Patents

Literature

31results about How to "Sleek appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

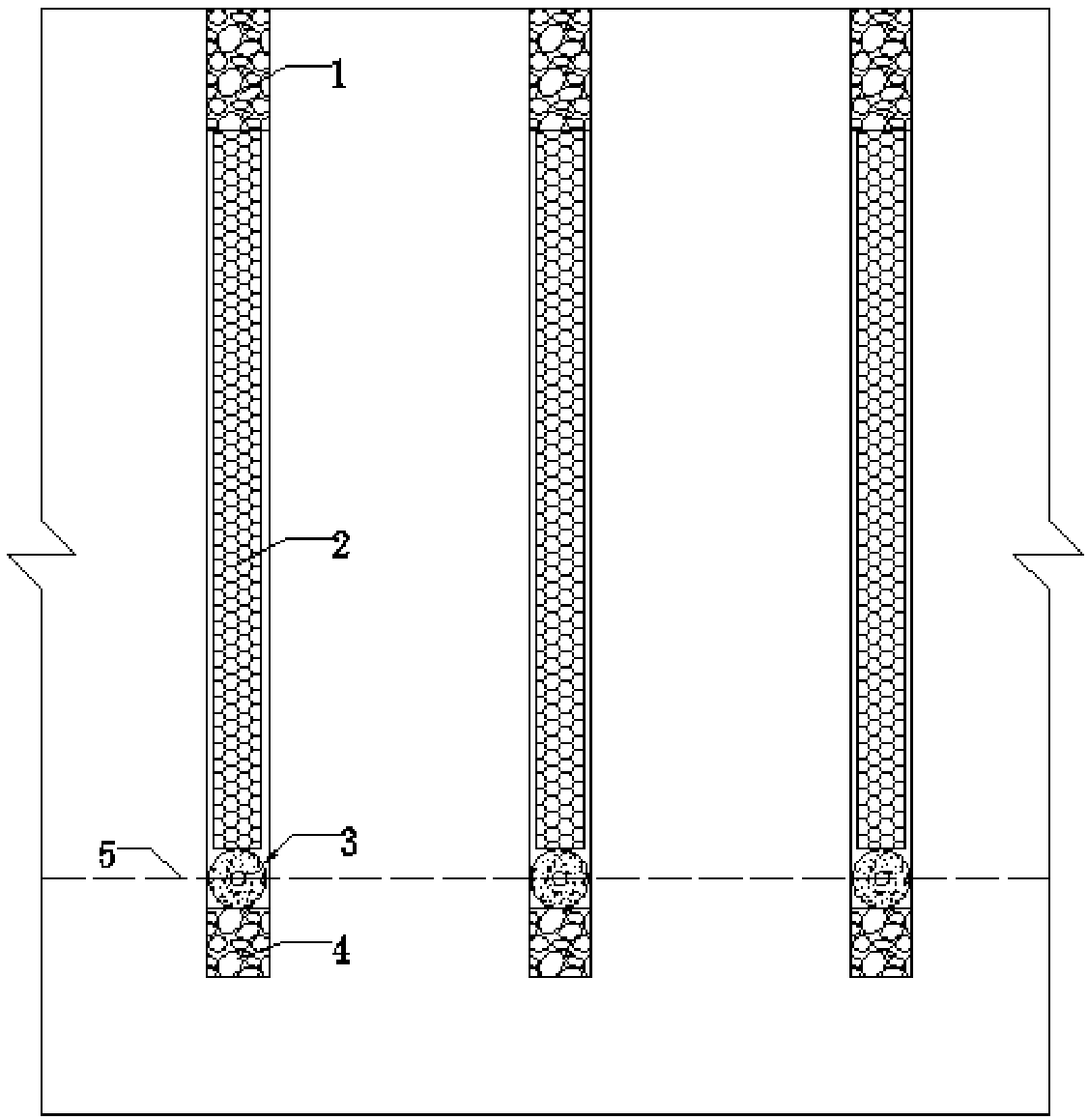

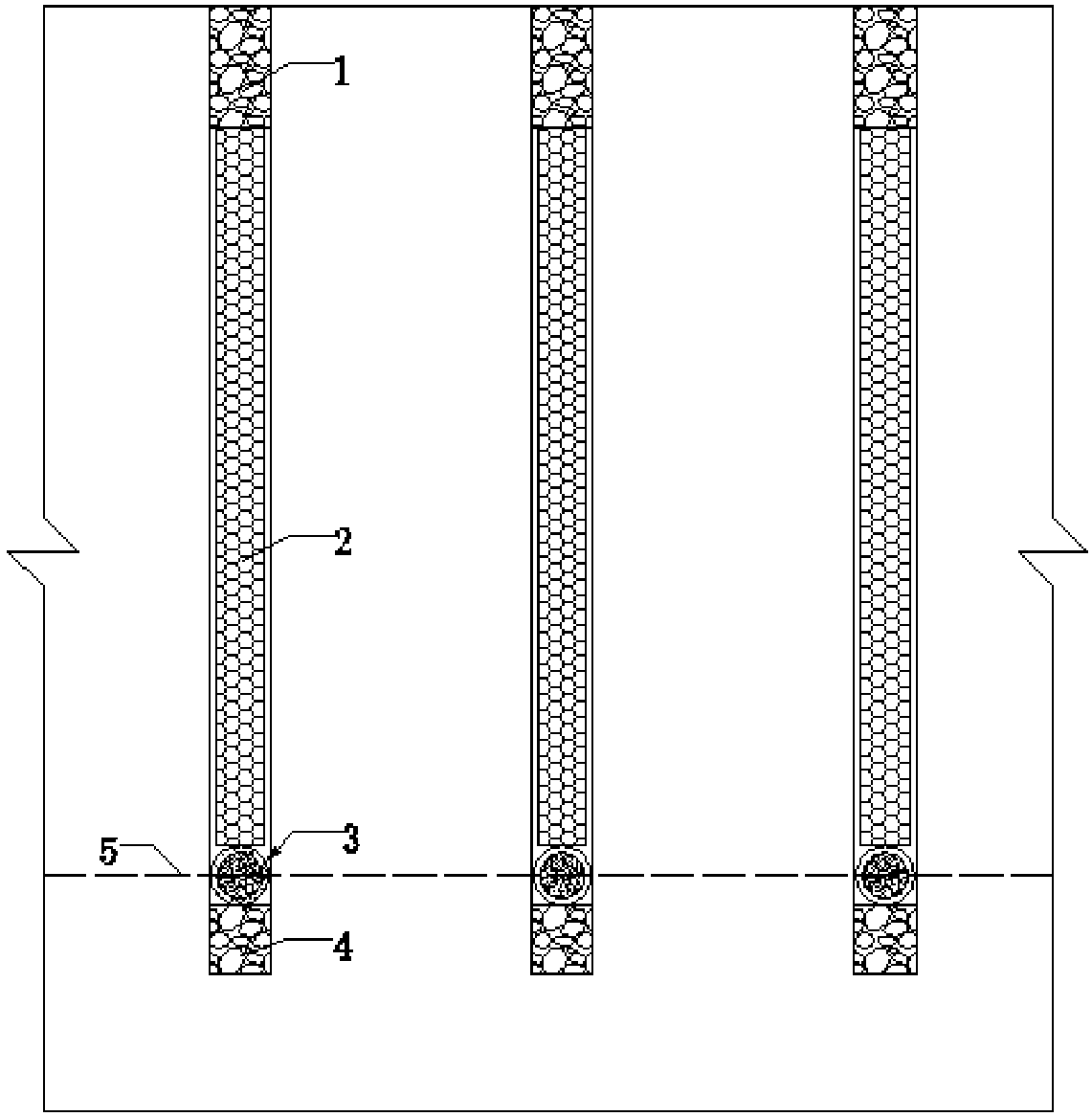

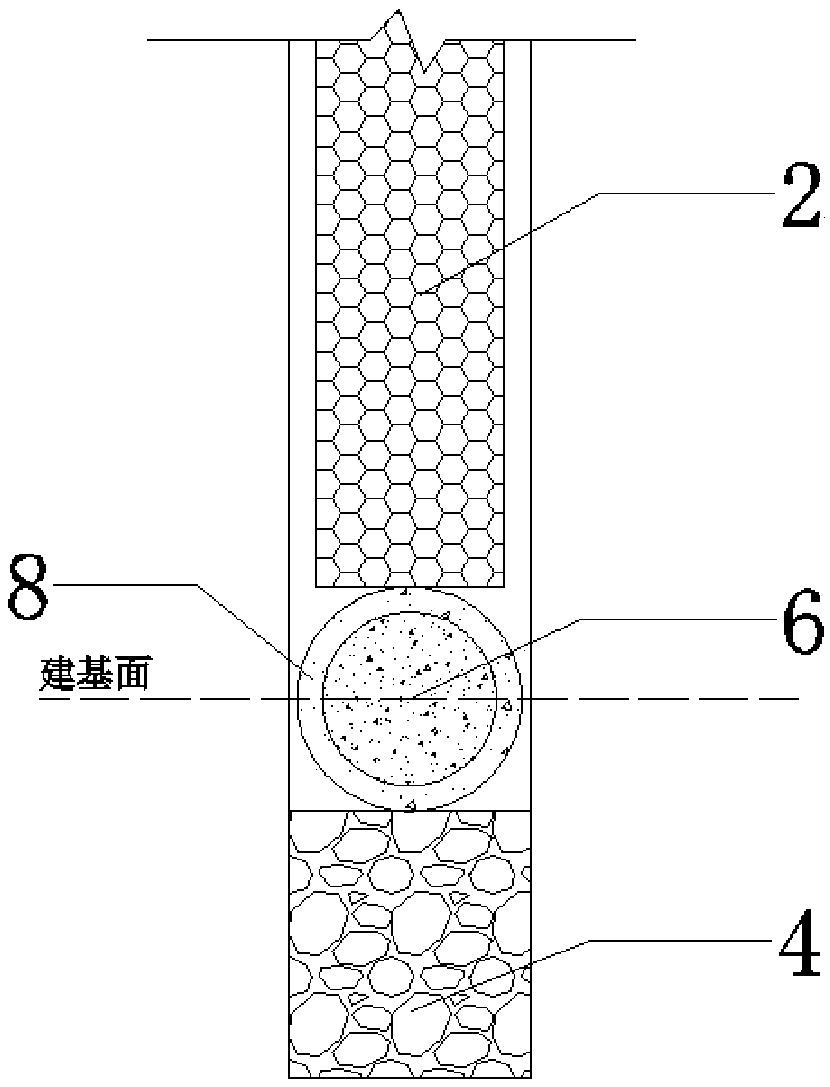

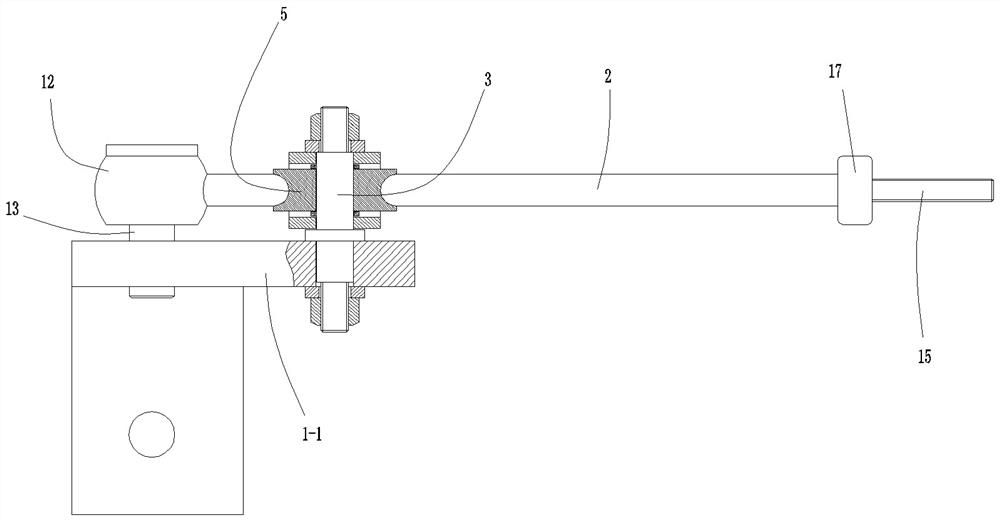

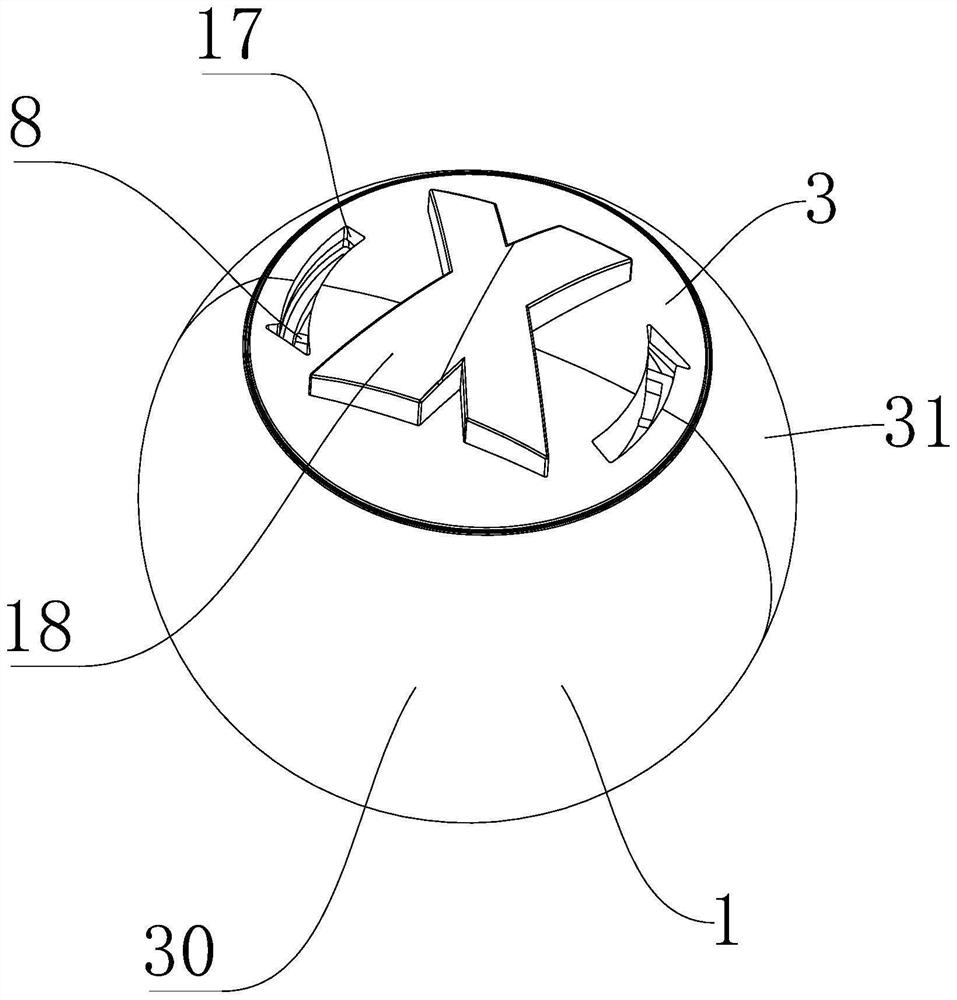

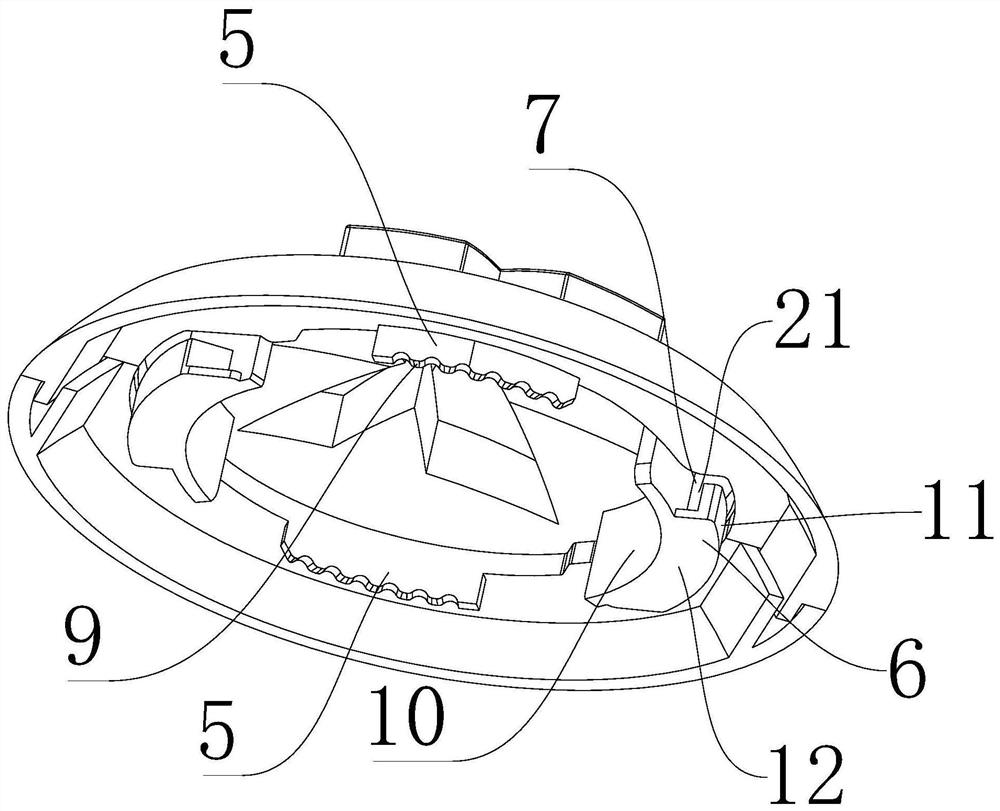

Impacting-shaping composite spherical energy dissipation structure for vertical hole blasting

ActiveCN106949797ASleek appearanceLittle effect of hole wall roughnessBlastingDetonationNuclear power

