A method for tightening an electromechanical brake, and an electromechanical brake

A brake, electromechanical technology, applied in the direction of brake components, brakes, brake types, etc., can solve problems such as poor characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

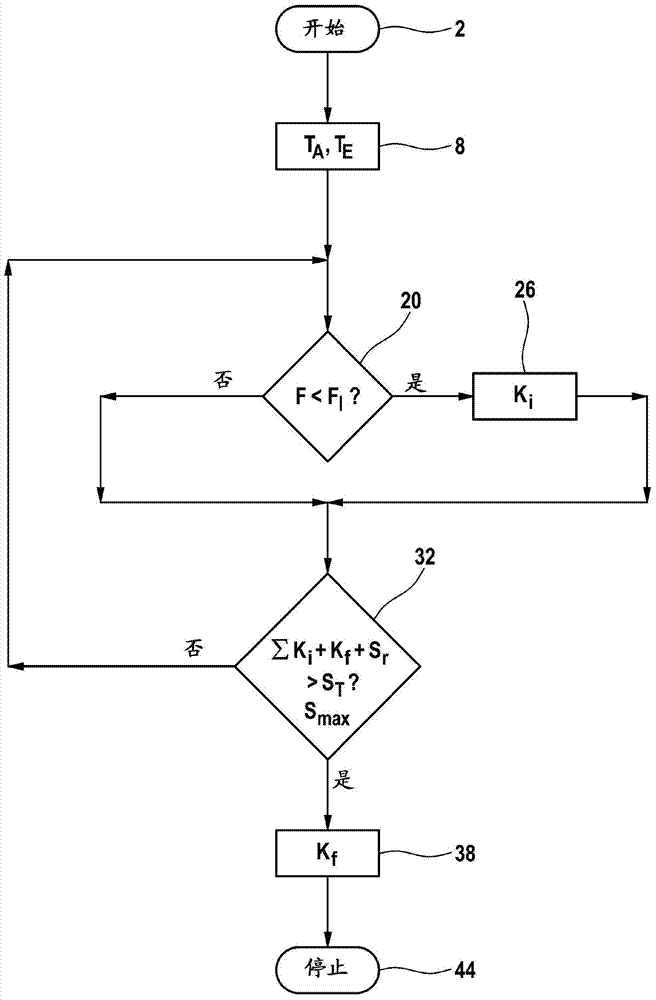

[0032] figure 1 A flow diagram of a preferred embodiment of the method according to the invention is shown in . At start 2, the vehicle is stopped and the parking brake function is activated. In box 8, with the help of the loss of clamping force within the first minute after start 2 and the starting temperature T of the brake disc A and predictable final temperature T E or difference T A -T E to determine the expected total clamping force loss S of the brake T .

[0033] Total clamping force loss S T The calculation of can also be carried out not only at the beginning of the method as shown here but between further method steps, so that the initially obtained values can be corrected to a certain extent if necessary.

[0034] In decision 20 it is checked whether the momentarily present force or the clamping force F is less than the minimum specified value F of the clamping force l (l stands for Limit). If this is the case, the method branches to box 26, where a force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com