Patents

Literature

65results about How to "Avoid self-destruct" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

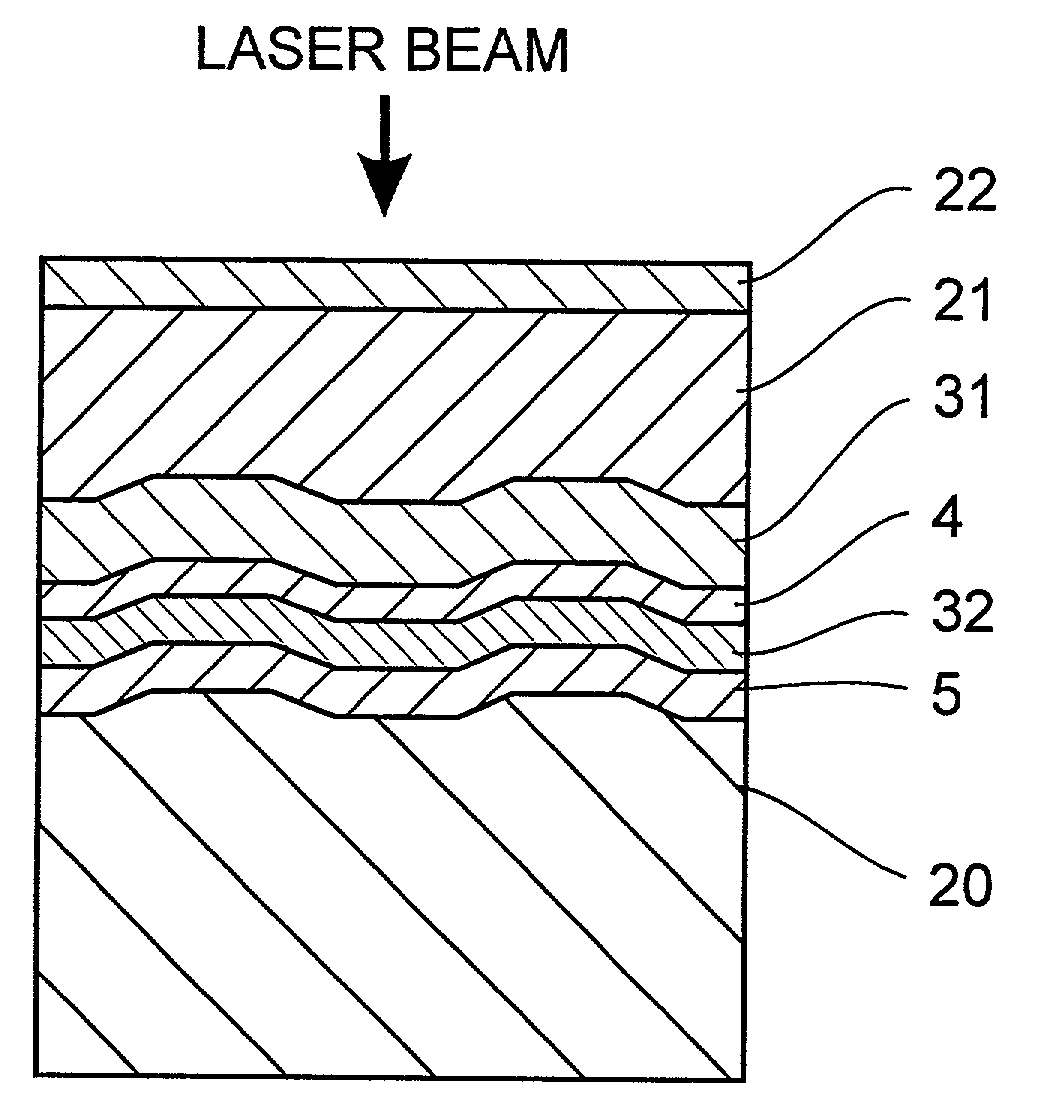

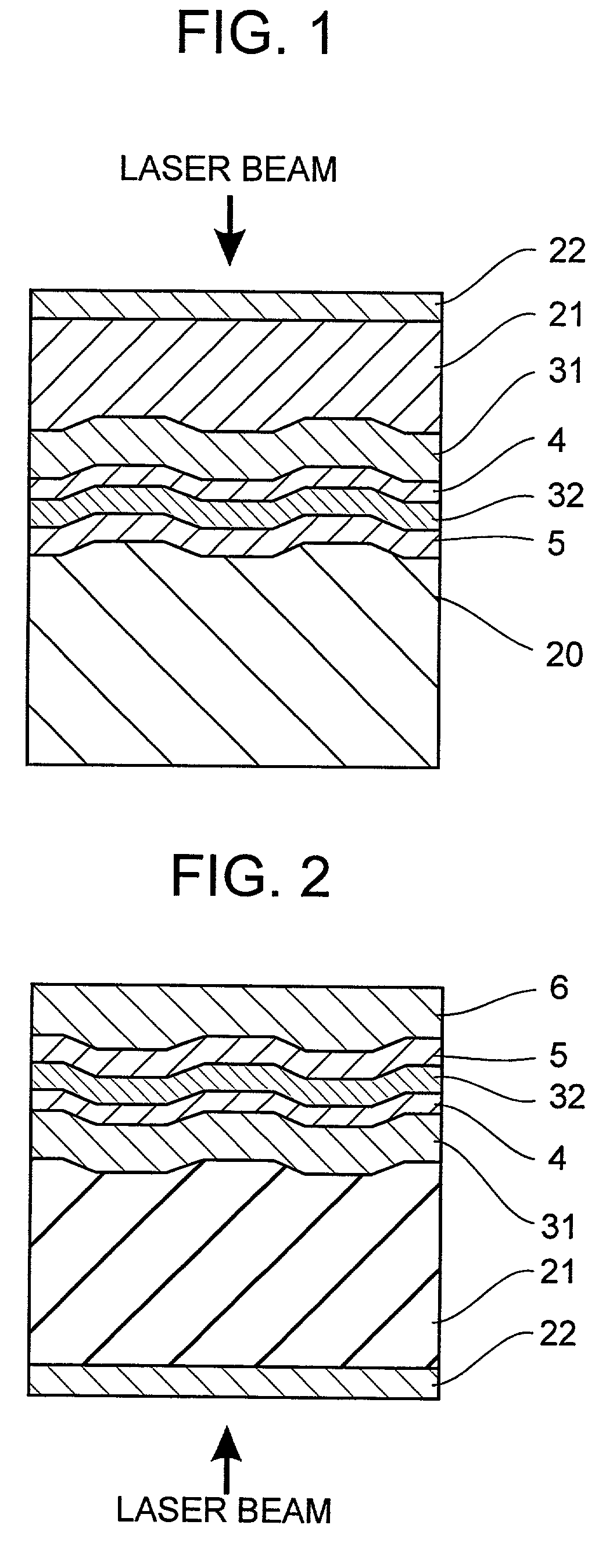

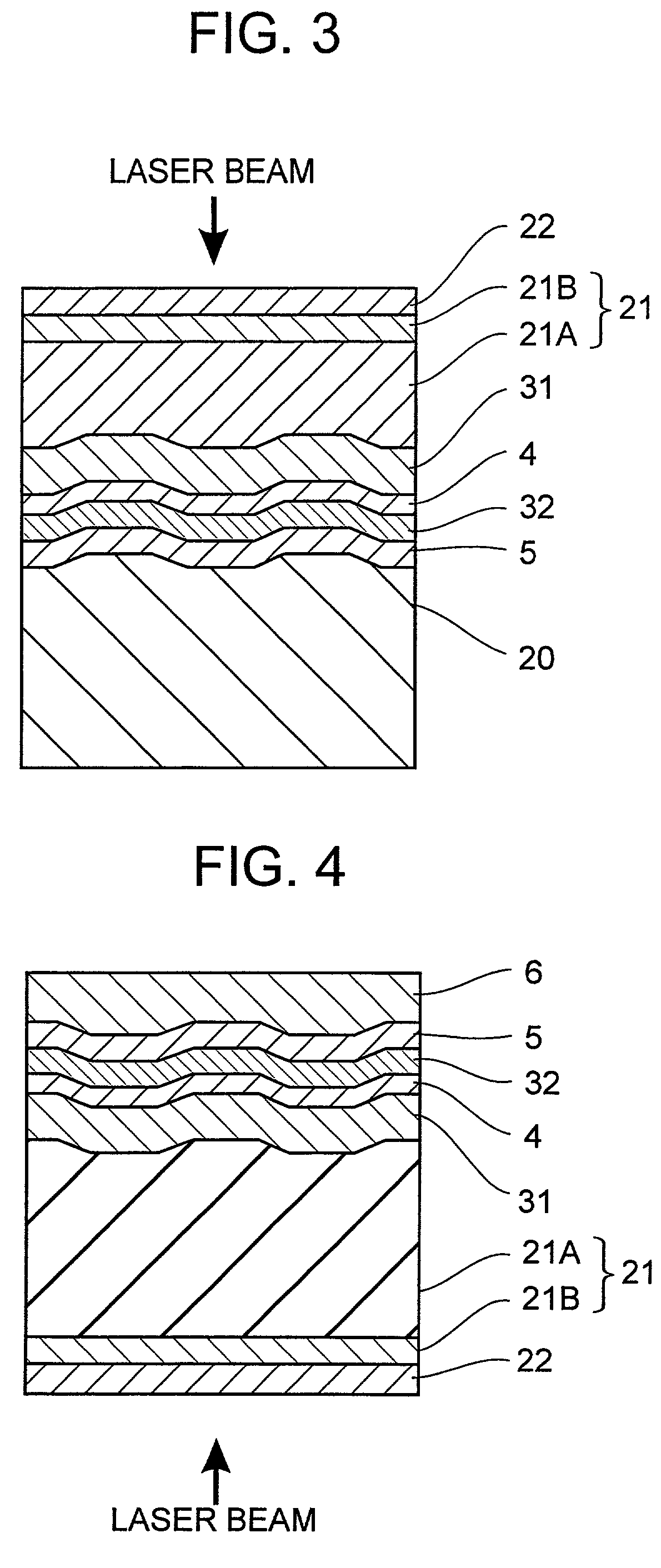

Optical information medium and evaluation method

InactiveUS20020054975A1Protect the surfaceExcellent abrasion resistanceRecord carriersInformation arrangementPolysilazaneOptical recording

An optical information medium has a light-transparent substrate and an information recording layer, wherein optical recording and / or reading is performed with a laser beam that enters the information recording layer from the light-transparent substrate side. A cured polysilazane film is disposed on the laser beam incident side of the light-transparent substrate, and the light-transparent substrate or the light-transparent substrate having the cured polysilazane film integrated thereon has a tensile modulus of at least 200 MPa. The medium on its laser beam incident side surface is improved in mar resistance.

