Patents

Literature

35results about How to "Increase the maximum amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

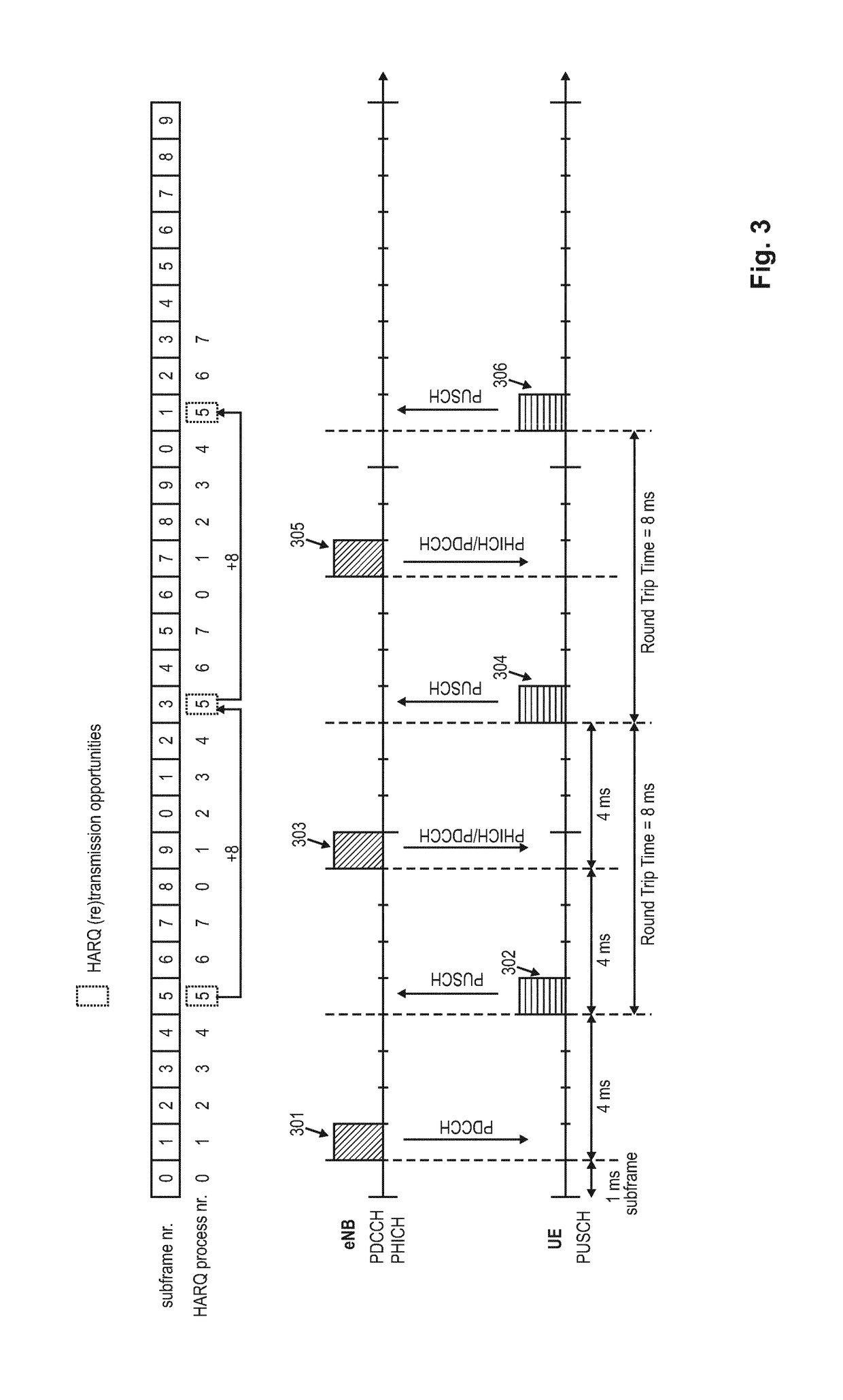

Improved uplink HARQ operation for prose-enabled ues participating in sidelink discovery operation

ActiveUS20190058986A1Easy to operateAvoid dataError prevention/detection by using return channelError prevention/detection by transmission repeatTransmission protocolPacket transmission

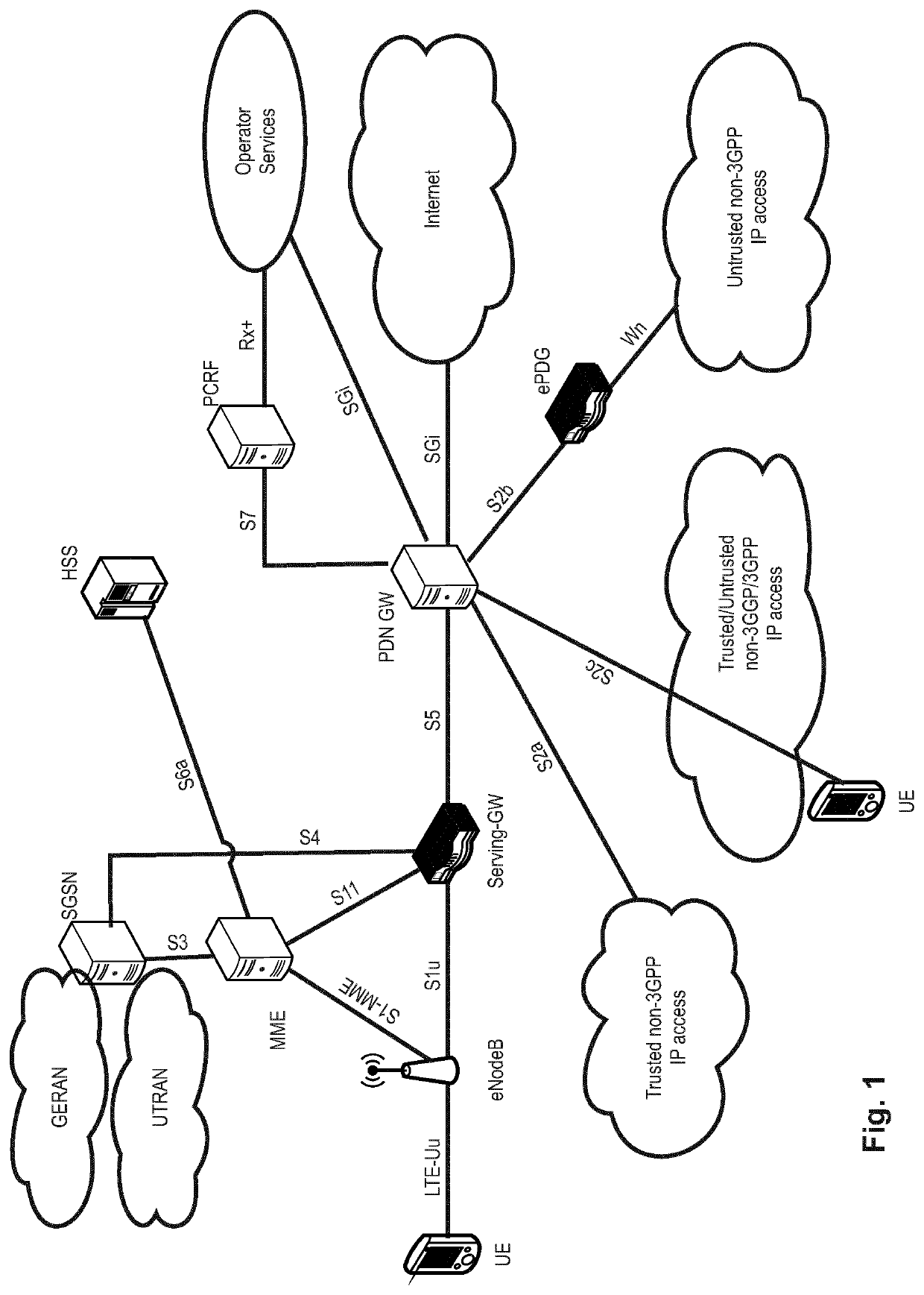

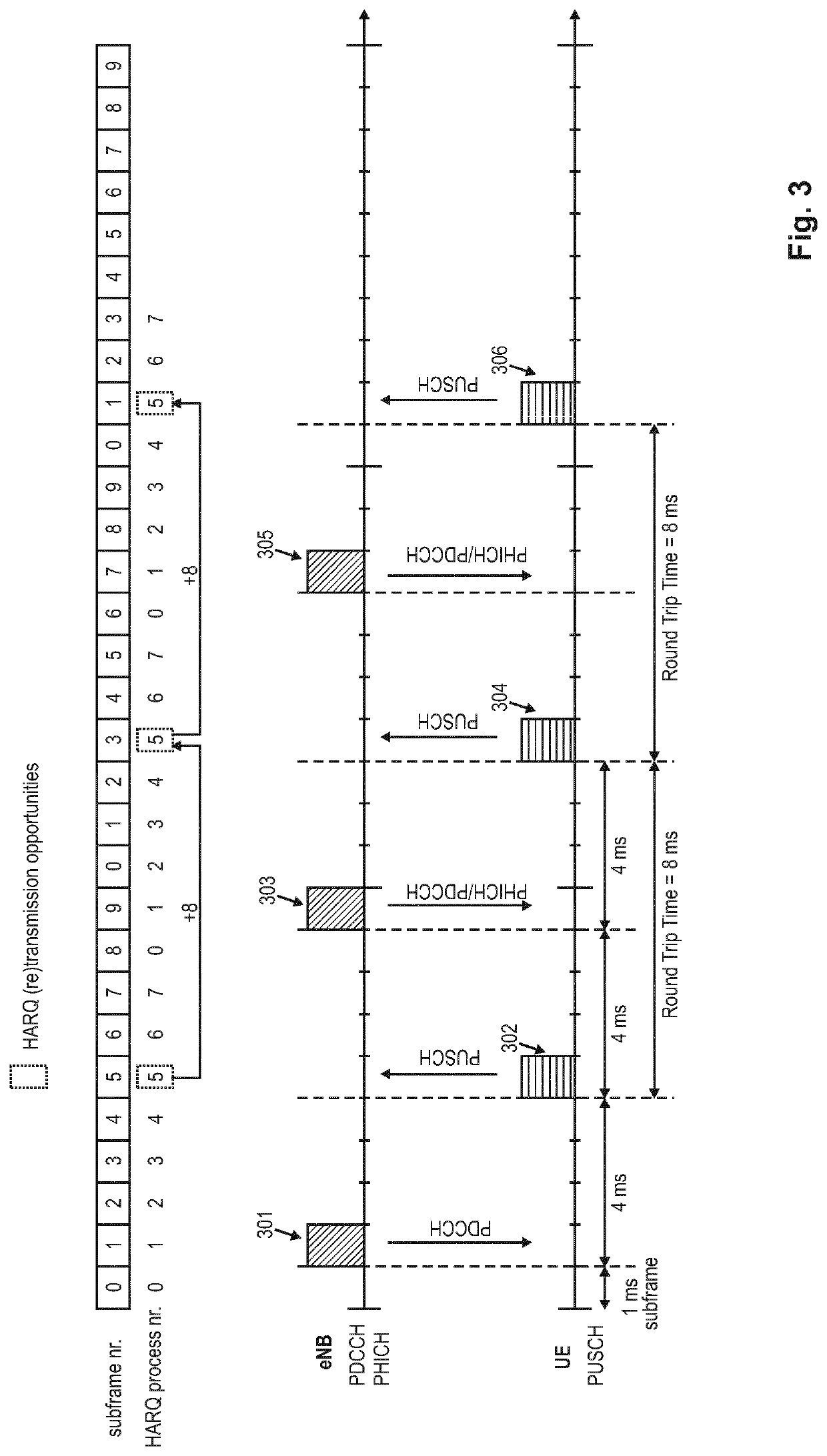

The invention relates to an improved transmission protocol for uplink data packet transmission. A transmission counter of the transmission protocol counts the number of transmissions the user terminal has performed for a data packet. The user terminal participates in sidelink discovery operation with other user terminals based on sidelink discovery gaps. The user terminal cannot transmit and / or receive signals under control of the transmission protocol when participating in sidelink discovery operation during the sidelink discovery gaps. A processor of the user terminal determines whether a retransmission of a data packet, which is triggered by the transmission protocol, was not performed because the transmission protocol operation collided with one of the sidelink discovery gaps. In case of collision, the processor operates the transmission counter such that the colliding retransmission of the data packet does not result in an increment of the transmission counter of the transmission protocol for the data packet.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

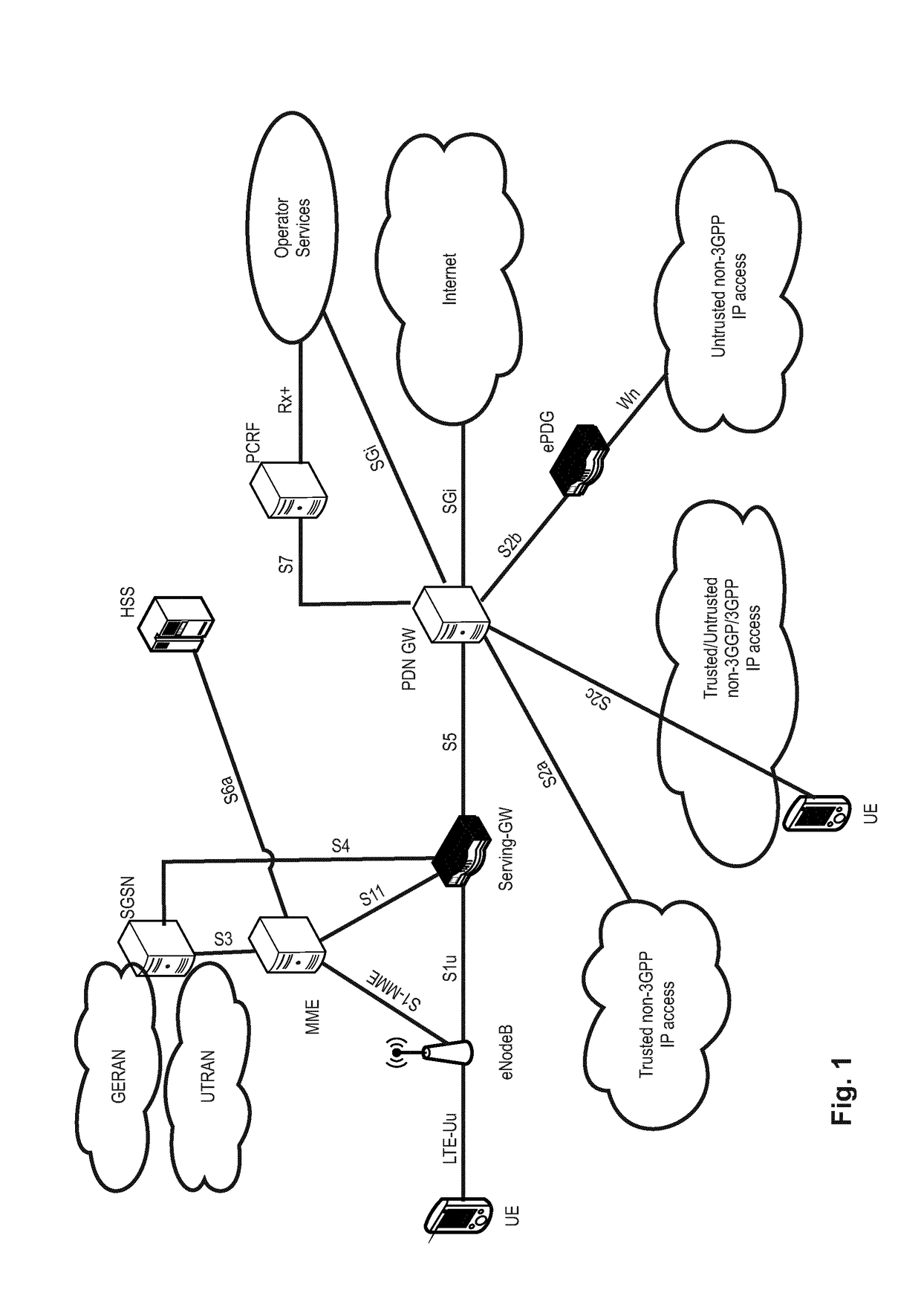

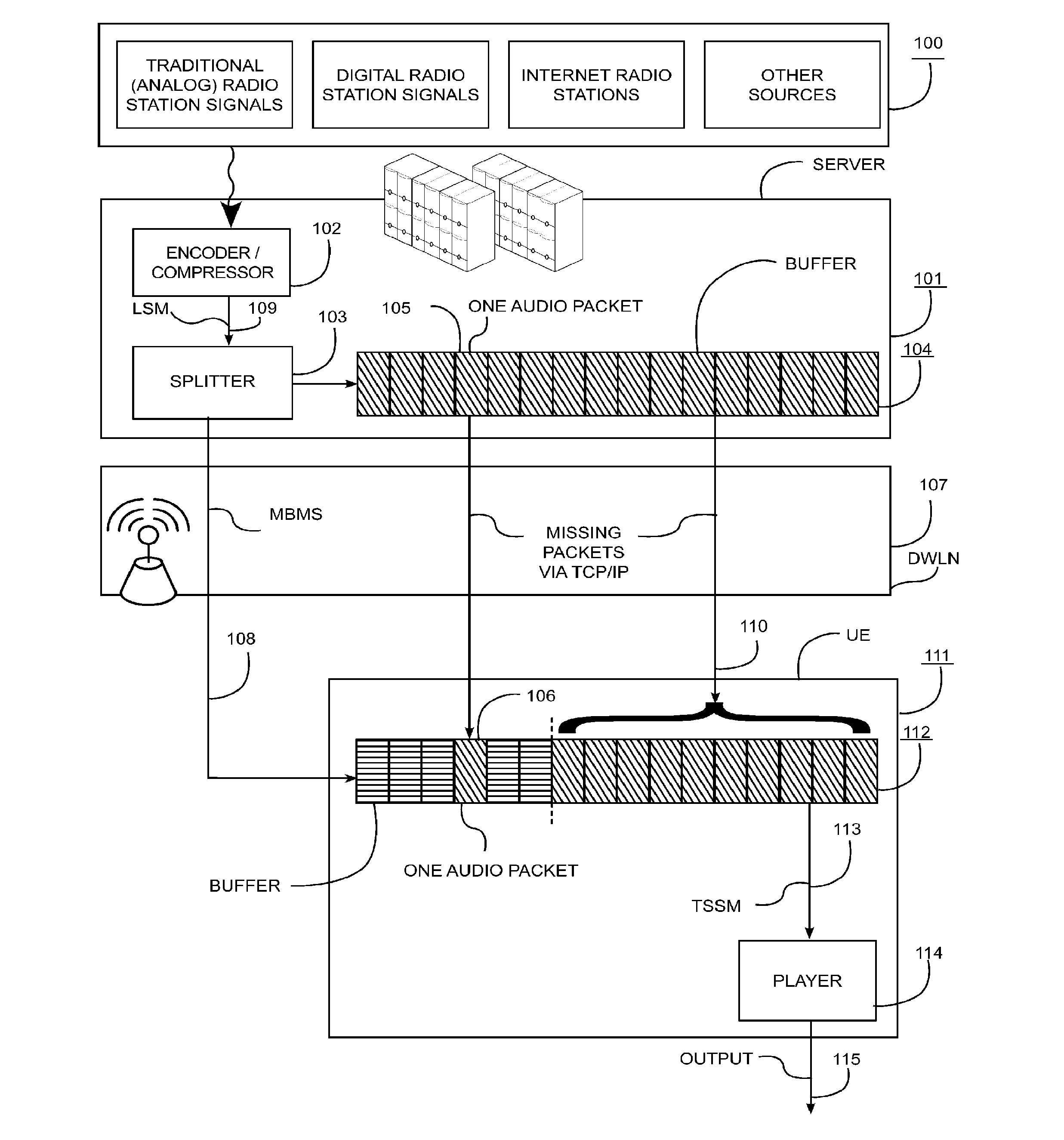

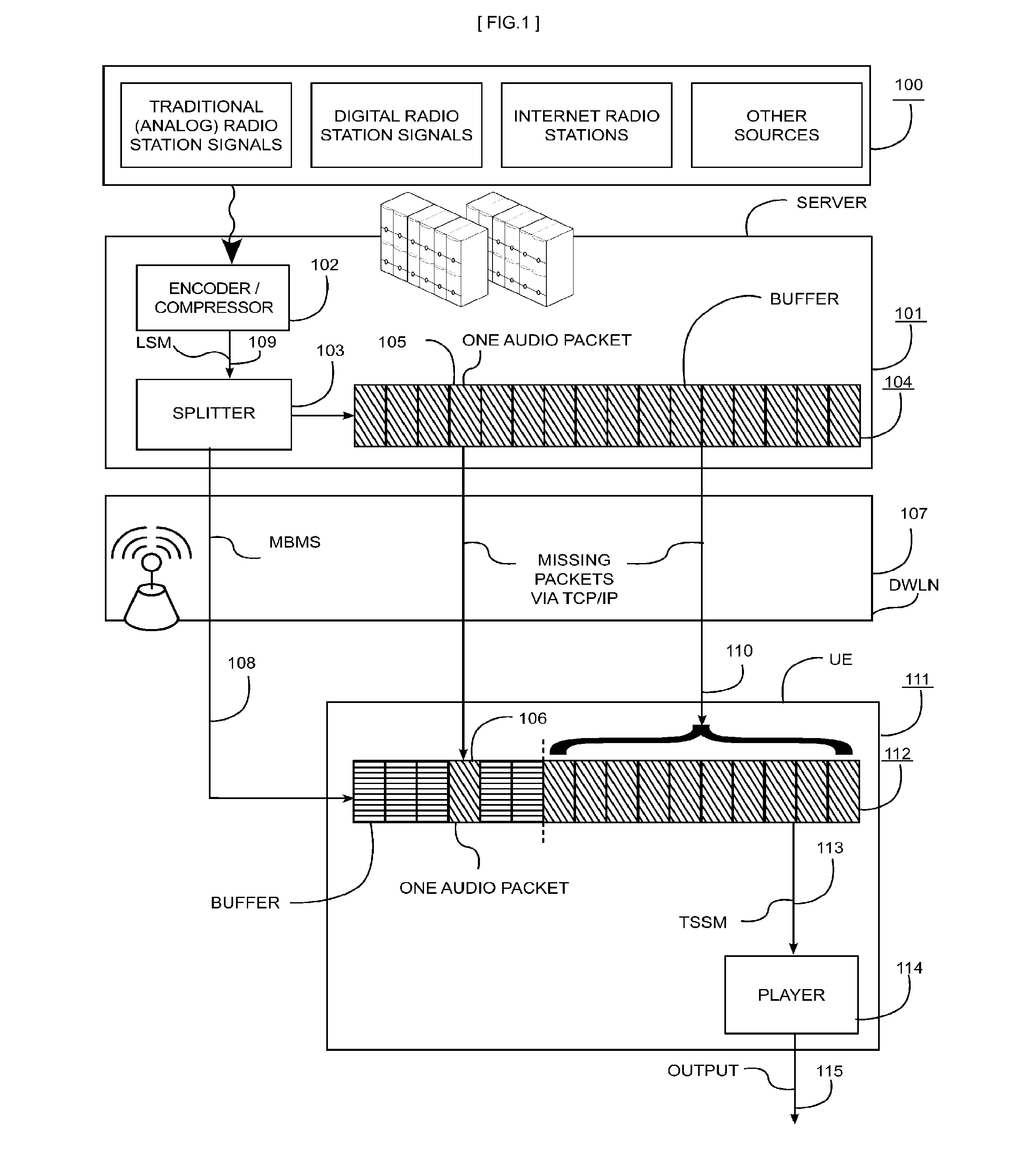

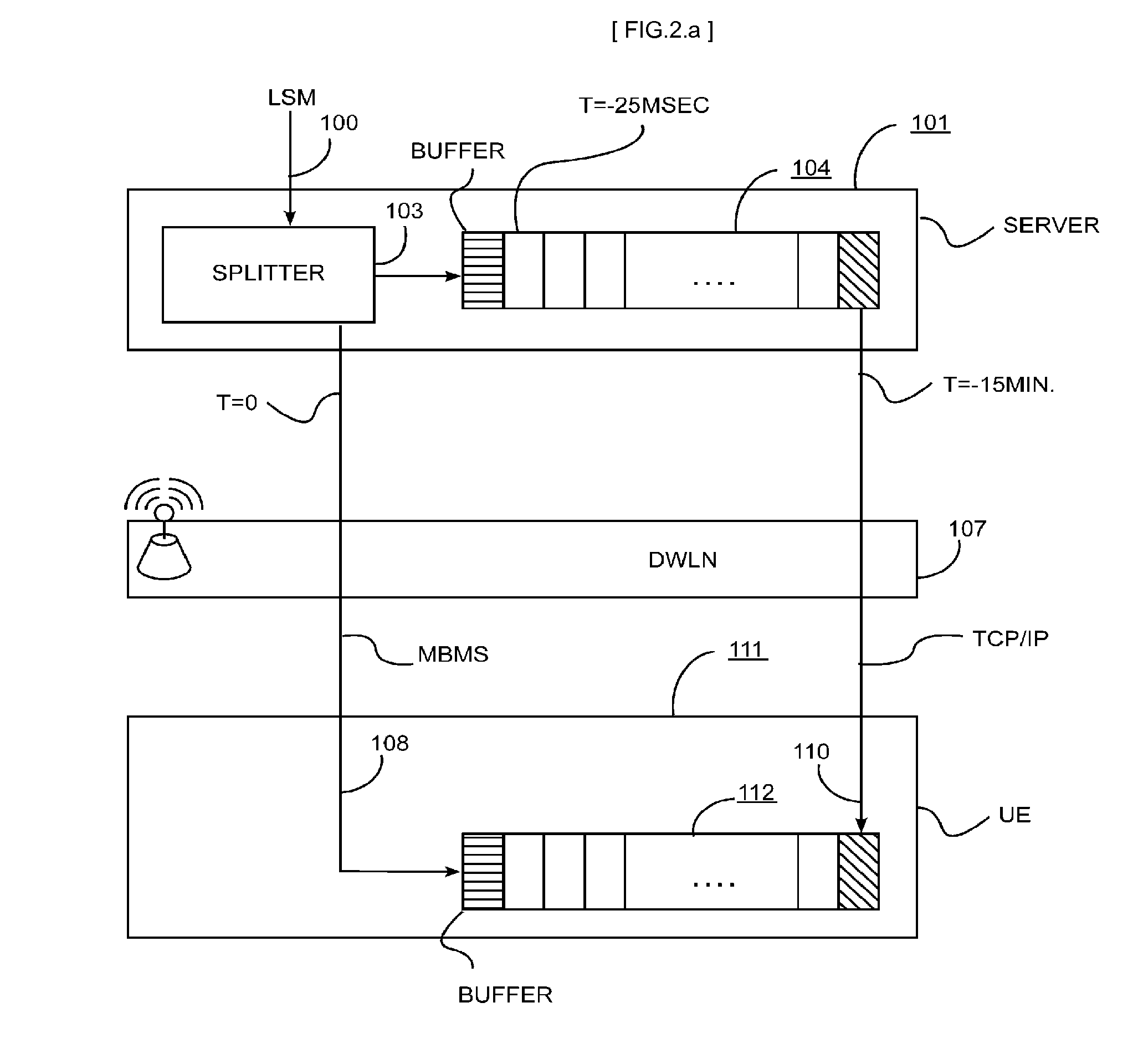

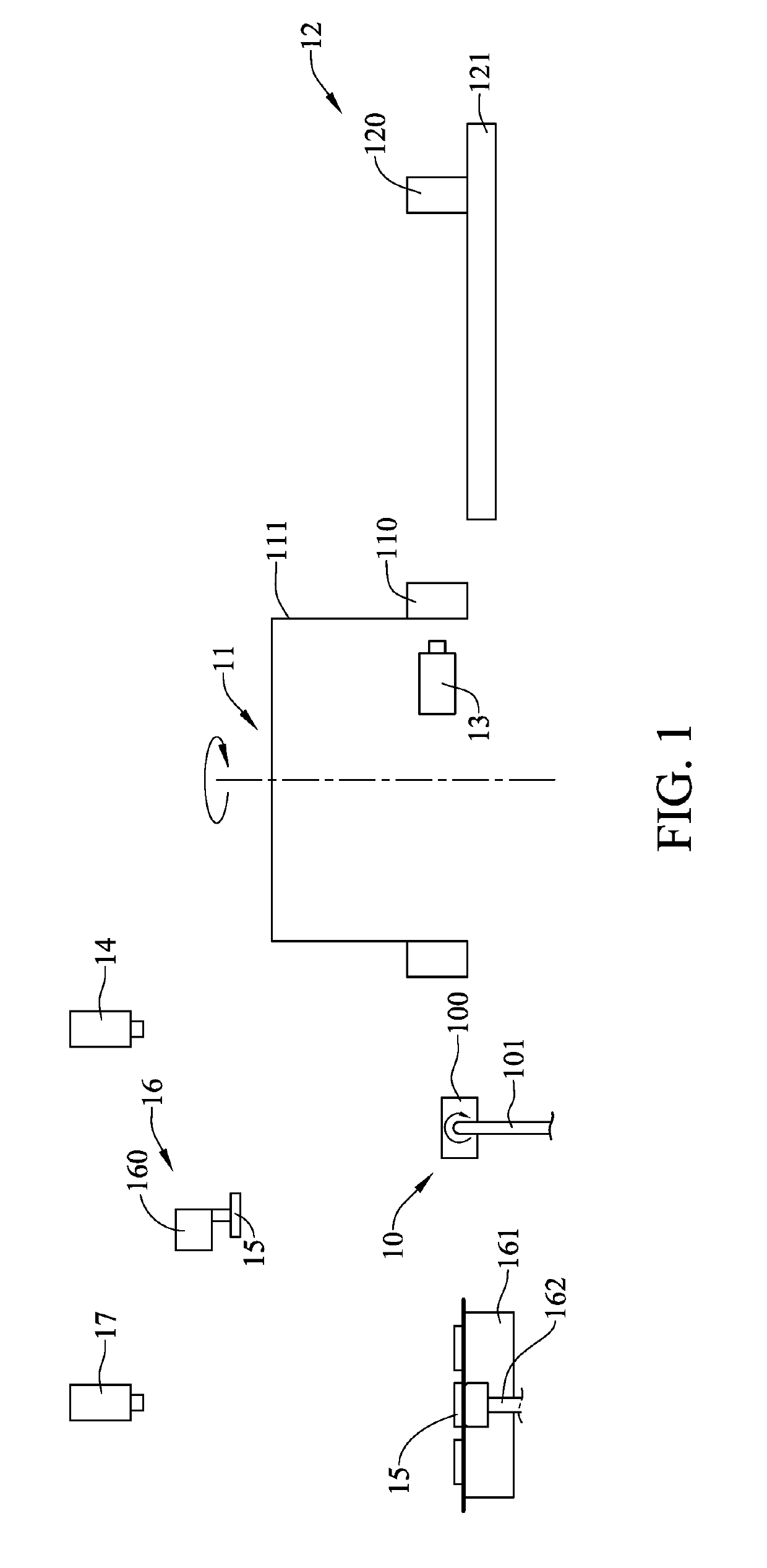

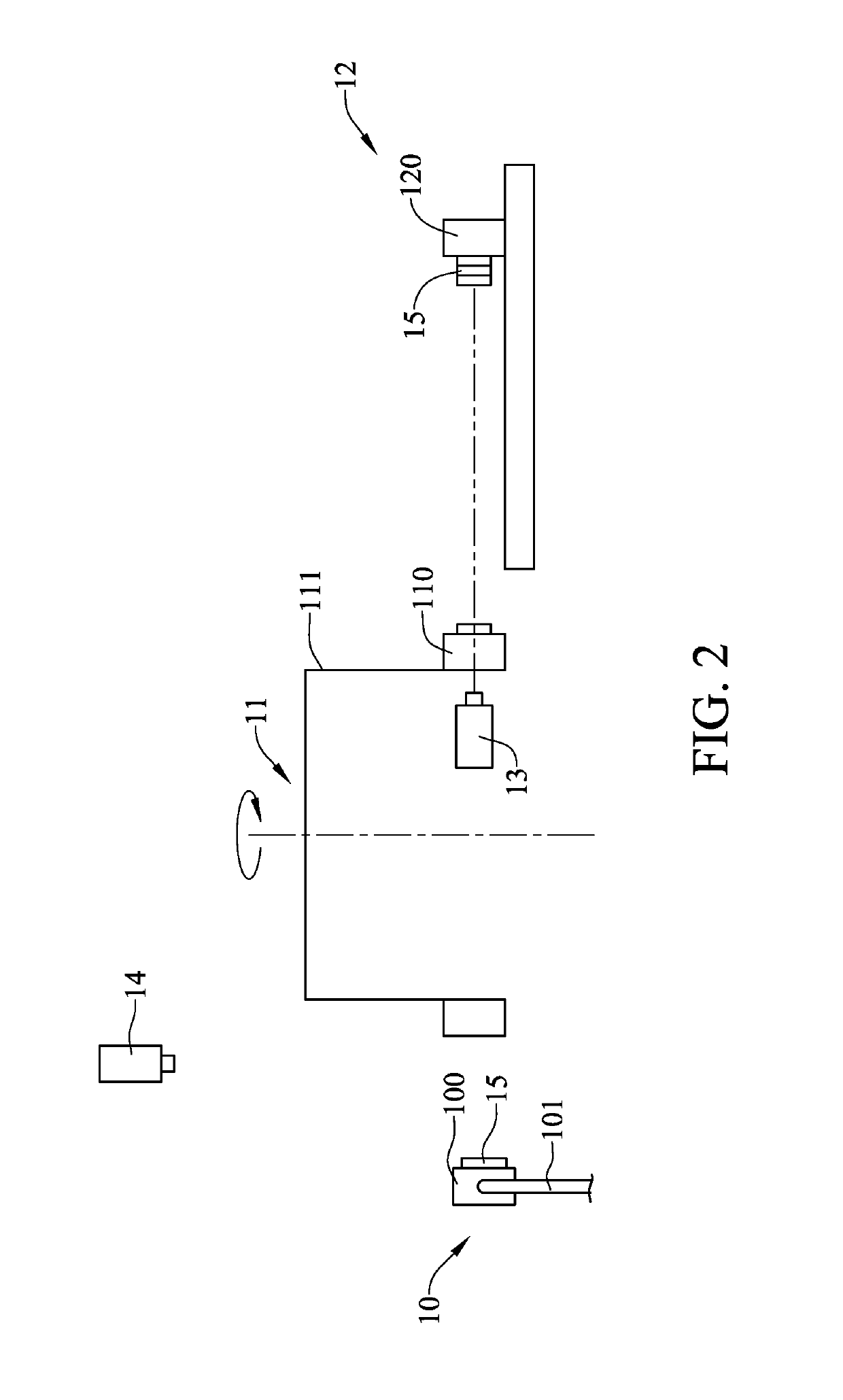

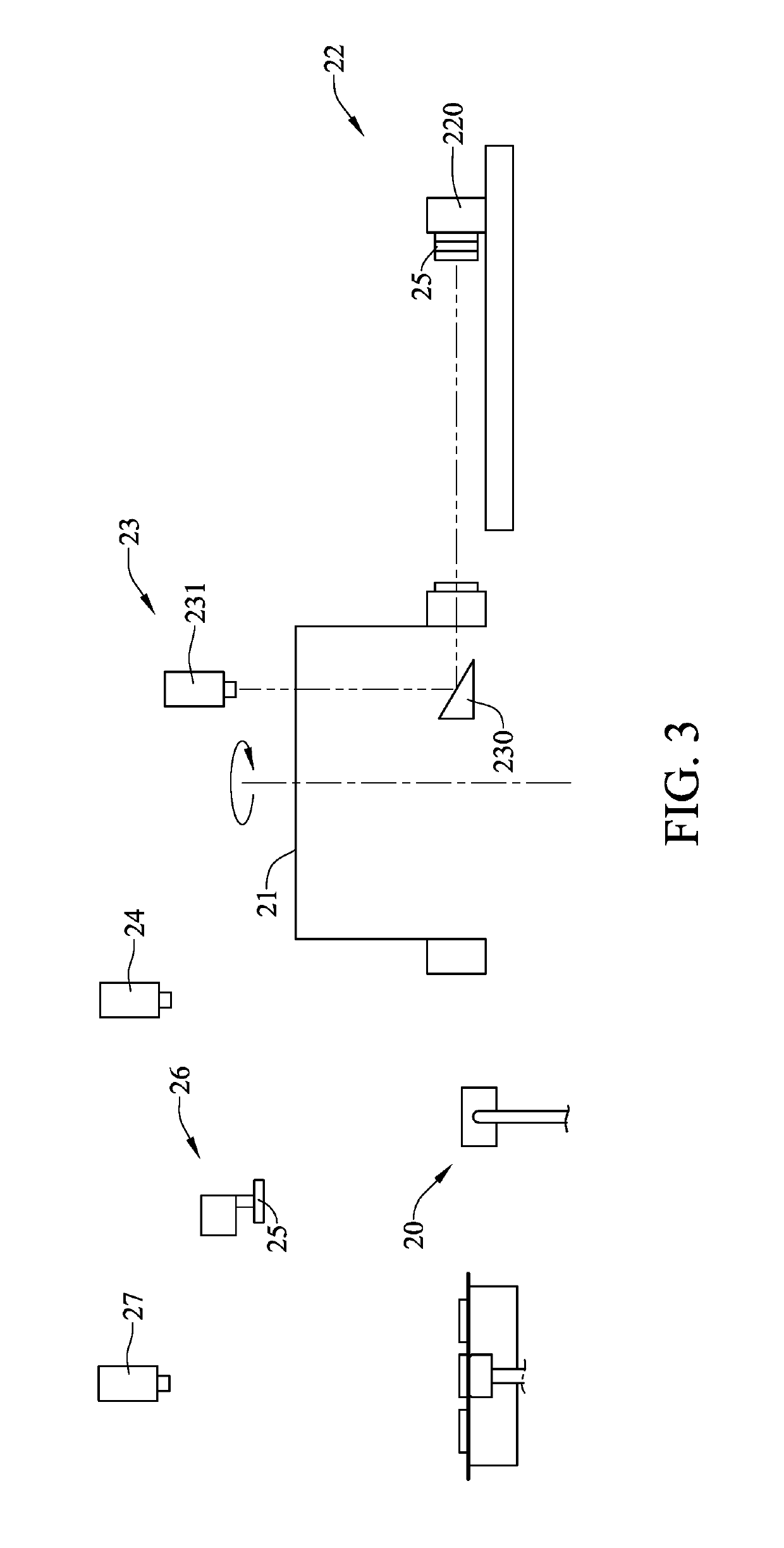

Systems and methods for transmission of uninterrupted radio, television programs and additional data services through wireless networks

ActiveUS20120099514A1Quality improvementIncrease the number ofError preventionBroadcast transmission systemsAviationStreaming data

A method and system for In-Dash Multimedia Players or Portable Multimedia Players for automotive, aviation, boating, and personal use that, exploiting the services and capabilities of the Digital Wireless Network DWLN (107), such as 3G network, and buffering the live stream data on both the Server (101) and User Equipment (111), combines in a novel synergistic integration a suite of new and known features such as: immediate and uninterrupted listening / viewing of Live Streaming Media LSM (109) by the user with or without optimization of the data bandwidth, and the provision to customize the commercial messages according to the user location, and the capability of reporting the customer choices and habits, and the automatic deletion of LSM after the time-shift time to benefit from copyright agreements.

