Stator for an electric motor

A technology of electric motors and stators, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve problems such as power loss, stator overheating, self-destruction, etc., and achieve the effect of reducing the corresponding temperature, reducing temperature, and preventing self-destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

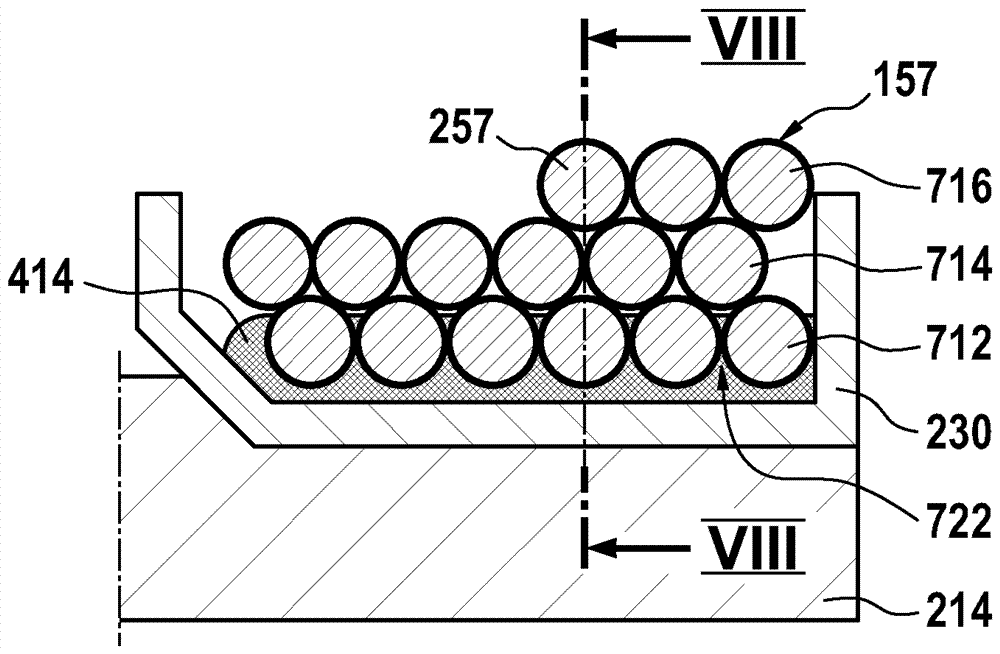

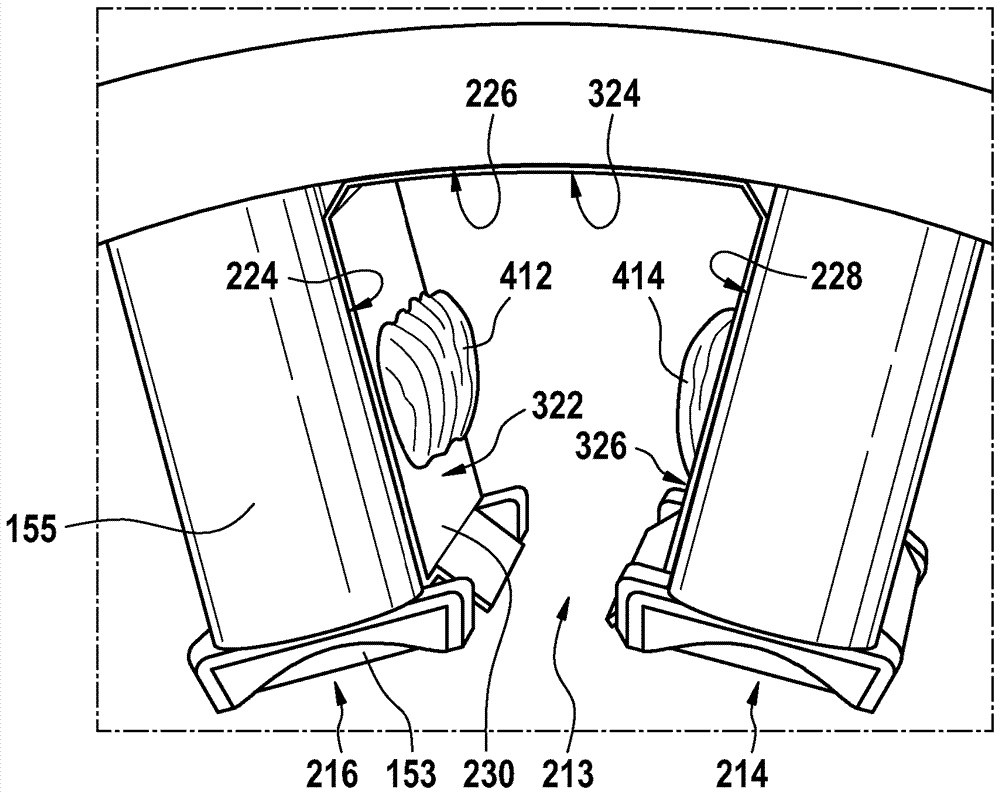

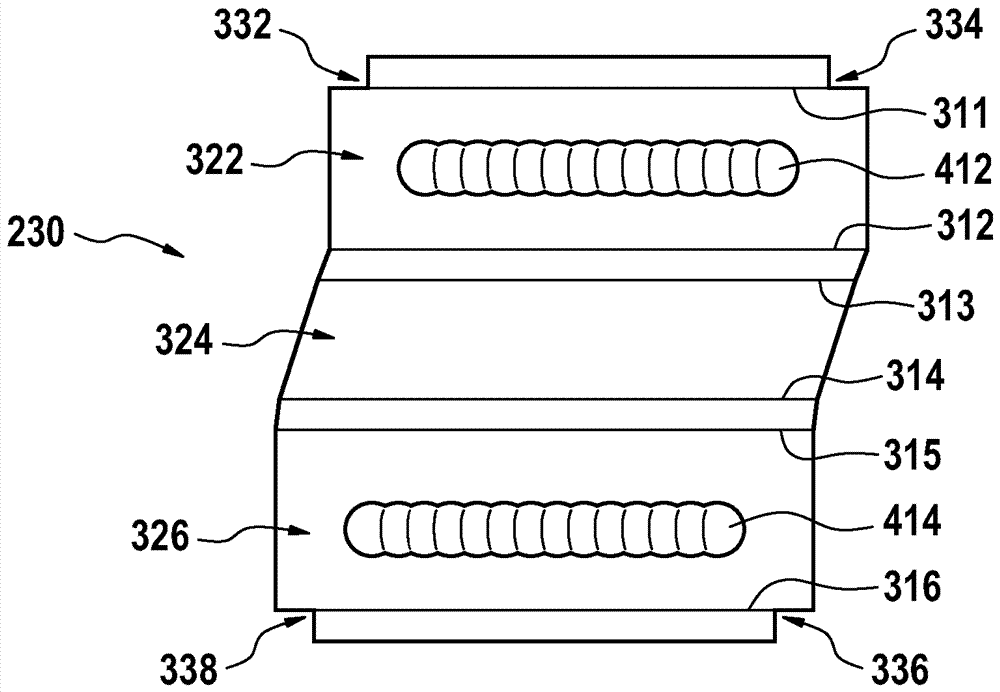

[0041] figure 1 An exemplary electric motor 100 , which is embodied as an inner rotor motor with an inner rotor 180 and an outer stator 150 , is shown. The electric motor illustrated has a stator core 153 provided at least in sections with a plastic casing 155 , on which a stator winding 157 is arranged. The outer stator 150 is hereinafter referred to simply as "stator 150" for simplicity of description.

[0042] It should be pointed out that figure 1 The electric motor 100 in is only schematically shown, this is because the structure and functionality of suitable electric motors are sufficiently known from the prior art, so that the electric motor 100 is omitted here for the purpose of brevity and simplification of the description. In-depth description. Furthermore, it should be pointed out that the electric motor 100 is shown as an inner rotor motor only by way of example and not in order to limit the invention, since the invention can also be used in an outer rotor motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com