Novel shell with reliable structure

A shell and reliable technology, applied in the field of gashapon machines, can solve the problems of blasting damage, breakage, and easy jamming of the spherical shell, and achieve the effect of avoiding excessive use, prolonging the service life, and being highly interesting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

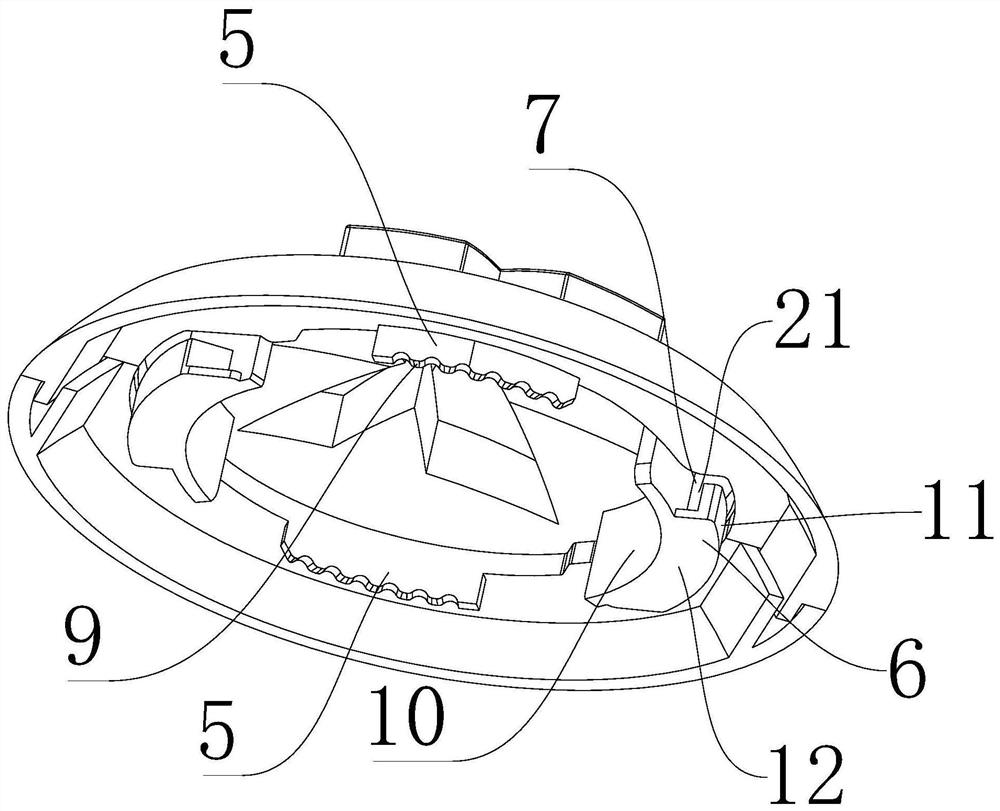

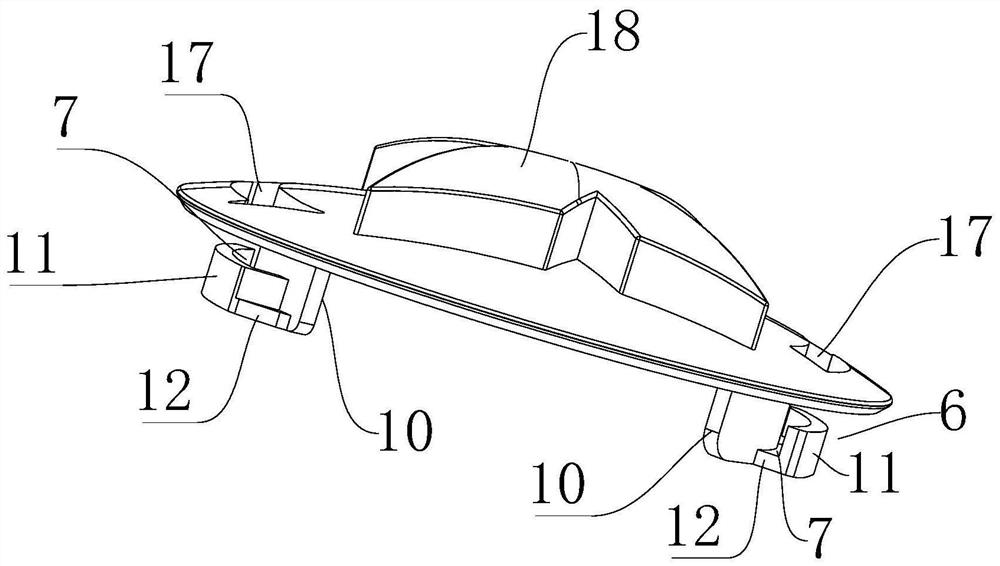

[0034] A new type of housing with reliable structure, including a housing 1 with a cavity for holding objects inside, the housing 1 is provided with an assembly port 2, the assembly port 2 is equipped with a cover body 3, the cover body 3 and the assembly port 2 are connected by a switch assembly 4. The switch assembly 4 includes a guide block 5 arranged inside the assembly port 2 and a guide female part 6 arranged on the lower side of the cover body 3 for matching with the guide block 5. The guide mother part 6 The guide groove 7 is provided with the guide groove 7; the guide groove 7 is provided with an entrance 21 for the guide block 5 to enter, and when the guide block 5 is matched and slid into the guide groove 7, the guide block 5 and the guide groove 7 realize the limit in the up and down direction. Locked, the cover 3 and the housing 1 are locked up and down to form an integral structure. The eggshell described in this embodiment is a combined structure of the cover bo...