Owner:TDK CORPARATION

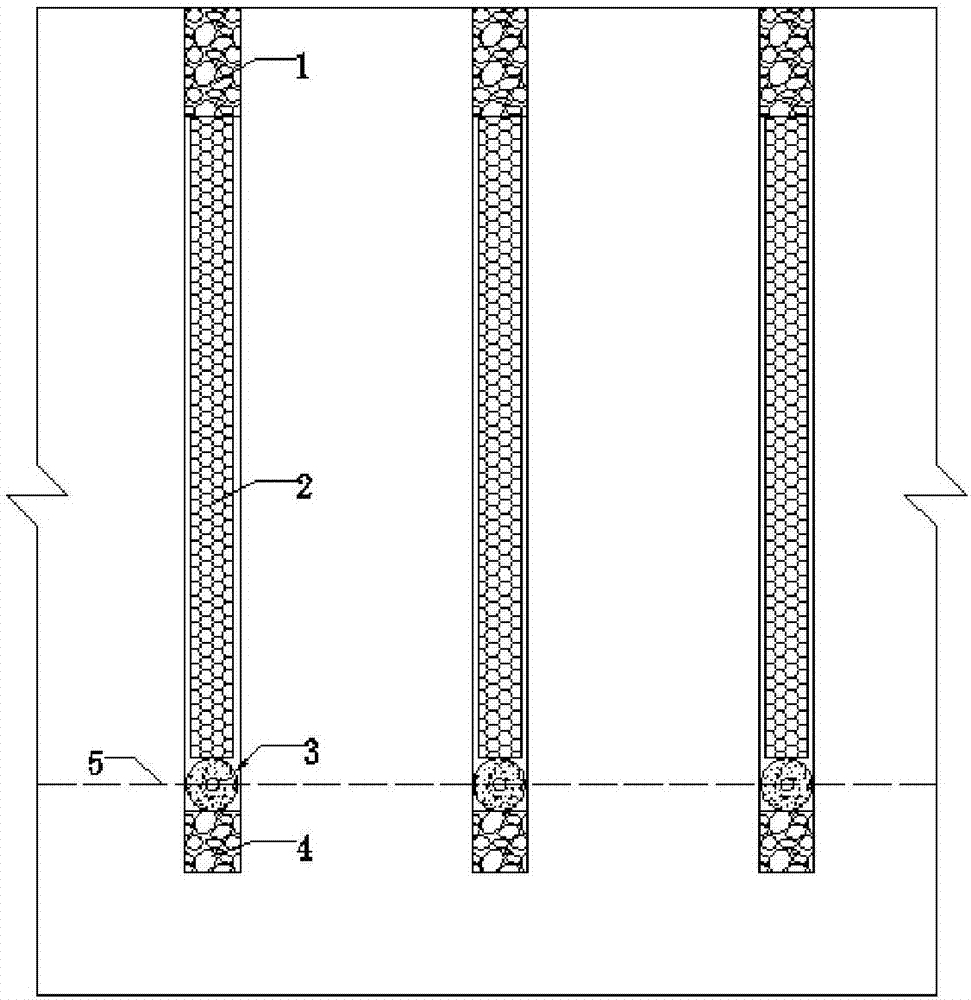

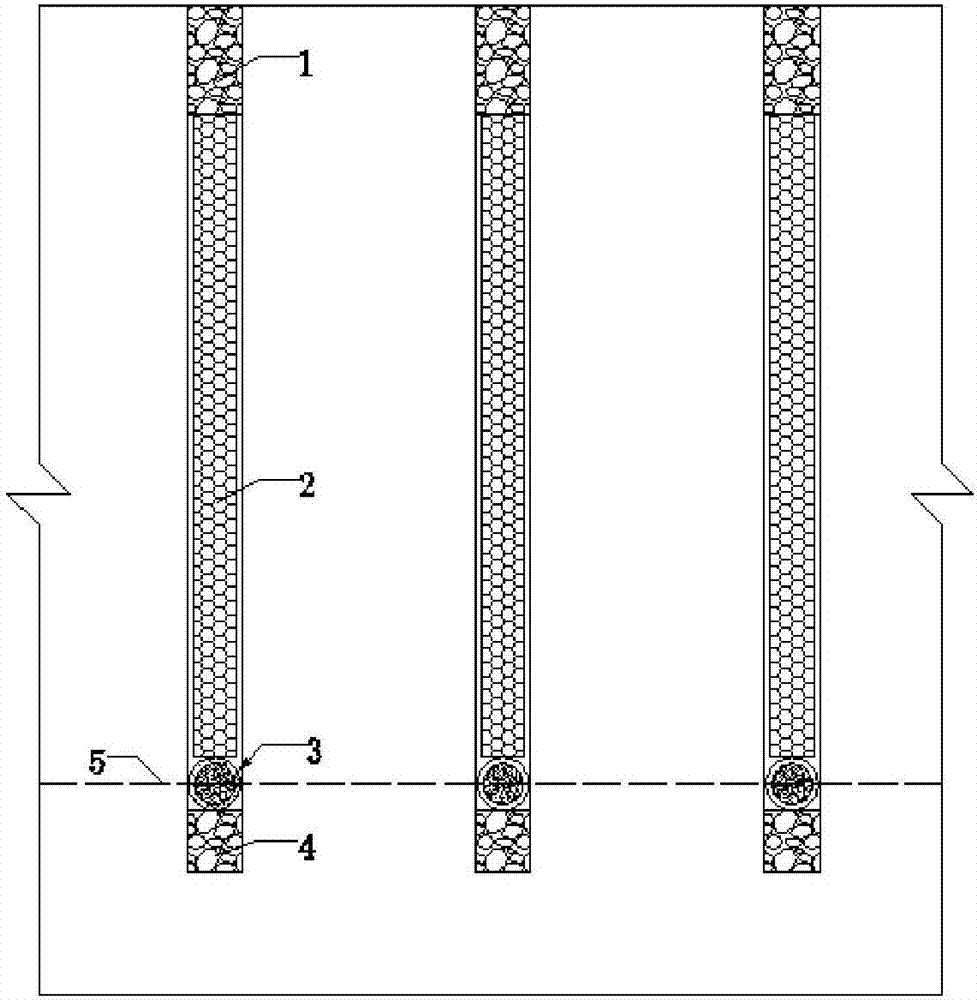

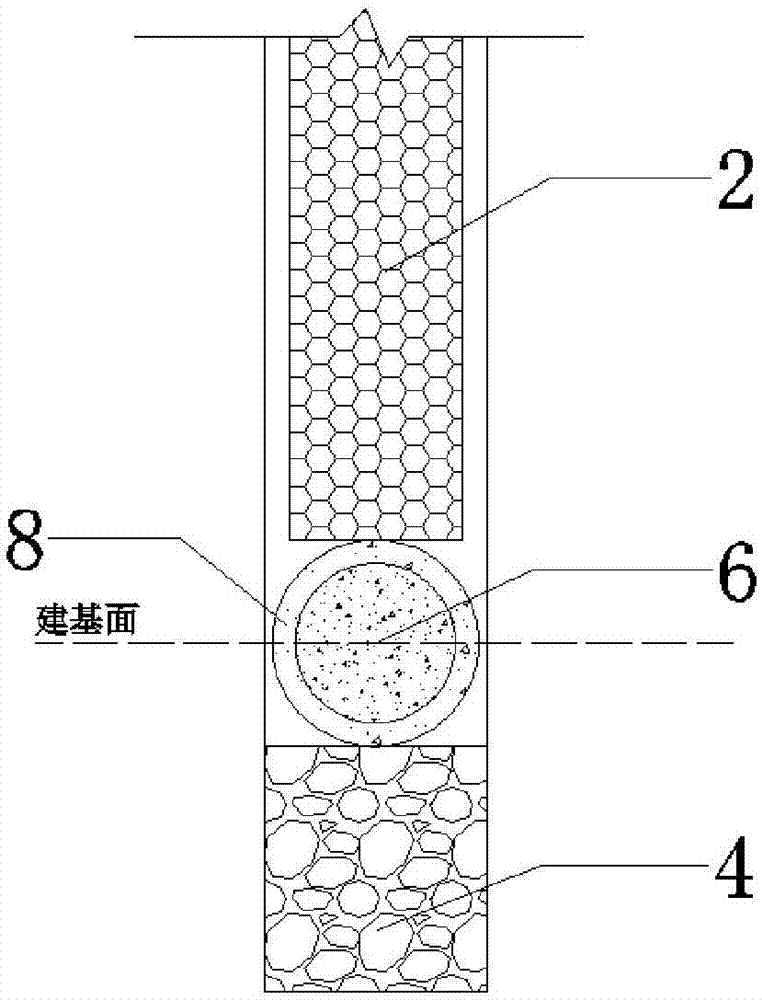

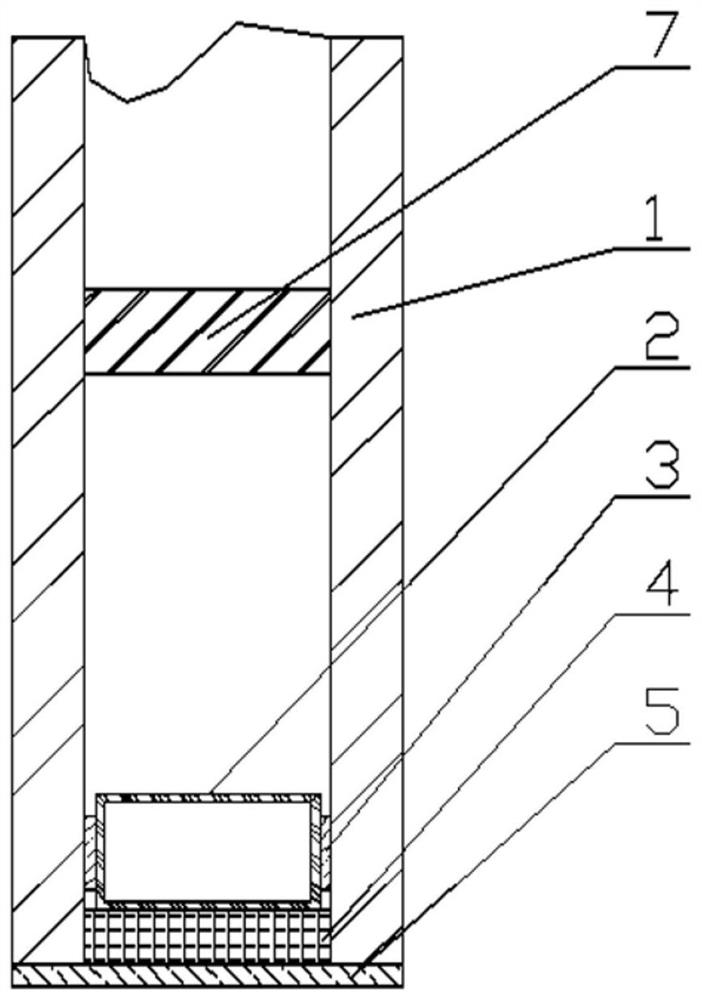

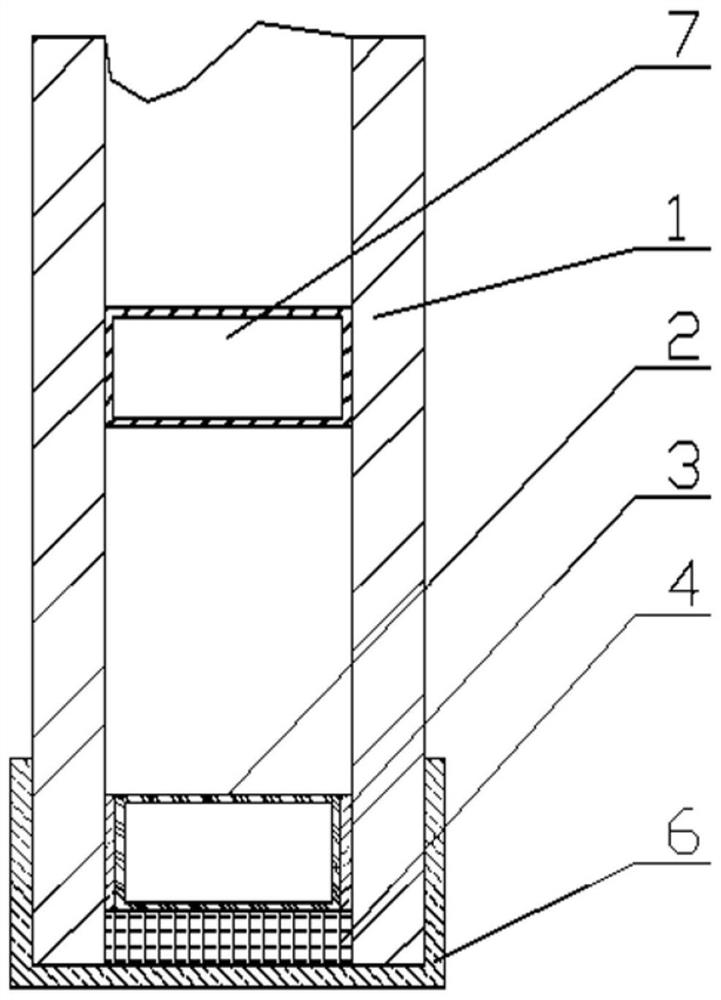

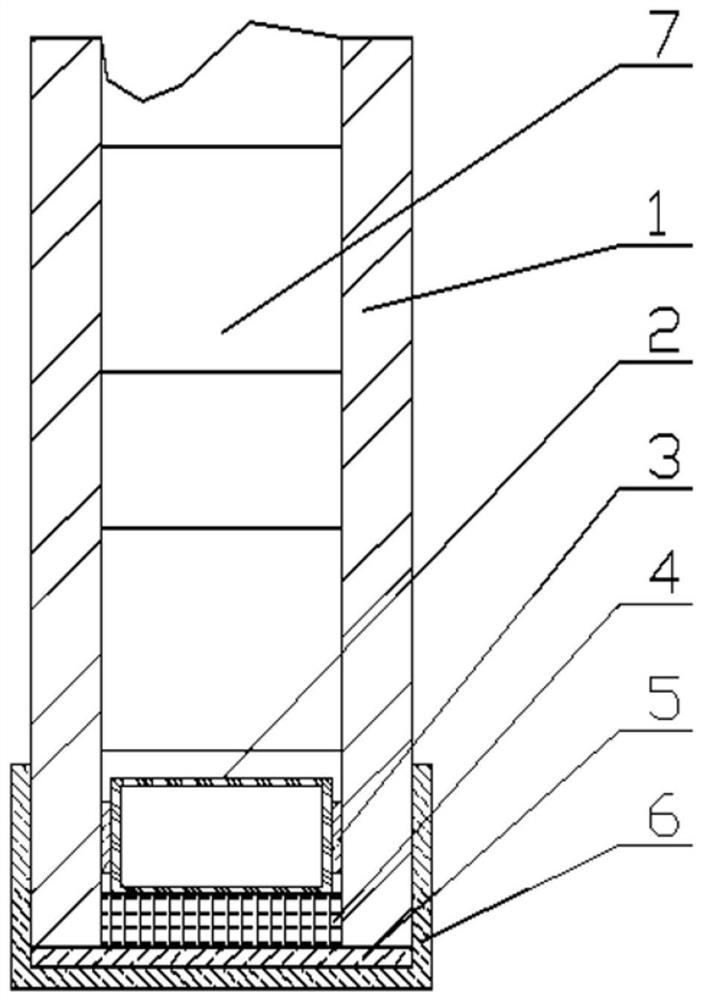

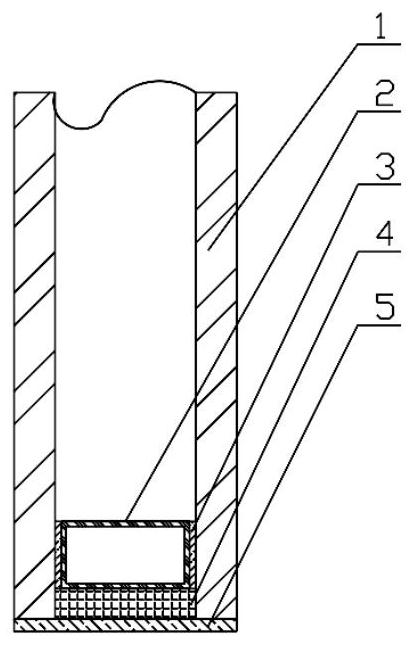

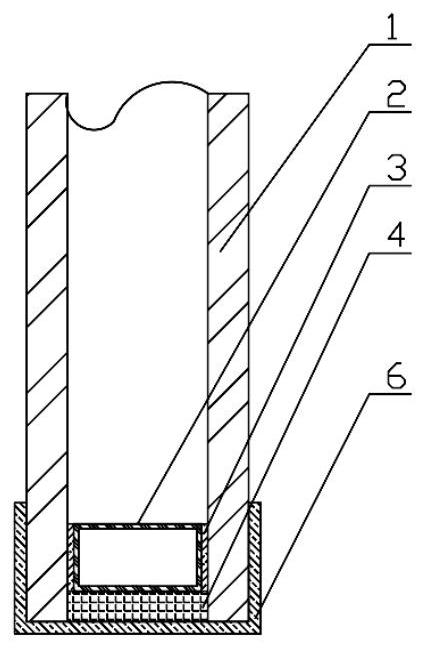

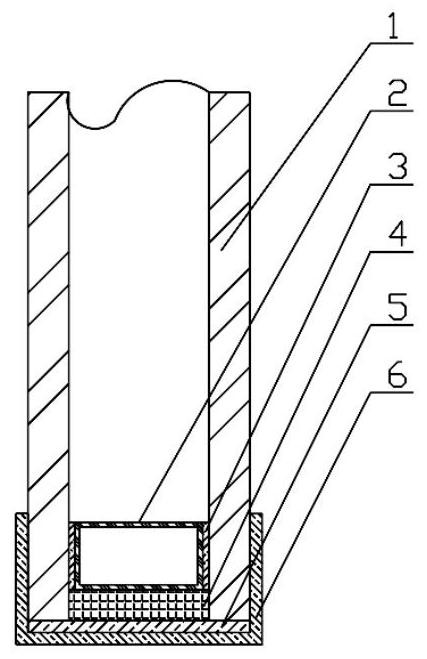

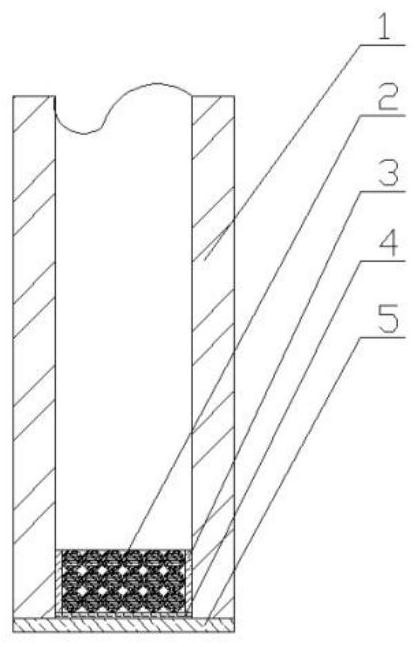

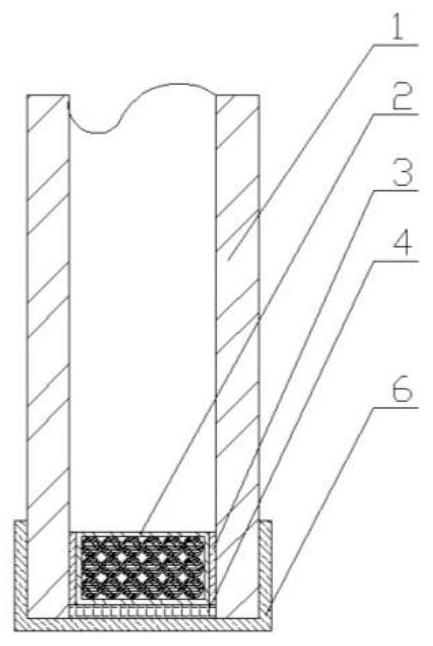

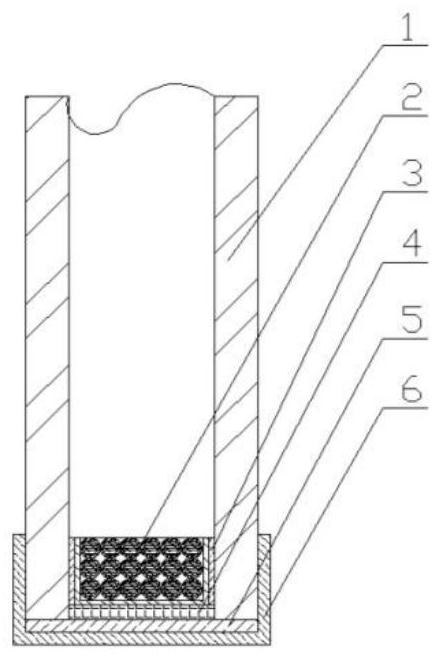

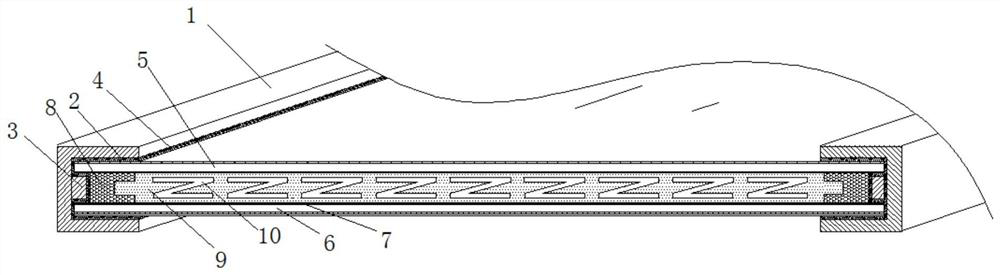

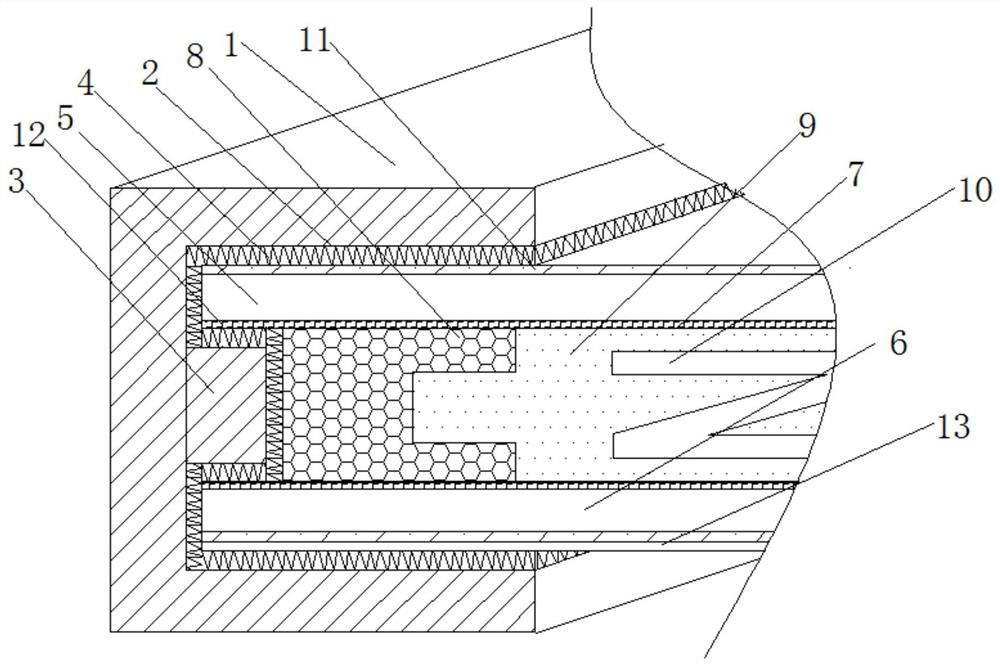

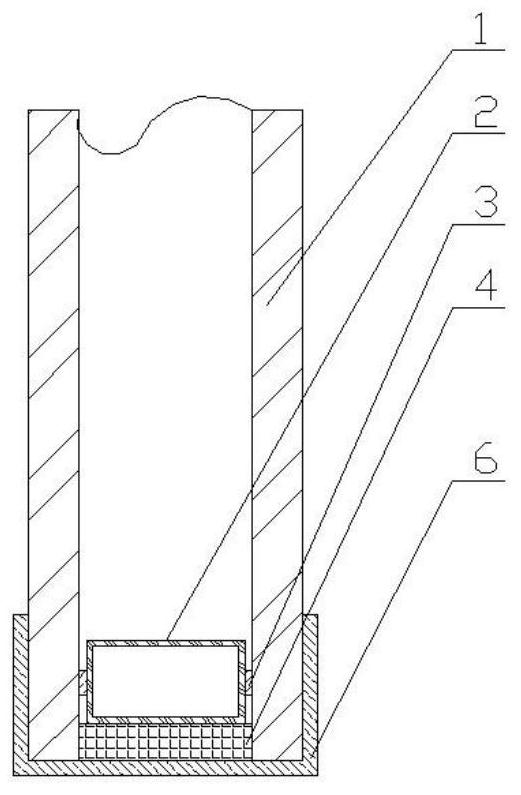

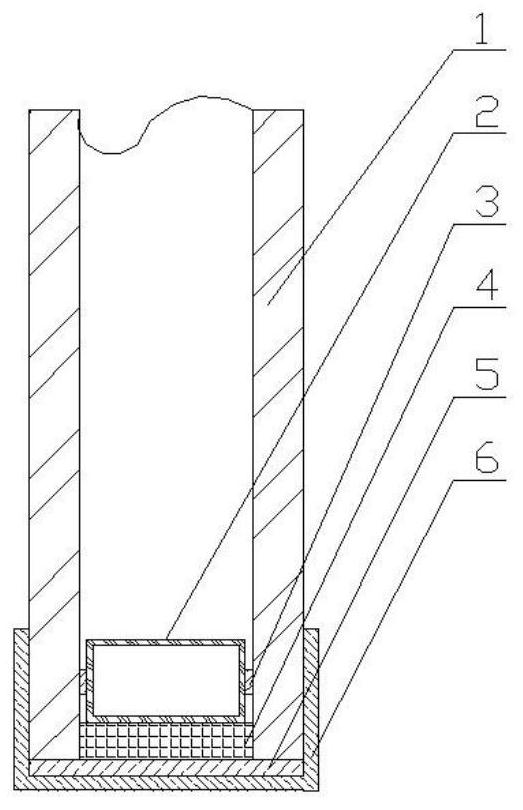

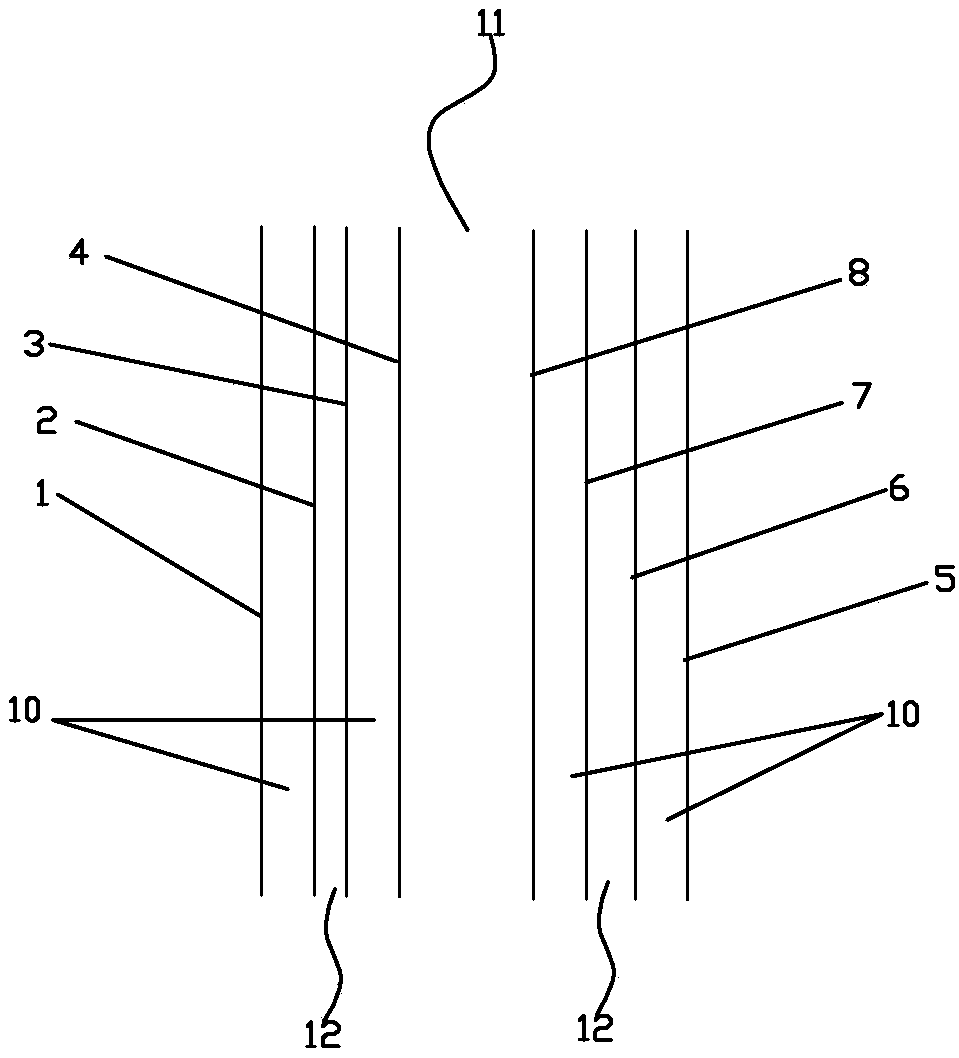

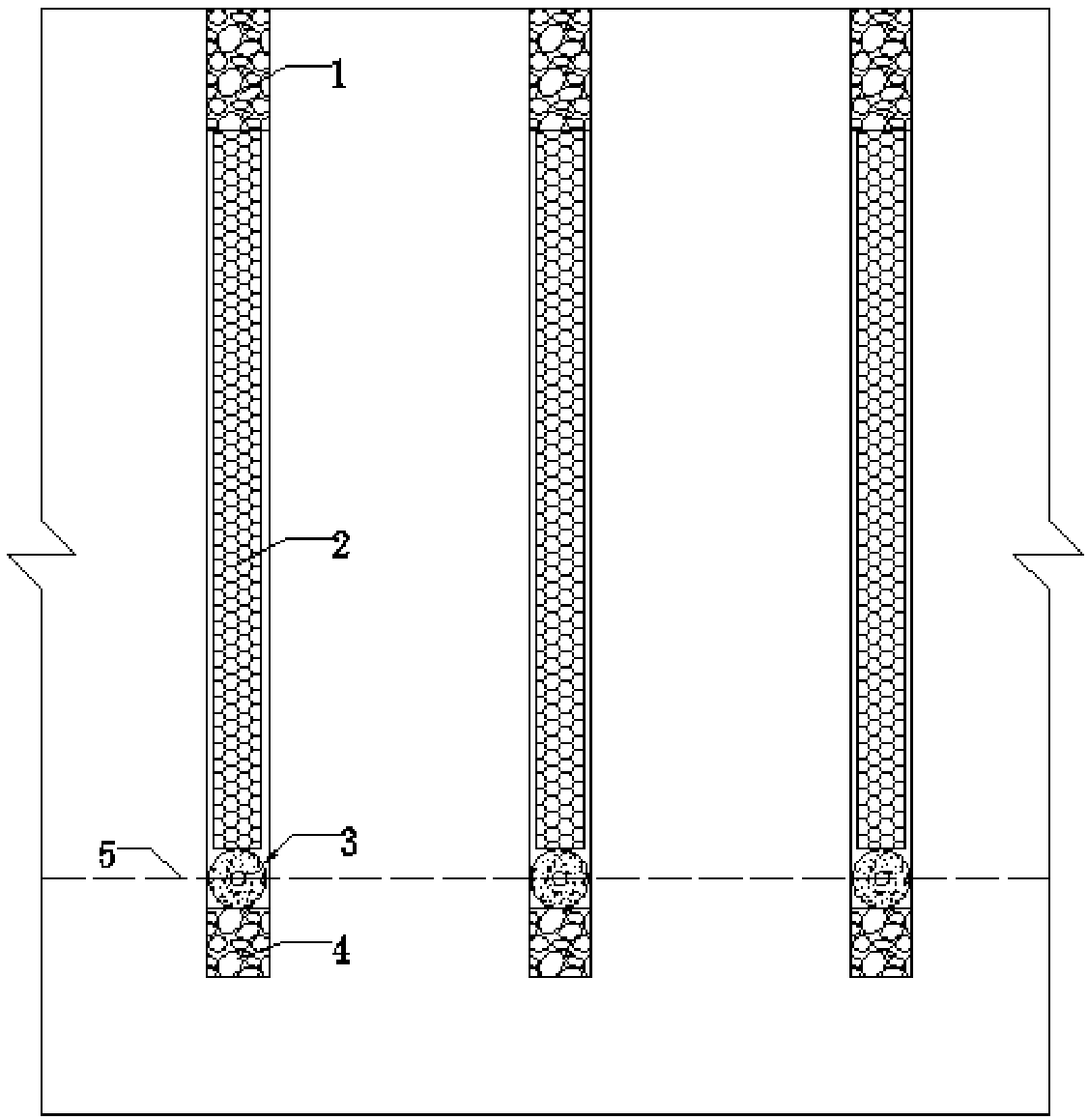

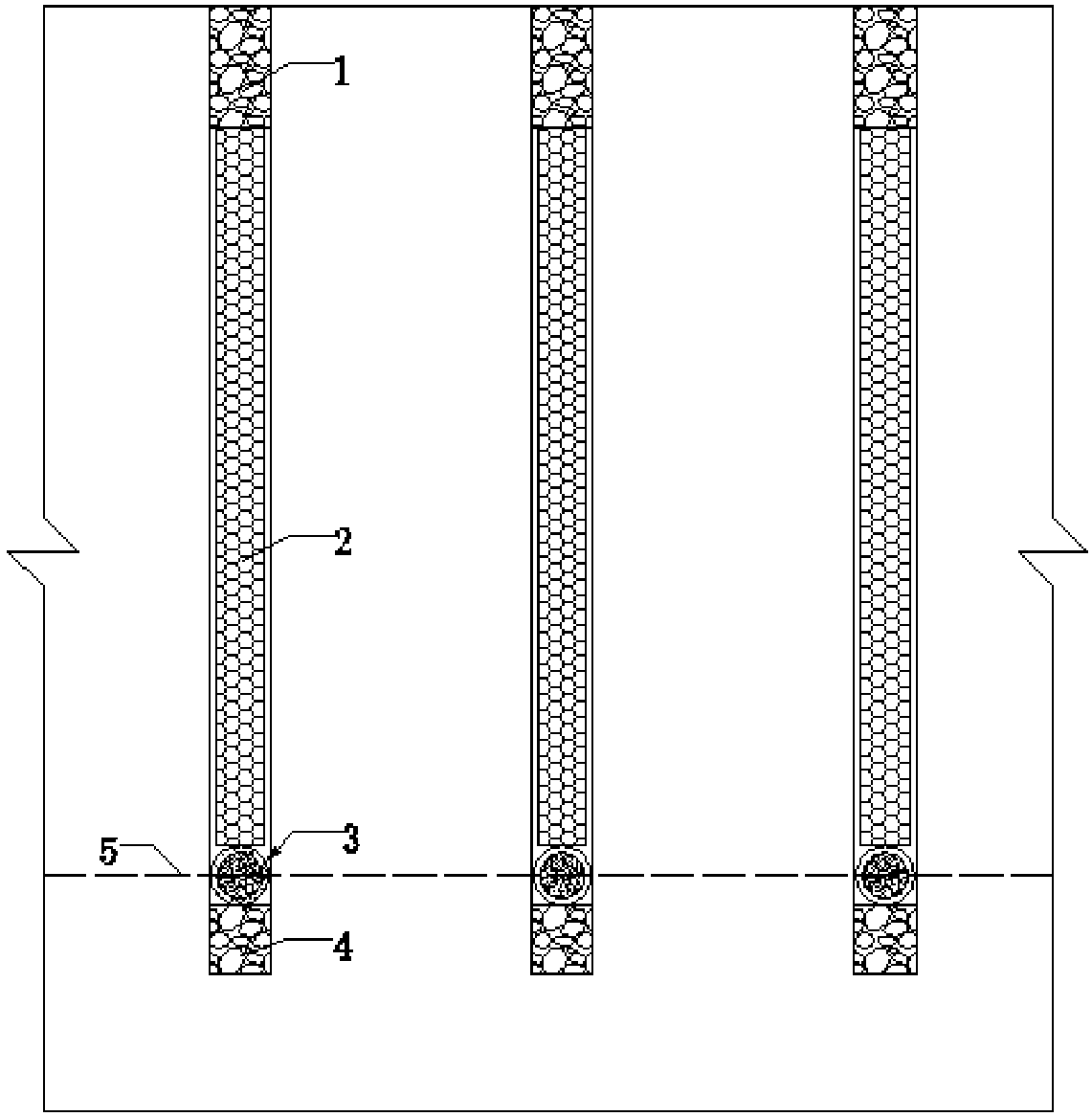

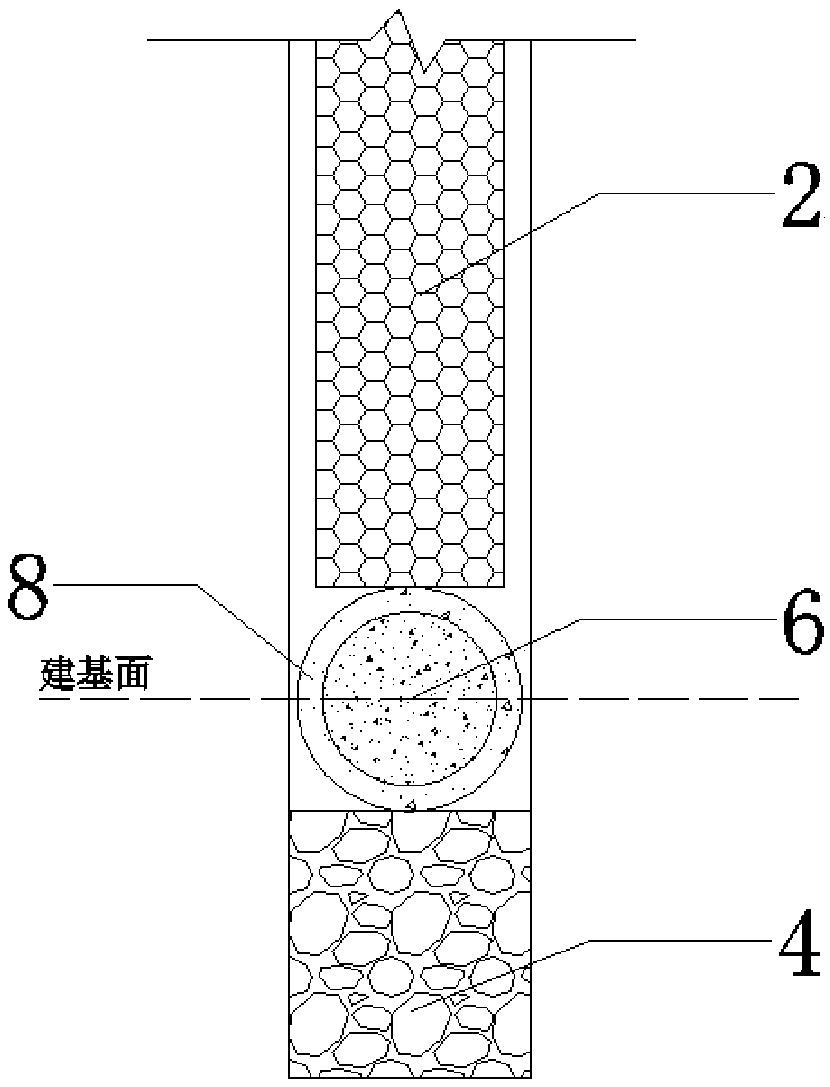

Impacting-shaping composite spherical energy dissipation structure for vertical hole blasting

ActiveCN106949797ASleek appearanceLittle effect of hole wall roughnessBlastingDetonationNuclear power

The invention provides an impacting-shaping composite spherical energy dissipation structure for vertical hole blasting. The energy dissipation structure comprises a composite spherical energy dissipation base and a buffer layer located below the composite spherical energy dissipation base, wherein the composite spherical energy dissipation base is of a double-layer structure which is soft externally and hard internally or hard externally and soft internally from outside to inside. According to the energy dissipation structure, under the action of an initial impact load after explosive detonation in a blast hole, the composite spherical energy dissipation base generates secondary plasticity, finally an ellipsoidal or a concave-shaped rigid cushion block reflects most of the explosion energy which is propagated in the rock mass below the hole bottom, meanwhile, the composite spherical energy dissipation base and the buffer layer absorb partial explosion energy in the deformation process, and therefore the rock on the foundation surface can be broken, the rock on the hole bottom can be protected, and the existing horizontal pre-cracking or smooth blasting technology can be partially replaced. The energy dissipation structure is simple and convenient to install, can partially replace the existing horizontal pre-cracking or smooth blasting technology and is suitable for protecting layer rock mass blasting excavation in the fields of water conservancy and hydropower, nuclear power, traffic and the like.

