Sustained-release micro-pellet of trimetazidine and preparation process thereof

A technology for sustained-release pellets and trimetazidine, which is applied in pharmaceutical formulations, medical preparations with non-active ingredients, cardiovascular system diseases, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 preparation containing pill core

[0057] (1) Prescription:

[0058] Trimetazidine Hydrochloride 250g

[0059] Microcrystalline Cellulose 750g

[0060] 50% ethanol appropriate amount

[0061] (2) Preparation process:

[0062] Get trimetazidine crude drug, pulverize and pass through a 100-mesh sieve, add microcrystalline cellulose, and fully mix; add an appropriate amount of wetting agent (such as 50% ethanol) to the mixed material to make soft material; Put it into the extruder and extrude it into a strip-shaped extrudate; quickly add the extrudate to the spheronizer for spheronizing, and take it out after a certain period of time to make pellets; bake the prepared pellets at 50°C for 3~ After 6 hours, dry pellets were obtained. Results The micropills were smooth and spherical in appearance. At this time, capsules could be filled directly or film-coated with water-soluble coating materials to obtain immediate-release micropills.

Embodiment 2

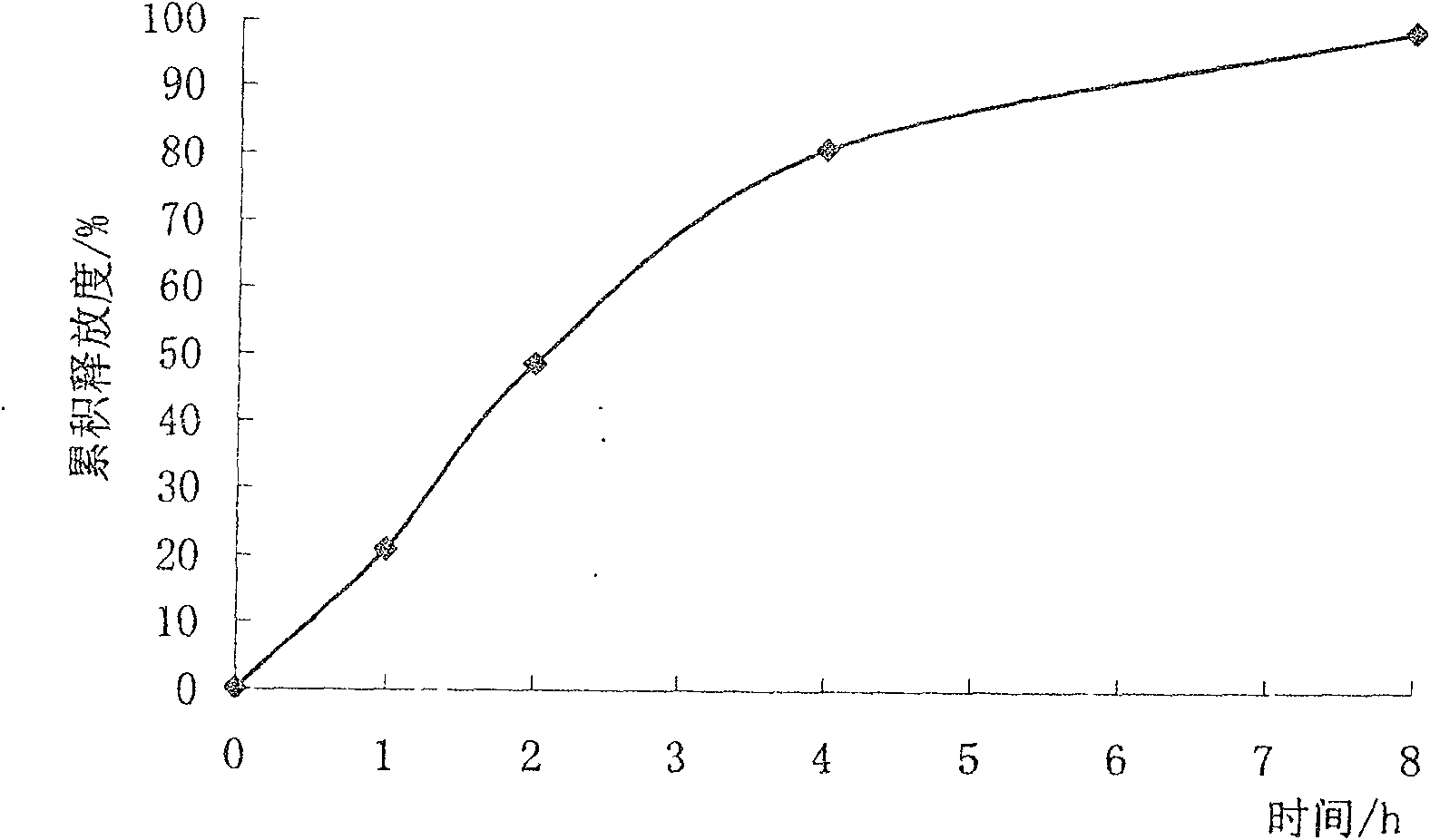

[0064] Coat the pellet core (that is, uncoated immediate-release pellets) prepared in Example 1 with Kollicoat SR 30D to obtain trimetazidine sustained-release pellets.