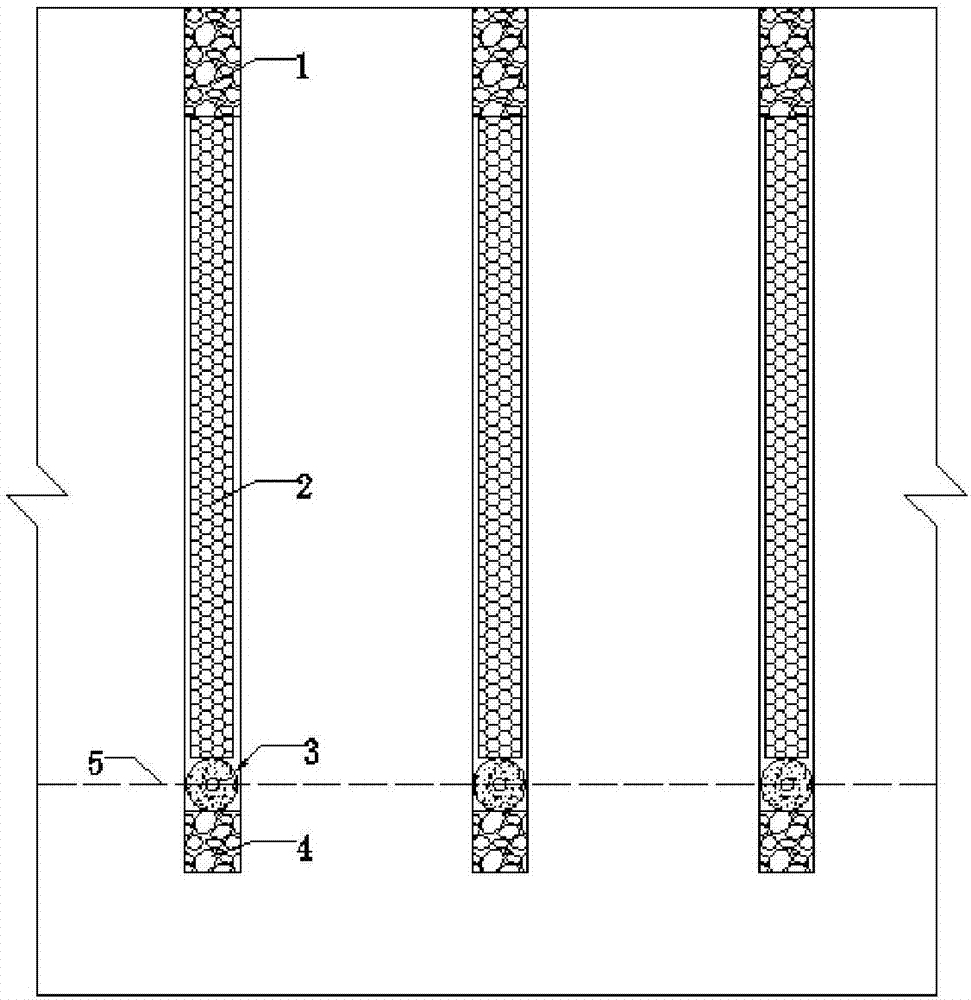

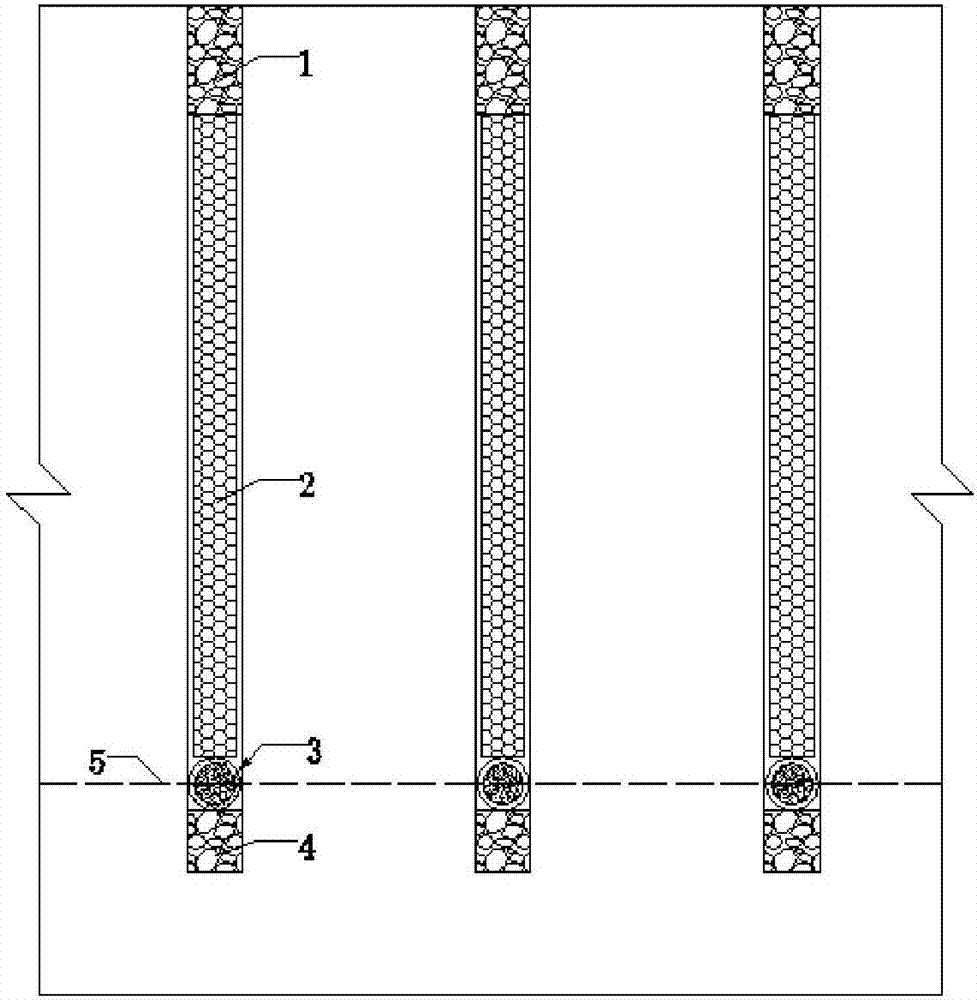

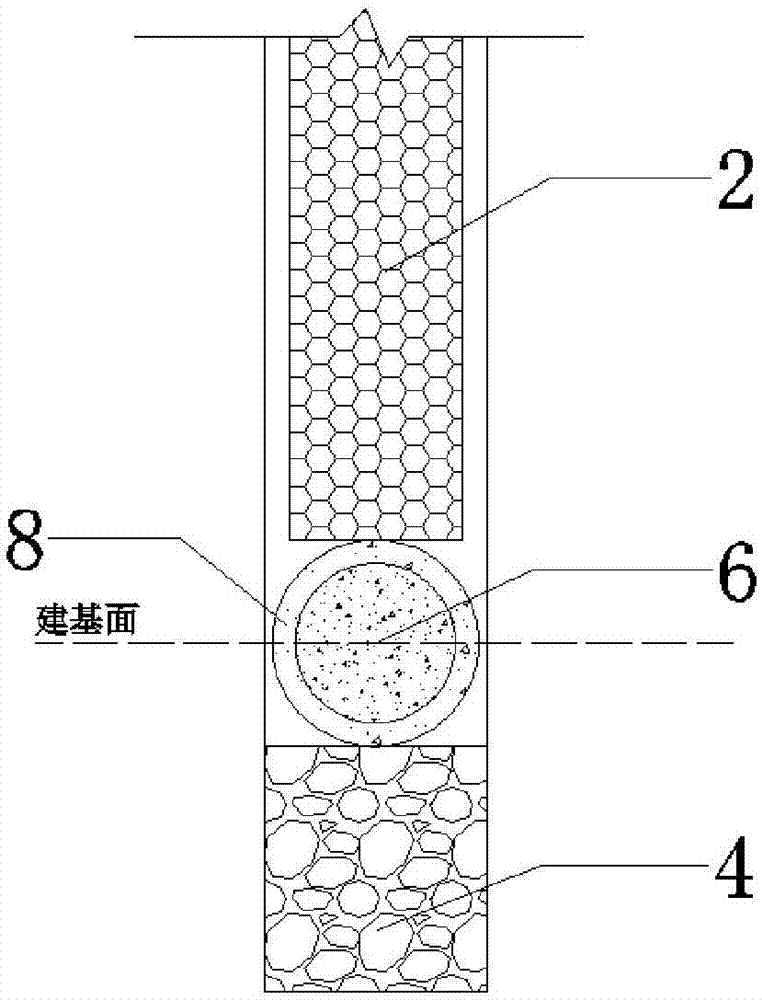

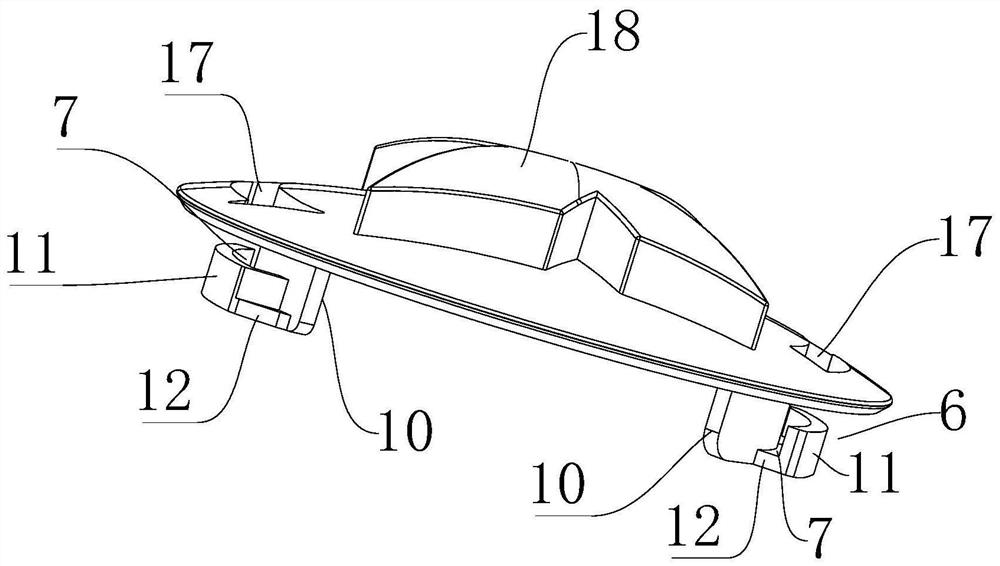

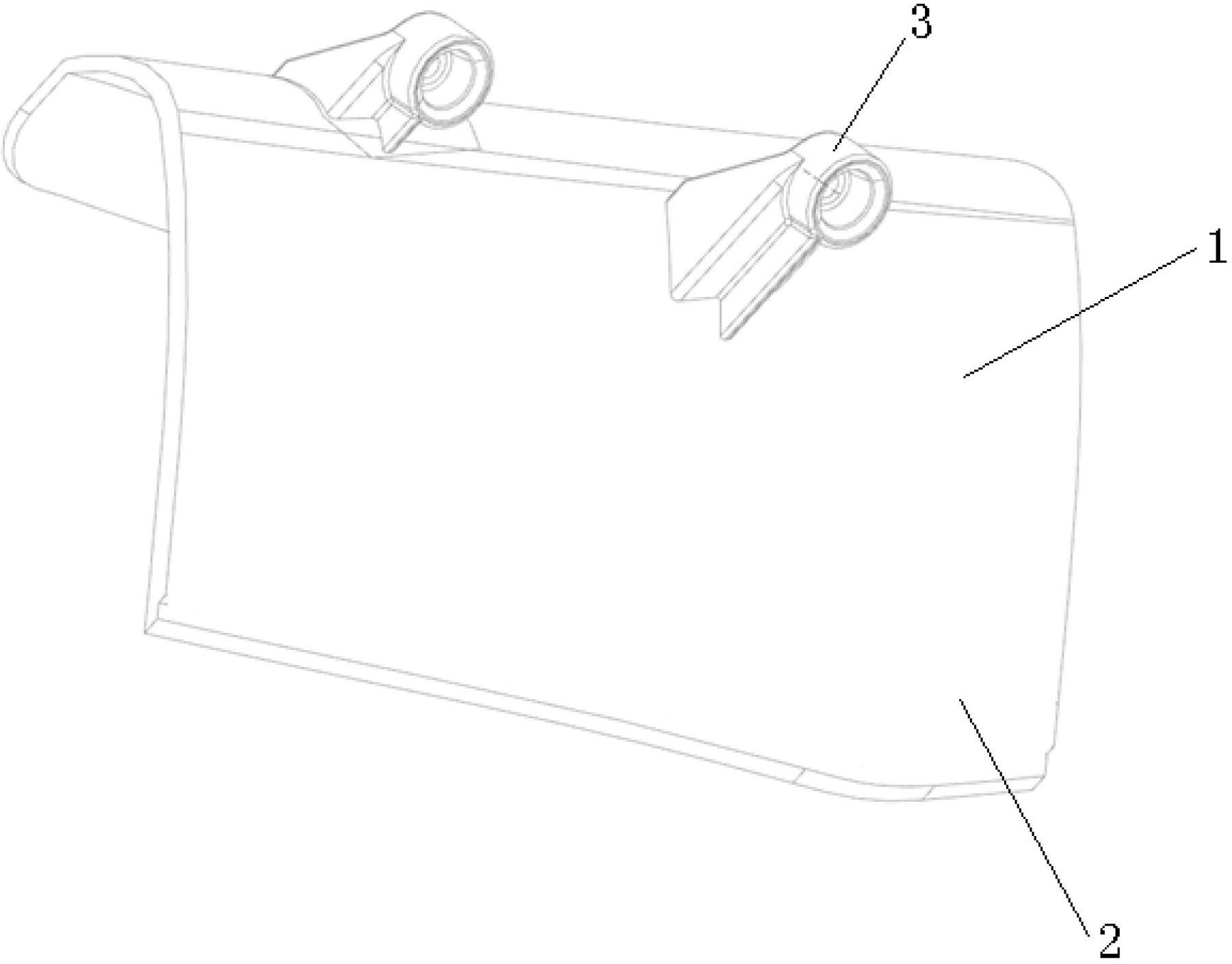

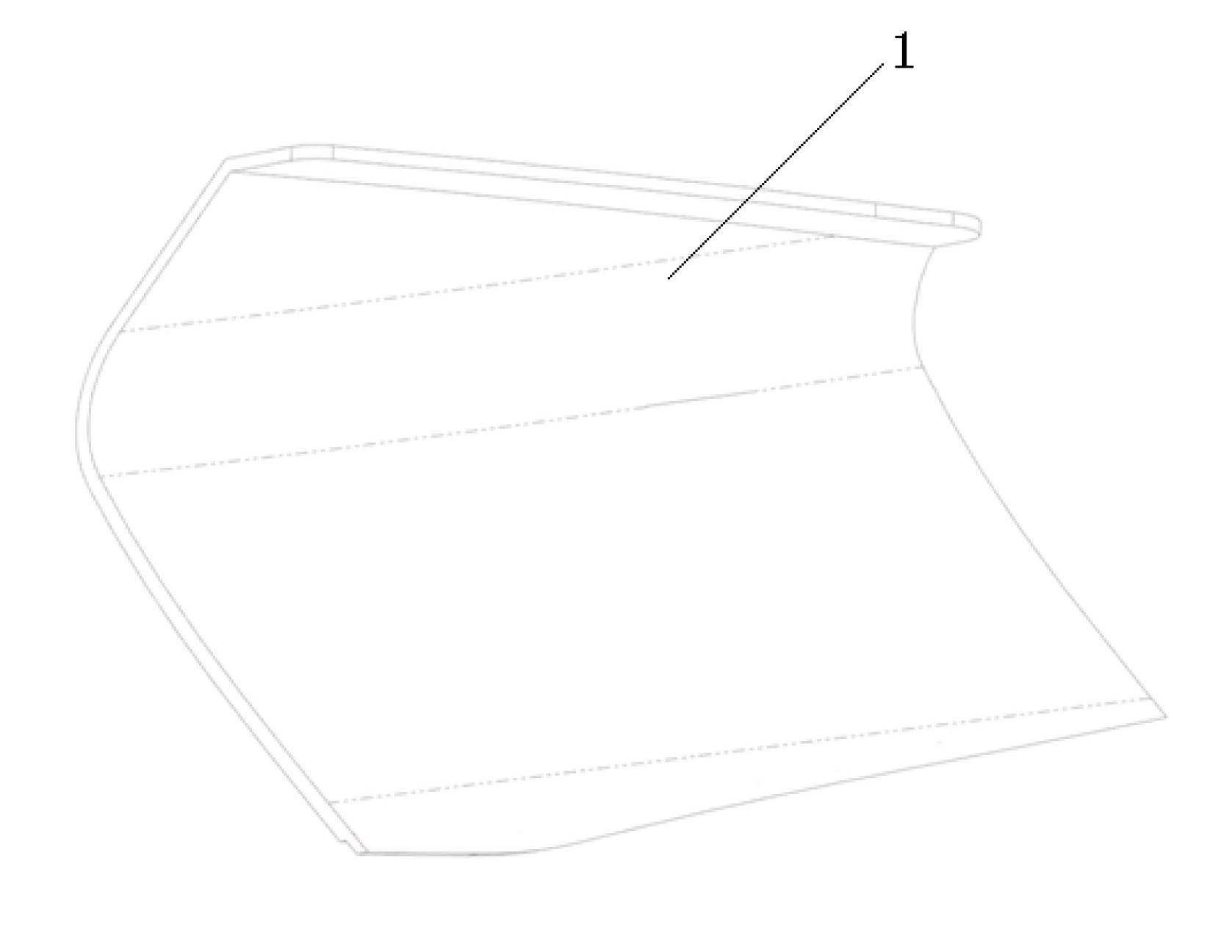

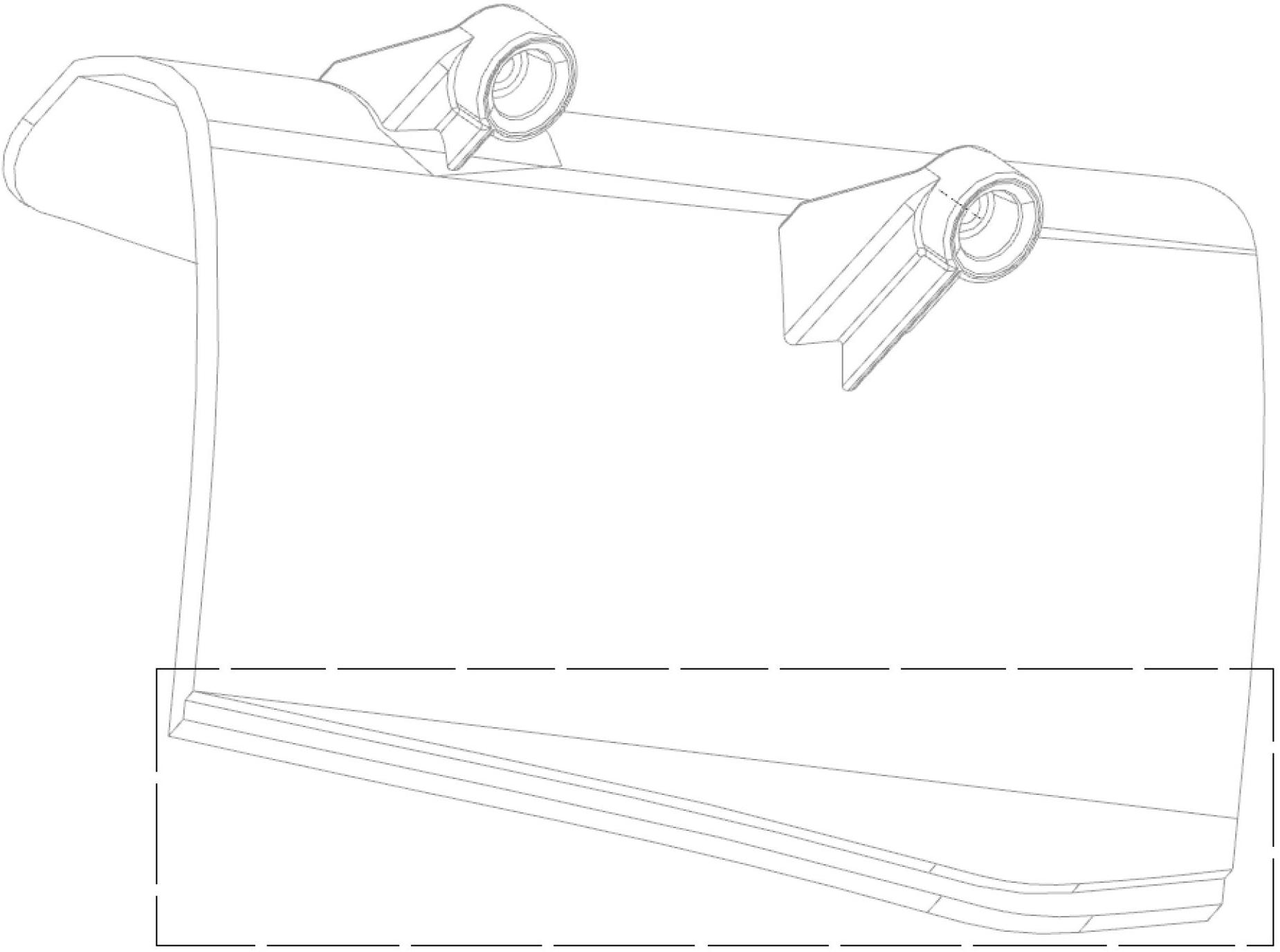

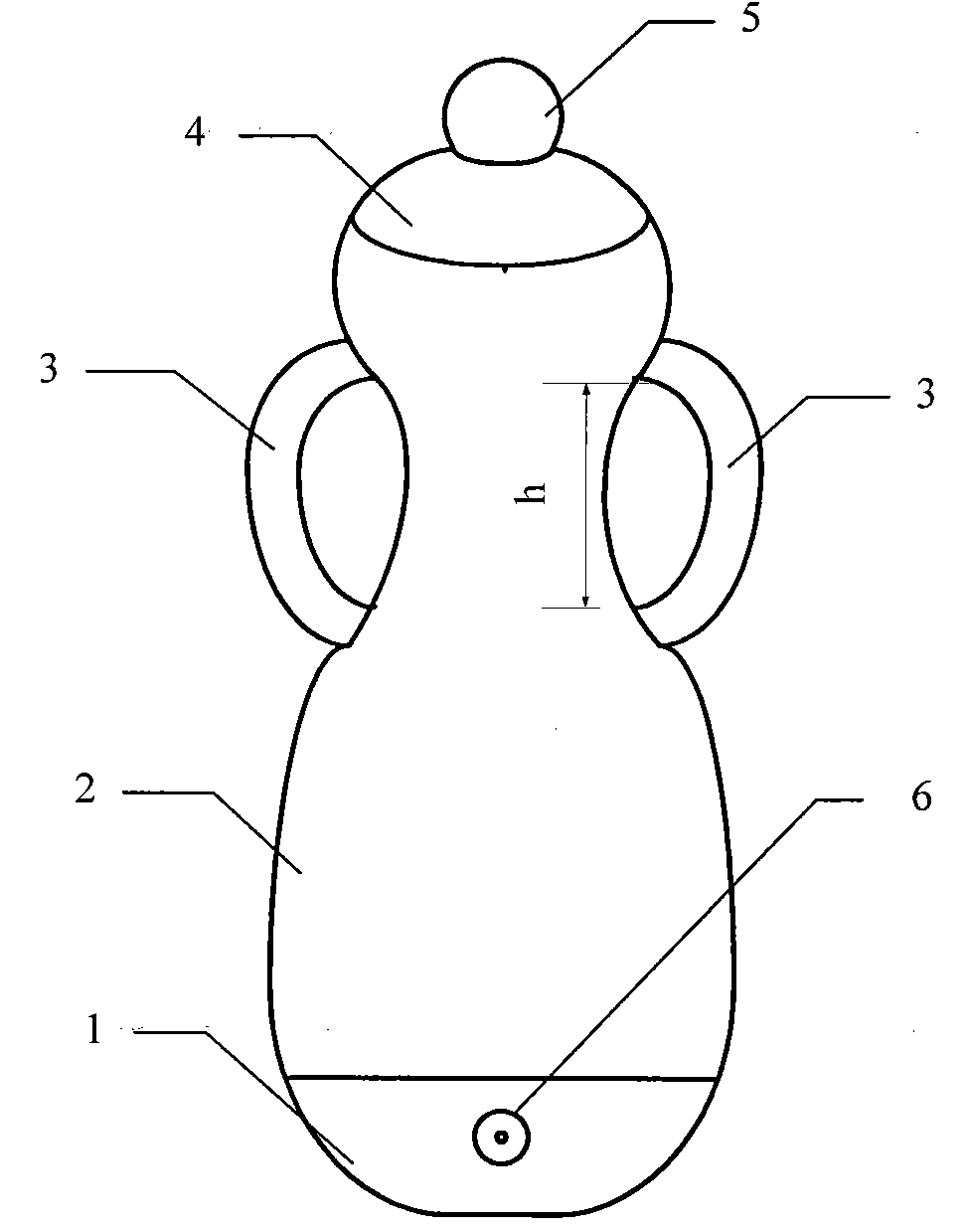

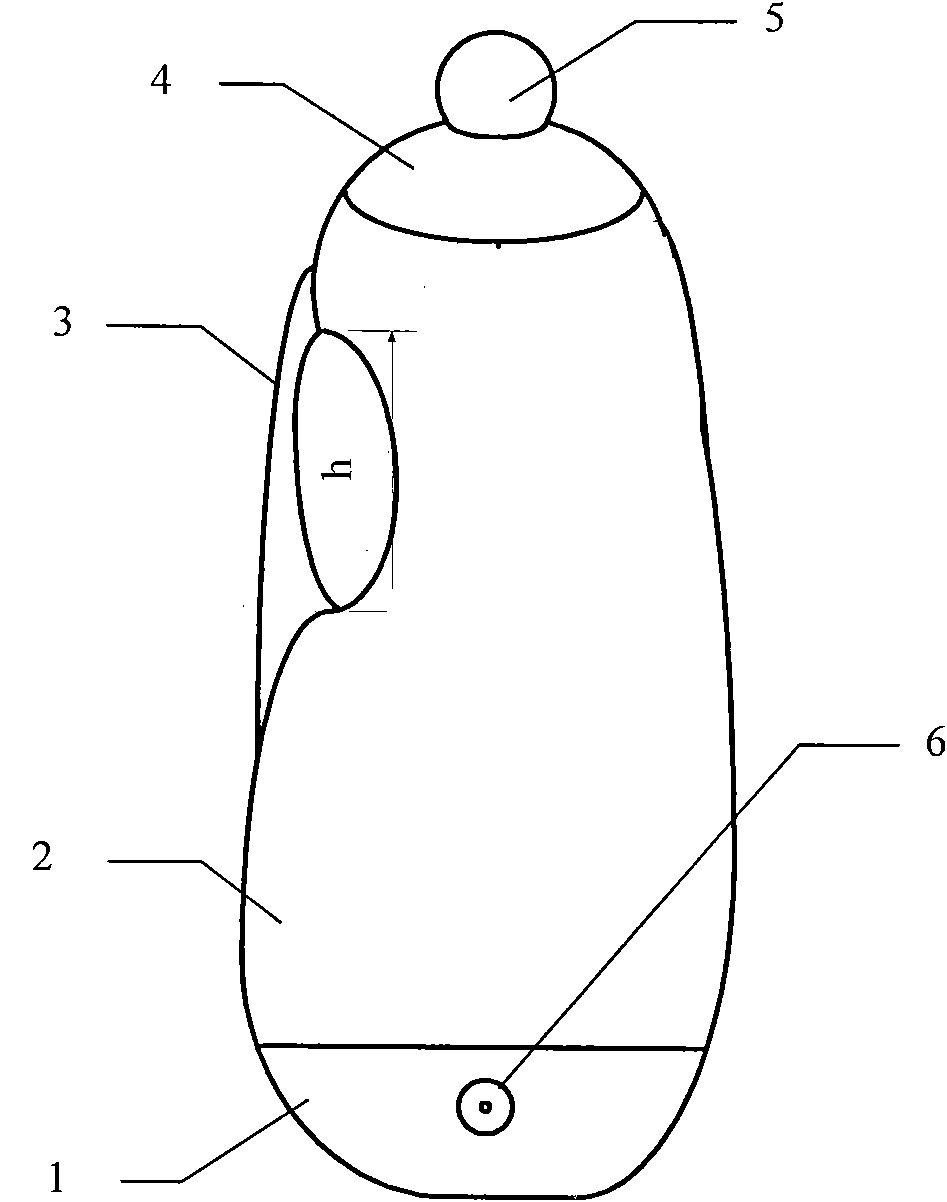

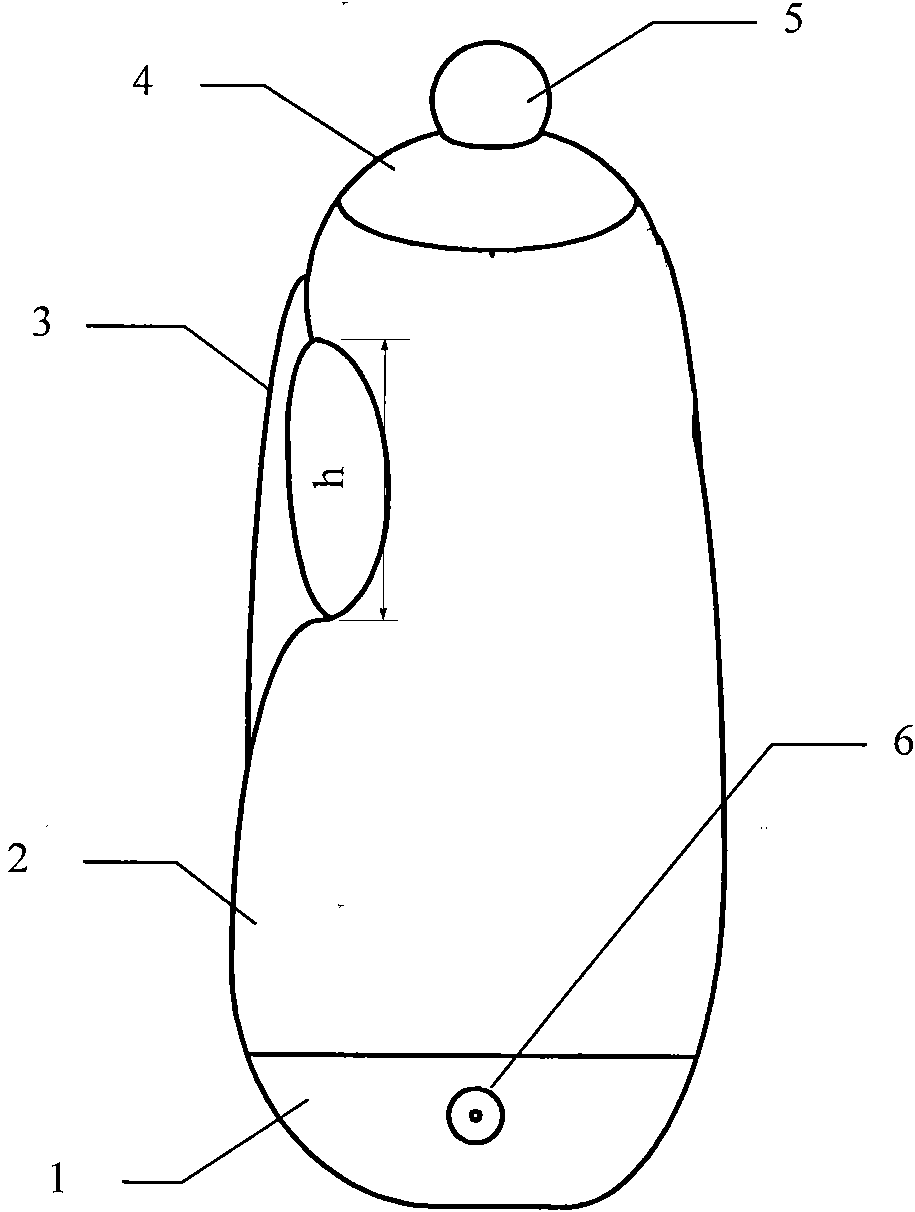

The invention provides an impacting-shaping composite spherical energy dissipation structure for vertical hole blasting. The energy dissipation structure comprises a composite spherical energy dissipation base and a buffer layer located below the composite spherical energy dissipation base, wherein the composite spherical energy dissipation base is of a double-layer structure which is soft externally and hard internally or hard externally and soft internally from outside to inside. According to the energy dissipation structure, under the action of an initial impact load after explosive detonation in a blast hole, the composite spherical energy dissipation base generates secondary plasticity, finally an ellipsoidal or a concave-shaped rigid cushion block reflects most of the explosion energy which is propagated in the rock mass below the hole bottom, meanwhile, the composite spherical energy dissipation base and the buffer layer absorb partial explosion energy in the deformation process, and therefore the rock on the foundation surface can be broken, the rock on the hole bottom can be protected, and the existing horizontal pre-cracking or smooth blasting technology can be partially replaced. The energy dissipation structure is simple and convenient to install, can partially replace the existing horizontal pre-cracking or smooth blasting technology and is suitable for protecting layer rock mass blasting excavation in the fields of water conservancy and hydropower, nuclear power, traffic and the like.