Owner:FOSCO BIANCHETTI

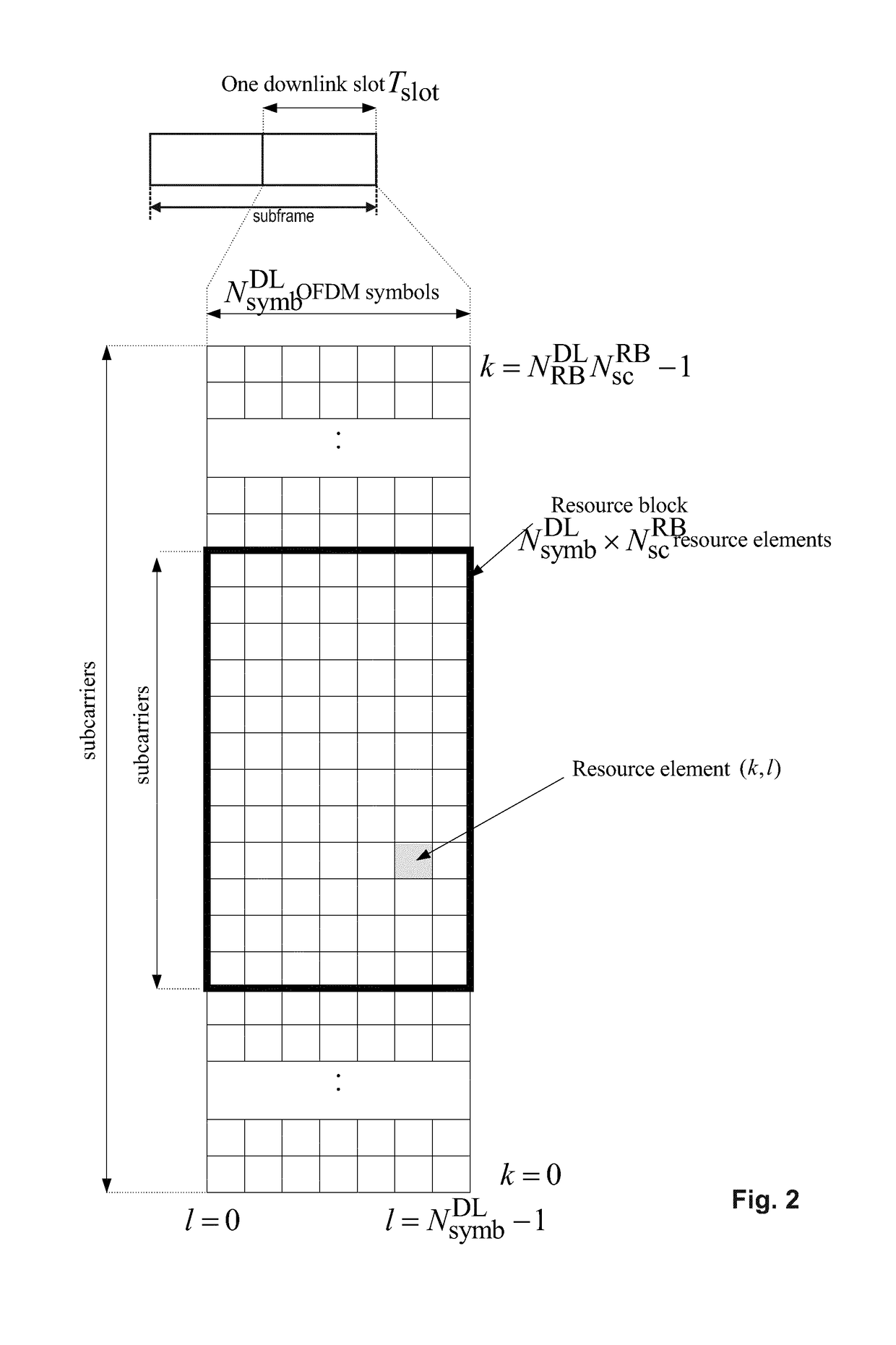

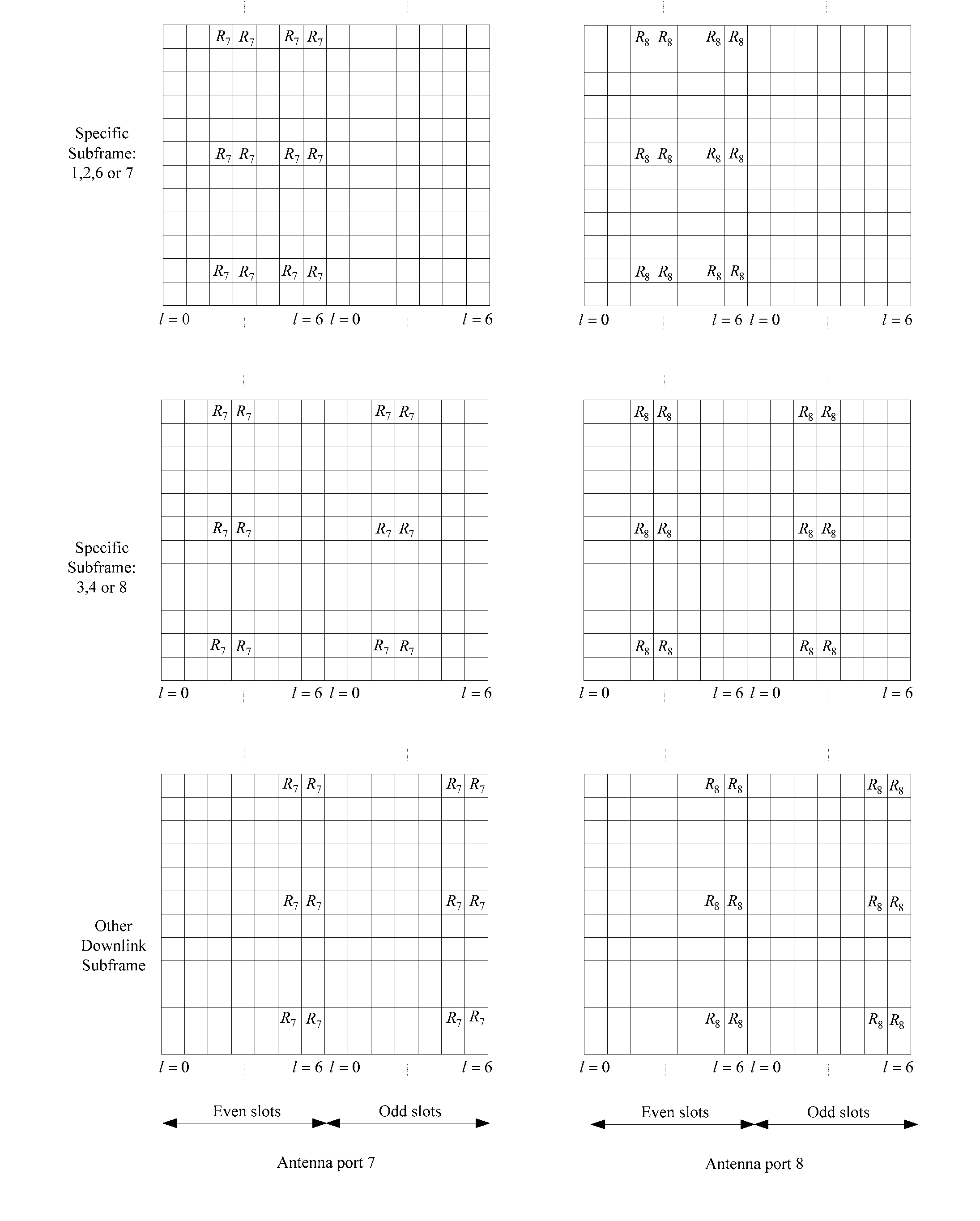

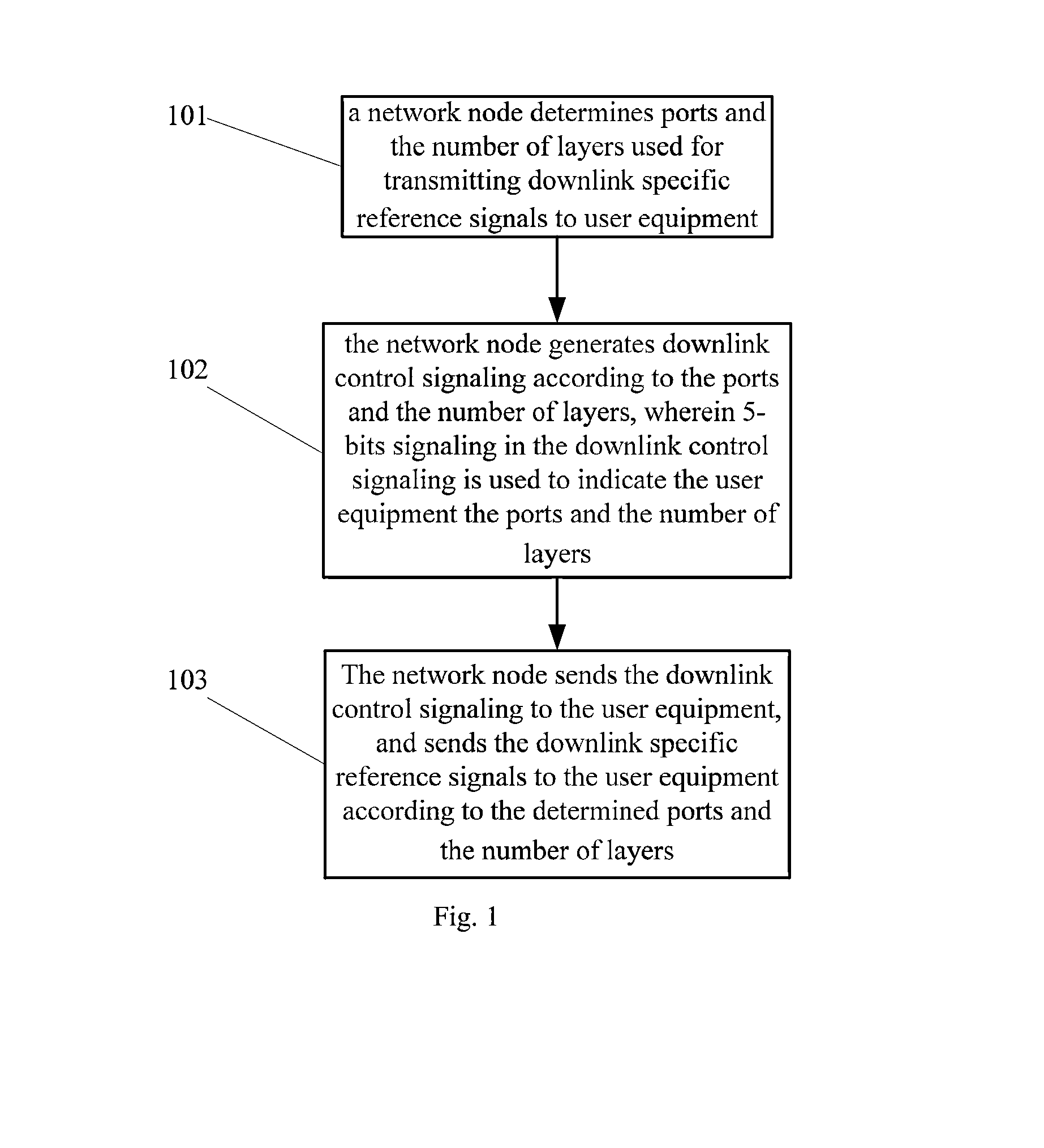

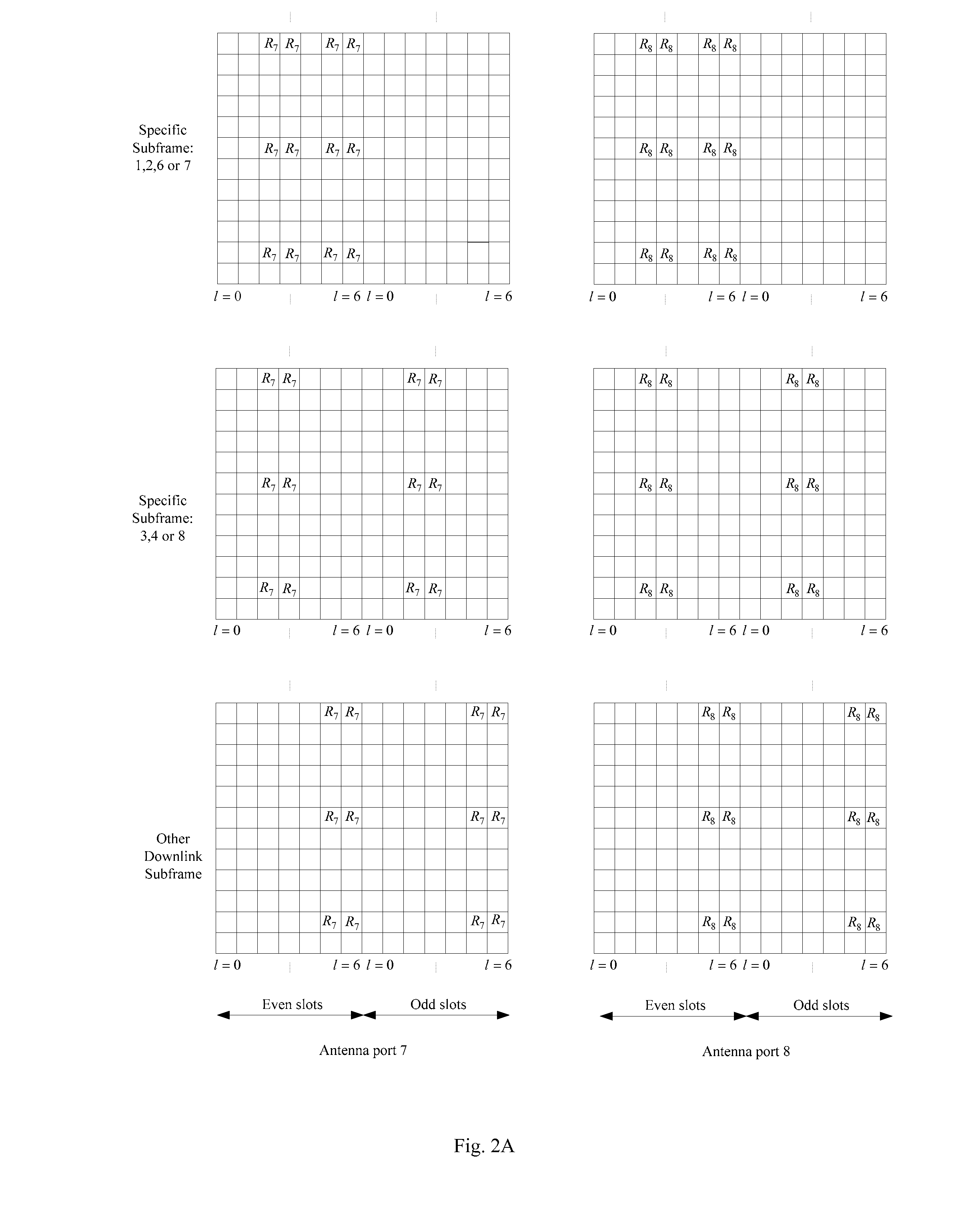

Reference signal sending method and apparatus

ActiveUS20150173052A1Increase the number ofIncrease the maximum amountTransmission path divisionSignal allocationMultiplexingControl signal

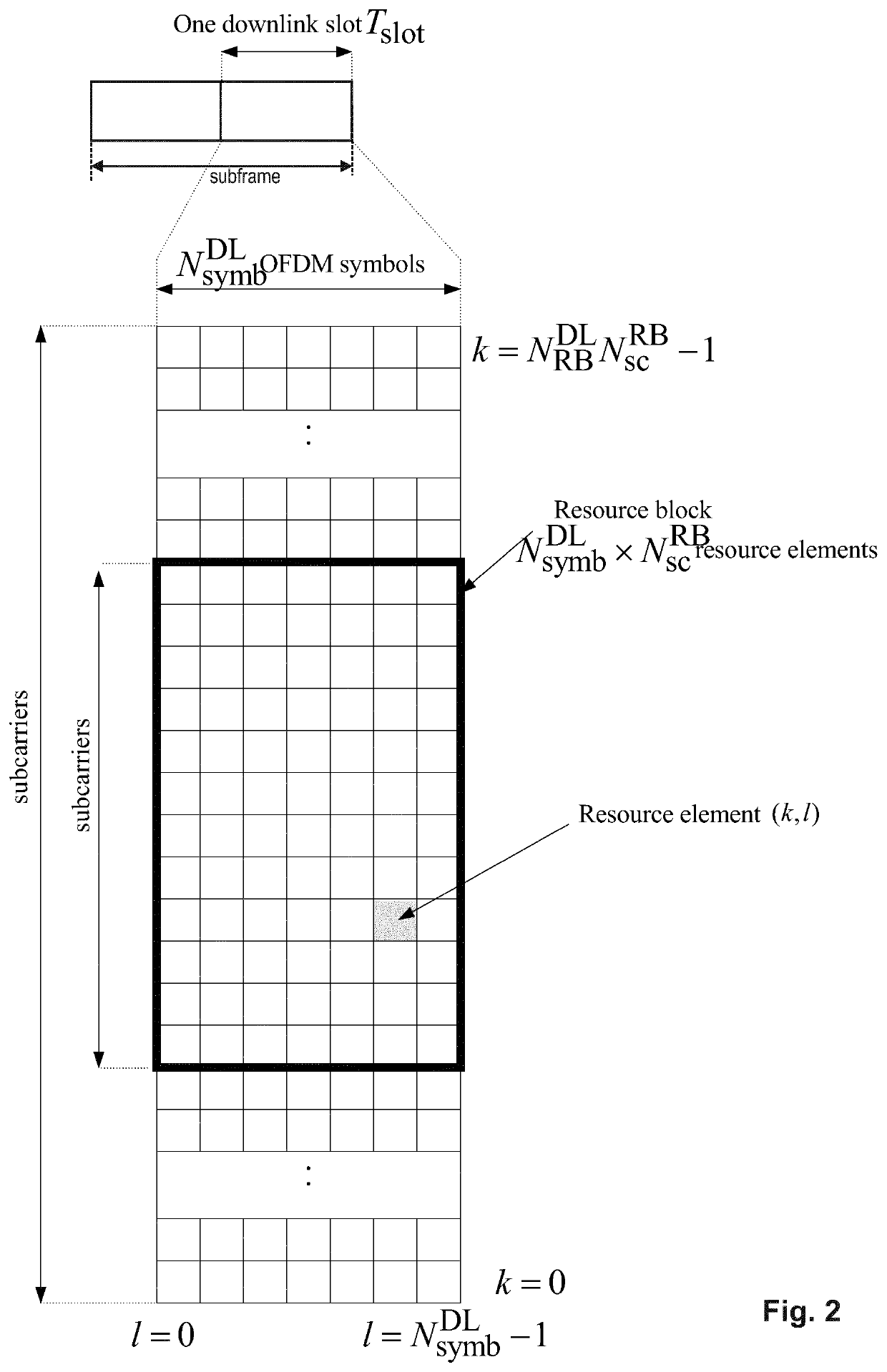

The embodiments of the present invention disclose a reference signal sending method and apparatus. The method includes: determining, by a network node, ports and the number of layers used for transmitting downlink specific reference signals to user equipment; generating, by the network node, downlink control signaling according to the ports and the number of layers, wherein 5-bits signaling in the downlink control signaling is used to indicate the user equipment the ports and the number of layers used for transmitting the downlink specific reference signals, in order to support multiplexing of at most eight user equipment; and sending, by the network node, the downlink control signaling to the user equipment, and sending the downlink specific reference signals to the user equipment according to the determined ports and the number of layers. By adopting the present invention, the maximum number of multiplexed streams may be increased.

Owner:HUAWEI TECH CO LTD

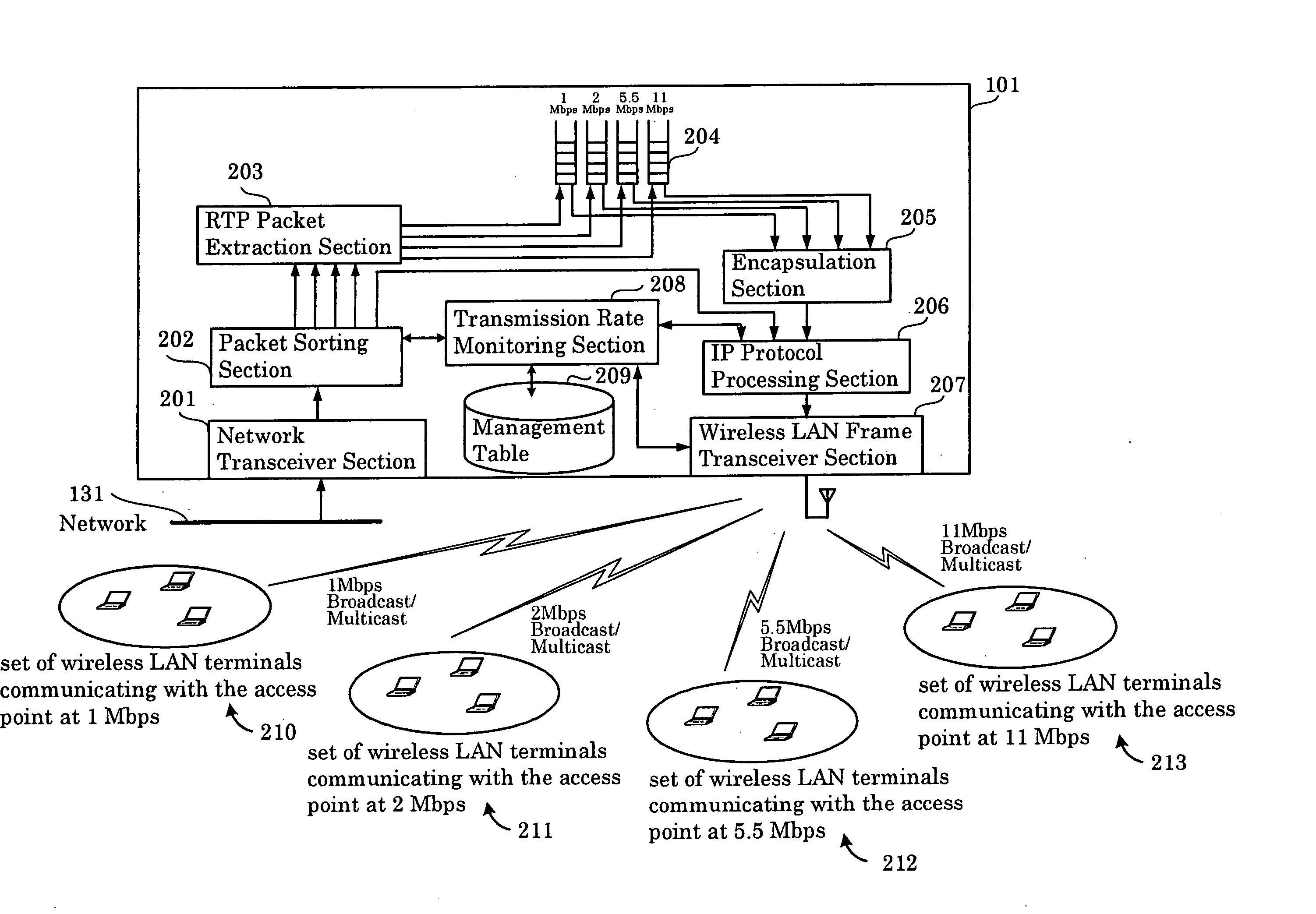

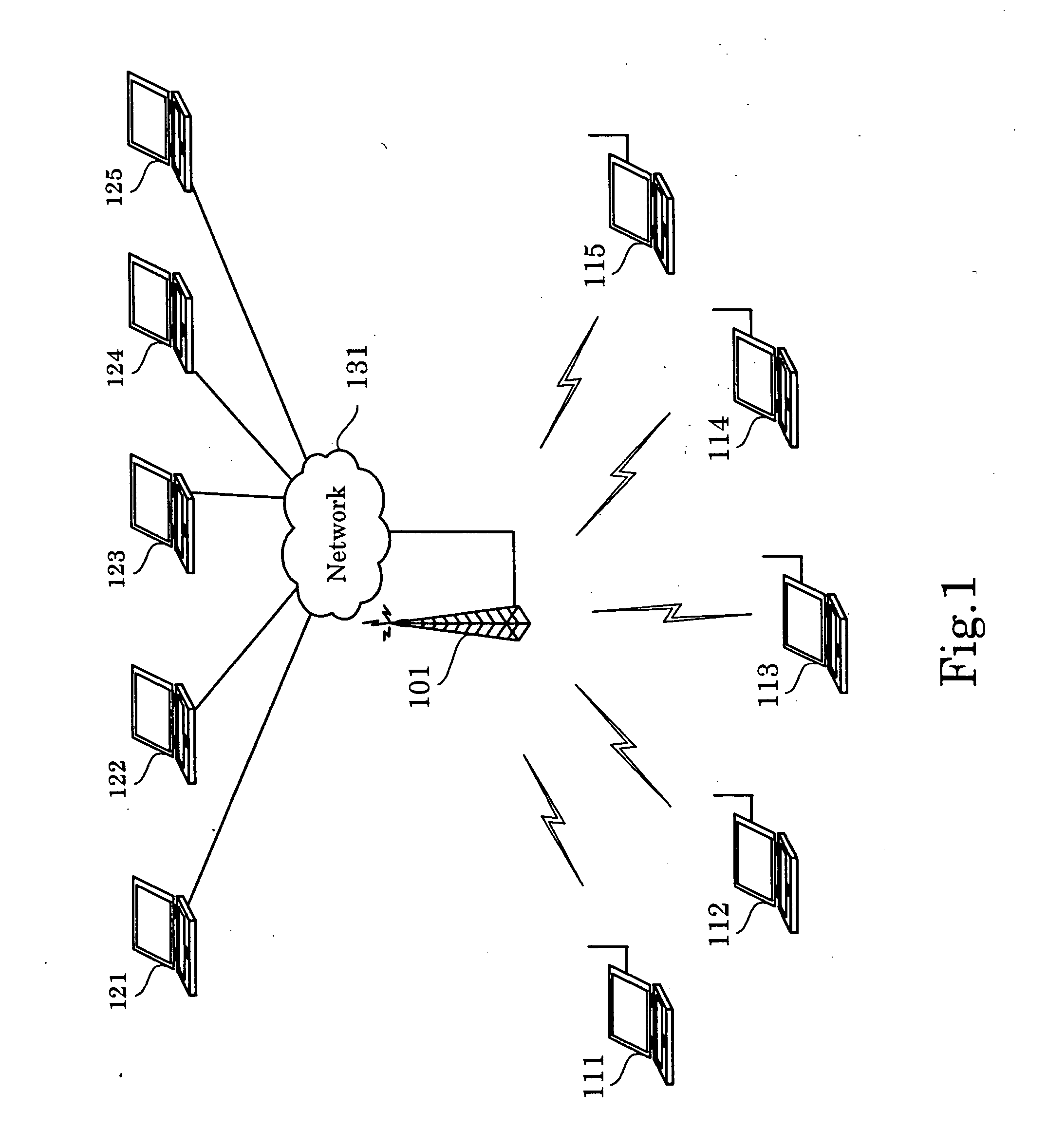

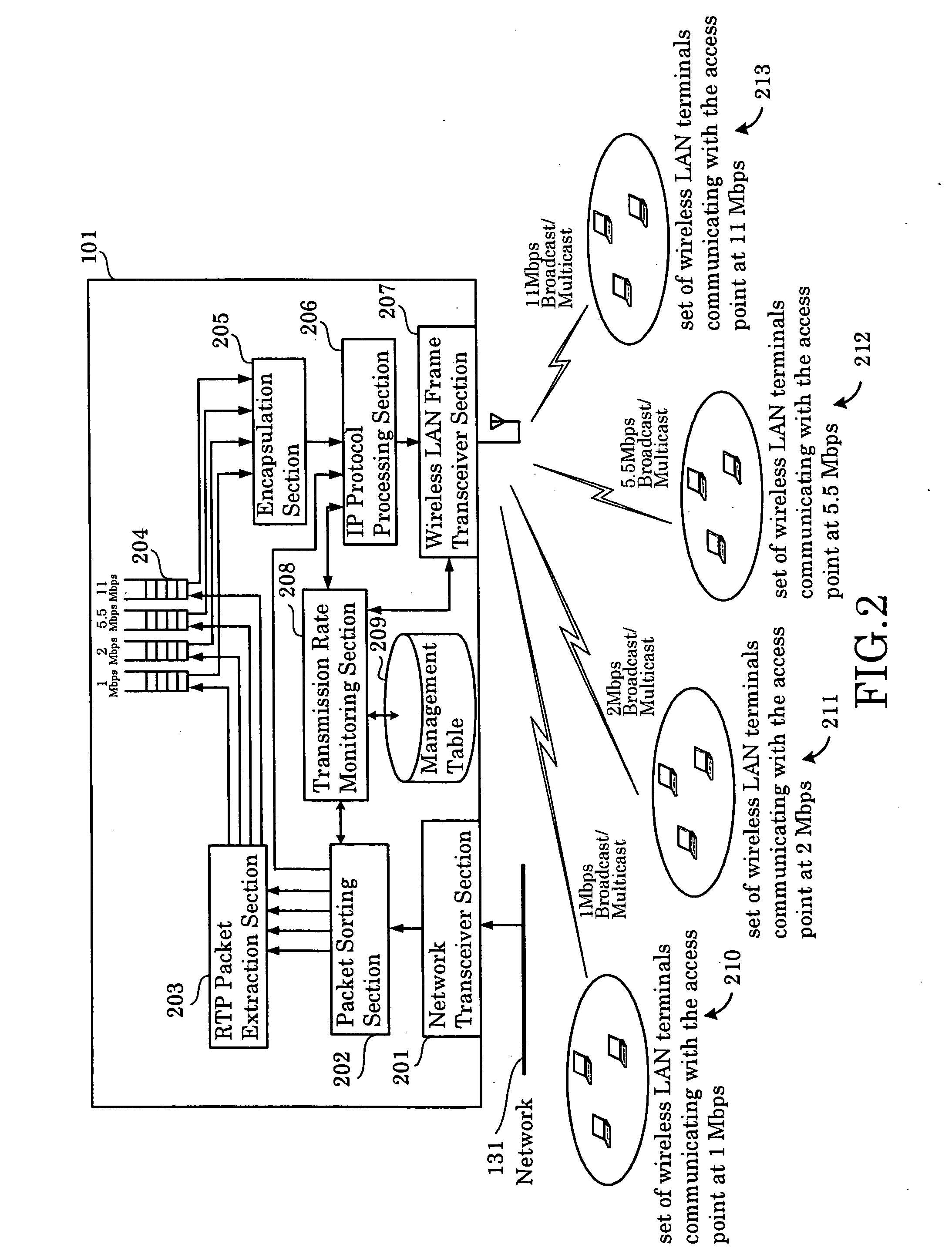

Packet transmission method and apparatus

InactiveUS20060227752A1Improve transfer rateIncrease the maximum amountNetwork traffic/resource managementNetwork topologiesPacket communicationWireless lan

When voice, video, and other communications requiring real-time processability are carried out using wireless packet communications in a wireless LAN etc., a technique is used, in which a plurality of packets are encapsulated in order to reduce the proportion occupied by the header relative to the entire frame. Because in the past packets were encapsulated without considering transmission rates used for data transmission between the base station and the terminals, all the packets had to be transmitted at the lowest transmission rate, which was inefficient. According to the present invention, not only are packets sorted based on whether they should be encapsulated or not, but, in addition, packets to be encapsulated are sorted according to the transmission rates, at which the terminals can communicate with the base station, and then encapsulated and transmitted at said transmission rates.

