Impacting-shaping composite spherical energy dissipation structure for vertical hole blasting

A spherical, energy-dissipating seat technology, applied in blasting and other directions, can solve the problems of non-smooth hole wall, low construction efficiency, collision and friction of hole wall, etc., and achieve the effect of improving safety, easy operation, and speeding up construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

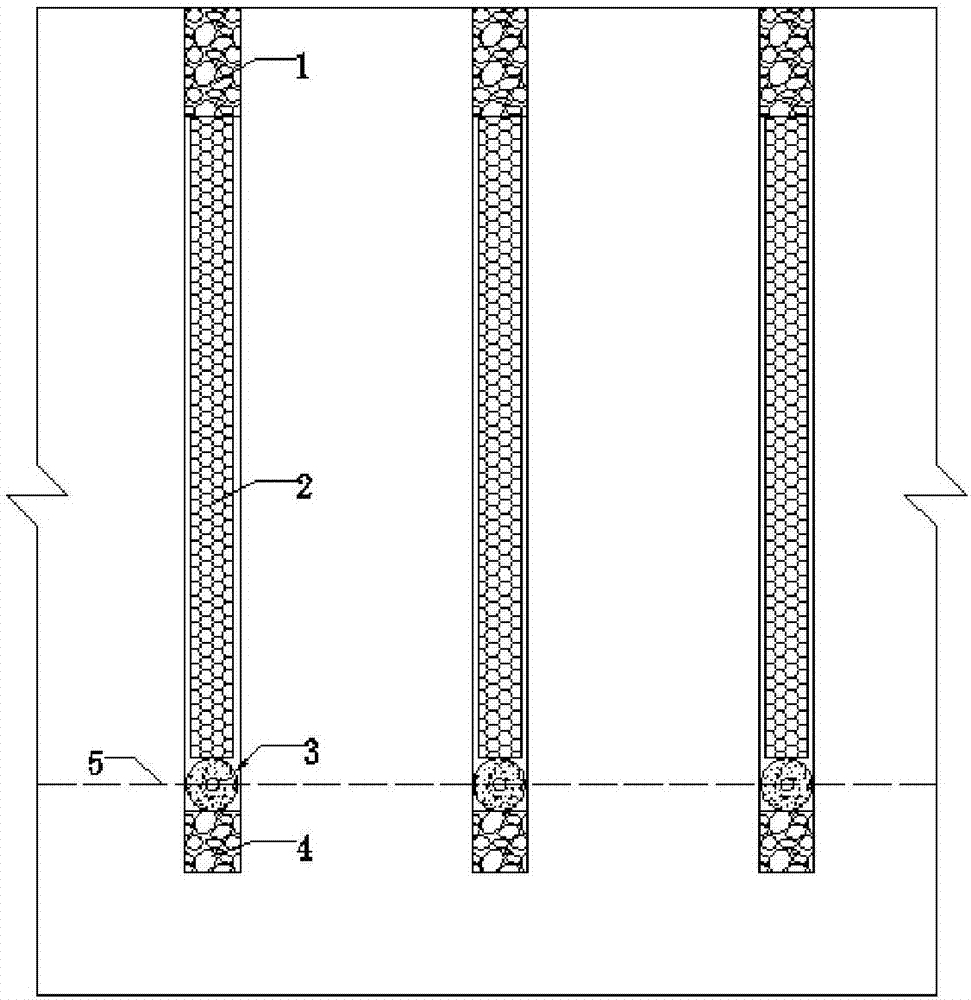

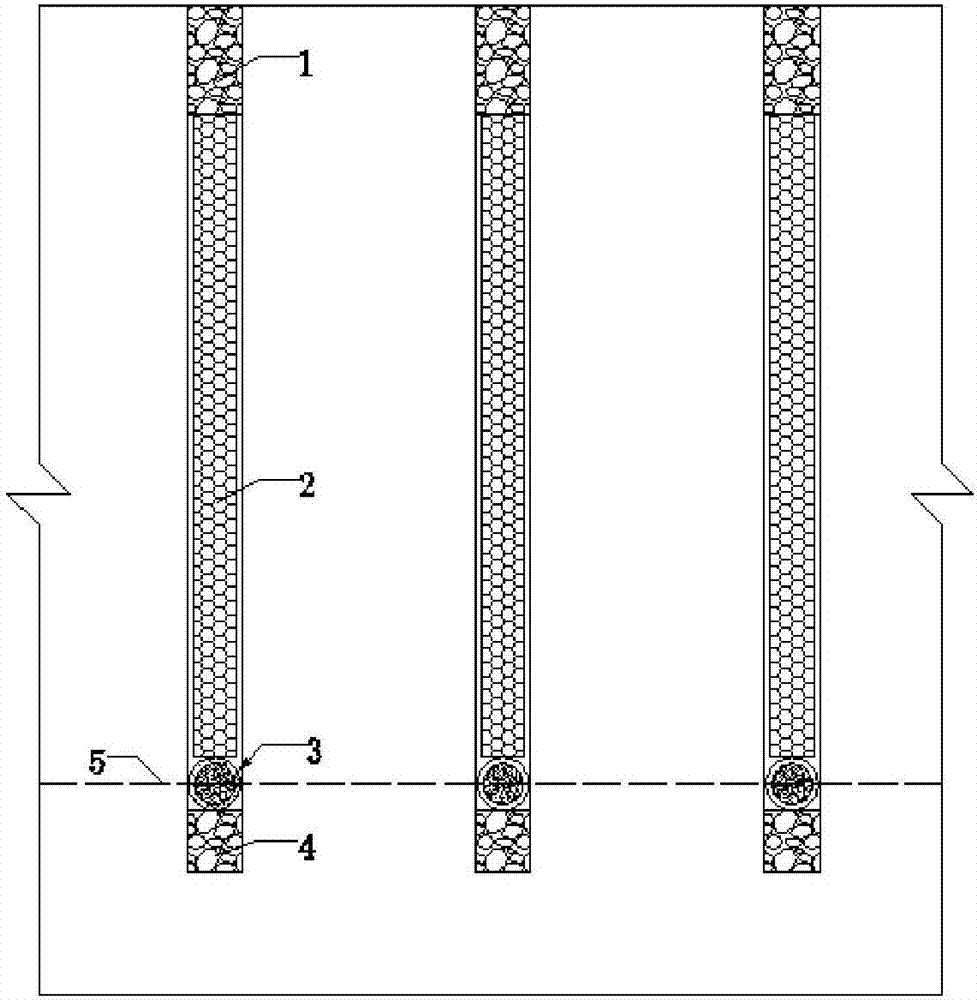

[0044] The rock foundation blasting excavation project of a water conservancy and hydropower project needs to improve the flatness of the foundation surface. Adopt deep hole step blasting, vertical blast hole, drilling diameter is Φ 炮孔 =90mm, the rock base is horizontal, the drilling depth is 10m, of which the over-depth is 0.3m, the plugging length is 2m, the hole spacing is 2.0-2.5m, and the hole bottom initiation method is adopted.

[0045] Using the "outside soft inside hard" type hole bottom energy dissipation structure of the present invention, the specific implementation steps are as follows:

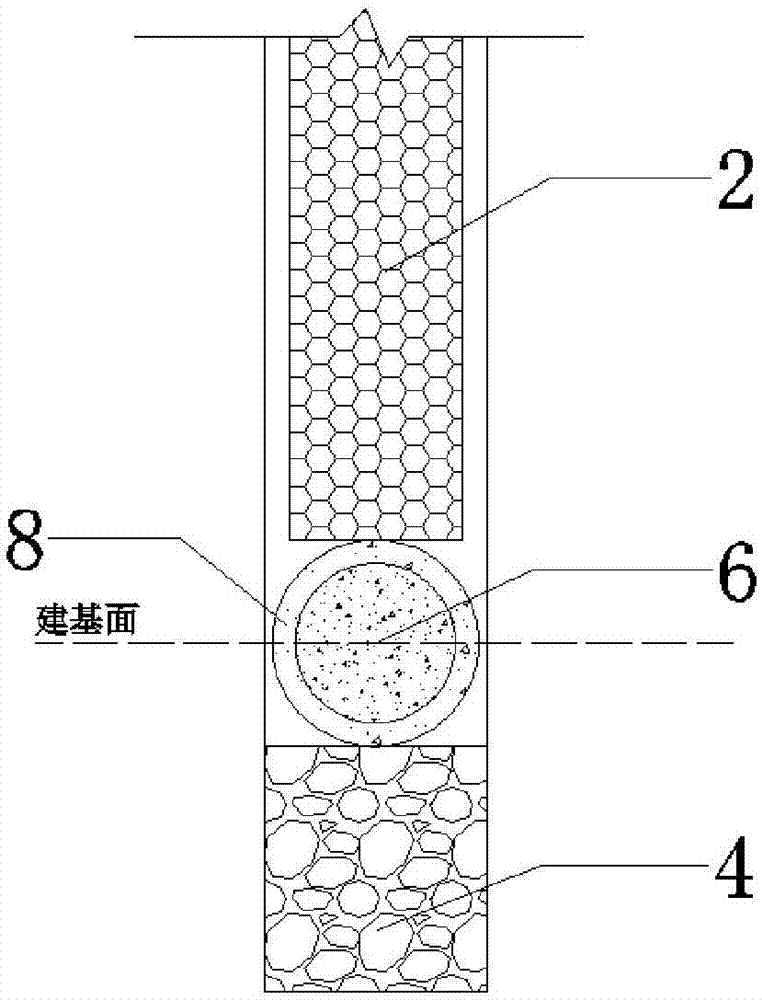

[0046] Step 1: Prefabricated energy dissipation structure,

[0047] According to the diameter of the designed blast hole, the energy dissipation structure is prefabricated, and the shape of the structure is as follows image 3 , 5 As shown, size requirements:

[0048] Φ 内 =70mm, Φ 外 =84mm.

[0049] According to the material conditions of cement, water, iron sand and high-e...

example 2

[0060] The rock foundation blasting excavation project of a water conservancy and hydropower project needs to improve the flatness of the foundation surface. Adopt deep hole step blasting, vertical blast hole, drilling diameter is Φ 炮孔 =90mm, the rock base is horizontal, the drilling depth is 10m, of which the over-depth is 0.3m, the plugging length is 2m, the hole spacing is 2.0-2.5m, and the hole bottom detonation method is adopted.

[0061] The specific implementation steps of the “outer hard inner soft” type hole bottom energy dissipation structure of the present invention are as follows:

[0062] Step 1: Prefabricated energy dissipation structure,

[0063] According to the diameter of the designed blast hole, the energy dissipation structure is prefabricated, and the shape of the structure is as follows Figure 4 , 6 As shown, size requirements:

[0064] Φ 内 =15mm, Φ 外 =84mm.

[0065] According to the material conditions of cement, water, iron sand and high-efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com