Owner:WUHAN UNIV

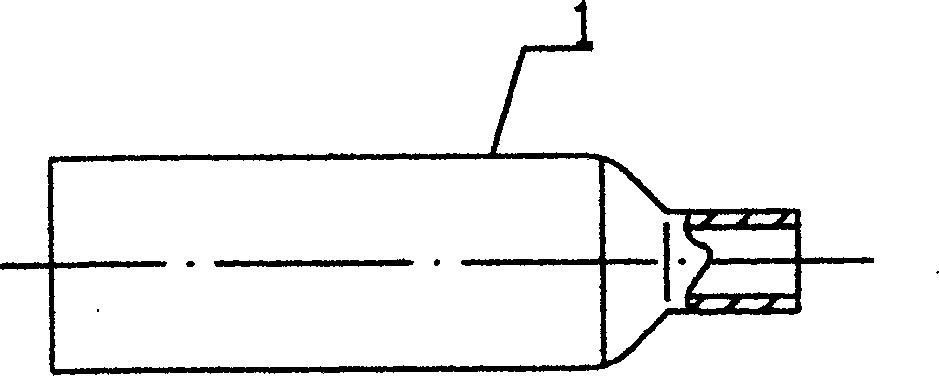

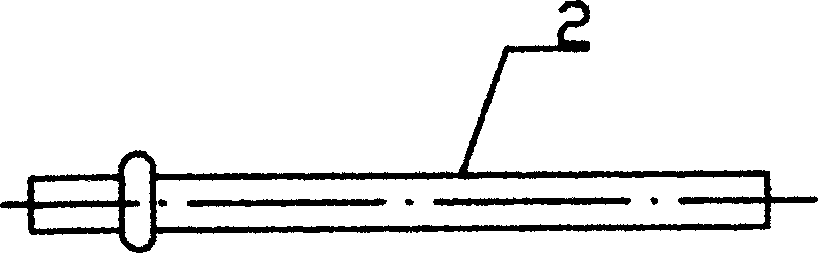

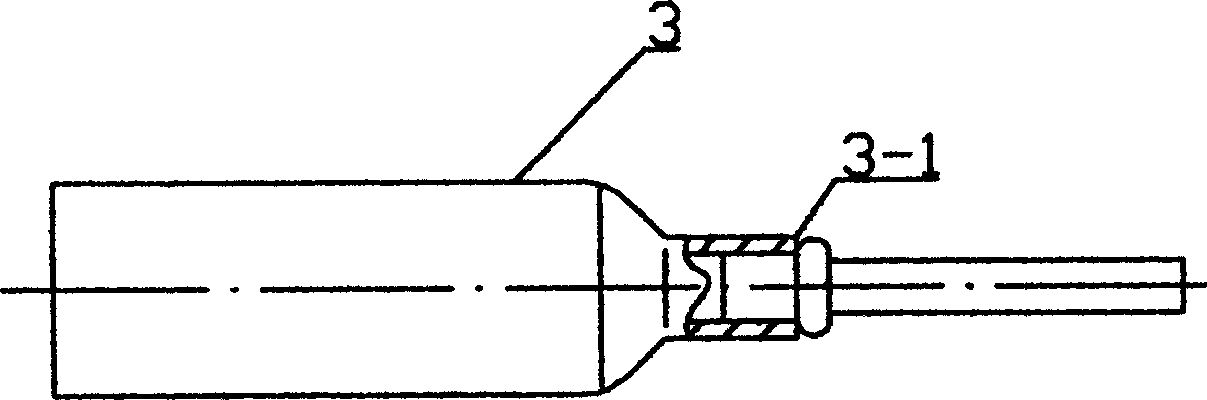

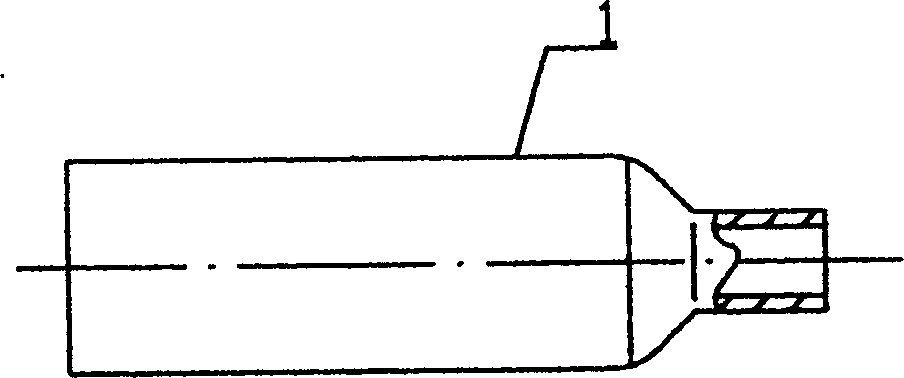

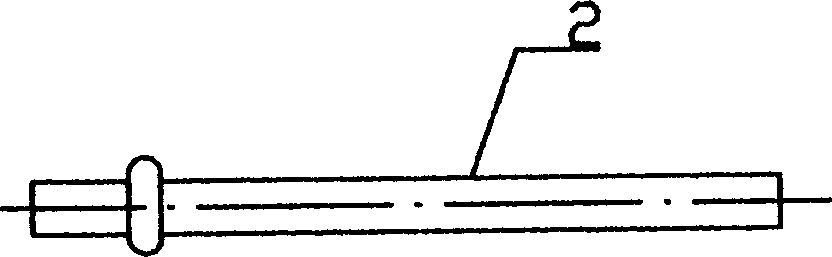

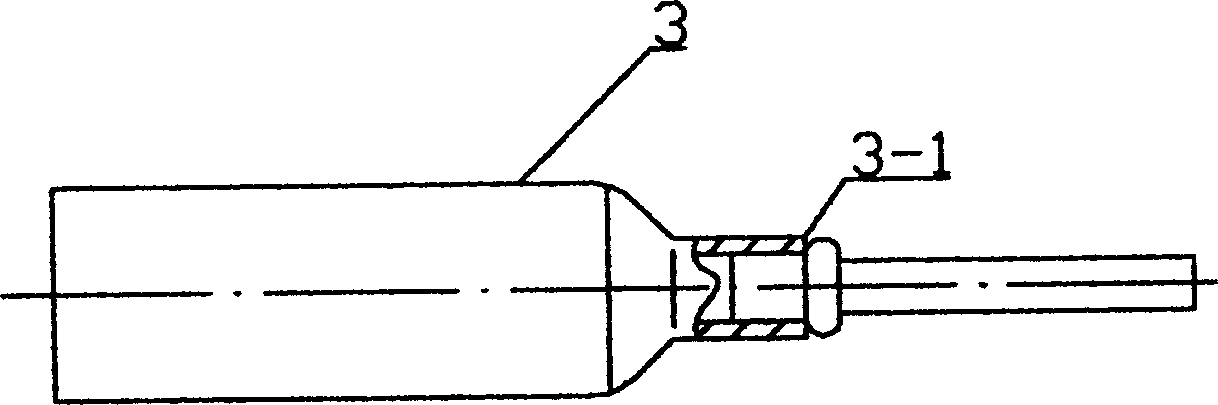

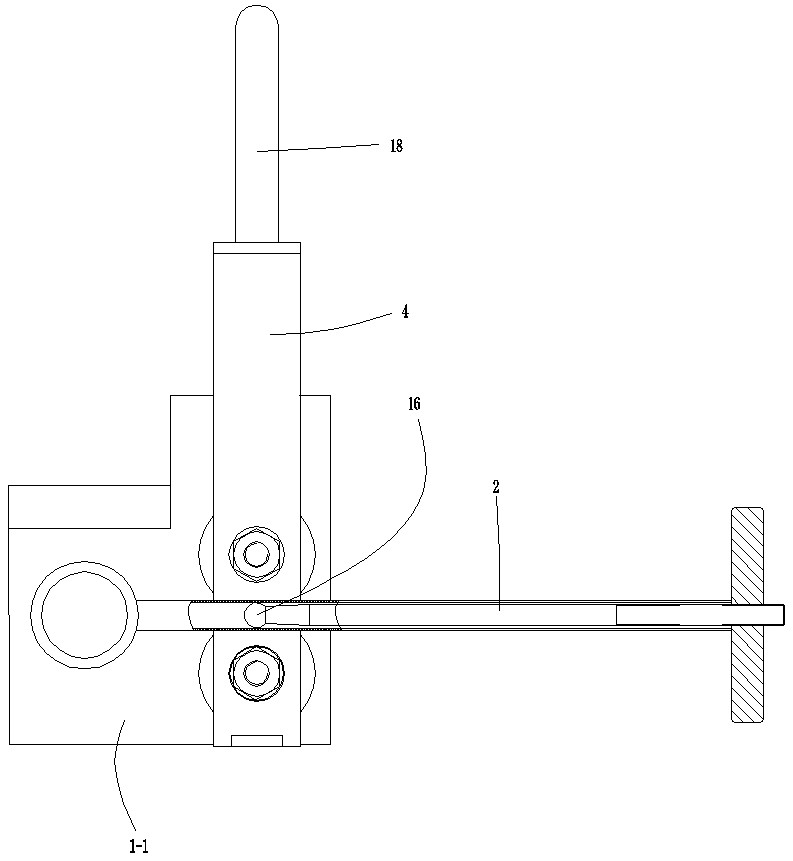

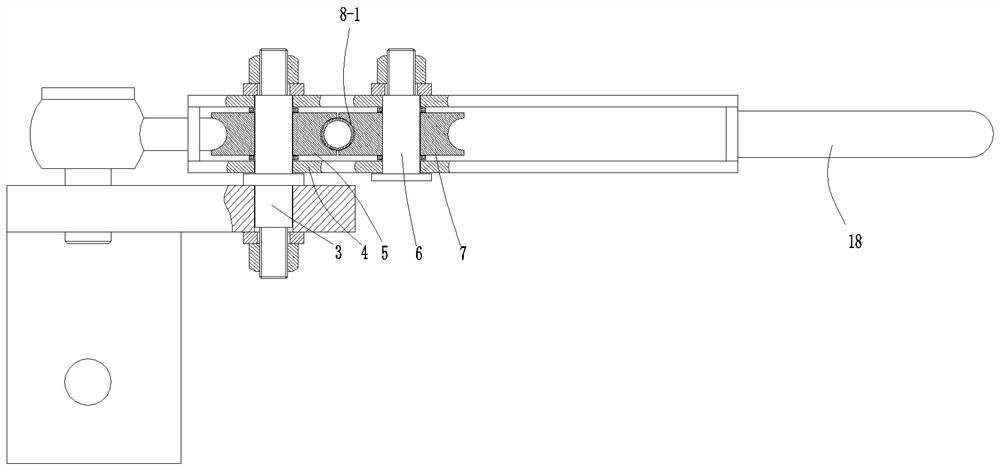

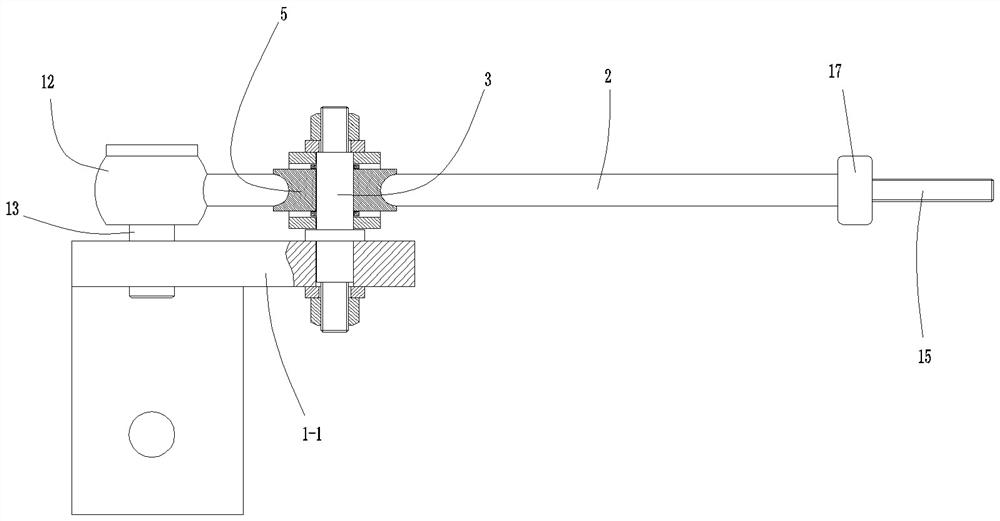

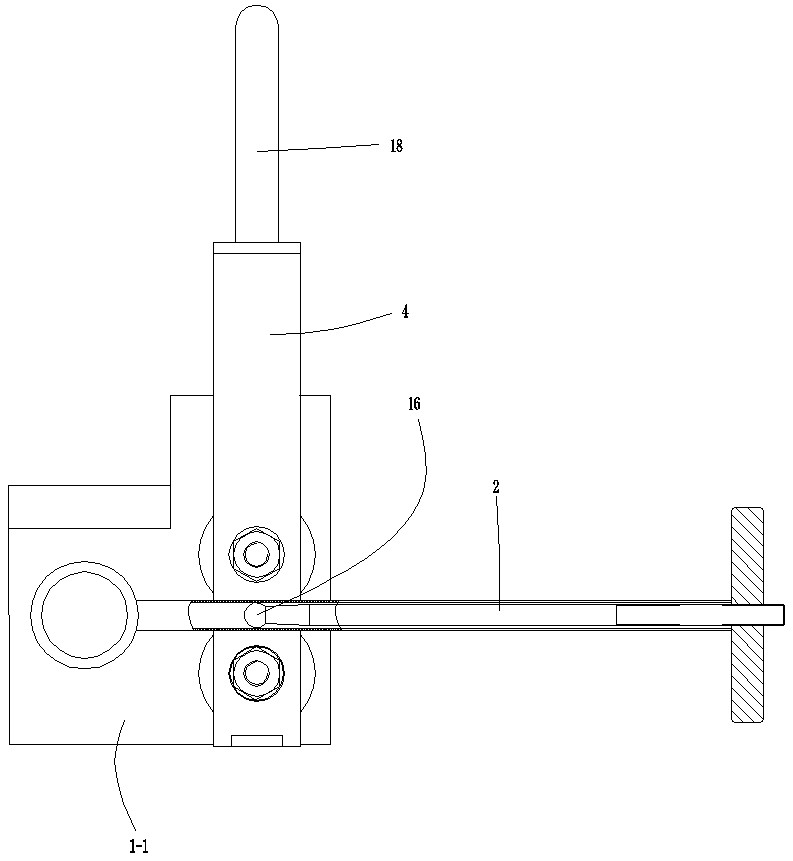

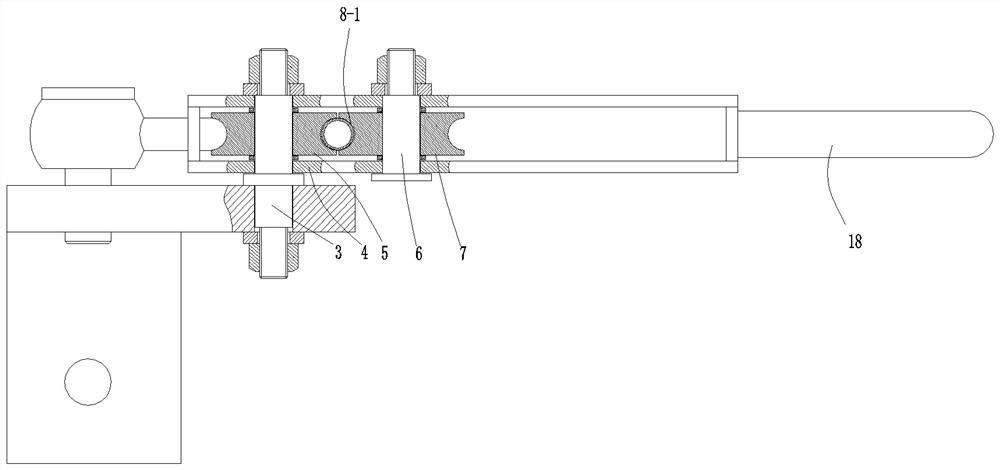

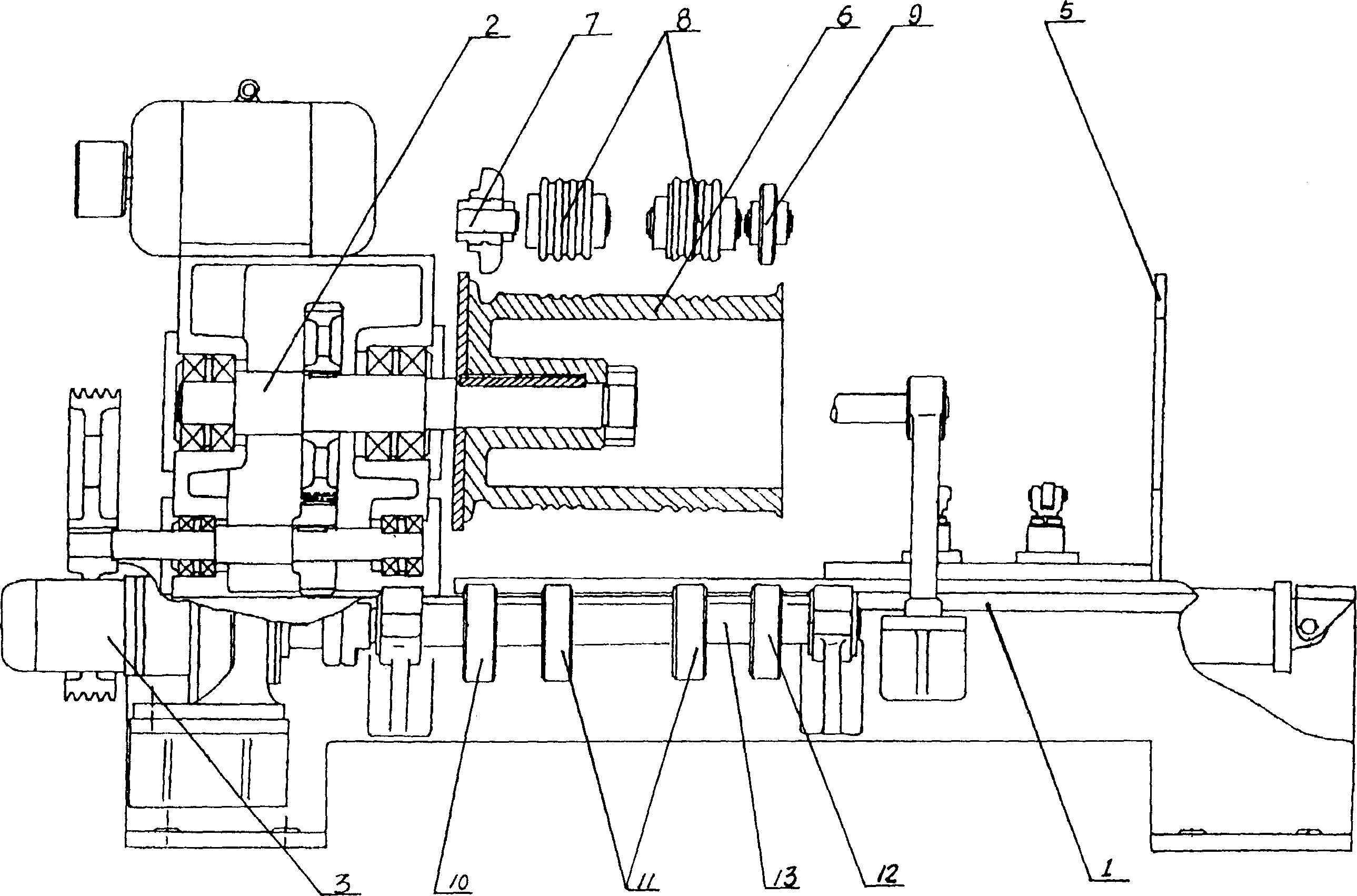

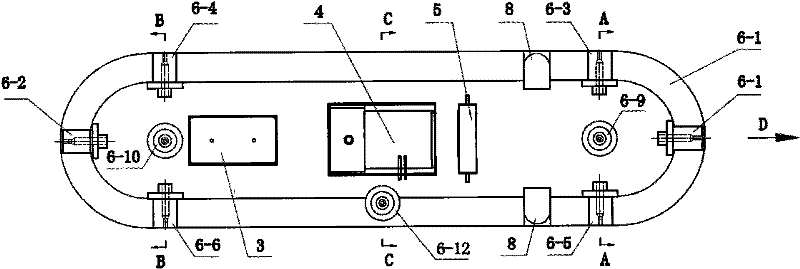

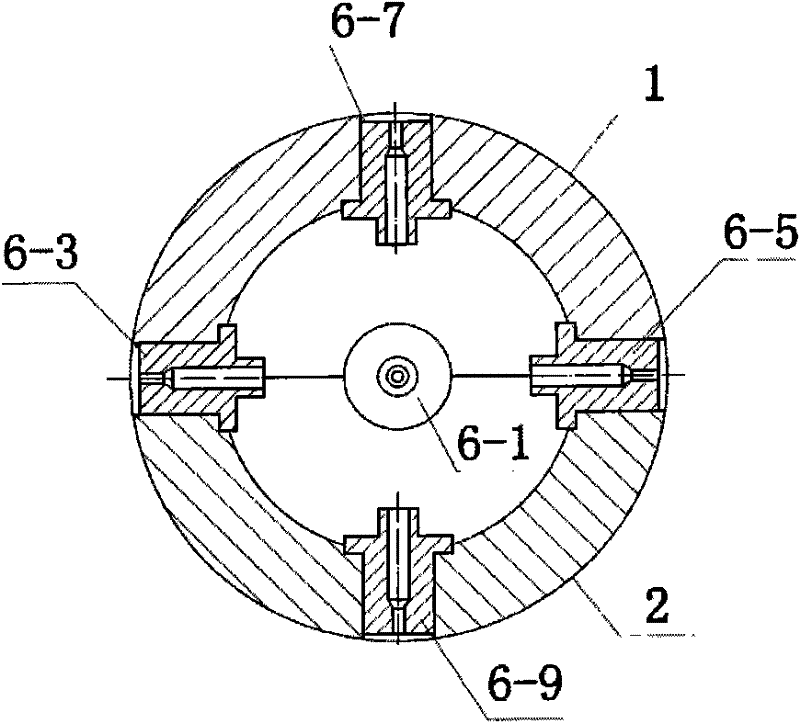

Method and apparatus for manufacturing reducing pipe

InactiveCN1528542ASleek appearanceIncrease productivityDrawing diesEngine componentsControl systemThin walled

The invention relates variable aperture tube making method and device, including tube end rotary forging and draw stretching. It first forges one end of the tube on the rotary forger into a smaller-aperture technical tube, which makes the