Embodiment 2

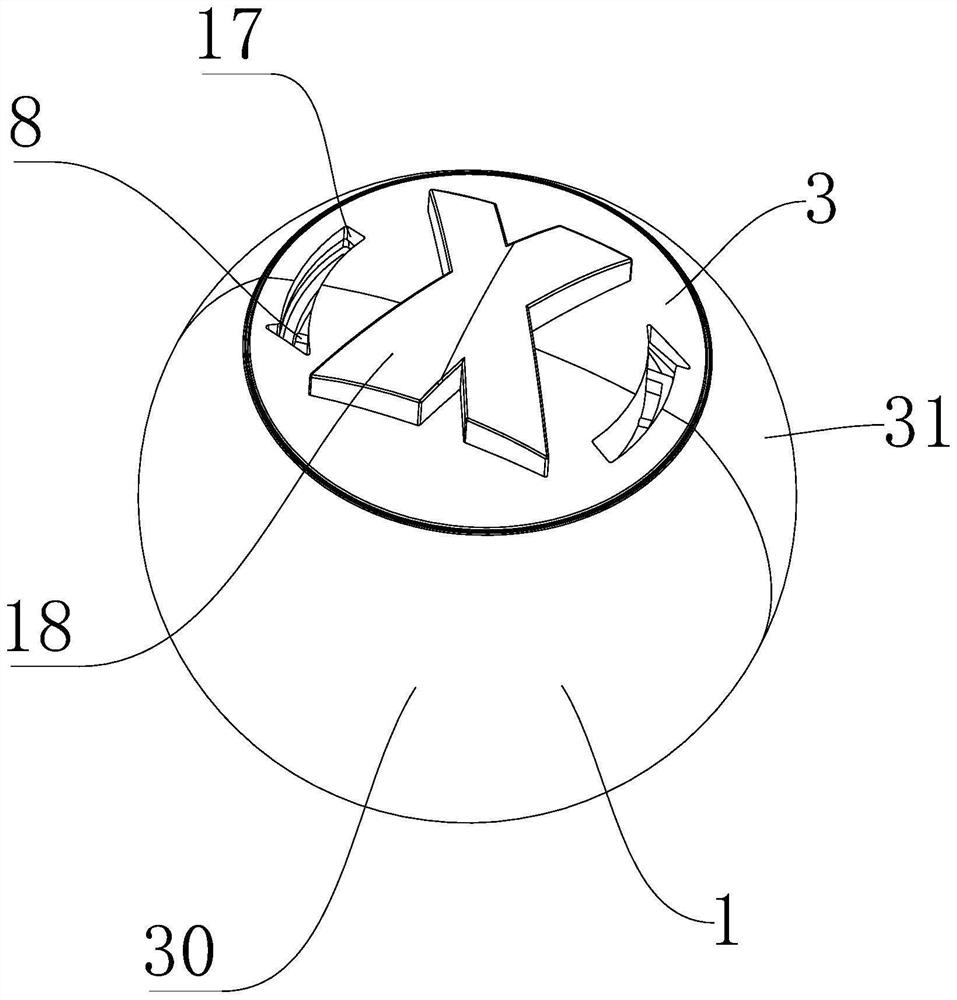

[0055] The difference between this embodiment and Embodiment 1 is that: in order to ensure the installation reliability and airtightness of the first spherical shell 30 and the second spherical shell 31, the first spherical shell 30 includes the first spherical shell 30 arranged along its edge. An assembly surface 301, the second spherical shell 31 includes a second assembly surface 311 arranged along its edge, the first assembly surface 301 is provided with a slot 302 along its shape track, and the second assembly surface 311 is provided with a plug-in groove along its shape track. Strip 312, when the first spherical shell 30 and the second spherical shell 31 are assembled, the insertion strip 312 is inserted into the slot 302, and the first assembly surface 301 and the second assembly surface 302 fit together so that the first spherical shell 30 and the second spherical shell Shell 31 forms a complete sphere. Wherein, the embedding groove 302 is an arc-shaped groove arranged...

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 is that: the outer surface of the cover body 3 is provided with an operation groove that is convenient for rotating the cover body 3 . Therefore, there is no raised part in the overall appearance of the cover body 3 , and the appearance is beautiful and round.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com