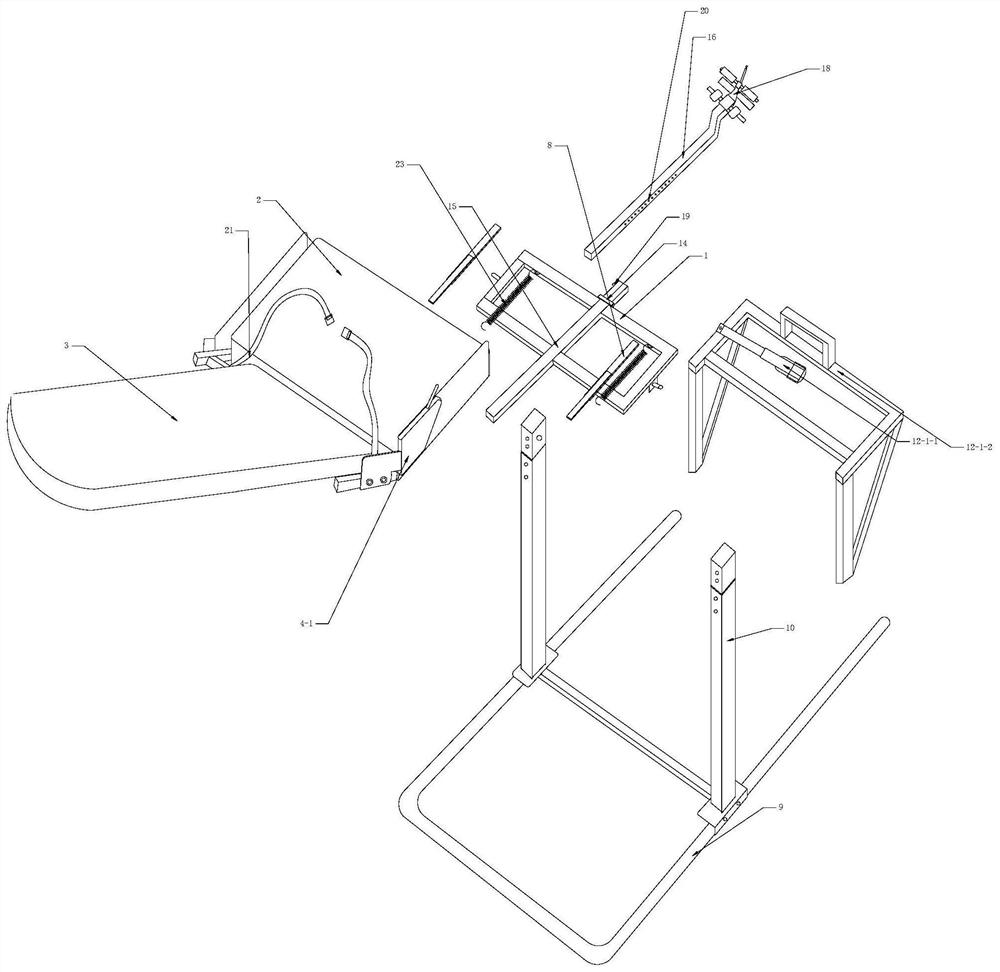

Leg pulling equipment and method

The invention discloses leg pulling equipment which comprises a rack, a rotating base, a sliding seat plate, a back plate, a rotating kinetic energy assembly, a back plate adjuster and a foot fixer, the rotating base is hinged to the rack, the sliding seat plate is slidably arranged on the rotating base, and the rotating kinetic energy assembly drives the rotating base to turn over; the turnover assembly adopts an electric push rod driving mode and a motor driving mode, the back plate is hinged to the rear portion of the sliding seat plate, the back plate adjuster is arranged between the back plate and the sliding seat plate and adjusts the angle of the back plate and the sliding seat plate from one to different v shapes, the back plate adjuster adopts a manual mechanical transmission mode and an electric transmission mode, and the foot fixer is arranged at the front end of the rotating base. According to the invention, through mutual cooperation of sliding of the sliding seat plate on the rotating base and angle adjustment of the sliding seat plate and the back plate, under the condition that the upper body of the human body does not stand upside down, only the legs of the human body are stretched with stable, continuous and controllable strength.

Owner:彭阔羽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com