stretching mould through to be clamped by the clamping module; using a hydraulic control system to drive clamping base and clamping module; inserting core rod with mould head in the copper tube to stretch by the stretching mould. It includes rotary forger and draw-stretching device. The clamping module, the stretching mould and the core rod makes up a stretching process line. The position of the core rod is adjustable and the stretching effect is good. The hydraulic control system is installed with travel switch to control stretching travel. It is applied to the control of thin-wall small-aperture copper tube and widely applied to cryogen pipeline in refrigerating industry.

Owner:广州冠华金属精工制造有限公司

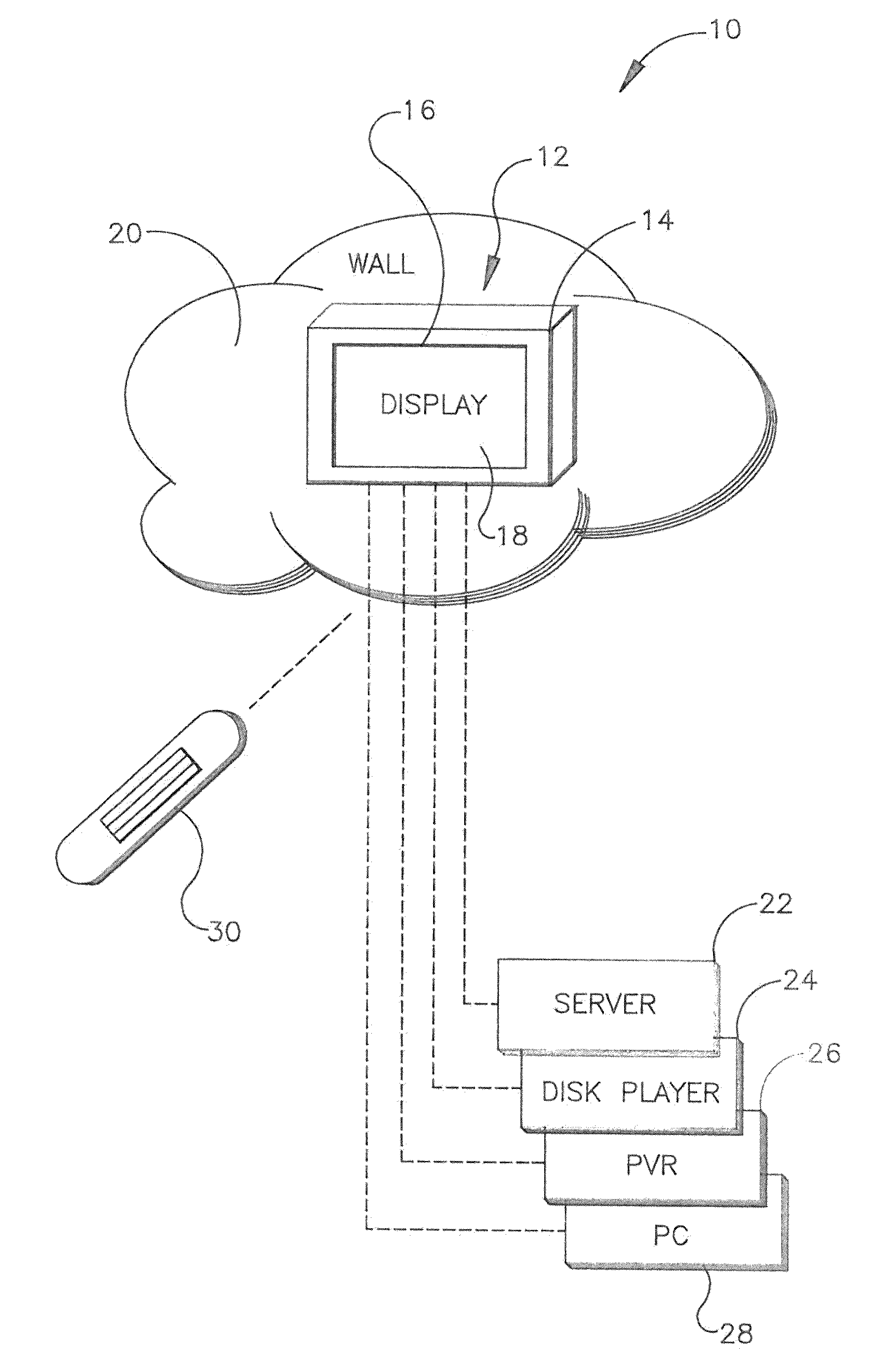

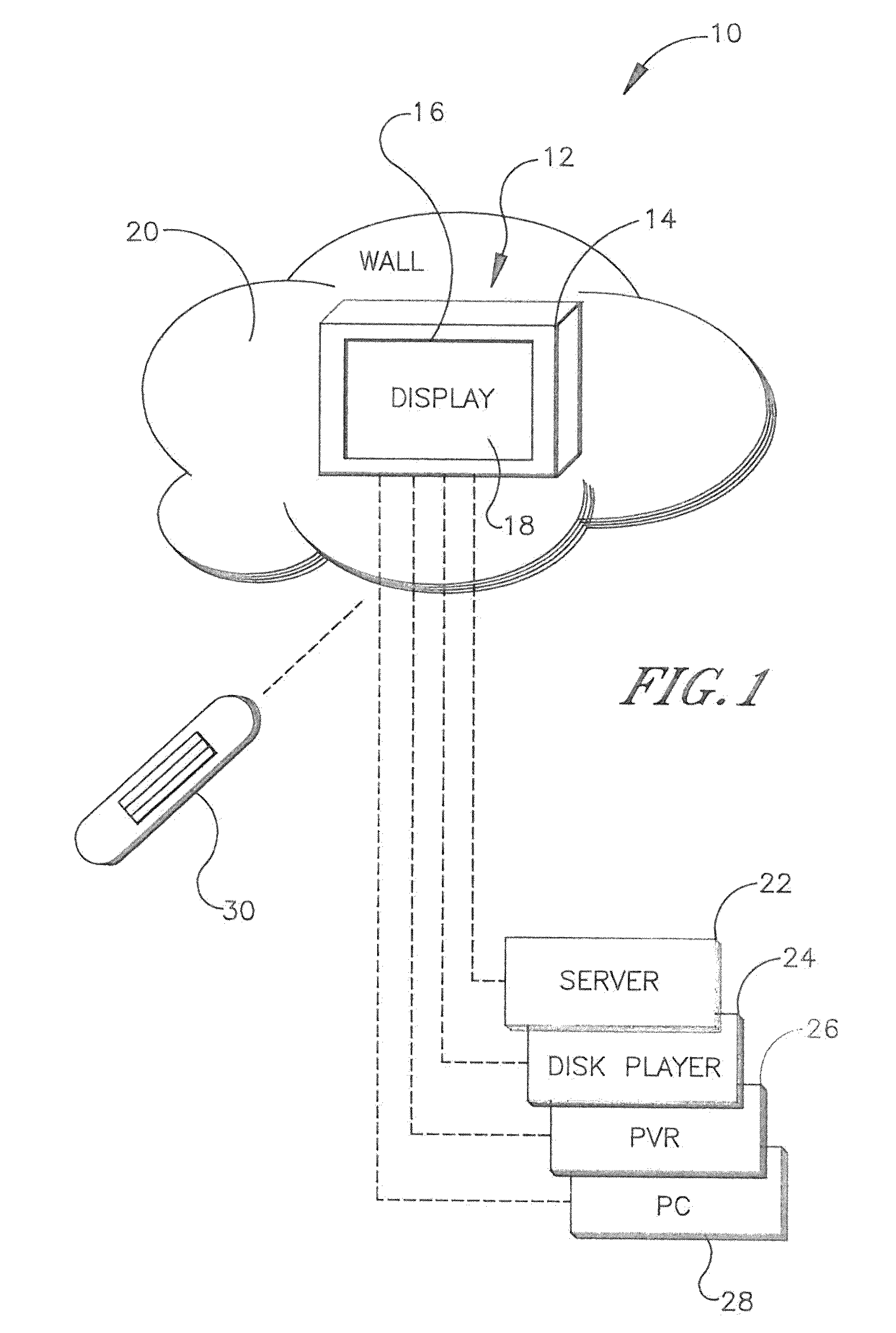

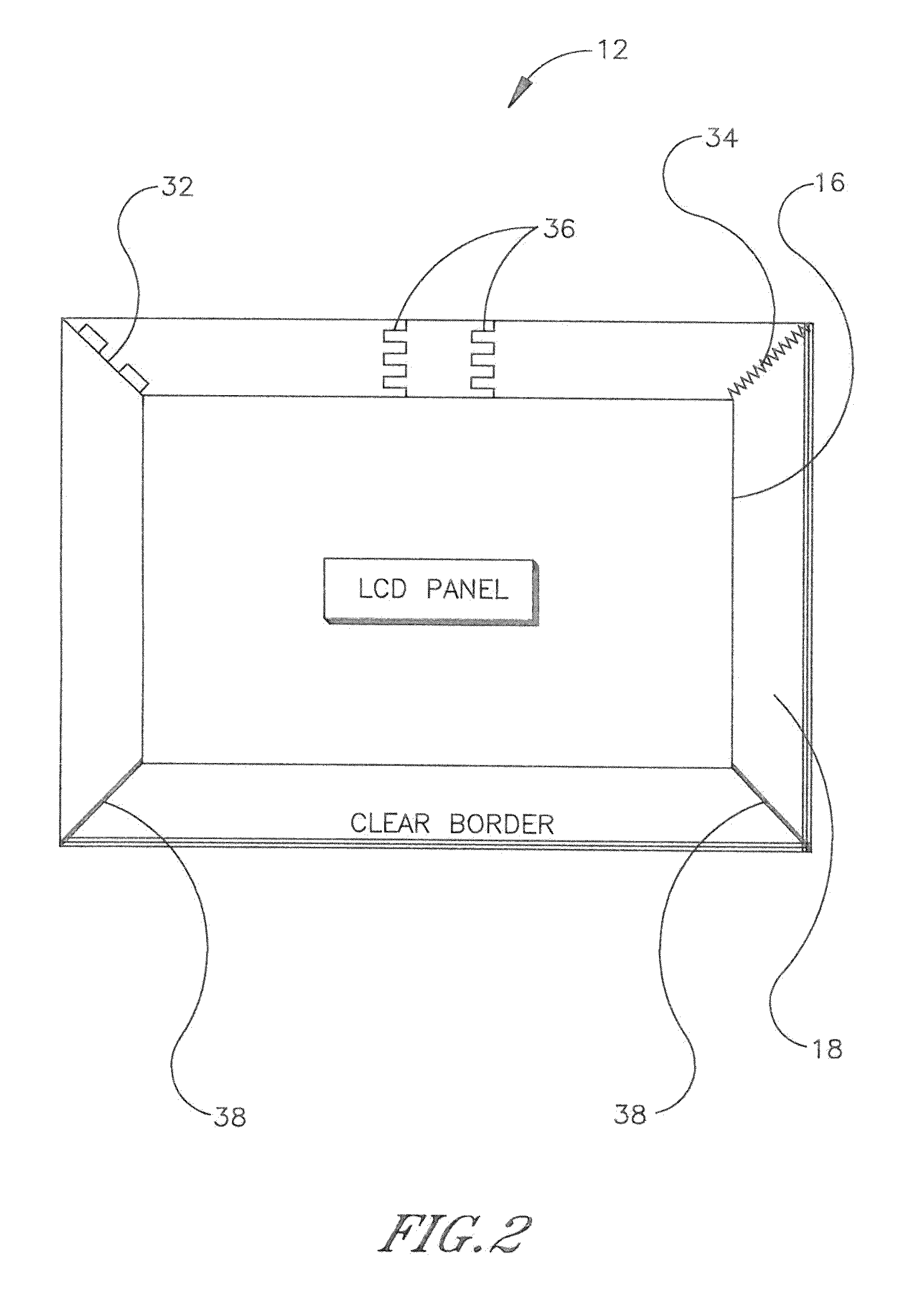

Embedded wireless antenna for network TV

InactiveUS20110078749A1Improve antenna performanceSleek appearanceTelevision system detailsAntenna supports/mountingsDisplay deviceChipset

