Method for operating a textile machine which is provided with a vacuum device and produces crosswound bobbins

A textile machine and negative pressure technology, which is applied in the field of manufacturing cross-winding bobbins, can solve the problems of unavailable, difficult textile machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

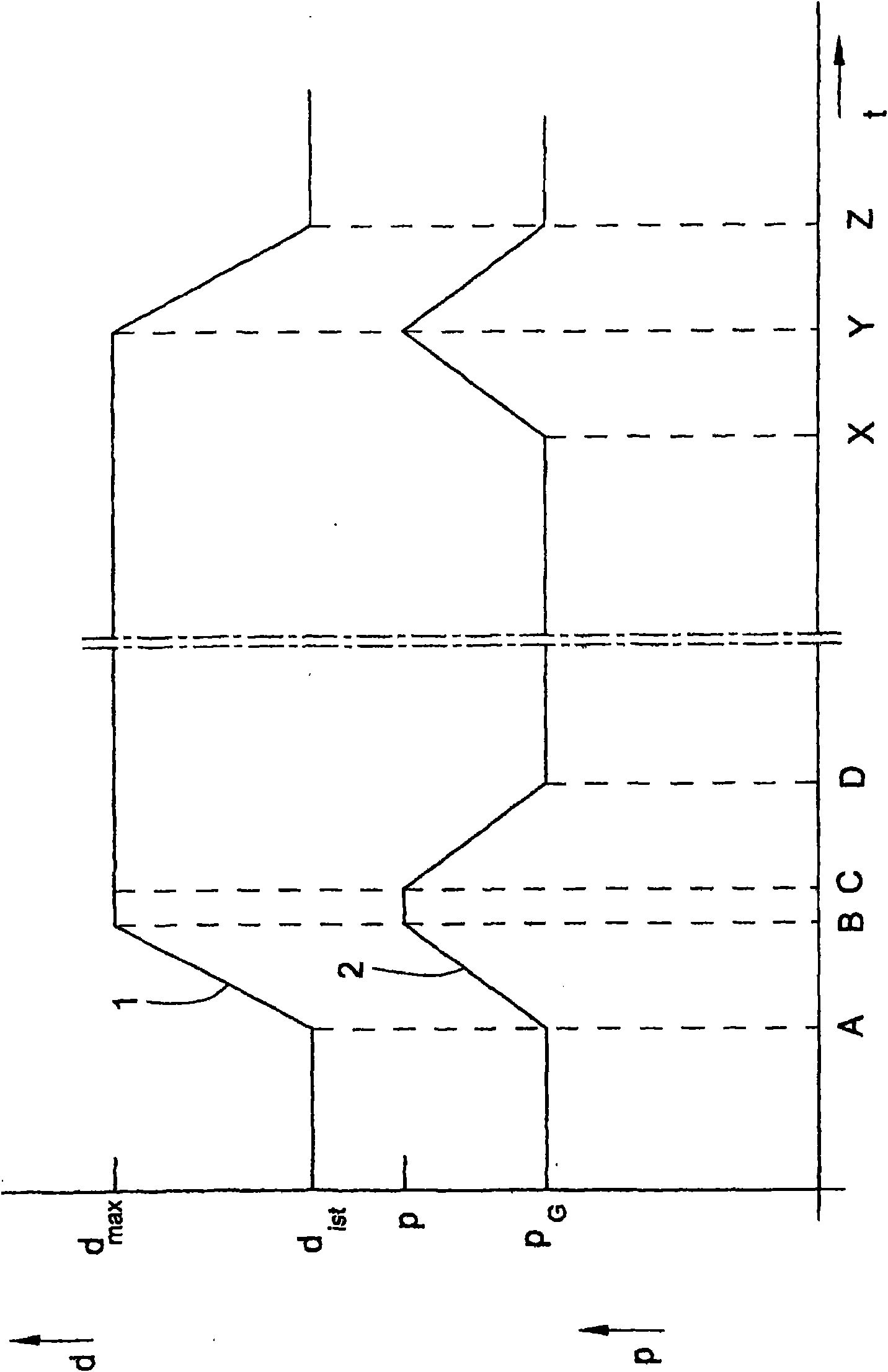

[0021] In the drawing, the rotational speed curve schematically represented by the passage curve 1 of the drive motor of the suction unit of the textile machine is shown graphically, and the passage curve 2 in the suction unit of the textile machine when the textile machine is restarted after a batch change Schematic representation of the negative pressure curve. In this case, the abscissa represents the time course of the method according to the invention, with A, B, C, etc. marking different points in time which will be described further below. The ordinate shows the negative pressure level p present in the textile machine suction system and the rotational speed level d of the drive motor of the textile machine suction unit.

[0022] When the open-end spinning machine is started up again after a batch change, a predeterminable negative pressure p first occurs in the suction device of the textile machine G , the negative pressure is specified in such a way that it satisfies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com