Fully automatic efficient flour producing machine

A milling machine, fully automatic technology, applied in the direction of grain processing, etc., can solve the problems that the operation handle does not conform to the rationality of human operation, cannot ensure the safety of personnel operation, slips and cannot work continuously, and achieve unit output and benefit improvement, The effect of convenient air volume distribution and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

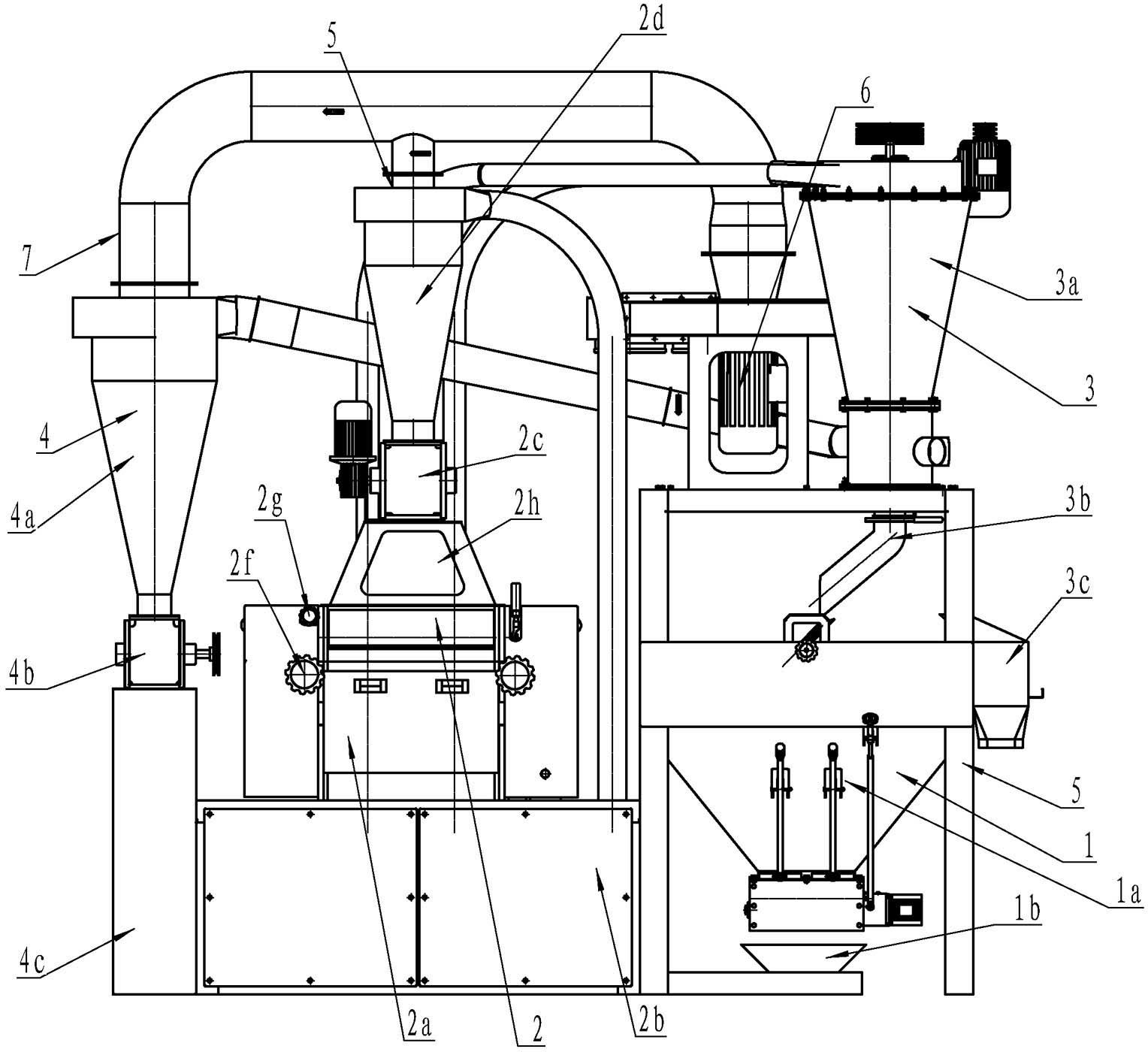

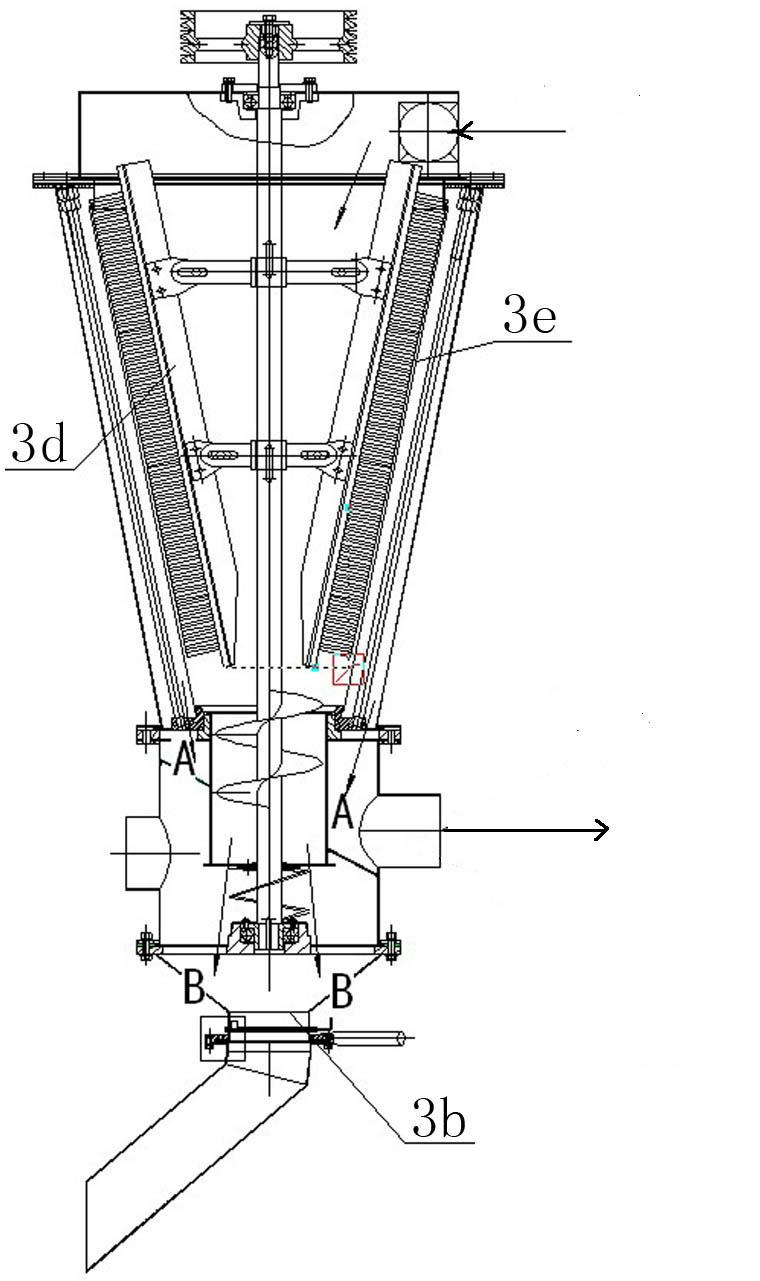

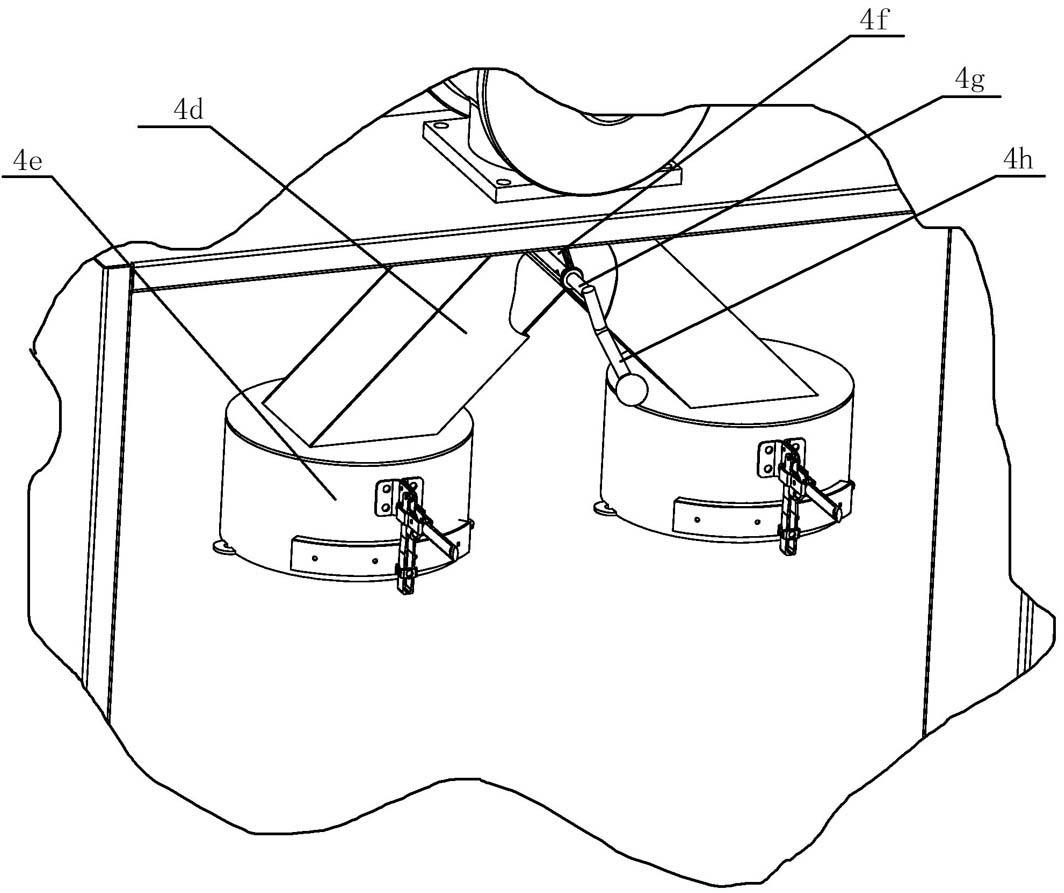

[0029] as attached figure 1 , 2 , 3, the present invention includes a frame 5, a feed feeding device 1 arranged on the frame 5, a milling device 2, a repeated screening device 3, a discharging bagging device 4, a centrifugal high-pressure blower 6 and various equipment rooms The connecting pipe of the feed feeding device 1 includes a large feeding hopper 1a and a material receiver 1b arranged at the outlet of the large feeding hopper 1a; the powder making mechanism 2 includes a single side mill 2a, a set The machine base 2b at the lower end of the unilateral pulverizer 2a, the fan shut-off assembly 2c arranged at the upper end of the unilateral pulverizer 2a, and the feeding Shacron 2d arranged at the upper end of the fan shut-off assembly 2c, the described feeding The top of the Shacron 2d is provided with a damper 2e, and the feeding Shacron 2d is connected with the material receiver 1b; the repeated screening device 3 includes a powder extraction device connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com