Owner:SONY CORP +1

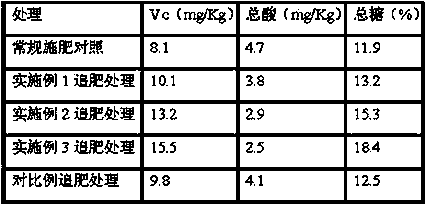

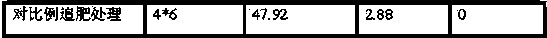

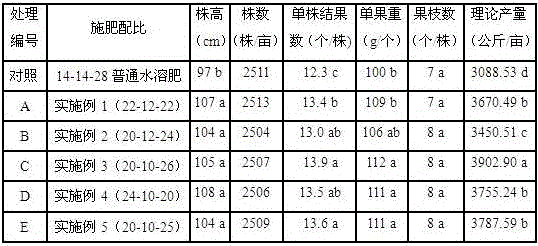

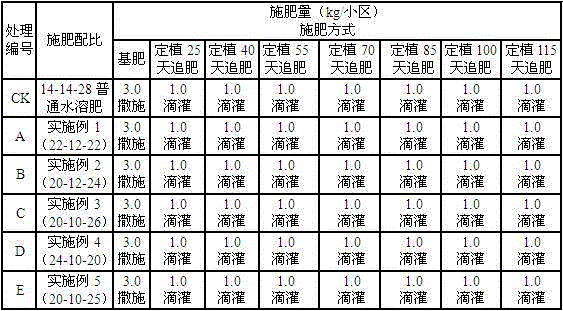

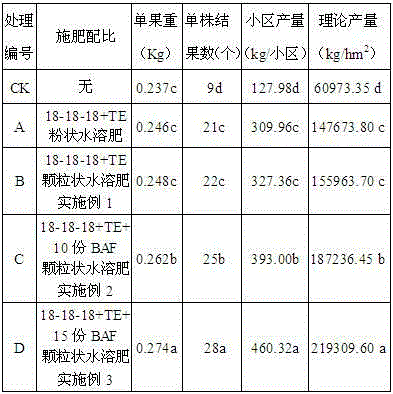

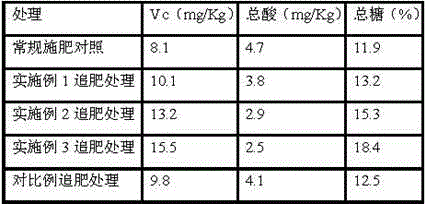

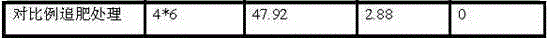

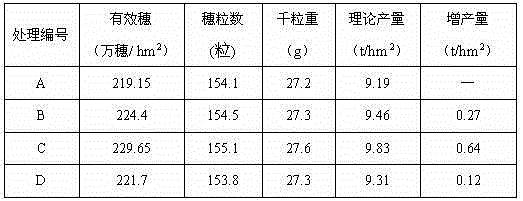

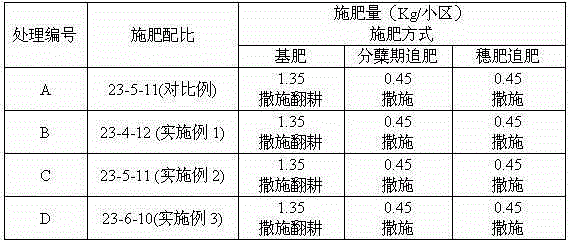

Seaweed essence-containing swelling fruit type major element water soluble fertilizer and preparation method thereof

ActiveCN104261952ANutrient balanceSleek appearanceNitrate fertilisersPotassium fertilisersHorticultureChemistry

The invention discloses a seaweed essence-containing swelling fruit type major element water soluble fertilizer and a preparation method thereof and belongs to the technical field of water soluble fertilizers. The fertilizer is prepared from the following raw materials in parts by mass: 373-400 parts of ammonium nitrate-phosphorus, 100-250 parts of potassium nitrate, 100-150 parts of monopotassium phosphate, 120-290 parts of potassium sulphate, 1-6.5 parts of boric acid, 1-5.0 parts of EDTA chelating zinc, 1-5.0 parts of EDTA chelating iron, 1-5.0 parts of EDTA chelating manganese and 1-7 parts of seaweed essence. Aiming at the defects in the prior art, based on a tower melt prilling compound fertilizer device, the fertilizer is obtained by scientifically and reasonably formulating according to current major element water soluble fertilizer, and is balanced and stable in nutrition, smooth in appearance, difficult to harden, fast to dissolve, free from residues, scientific and reasonable in formula, efficient and safe and comprehensive in nutrition.

Owner:STANLEY AGRI GRP CO LTD

Organic manure special for green nuisanceless farm products and preparation method thereof

InactiveCN1559990AWide variety of sourcesLarge reservesFertiliser formsFertilizer mixturesAdhesiveBran

The invention discloses a green harmless special organic fertilizer for farm produces, mixed of natural humic acid, peanut bran powder, bean cake, tea-leaf, adhesive, acid salt tolerance and regulating substance in weight ratios of 10-40 shares, 20-30 shares, 10-20 shares, 10-40 shares, 10-15 shares, and 3-8 shares, respectively; and its preparing method: crushing materials, adding in adhesive and premixing, and refining by the process 'secondary making particles, secondary drying' to make it. It has uniform and smooth particles, no phenomena of 'dirty, foul, wet, loose', etc, and no pollution to the environment, and is rich in nutrient substances of N, P, K, amino acid, S, Zn, Fe, Ca, Mg, etc, and has a pH value at 5.0-8.5; the content of heavy metals, harmful germs, hormones and drug residues is low, and it has no radiation. It can remarkably improve the quality of farm, produces, improve soil structure, and be suitable for the standard production of green harmless farm produces.

Owner:广东省农业科学院土壤肥料研究所

Macroelement water-soluble fertilizer containing potassium fulvate and preparation method of macroelement water-soluble fertilizer

InactiveCN109279970ASleek appearanceReduce moistureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAmmonium sulfateChemistry

The invention discloses a macroelement water-soluble fertilizer containing potassium fulvate. The water-soluble fertilizer is prepared by mixing and grinding the following raw materials, and is prepared by mixing the following components in parts by weight: 30-50 parts of urea, 20-30 parts of potassium nitrate, 10-20 parts of potassium dihydrogen phosphate, 3-7 parts of nitro phosphate, 4-8 partsof ammonium sulfate, 2-4 parts of potassium fulvate, 0.1-0.2 part of compound sodium nitrophenolate, 0.04-0.06 part of sodium naphthalene acetate, 0.3-0.5 part of sodium dodecyl benzene sulfonate, 0.08-0.12 part of a stabilizer, 2-4 parts of boric acid, 0.03-0.05 part of a fertilizer synergist, 3-7 parts of ethylene diamine tetraacetic acid (EDTA) chelated iron, 3-7 parts of EDTA chelated zinc and3-7 parts of EDTA chelated manganese. The preparation method comprises the following steps: putting the raw materials into a stirring device for mixing under a dry production environment according tothe proportions, then carrying out crushing, and carrying out packaging to obtain a finished product. The macroelement water-soluble fertilizer can provide comprehensive and balanced nutrition for growth and development of crops, and is not caked easily during a storage period.

Owner:徐州聚友信息技术有限公司

Potassium nitrate co-production tower-type melt micrograin water-soluble fertilizer and preparing method thereof

InactiveCN105693334ANutrient balanceSleek appearanceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAmmonium polyphosphateNutrient

The invention discloses a potassium nitrate co-production tower-type melt micrograin water-soluble fertilizer and a preparing method thereof and belongs to the technical field of water-soluble fertilizer production. The potassium nitrate co-production tower-type melt micrograin water-soluble fertilizer is prepared from potassium nitrate concentrated solution, urea, industrial monoammonium phosphate, water-soluble ammonium polyphosphate, potassium sulfate, EDTA-Fe, EDTA-Zn, EDTA-Mn, boric acid and ammonium heptamolybdate. The potassium nitrate co-production tower-type melt micrograin water-soluble fertilizer is balanced and stable in nutrient, has a microgranular shape and smooth appearance, is not prone to hardening, can be absorbed and utilized by crops easily, and contains comprehensive nutrients. The fully-automatic dispensing equipment production technology is adopted, dispensing, mixing and packaging are integrated and achieved automatically, the technology is environmentally friendly, energy is saved, and production is easy.

Owner:STANLEY AGRI GRP CO LTD

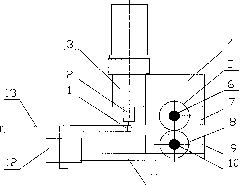

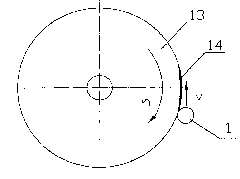

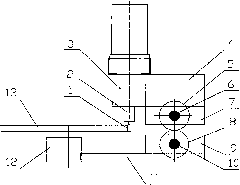

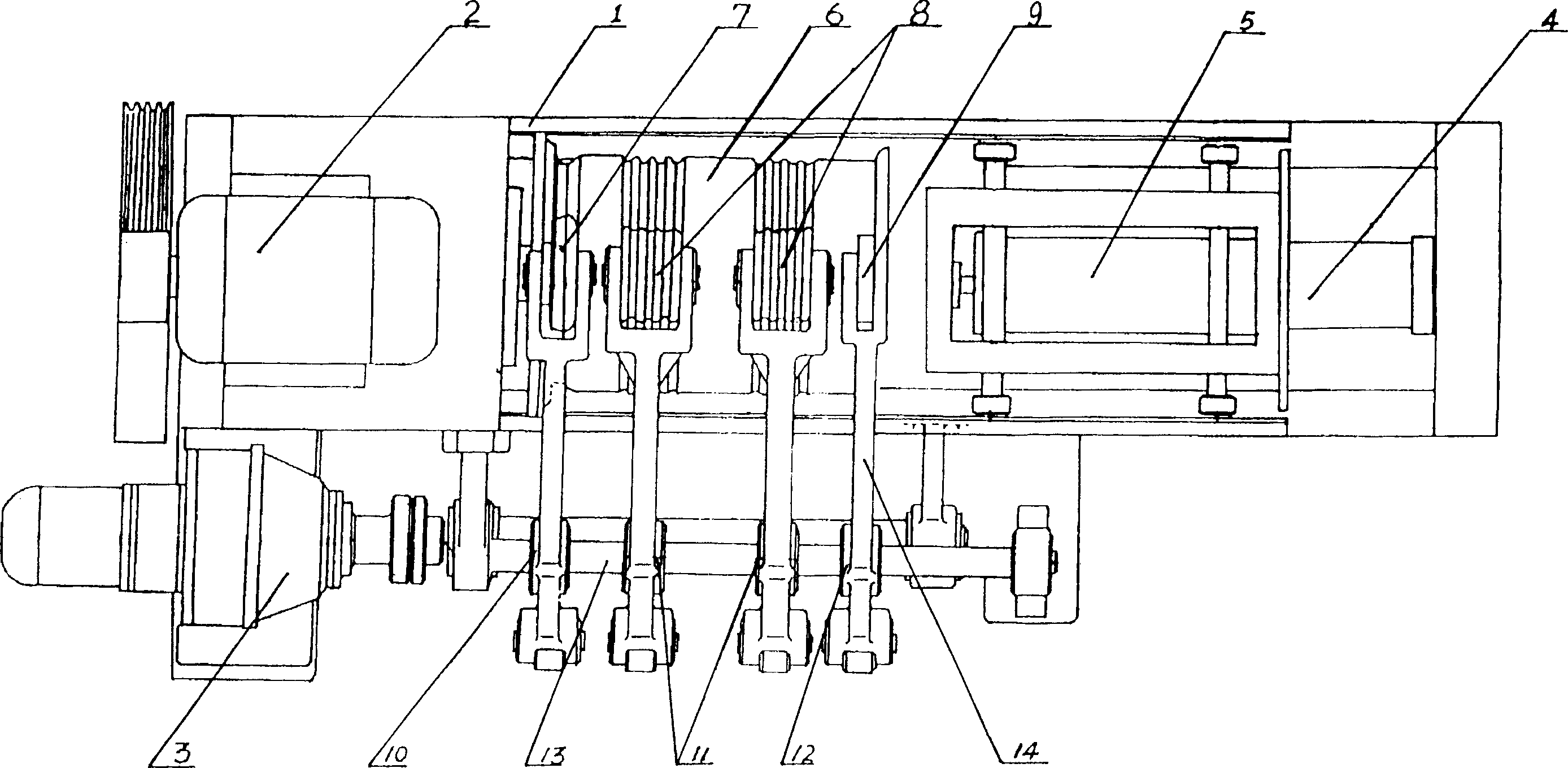

Arc grinding device with balanced driven disc

InactiveCN101823225AHigh precisionChange manual grindingGrinding machinesBalancing machineWeight decreasing

The invention relates to an arc grinding device with a balanced driven disc, comprising a cutter (1), a cutter holder (2), a power head (3), a radial slide block (4), a first gear (5), a first screw rod (6), an upper sliding seat (7), a second gear (8), a lower sliding seat (9), a second screw rod (10), racks (11), a third gear (12) and a workpiece (13). The invention can realize the direct grinding for weight decrease by installing the arc grinding device on a balancing machine, greatly enhances the balancing efficiency and the precision of the balancing machine by changing the traditional manual grinding, and has good product appearance because the appearance is smoothly transited during the grinding; those are not realized by the manual grinding for the weight decrease; and in addition, grinding crumbs are sucked away during mechanical grinding, thereby protecting the operating environment.

