Reverse osmosis membrane rolling device

A technology of reverse osmosis membrane and membrane sheet, applied in reverse osmosis, semi-permeable membrane separation, membrane technology and other directions, can solve problems such as tension can not be kept stable, adverse effect of reverse osmosis membrane, affecting production efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

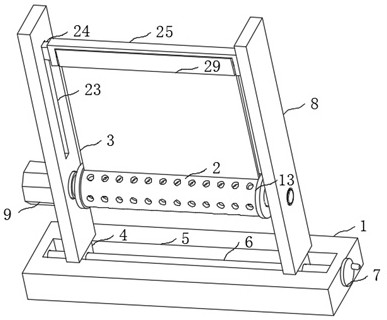

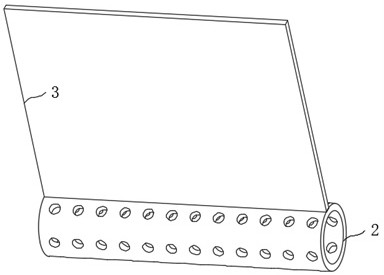

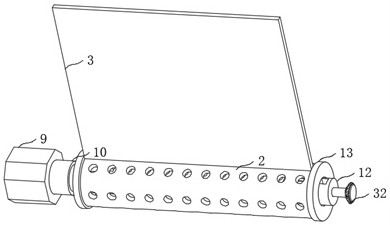

[0028] refer to Figure 1-2 , a reverse osmosis membrane rolling device, including a base 1 and a membrane 3 fixedly installed on a roll 2, and two installation rods 8 are installed on the base 1 through a moving mechanism.

[0029] The moving mechanism consists of a chute 5, a two-way screw mandrel 6, an adjustment handle 7 and two slide blocks 4.

[0030] The chute 5 is opened on the base 1, the two-way screw rod 6 is rotatably connected to the base 1, and the two sliders 4 are fixedly installed on the lower ends of the two installation rods 8 respectively, and both sliders 4 are slidably connected in the chute 5 , the two sliders 4 are threadedly connected with one end of the two-way screw rod 6 located in the chute 5, the adjustment handle 7 is fixedly installed on the end of the two-way screw rod 6 outside the base 1, and the two-way screw rod 6 is connected with the two sliders 4, when the adjustment handle 7 is turned, the two sliders 4 drive the two installation rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com