Owner:WUHAN UNIV

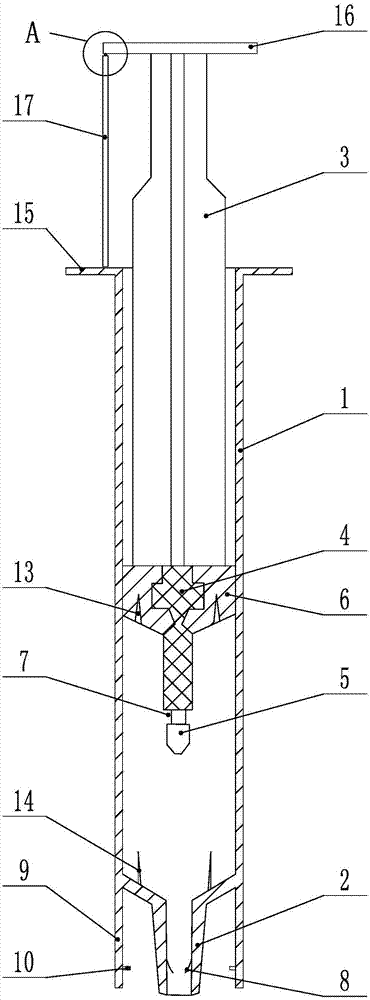

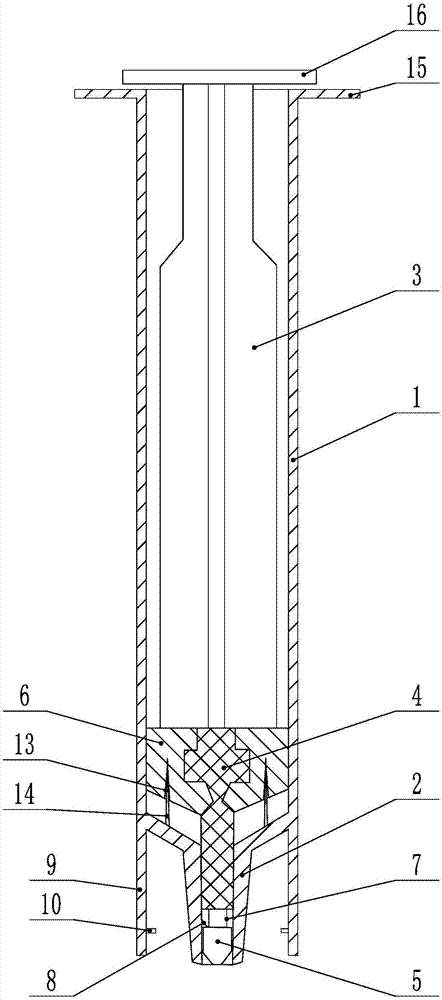

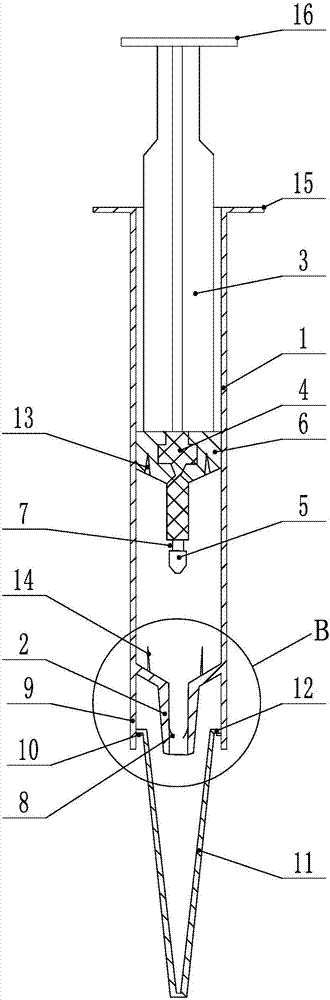

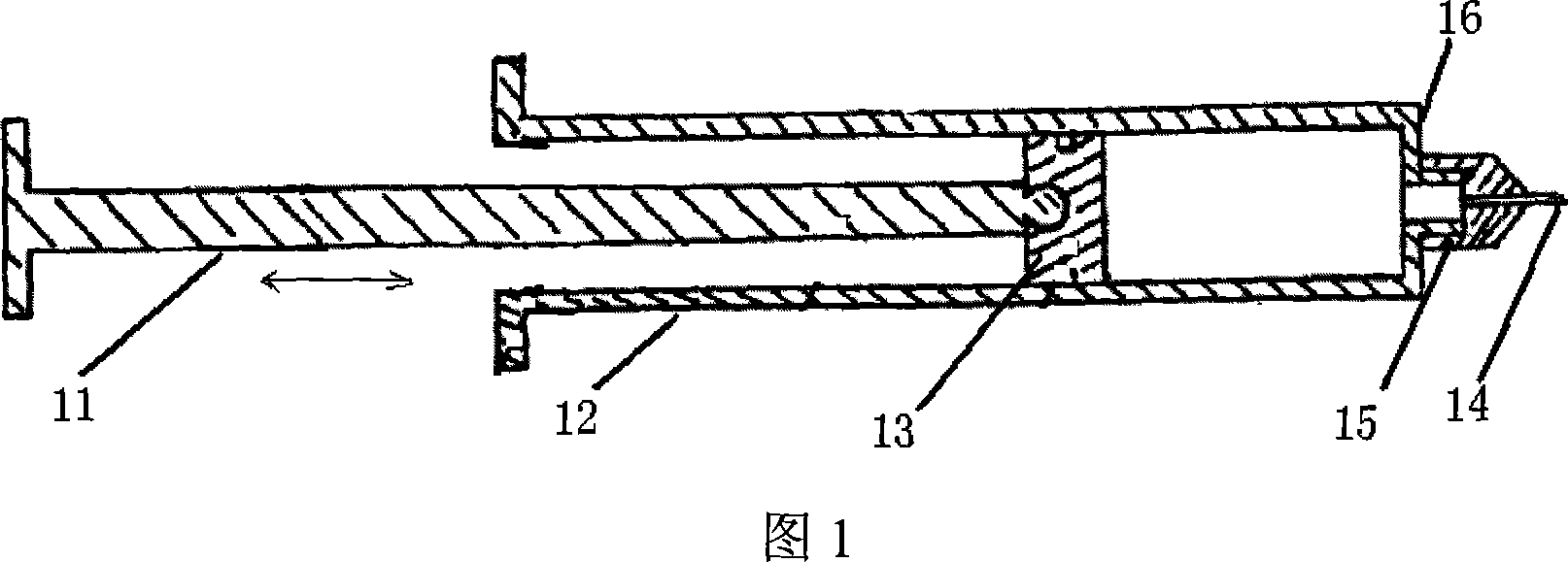

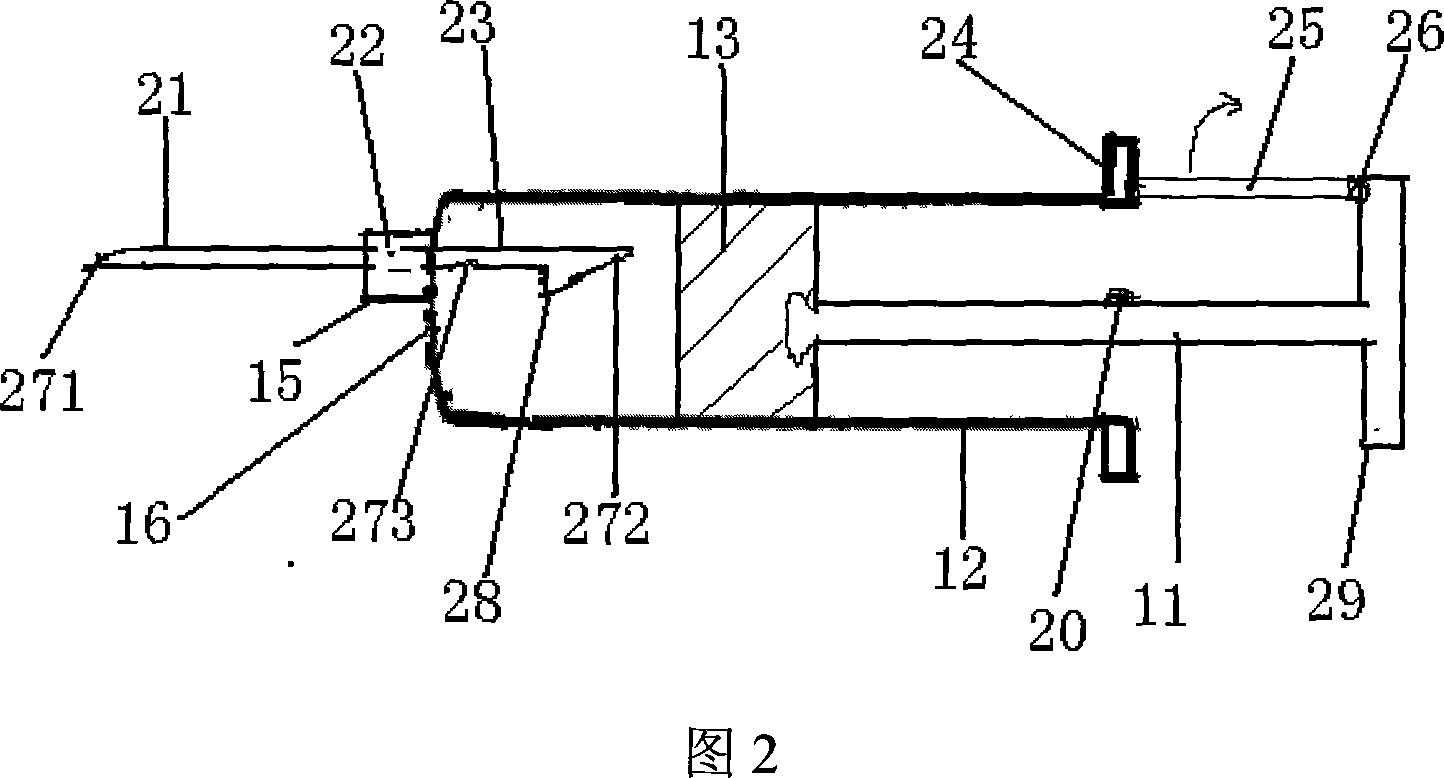

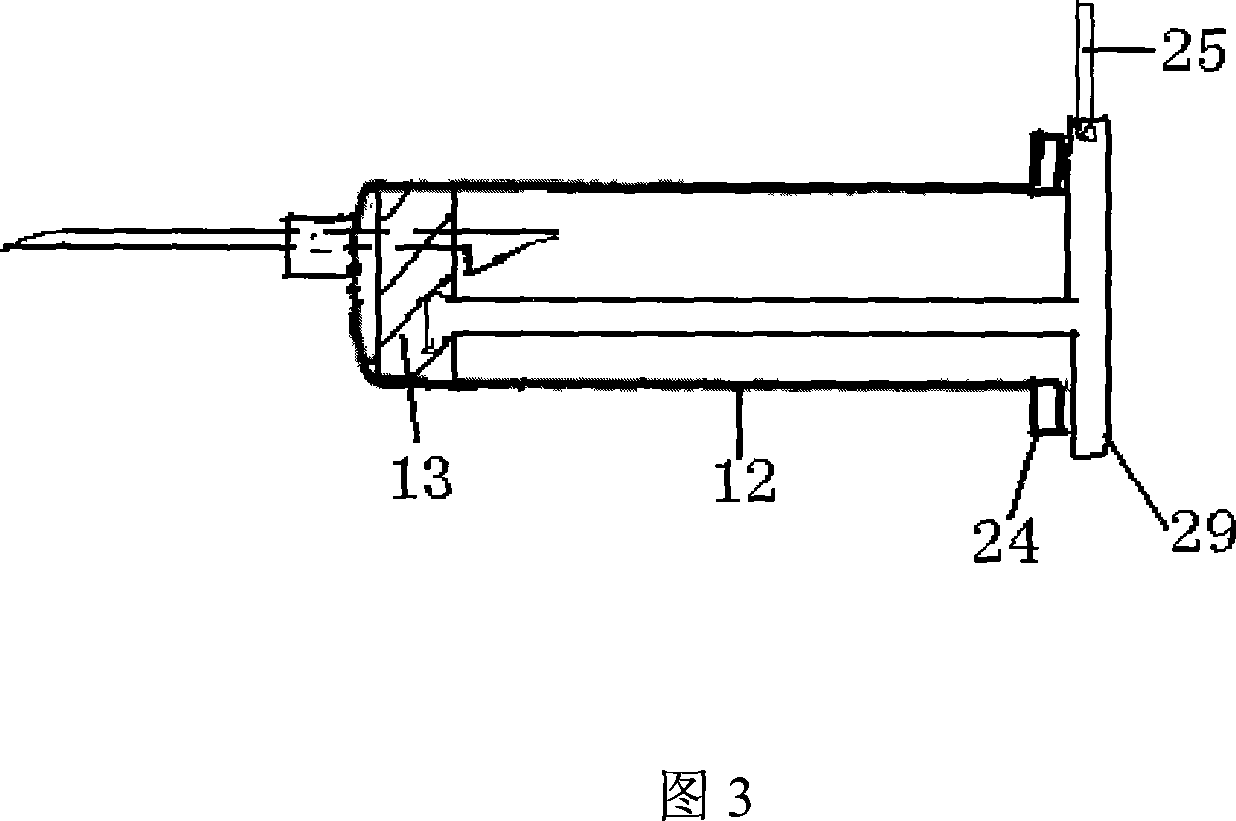

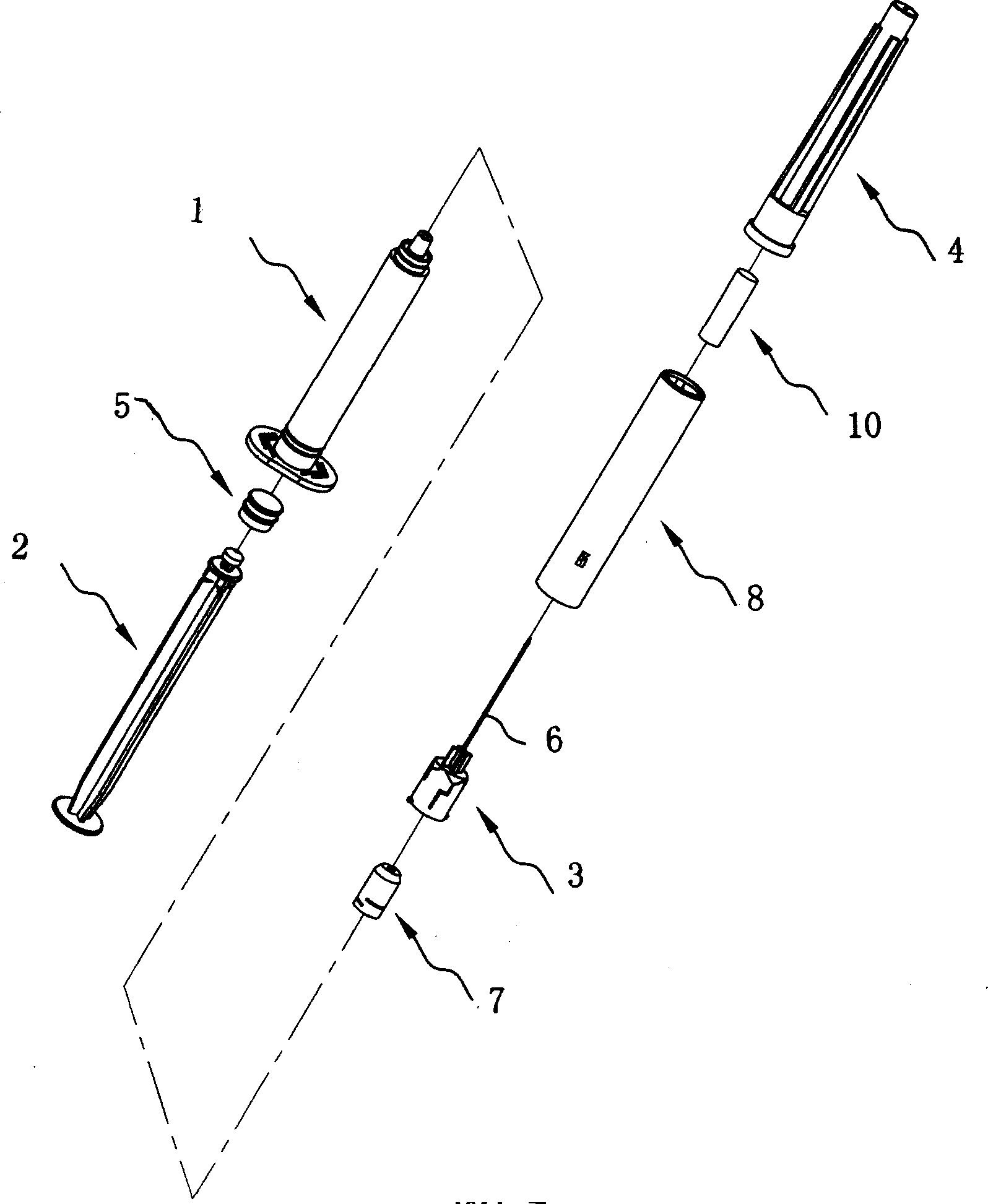

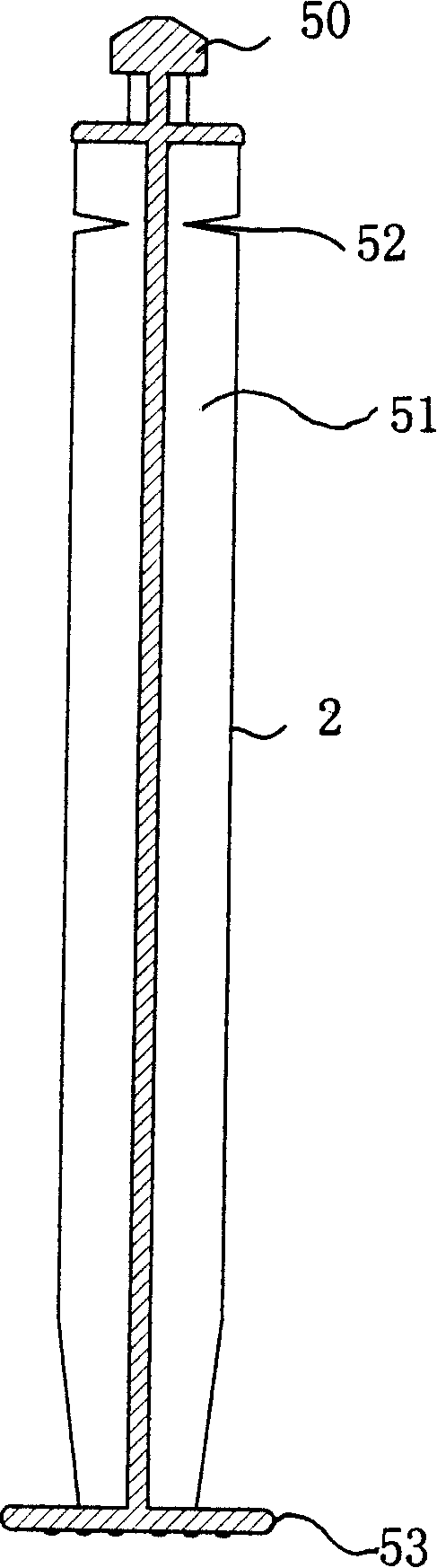

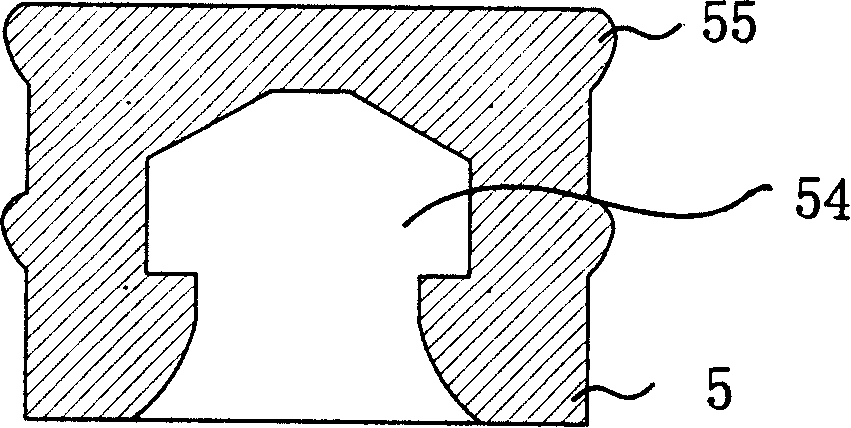

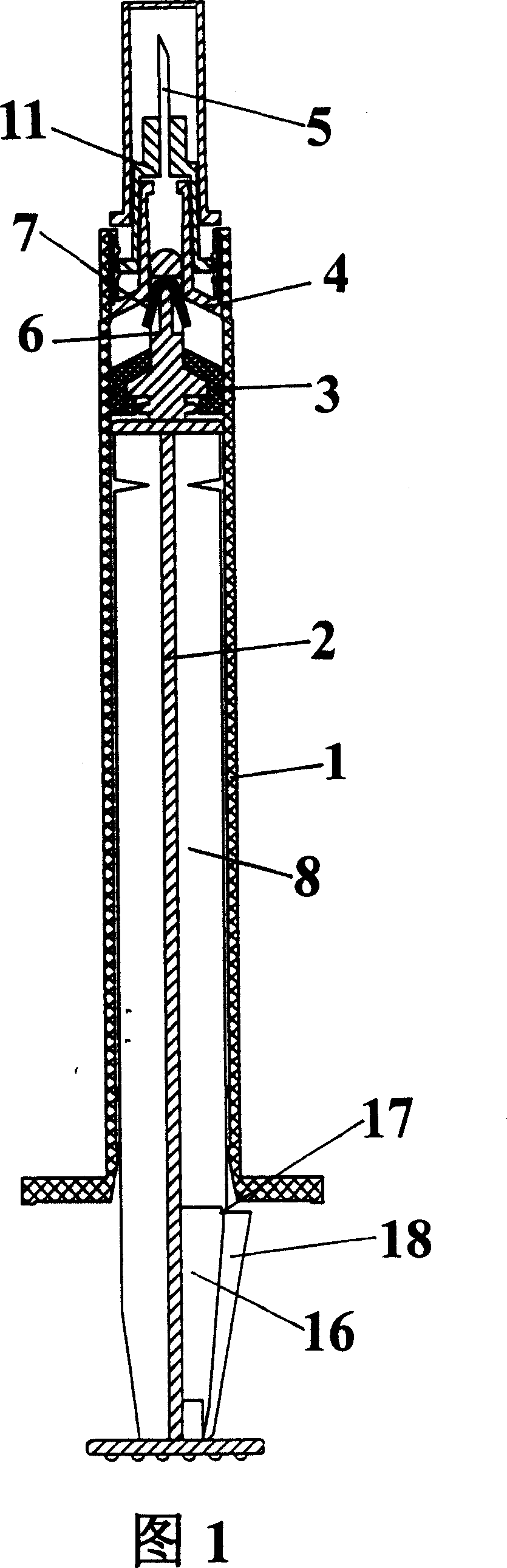

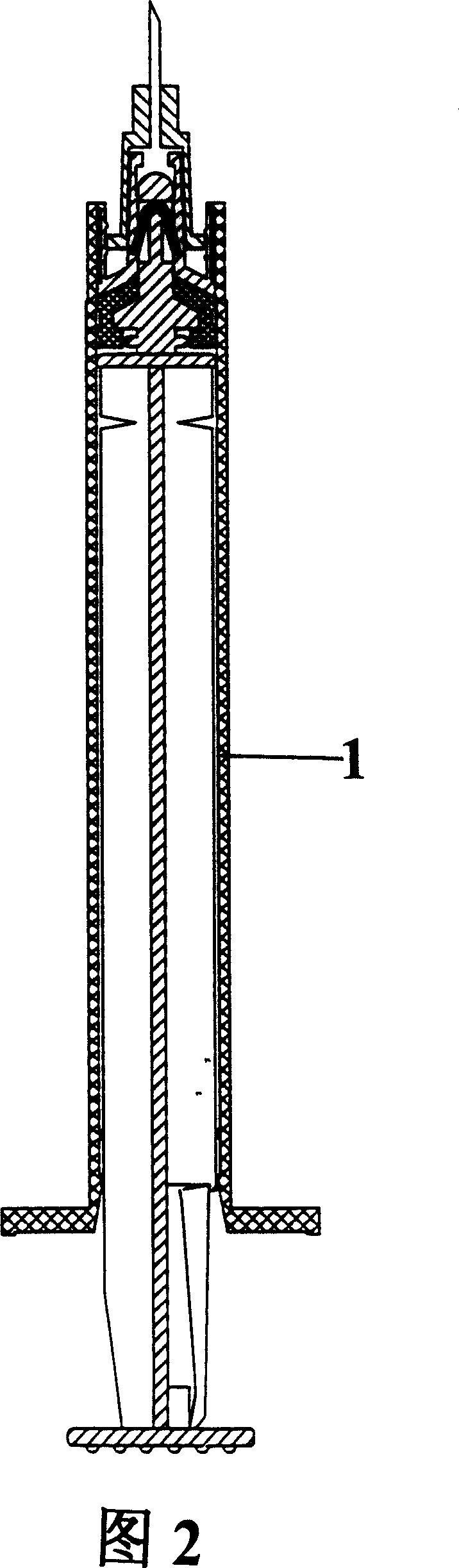

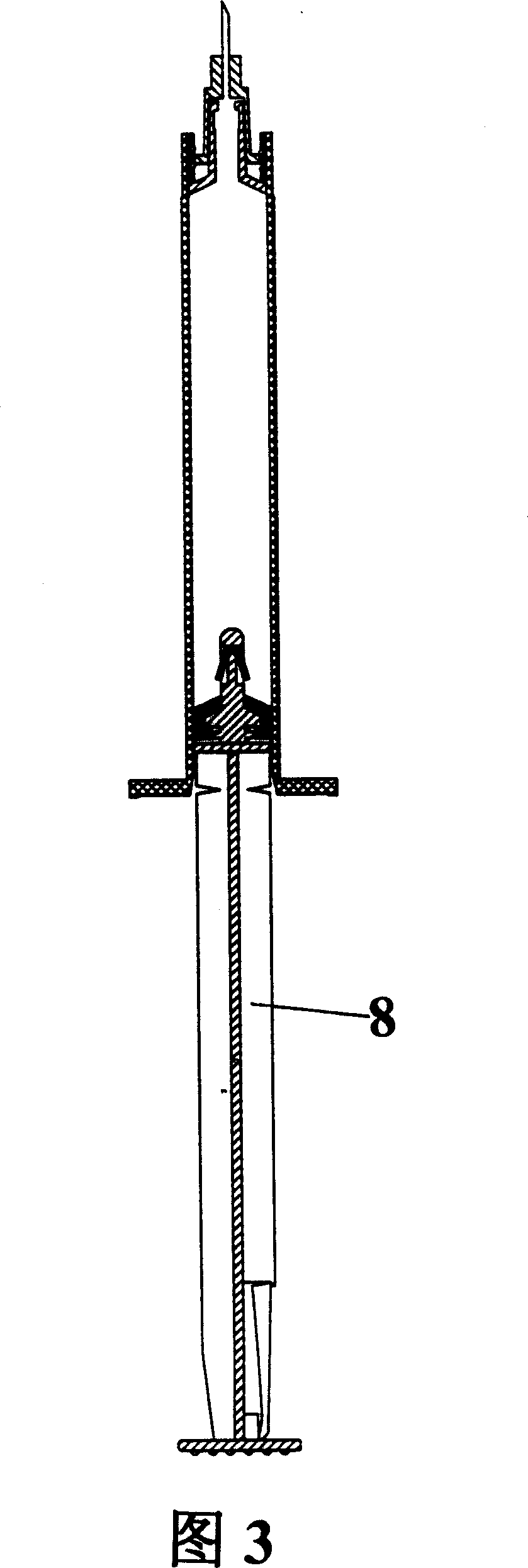

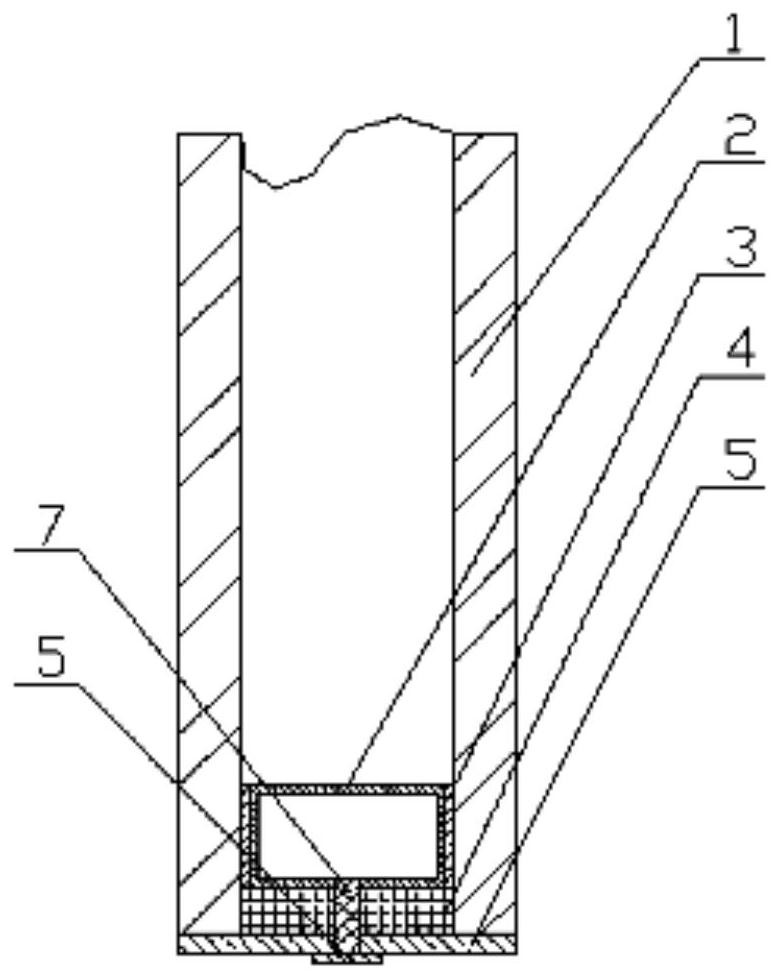

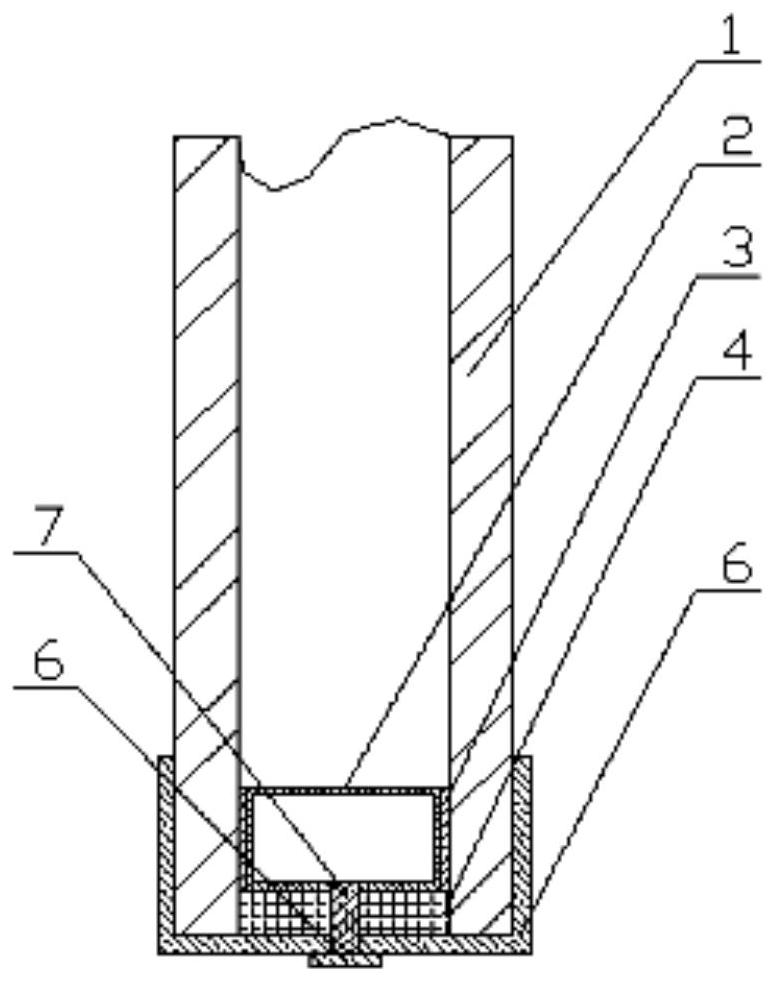

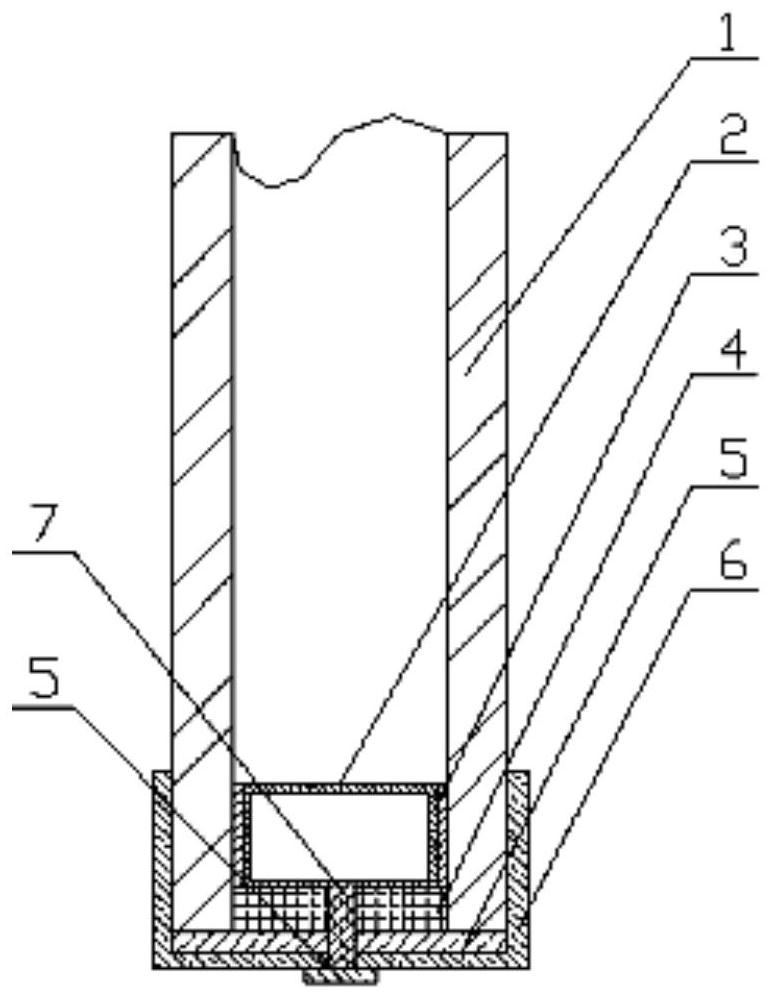

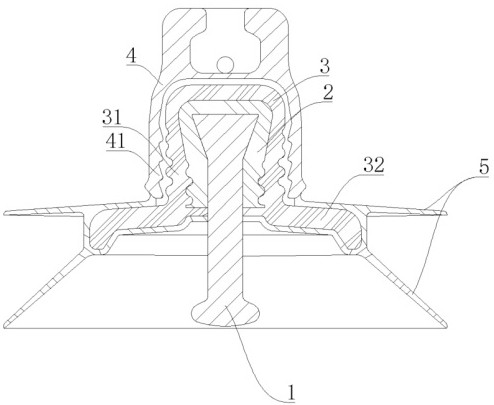

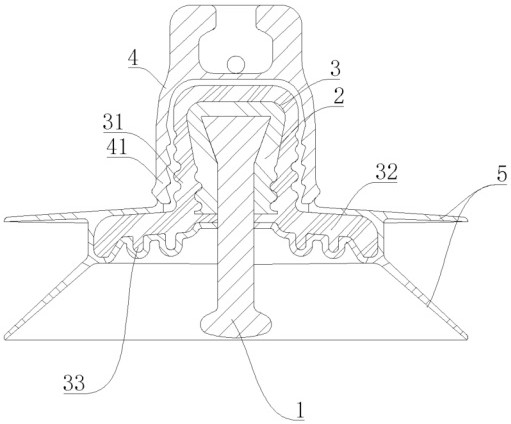

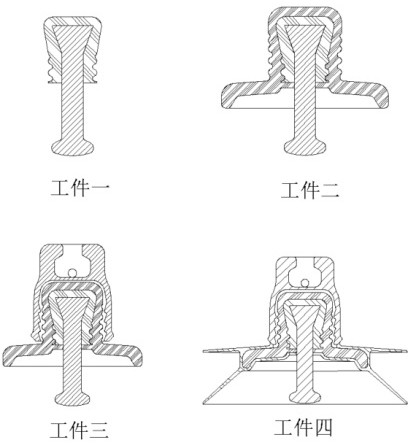

Disposable syringe

InactiveCN107469199AAvoid cross propagationImprove safety and reliabilityInfusion syringesMedical devicesEngineeringSyringe needle

The invention belongs to the technical field of medical instruments, and relates to a disposable syringe. The lower end of a syringe body is provided with a needle base, a pushing rod is arranged in the syringe body, a connecting block is arranged on the lower end of the pushing rod, a rod head is mounted on the lower end of the connecting block, a piston is connected with the pushing rod through the connecting block and can move inside the syringe body along with the pushing rod, and an annular groove is formed in the outer cylindrical surface of the lower end of the rod head; a first elastic clamping claw is arranged on the inner wall of the needle base and clamped with the annular groove in the rod head to achieve a self-destruction function; a protective cover is arranged outside the needle base on the lower end of the syringe body and is of an integrated structure with the syringe body, a second elastic clamping claw is arranged on the lower end of the inner wall of the protective cover, the upper end of a needle locking cover is provided with an annular convex rim, the needle locking cover stretches from the lower end of the second elastic clamping claw into the protective cover, and the second elastic clamping claw is arranged on the bottom plane of the annular convex rim to lock a syringe needle; the disposable syringe achieves self-destruction functions of the syringe body, the pushing rod, the piston and the syringe needle, and improves the safety and reliability of the usage of the medical instruments.