Owner:XIAOGAN XINYA TECH

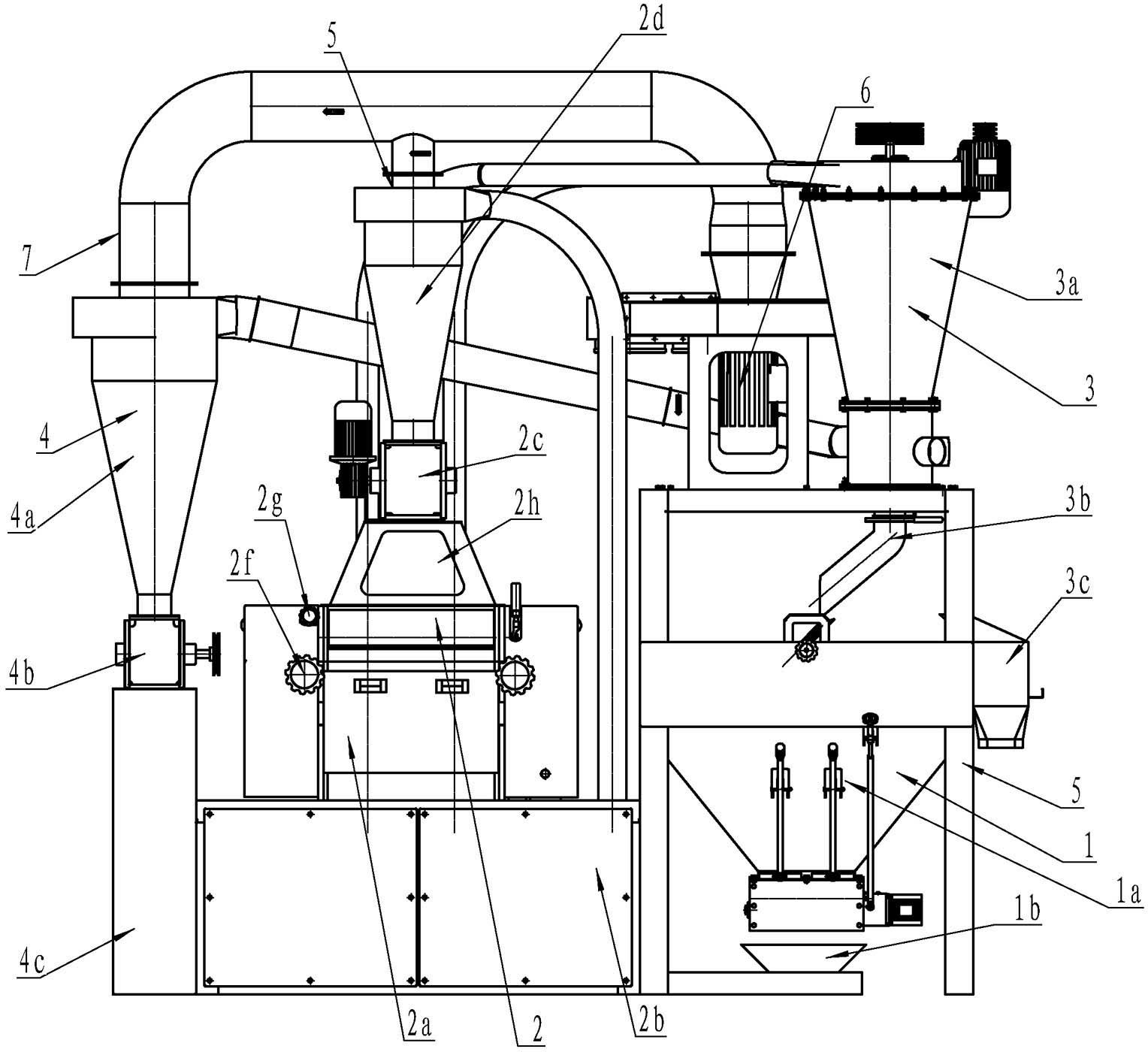

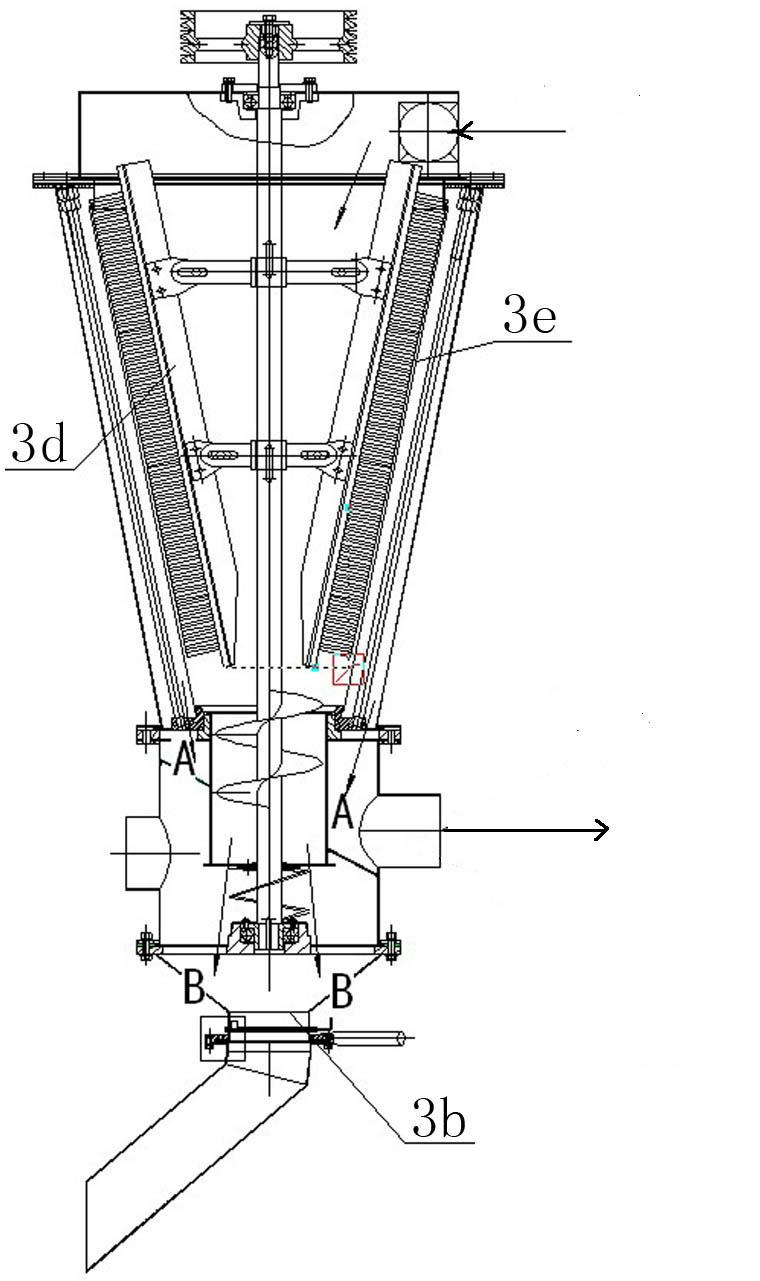

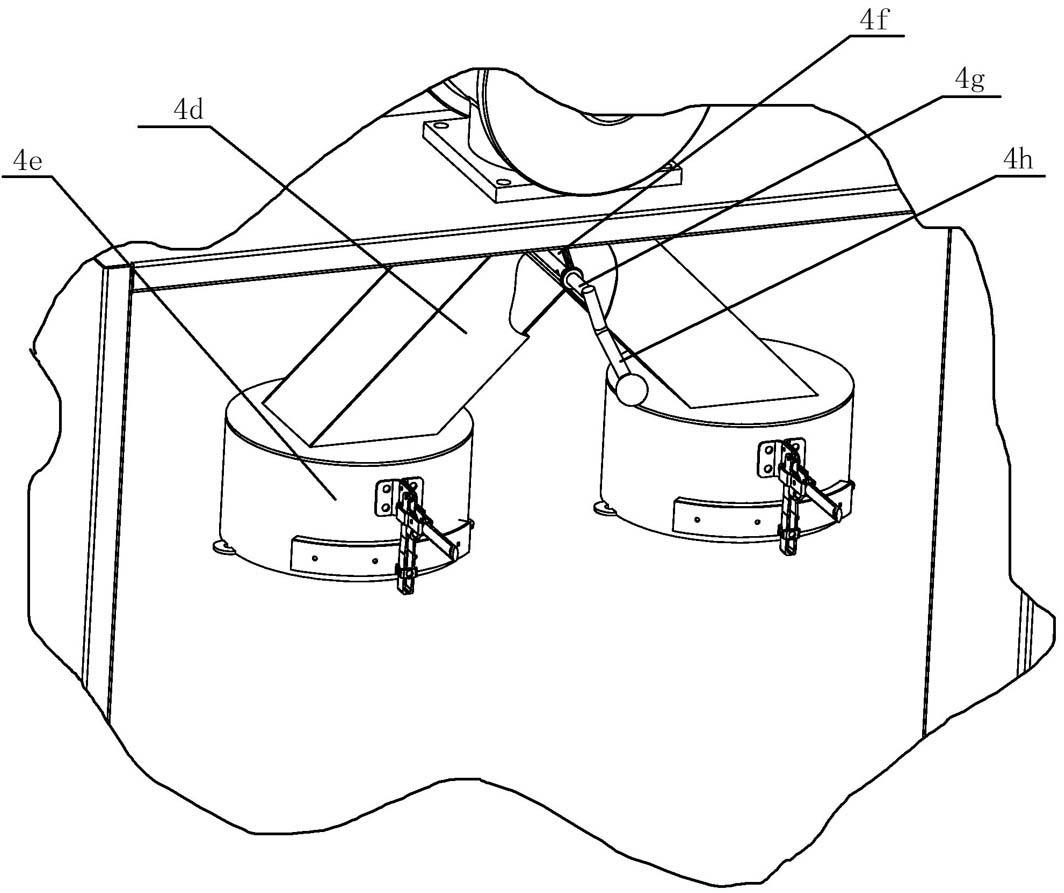

Fully automatic efficient flour producing machine

The invention relates to a fully automatic efficient flour producing machine, which comprises a rack, a feeding device arranged on the rack, a flour producing device, a repeatedly screening device, a discharged material bagging device, a centrifugal high-pressure fan and communication pipes between devices. A flour lifter is arranged above a Toro rack so as to make materials flow into a large WLDA feeding hopper by self gravity, energy consumption in repeated lifting and unloading is reduced, and simultaneously the structure is more compact. Components of a hopper under a mill and an induction material receiver make the materials respectively enter the flour lifter so as to increase the unit yield of flour ground by a single machine and improve the economic benefits. A flour outlet prong in a flour receiving cabinet is matched with a poking hopper to control the flour to be discharged from different outlets, and flour bags at both sides respectively receive the materials to realize continuous bagging. Three air doors are arranged to control the air volume balance of each air transport system so as to make the whole flour producing system more efficient.

Owner:HEBEI PINGLE FLOUR MACHINERY GROUP

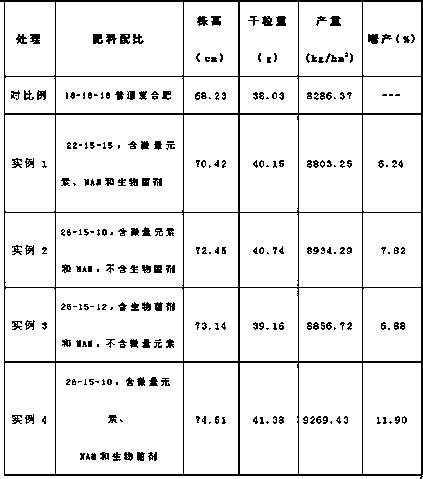

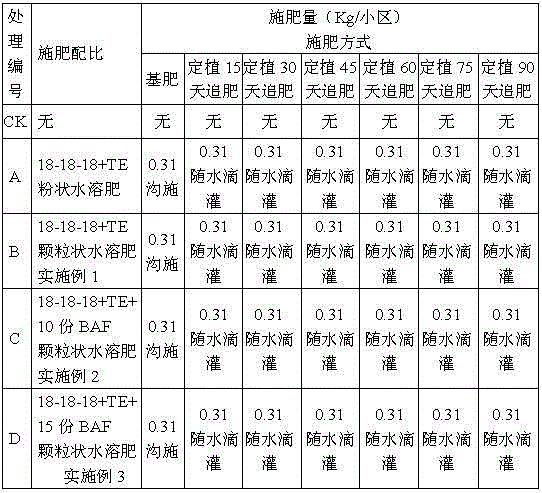

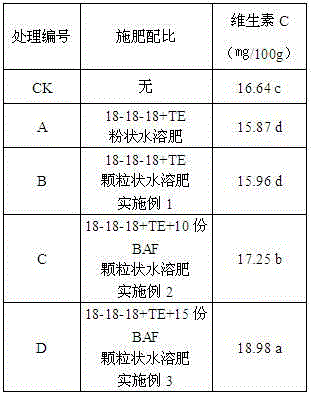

Long-acting total-nutrient wheat special-purpose fertilizer suitable for straw turnover, and processing method thereof

InactiveCN108456046ASleek appearanceNot easy to hardenAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersChelated zincPhosphate

The invention discloses a long-acting total-nutrient wheat special-purpose fertilizer suitable for straw turnover. The long-acting total-nutrient wheat special-purpose fertilizer suitable for straw turnover is composed of, by weight, 400 to 550 parts of urea, 150 to 300 parts of potassium chloride, 200 to 300 parts of monoammonium phosphate, 1 to 10 parts of inhibitor NAM, 1 to 10 parts of boric acid, 1 to 10 parts of EDTA chelated zinc, 1 to 10 parts of EDTA chelated copper, 1 to 10 parts of EDTA chelated manganese, 1 to 10 parts of EDTA chelated iron, 0.1 to 0.4 part of ammonium heptamolybdate, and 0.1 to 0.4 part of a bacterial preparation. The long-acting total-nutrient wheat special-purpose fertilizer possesses following advantages: 1, the appearance is smooth, caking is not easily caused; 2, nutrient combination is balance, and stable; 3, fertilizer effect lasts long, utilization rate is high, labor intensity is reduced, and environment pollution is reduced; 4, nutrients are comprehensive; and 5, the bacterial preparation is contained.

Owner:HUBEI NEWYANGFENG FERTILIZER STOCK

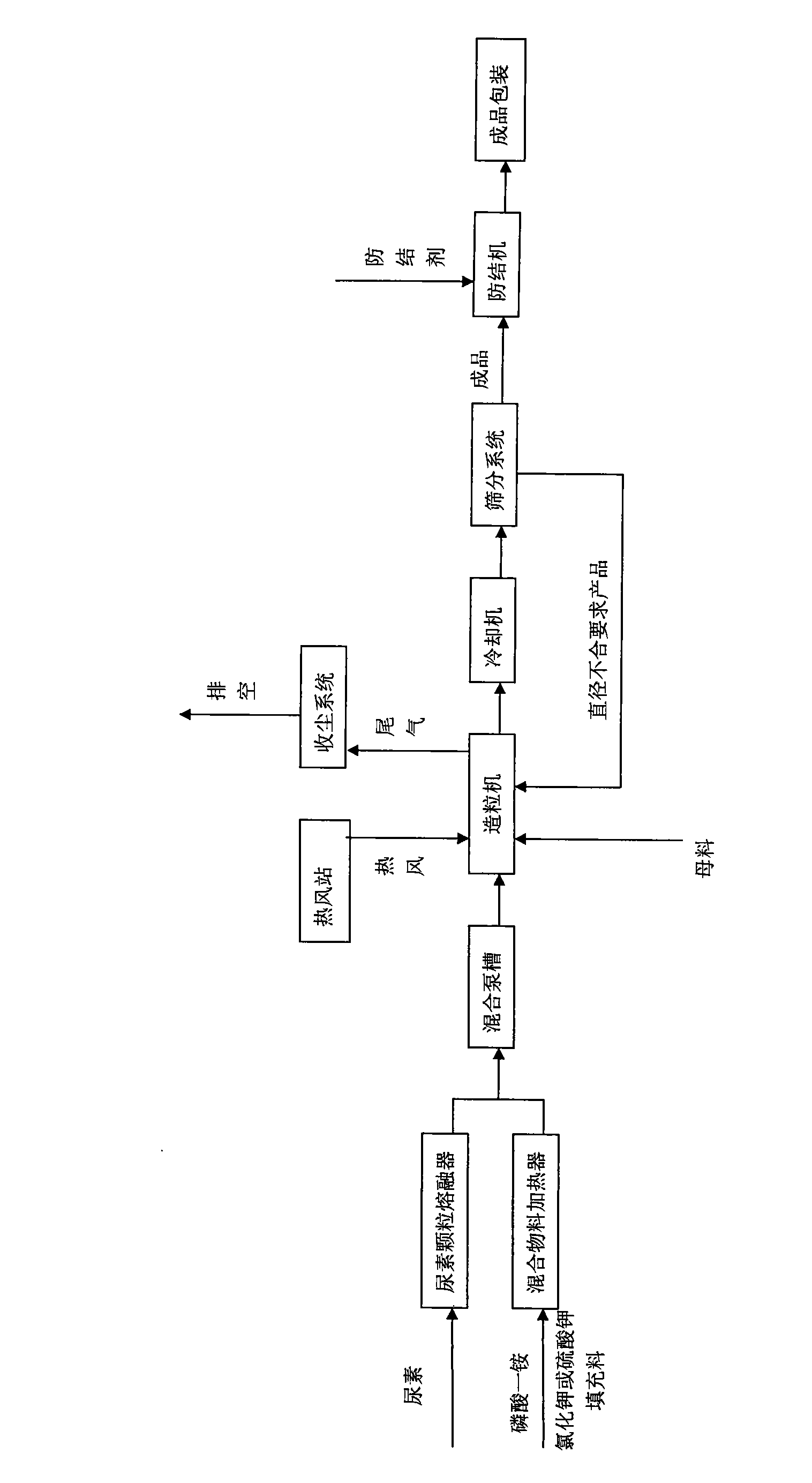

Method for manufacturing formula compound fertilizer

InactiveCN101633582AImprove product qualitySleek appearanceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersNitrogenChloride

The invention relates to a method for manufacturing a formula compound fertilizer, which is characterized in that: a master batch with certain nutrient proportion is fed into a horizontal granulator through a transmission system; dried and heated ammonium phosphate, potassium chloride or a mixture of potassium sulfate, stuffing and the like are mixed together with molten urea in a urea melter, and the mixture are fed into a mixed slurry pump groove through a mixed slurry delivering pipe to generate fusant slurry; and the fusant slurry is mechanically atomized by pressurizing through a slurry pump and is sprayed into the master batch of the granulator. The method can freely adjust the nutrient proportion of nitrogen, phosphorus, potassium and the like according to the demands so as to produce compound fertilizer products with different nutrient proportions, and the method realizes granulation in the horizontal granulator and completes spraying to improve the production efficiency. Simultaneously, the method is not influenced by geographic conditions, and saves investment by two third than the tower compound fertilizer technology.

Owner:SICHUAN YINGFENG IND

Method for improving concentricity and finish of rotor shaft

InactiveCN104191326AHigh concentricityBeating volume noEdge grinding machinesRevolution surface grinding machinesLithiumAlloy

A method for improving the concentricity and the finish of a rotor shaft includes the following technological processes that first, the length of a hole lapping machine of a workpiece is adjusted according to the size of the workpiece; second, the workpiece is placed on the hole lapping machine in a double-top mode, extra-high-quality lithium base grease is smeared all over the portions at the two ends, of a center hole of the workpiece, and the workpiece is ground for one minute on the hole lapping machine; second, two tip portions of the hole lapping machine contain specially-made sand alloy, and due to the sand alloy, not only can the precision of the center hole of the workpiece not be reduced, but also the surfaces on the two sides of the center hole are smooth and free of burrs; fourth, the ground workpiece is fine ground. The concentricity of the rotor shaft machined with the method is improved a lot, the jerk value of the rotor shaft is almost zero, the working efficiency is greatly improved, the rejection rate is reduced to 1%. from 5%, and machined products are bright and smooth in appearance.

Owner:李洪波

Method for coating chemical milling protection adhesive film during chemical milling

The invention relates to the field of chemical milling, in particular to a method for coating a chemical milling protection adhesive film during chemical milling. The method comprises the steps of protection adhesive liquid preparation, surface cleaning of a workpiece to be coated, protection adhesive coating and post-processing of coating. Firstly, protection adhesive liquid capable of shortening the airing time and increasing the thickness of the adhesive film is prepared, and compared with protection adhesive liquid sold on the market, the protection adhesive liquid has the characteristics that the concentration of paint film components is higher, the viscosity is higher, and thinning agent components can be evaporated rapidly. Then, an original damaged protection adhesive film formed by laser engraving is adopted, and the integrity of apparent shape and the accuracy of dimension of pieces are guaranteed after chemical milling is completed. By utilizing the theory that homogeneous substances of organic solvent are soluble, a metal base body and the damaged protection adhesive film are coated with the protection adhesive liquid, and the bonding force between the base body and the damaged protection adhesive film is improved. By means of the method for coating the chemical milling protection adhesive film during chemical milling, the airing time after coating is shortened, the thickness of the coated adhesive film is increased, and the bonding force between the base body and the adhesive film is good.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Tower-type melt granulation water-soluble fertilizer containing fulvic acid potassium macroelement and preparation method for fertilizer

ActiveCN103664301BNutrient balanceNutrient stabilityFertilizer mixturesEthylene diaminePotassium nitrate

The invention discloses a tower-type melt granulation water-soluble fertilizer containing fulvic acid potassium macroelement and belongs to the technical field of water-soluble fertilizers. The water-soluble fertilizer is prepared from the following raw materials in parts by weight: 490-510 parts of ammonium nitrate-phosphorus, 170 parts of nitrate potassium, 299-304 parts of monopotassium phosphate, 6 parts of boric acid, 3.3 parts of EDTA (ethylene diamine tetraacetic acid) zinc, 7.7 parts of EDTA ferrum, 4 parts of EDTA manganese and 0 to 15 parts of fulvic acid potassium. The tower-type melt granulation water-soluble fertilizer is balanced and stable in nutrition, has a smooth appearance, is difficult to harden, has a scientific and reasonable formula, is comprehensively nutritious and deserves to be popularized.

Owner:STANLEY AGRI GRP CO LTD

Impact-shaped composite spherical energy-dissipating structure for vertical hole blasting

ActiveCN106949797BSleek appearanceLittle effect of hole wall roughnessBlastingDetonationNuclear power

The invention provides an impacting-shaping composite spherical energy dissipation structure for vertical hole blasting. The energy dissipation structure comprises a composite spherical energy dissipation base and a buffer layer located below the composite spherical energy dissipation base, wherein the composite spherical energy dissipation base is of a double-layer structure which is soft externally and hard internally or hard externally and soft internally from outside to inside. According to the energy dissipation structure, under the action of an initial impact load after explosive detonation in a blast hole, the composite spherical energy dissipation base generates secondary plasticity, finally an ellipsoidal or a concave-shaped rigid cushion block reflects most of the explosion energy which is propagated in the rock mass below the hole bottom, meanwhile, the composite spherical energy dissipation base and the buffer layer absorb partial explosion energy in the deformation process, and therefore the rock on the foundation surface can be broken, the rock on the hole bottom can be protected, and the existing horizontal pre-cracking or smooth blasting technology can be partially replaced. The energy dissipation structure is simple and convenient to install, can partially replace the existing horizontal pre-cracking or smooth blasting technology and is suitable for protecting layer rock mass blasting excavation in the fields of water conservancy and hydropower, nuclear power, traffic and the like.

Owner:WUHAN UNIV

A kind of water-soluble fertilizer containing seaweed essence and expanding fruit type macroelement and preparation method thereof

ActiveCN104261952BNutrient balanceNutrient stabilityNitrate fertilisersPotassium fertilisersPotassium nitrateAgricultural science

The invention discloses a water-soluble fertilizer containing seaweed fine puffed fruit and a preparation method thereof, belonging to the technical field of water-soluble fertilizers. The raw material components are as follows, all in parts by mass: 373-400 parts of ammonium phosphorus nitrate, 100-250 parts of potassium nitrate, 100-150 parts of potassium dihydrogen phosphate, 120-290 parts of potassium sulfate, 1-6.5 parts of boric acid, EDTA Chelated zinc 1-5.0 parts, EDTA chelated iron 1-5.0 parts, EDTA chelated manganese 1-5.0 parts, seaweed essence 1-7 parts. The present invention aims at the deficiencies of the prior art, on the basis of the tower-type melt granulation compound fertilizer device, combined with the actual situation of the current water-soluble fertilizer with a large number of elements, the fertilizer obtained by scientific and reasonable formula is balanced and stable in nutrition, smooth in appearance, and not easy to harden , fast dissolution, no residue, scientific and reasonable formula, high efficiency and safety, comprehensive nutrition.

Owner:STANLEY AGRI GRP CO LTD

Method and apparatus for manufacturing reducing pipe

InactiveCN1234480CSleek appearanceIncrease productivityDrawing diesEngine componentsControl systemEngineering

The invention relates variable aperture tube making method and device, including tube end rotary forging and draw stretching. It first forges one end of the tube on the rotary forger into a smaller-aperture technical tube, which makes the stretching mould through to be clamped by the clamping module; using a hydraulic control system to drive clamping base and clamping module; inserting core rod with mould head in the copper tube to stretch by the stretching mould. It includes rotary forger and draw-stretching device. The clamping module, the stretching mould and the core rod makes up a stretching process line. The position of the core rod is adjustable and the stretching effect is good. The hydraulic control system is installed with travel switch to control stretching travel. It is applied to the control of thin-wall small-aperture copper tube and widely applied to cryogen pipeline in refrigerating industry.

