Point-bonding sealed hollow glass and manufacturing method thereof

A glass, point-bonding technology, applied in the installation of window glass, parallel glass structure, improvement of windows/doors, etc., can solve the problems of easy formation of cold bridges, shortened life, damage to the butyl sealant layer, etc., to simplify production Process, sound insulation performance improvement, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

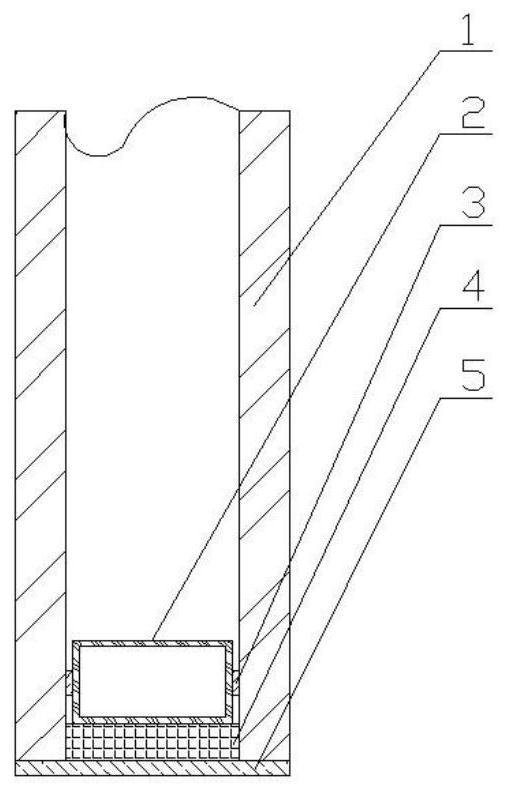

[0059] Embodiment 1 of the present invention provides a kind of hollow glass of point bonding sealing, such as figure 1 with Figure 10 As shown, it includes two pieces of glass 1, four spacers 2, a first sealant 3 and molecular sieves, a second sealant 4 and a third sealant 5; two pieces of glass 1 are provided with a spacer 2; Four spacers 2 are arranged on the periphery of the glass 1 in four sections to form a closed spacer frame; the first sealant 3 is set between the glass 1 and the spacer 2; molecular sieves are filled in the spacer frame; the second sealing Both the glue 4 and the third sealing glue 5 are arranged between two adjacent pieces of glass 1 , and are located on the outer side of the spacer 2 in turn.

[0060] Among them, the distance between two adjacent pieces of glass 1 is 3 mm, the glass 1 is ordinary glass, the spacer 2 is a warm edge spacer prepared by a mold, the first sealing glue 3 is butyl glue, and the second sealing glue 4 is a stainless steel ...

Embodiment 2

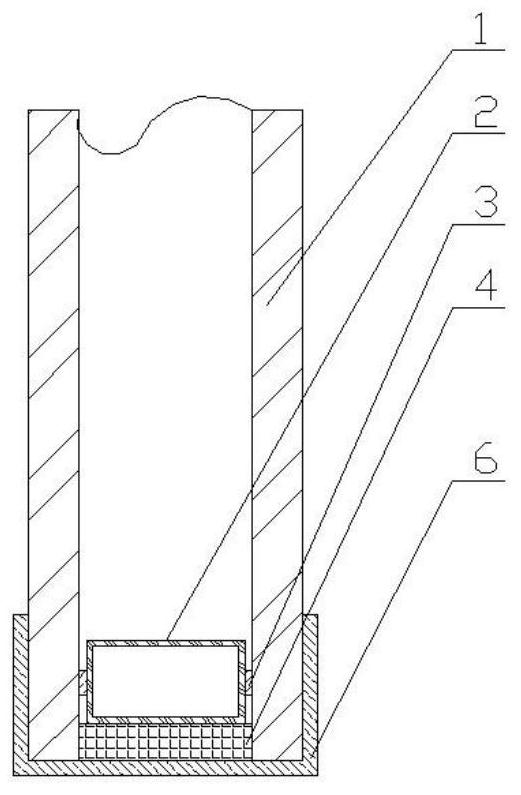

[0070] Embodiment 2 of the present invention provides a kind of hollow glass of point bonding sealing, such as figure 2 with Figure 11 As shown, it includes two pieces of glass 1, four spacers 2, a first sealant 3 and molecular sieves, a second sealant 4 and a fourth sealant 6; a spacer 2 is arranged between two pieces of glass 1; Four spacers 2 are arranged on the periphery of the glass 1 in four sections to form a closed spacer frame; the first sealant 3 is set between the glass 1 and the spacer 2; molecular sieves are filled in the spacer frame; the second sealing The glue 4 is arranged between two adjacent pieces of glass 1 and is located on the outer side of the spacer bar 2 ; the fourth sealing glue 6 is arranged on the sides and outer surfaces of the two adjacent pieces of glass 1 .

[0071] Among them, the distance between two adjacent pieces of glass 1 is 30 mm, the glass 1 is ultra-clear glass, the spacer 2 is an aluminum spacer prepared by a mold, the first seali...

Embodiment 3

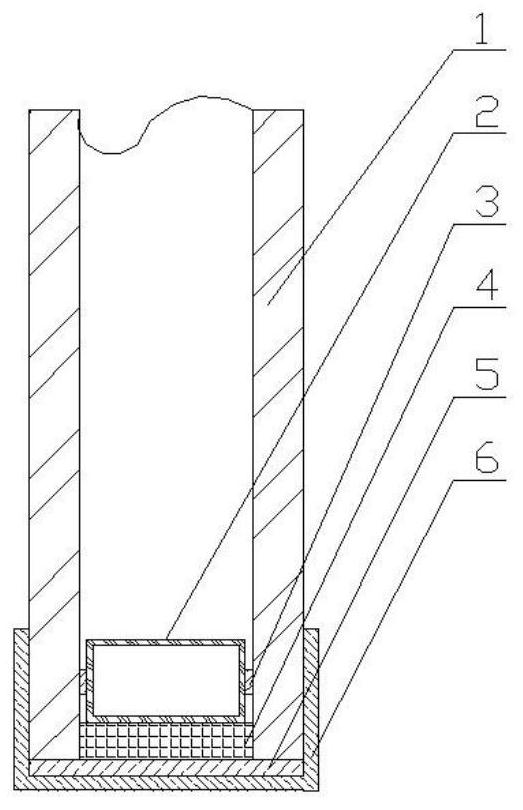

[0081] Embodiment 3 of the present invention provides a kind of point-bonded and sealed insulating glass, such as image 3 with Figure 12 As shown, it includes two pieces of glass 1, four spacers 2, the first sealing glue 3 and molecular sieve, as well as the second sealing glue 4, the third sealing glue 5 and the fourth sealing glue 6; There are spacer bars 2 between them; four spacer bars 2 are arranged on the periphery of the glass 1 in four sections to form a closed spacer frame; the first sealant 3 is set between the glass 1 and the spacer bar 2; molecular sieves are filled in the spacer In the frame; the second sealing glue 4 and the third sealing glue 5 are arranged between two adjacent pieces of glass 1, and are located on the outer side of the spacer bar 2 in turn; the fourth sealing glue 6 is arranged between two adjacent pieces of glass 1 The sides of the glass 1 and the edges of the outer surface.

[0082] Wherein, the distance between two adjacent pieces of gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com