Arc grinding device with balanced driven disc

A grinding and balancing technology, applied in the direction of grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve problems such as time-consuming and laborious, poor product appearance, harsh working environment, etc., to achieve protection of the working environment, smooth transition of appearance, and product quality Good looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

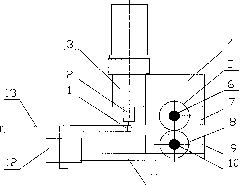

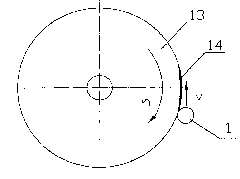

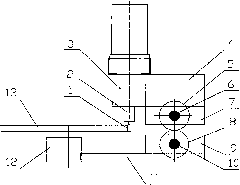

[0018] according to figure 1 , figure 2 As shown, a circular arc grinding device with driven disk balance includes: a tool 1, a tool holder 2 and a power head 3, as well as a radial slider 4, a first gear 5, a first screw 6, an upper slide Seat 7, second gear 8, slide seat 9, second screw mandrel 10, rack 11 and the 3rd gear 12.

[0019] The power head 3 is fixedly connected with the radial slider 4 .

[0020] The radial slider 4 is slidably connected with the upper sliding seat 7 , and the transmission rack 11 is slidably connected with the lower seat 9 .

[0021] The first threaded mandrel 6 is threaded with the upper sliding seat 7 , and the second threaded mandrel 10 is threaded with the lower seat 9 .

[0022] The first gear 5 is meshed with the second gear 8 , and the rack 11 is meshed with the third gear 12 .

[0023] The first threaded mandrel 6 is connected with the first gear 5 , and the second threaded mandrel 10 is connected with the second gear 8 .

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com