Owner:广州冠华金属精工制造有限公司

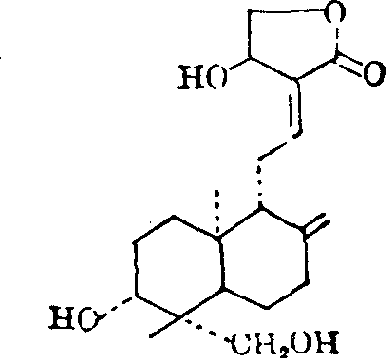

Andrographolide soft capsule and preparing method thereof

InactiveCN1287786CDisintegrates quicklyImprove bioavailabilityOrganic active ingredientsCapsule deliveryVegetable oilAdjuvant

Owner:XIAN CHIHO PHARMA

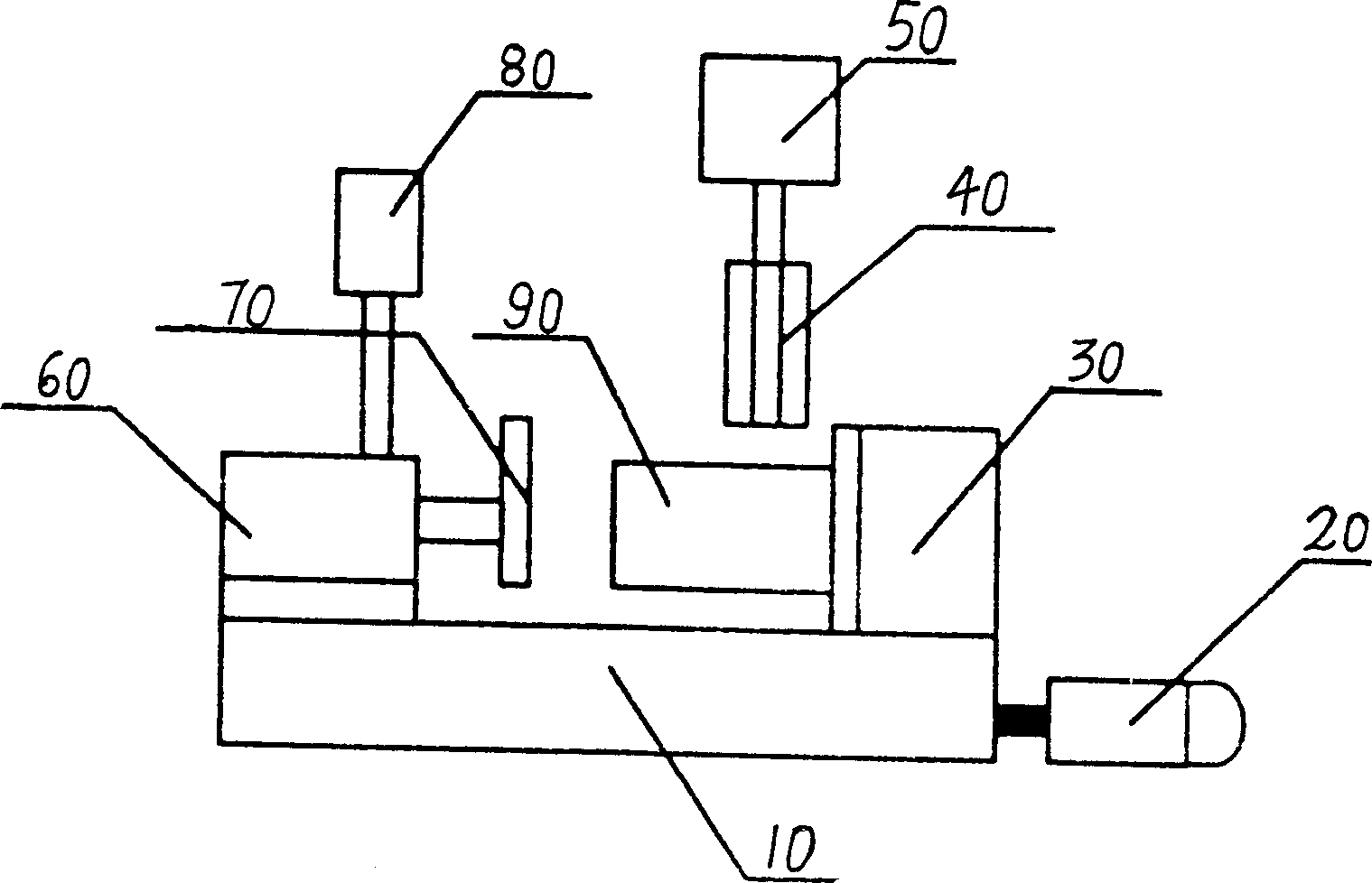

Bending method of to-be-bent pipe fitting for spraying atomization in deodorization equipment

ActiveCN112742932ASleek appearanceReduce investmentAir quality improvementPipe fittingStructural engineering

The invention discloses a bending method of a to-be-bent pipe fitting for spraying atomization in deodorization equipment. The bending method comprises the following steps that firstly, a positioning support is fixed to a bench vice; secondly, the front end of the to-be-bent pipe fitting penetrates through a pipe bending hole, and the to-be-bent position of the to-be-bent pipe fitting is located at the pipe bending hole; thirdly, a movable screw rod is inserted into an inner hole of the to-be-bent pipe fitting, and a tightening nut is adjusted to enable a supporting ball to be located at the pipe bending hole; fourthly, the right hand applies force through a force applying rod to enable a fixed and movable pulley fixing rotary arm to rotate outwards around a first positioning shaft, and the left hand rotates the tightening nut to enable the supporting ball to be located at the stressed part of the bent pipe fitting all the time; and fifthly, the to-be-bent pipe fitting is bent to the needed angle. By means of the bending method of the to-be-bent pipe fitting for spraying atomization in the deodorization equipment, it can be guaranteed that the bent pipe part is not flat, not wrinkled and not broken, the appearance is smooth, the method is very suitable for product trial-manufacturing and small-batch production, manual operation is easy, investment is small, and the effect is fast.

Owner:ZHEJIANG AIKELE ENVIRONMENTAL PROTECTION

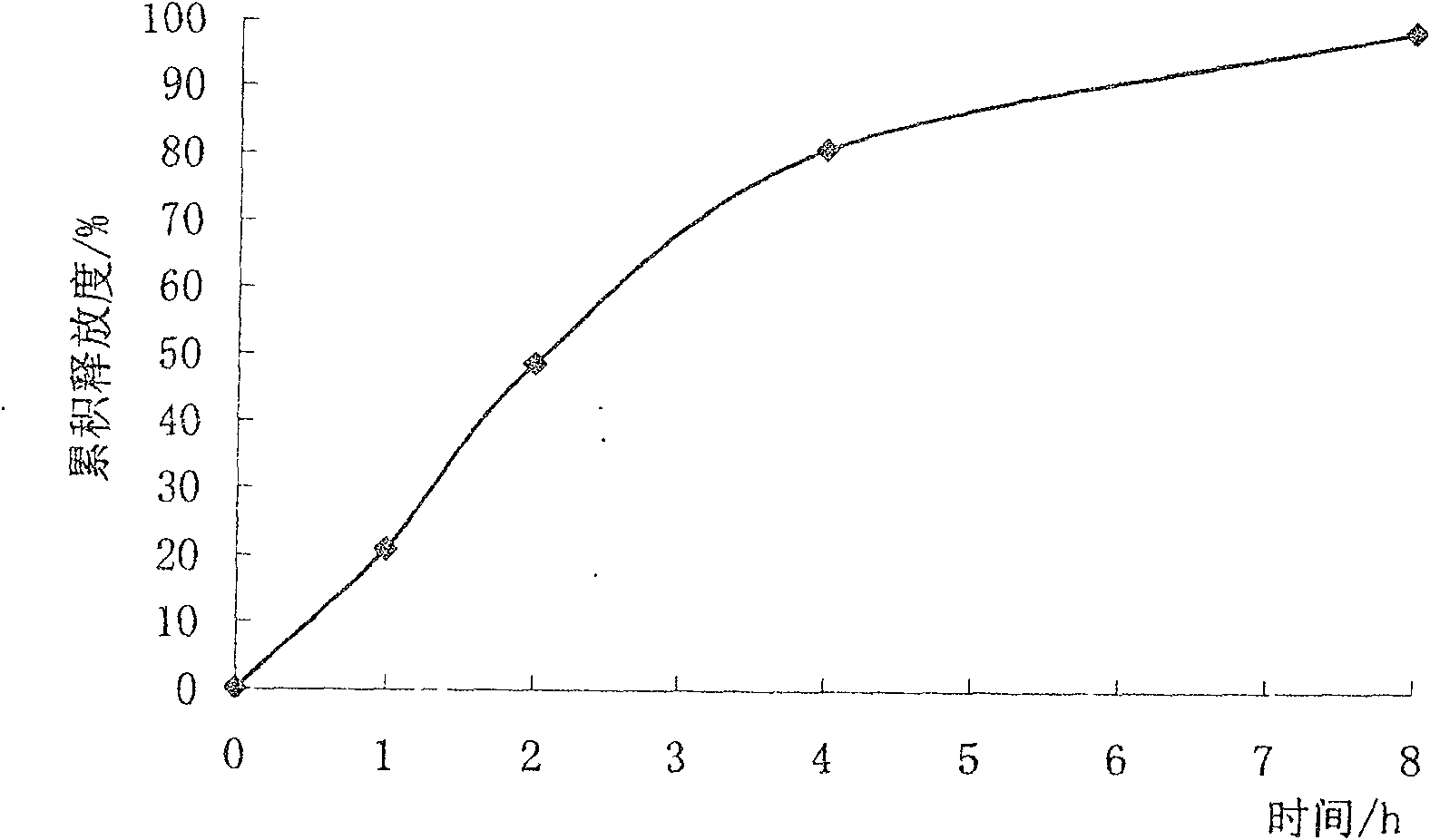

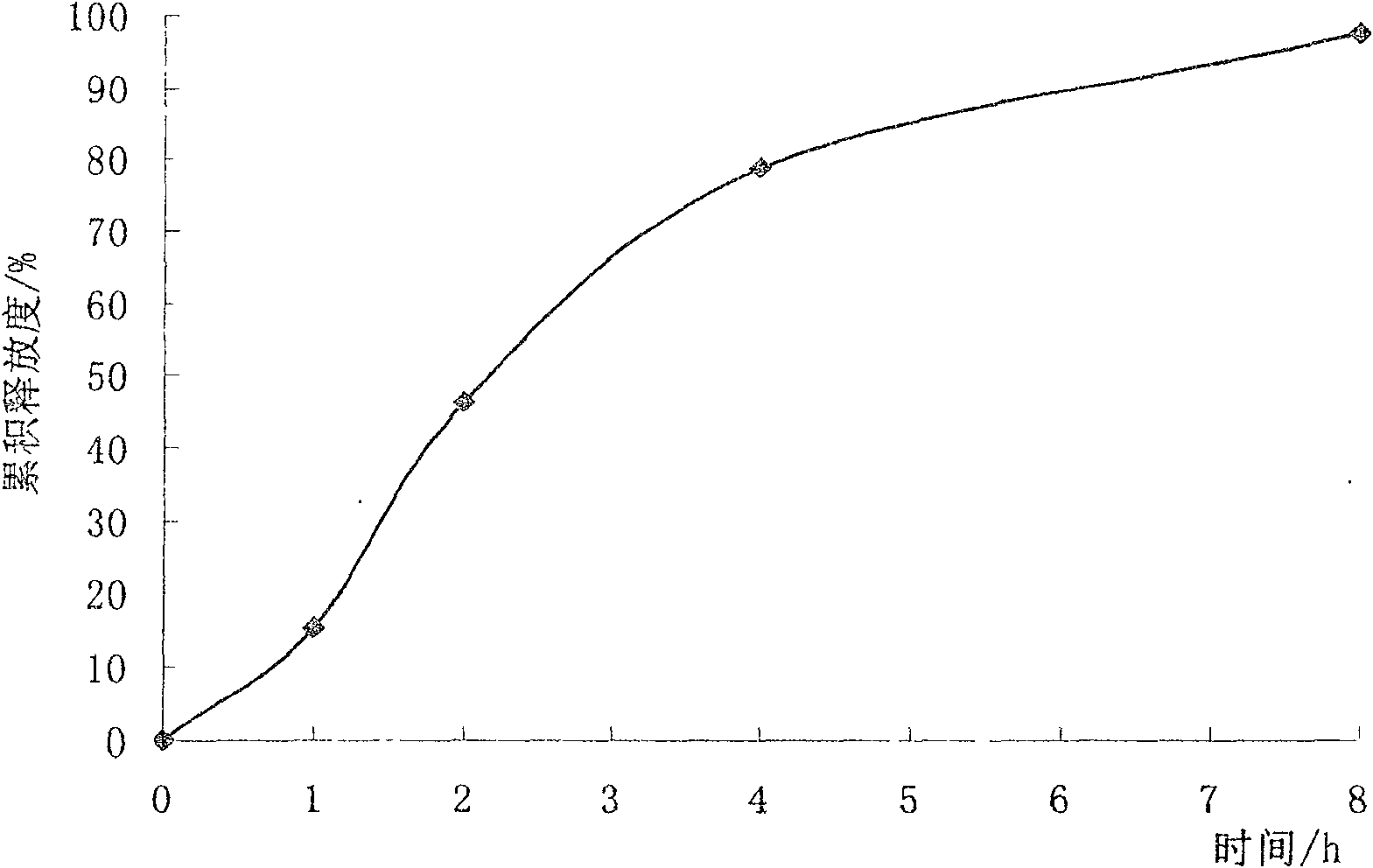

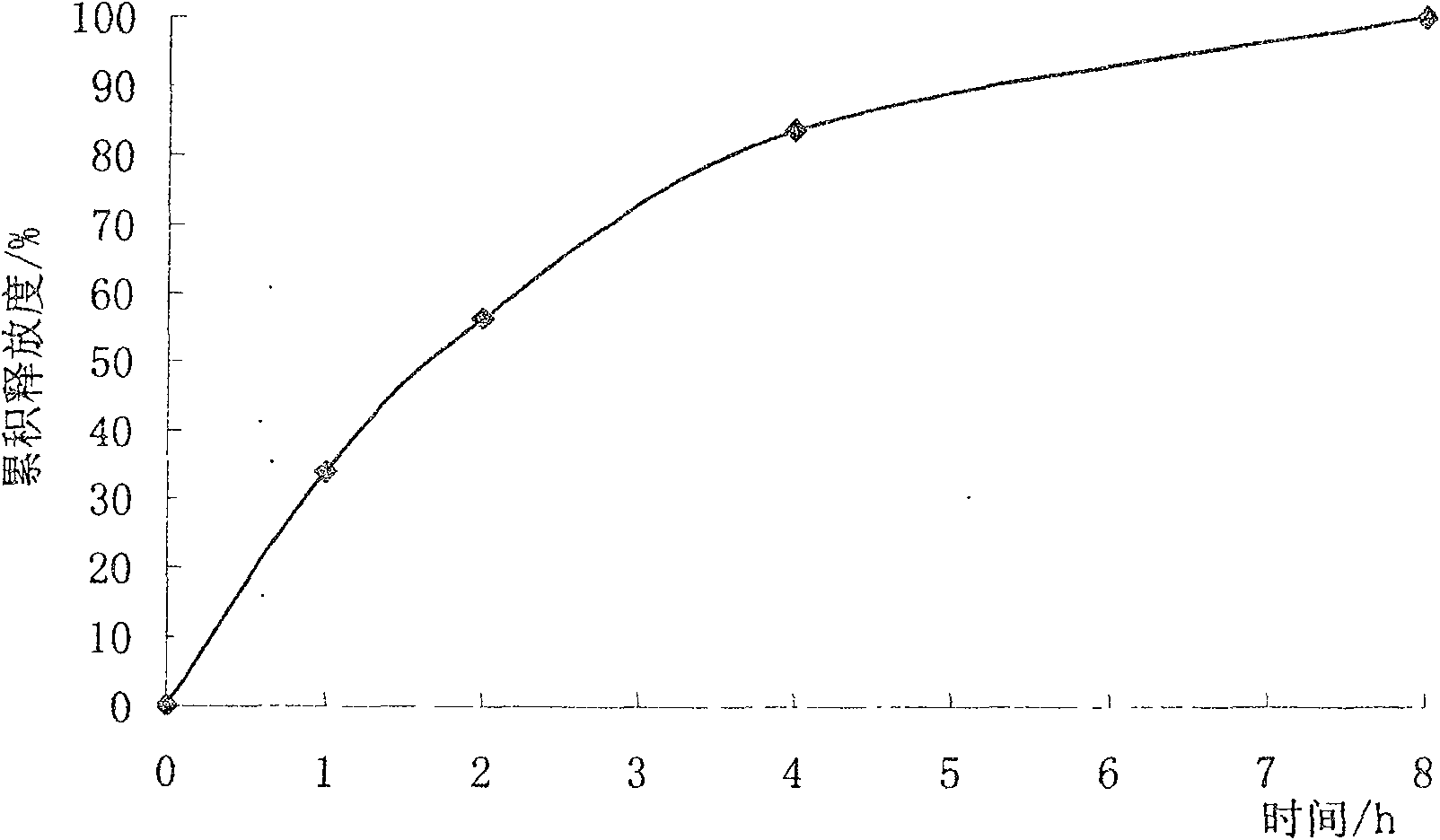

Sustained-release micro-pellet of trimetazidine and preparation process thereof

InactiveCN100571703CImprove liquidityUniform absorption rate in the bodyOrganic active ingredientsPharmaceutical non-active ingredientsSustained release pelletsMedicine

The invention relates to a slow-release micro drop whose active component is Humeitashen or other salt, wherein it is formed by element and film layer that controlling the drug release, whose weight ratio is 20:1-5:1; the Humeitashen content of element is 10-60%. The invention mainly uses protrusion method to prepare drop, and uses fluidize bed to pack.

Owner:SHANDONG INST OF PHARMA IND

Bent pipe machining device of small-diameter thin-walled pipe for spraying and atomizing in deodorization equipment

PendingCN112642894ASleek appearanceEasy to operate by handMetal-working feeding devicesPositioning devicesThin walledBatch production

The invention discloses a bent pipe machining device of a small-diameter thin-walled pipe for spraying and atomizing in deodorization equipment, the bent pipe machining device comprises a positioning bracket, a fastening assembly, a first positioning shaft, a fixed and movable pulley fixing rotating arm, a fixed pulley and a movable pulley, and the peripheries of the fixed pulley and the movable pulley are respectively provided with a circular arc groove matched with the outer wall of a to-be-bent pipe fitting. One end of the to-be-bent pipe fitting penetrates through a pipe bending hole and is fastened to the fastening assembly, the to-be-bent position of the to-be-bent pipe fitting is located at the pipe bending hole, and a supporting ball at the front end of a movable screw rod is always located at the stressed position of the pipe bending hole by adjusting a tightening nut. The bent pipe machining device of the small-diameter thin-walled pipe for spraying and atomizing in the deodorization equipment can ensure that the bent pipe part is not flat, wrinkled or broken, the appearance is smooth, and the bent pipe machining device is very suitable for trial production of products and small-batch production, simple in manual operation, low in investment and quick in effect taking.

Owner:ZHEJIANG AIKELE ENVIRONMENTAL PROTECTION

Mouth reducing maching for packaging steel bucket

The present invention relates to the field of packing container producing equipment technology and is especially a kind of mouth reducing machnie for completing the steps of reducing mouth, flanging and rolling ribs. The technological scheme is to connect the feeding cylinder for the control of forming roller to the forming roller. The present invention can raise the forming speed, produce smooth necking and prevent thinning of the sheet during formation.