Owner:ZHEJIANG OCEAN UNIV

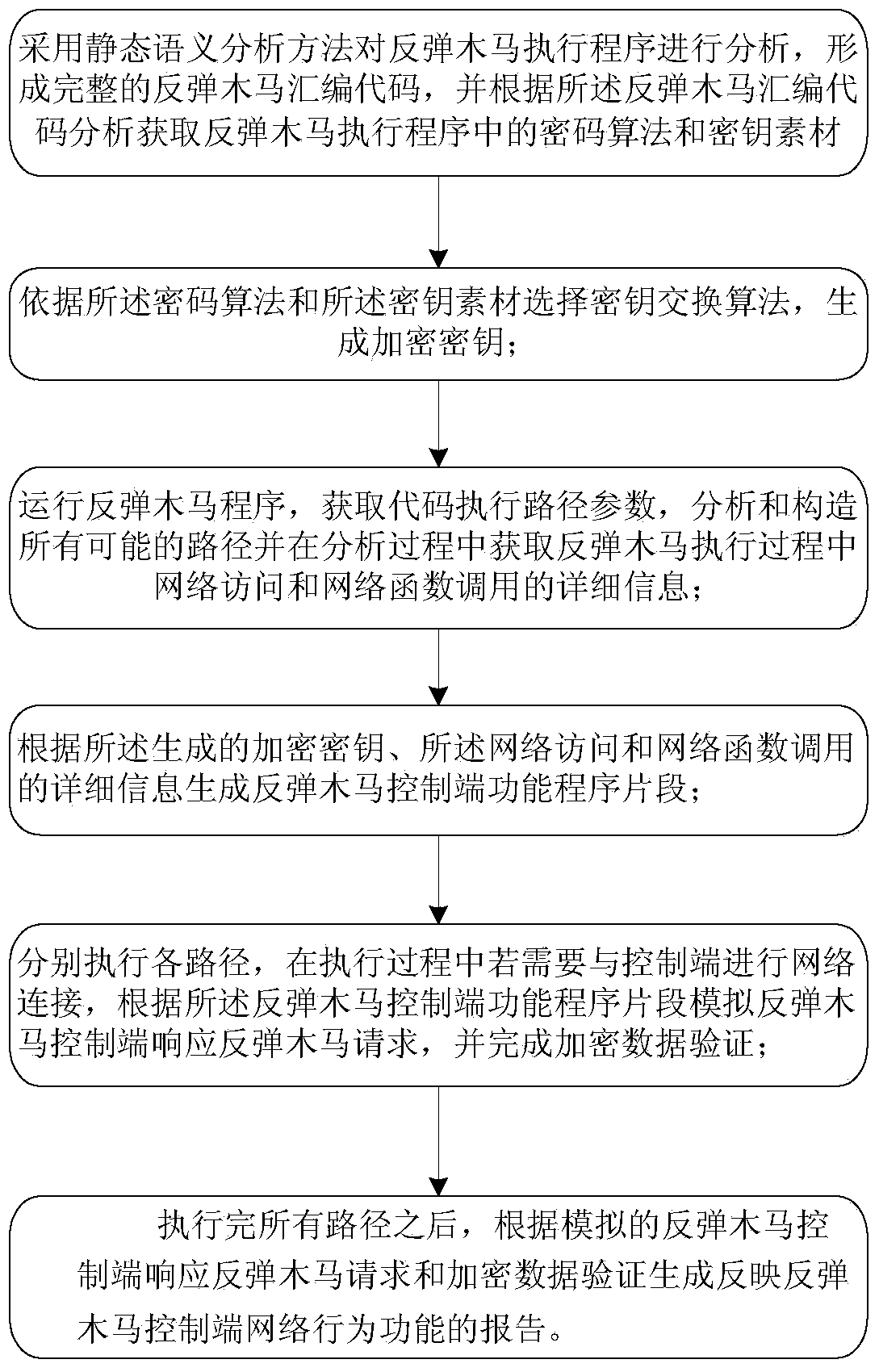

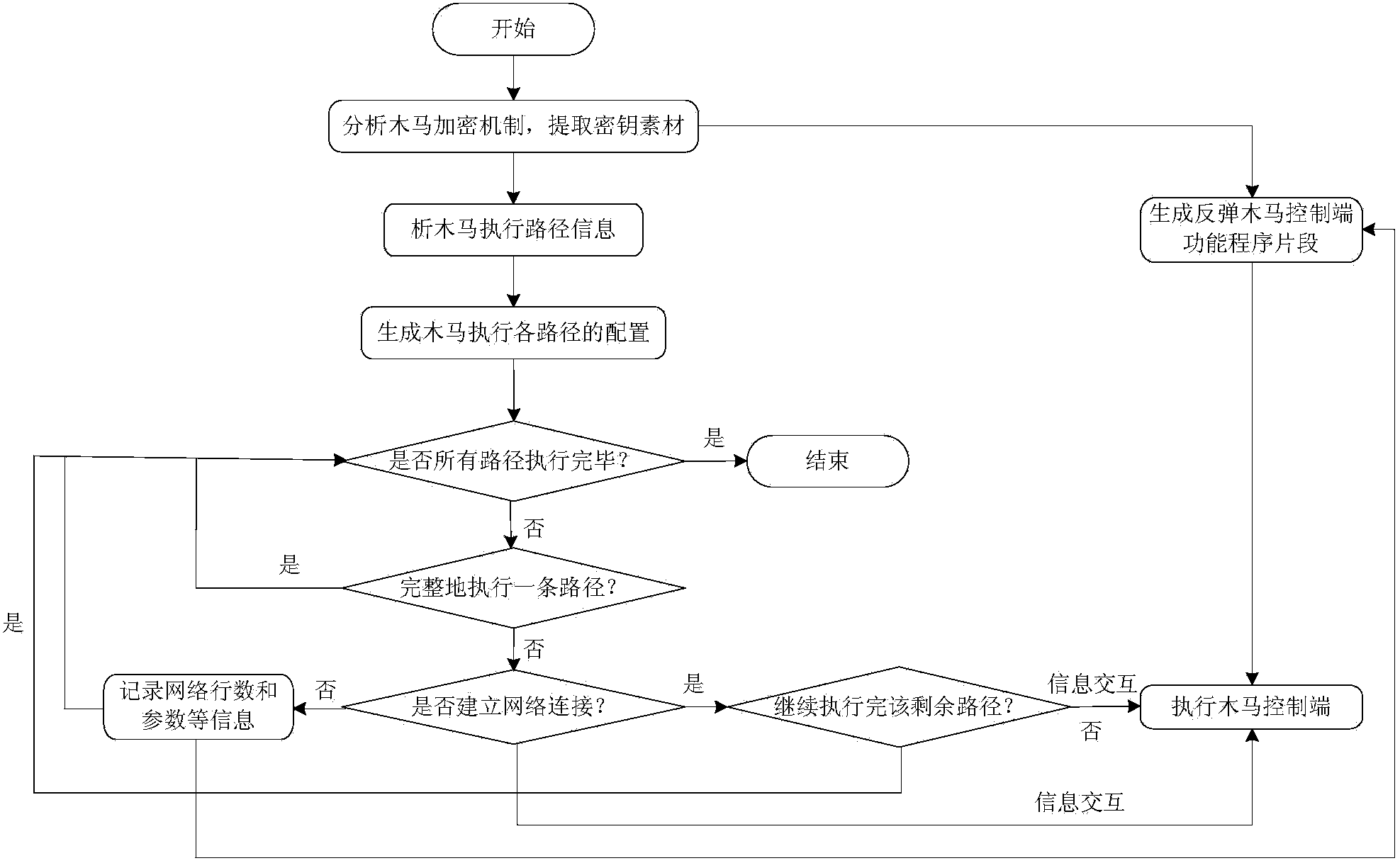

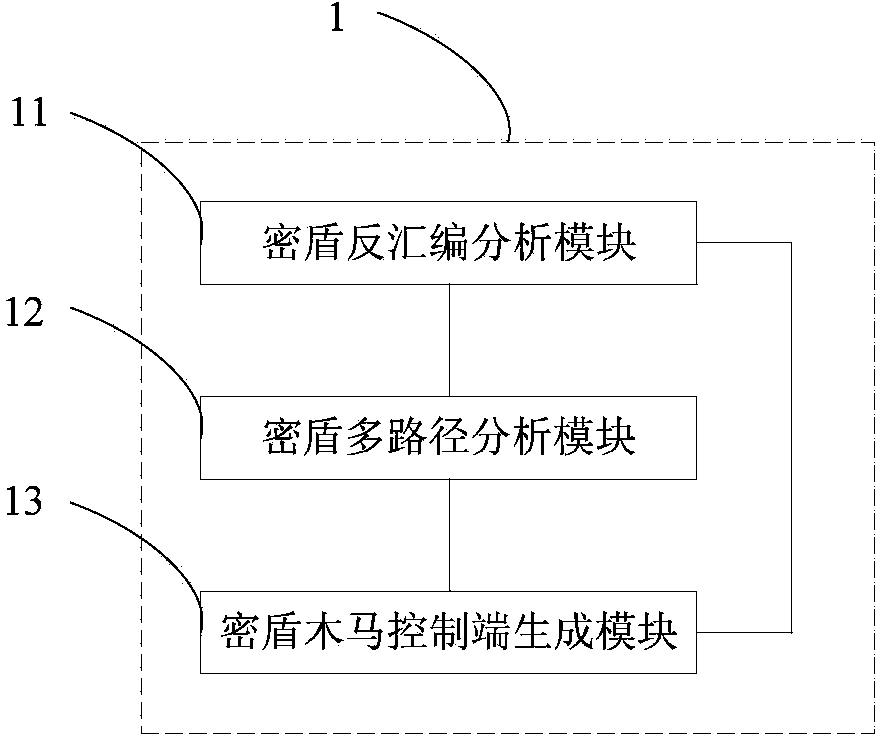

Method and system for recall Trojan horse control site network behavior function reconstruction

InactiveCN103491077AMaster sabotageDetailed and fine-grained analysisData switching networksData validationProgram segment

The invention provides a method and system for recall Trojan horse control site network behavior function reconstruction. The system comprises a secret shield disassembling analyzing module, a secret shield multi-path analyzing module and a secret shield Trojan horse control site generating module. The secret shield disassembling analyzing module analyzes a recall Trojan horse executive program by means of a static semantic analysis method so as to form a complete recall Trojan horse assembly code and obtain a code algorithm and a secret key material. The secret shield multi-path analyzing module obtains code execution path parameters, analyzes and constructs all possible paths, obtains detail information of network visiting and network function calling in the recall Trojan horse execution process and executes the paths. The secret shield Trojan horse control site generating module generates recall Trojan horse control site function program segments according to a generated encrypted secret key and the detail information of network visiting and network function calling, simulates a recall Trojan horse control site to respond to a recall Trojan horse request, finishes encrypted data verification and generates a report capable of reflecting recall Trojan horse control site network behavior functions. The method and system can safely and effectively reconstruct important functions of recall Trojan horse control site network behaviors.