Owner:NEC CORP

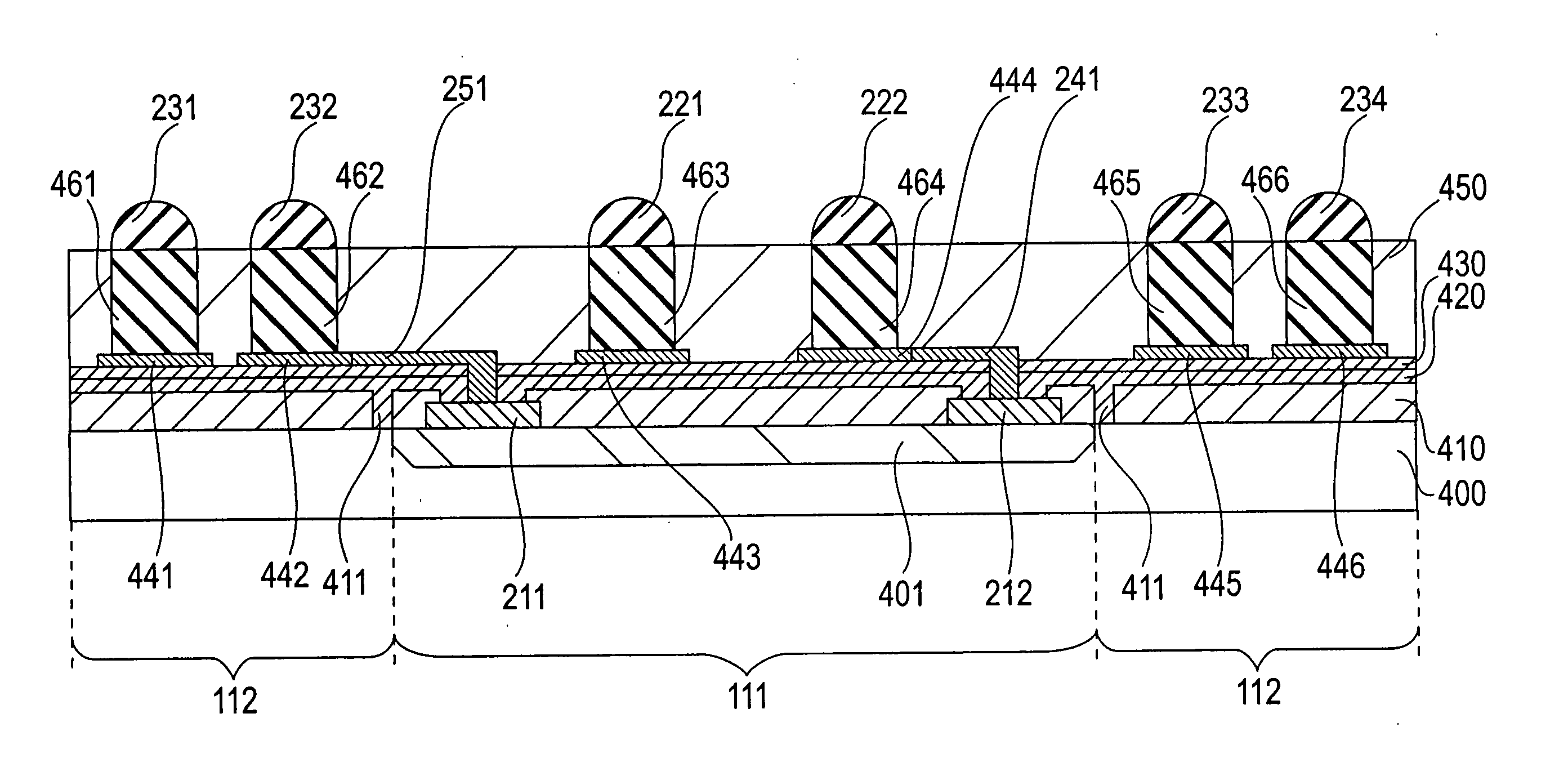

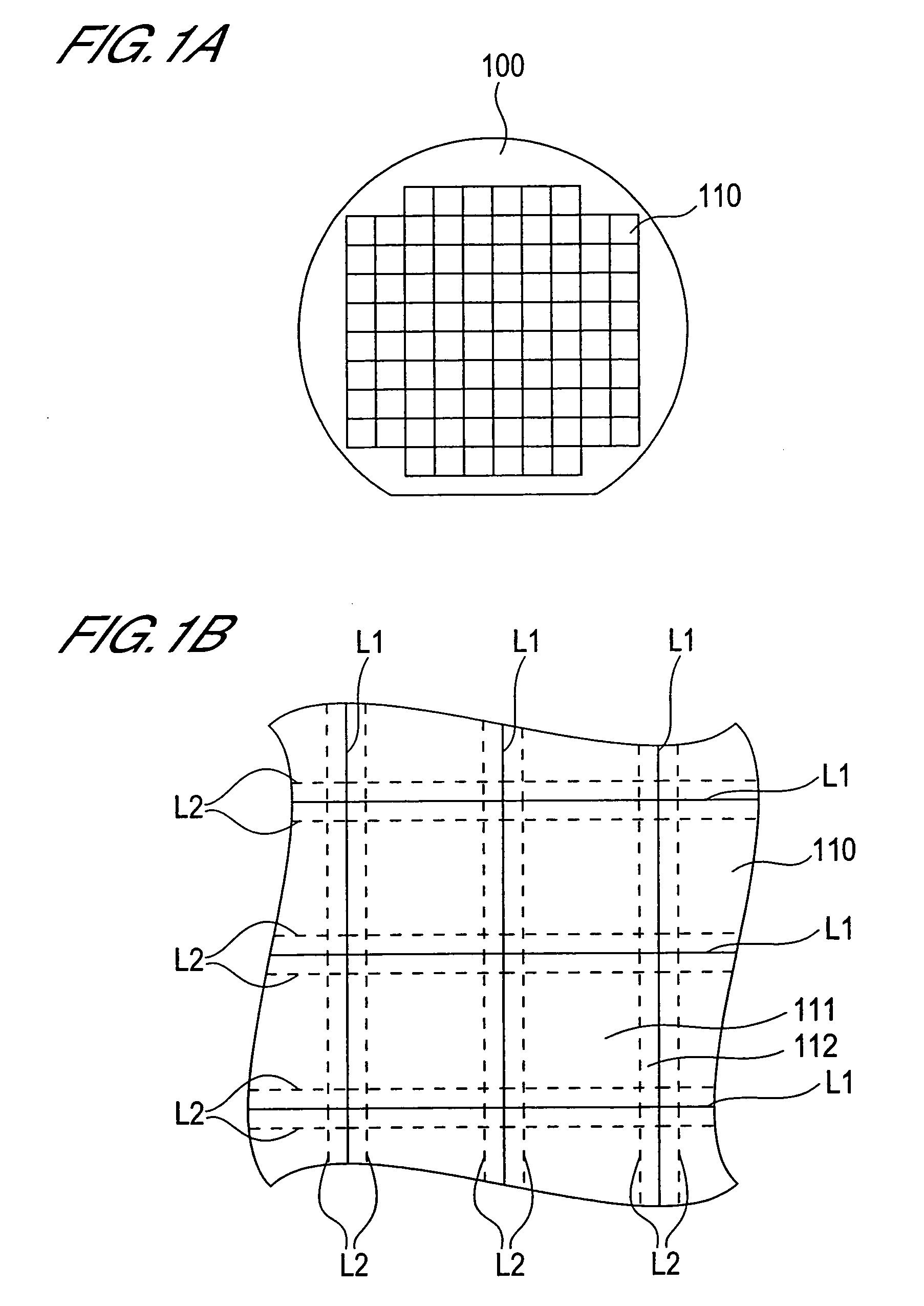

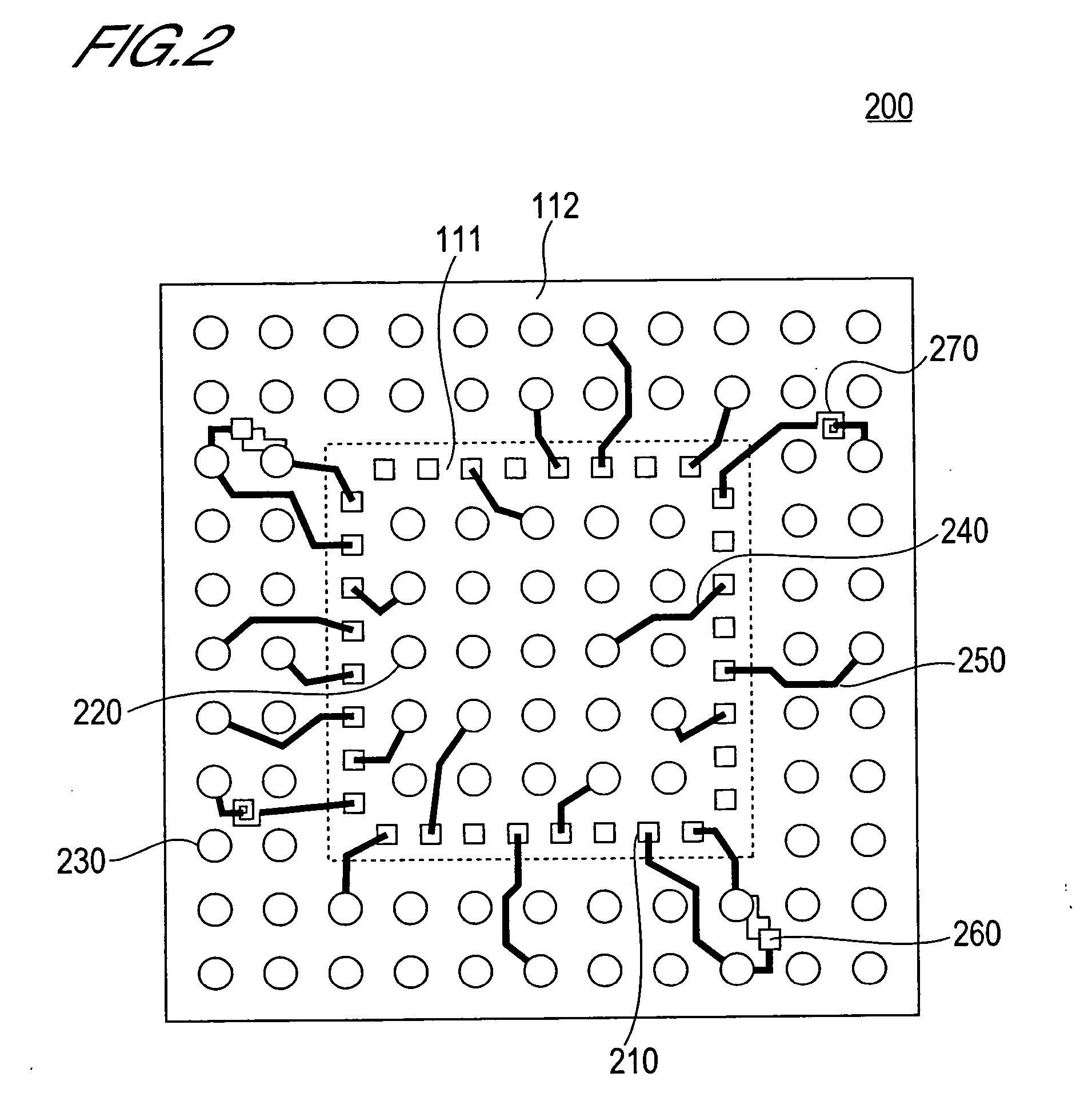

Semiconductor device

InactiveUS20060157845A1Increase the maximum amountIntegrated reductionSemiconductor/solid-state device detailsSolid-state devicesDevice materialChip size

When an integrated circuit is formed in a semiconductor wafer, the integrated circuit is formed only in the central part of each chip region. In a case where packaging other than a chip size package is made, only the central part in which the integrated circuit is formed is cut from the wafer. In a case where a chip size package is made, the chip region is cut from the wafer after forming the redistribution wiring and external terminals and so forth over the whole of the chip region. As a result, the design of the integrated circuit and part of the fabrication process thereof can be shared by a chip which is mounted in a chip size package and a chip which is mounted in another type of package.

Owner:LAPIS SEMICON CO LTD

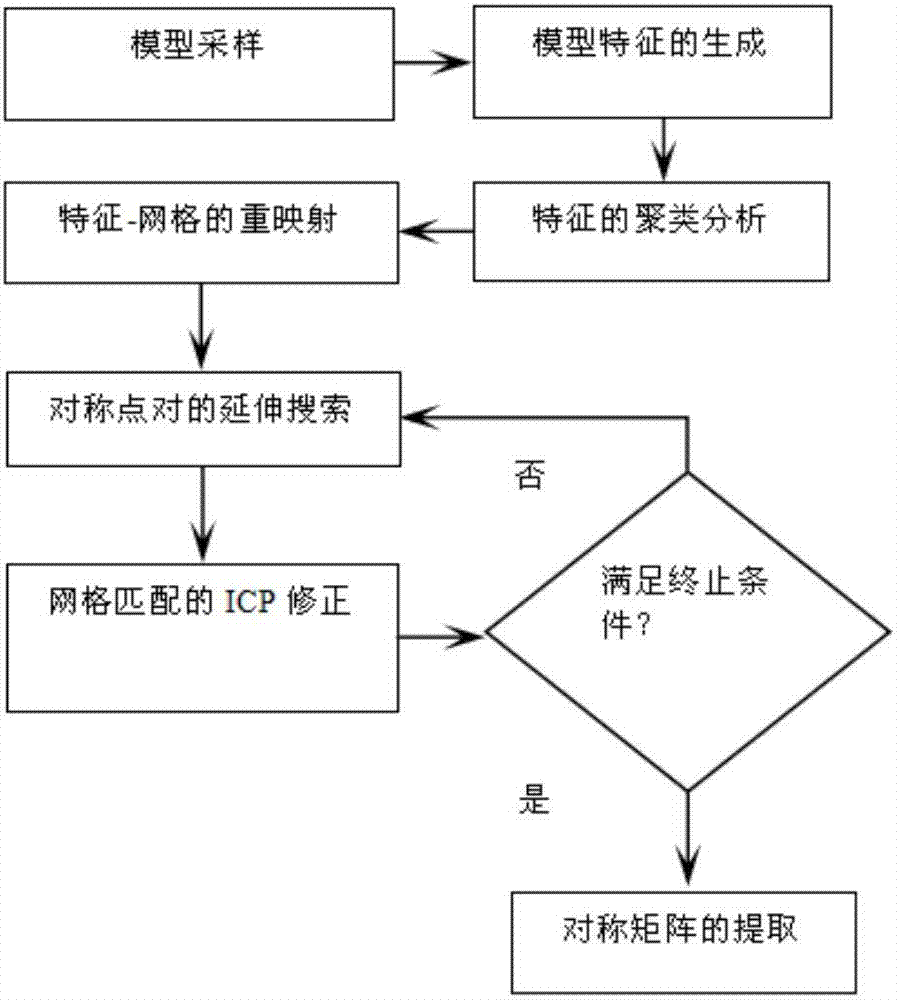

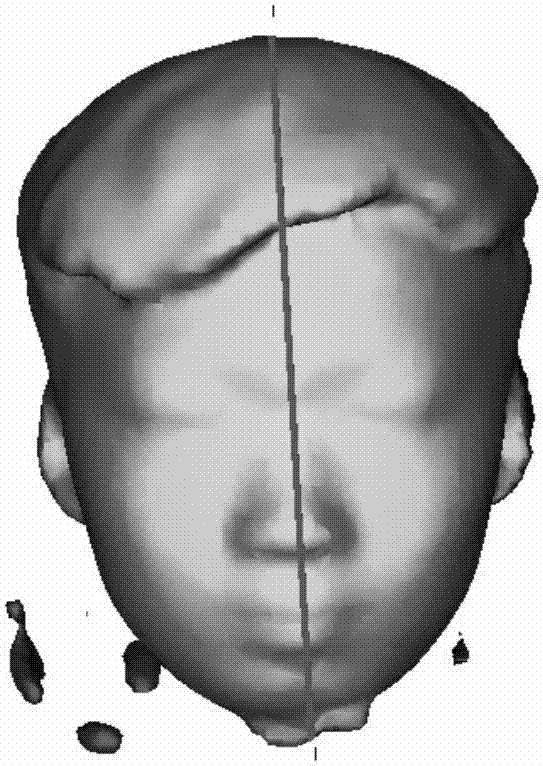

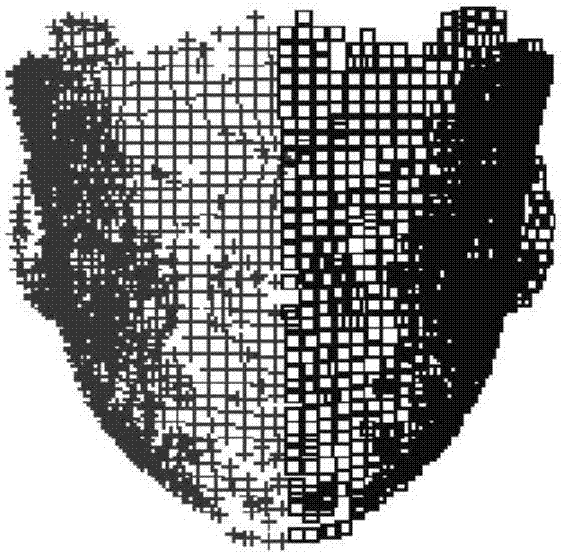

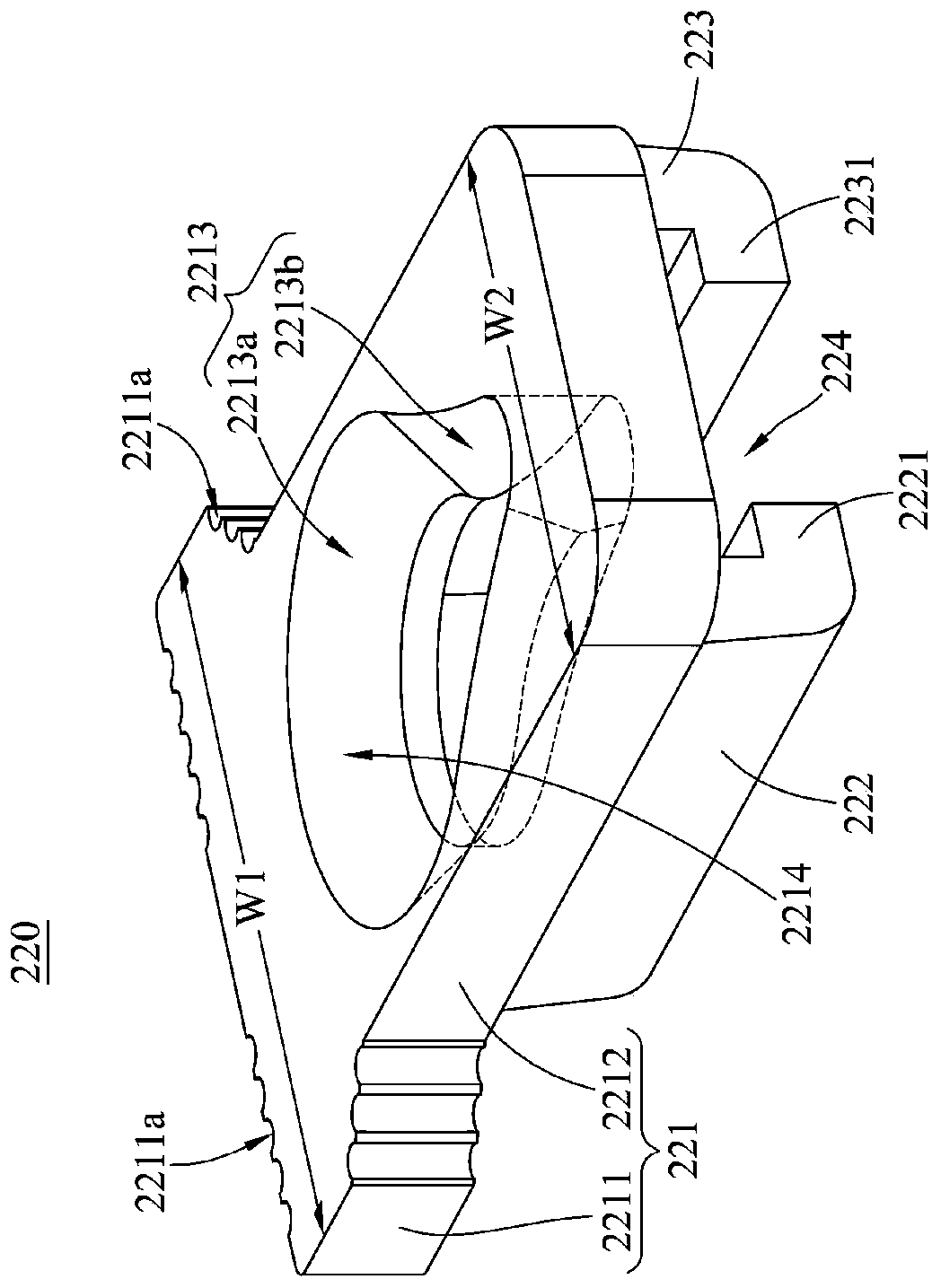

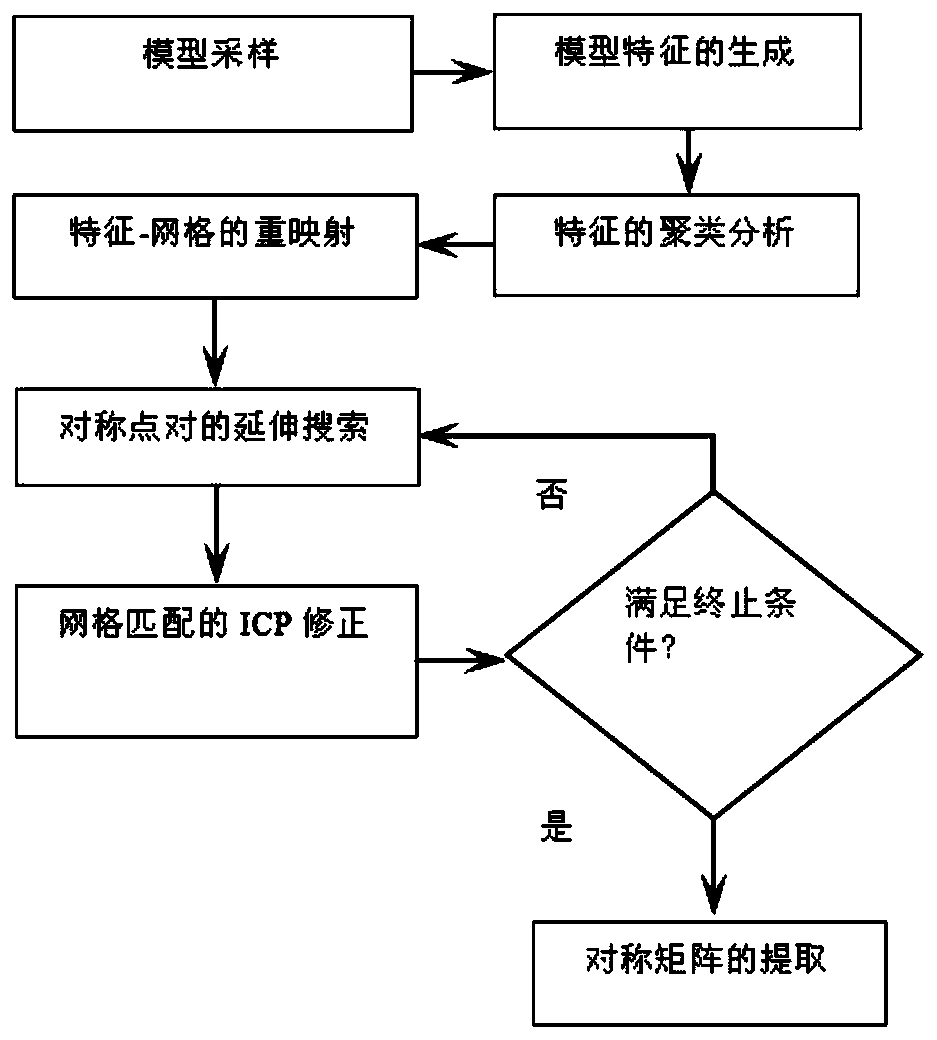

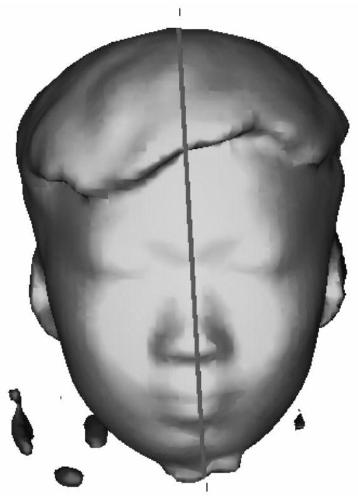

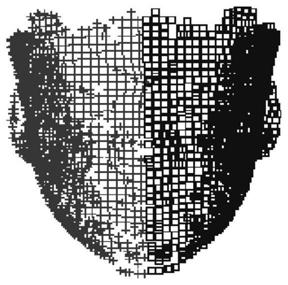

Symmetry analysis method for three-dimensional face model

ActiveCN107146251AIncrease the maximum amountImprove effectivenessImage enhancementImage analysisFeature extractionRelaxation factor

The present invention discloses a symmetry analysis method for a three-dimensional face model. The method comprises: sampling an input face model, and pairing sampling results so as to obtain symmetrical features; and extracting and clustering the obtained symmetrical features, so as to obtain a symmetry relation of the model. According to the method, a PCA constraint is added during feature extraction, which effectively increase the maximum number of initial sampling points when computing resources are limited; by improving the extraction method for the symmetrical feature, the validity of the clustering result is enhanced; and by adding a relaxation factor during feature-grid reassignment, stability of results is ensured and the matching is extended to the whole model. A test is performed on a face model that is acquired at Kinect and reconstructed using KinectFusion, and the validity of the method is verified.

Owner:ZHEJIANG UNIV

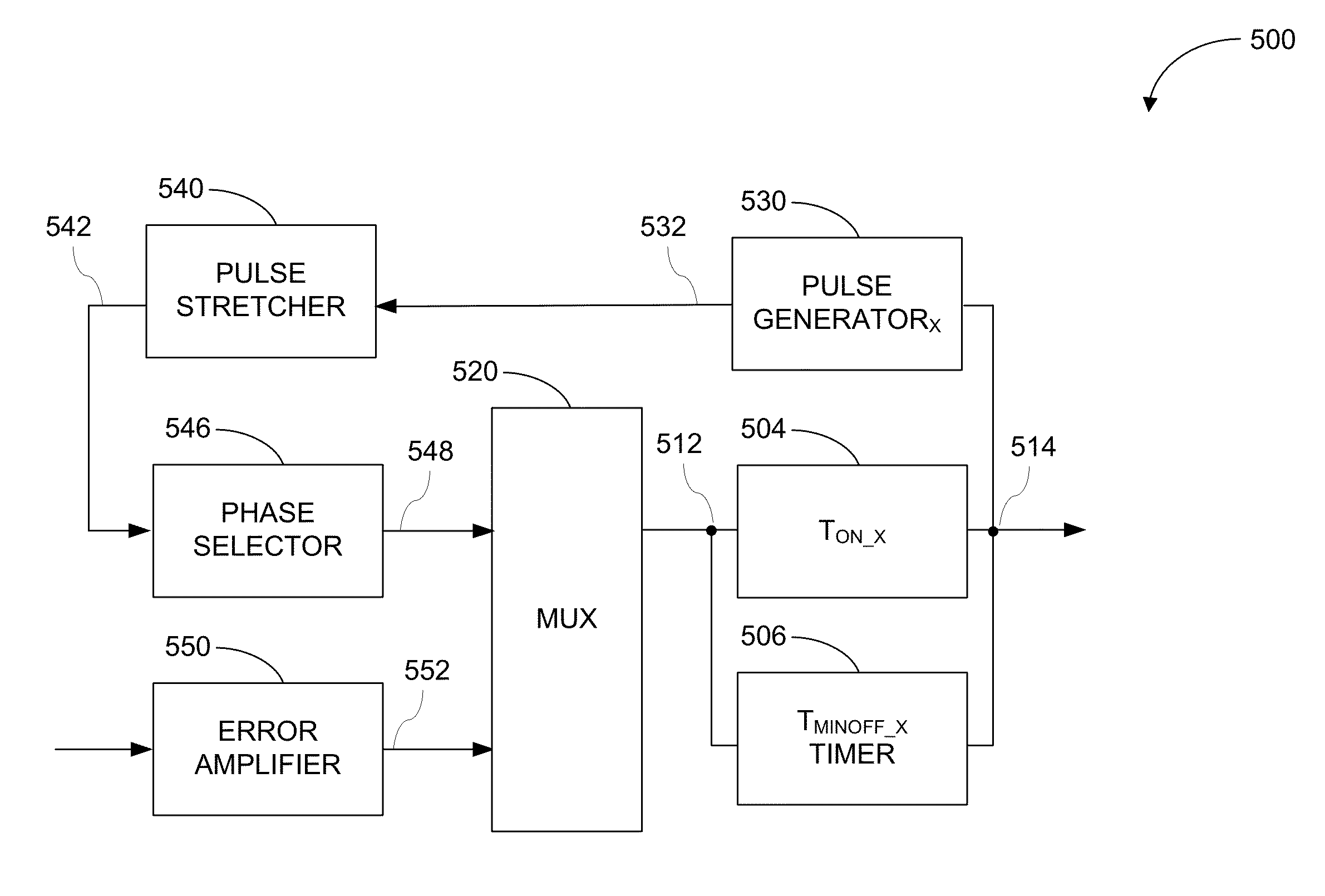

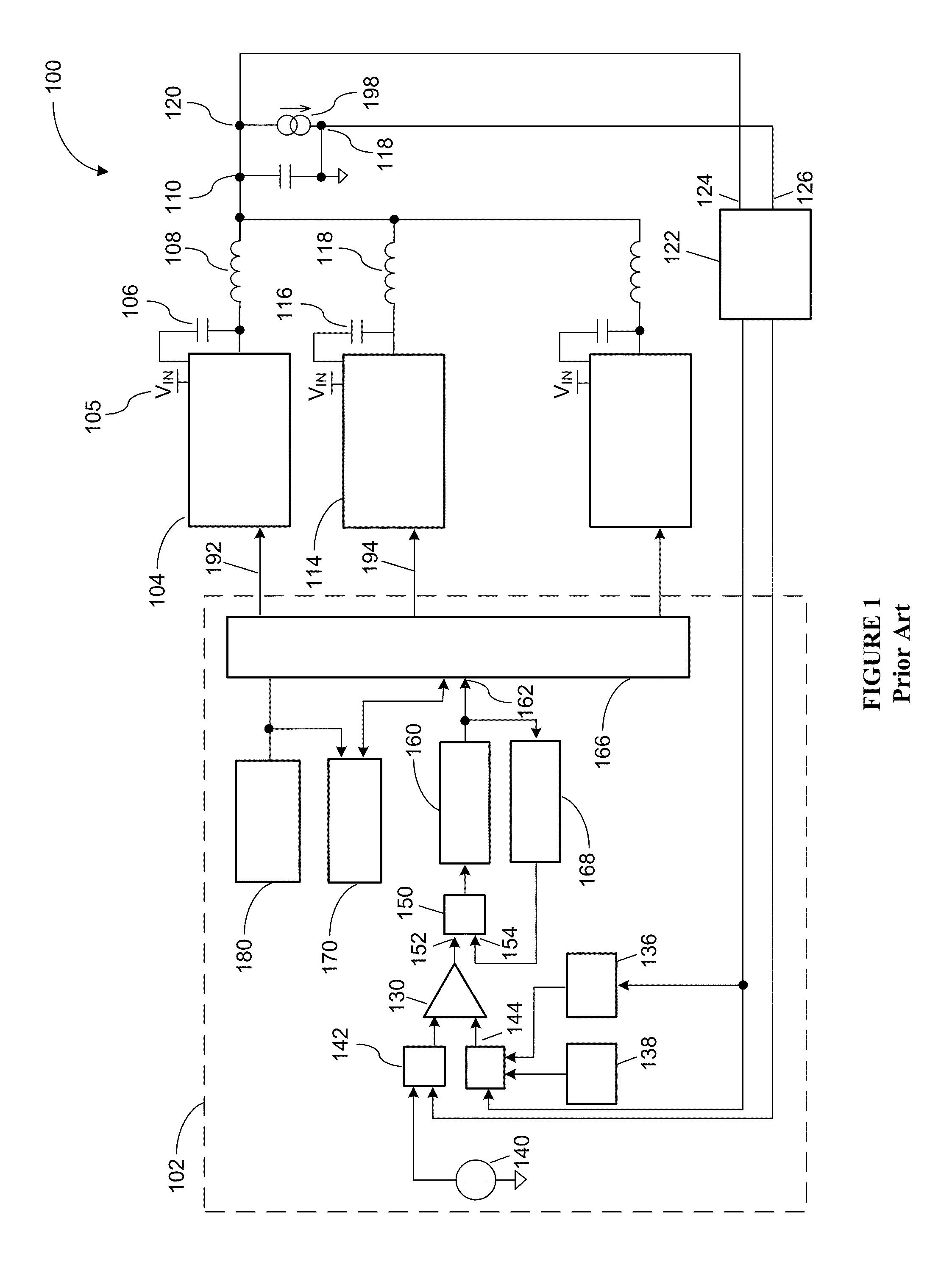

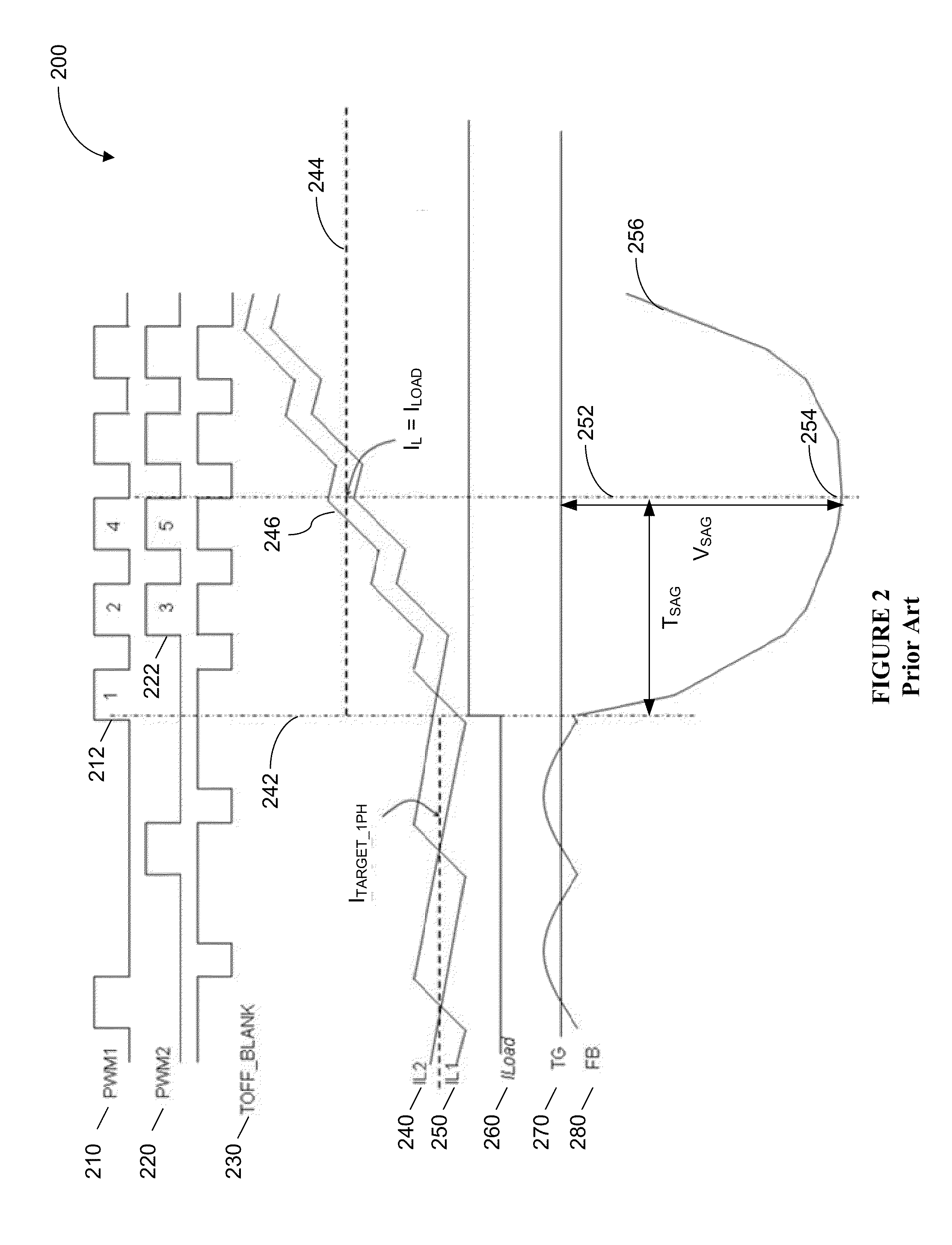

Systems and Methods to Control DC/DC Multiphase Switching Regulators

ActiveUS20140300331A1Take periodImprove transient responseDc-dc conversionElectric variable regulationSwitching frequencyControl theory