Owner:东莞振华泰丰实业发展有限公司

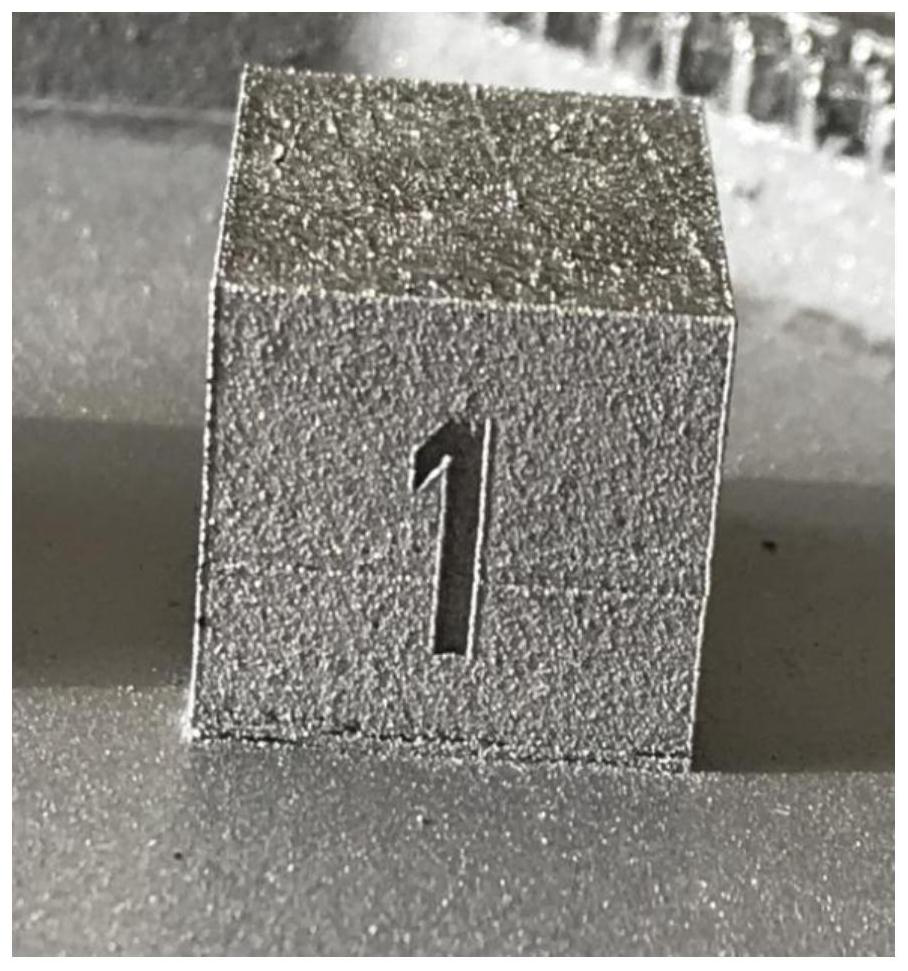

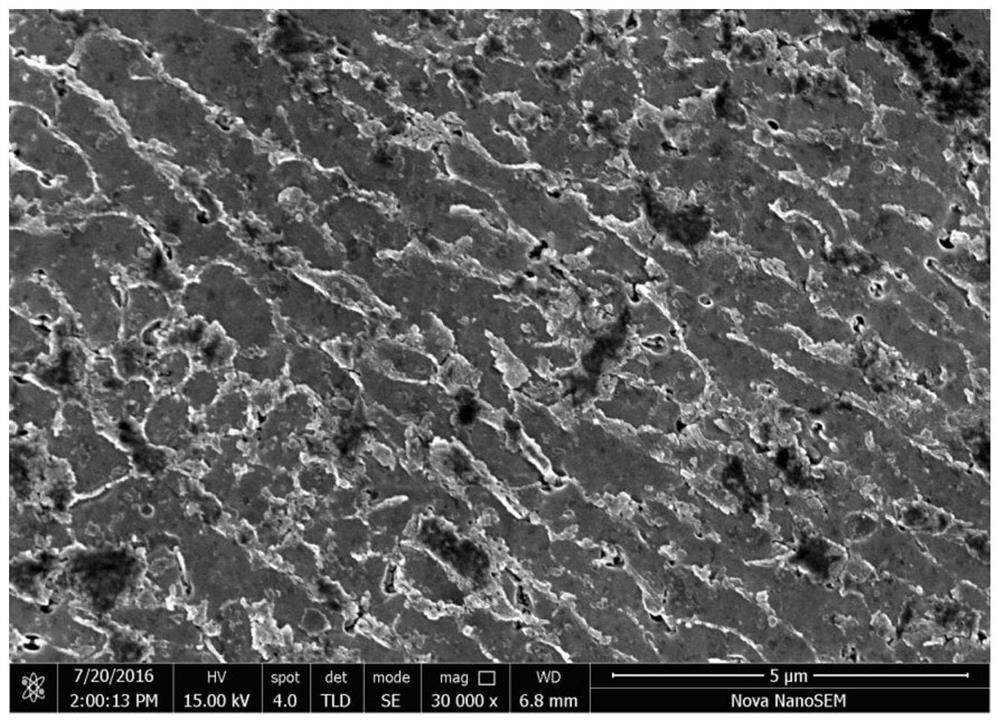

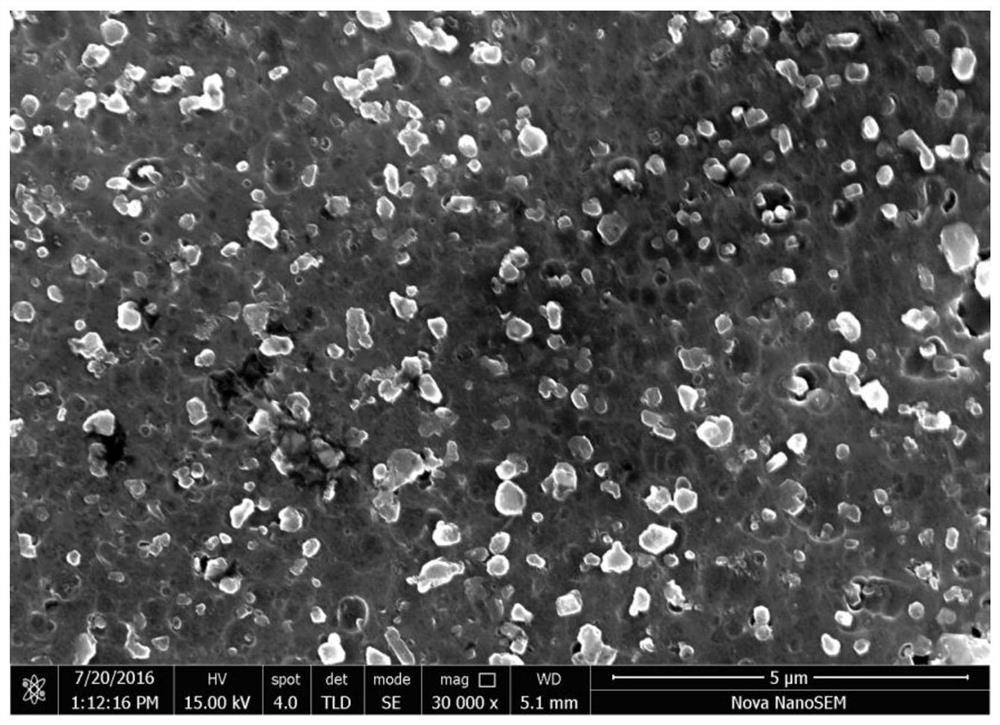

Method for modifying eutectic silicon in aluminum alloy prepared by SLM

ActiveCN112775439ARealize metamorphic effectShape is easy to controlAdditive manufacturing apparatusManufacturing technologyMetallic materials

The invention discloses a method for modifying eutectic silicon in aluminum alloy prepared by SLM, and belongs to the field of metal material additive manufacturing. The method comprises the following steps that A, aluminum alloy powder is prepared into an aluminum alloy workpiece through SLM; and B, in the process of preparing the aluminum alloy workpiece through SLM, the aluminum alloy workpiece is subjected to thermal vibration treatment; and the specific operation of the thermal vibration treatment comprises the steps that after each printing period, a substrate and an inner cavity of SLM equipment is heated, heat preservation is conducted and then cooling is conducted to a preheating temperature of the substrate until the aluminum alloy workpiece is prepared. According to the method, the modification effect of the eutectic silicon is realized by adopting a thermal vibration treatment mode in the SLM process, the treated eutectic silicon structure presents a fine and smooth appearance, and no defects such as holes and cracks are found in the material. According to the method, no additional chemical elements and additional mechanical fields need to be added, operation is easy, the process is easy to control, and huge potential is provided for application of the aluminum alloy additive manufacturing technology in the aerospace field.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Novel shell with reliable structure

ActiveCN114566012AFirmly connectedExtended service lifeApparatus for meter-controlled dispensingEngineeringStructural engineering

The invention relates to the field of twist egg machines, and discloses a novel shell with a reliable structure, which comprises a shell internally provided with a cavity for containing objects, an assembly opening is formed in the shell, a cover body is assembled in the assembly opening, and the cover body and the assembly opening are connected through a switch assembly. The switch assembly comprises a guide block arranged on the inner side of the assembly opening and a guide female part arranged on the lower side of the cover body and used for being matched with the guide block, and a guide groove is formed in the guide female part. The guide groove is provided with an inlet for the guide block to enter, when the guide block slides into the guide groove in a matched mode, limiting locking in the vertical direction is achieved between the guide block and the guide groove, and the first spherical shell and the second spherical shell can rotate around the connecting piece. After the first spherical shell and the second spherical shell are covered, an assembly opening is formed in one end, and the cover body and the shell are locked up and down to form an integral structure. The shell has the advantages of being attractive in appearance, reliable in structure, round in overall surface, high in interestingness and the like.

Owner:酉阳土家族苗族自治县知识产权服务中心

Organic manure special for farm products and preparation method thereof

InactiveCN1272288CWide variety of sourcesLarge reservesFertiliser formsFertilizer mixturesAdhesiveBran

The invention discloses a green harmless special organic fertilizer for farm produces, mixed of natural humic acid, peanut bran powder, bean cake, tea-leaf, adhesive, acid salt tolerance and regulating substance in weight ratios of 10-40 shares, 20-30 shares, 10-20 shares, 10-40 shares, 10-15 shares, and 3-8 shares, respectively; and its preparing method: crushing materials, adding in adhesive and premixing, and refining by the process 'secondary making particles, secondary drying' to make it. It has uniform and smooth particles, no phenomena of 'dirty, foul, wet, loose', etc, and no pollution to the environment, and is rich in nutrient substances of N, P, K, amino acid, S, Zn, Fe, Ca, Mg, etc, and has a pH value at 5.0-8.5; the content of heavy metals, harmful germs, hormones and drug residues is low, and it has no radiation. It can remarkably improve the quality of farm, produces, improve soil structure, and be suitable for the standard production of green harmless farm produces.

Owner:广东省农业科学院土壤肥料研究所

Injection molding piece

InactiveCN102672874ASleek appearanceNo injection defectsCoatingsEngineeringInjection molding machine

Owner:KUSN TUOAN PLASTIC PRODS

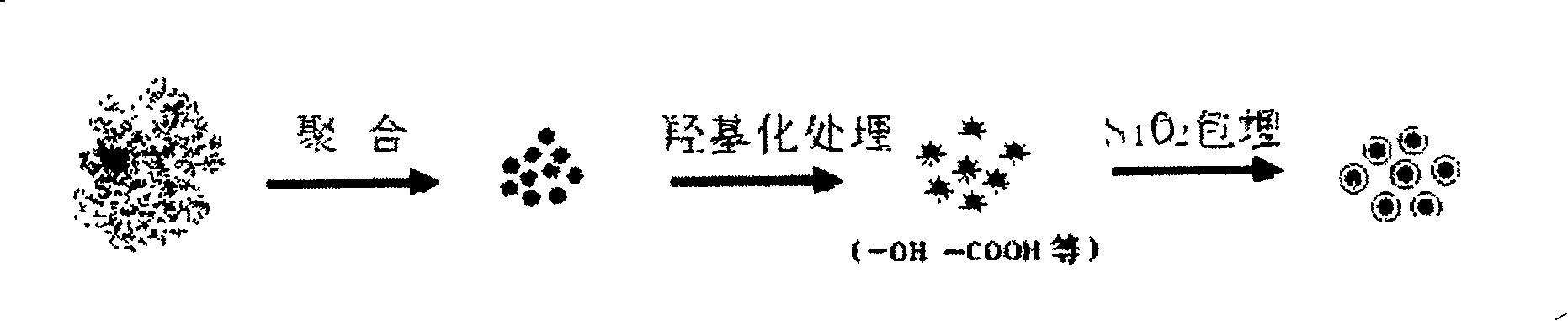

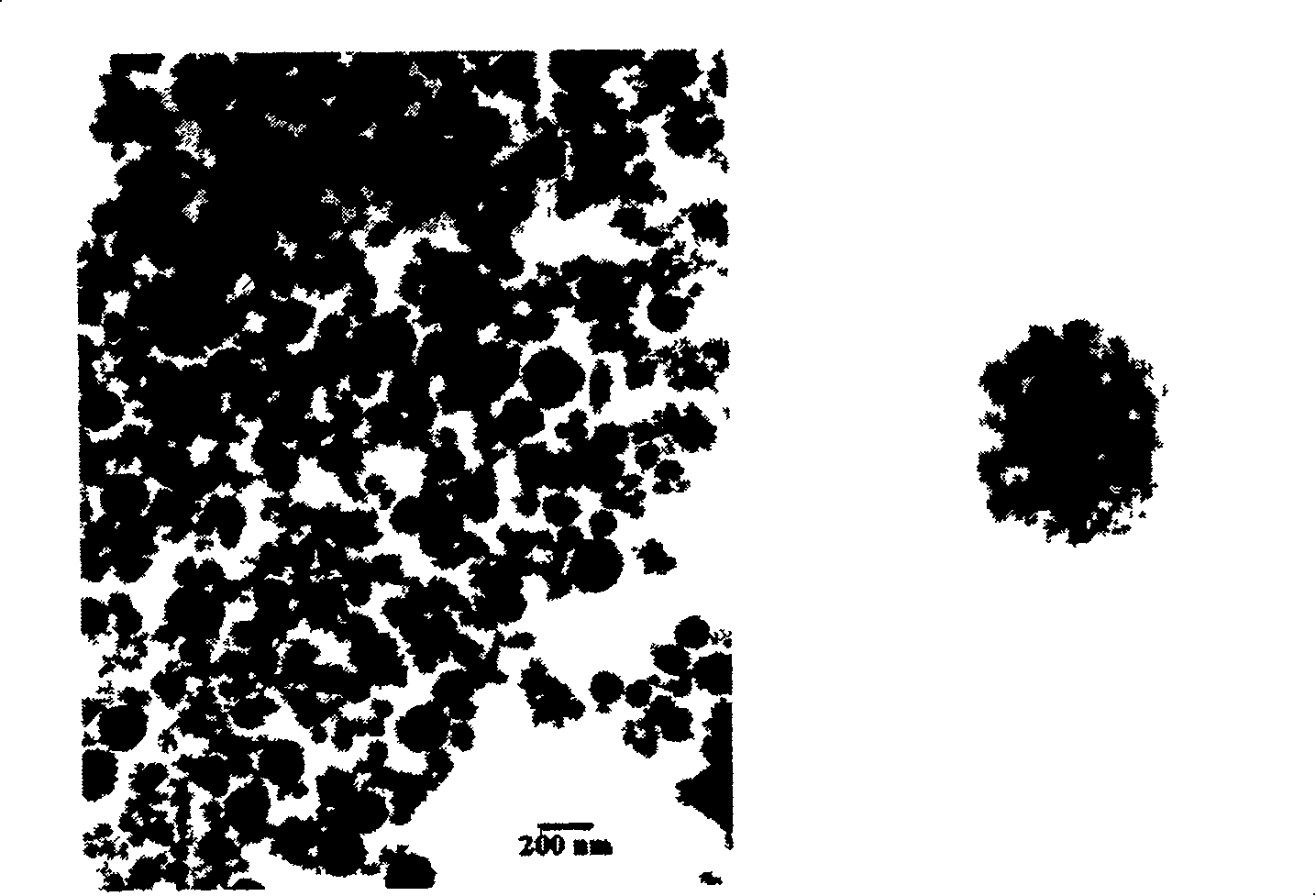

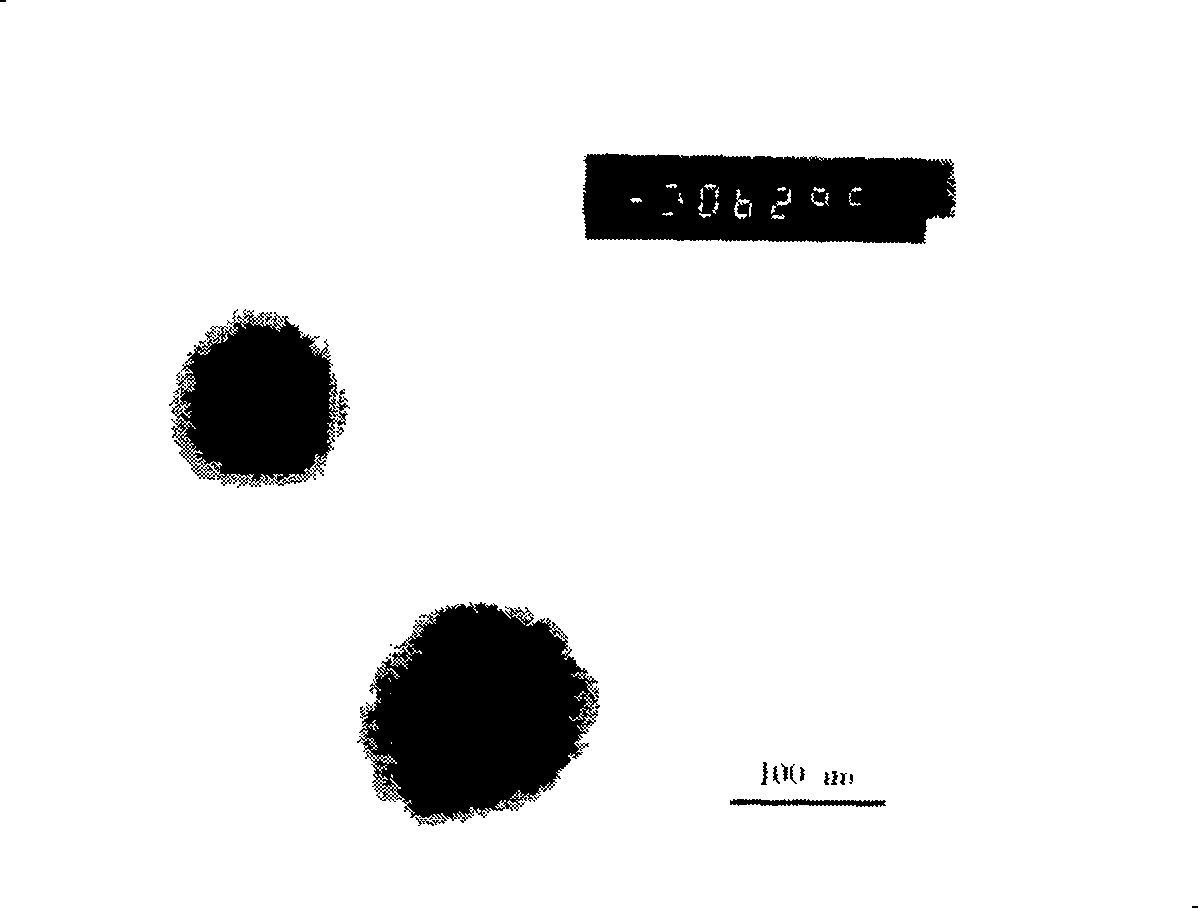

Method for preparing silicon dioxide embedded nano composite particles

InactiveCN100398493CIncrease the maximum amountNarrow particle size distributionInorganic material magnetismNanoparticleMethacrylate methyl

The invention is a method for preparing SiO2-coated magnetic nano composite particles, characterized in comprising the steps of: a. firstly preparing magnetic nano particles by codeposition process; b. coating the magnetic nano particles with vinyl acetate or methyl methacrylate, and then hydroxylating to obtain magnetic nano composite particles; c. coating the magnetic nano composite particles with SiO2. By hydroxylation of the magnetic particles, it can increase the maximum addition of magnetic particles in the reacting course, thus increasing the prepared quantity of the composite particles in Stober course, and the obtained composite particles are distributed narrowly and have round appearance, completely reaching the commercialization standard.

Owner:NANTONG DOUBLE GREAT TEXTILE +1

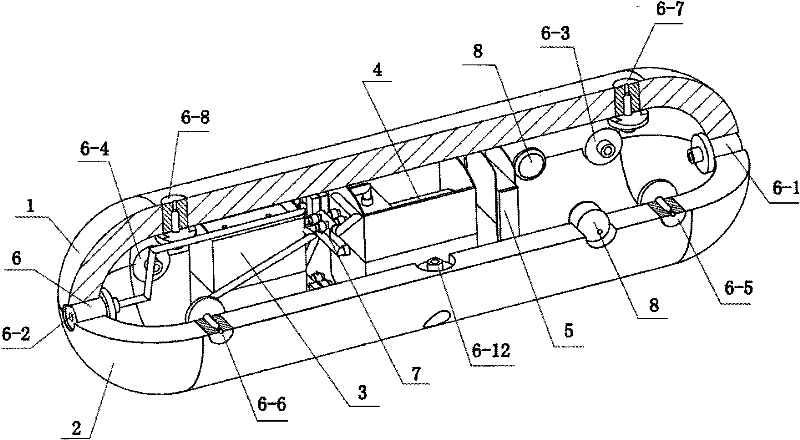

Jet flow-driven blood vessel robot

The invention discloses a jet flow-driven blood vessel robot, which consists of a capsule-shaped shell, a liquid flow control device, a wireless receiving control block (5) and an operating device (8), wherein the liquid flow control device, the wireless receiving control block (5) and the operating device (8) are arranged in the shell and use blood as a medium; the liquid flow control device consists of a variable pump (4), 12 suction and spray nozzles (6) and 24 two-position two-way electromagnetic valves (7); the inlet and outlet of each suction and spray nozzle (6) are connected with two pipes which are connected with a two-position two-way electromagnetic valve (7) in series respectively, one of the two pipes is connected with the inlet of the variable pump (4), and the other one of the two pipes is connected with the outlet of the variable pump (4); the 12 suction and spray nozzles (6) are embedded on the wall of the shell and the suction and spray openings face the outside of the shell; and the suction and spray nozzles (6) are cylinders, through holes are formed in the bodies axially, one end of each through hole is an access hole and the other end of the through hole is an inward contracted micro suction and spray nozzle. The jet flow-driven blood vessel robot of the invention is simple and convenient in control and can move flexibly.

Owner:GUANGZHOU UNIVERSITY

Tower-type melt granulation fertilizer special for improvement of acid soil and preparation method thereof

InactiveCN105348015ANutrient balanceNutrient stabilityOrganic fertilisersSolid/semi-solid fertilisersSoil qualityChloride

The invention discloses tower-type melt granulation fertilizer special for improvement of acid soil and a preparation method thereof, belonging to the technical field of agricultural fertilizer. The fertilizer is prepared from urea, calcium magnesium phosphate, potassium chloride, potassium humate and filler. According to the tower-type melt granulation fertilizer special for improvement of acid soil, provided by the invention, aiming at the defects of the prior art, on the basis of a tower-type melt granulation compound fertilizer facility, the fertilizer is scientifically and reasonably prepared by combining the actual condition of the acid soil, and has the advantages of being balanced in nutritive substances, stable, smooth in appearance, and not easy to harden; the acid soil can be improved, and the soil acidity can be reduced; the formula is reasonable, the nutrition is comprehensive. The fertilizer can be used for comprehensively improving the acid soil, and improving the soil quality to increase the yield of crops.

Owner:STANLEY AGRI GRP CO LTD

Heating milk bottle with handle and using method

The invention discloses a heating milk bottle with a handle and a using method. The heating milk bottle consists of a bottle body, a bottle cap and a nipple. The heating milk bottle is characterized in that: the middle upper part of the bottle body has slender waist-shaped deformation, 1 to 2 clamping grooves are processed on the slender waist-shaped upper and lower parts, the arc handle is arranged on the clamping grooves, and the outer side of the handle is 10 millimeters lower than the outer side of the bottle body. The handle can be detached freely. The outside wall of a heater at the bottom of the bottle body is provided with a DC / 3V power supply jack. The heating milk bottle can meet milk drinking of an infant, also can meet grabbing exercise of the infant, and meanwhile can heat the milk in the bottle.

Owner:徐紫宸

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com