Owner:WUXI CINSEC INFORMATION TECH

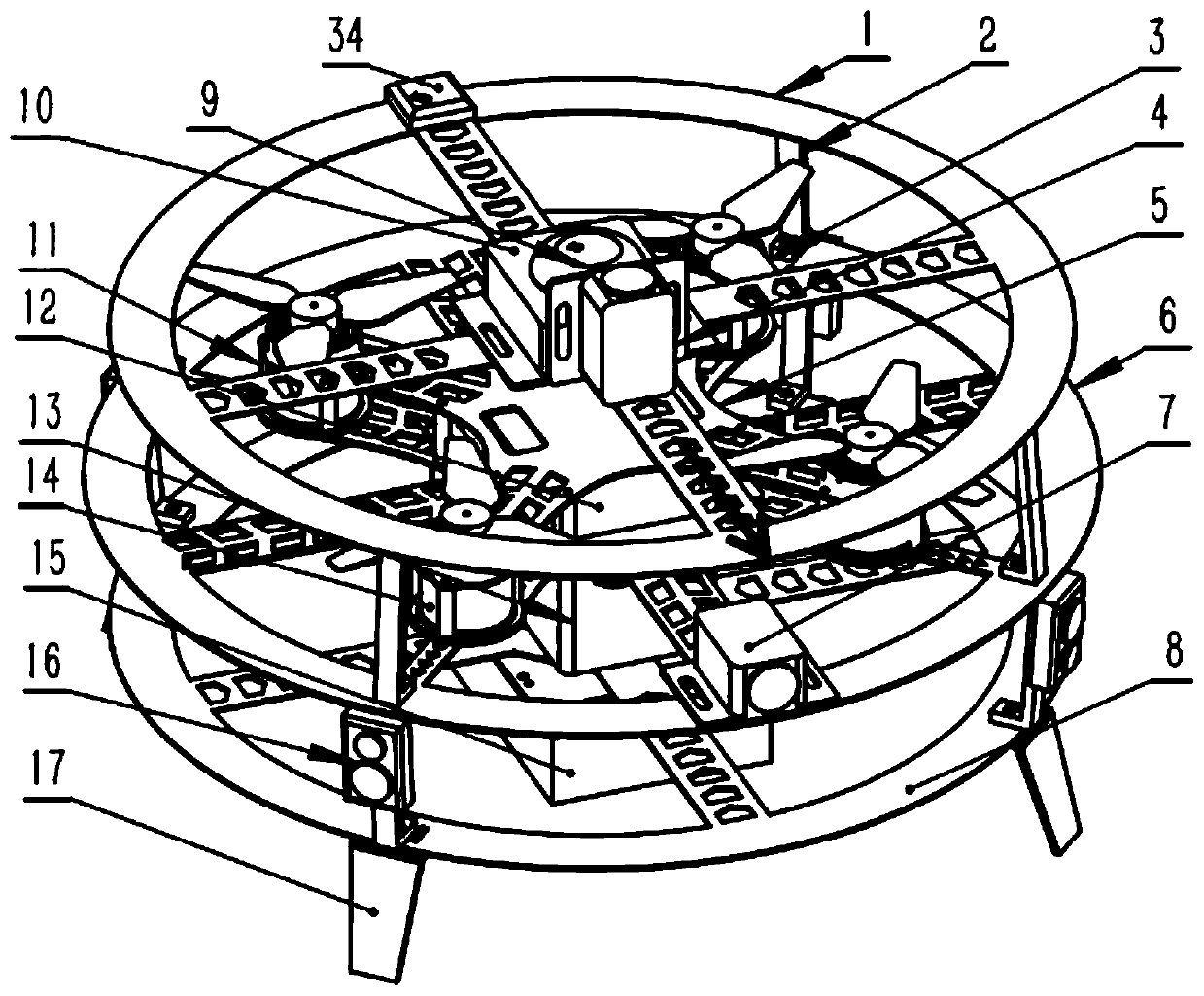

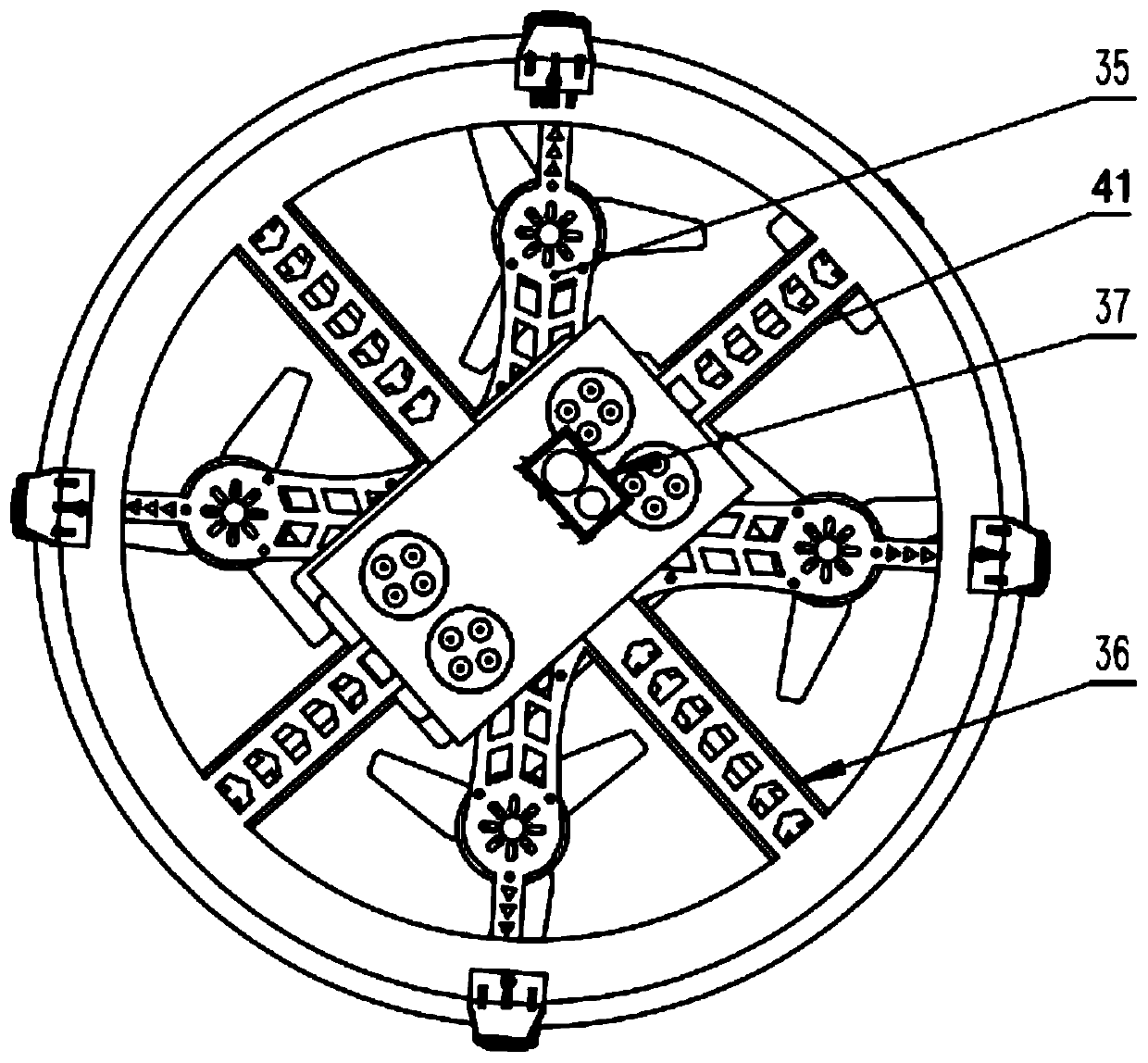

Explosion-proof type quadrotor unmanned aerial vehicle for underground coal mine

ActiveCN110182365ASmall sizeIncrease loading capacityAircraft componentsRotocraftBrushless motorsEngineering

The invention provides an explosion-proof type quadrotor unmanned aerial vehicle for an underground coal mine, and belongs to the field of underground coal mine inspection and rescue. A flight controlmodule, a data transmission image transmission module, a battery module, a power system and a sensor system of the quadrotor unmanned aerial vehicle are all installed in a rack, a camera module is arranged on the rack; the battery module provides power energy for the whole unmanned aerial vehicle, and the battery module is positioned at the bottom of a second middle layer; a data transmission image transmission sealing box of the data transmission image transmission module is fixed on the top of the rack, and the rack on one side of the installation data transmission sealing box is the position of a machine head; a brushless motor of the power system module is positioned in the rack and is fixed on a first middle layer; the output of the sensor system and the flight control module are intwo-way communication with a ground end of the unmanned aerial vehicle through a unmanned aerial vehicle end of the data transmission image transmission module; and image signals of the camera moduleare transmitted to video equipment at the ground end of the data transmission image transmission module. The explosion-proof type quadrotor unmanned aerial vehicle for the underground coal mine has the advantages that the structure is stable and firm, the size is small, the reaction is sensitive, an inspection survey task can be completed under the condition of no GPS in the underground coal mine,the intelligent operation is realized, the endurance time is long, and a main body is of a modular structure.

Owner:CHINA COAL RES INST +1

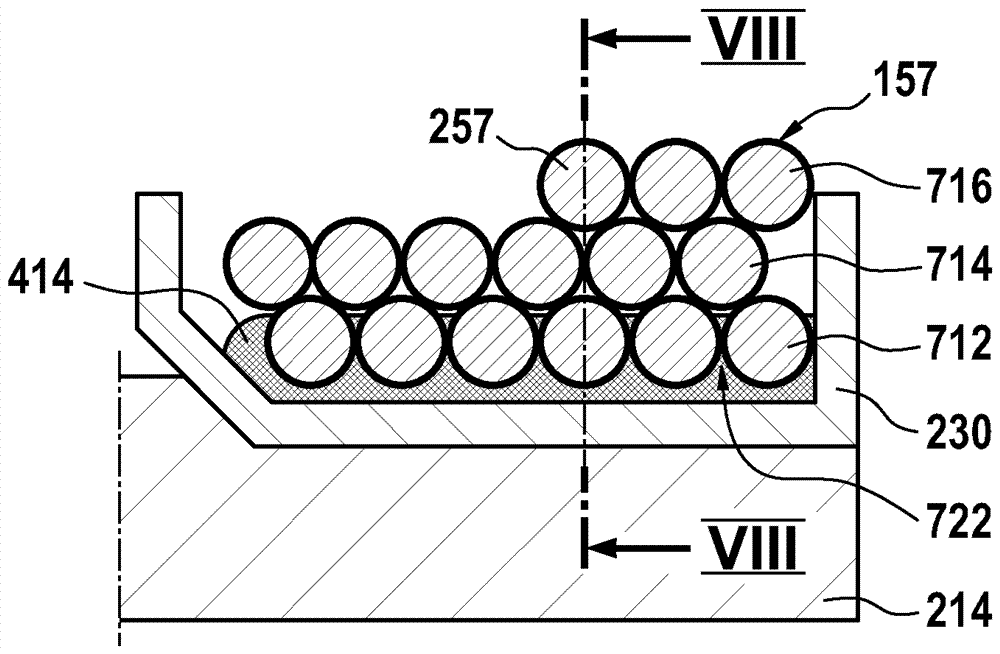

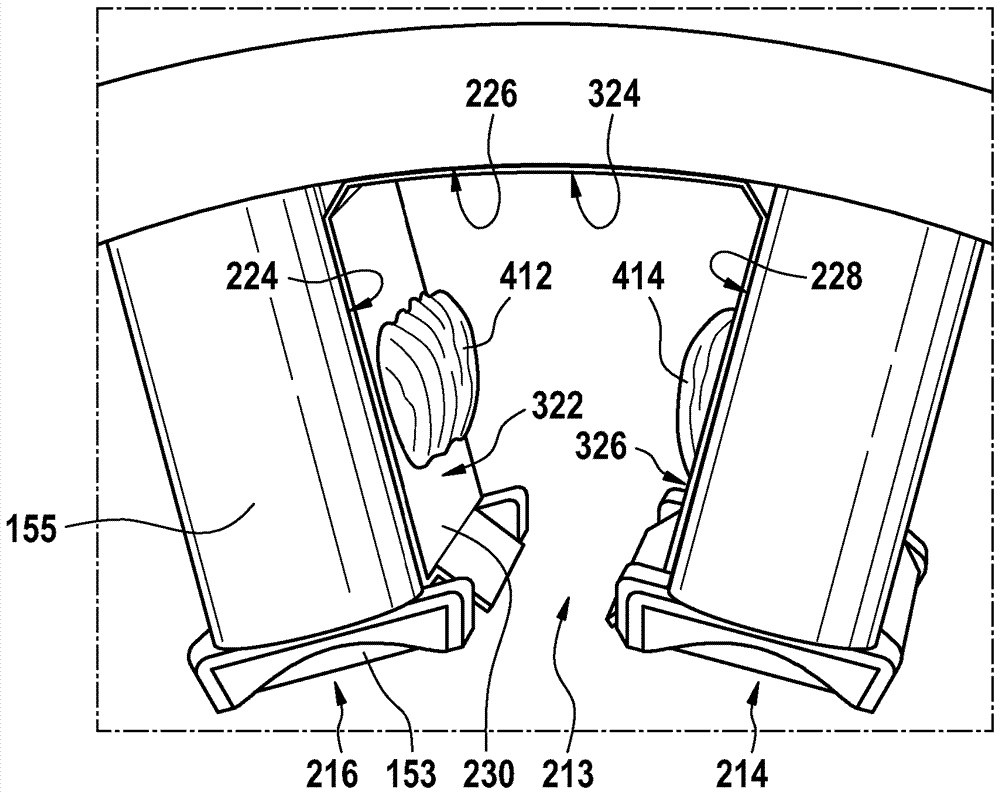

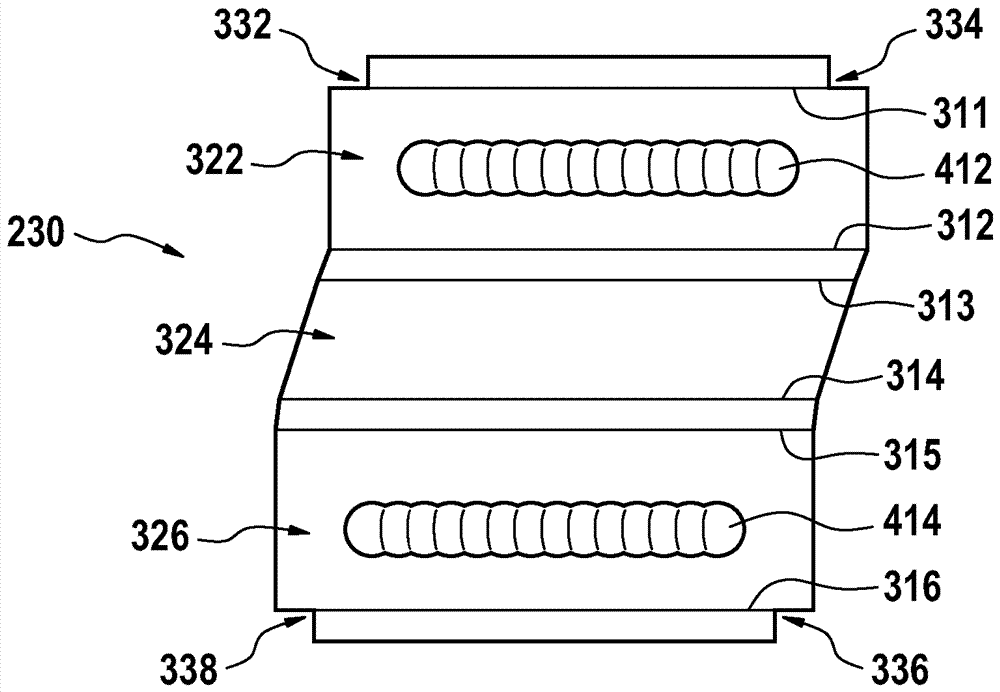

Stator for an electric motor

ActiveCN107112840AReduce the temperatureExtended service lifeWindings insulation shape/form/constructionCooling/ventillation arrangementElectricityHeat conducting

In a stator (150) for an electric motor comprising a stator core (153) which has at least one stator tooth (214) which is provided with a first winding section (257) of an associated stator winding (157), wherein insulating paper (230) is arranged at least in sections in the region between the first winding section (257) and the first stator tooth (214) to electrically insulate the stator core (153) from the stator winding (157), a thermally conducting intermediate layer is arranged at least in sections in the region between the insulating paper (230) and a winding layer of the first winding segment (257) facing the insulating paper (230) for a planar heat-conducting connection of the first winding section (257) to the first stator tooth (214).

Owner:ROBERT BOSCH GMBH

Negative-pressure hollow glass, manufacturing method and application

PendingCN112431519AEliminate respirationExtended service lifeConstruction materialWallsMolecular sievePumping vacuum

The invention belongs to the technical field of hollow glass production, and discloses negative-pressure hollow glass, a manufacturing method and application. The negative-pressure hollow glass comprises glass, spacing bars, molecular sieves, supporting materials, sealing layers bonded between the glass and the spacing bars, and sealing layers bonded between the glass and the peripheries of the spacing bars. A hollow layer is vacuumized to be in a negative pressure state, the air pressure of the hollow layer is smaller than the external pressure all the time in the use process of the hollow glass, the breathing phenomenon of the hollow glass is eliminated, an edge sealing structure is not subjected to repeated acting force generated by the breathing phenomenon, and the service life of theedge sealing structure and the service life of the hollow glass can be remarkably prolonged; due to the fact that the supporting materials are arranged in the hollow layer, the glass cannot deform, agood mirror surface effect can be kept all the time, and the appearance of a building is more attractive; and the spacing bars are adopted to replace spacing frames to be directly bonded on the glass,the technological process of manufacturing the spacing frames is omitted, mechanical and automatic production is facilitated, the placement speed is high, and the installation precision is high.

Owner:WEIHAI RUNFENG GLASS

Disposable syringe and its usage

InactiveCN101066485AChange appearanceAvoid self-destructInfusion syringesInfusion needlesEngineeringSyringe needle

The disposable syringe consists of one syringe needle, one needle cylinder with one nipple connected to the front end, one piston and one push rod connected to the piston. It features the syringe needle, which has a central hole, a middle part fixed inside the nipple, an front end exposed beyond the needle cylinder, a rear part inside the needle cylinder and with a barb and a third hole.

Owner:胡菊莲

Quick-assembled hollow glass, manufacturing method and application

PendingCN112431520AImprove insulation performanceImprove protectionConstruction materialWallsMolecular sieveAdhesive

The invention belongs to the technical field of production of hollow glass, and discloses quick-assembled hollow glass, a manufacturing method and application. Two pieces of glass are provided; the two pieces of glass are equal in length and width; spacing bars are directly bonded to the periphery of the bonding surface of the first piece of glass in a segmented manner to form a closed frame; thesecond piece of glass is bonded to the other surfaces of the spacing bars, and the peripheries of the two pieces of glass are aligned; the glass and the spacing bars are bonded together through sealant or structural adhesive or double-sided adhesive tape; a closed hollow layer is formed between the two pieces of glass and the spacing bars; the spacing bars are cavity bars; molecular sieves are poured into cavities in the spacing bars; the outer side edges of the two pieces of glass and the spacing bars are integrally sealed through one or more of sealant, structural adhesive, sealing tape andsealing adhesive tape; and the edge-sealed hollow glass can be directly transported and used without maintenance and solidification. The quality of the hollow glass is improved, the production periodis shortened, and the production efficiency is improved.

Owner:温州前瞻玻璃科技有限公司

Improved tempered glass

InactiveCN107618236AStrong disinfectantImprove the bactericidal effectSynthetic resin layered productsGlass/slag layered productsPolyesterToughened glass

The invention discloses an improved tempered glass which comprises a first tempered glass layer and a second tempered glass layer, wherein a polyester buffering layer is arranged between the first tempered glass layer and the second tempered glass layer; an anti-explosion layer is arranged on the side surface of the second tempered glass layer, away from the first tempered glass layer; a thermochromic coating is arranged on the side surface of the anti-explosion layer; a nano-silver layer is arranged on the side surface of the first tempered glass layer, away from the second tempered glass layer; an anti-blue light coating is arranged on the side surface of the nano-silver layer. The improved tempered glass is beneficial to popularization and application.

Owner:四川鑫利民钢化玻璃有限公司

Safety self-destruction type hemostix

InactiveCN101167651AReasonable structureNovel design conceptDiagnostic recording/measuringSensorsNeck positionFully automatic

The invention discloses a safety self-destroying hemostix, and is characterized in that a cylinder neck positioned on the end portion of a casing is sheathed with a casing sealing-plug, a needle seat is sheathed outside the casing sealing-plug, a safety casing pipe is sheathed on the outer portion of the casing, and the end portion of the needle seat is sheathed with a needle tube sheath in which an anticoagulant storage tube is arranged. The invention has the advantages of reasonable structure, novel design conception, easy and flexible manipulation, and convenient and fully automatic assembly. The production is an overall plastic element, thus the cost is low, the production also has a safety device which can effectively prevent the accidental injure of medical staff in manipulation and avoid accidental infection, the production realizes self-destroying step by step in using process, the dismounting components can not be assembled again, thereby the actual complete self-destroying is realized. By applying the invention, a used hemostix cannot be used again, and the shortages and defects existing in the prior productions are overcome.

Owner:KUN SHAN MEDSAFE MEDICAL TECH

Hollow glass with edge sealed by PUR glue and manufacturing method thereof

PendingCN112983204AExtended service lifeImprove initial tackClimate change adaptationWindows/door improvementMolecular sieveMoisture absorption

The invention belongs to the technical field of production of hollow glass, and discloses hollow glass with the edge sealed by PUR glue and a manufacturing method thereof. The hollow glass with the edge sealed by the PUR glue comprises glass, spacing bars, a bonding seal between the glass and the spacing bars and a bonding seal on the periphery of the glass, wherein the bonding seal between the glass and the spacing bars and the bonding seal on the periphery of the glass adopt PUR glue, and the bonding force and the sealing performance are improved by utilizing the chemical reaction between the PUR glue and water adsorbed on the surfaces of the glass and the spacing bars, so that the service life of the hollow glass is prolonged; small-specification hollow glass with a large glue proportion is used, moisture in the hollow cavity is absorbed by utilizing a moisture absorption effect generated by a wet reaction curing mechanism of the PUR glue, and no molecular sieve is arranged in the spacing bars; and large-specification hollow glass with a small glue proportion is used, molecular sieves are arranged in spacing bars, and preferably, the molecular sieves with a slow absorption function are adopted. The method is simple in technological process, high in mechanization and automation degree, short in production period, high in production efficiency and good in product quality.