Various embodiments of the invention provide extend the switching frequency range of DC / DC multiphase switching regulators in order to overcome prior art frequency limitations in the number of available phases, for example, in low input to output ratio applications. In certain embodiments, this is accomplished by enabling partial overlap between multiple phases using asynchronous logic. The invention is easily scalable without introducing significant silicon area penalties.

Owner:MAXIM INTEGRATED PROD INC

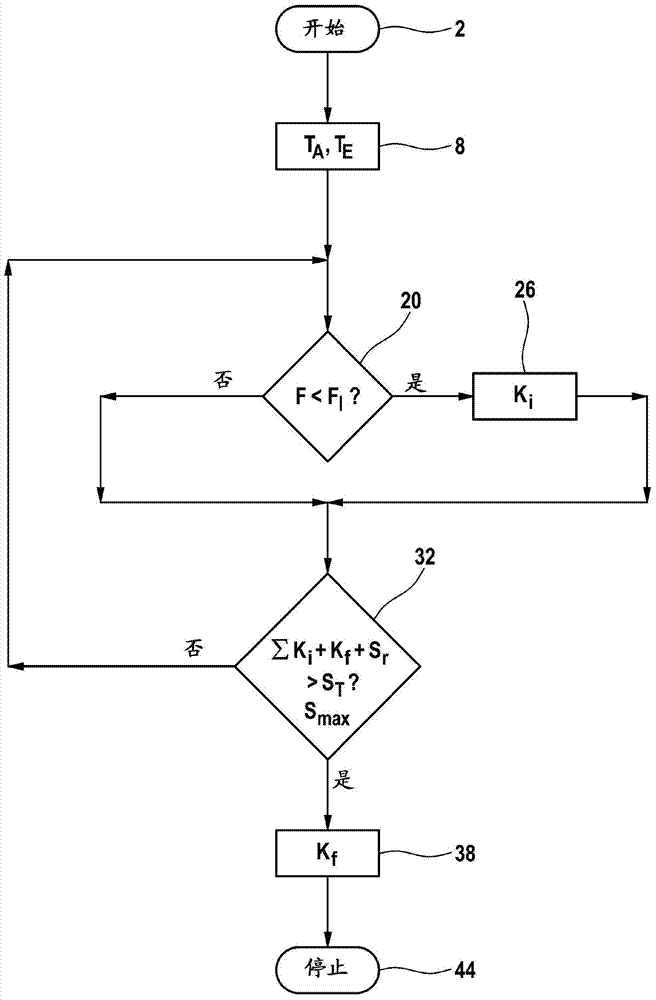

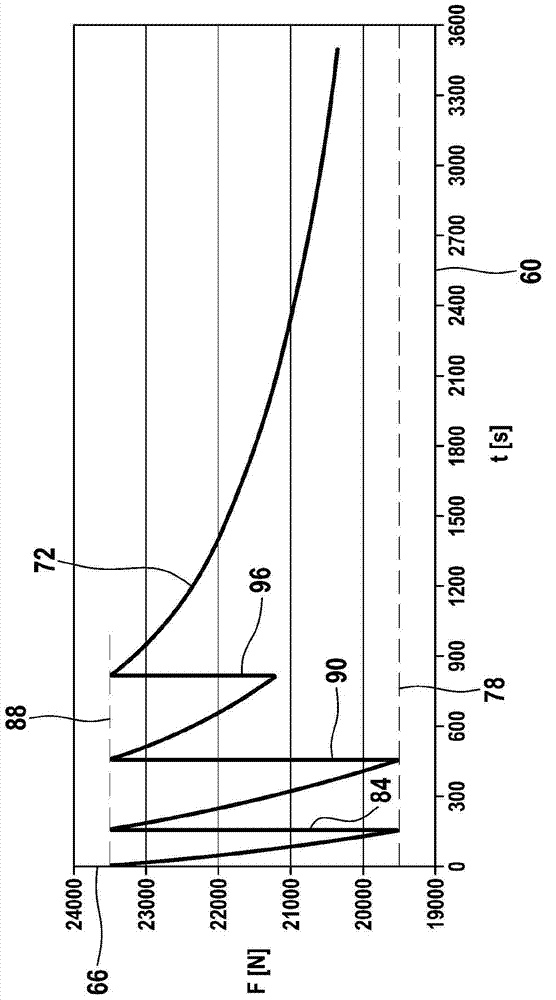

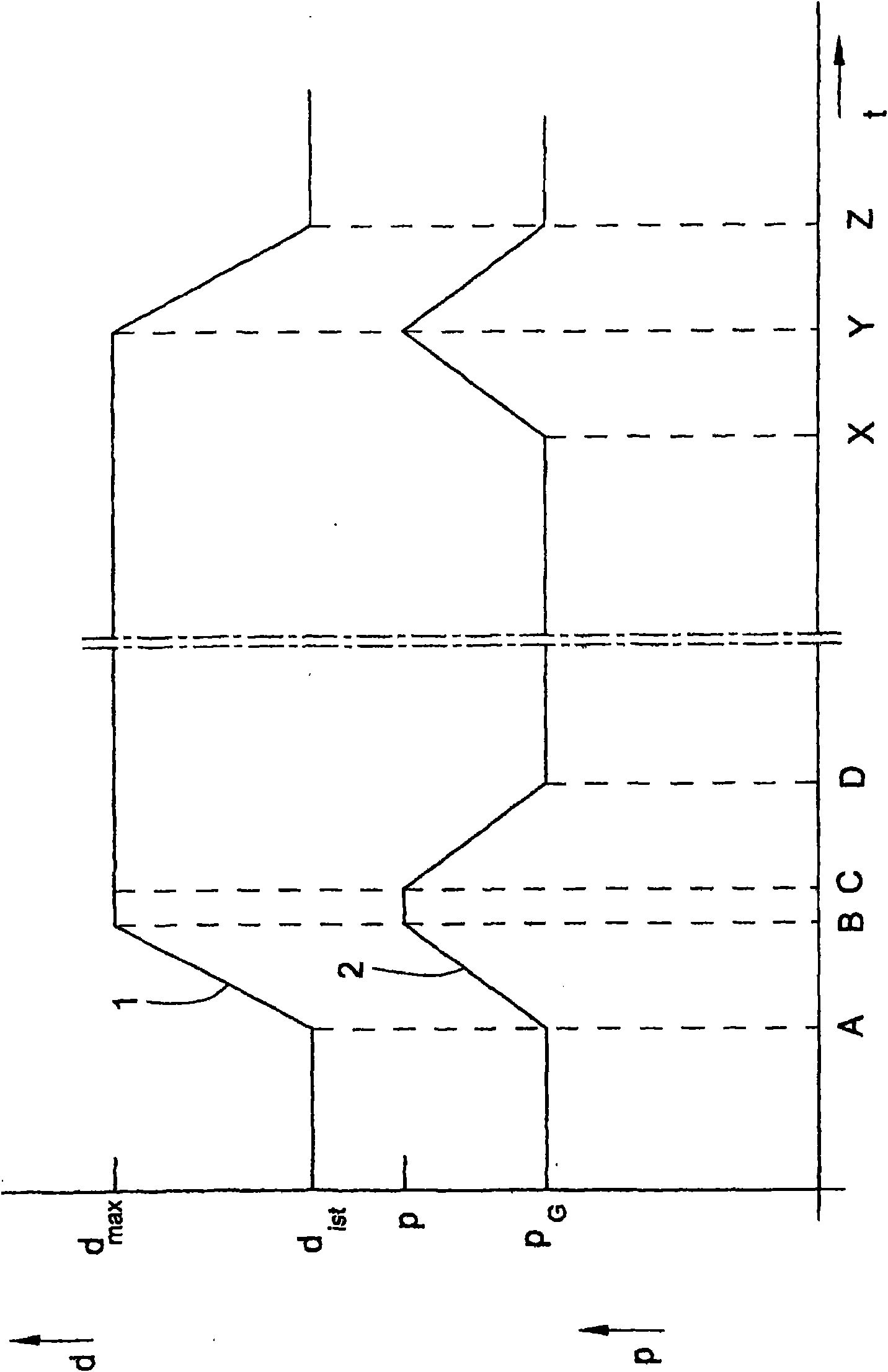

A method for tightening an electromechanical brake, and an electromechanical brake

InactiveCN103687767AAvoid clamping forceIncrease clamping forceBraking action transmissionBrake control systemsEngineeringActuator

The invention relates to a method for tightening an electromechanical brake having an actuator which is driven by an electric motor and which presses a brake element against a brake body with a force stroke in order to implement a parking brake functionality, wherein for the purpose of tightening a number of chronologically successive force strokes are carried out, the intention being to configure the tightening process as effectively and reliably as possible. For this purpose, the force strokes are each applied as soon as the tensioning force of the brake drops below a predefined tensioning force minimum setpoint value, wherein the respective force stroke is applied in such a way that a predefined maximum tensioning force is not exceeded, wherein the expected total loss of tensioning force is determined on the basis of the initial temperature of the brake body and the expected final temperature of the brake body, and wherein the time of a last force stroke is selected in such a way that at this time the sum of the previous force strokes, the last force stroke and the still expected loss of tensioning force exceeds the expected total loss of tensioning force.

Owner:CONTINENTAL TEVES AG & CO OHG

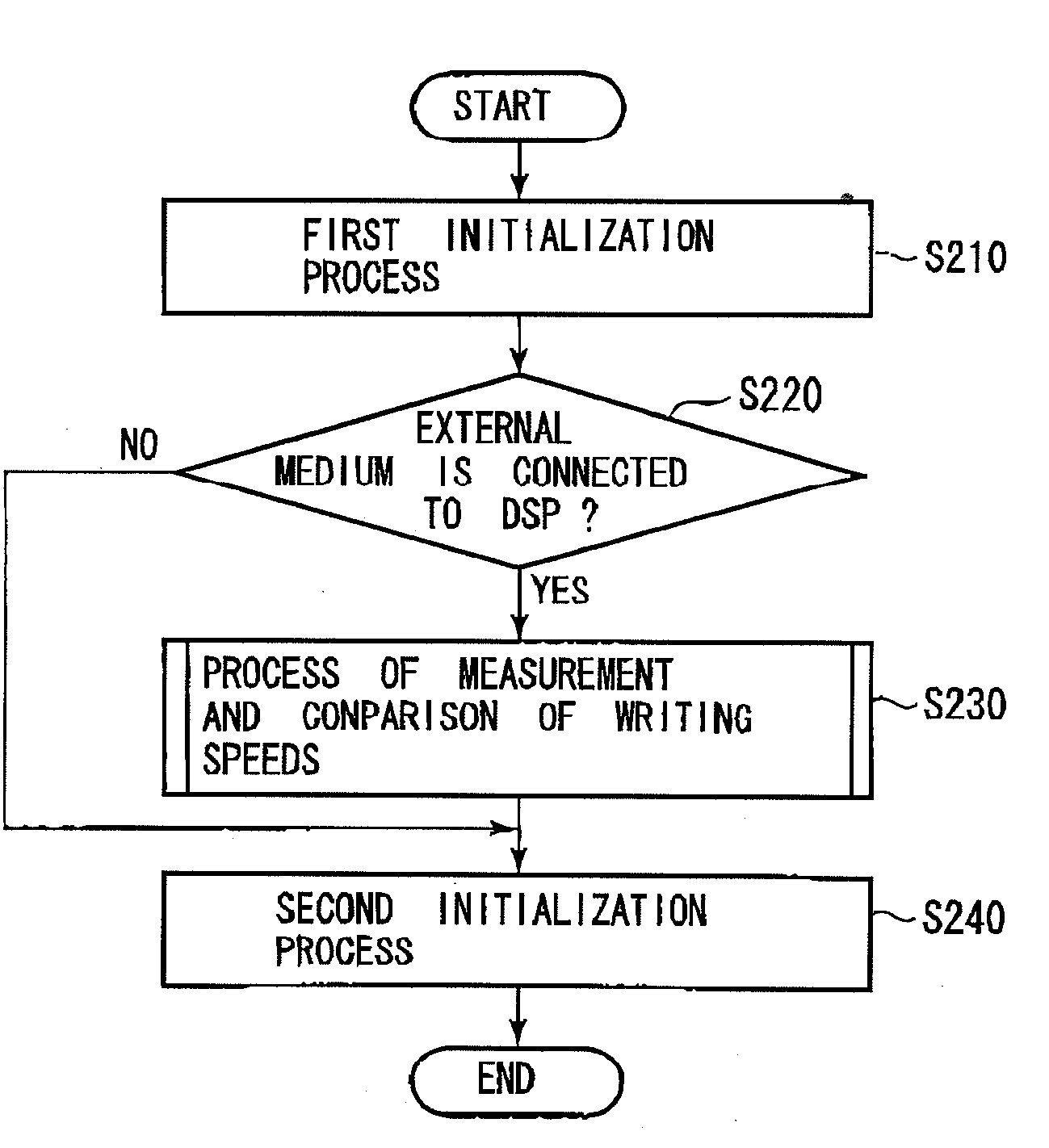

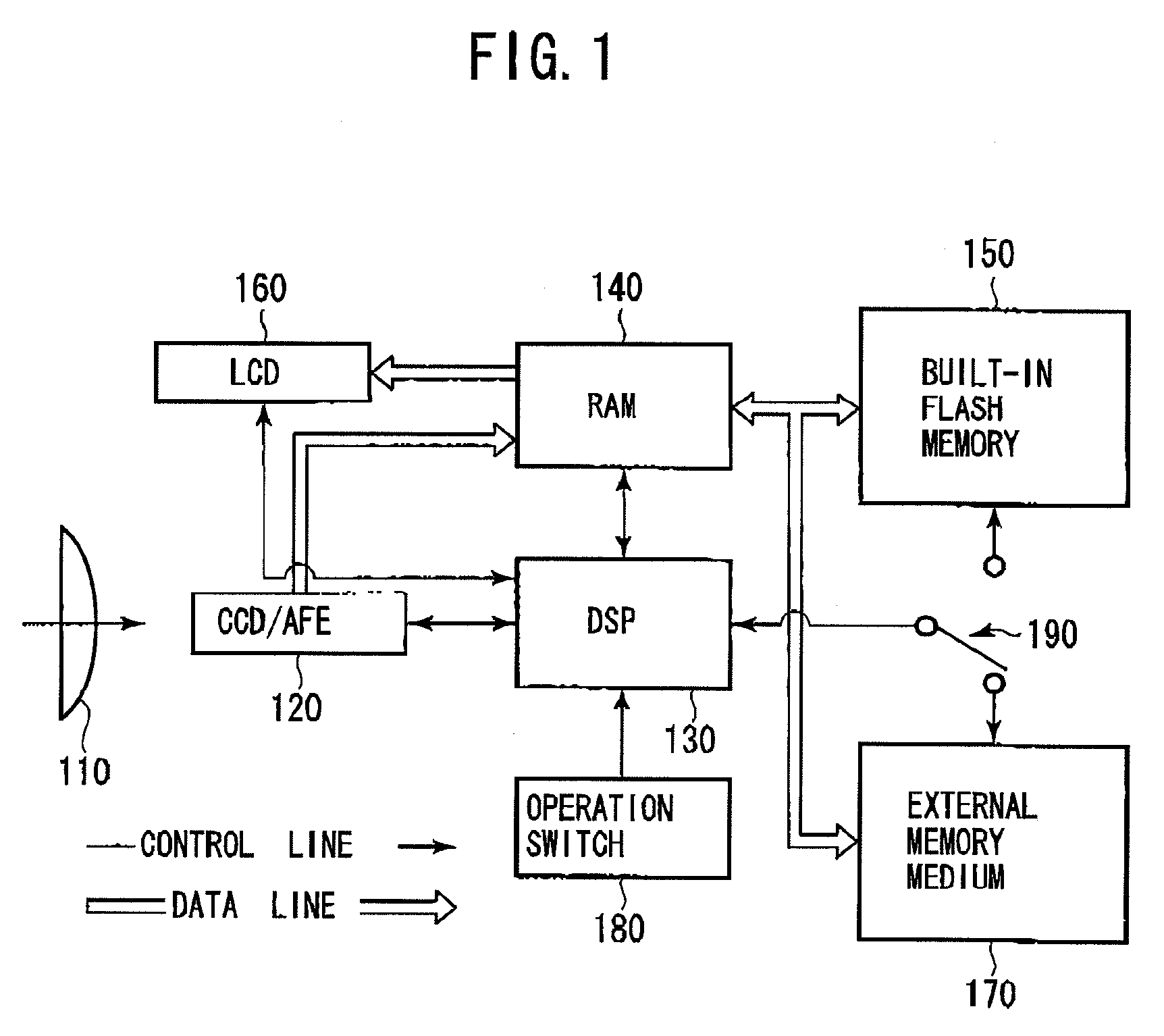

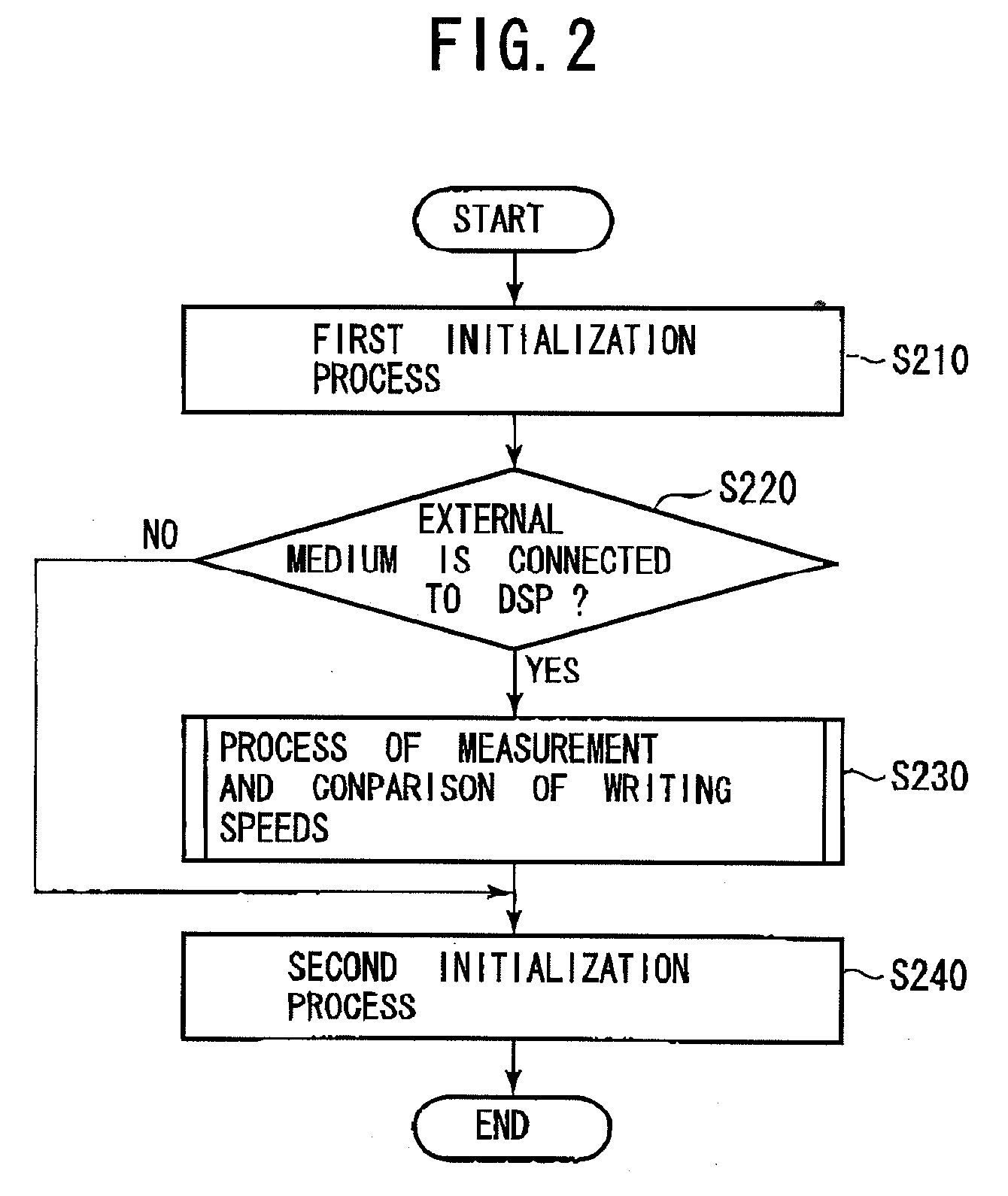

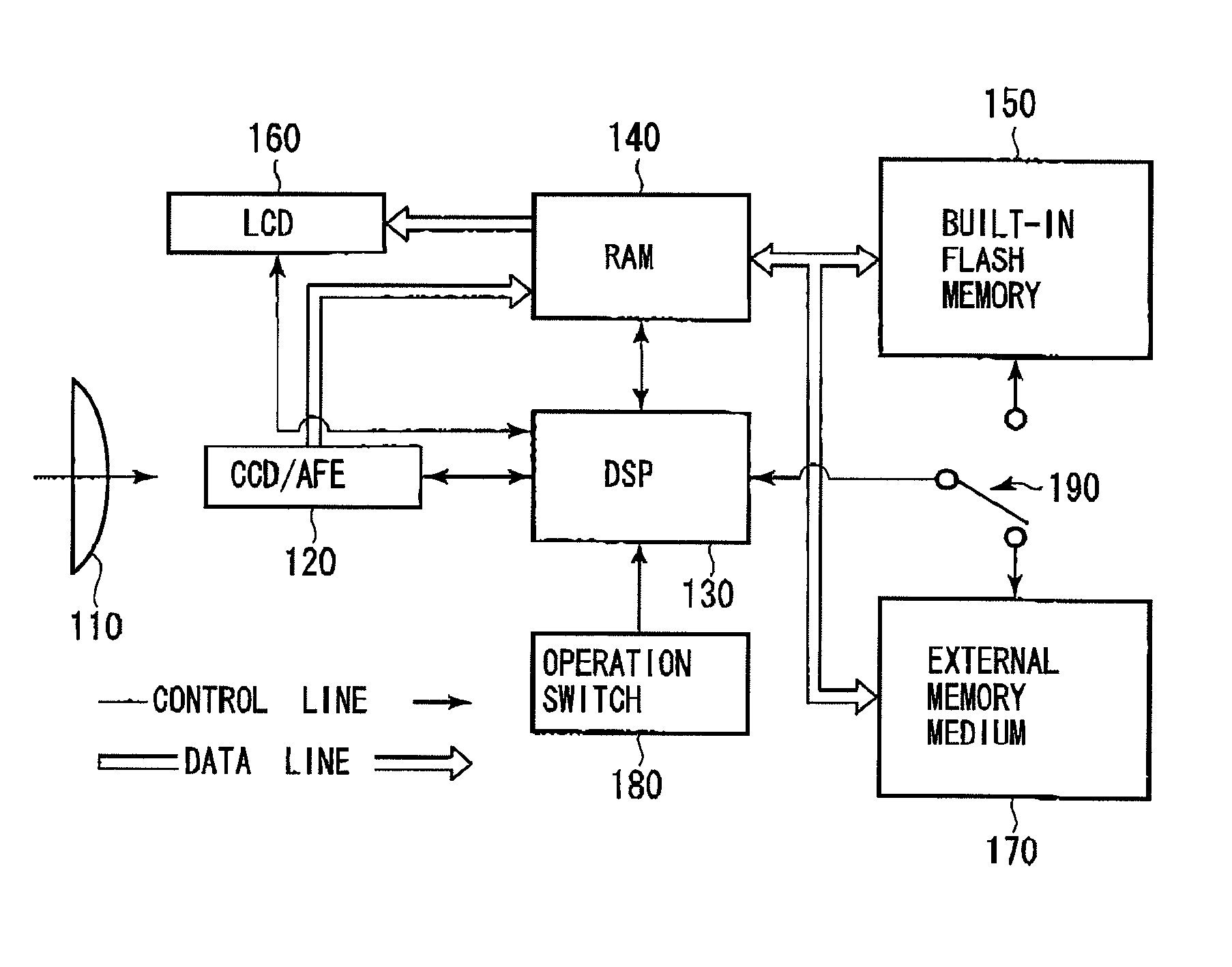

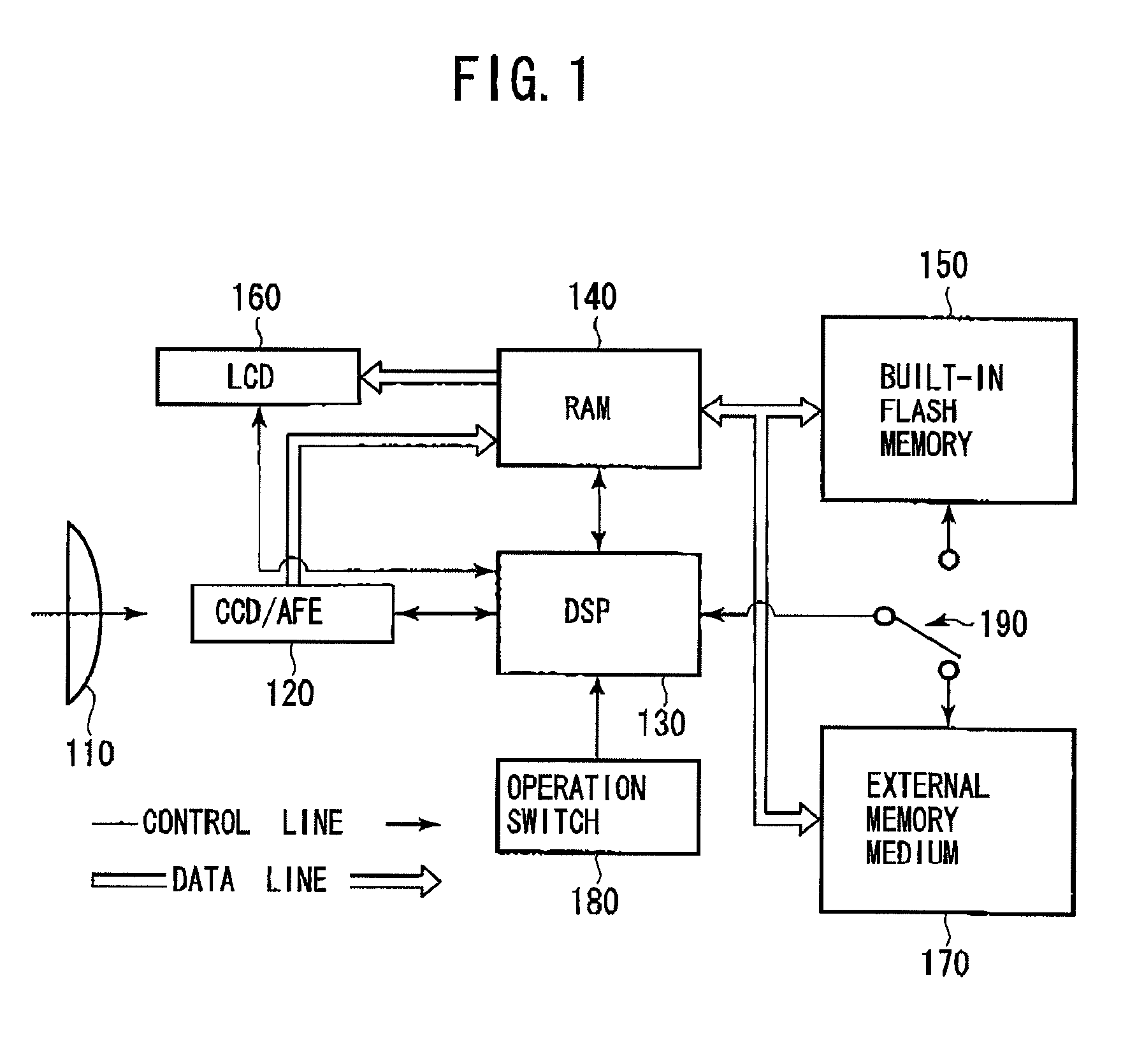

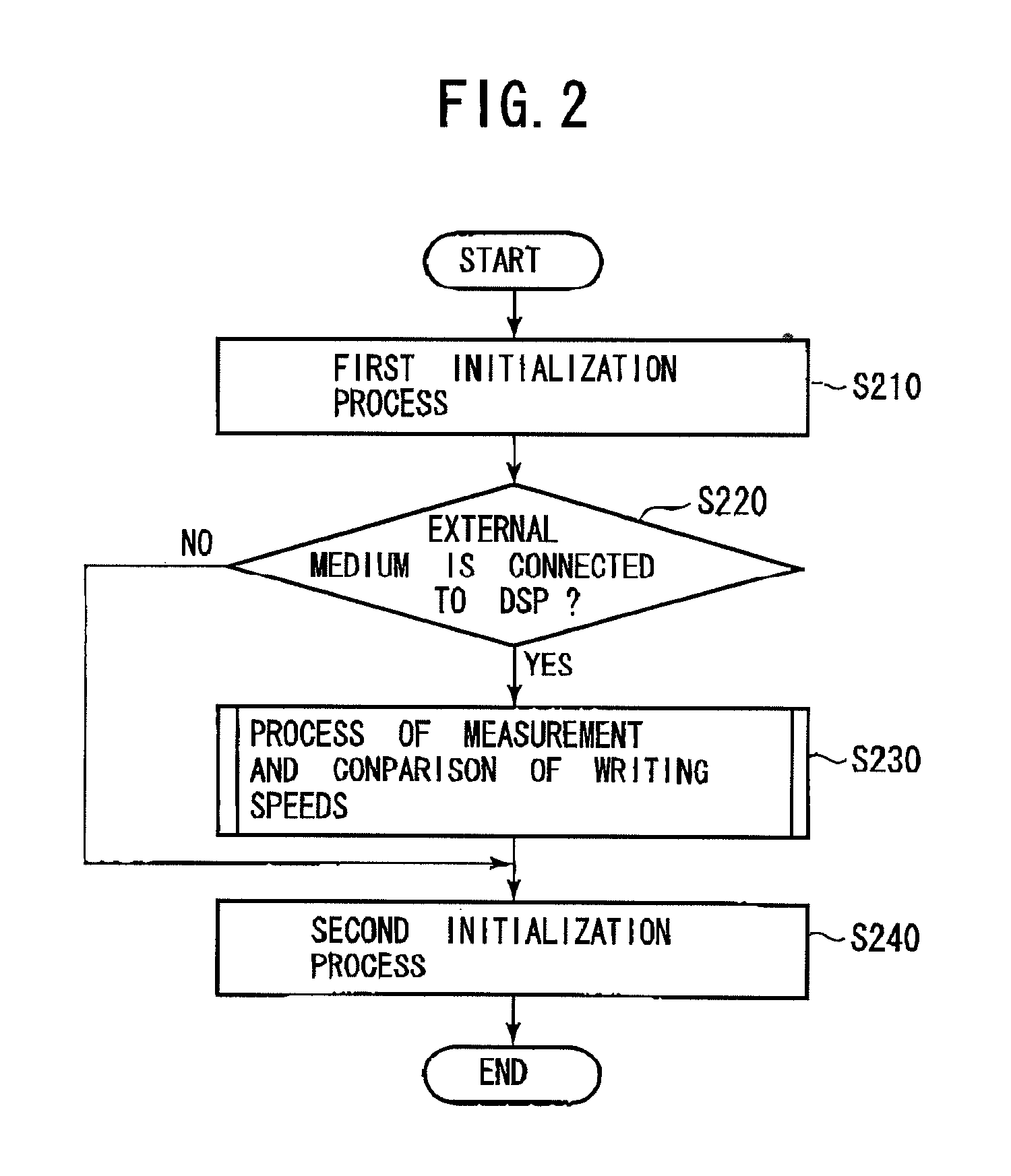

Image-capturing apparatus

InactiveUS20080062184A1Reduce storage timeIncrease the maximum amountTelevision system detailsImage memory managementDummy dataImage capture

An image-capturing apparatus is provided having a storage control device, a writing speed measuring device, and a selecting device. The storage control device writes image data into memory devices. The writing speed measuring device measures the writing speed of the memory devices by writing dummy data into the memory devices. The selecting device compares the writing speeds of the memory devices, and selects the memory device having the fastest writing speed. The storage control device stores image data in the selected memory device.