[0065] (1) Prescription of coating solution:

[0066] Kollicoat SR 30D 100g

[0067] Propylene glycol 3g

[0069] water 250g

[0070] (2) Preparation process:

[0071] Mix Kollicoat SR 30D and water evenly, add propylene glycol and talcum powder, stir at high speed and homogenize to obtain the coating solution. Using low-spray micro-fluidized bed equipment, add 120 g of uncoated trimetazidine immediate-release pellets of 18 to 24 meshes into the fluidization chamber, use a spray gun with a nozzle diameter of 1 mm, and adjust the fan frequency converter to make the blast flow approx. 125L·min-1, so that most of the pellets are blown up 7-12cm in the fluidization chamber, the atomizing gas pressure is adjusted to 0.2Mpa, and the flow rate of the constant flow pump is 0.9-1.2mL·min-...

Embodiment 3

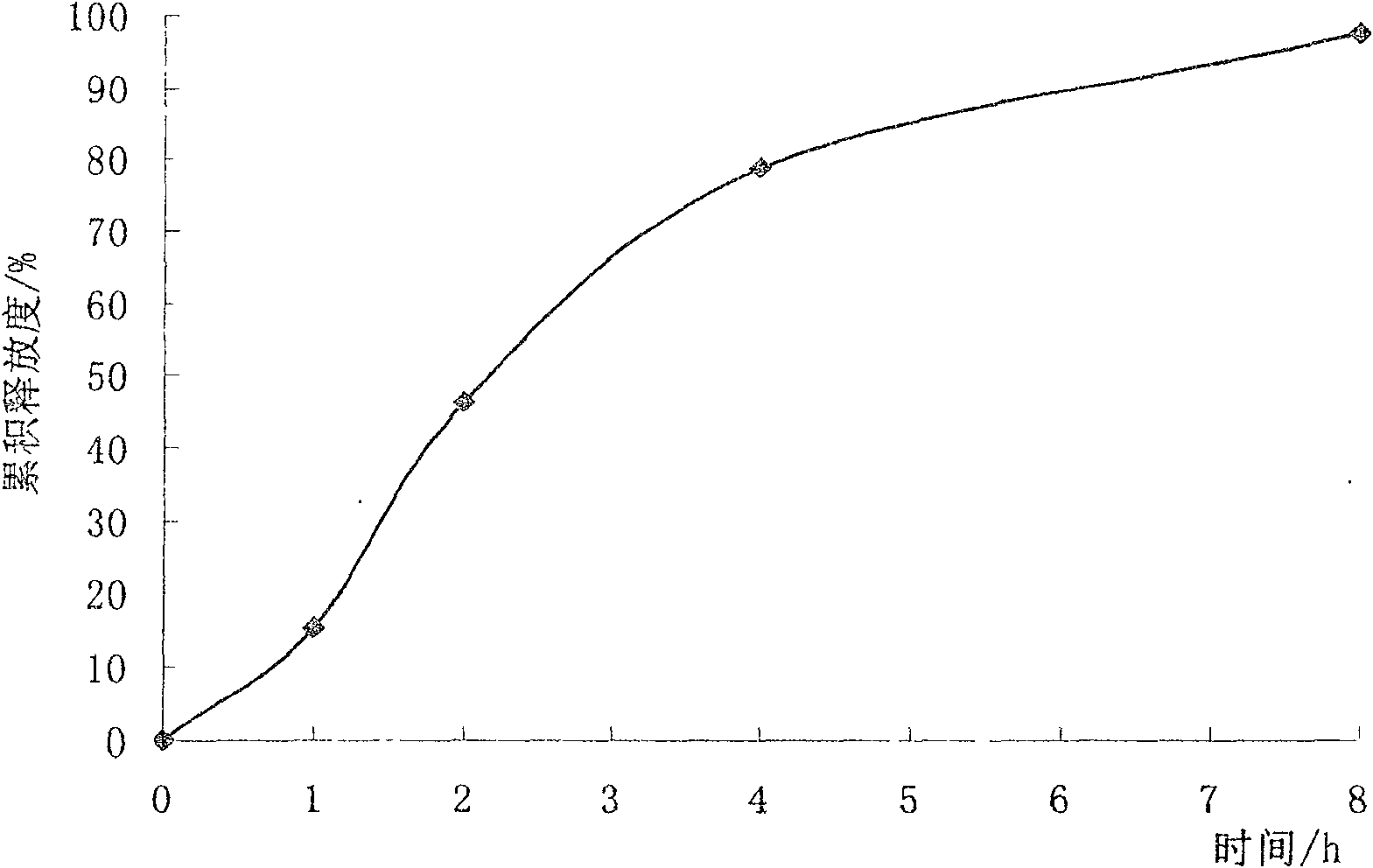

[0074] The drug-containing pellet cores (ie uncoated immediate-release pellets) prepared in Example 1 were coated according to the following coating solution prescription to obtain trimetazidine sustained-release pellets.

[0075] (1) Prescription of coating solution:

[0076] Eudragit NE 30D 100g

[0077] 5% HPMC solution 8mL

[0079] water 110g

[0080] (2) Preparation process:

[0081] Take Eudragit NE 30D, HPMC and talcum powder according to the above prescription, homogenize at a high speed, and then coat. After the clothes are finished, put them in a constant temperature oven at 40°C and dry them for 6 hours. Every capsule packs 150mg coated pellets (equivalent to trimetazidine hydrochloride 35mg), measures release rate with the method described in embodiment 2, the result is as follows figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com