Owner:温州前瞻玻璃科技有限公司

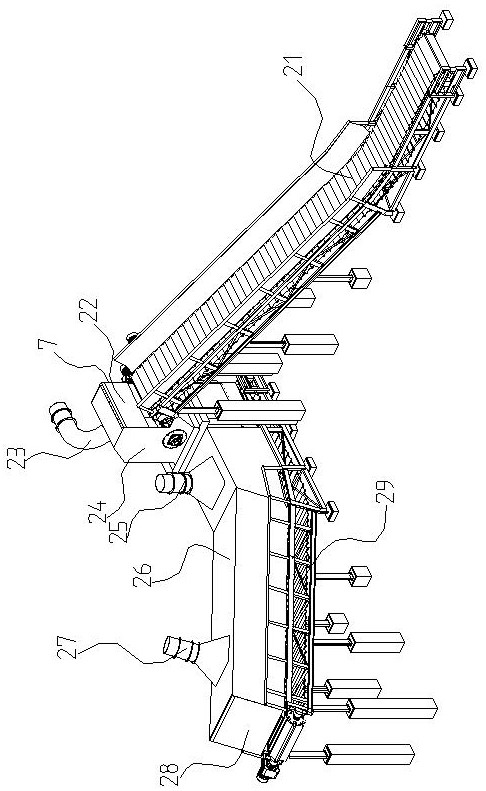

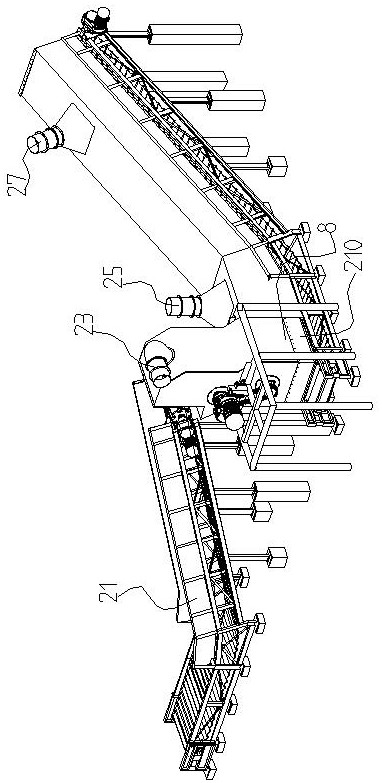

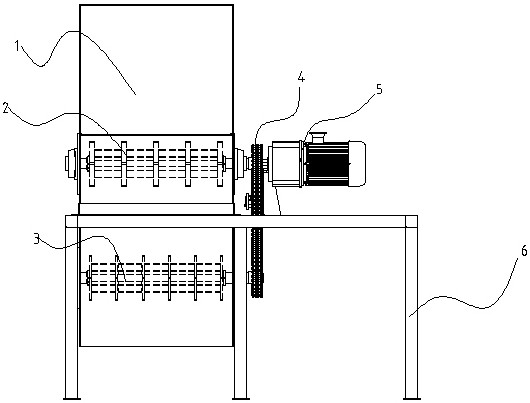

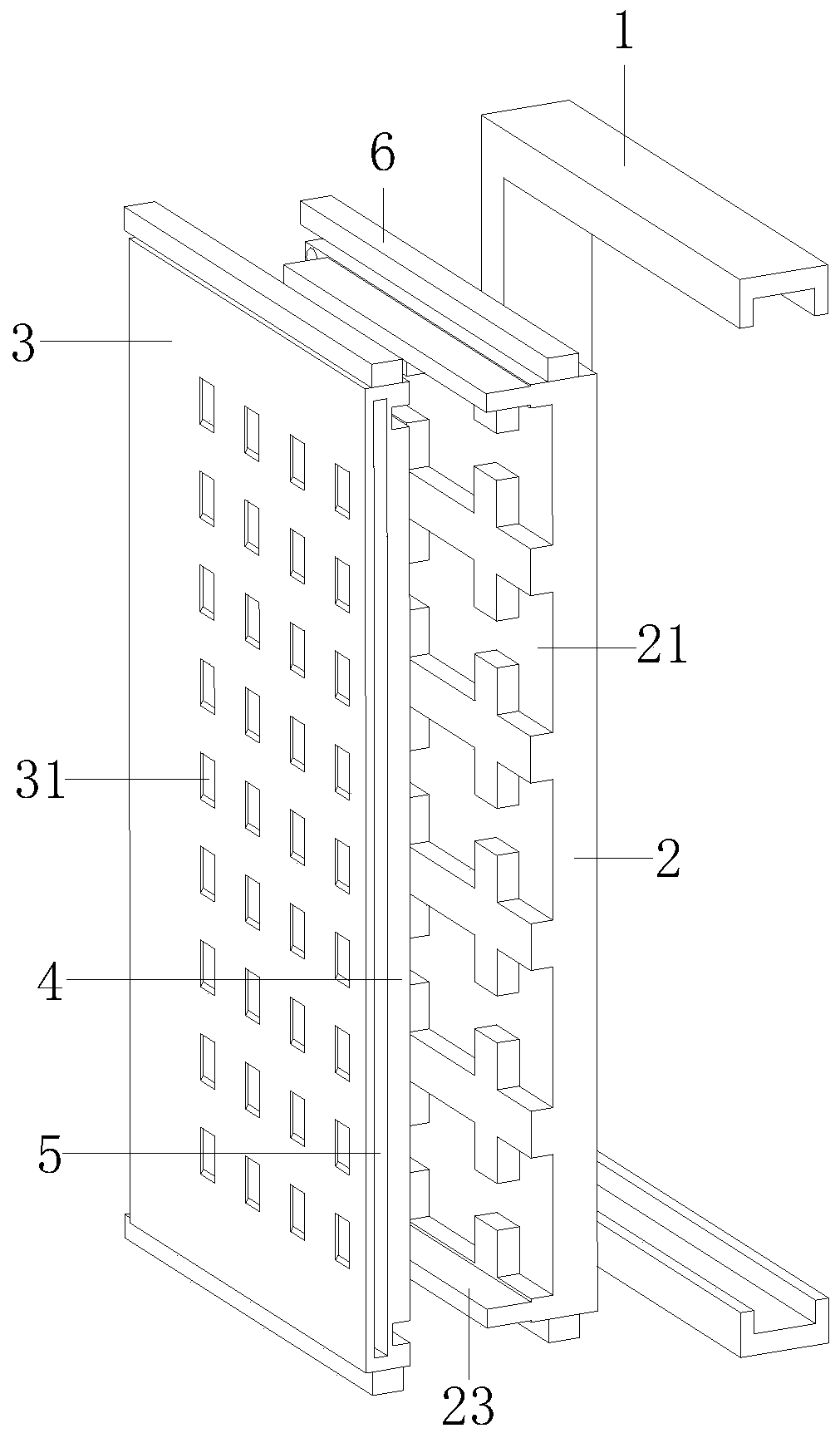

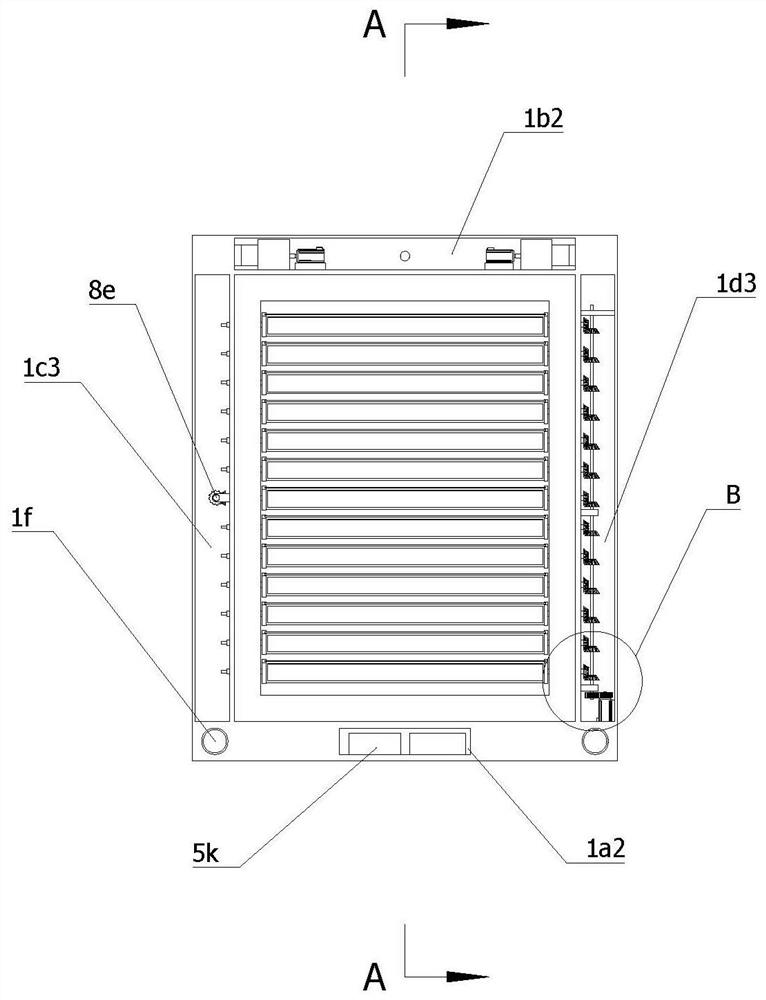

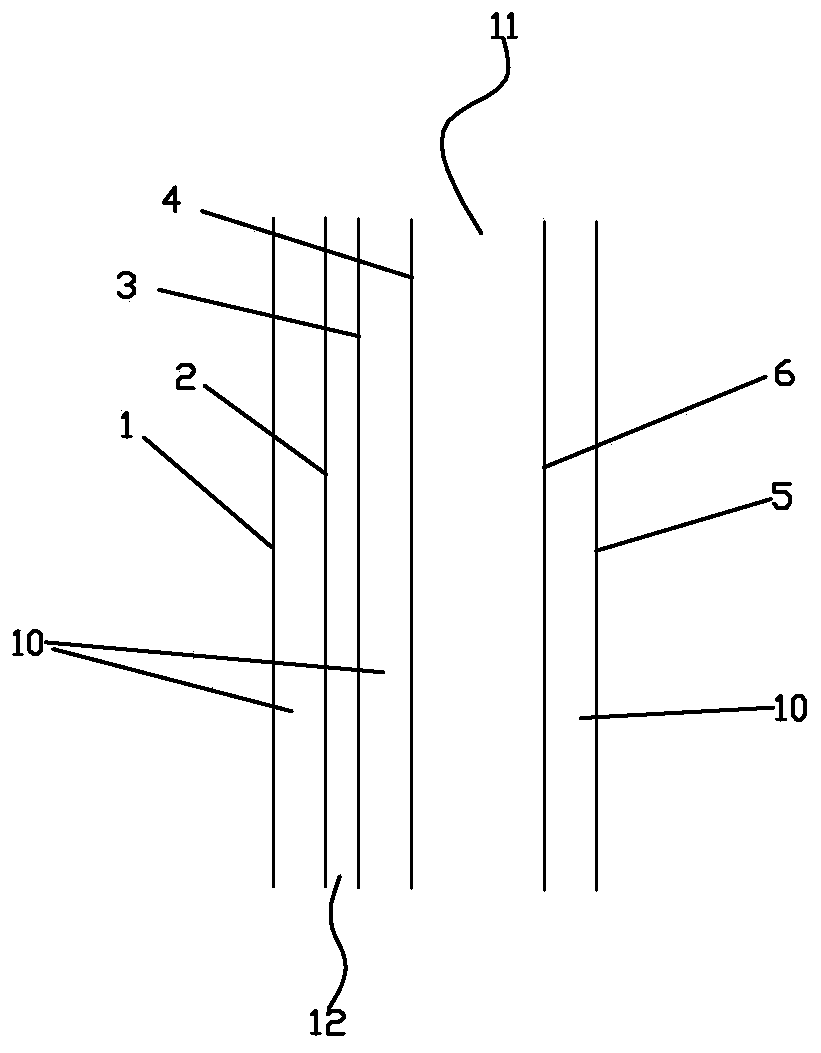

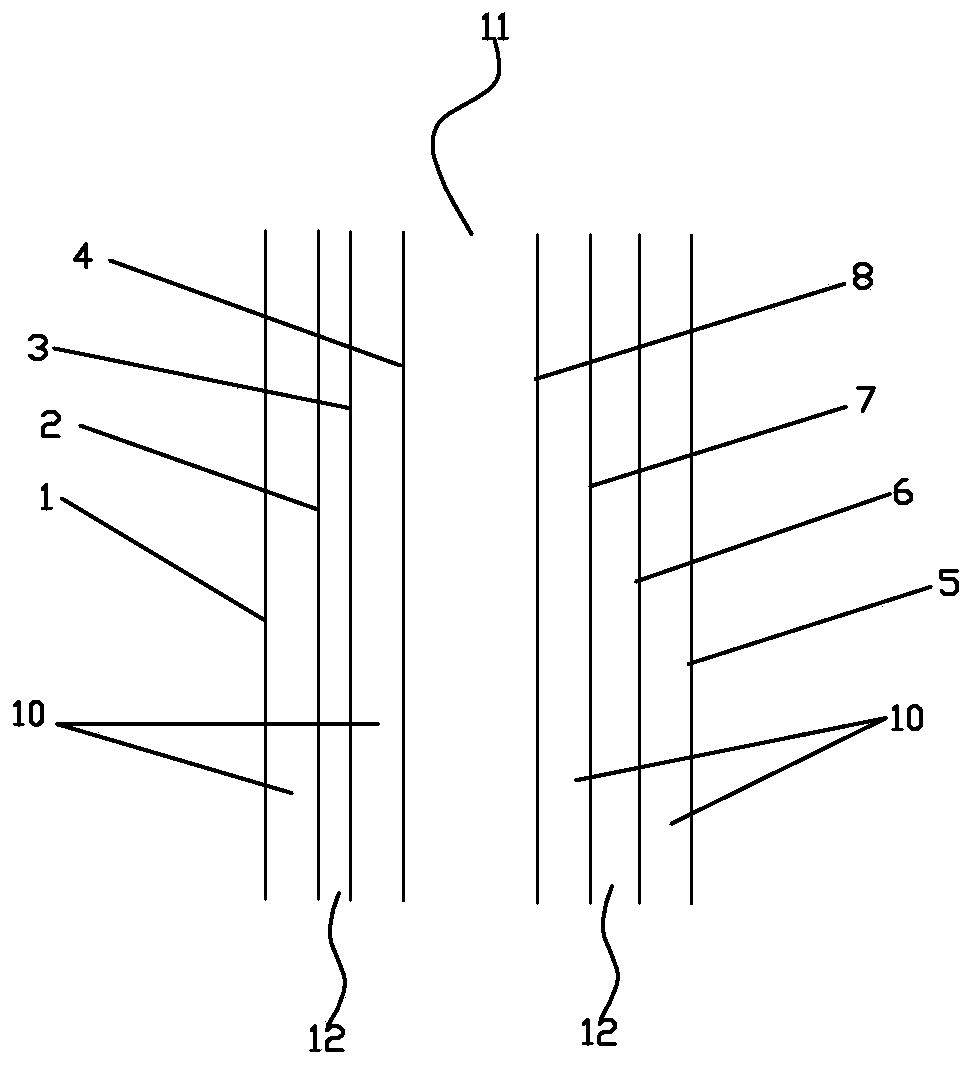

Waste paper bale breaking system based on vertical bale breaking machine

ActiveCN112278477ASpread out fastSimple structureUnpacking by cuttingDust controlProcess engineering

The invention discloses a waste paper bale breaking system based on a vertical bale breaking machine. The waste paper bale breaking system comprises the vertical bale breaking machine. The vertical bale breaking machine is mainly composed of a shell and paper breaking rollers arranged in the shell. The paper breaking rollers include the upper paper breaking rollers and the lower paper breaking rollers which are arranged in the shell in parallel up and down, the upper paper breaking rollers and the lower paper breaking rollers are connected through a transmission chain to rotate in the same direction, and the upper paper breaking rollers and the lower paper breaking rollers are each provided with a bale breaking fly-cutter structure. A feeding port is formed in the upper portion of the shell and connected with a feeding conveyor, the feeding end of the feeding conveyor is connected with an iron wire removing conveyor, waste paper on the iron wire removing conveyor is longitudinally stacked and baled, and a waste paper bale breaker is arranged between the feeding conveyor and the iron wire removing conveyor. A discharging port is formed in the bottom of the shell and is connected with a discharging conveyor. By optimizing the bale breaking machine and the aspects of feeding, dust removal and the like, the bale breaking efficiency is greatly improved, the service life of equipmentis prolonged, and the field operation environment is improved.

Owner:ZHENGZHOU LEIZHAN TECH PAPER MACHINERY

Floor building glass

InactiveCN112049548APrevent burstTo achieve the effect of heat preservation and noise reductionConstructions elementsGlass/slag layered productsArchitectural glassInsulation layer

The invention relates to the technical field of glass, in particular to floor building glass. The floor building glass comprises a window frame body, wherein a mounting groove is formed in the right side of the interior of the window frame body, a warm edge spacing strip is welded to the interior of the mounting groove, a hot melt adhesive layer is bonded to the interior of the mounting groove, aglass inner plate and a glass outer plate are bonded to the interior of the hot melt adhesive layer, sound insulation cotton and a transparent silica gel panel are bonded to the interior of a cavity,and a sound insulation layer is arranged in the transparent silica gel panel. According to the floor building glass, the mounting groove is formed in the window frame body to achieve the effect of mounting the glass, the warm edge spacing strip is arranged to achieve the effects of heat preservation and noise reduction, the hot melt adhesive layer is arranged to achieve the effect of bonding and fixing the glass inner plate and the glass outer plate, when the glass is impacted by collision, the transparent silica gel panel can achieve the effect of shock absorption, the problem of glass burstis prevented to a certain extent, and the sound insulation cotton and the sound insulation layer can achieve the sound insulation effect.

Owner:恩平市鸿玻建材有限公司

Point-bonding sealed hollow glass and manufacturing method thereof

PendingCN112412275AReduce contact areaImprove insulation performanceConstruction materialClimate change adaptationMolecular sieveAdhesive

The invention discloses point-bonding sealed hollow glass. The hollow glass comprises a plurality of pieces of glass, a plurality of spacing bars, a first sealing adhesive, a molecular sieve, and at least one of a second sealing adhesive, a third sealing adhesive and a fourth sealing adhesive; the spacing bars are arranged between the adjacent pieces of glass; the spacing bars are arranged on theperiphery of the glass in a segmented mode to form a closed spacing frame; the molecular sieve is filled in the spacing frame; the first sealing adhesive is arranged between the glass and the spacingbars; the second sealing adhesive is arranged between the adjacent pieces of glass and is positioned on the outer side edges of the spacing bars; or the third sealing adhesive is arranged between theadjacent pieces of glass and located on the outer side edges of the spacing bars; or the third sealing adhesive is arranged between the adjacent pieces of glass and located on the outer side edge of the second sealing adhesive; or the fourth sealing adhesive is arranged at the edge parts of the side surface and the outer surface of the adjacent glass. The point-bonding sealed hollow glass is simple in technological process, high in mechanization and automation degree, short in production period, high in production efficiency and good in product quality, and the service life of the hollow glasscan be greatly prolonged.

Owner:WEIHAI RUNFENG GLASS

Solar photovoltaic glass curtain wall

InactiveCN110424592AReduce wind resistanceReduce impact forcePhotovoltaic supportsWallsTransmittanceEngineering

The invention discloses a solar photovoltaic glass curtain wall which comprises an aluminum alloy outer frame, back side glass and low iron glass. A nonopaque outer protecting plate capable of deforming finely is mounted on the side, deviated from the back side glass, of the low iron glass. According to the solar photovoltaic glass curtain wall, in a process that sunlight irradiating on the outerprotecting plate is absorbed by a solar battery piece by penetrating through the outer protecting plate and the low iron glass, it is ensured that solar energies at different irradiation angles can penetrate through the outer protecting plate and the low iron glass and then irradiate to the solar battery piece, so that the electric energy is generated to the maximum extent while the solar ray transmittance is guaranteed. Meanwhile, a buffer air chamber is formed in a mounting gap while the outer protecting plate is extruded passively to deform finely, so that conditions that migrant birds hitting against the outer protecting plate are dead as a result of an excessive impact force and the glass curtain wall formed by the outer protecting plate, the low iron glass and the back side glass andthe like is unstable as the outer protecting plate is hit are prevented.

Owner:ANHUI UNIV OF SCI & TECH

Glass film

The invention relates to a glass film which is prepared from the following raw materials in parts by weight: 6-9 parts of silane coupling agent, 3-5 parts of hollow glass microsphere, 4-6 parts of methyl fiber, 1-5 parts of film-forming assistant, 6-10 parts of dichlorotetra-fluoroethane, 4-9 parts of trinitrotoluene, 3-6 parts of antimony trioxide, 5-9 parts of methyl methacrylate, 1-5 parts of nicotinic acid, 4-9 parts of ferric orthophosphate, 2-6 parts of starch, 3-9 parts of dodecyl glucoside, 4-8 parts of glycerol, 5-9 parts of 1,4-cyclohexyl dimethanol and 3-5 parts of sodium peroxide. The glass film has favorable effects of heat insulation property and glass selfbursting prevention, and can enhance the appearance rating of the glass.

Owner:QINGDAO CHANGANDA PHARMA IND CO LTD

A safe self-destruction syringes with exchangeable needle

InactiveCN101007194AAvoid self-destructPrevent accidental scrappingInfusion syringesIntravenous devicesEngineeringSyringe needle

The invention disclosed a kind of safe self-destruction syringe which can change pinhead. The characteristic of the invention: there's a connecting tray in tube neck at the front end of the outer encasement; the connecting tray is made by outer wall connecting with the inner wall; they were cylinders and be connected as concentric circle; there is space between the outer and inner walls; the inner wall of the connecting tray connects the pinhead tray. The invention has simple and proper design, good utility, good stability, simple operation (manual operation), good effects of self-destruction, wide serviceable range; it can be easily universalized.