Owner:RICOH IMAGING COMPANY

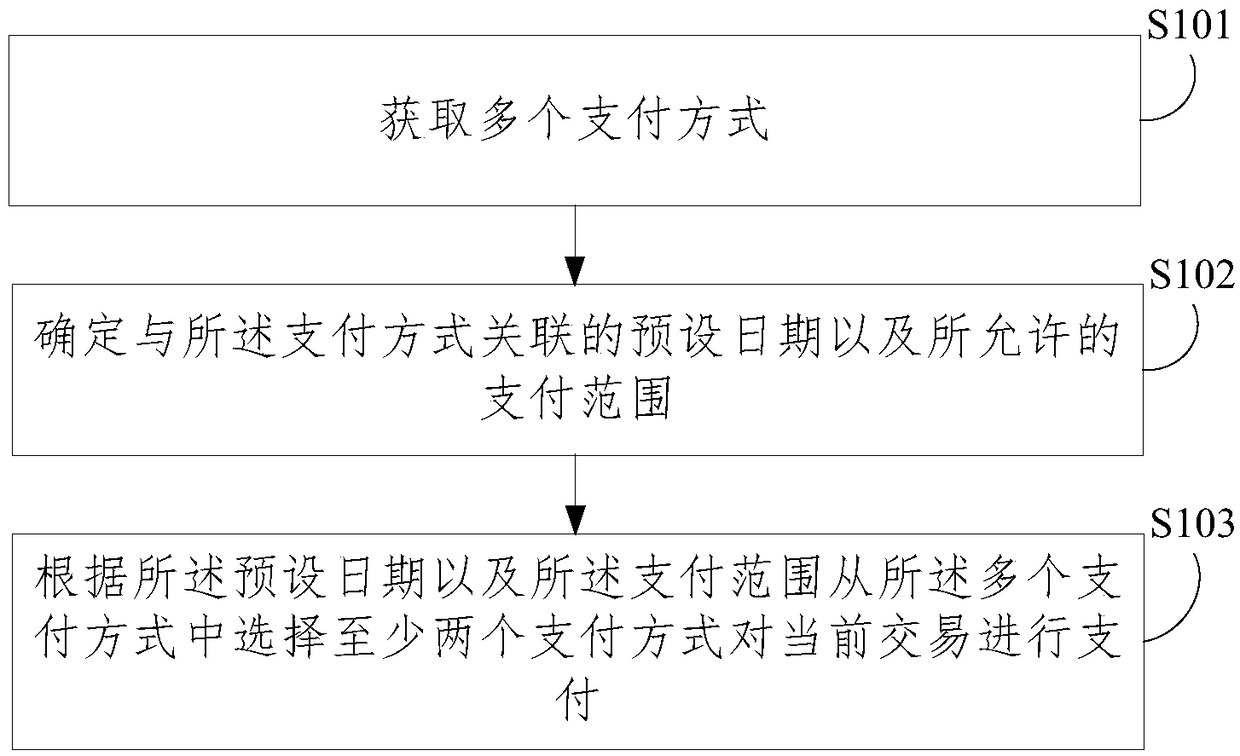

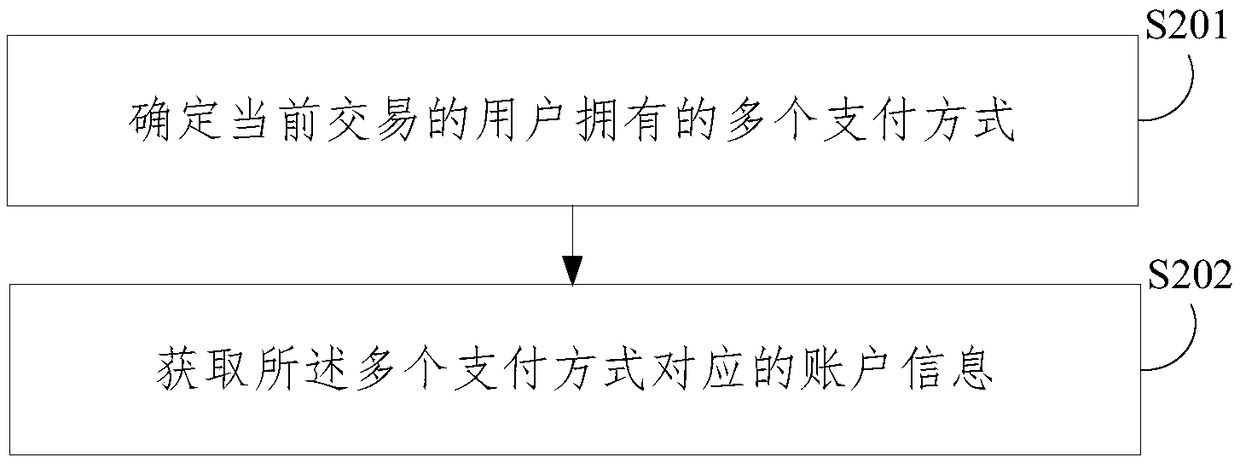

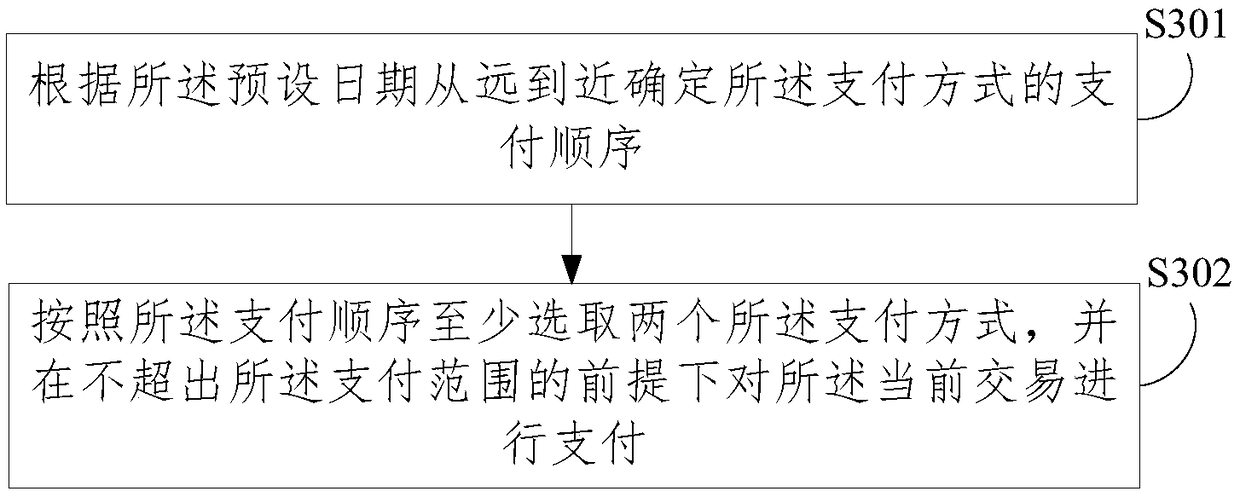

Payment method, apparatus, electronic device and storage medium

InactiveCN109118235AImprove experienceSave the process of manually selecting a payment methodProtocol authorisationPaymentComputer hardware

Embodiments of the present disclosure disclose a payment method, an apparatus, an electronic device, and a storage medium. The method comprises the following steps: acquiring a plurality of payment methods; determining a preset date associated with the payment method and an allowable payment range; at least two payment methods are selected from the plurality of payment methods according to the preset date and the payment range to pay for the current transaction.

Owner:LAKALA PAYMENT CO LTD

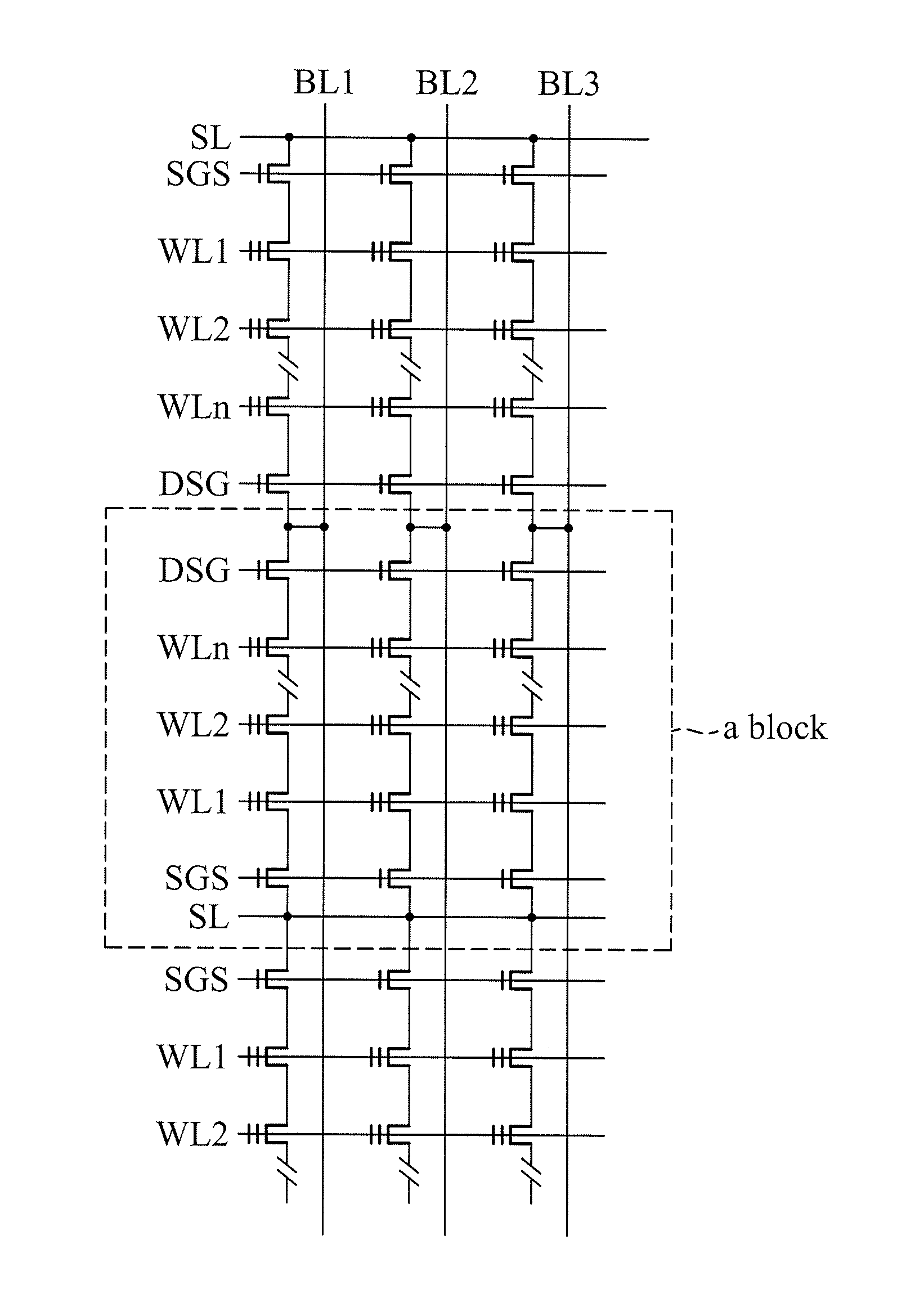

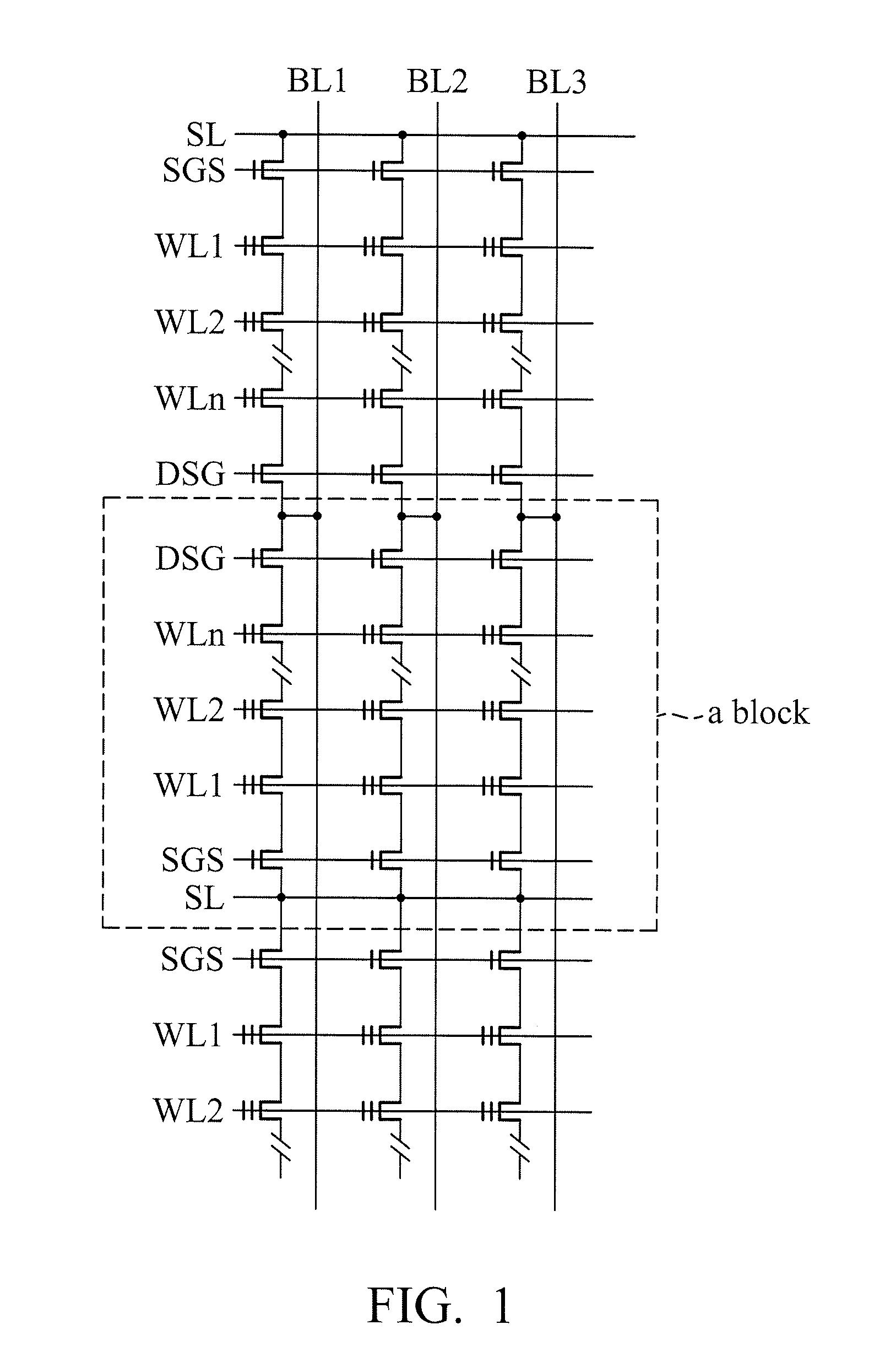

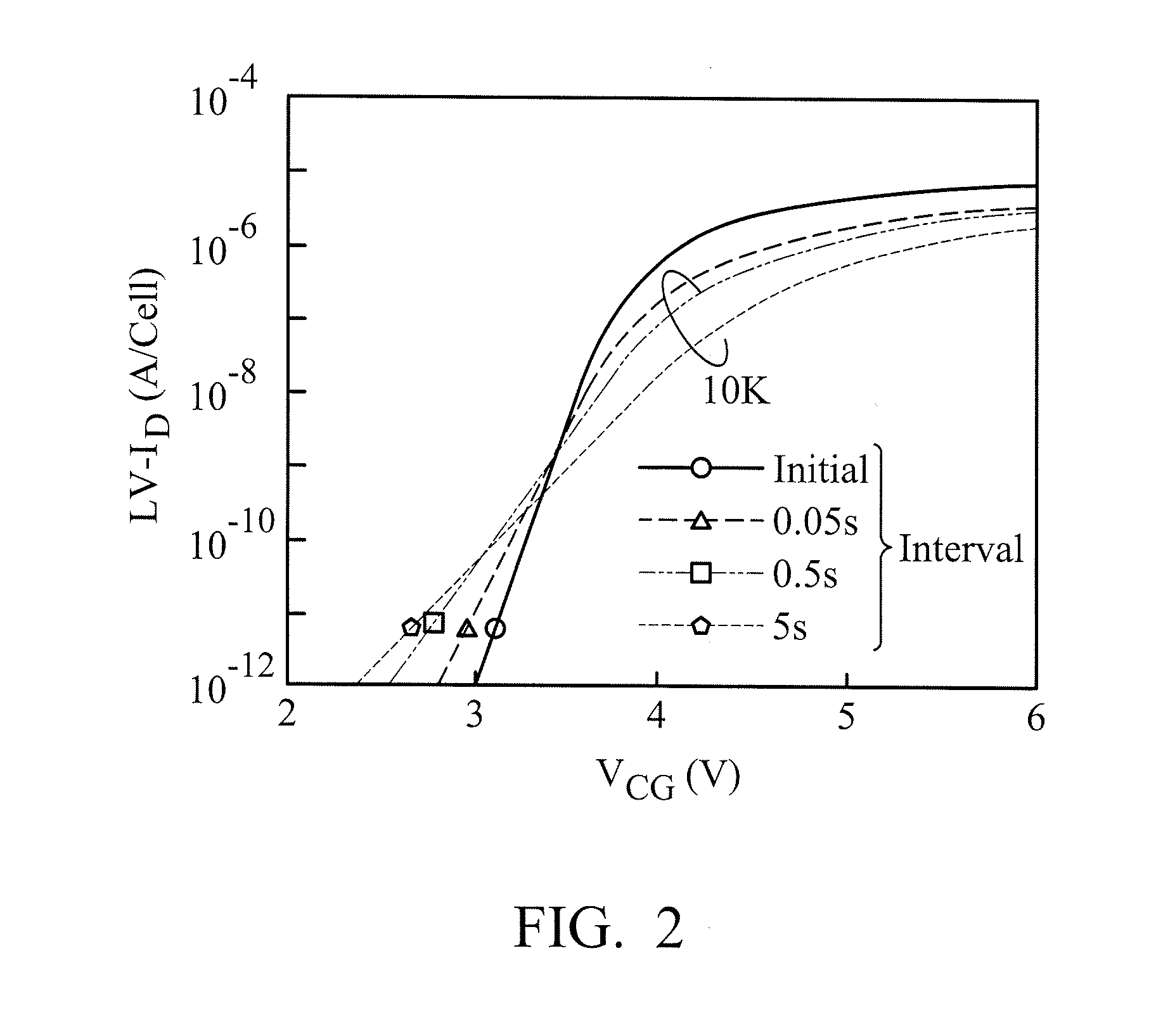

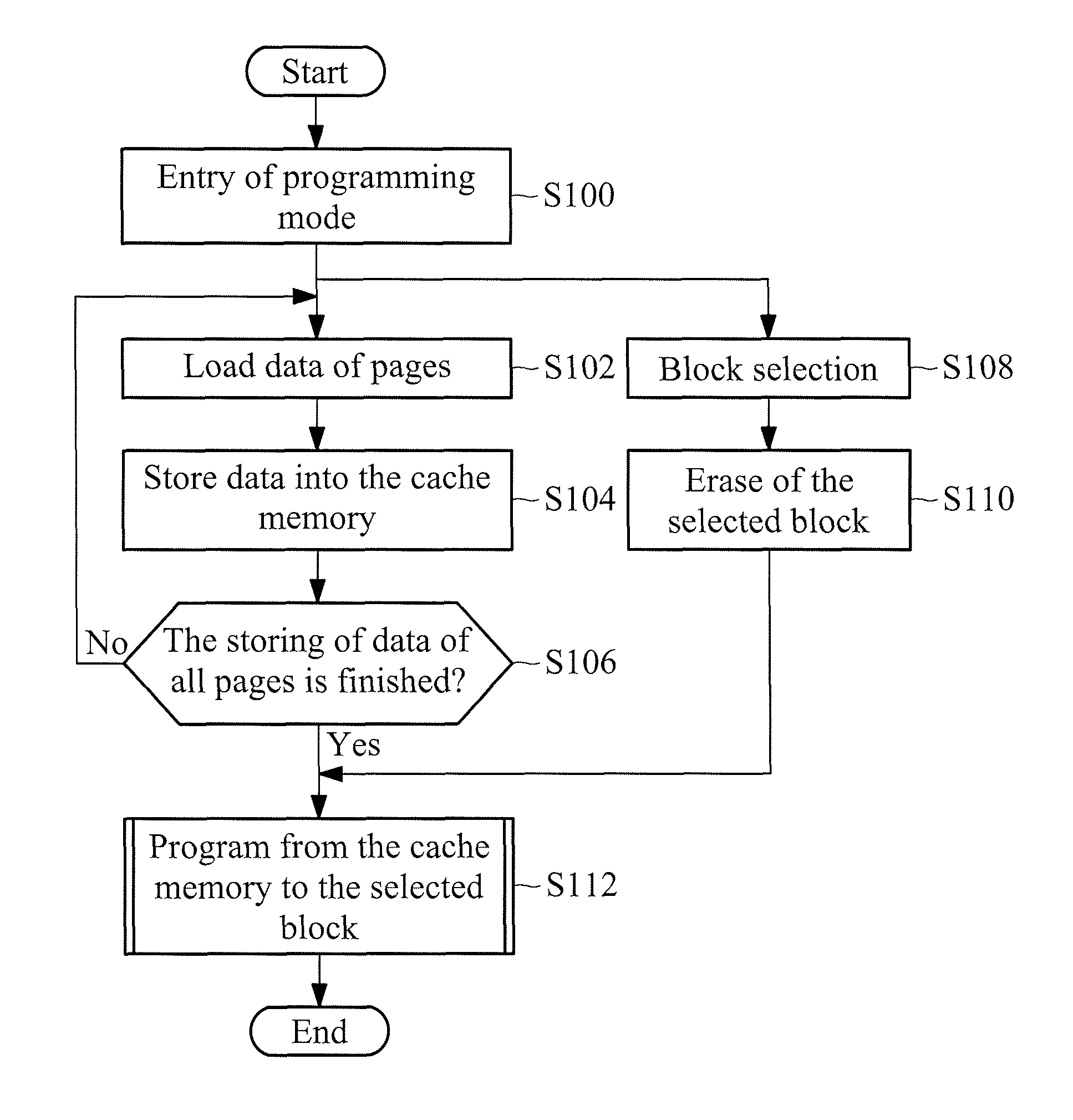

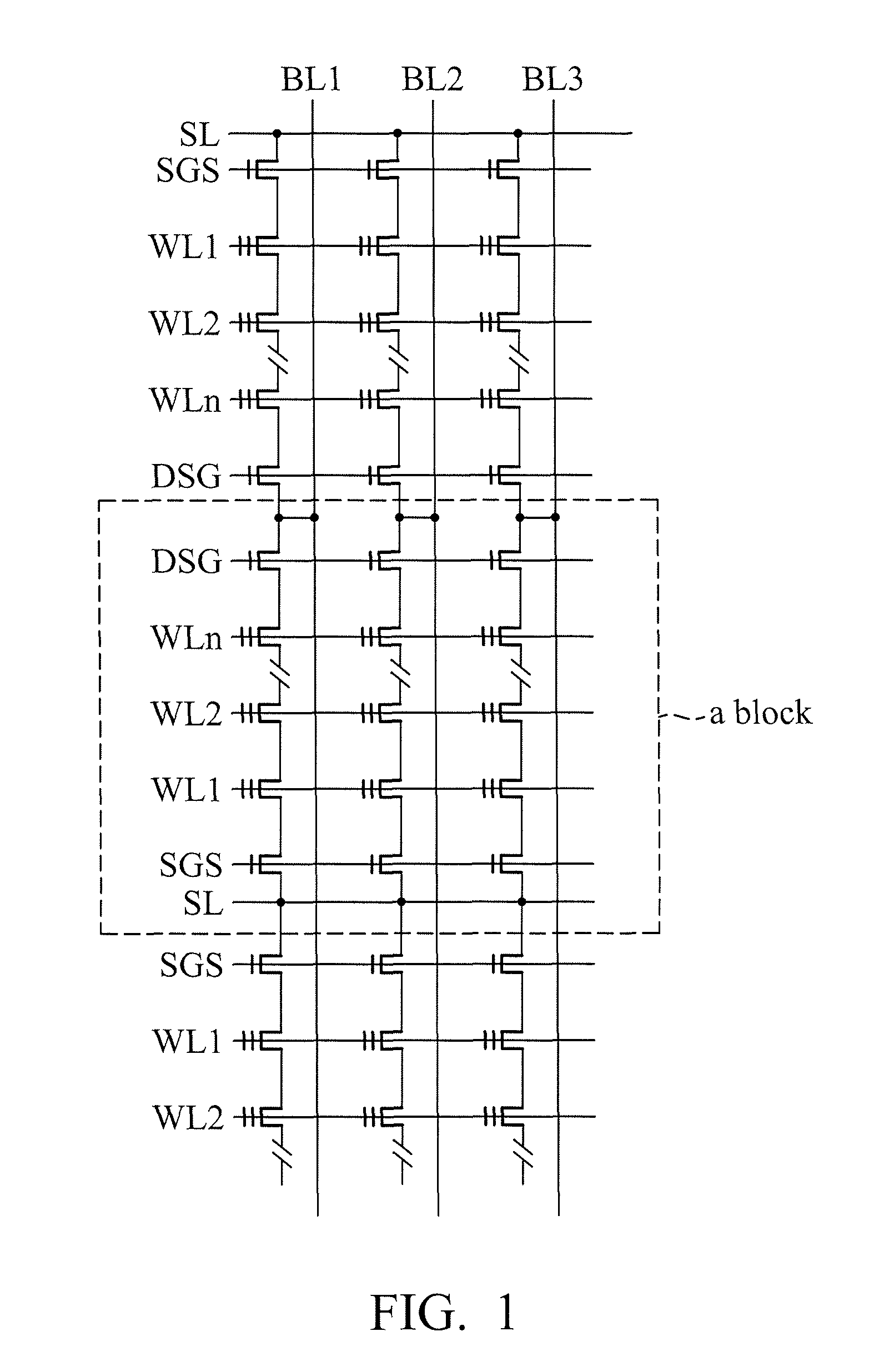

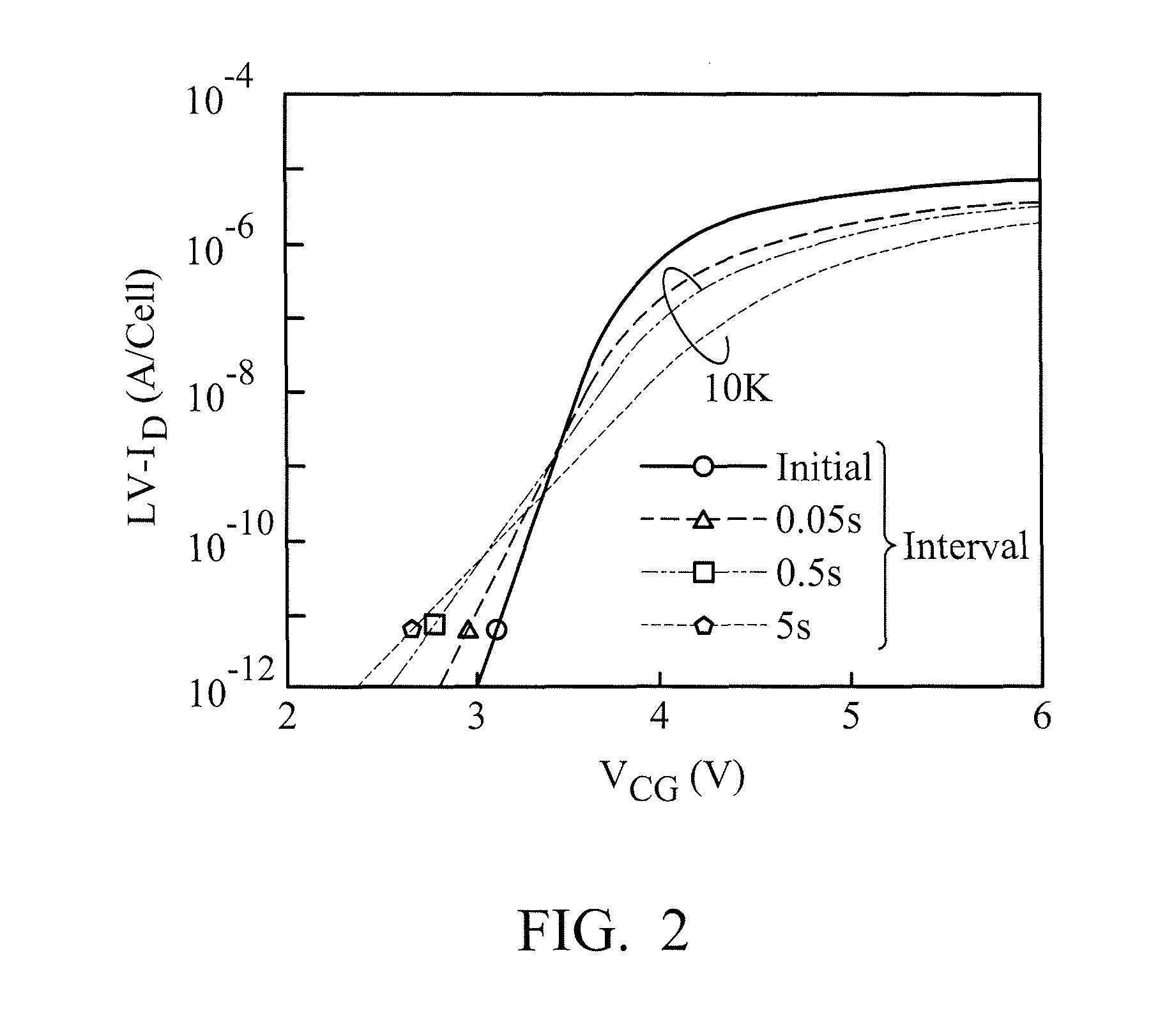

Programming method for NAND-type flash memory

ActiveUS20160125947A1Increase the maximum amountHigh-speed programming operationRead-only memoriesDigital storageProgramming methodFlash memory

The invention provides a programming method for a NAND-type flash memory capable of reducing the drop in reliability due to data-rewriting. The programming method includes: when a block program mode is executed to perform programming for a plurality of pages in a block, while the data to be programmed is being loaded into a cache memory; and erasing the selected block; and programming the data to be programmed which is loaded into the cache memory to the erased block.