Owner:SHANGHAI DO FOR CARE INTELLIGENT TECH CO LTD

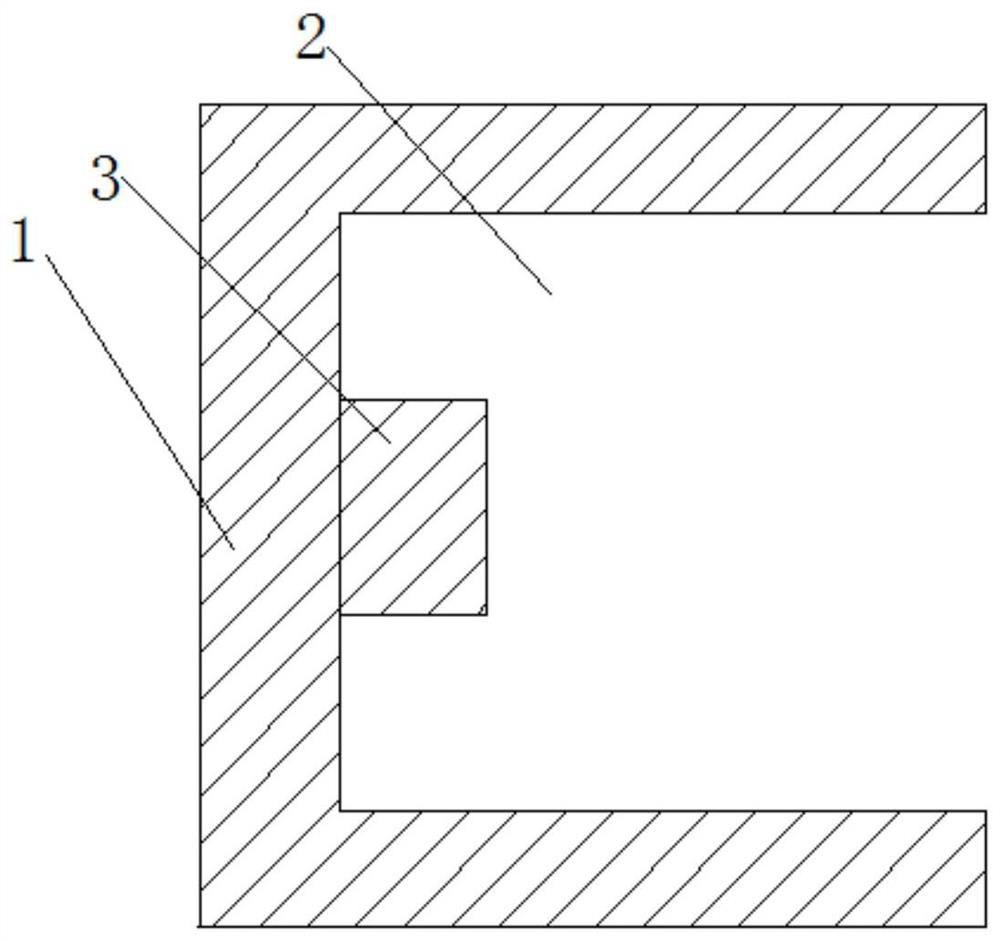

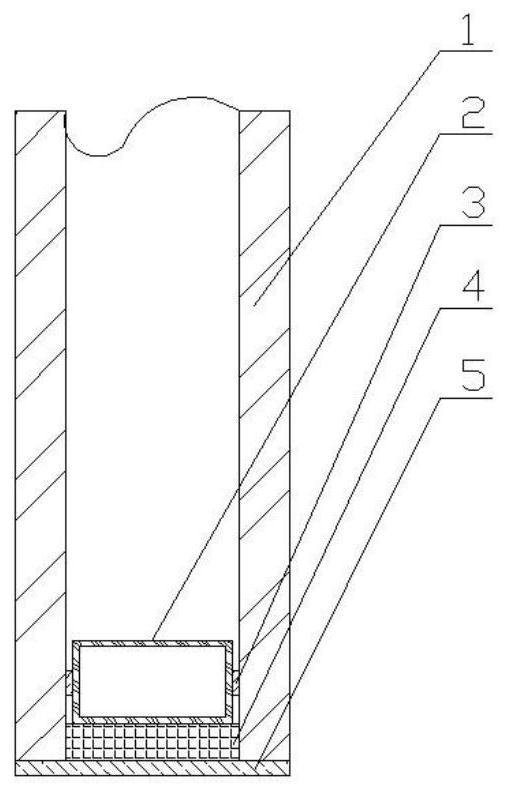

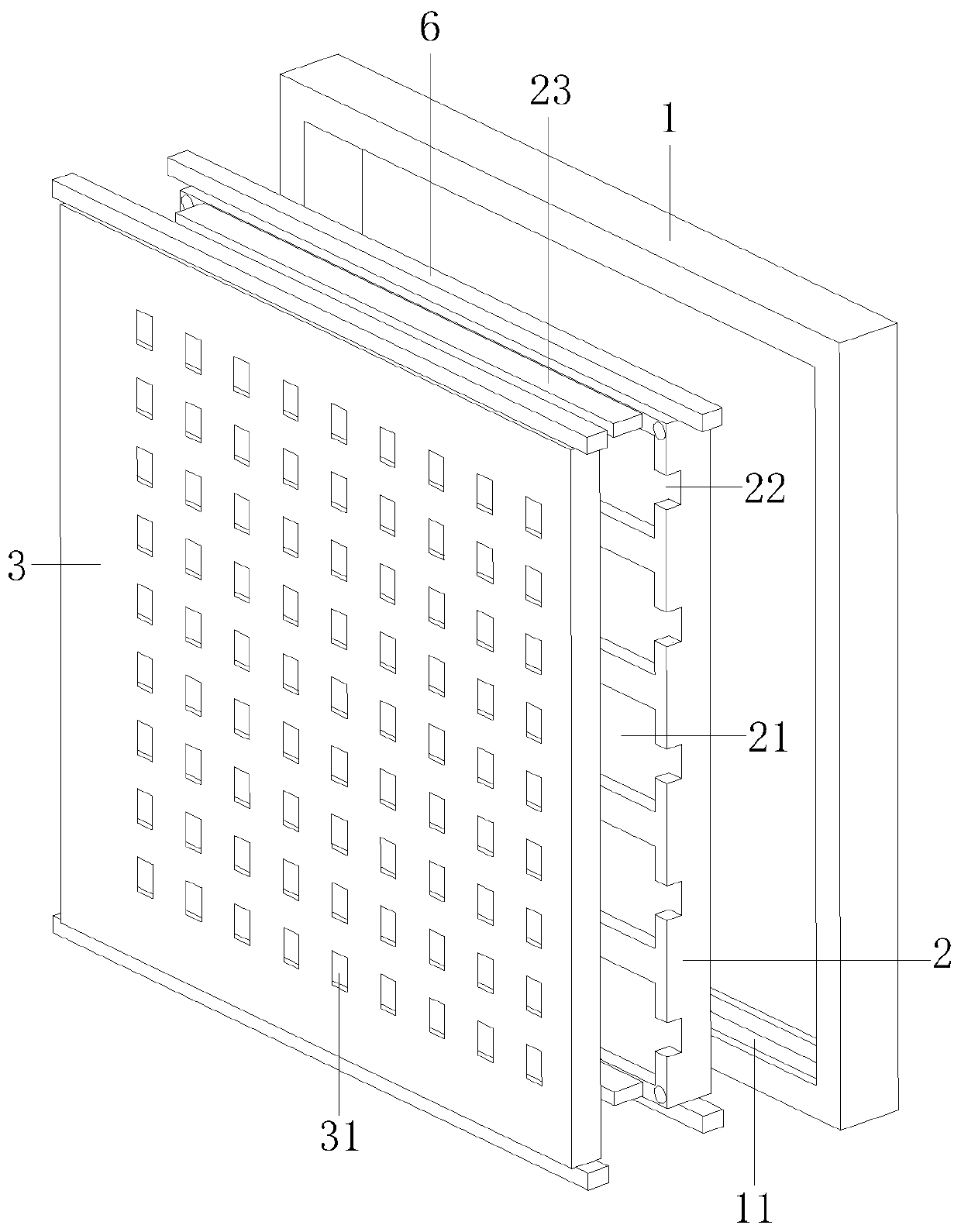

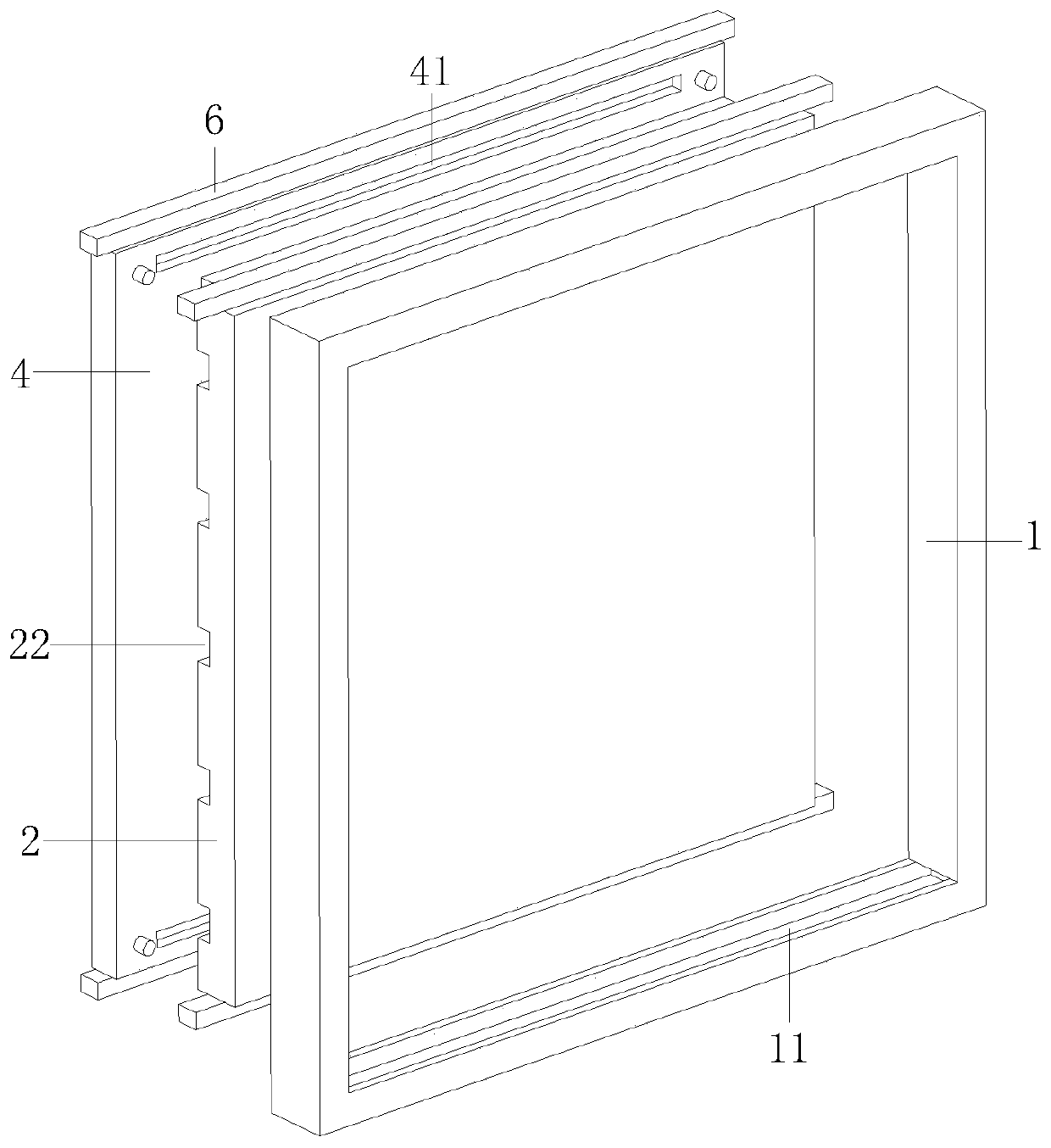

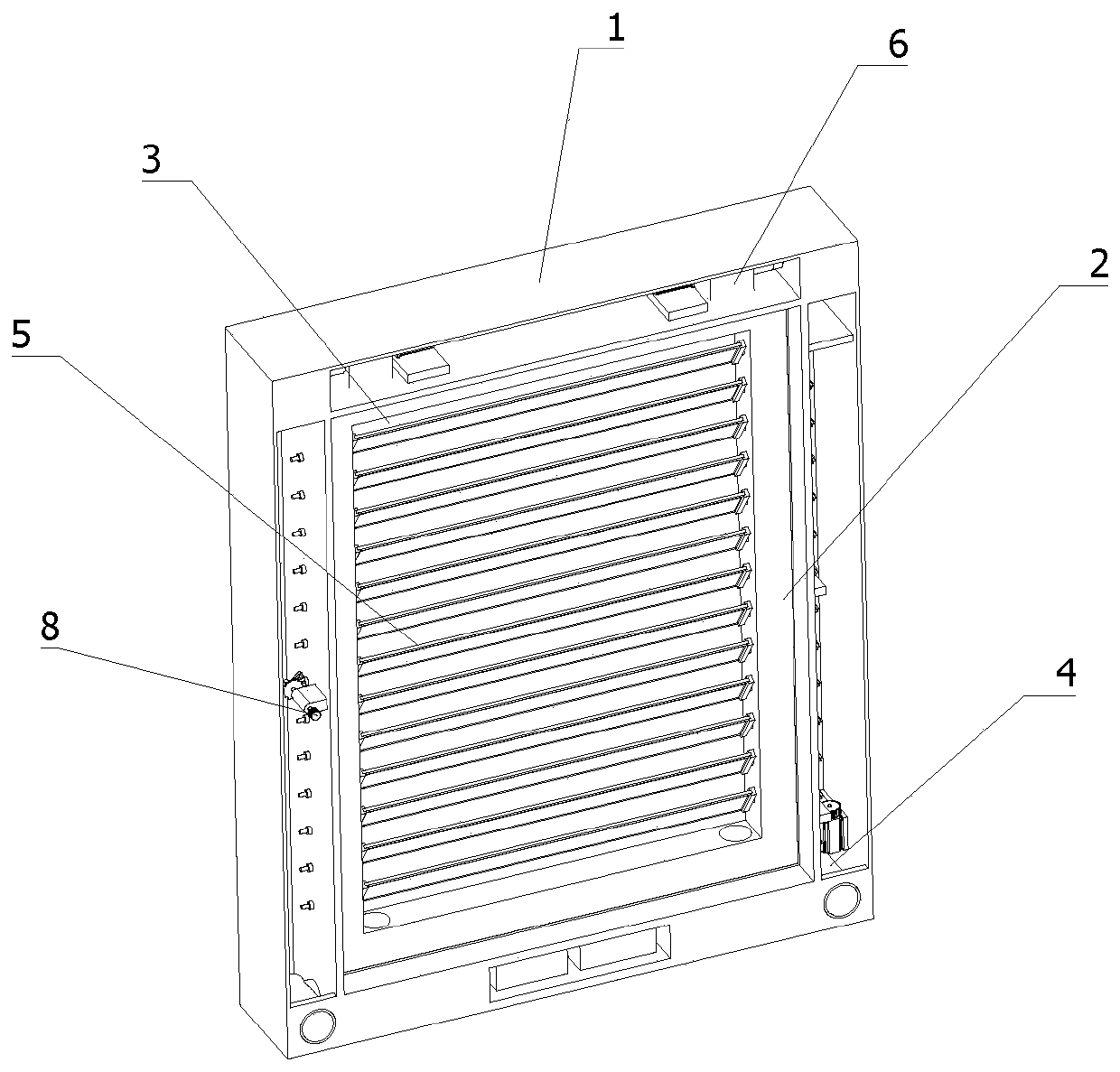

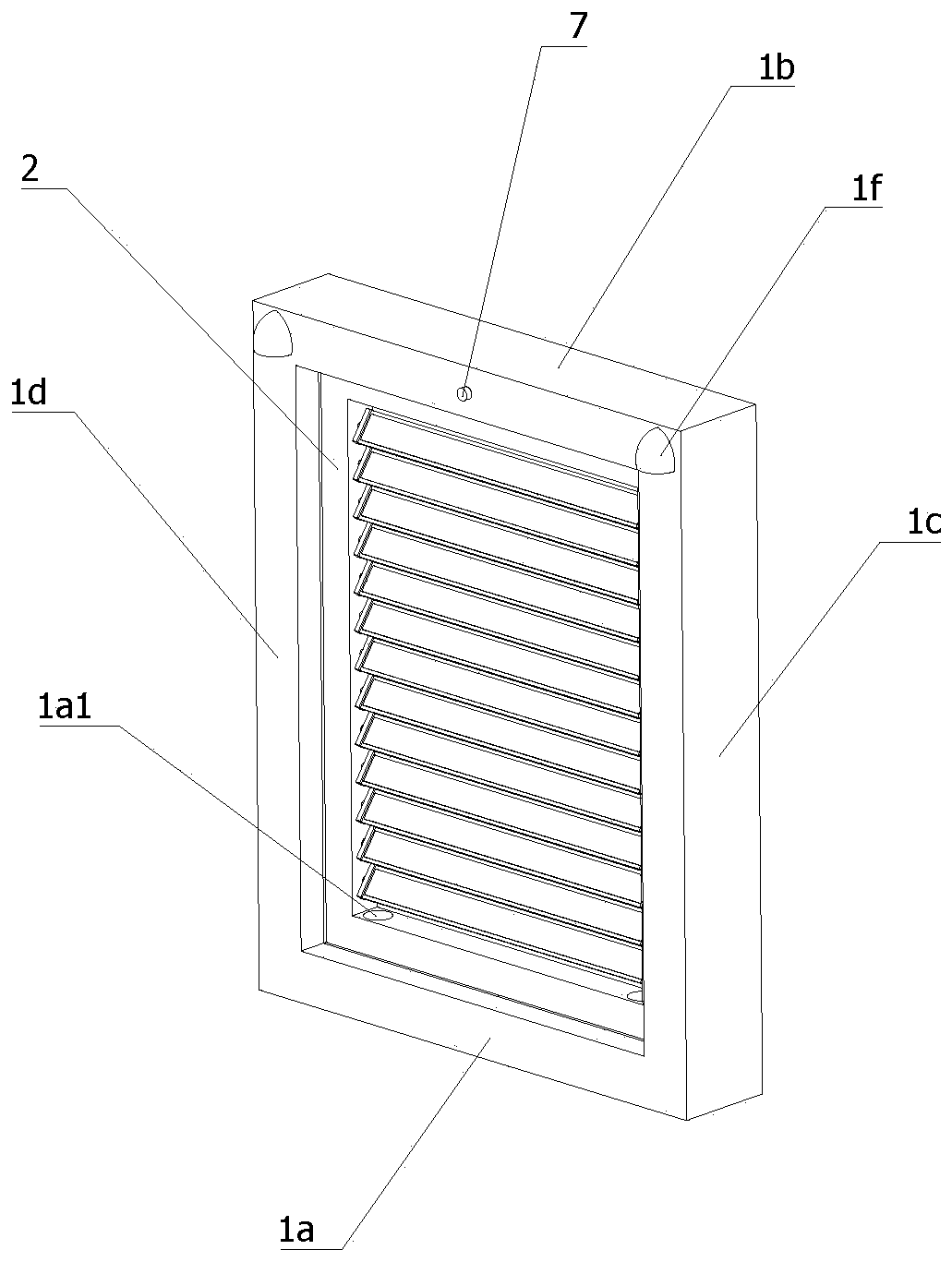

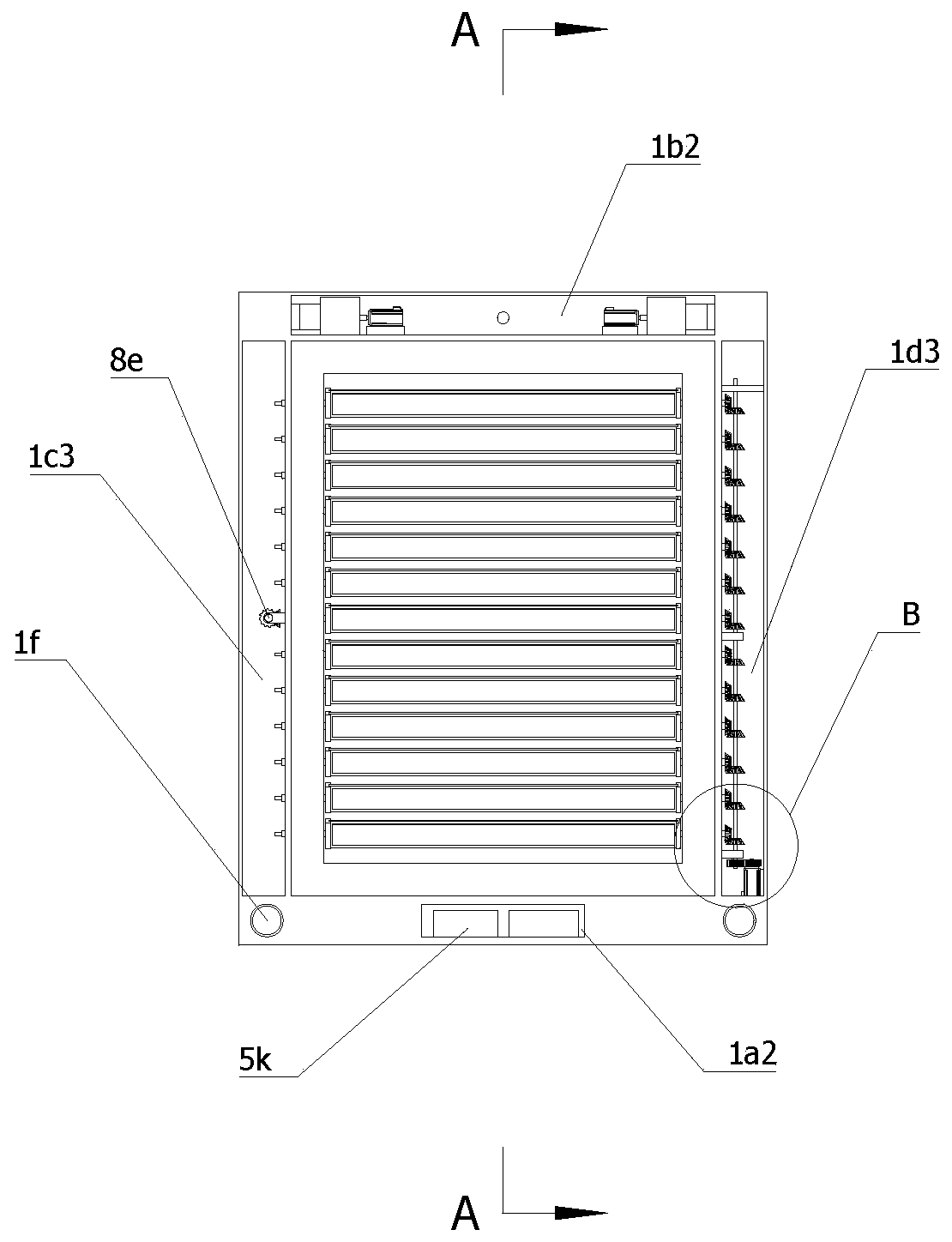

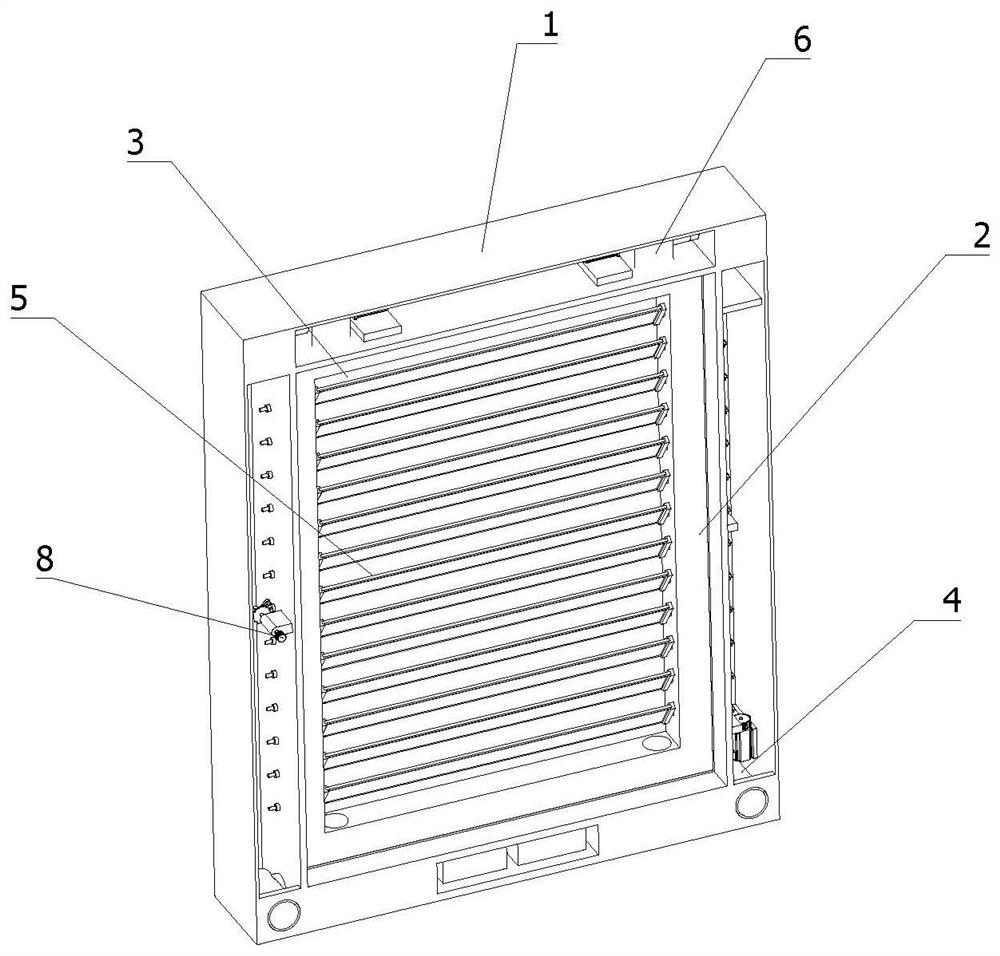

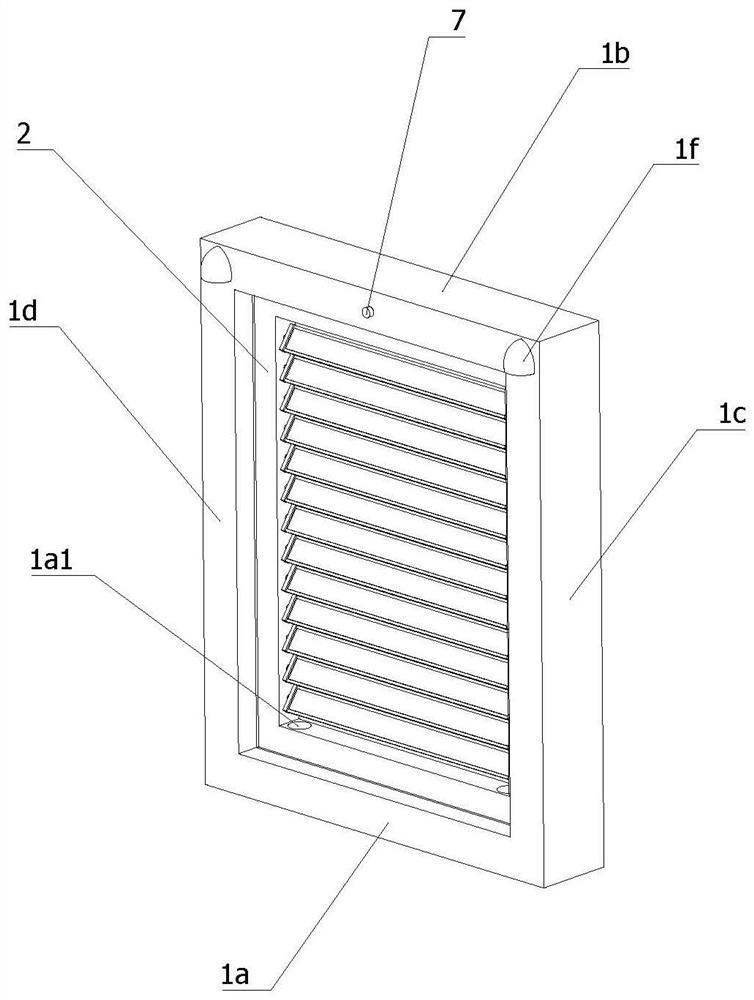

Curtain wall glass frame structure with building curtain wall ventilation function

ActiveCN110847450AAvoid self-destructAvoid crackingWallsLighting and heating apparatusMechanical engineeringClassical mechanics

The invention relates to the technical field of glass curtain wall structures, in particular to a curtain wall glass frame structure with a building curtain wall ventilation function. The curtain wallglass frame structure comprises a curtain wall frame, a curtain wall frame, a curtain wall frame, a communication pipe, a solar energy storage mechanism, a top communication mechanism, an illumination sensor and a control mechanism. A first glass plate and a second glass plate are arranged on the two sides of the curtain wall frame. The communication pipe is arranged in the bottom end of the curtain wall frame. A sealed space is formed between the first glass plate and the second glass plate, and the bottom end of the sealed space communicates with the inner side of the curtain wall through the communication pipe. The solar energy storage mechanism is arranged in the sealed space, the top communication mechanism is arranged in the top end of the curtain wall frame, the top end of the sealed space communicates with the outer side of the curtain wall through the top communication mechanism, the illumination sensor is arranged in the curtain wall frame, and the work end of the illumination sensor faces the outer wall of the curtain wall. The mechanisms are electrically connected with a control module. By means of the device, the phenomenon that the glass curtain wall can be explodedin the high-temperature state can be effectively prevented.

Owner:云南建设装饰集团有限公司

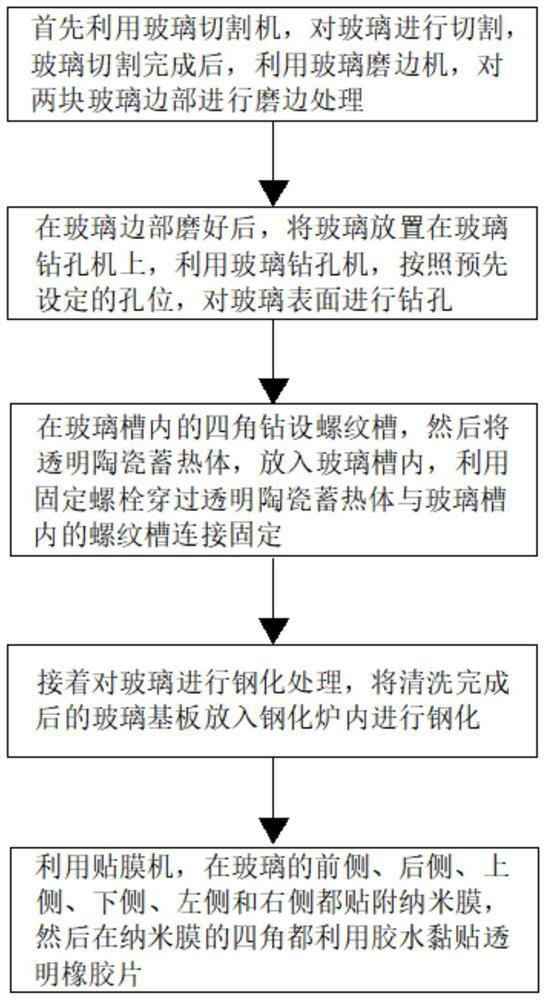

Preparation method of building curtain wall glass

The invention relates to the technical field of building curtain wall glass, and discloses a preparation method of a building curtain wall glass. The preparation method comprises the following steps of S1, cutting glass by using a glass cutting machine, and carrying out edge grinding treatment on the glass edge by using a glass edge grinding machine after the glass cutting is completed, using a specially-made grinding wheel for grinding the edge part of the glass, and meanwhile using circulating water for cooling so as to prevent damage caused by temperature rise of the edge part during edge grinding, and cleaning after the glass edge part being ground. According to the preparation method, threaded grooves are drilled in the four corners in a glass groove, then a transparent ceramic heat accumulator is placed in the glass groove, fixing bolts penetrate through the transparent ceramic heat accumulator to be fixedly connected with the threaded grooves in the glass groove, the ceramic heat accumulator can be combined with the curtain wall glass, and in the usually use process of the curtain wall glass, the ceramic heat accumulator absorbs heat and radiates heat at night to heat the glass, so that spontaneous explosion caused by overlarge temperature difference of the glass is avoided.

Owner:纵横环境建设有限责任公司

Production method of tempered glass with surface coating

InactiveCN109231803AAvoid self-destructHigh mechanical strengthCoatingsGlass tempering apparatusLithium oxideAlcohol

The invention discloses a production method of tempered glass with a surface coating. The production method comprises the steps as follows: (1) placing glass on a roller table, sending the glass intoa tempering furnace through the roller table, leaving the glass to stand at 600-610 DEG C for 10-15 min, then, uniformly and slowly decreasing the temperature in the furnace to 180-200 DEG C within 40min, and leaving the glass to stand in the furnace for 5-8 min; (2) after taking the glass out of the furnace, and coating the glass with a coating prepared from raw materials as follows: 4-8 parts of metasilicic acid, 5-10 parts of nano cobalt oxide, 3-7 parts of lithium oxide, 4-10 parts of nano molybdenum trioxide, 3-9 parts of disilicic acid, 70-85 parts of ethyl alcohol, 6-12 parts of sepiolite powder and 3-6 parts of calcium oxide. The tempered glass has the characteristics of high production yield, high strength and good self-cleaning effect.

Owner:创建节能玻璃(贵州)有限公司

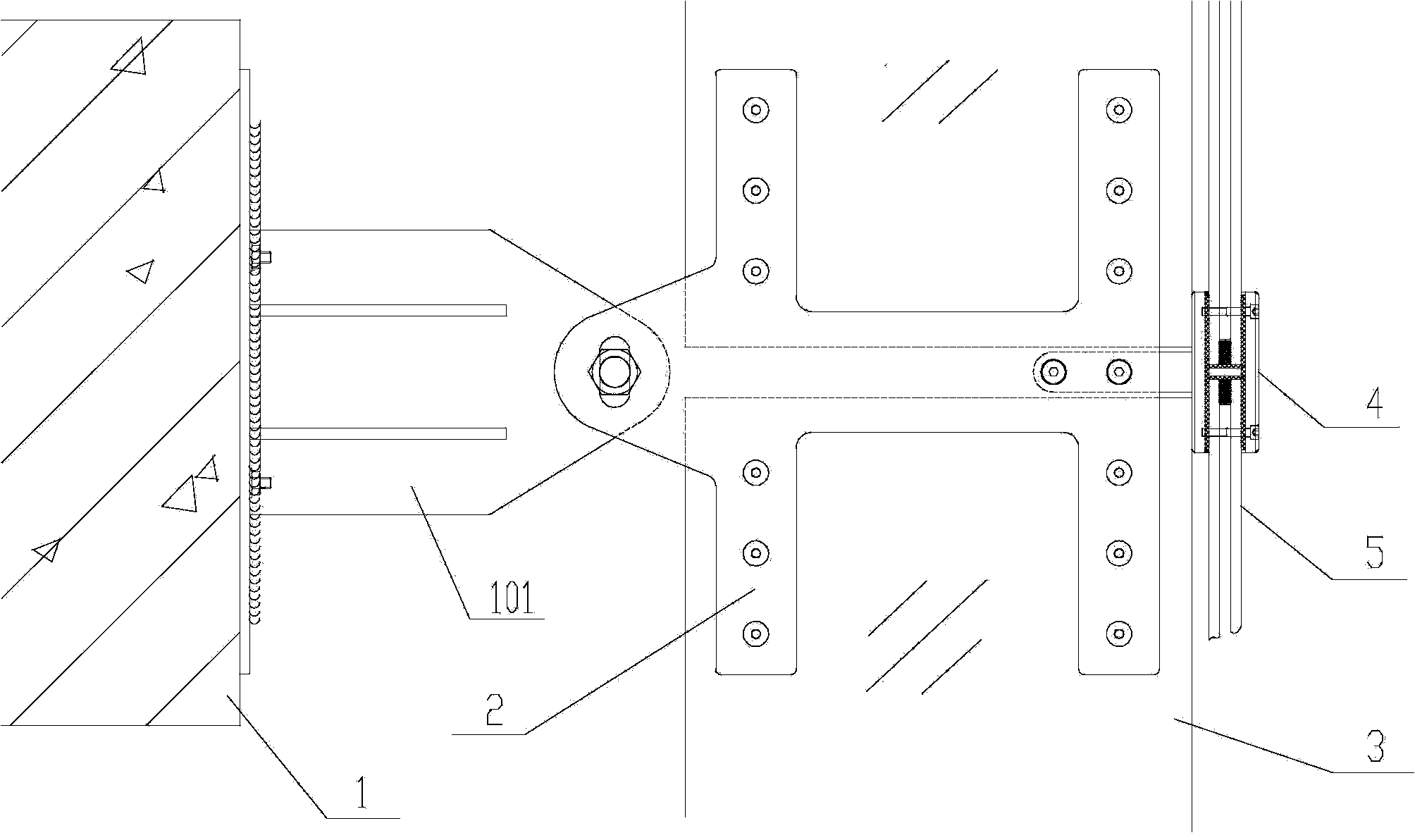

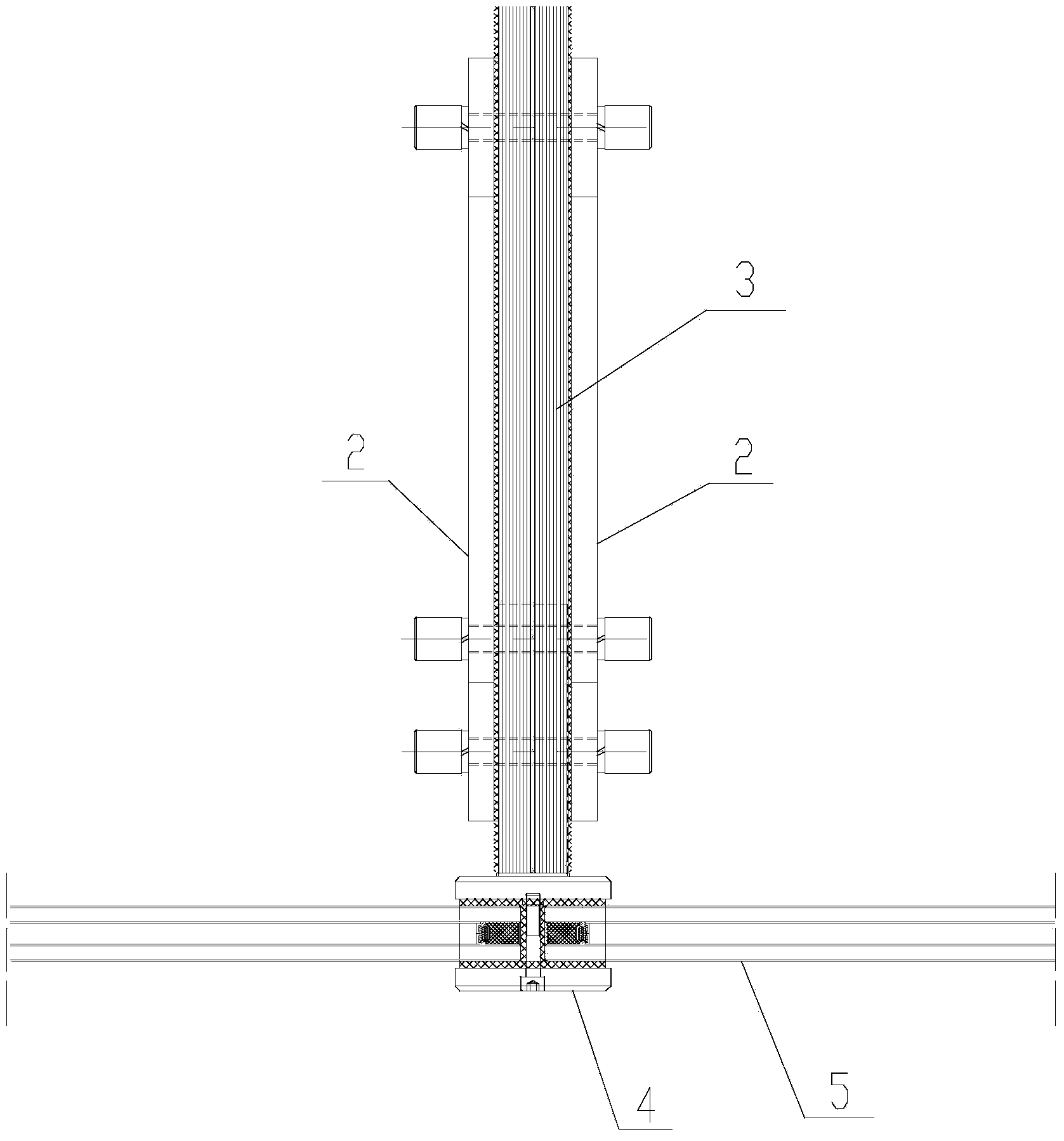

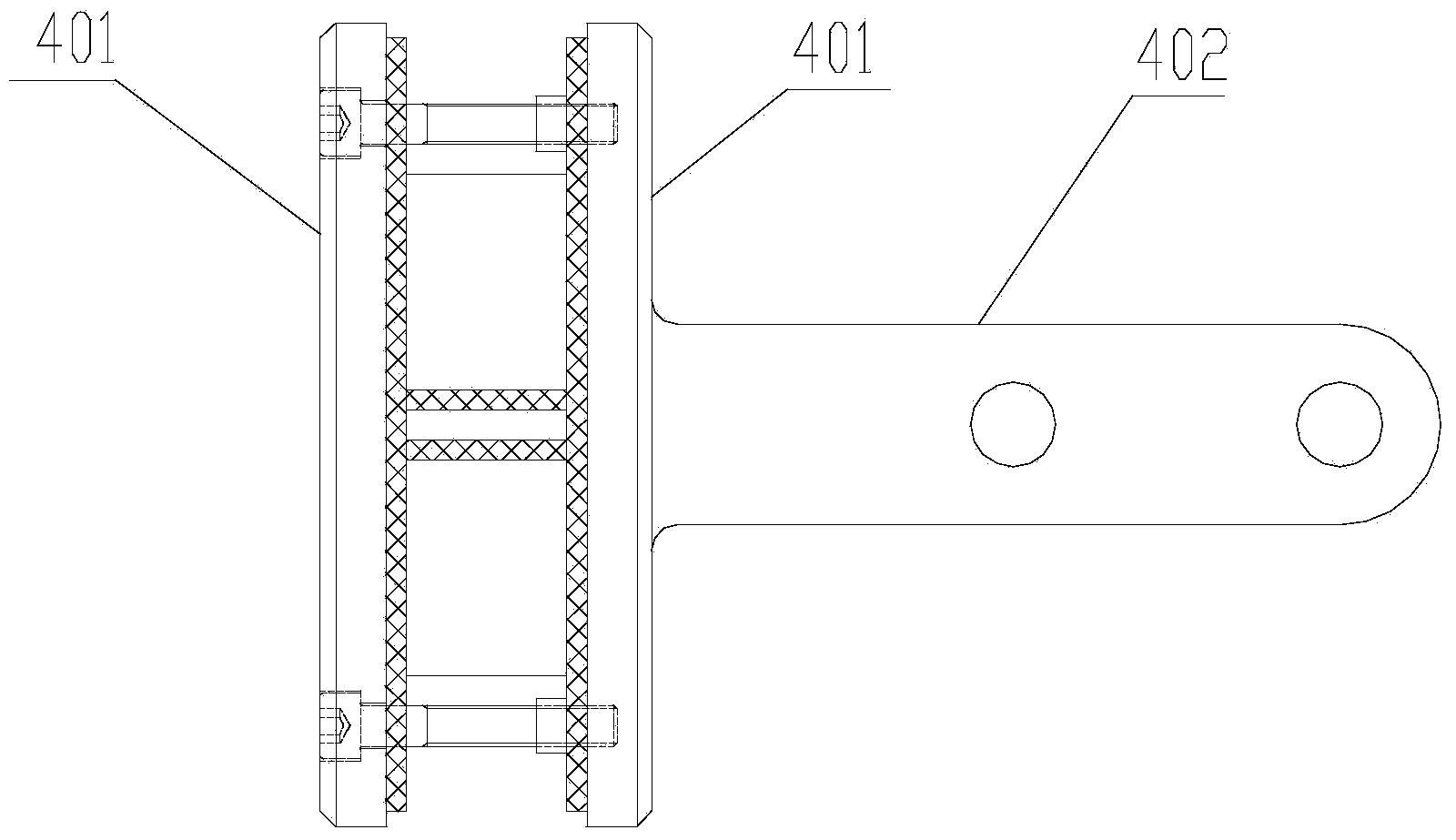

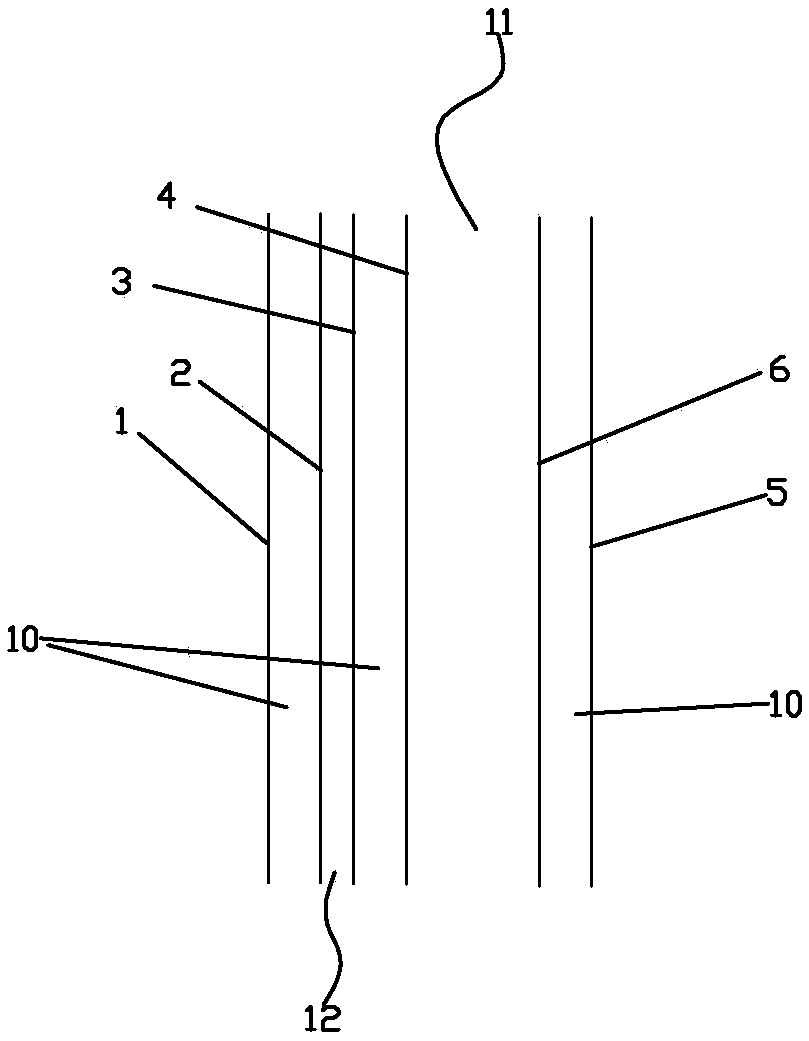

Point-connection glass curtain wall

The invention discloses a point-connection glass curtain wall and relates to the technical field of building engineering. The point-connection glass curtain wall comprises a building main body, two rib clamping plates, a glass rib, a clamp and a glass plate block, wherein two clamping blocks are arranged at one end of the clamp, and a fixing block is arranged at the other end of the clamp; the edge of the glass plate block is clamped by the clamping blocks and screwed down and fixed through bolts; the fixing block is perpendicular to the glass plate block, and the glass rib and a fixing block of the clamp are arranged side by side; the fixing block of the clamp and the glass rib are clamped and fixed together by the two rib clamping plates, and one end of each rib clamping plate is fixed with the building main body through an embedded part.

Owner:SUZHOU GOLD MANTIS CURTAIN WALL CO LTD

Silica sol enhanced hollow safety glass and preparation method thereof

ActiveCN108751733AHigh strengthWeight increaseSynthetic resin layered productsConstructions elementsLaminated glassSafety glass

The invention discloses silica sol enhanced hollow safety glass and a preparation method thereof. The silica sol enhanced hollow safety glass comprises three layers, wherein the first layer is sandwich glass; the second layer is of a hollow structure; the third layer is single-layer glass or sandwich glass; the contact surface of the first layer and the second layer is a first contact surface; thecontact surface of the second layer and the third layer is a second contact surface; at least one surface of the first contact surface and the second contact surface is provided with a silica sol coating; the thickness of the silica sol coating is 1 to 20 mum; the silica content of the silica sol coating is not lower than 95 percent. The silica sol enhanced hollow safety glass has high bending strength and anti-impact capability; the spontaneous explosion risk is eliminated; the cost is reduced.

Owner:XIAMEN UNIV

Glass production method

InactiveCN109721228AAvoid self-destructHigh mechanical strengthGlass tempering apparatusCobalt oxideSepiolite

The invention discloses a glass production method, which comprises: (1) placing a glass on a roller table, feeding into a tempering furnace through the roller table, standing for 10-15 min at a temperature of 600-610 DEG C, uniformly and slowly reducing the temperature in the furnace to 180-200 DEG C within 40 min, and standing the glass in the furnace for 5-8 min; and (2) taking the glass out ofthe furnace, and coating the glass with a layer of a coating material, wherein the coating material is prepared from the following raw materials: metasilicic acid, nanometer cobalt oxide, zirconia, dimethyl silicone oil, acrylic acid, ethanol, sepiolite powder and calcium oxide. The obtained glass of the present invention has characteristics of high production yield, high strength and good self-cleaning effect.

Owner:创建节能玻璃(贵州)有限公司

Fireproof hollow glass, manufacturing method and application

InactiveCN112431521ARealize automatic placementGuaranteed straightnessFireproof doorsNoise insulation doors/windowsSealantCeramic materials

The invention belongs to the technical field of fireproof glass, and discloses fireproof hollow glass, a manufacturing method and application. The fireproof hollow glass is provided with two pieces ofglass, bonding sealing between the glass and spacing bars, and bonding sealing at the periphery of the glass; the two pieces of glass are equal in length and width; at least one piece of glass is fireproof glass; the fireproof glass is preferentially installed on the indoor side; the spacing bars are directly adhered to the periphery of the adhering surface of the first piece of glass in sectionsto form a closed frame, or the spacing bars are adhered to the periphery of the adhering surface of the first piece of glass after being manufactured into a spacing frame; the second piece of glass is adhered to the other surfaces of the spacing bars; the peripheries of the two pieces of glass are aligned; and the glass and the spacing bars are adhered together through sealant or structural adhesive or double-sided adhesive tape or edge sealant. The fireproof hollow glass is simple in structure, good in fireproof performance and long in service life, and the fireproof hollow glass not only has a fireproof effect, but also has good heat insulation and sound insulation effects.

Owner:WEIHAI RUNFENG GLASS

Disc-shaped suspension type composite insulator and manufacturing method thereof

ActiveCN113270236AGuaranteed safe operationOne-time molding process is simpleSuspension/strain insulatorsComposite insulatorsAdhesive

The invention discloses a disc-shaped suspension type composite insulator and a manufacturing method thereof, the disc-shaped suspension type composite insulator comprises a steel foot, a cylindrical head, a core disc and an iron cap are sequentially arranged on the outer side of the upper portion of the steel foot, the lower portion of the core disc is connected with an umbrella skirt, and the disc-shaped suspension type composite insulator is characterized in that the cylindrical head and the core disc are of an integrated structure. The beneficial effects are that the problems that the iron cap and the steel leg need to be maintained in a water pool, the process is tedious and the yield is low when the iron cap and the steel leg are cemented into a whole through a cement adhesive in the prior art are solved, the one-time forming process is simple, the yield is high, the weight is light, and the safe operation of a power grid is better ensured.

Owner:青州市力王电力科技有限公司

Manufacturing method of anti-scraping toughened glass

The invention discloses a manufacturing method of anti-scraping toughened glass. The manufacturing method comprises the following steps: (1) conveying glass into a tempering furnace, keeping the temperature at 580-600 DEG C for 20-30 minutes, uniformly reducing the temperature in the furnace to 200-220 DEG C within 30 minutes, and keeping the temperature for 10-15 minutes after the temperature isreduced to 200-220 DEG C; (2) taking out the glass from the furnace, and then coating the glass with a layer of a coating, wherein the coating is prepared from the following raw materials: 5-10 partsof metasilicic acid, 15-25 parts of trimethylolpropane triacrylate (TMPTA), 1-4 parts of aluminum oxide, 18-30 parts of poly(ethyl acrylate), 5-12 parts of pyrosilicic acid, 85-90 parts of glycerol, 15-25 parts of pentaerythritol triacrylate (PETA), 2-5 parts of calcium oxide and 0.5-3 parts of carbon fibers; (3) putting the glass coated with the coating in the step (2) into potassium nitrate molten salt for reacting for 15-20min; (4) putting the glass in the step (2) into hot water with a temperature of 80-90 DEG C for immersion for 8-10min; and (5) taking out the glass obtained in the step (4), and carrying out natural cooling to obtain the toughened glass. The manufacturing method has the characteristic of enhancing anti-scraping performance of glass.

Owner:正安鑫旺钢化玻璃有限公司

Impact-shaped composite spherical energy-dissipating structure for vertical hole blasting

ActiveCN106949797BSleek appearanceLittle effect of hole wall roughnessBlastingDetonationNuclear power

The invention provides an impacting-shaping composite spherical energy dissipation structure for vertical hole blasting. The energy dissipation structure comprises a composite spherical energy dissipation base and a buffer layer located below the composite spherical energy dissipation base, wherein the composite spherical energy dissipation base is of a double-layer structure which is soft externally and hard internally or hard externally and soft internally from outside to inside. According to the energy dissipation structure, under the action of an initial impact load after explosive detonation in a blast hole, the composite spherical energy dissipation base generates secondary plasticity, finally an ellipsoidal or a concave-shaped rigid cushion block reflects most of the explosion energy which is propagated in the rock mass below the hole bottom, meanwhile, the composite spherical energy dissipation base and the buffer layer absorb partial explosion energy in the deformation process, and therefore the rock on the foundation surface can be broken, the rock on the hole bottom can be protected, and the existing horizontal pre-cracking or smooth blasting technology can be partially replaced. The energy dissipation structure is simple and convenient to install, can partially replace the existing horizontal pre-cracking or smooth blasting technology and is suitable for protecting layer rock mass blasting excavation in the fields of water conservancy and hydropower, nuclear power, traffic and the like.

Owner:WUHAN UNIV

A curtain wall glass frame structure with building curtain wall ventilation function

ActiveCN110847450BAvoid self-destructAvoid crackingLighting and heating apparatusWallsSolar energy storageClassical mechanics

The invention relates to the technical field of glass curtain wall structures, in particular to a curtain wall glass frame structure with a building curtain wall ventilation function. The curtain wallglass frame structure comprises a curtain wall frame, a curtain wall frame, a curtain wall frame, a communication pipe, a solar energy storage mechanism, a top communication mechanism, an illumination sensor and a control mechanism. A first glass plate and a second glass plate are arranged on the two sides of the curtain wall frame. The communication pipe is arranged in the bottom end of the curtain wall frame. A sealed space is formed between the first glass plate and the second glass plate, and the bottom end of the sealed space communicates with the inner side of the curtain wall through the communication pipe. The solar energy storage mechanism is arranged in the sealed space, the top communication mechanism is arranged in the top end of the curtain wall frame, the top end of the sealed space communicates with the outer side of the curtain wall through the top communication mechanism, the illumination sensor is arranged in the curtain wall frame, and the work end of the illumination sensor faces the outer wall of the curtain wall. The mechanisms are electrically connected with a control module. By means of the device, the phenomenon that the glass curtain wall can be explodedin the high-temperature state can be effectively prevented.

Owner:云南建设装饰集团有限公司

A kind of insulating safety glass reinforced by silica sol and preparation method thereof

ActiveCN108751733BHigh strengthWeight increaseSynthetic resin layered productsConstructions elementsSilicon oxideSilicon dioxide

The invention discloses silica sol enhanced hollow safety glass and a preparation method thereof. The silica sol enhanced hollow safety glass comprises three layers, wherein the first layer is sandwich glass; the second layer is of a hollow structure; the third layer is single-layer glass or sandwich glass; the contact surface of the first layer and the second layer is a first contact surface; thecontact surface of the second layer and the third layer is a second contact surface; at least one surface of the first contact surface and the second contact surface is provided with a silica sol coating; the thickness of the silica sol coating is 1 to 20 mum; the silica content of the silica sol coating is not lower than 95 percent. The silica sol enhanced hollow safety glass has high bending strength and anti-impact capability; the spontaneous explosion risk is eliminated; the cost is reduced.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com