Owner:WINBOND ELECTRONICS CORP

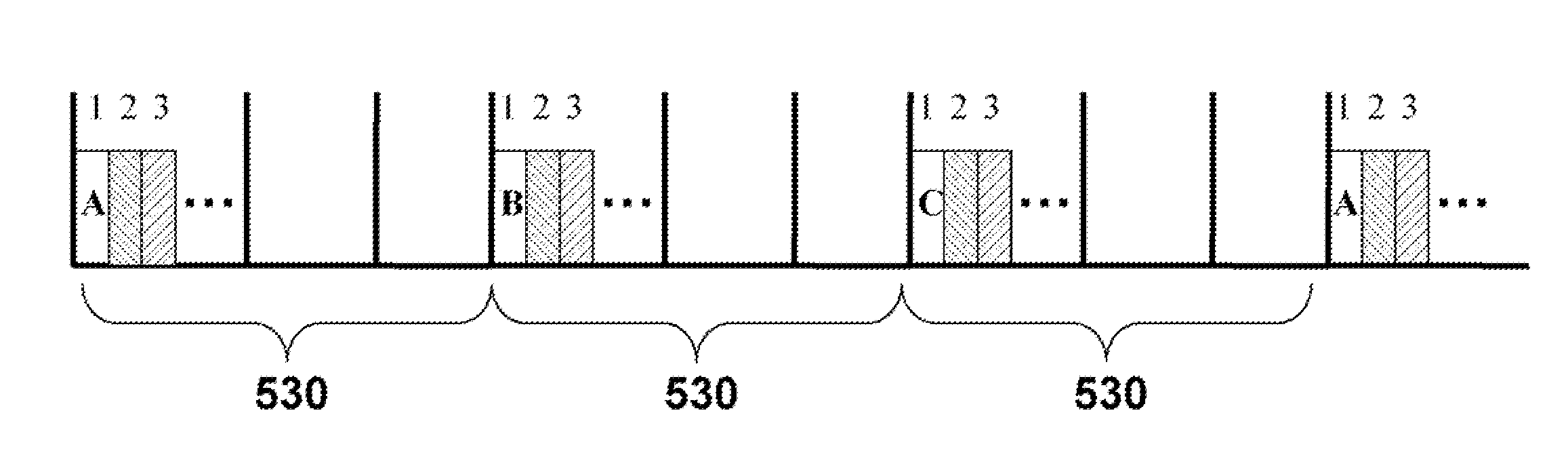

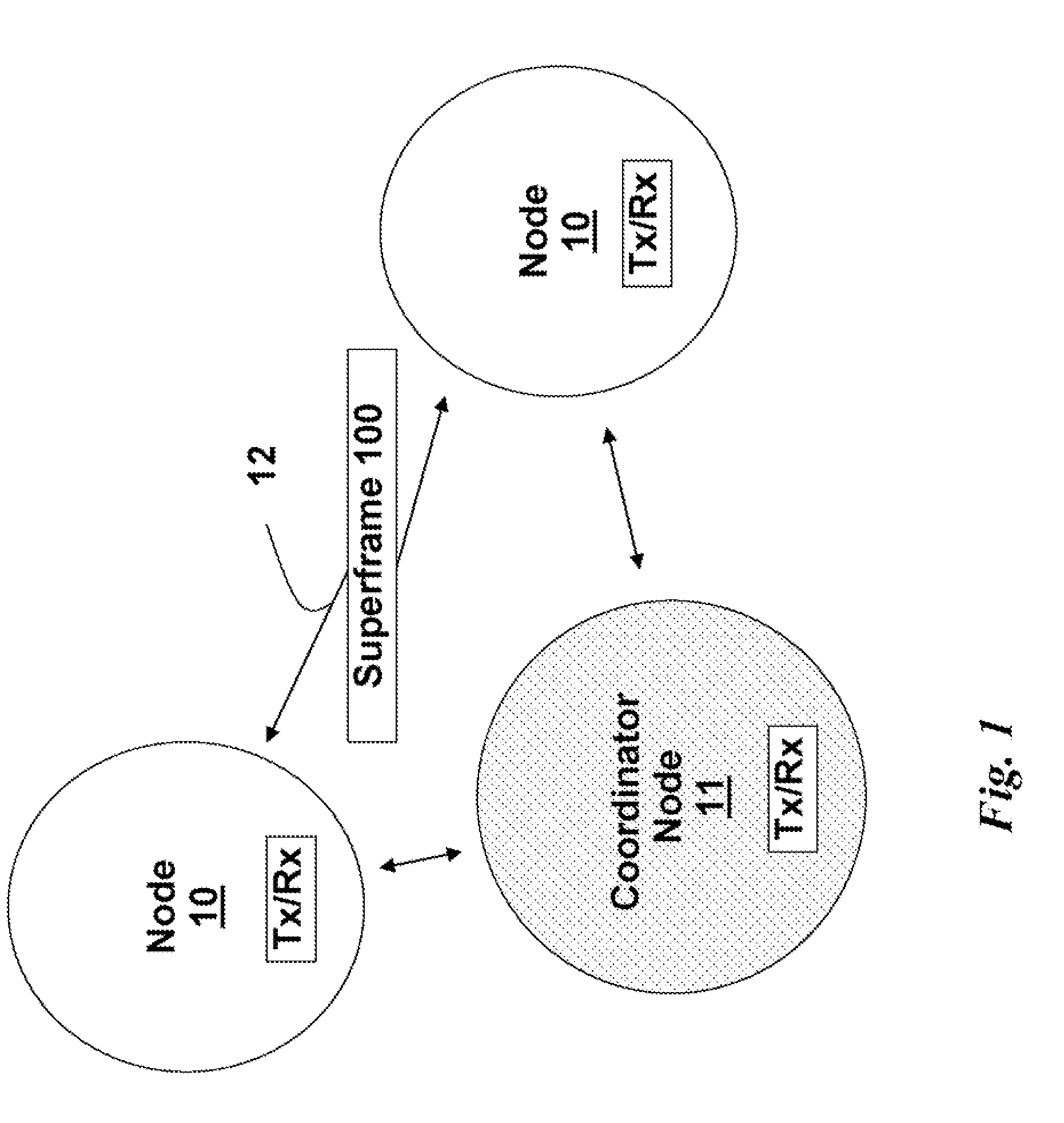

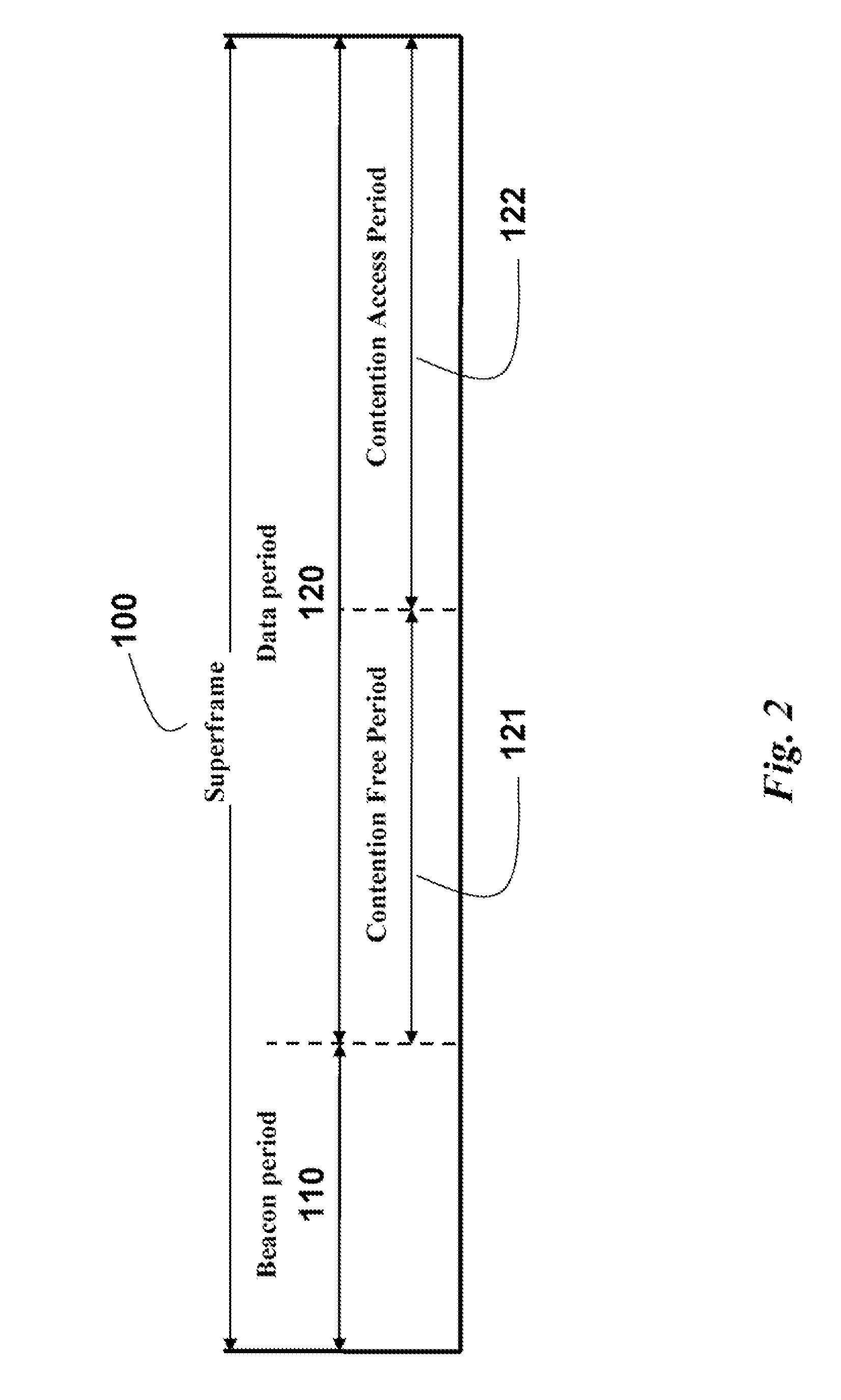

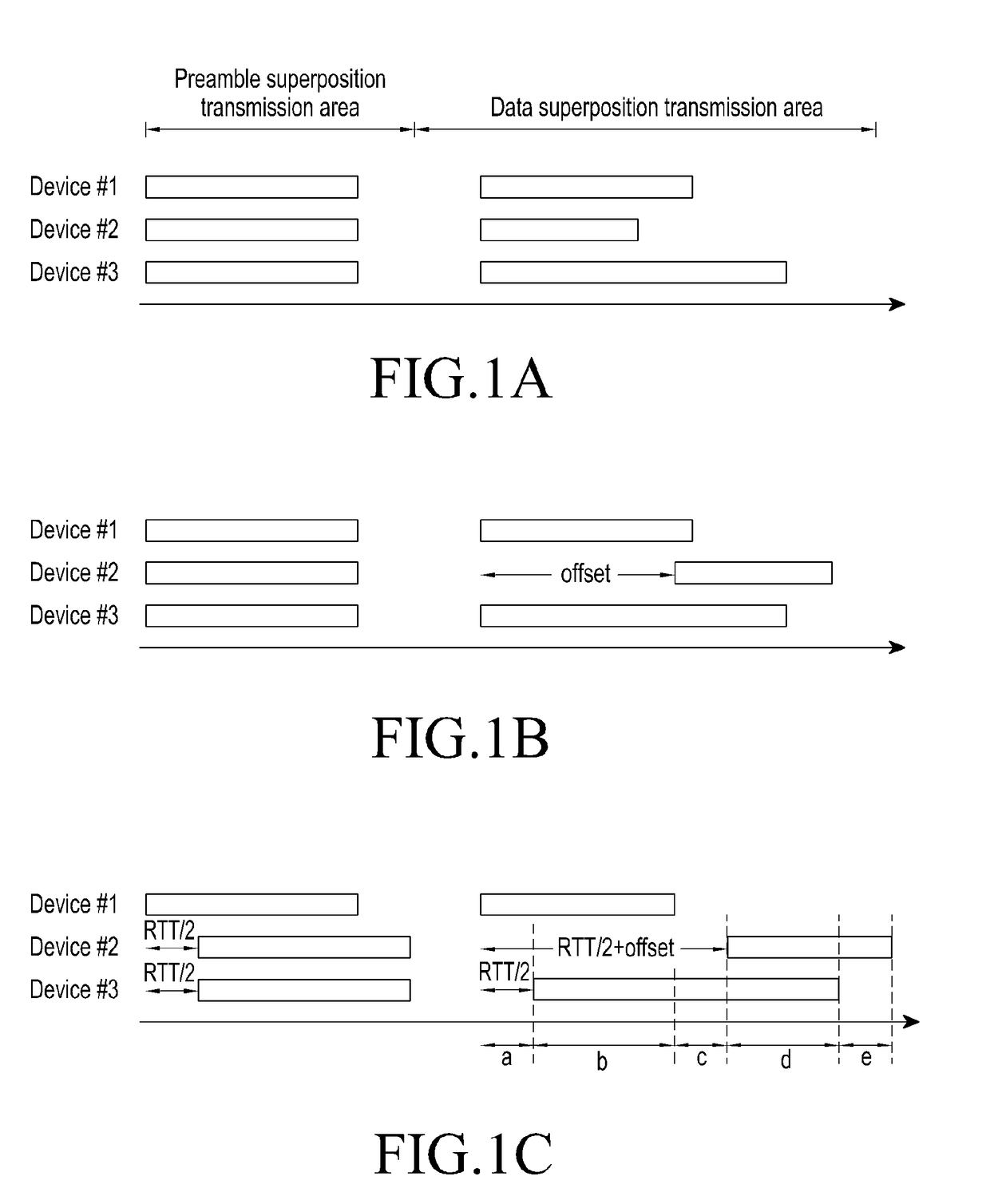

Timeslot sharing protocol for wireless communication networks

InactiveUS8571003B2Increase the maximum amountReduce power consumptionAssess restrictionNetwork topologiesInformation transmissionDistributed computing

A method for transmitting information in a communication network of multiple nodes, in which information transmission is partitioned into successive superframes, and in which each superframe is partitioned into a beacon period followed by a data period, which may consist of a contention free period (CFP), and each beacon period and CFP of the data period is partitioned into timeslots. The method includes allocating to at least a first node of the multiple nodes a designated timeslot in which to transmit data in at least one of a plurality of superframes, and allocating to at least a second node of the multiple nodes the same designated timeslot in which to transmit information during at least one subsequent superframe.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Method for operating a textile machine which is provided with a vacuum device and produces crosswound bobbins

ActiveCN101600828AIncrease the maximum amountIncrease the number ofFilament handlingDrafting machinesDrive motorBobbin

The invention relates to a method for optimizing the number of workstations, which can be supplied with additional vacuum simultaneously on account of circuits, of a textile machine which has a multiplicity of workstations, wherein the textile machine has a vacuum system with at least one vacuum assembly, the vacuum output of which can be increased via the rotational speed of its drive motor, regulated by monitoring of the vacuum level, until a maximum rotational speed is reached. There is provision according to the invention for a value for a rotational speed reserve to be calculated from the known maximum rotational speed of the drive motor of the vacuum assembly, which maximum rotational speed defines the maximum vacuum output of the vacuum system of the textile machine, and from a prevailing actual rotational speed of the drive motor of the vacuum assembly, which actual rotational speed results from the current vacuum requirement of the textile machine, using which value for a rotational speed reserve the number of workstations is determined which can still be supplied with additional vacuum. A maximum number of workstations which can be supplied simultaneously with additional vacuum is determined from this number, increased by the number of workstations which are currently already being supplied with additional vacuum on the basis of the actual rotational speed of the drive motor, and vacuum requirements are rejected which exceed this maximum number of circuits.

Owner:SAURER GERMANY GMBH & CO KG

Uplink HARQ operation for prose-enabled UEs participating in sidelink discovery operation

ActiveUS10667119B2Easy to operateAvoid dataError prevention/detection by using return channelError prevention/detection by transmission repeatTransmission protocolTelecommunications

The invention relates to an improved transmission protocol for uplink data packet transmission. A transmission counter of the transmission protocol counts the number of transmissions the user terminal has performed for a data packet. The user terminal participates in sidelink discovery operation with other user terminals based on sidelink discovery gaps. The user terminal cannot transmit and / or receive signals under control of the transmission protocol when participating in sidelink discovery operation during the sidelink discovery gaps. A processor of the user terminal determines whether a retransmission of a data packet, which is triggered by the transmission protocol, was not performed because the transmission protocol operation collided with one of the sidelink discovery gaps. In case of collision, the processor operates the transmission counter such that the colliding retransmission of the data packet does not result in an increment of the transmission counter of the transmission protocol for the data packet.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

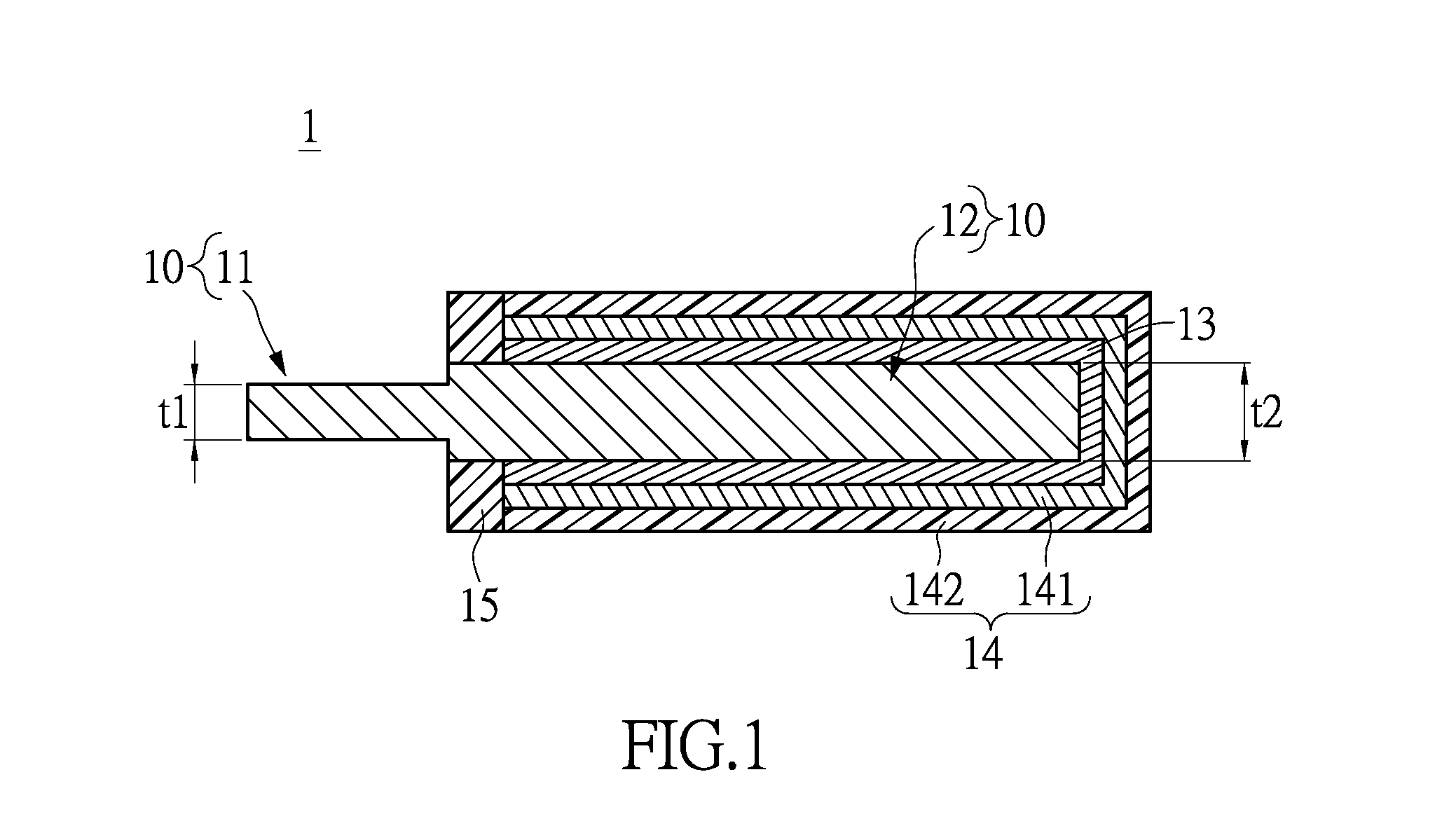

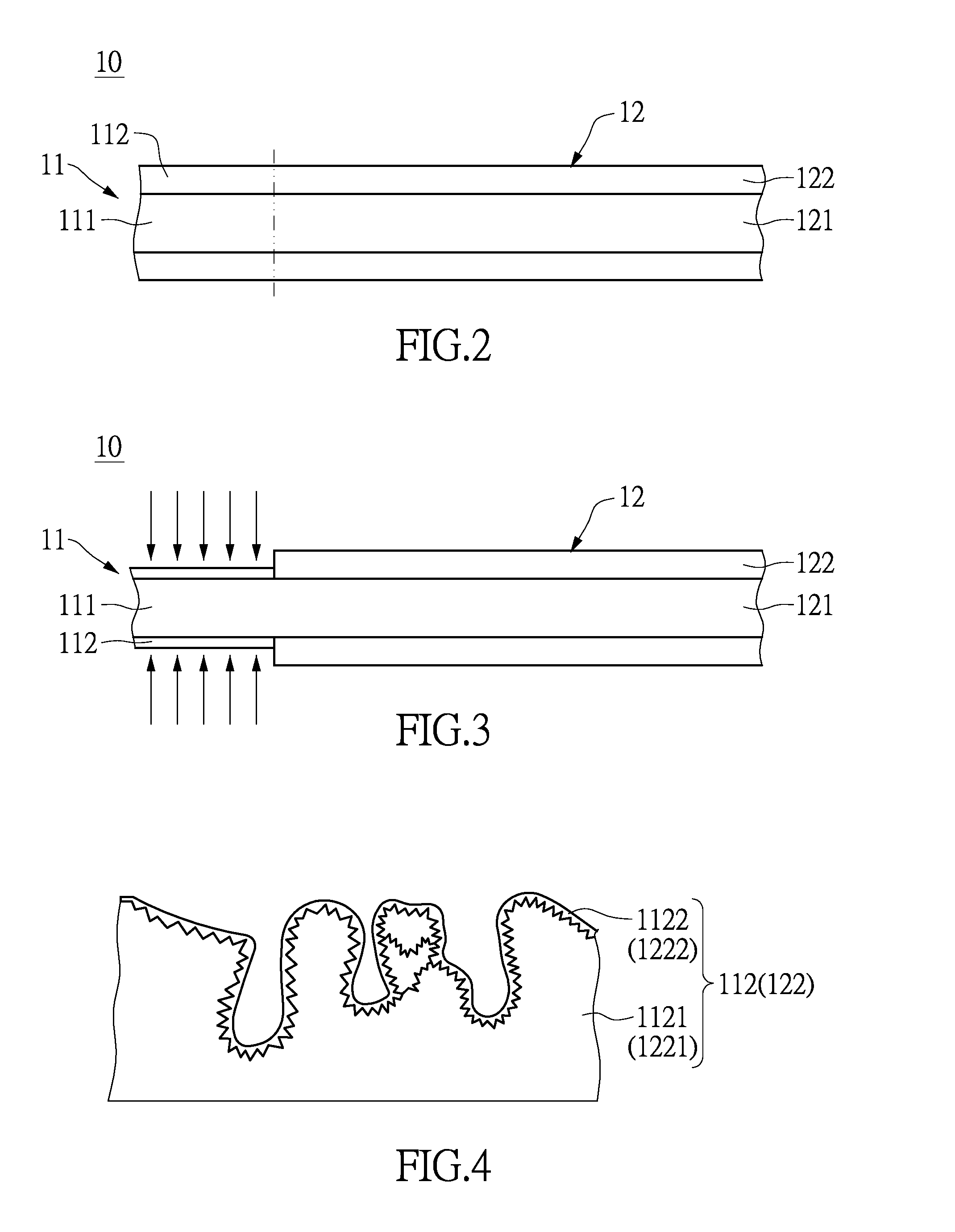

Solid-state electrolytic capacitor with improved metallic anode and method for manufacturing the same

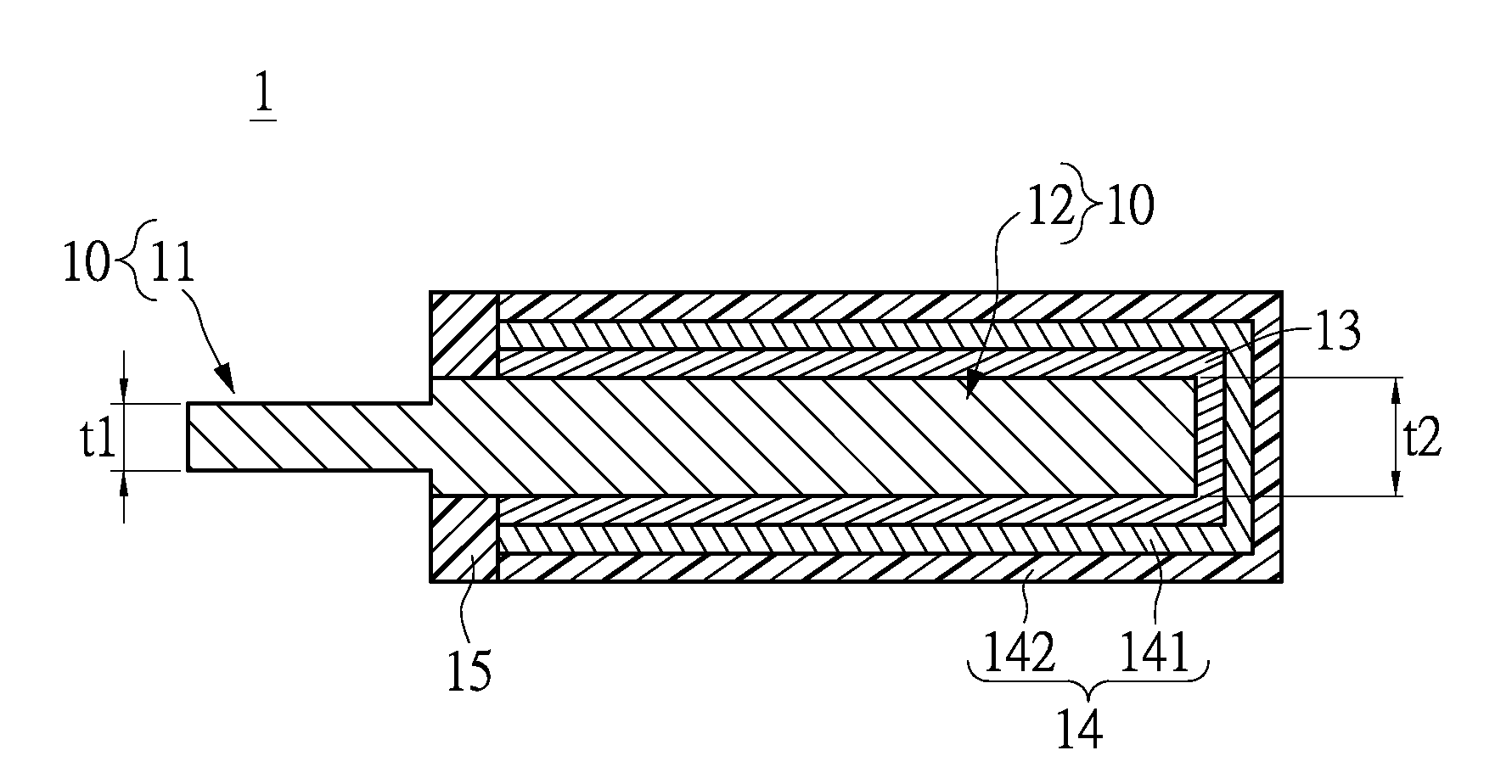

ActiveUS20160118195A1Improved metallic anodeIncrease the maximum amountSolid electrolytic capacitorsLiquid electrolytic capacitorsSolid-stateAluminum electrolytic capacitor

The instant disclosure relates to a solid electrolytic capacitor with improved metallic anode and a method for manufacturing the same. The solid electrolytic capacitor includes a substrate layer, a conductive polymer layer and an electrode layer. The substrate layer has a cathode portion and an anode portion having a smaller thickness than the cathode portion. The conductive polymer layer is formed to cover the cathode portion of the substrate layer. The electrode layer is formed to cover the conductive polymer layer. Therefore, the instant solid electrolytic capacitor can be applied to a packing process, and welding success yield rate can be improved.

Owner:APAQ TECH

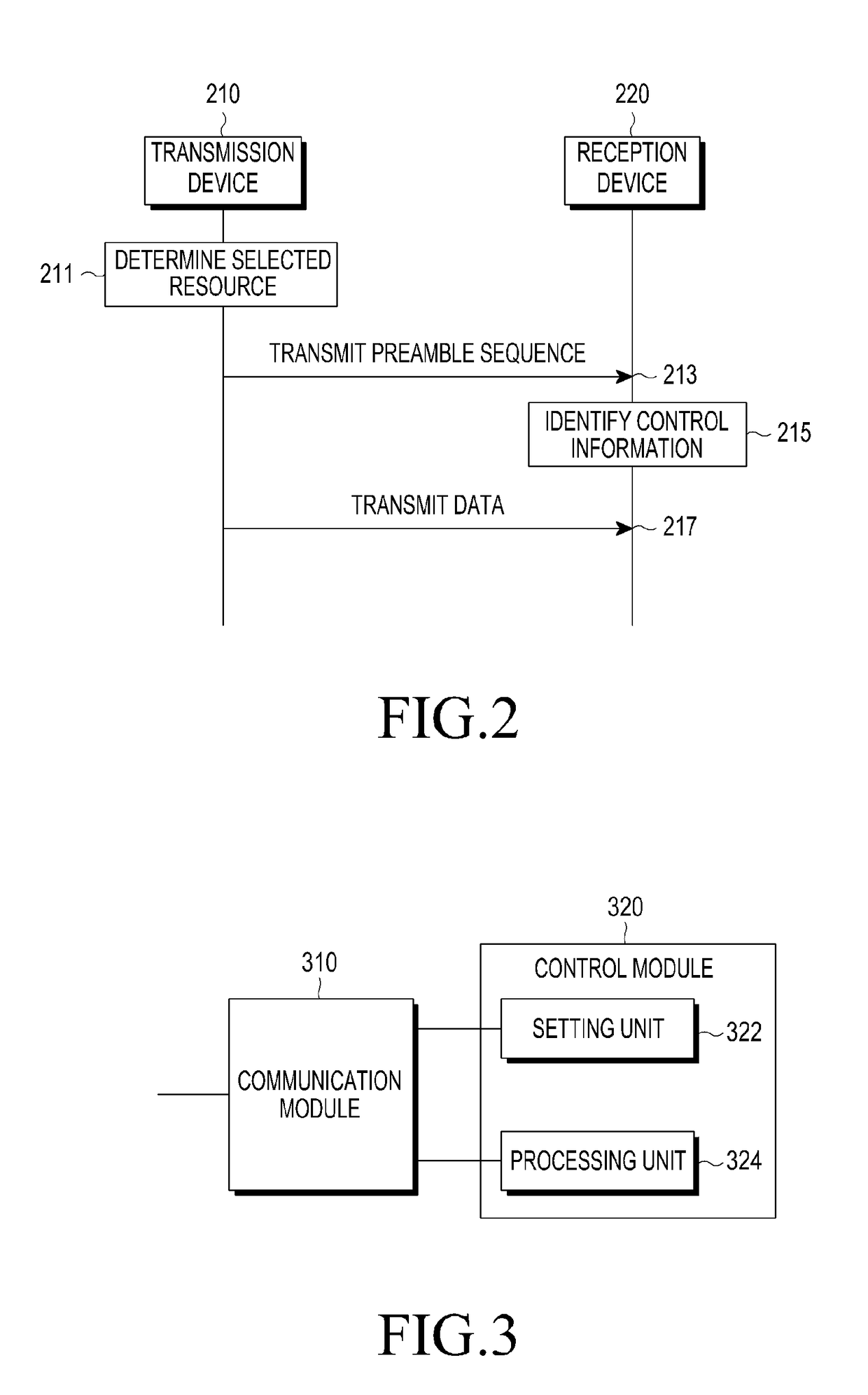

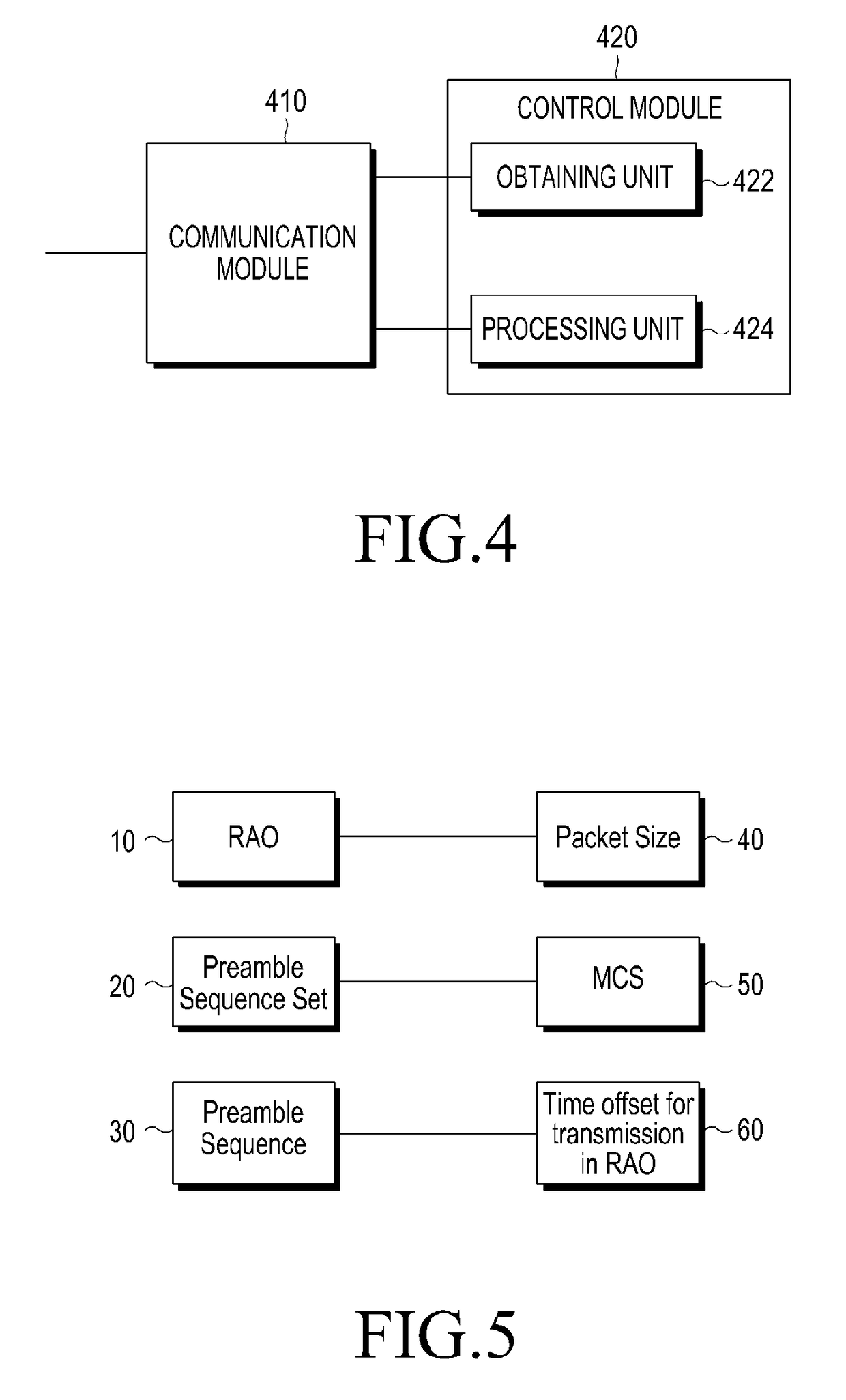

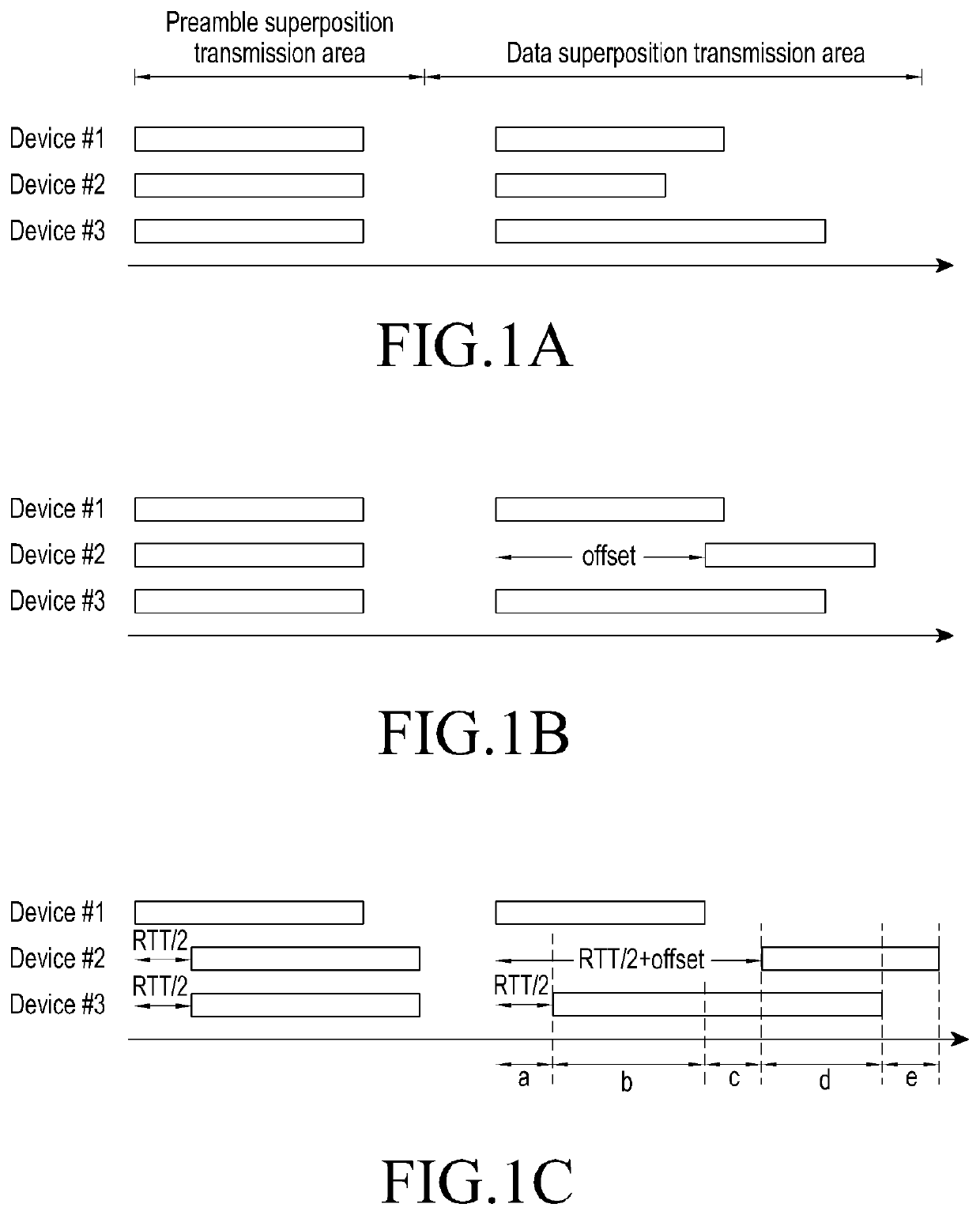

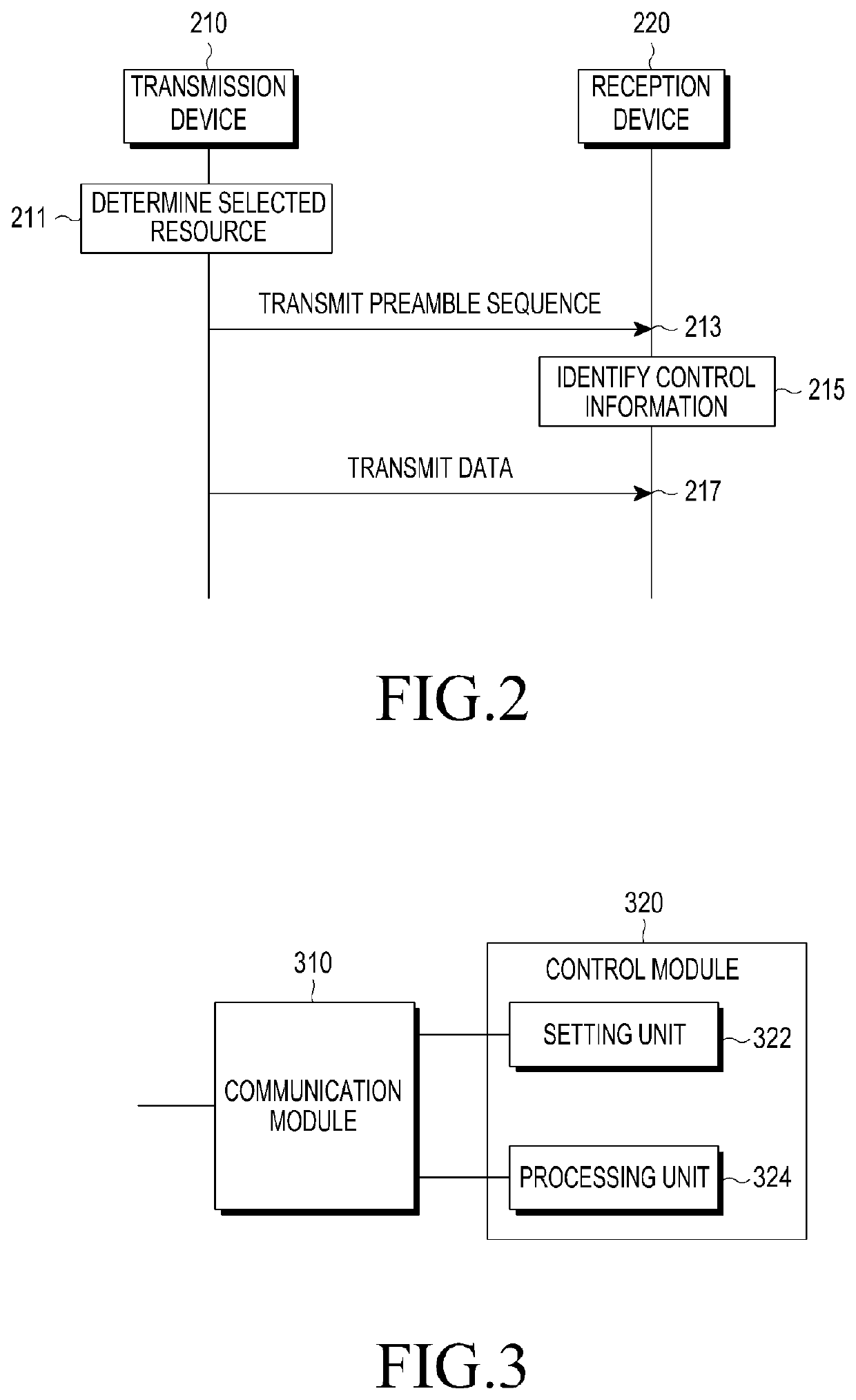

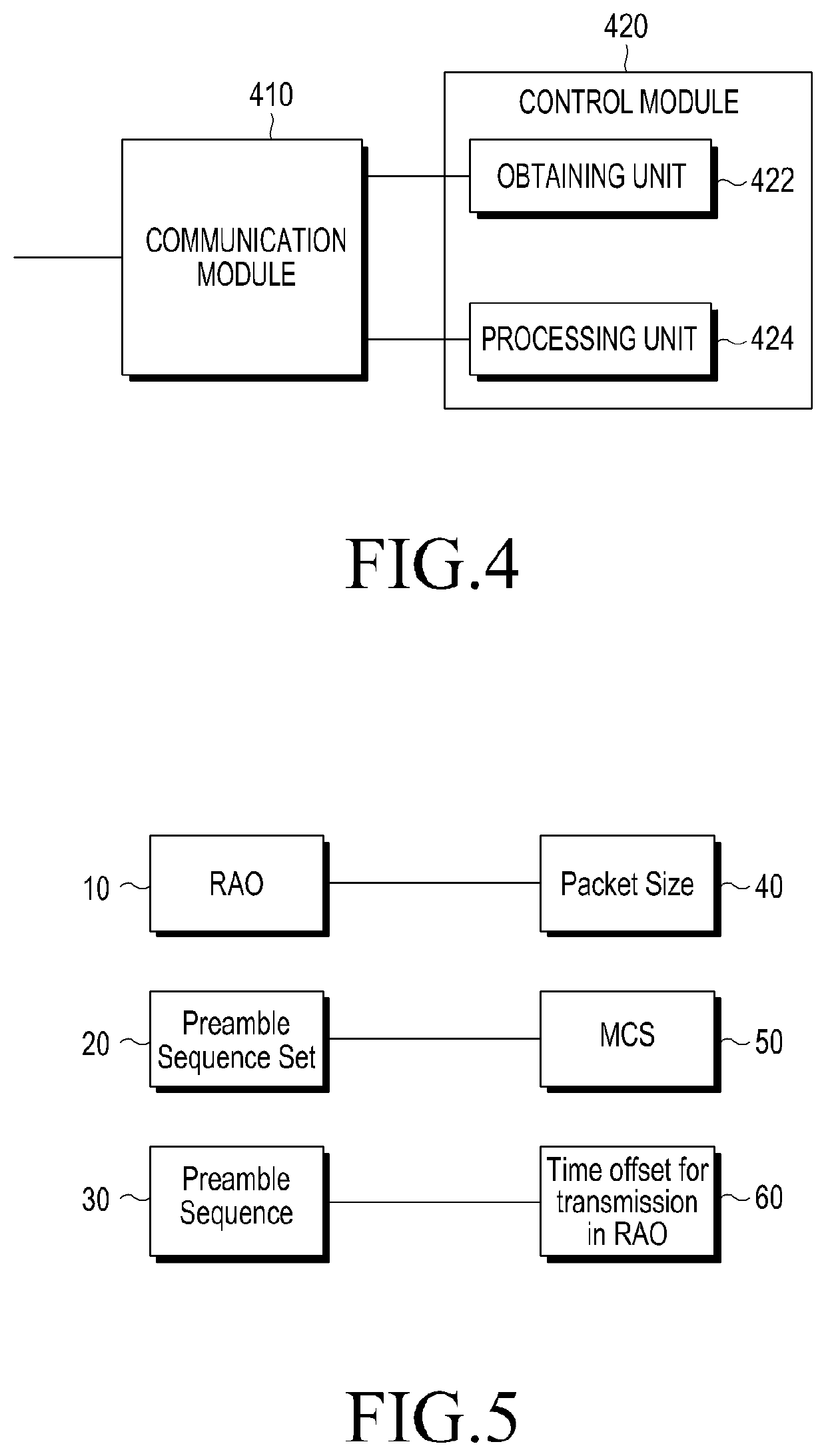

Device and method for transmitting/receiving data in wireless communication system

ActiveUS20190007968A1Prevent interferenceIncrease the maximum amountSignalling characterisationMulti-frequency code systemsData transmissionComputer hardware

The present disclosure relates to a communication technique for converging, with an IoT technology, a 5G communication system for supporting a higher data transmission rate than a 4G system, and a system therefor. The present disclosure may be applied to intelligent services, such as smart homes, smart buildings, smart cities, smart cars or connected cars, health care, digital education, retail businesses, and security and safety related services, on the basis of 5G communication s technologies and IoT-related technologies. To this end, a communication device may determine control information for a superposition transmission, and acquire selection sources in response to the determined control information. The communication device may transmit a preamble sequence on the basis of the acquired selection sources in a preamble transmission area according to the superposition transmission, and transmit data using the determined control information in a data superposition transmission area according to the superposition transmission.

Owner:SAMSUNG ELECTRONICS CO LTD

Image-capturing apparatus

InactiveUS8026957B2Reduce storage timeIncrease the maximum amountTelevision system detailsImage memory managementDummy dataControl equipment

An image-capturing apparatus is provided having a storage control device, a writing speed measuring device, and a selecting device. The storage control device writes image data into memory devices. The writing speed measuring device measures the writing speed of the memory devices by writing dummy data into the memory devices. The selecting device compares the writing speeds of the memory devices, and selects the memory device having the fastest writing speed. The storage control device stores image data in the selected memory device.

Owner:RICOH IMAGING COMPANY

Preparation method of micro-nano-scale desulfurization adsorbent

InactiveCN109482134ALarge specific surface areaPromote adsorptionOther chemical processesGaseous fuelsBiogasMicro nano

The invention belongs to the field of biogas purification in the pulping and papermaking industry, and particularly relates to a preparation method of a micro-nano-scale desulfurization adsorbent. Thepreparation method of the micro-nano-scale desulfurization adsorbent is mainly used for desulfurization of biogas produced by pulping and papermaking comprehensive wastewater. The preparation methodof the micro-nano-scale desulfurization adsorbent disclosed by the invention comprises the steps of mixing nano-scale iron oxide particles with an inorganic pore-forming agent, an organic pore-formingagent and a base material; adding water into the mixture and uniformly stirring; performing extrusion-molding the mixture; then calcinating the mixture at a high temperature and cooling the mixture to obtain the micro-nano-scale desulfurization adsorbent. According to the preparation method, the micro-nano structure of the desulfurization adsorbent is constructed by preparing the nano-scale ironoxide particles and using the micro-nano channel technology, thereby greatly increasing the specific surface area of the desulfurizing agent, greatly improving the adsorption of the nano-scale iron oxide particles for hydrogen sulfide, further increasing the maximum amount of sulfur which can be removed by the desulfurizing agent in unit mass and breaking through the technical bottleneck of low efficiency of biogas desulfurization.

Owner:SHANDONG HUATAI PAPER

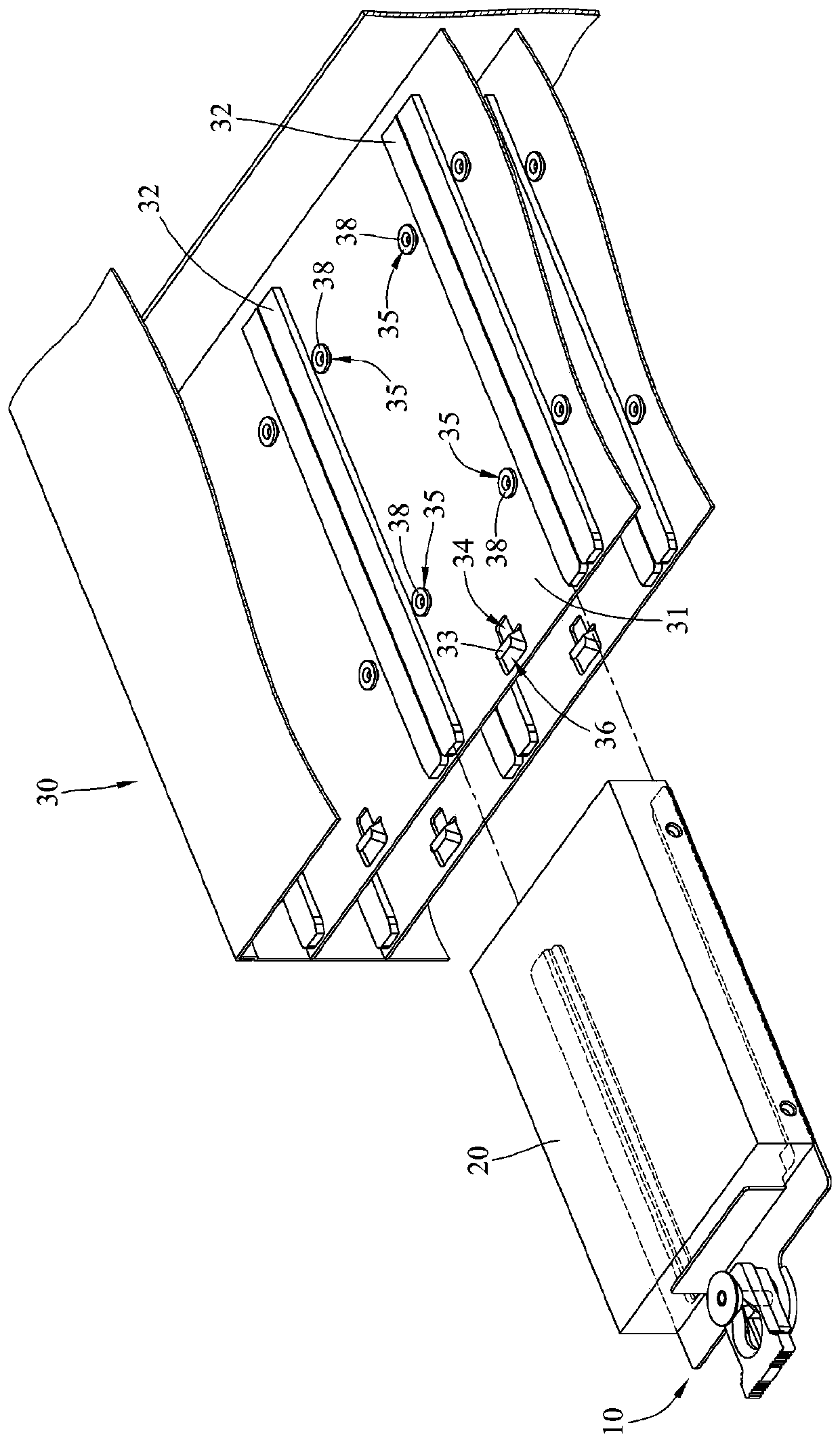

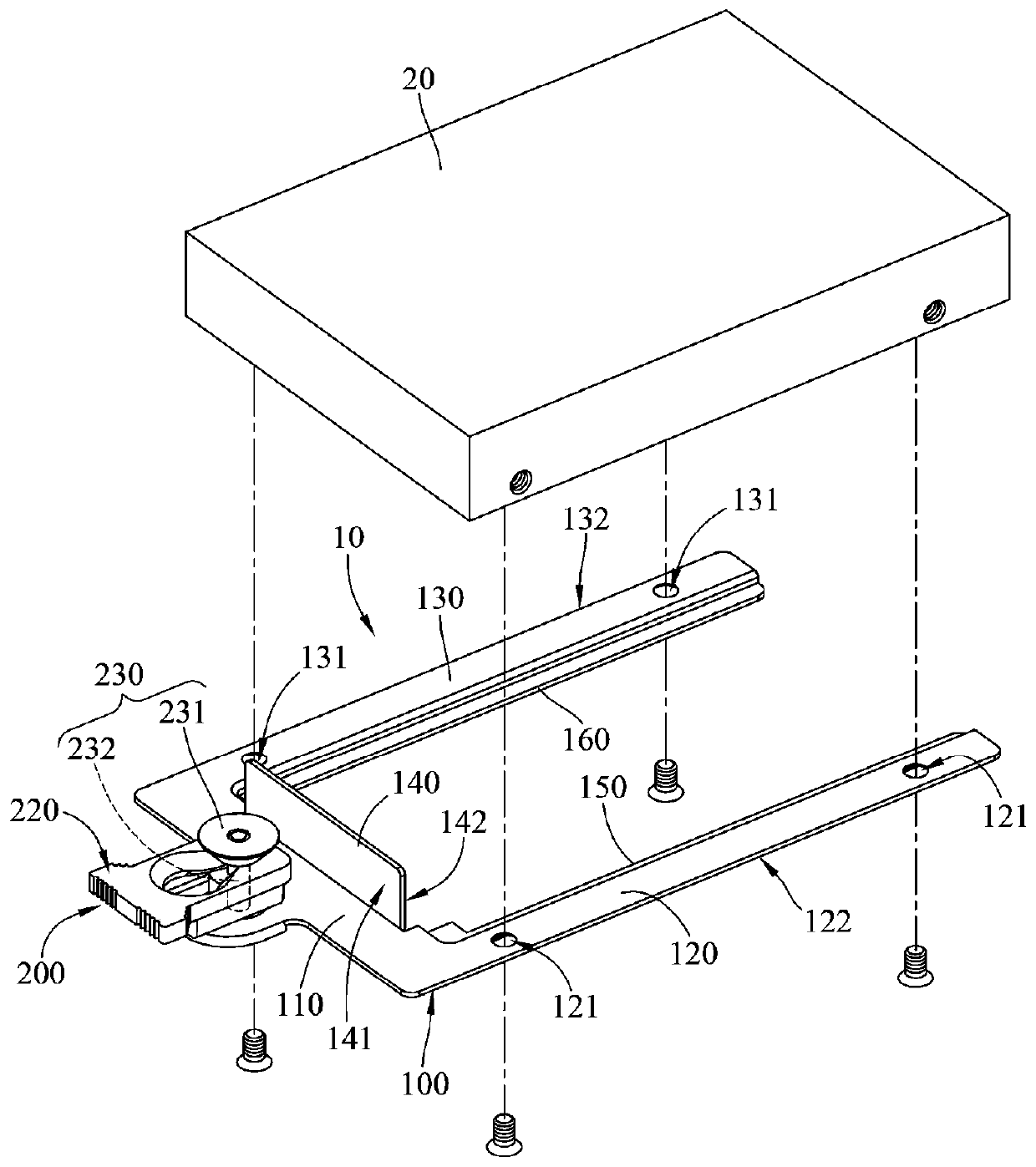

Hard disk bearing disk

ActiveCN109947206ABig spaceIncrease the maximum amountDigital processing power distributionEngineeringMechanical engineering

The invention discloses a hard disk bearing disk. The hard disk bearing disk comprises an additional circuit board and a clamping assembly. The additional circuit board is provided with two side edgeswhich are opposite to each other and parallel to the installation direction of the hard disk bearing disk. And a distance is kept between the clamping assembly and the two side edges. The clamping assembly comprises a fixing piece, an operating piece and a clamping and fixing piece. The fixing piece is fixed on the additional circuit board. The operating member is slidably disposed on the fixingmember. The operation piece is provided with a guide groove. The guide groove comprises a clamping section and a reducing section which are connected. The clamping piece comprises a head part and a body part which are connected. The head portion is wider than the body portion, and the body portion penetrates through the guide groove and the fixing piece in a sliding mode. When the operation pieceis located at the clamping position, the head portion is located at the clamping section, and the body portion is clamped to the machine shell. When the operation piece moves from the clamping position to the releasing position, the reducing section moves towards the head part, so that the operation piece abuts against the head part, the head part is separated from the guide groove, and the body part is separated from the machine shell.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

A Symmetry Analysis Method of 3D Face Model

ActiveCN107146251BIncrease the maximum amountImprove effectivenessImage enhancementImage analysisFeature extractionAlgorithm

The present invention discloses a symmetry analysis method for a three-dimensional face model. The method comprises: sampling an input face model, and pairing sampling results so as to obtain symmetrical features; and extracting and clustering the obtained symmetrical features, so as to obtain a symmetry relation of the model. According to the method, a PCA constraint is added during feature extraction, which effectively increase the maximum number of initial sampling points when computing resources are limited; by improving the extraction method for the symmetrical feature, the validity of the clustering result is enhanced; and by adding a relaxation factor during feature-grid reassignment, stability of results is ensured and the matching is extended to the whole model. A test is performed on a face model that is acquired at Kinect and reconstructed using KinectFusion, and the validity of the method is verified.

Owner:ZHEJIANG UNIV

Programming method for NAND-type flash memory

ActiveUS9514826B2Increase the maximum amountShorten the overall cycleRead-only memoriesProgramming patternsProgramming method

Owner:WINBOND ELECTRONICS CORP

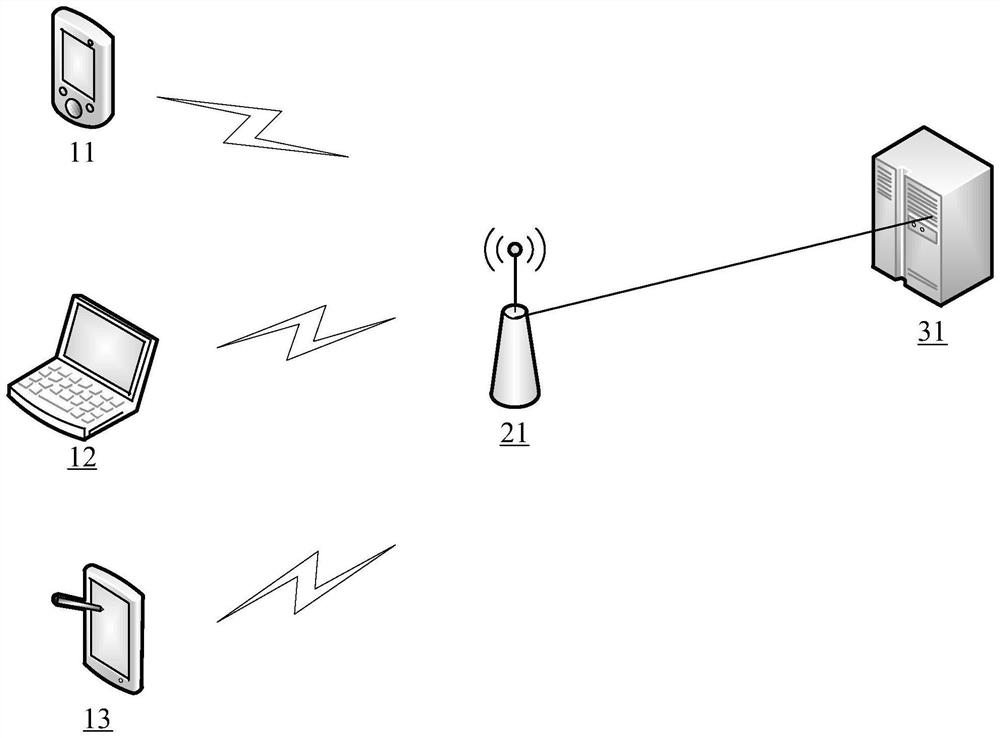

Beacon frame sending method and device, storage medium and AP

PendingCN114844607AIncrease the maximum amountShorten the lengthChannel coding adaptationPilot signal allocationWireless transmissionBeacon frame

The embodiment of the invention discloses a beacon frame sending method and device, a storage medium and an AP, and belongs to the field of wireless communication. By improving the structure of the beacon frame, not only can the maximum number of STAs associated with the AP be expanded, but also the length of the beacon frame can be greatly shortened, so that the transmission time of the beacon frame is shortened, the wireless transmission efficiency is improved, and the wireless transmission throughput is increased. Besides, the length of the beacon frame is relatively low, so that the STA under the low-power-consumption node can monitor the beacon frame with less time, the standby power consumption of the STA can be reduced, and the standby time of the STA can be prolonged.

Owner:ZHUHAI HUGE IC CO LTD

A domestication process of gradient dynamic activated sludge under aerobic conditions

InactiveCN104528928BIncrease the number ofIncrease the maximum number ofSustainable biological treatmentBiological water/sewage treatmentActivated sludgeMicroorganism

Owner:ZHEJIANG SCI-TECH UNIV

Vertically die-stacked bonder and method using the same

ActiveUS10438917B2Increase production speedLow production costSemiconductor/solid-state device detailsSolid-state devicesProduction rateEngineering

Owner:GALLANT MICRO MACHINING

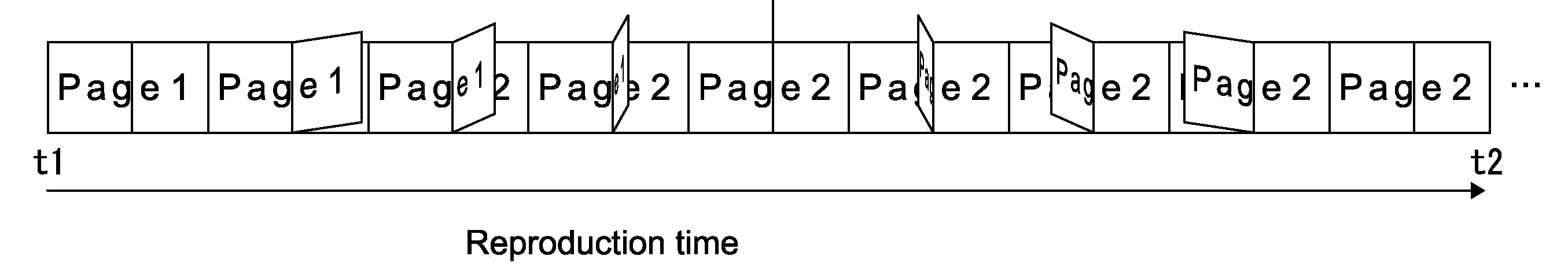

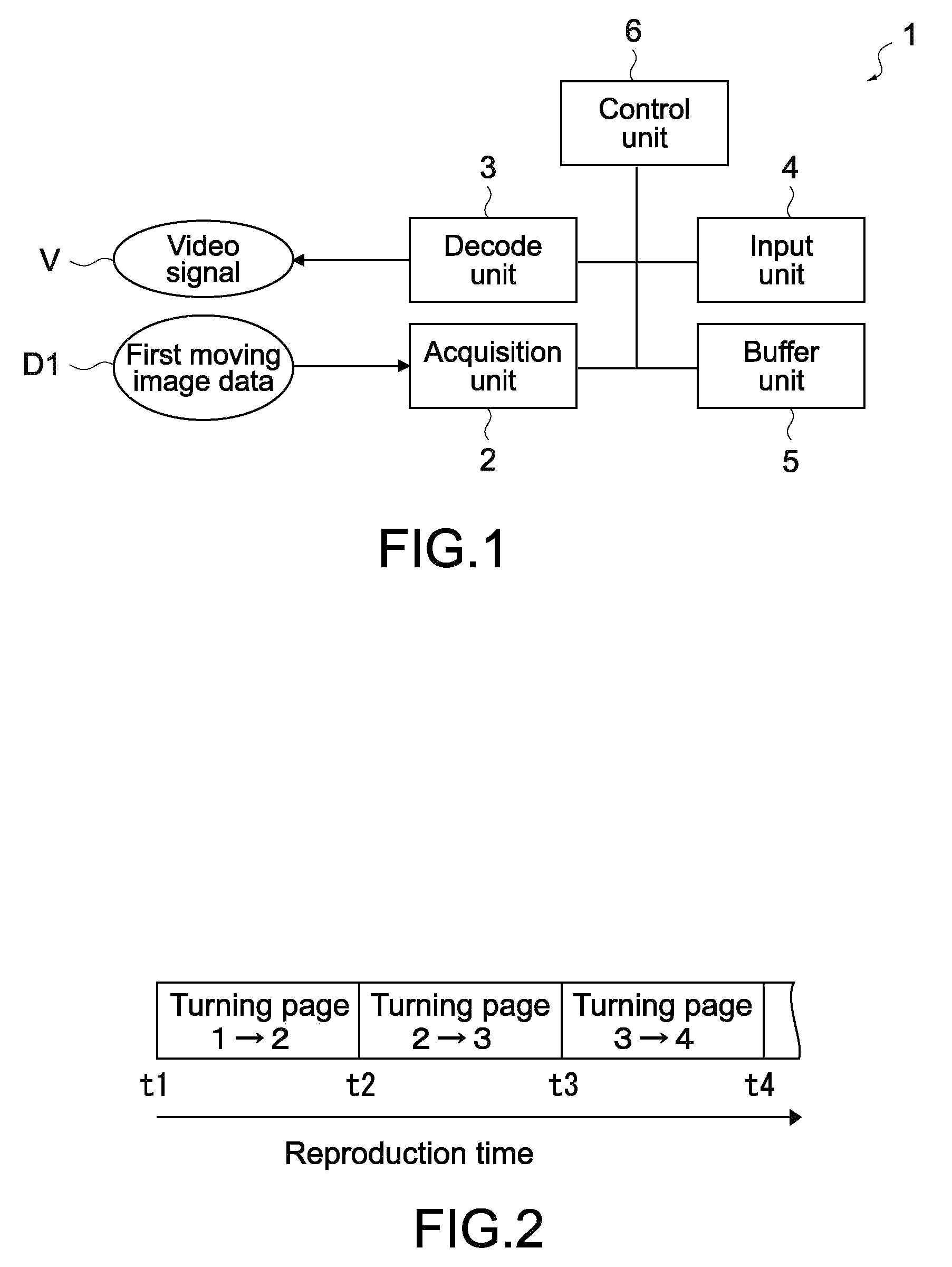

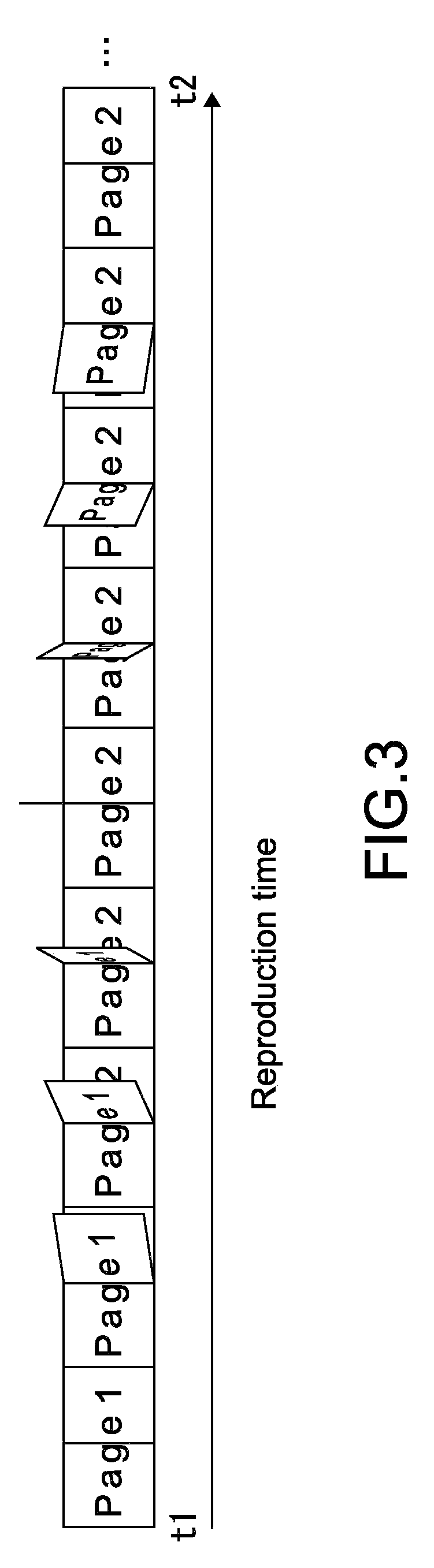

Information processing apparatus, information processing method, and program therefor

InactiveUS20110289446A1Increasing second speedReducing second speedInput/output processes for data processingInformation processingReproduction speed

Provided is an information processing apparatus including an acquisition unit, a reproduction unit, an input unit, and a control unit. The acquisition unit obtains, of moving image data including images of pages having serial page numbers and an image of motion of turning the pages one by one in order of the page numbers, first moving image data in which a page time being a time on the moving image data is assigned to each page. The reproduction unit reproduces the first moving image data, generates a moving image, and displays the moving image on a display screen. The input unit receives a designation of a second page different from a first page of the first moving image data currently displayed on the display screen. The control unit calculates a page time difference therebetween and controls a reproduction speed of the first moving image data depending on it.

Owner:SONY CORP

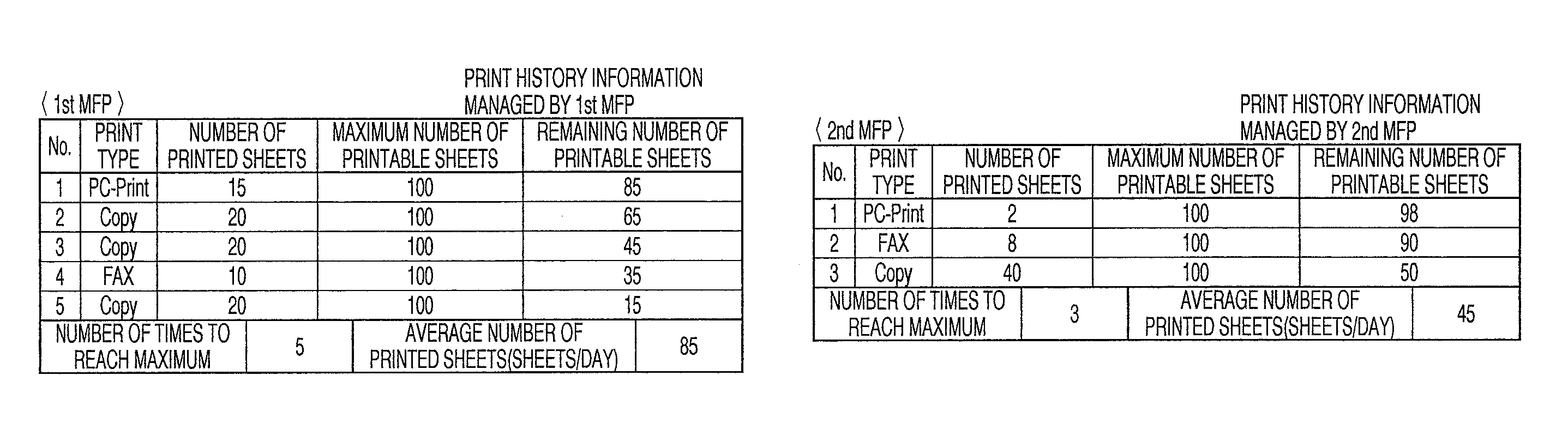

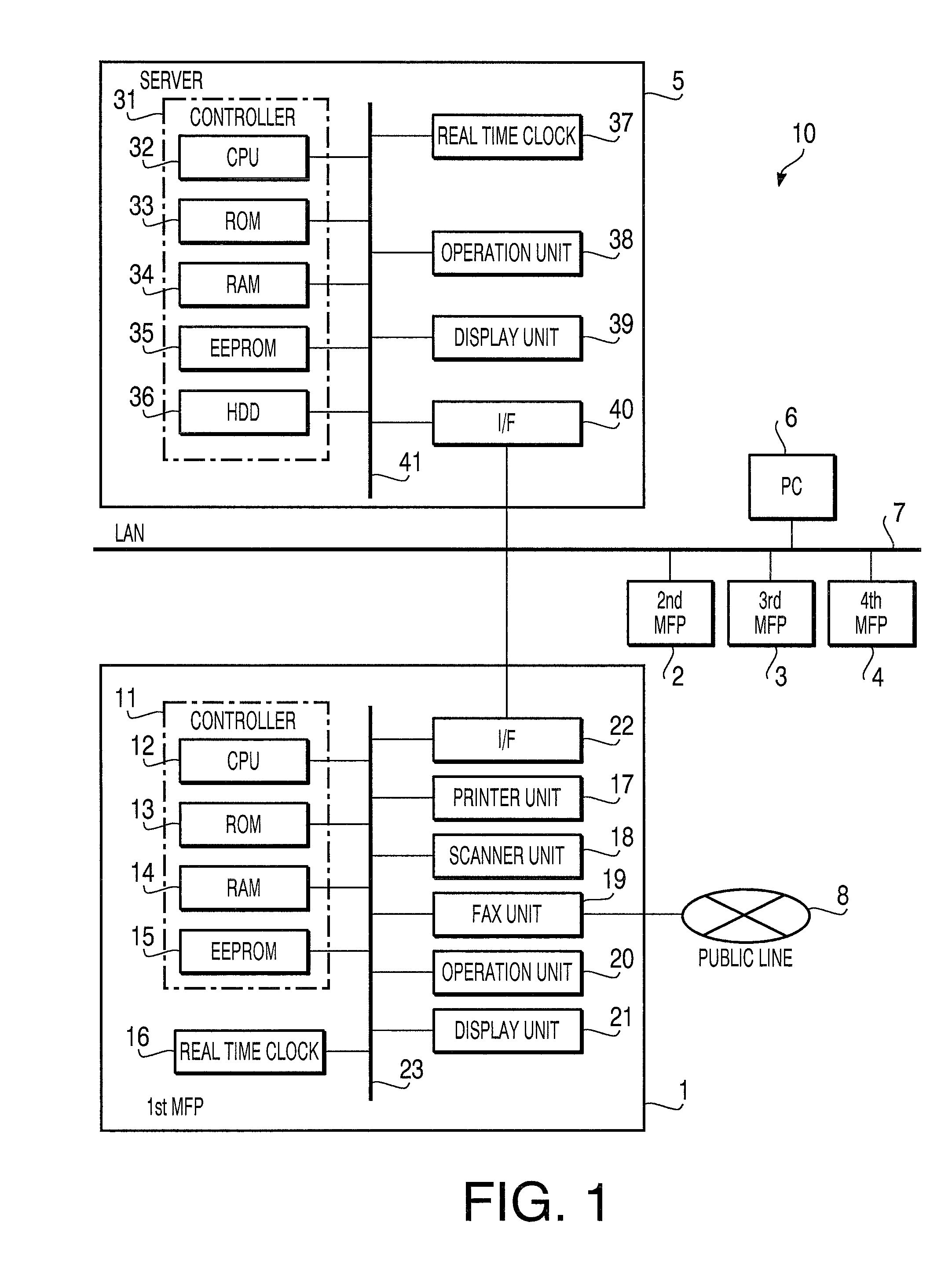

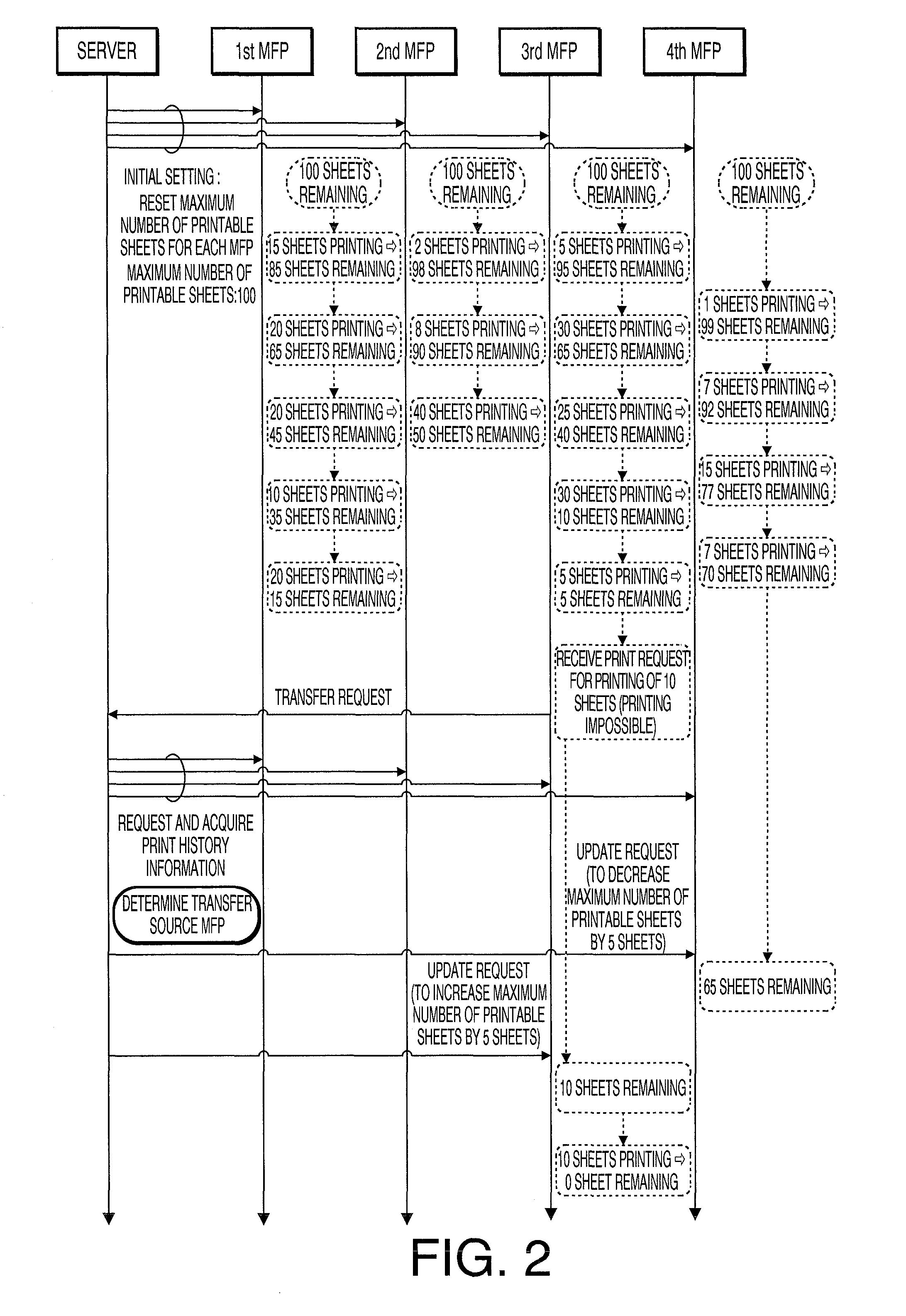

Printing system and server therefor

ActiveUS8228546B2Increase the maximum amountIncrease the number ofDigitally marking record carriersDigital computer detailsComputer engineering

A printing system includes a server and a plurality of printing devices connected with the server via a network. A maximum number of printable sheets is set for each of the printing devices. Upon receipt of a print request, when determining that a remaining number of printable sheets is insufficient, a first printing device issues a transfer request to the server. In response to the transfer request, the server selects a second printing device that cedes at least part of the maximum number of printable sheets therefore, based on respective frequencies of printing operations of the printing devices other than the first printing device, and issues a transfer instruction to each of the first printing device and the second printing device, the transfer instruction causing the first and second printing devices to increase and decrease their maximum numbers of printable sheets, respectively.

Owner:BROTHER KOGYO KK

Device and method for transmitting/receiving data in wireless communication system

ActiveUS10952259B2Increase the maximum amountHigh pass loss occurring in a ultrahigh frequency band may be alleviatedMulti-frequency code systemsSignalling characterisationCommunications systemTechnology fusion

The present disclosure relates to a communication technique for converging, with an IoT technology, a 5G communication system for supporting a higher data transmission rate than a 4G system, and a system therefor. The present disclosure may be applied to intelligent services, such as smart homes, smart buildings, smart cities, smart cars or connected cars, health care, digital education, retail businesses, and security and safety related services, on the basis of 5G communication s technologies and IoT-related technologies. To this end, a communication device may determine control information for a superposition transmission, and acquire selection sources in response to the determined control information. The communication device may transmit a preamble sequence on the basis of the acquired selection sources in a preamble transmission area according to the superposition transmission, and transmit data using the determined control information in a data superposition transmission area according to the superposition transmission.

Owner:SAMSUNG ELECTRONICS CO LTD

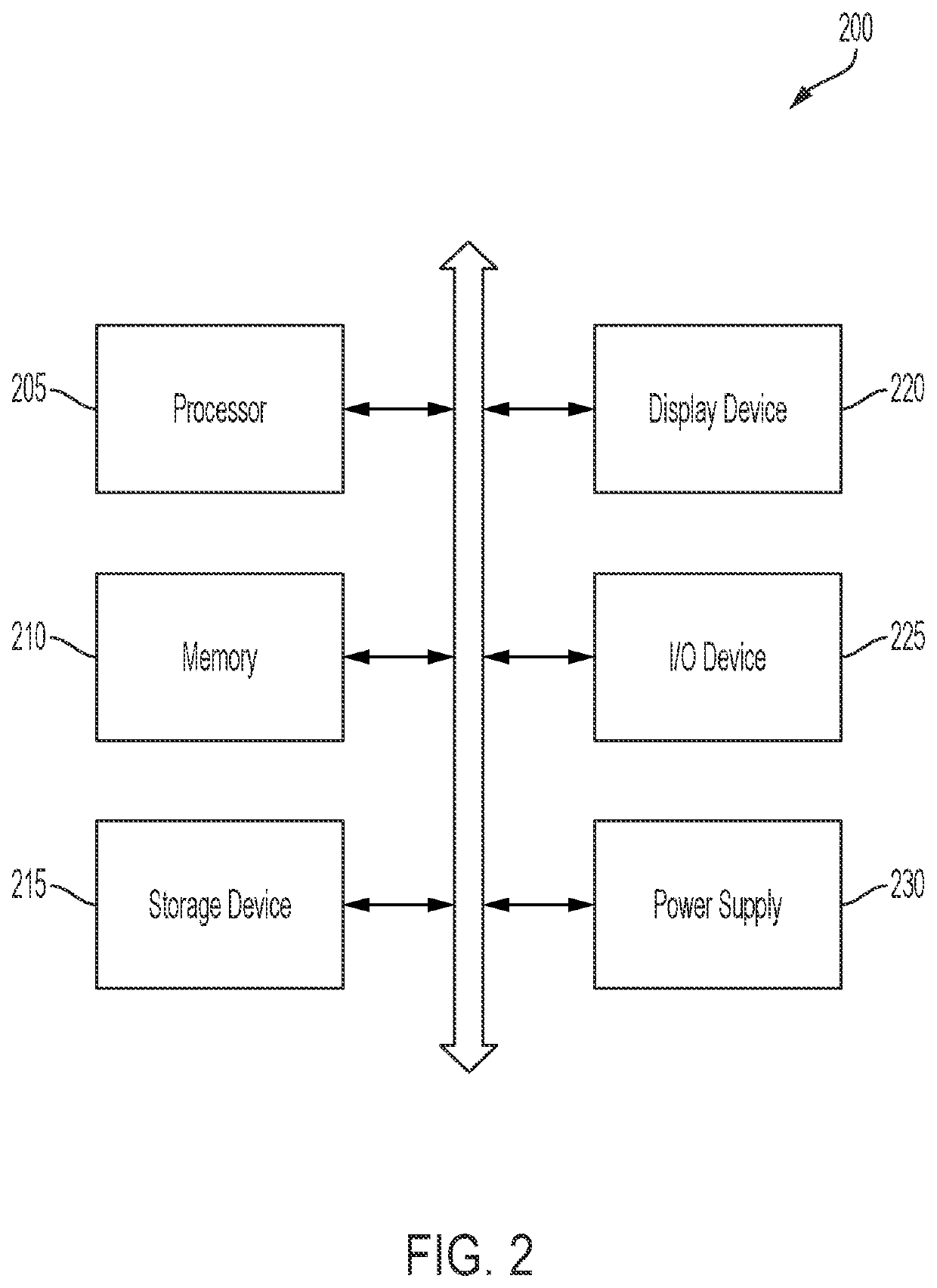

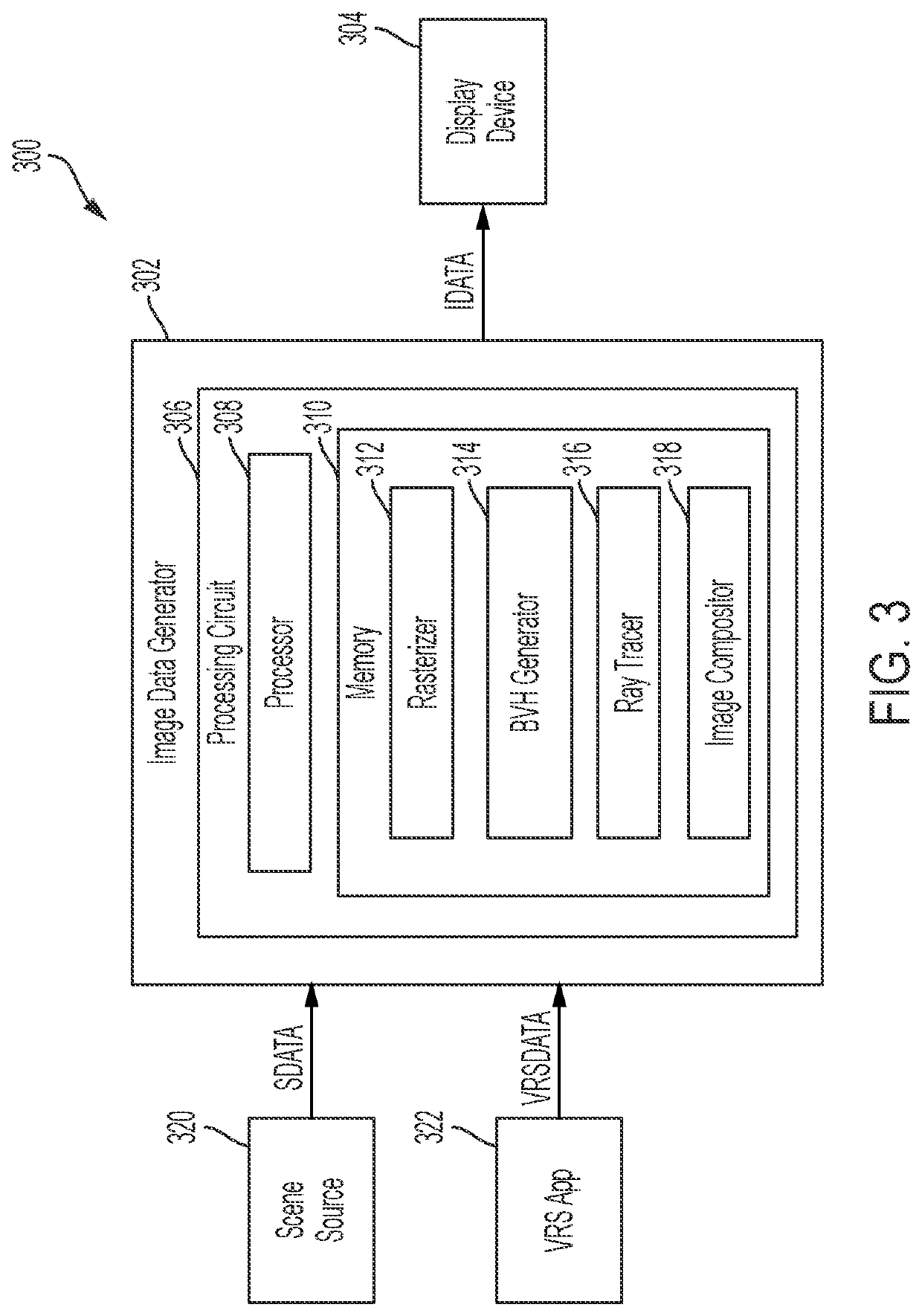

Systems and methods of adaptive, variable-rate, hybrid ray tracing

PendingUS20220301233A1Increase the maximum amountReduce the numberImage analysis2D-image generationPhysicsScreen space

A hybrid ray tracing system includes: a processor; and memory including instructions that, when executed by the processor, cause the processor to: identify a subset of pixels of an image to be ray-traced based on variable rate shading (VRS) screenspace image data; set, based on the VRS screenspace image data, one or more material properties of at least one object corresponding to the subset of pixels; and perform ray-tracing for the subset of pixels to generate a ray-traced image. The ray-tracing includes performing a limited ray casting process based on the set one or more material properties.

Owner:SAMSUNG ELECTRONICS CO LTD

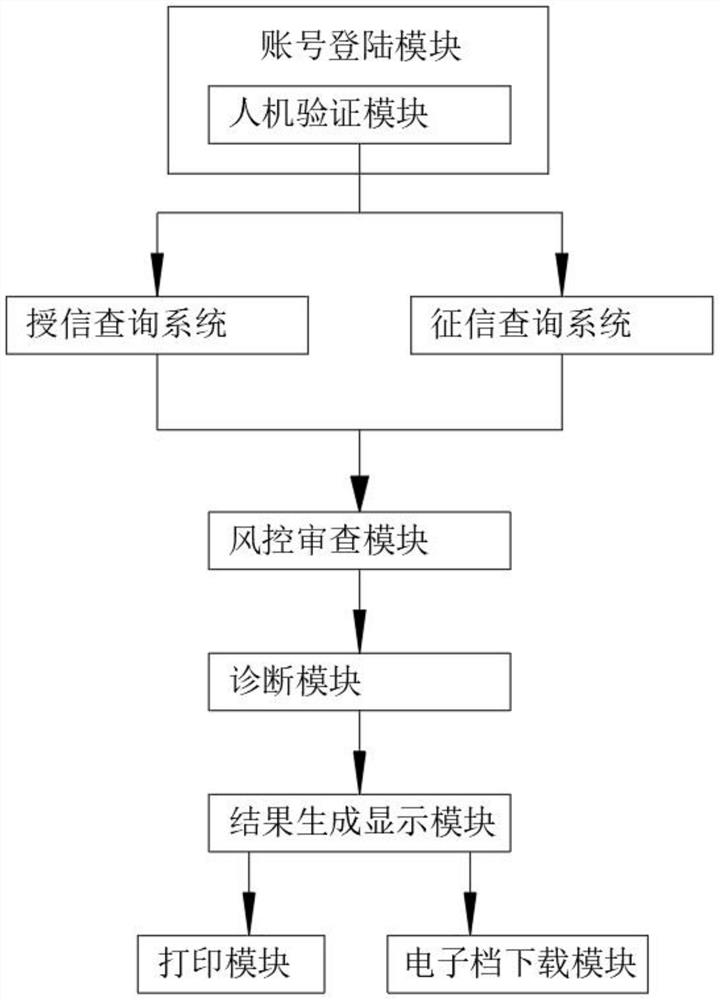

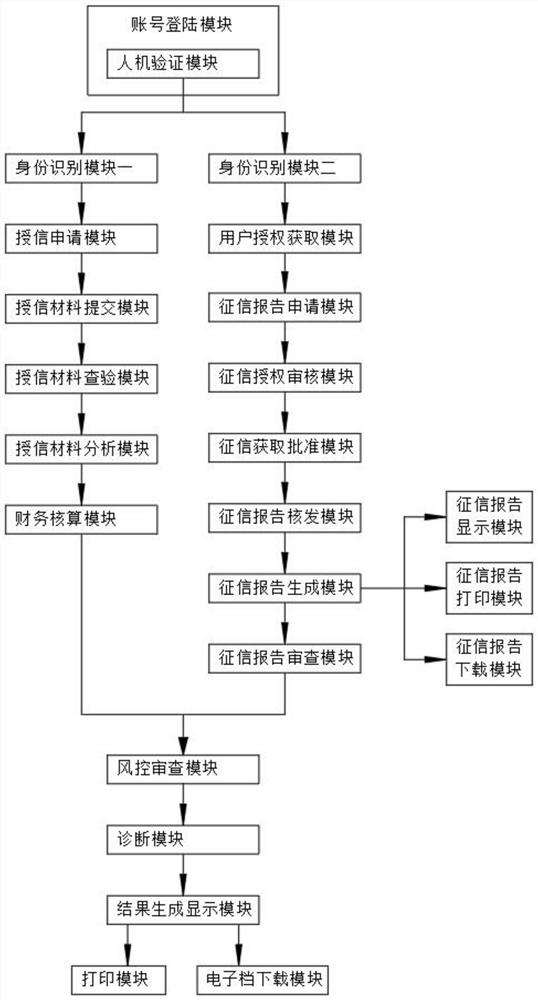

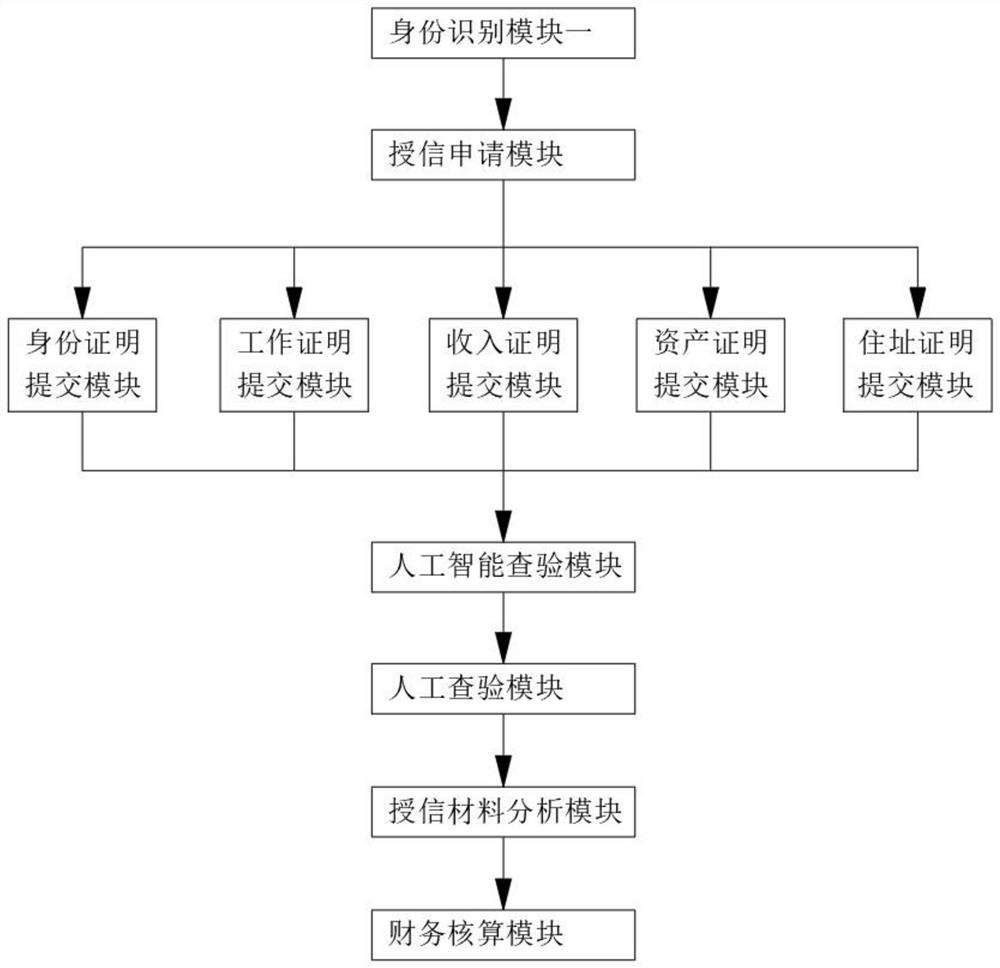

Credit granting query and diagnosis loan assisting system

The invention discloses a credit granting query and diagnosis loan assisting system which comprises an account login module, the account login module can provide account registration, account login and password retrieval functions for clients, and the account login module is connected with a credit granting query system and a credit investigation query system. The credit granting query system is used for analyzing the specific credit granting condition of the user according to the material provided by the user, and the credit investigation query system is used for obtaining the credit investigation report of the user according to the authorization of the user. Therefore, materials of the client can be pre-reviewed before loan, whether the client can successfully pass loan approval or not is judged, and the maximum amount of loan can be improved by optimizing personal information of the client.

Owner:上海数新信息科技有限公司

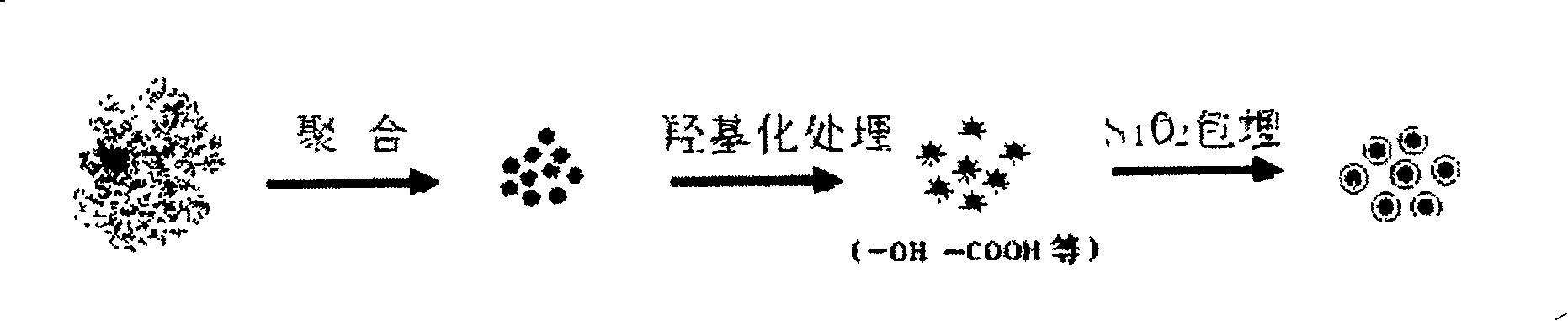

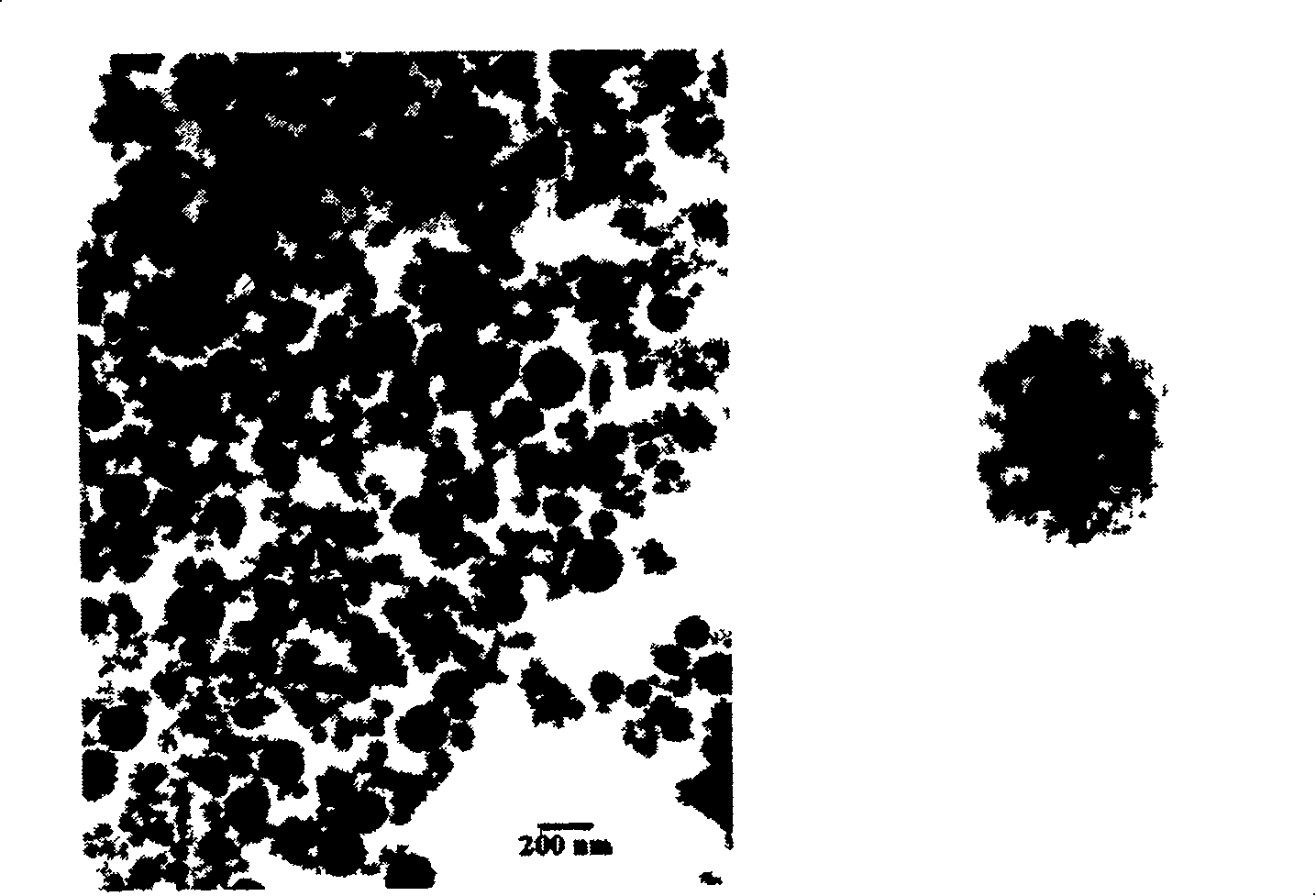

Method for preparing silicon dioxide embedded nano composite particles

InactiveCN100398493CIncrease the maximum amountNarrow particle size distributionInorganic material magnetismNanoparticleMethacrylate methyl

The invention is a method for preparing SiO2-coated magnetic nano composite particles, characterized in comprising the steps of: a. firstly preparing magnetic nano particles by codeposition process; b. coating the magnetic nano particles with vinyl acetate or methyl methacrylate, and then hydroxylating to obtain magnetic nano composite particles; c. coating the magnetic nano composite particles with SiO2. By hydroxylation of the magnetic particles, it can increase the maximum addition of magnetic particles in the reacting course, thus increasing the prepared quantity of the composite particles in Stober course, and the obtained composite particles are distributed narrowly and have round appearance, completely reaching the commercialization standard.

Owner:NANTONG DOUBLE GREAT TEXTILE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com