Patents

Literature

88results about How to "Realize automatic placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

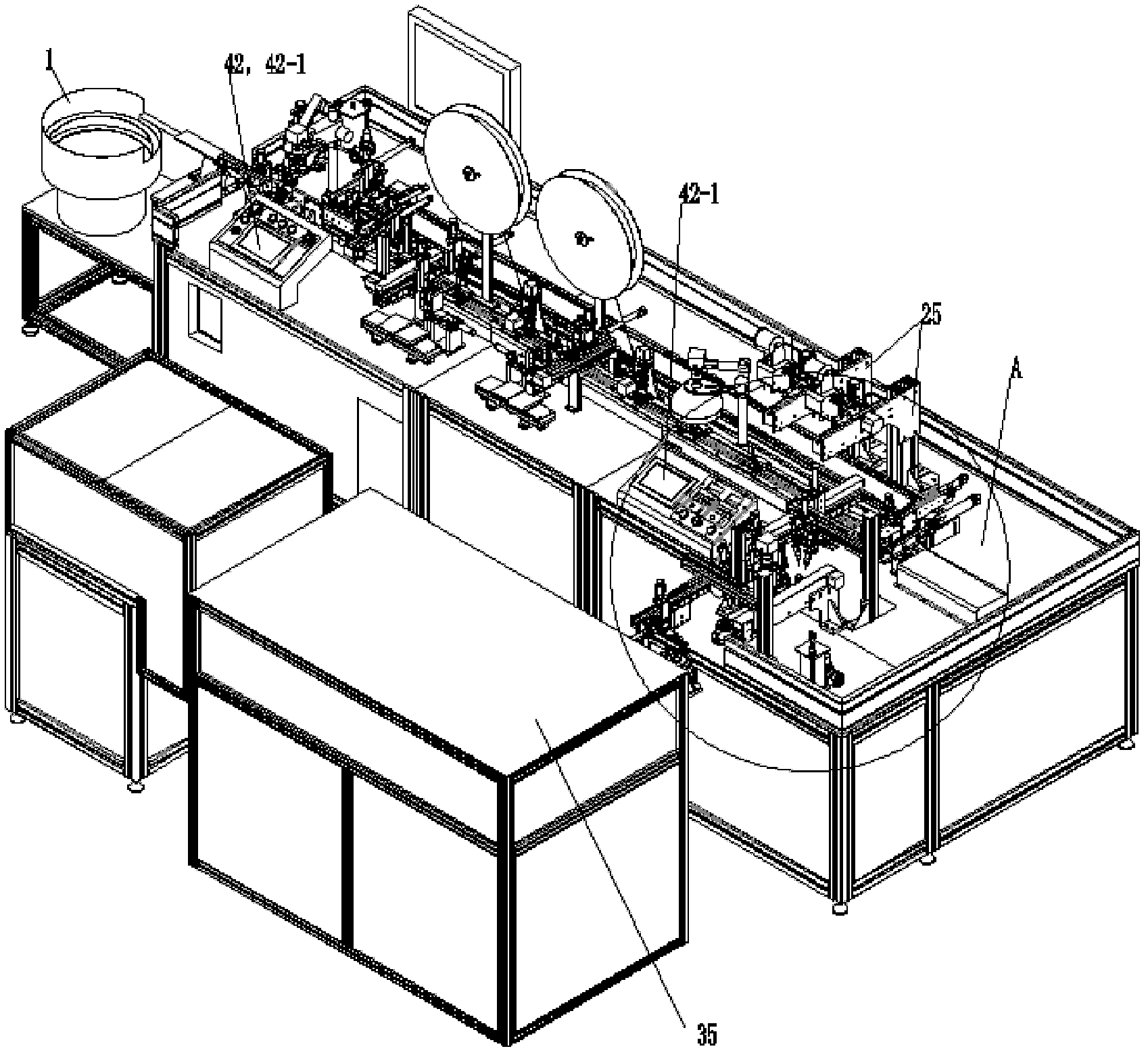

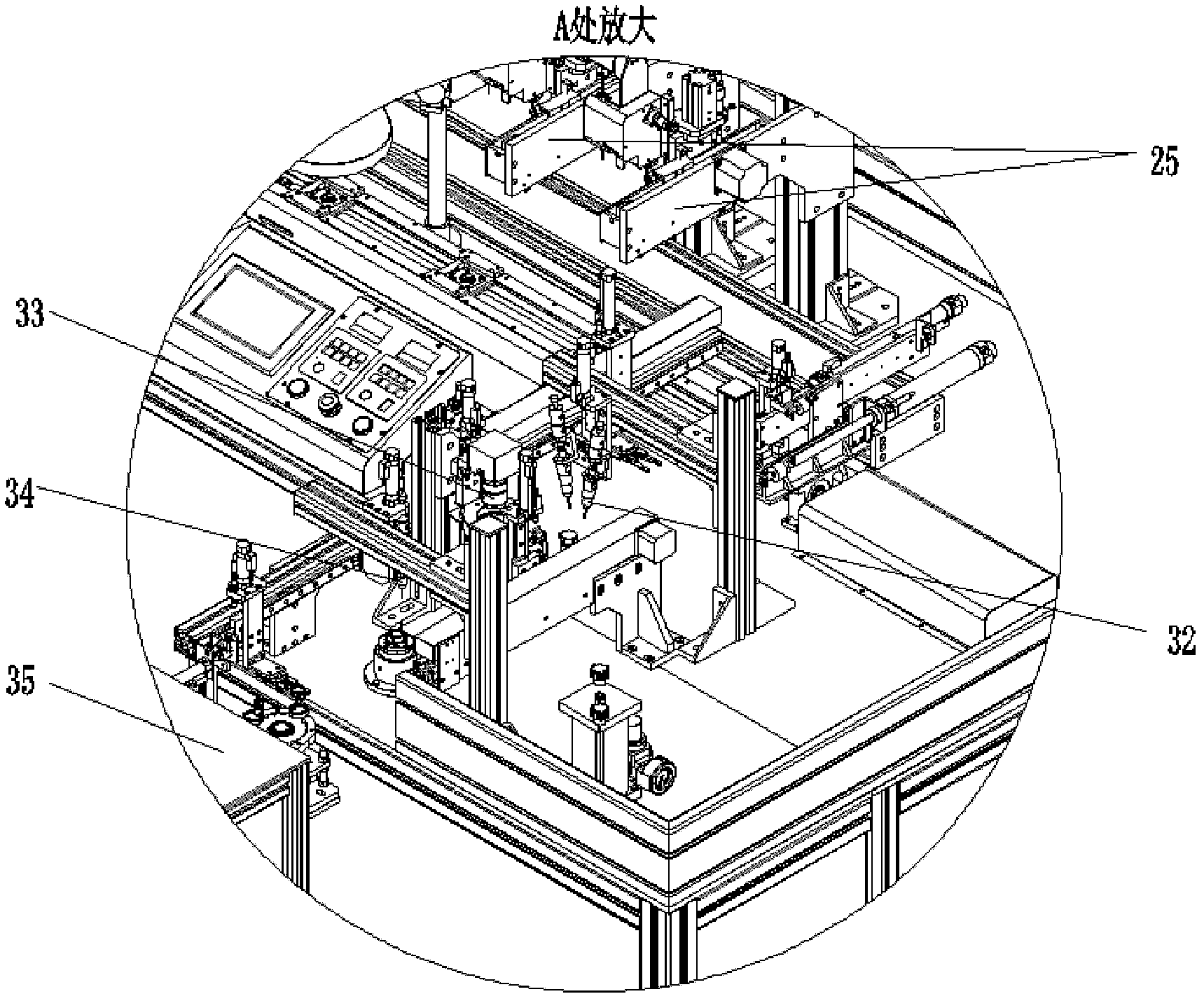

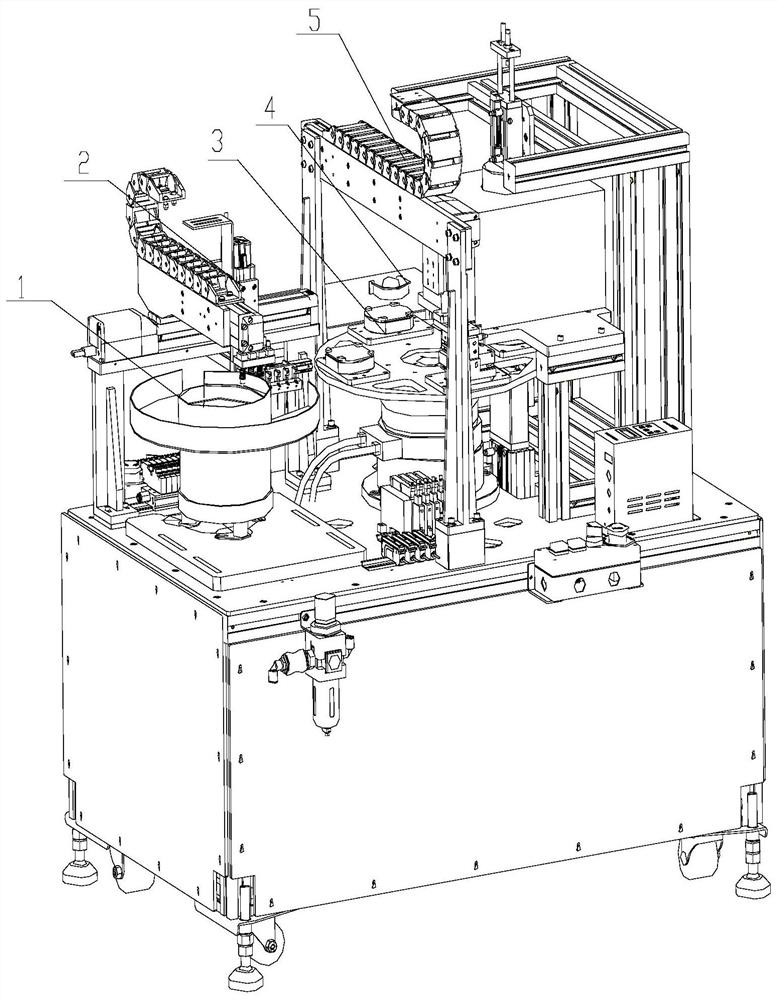

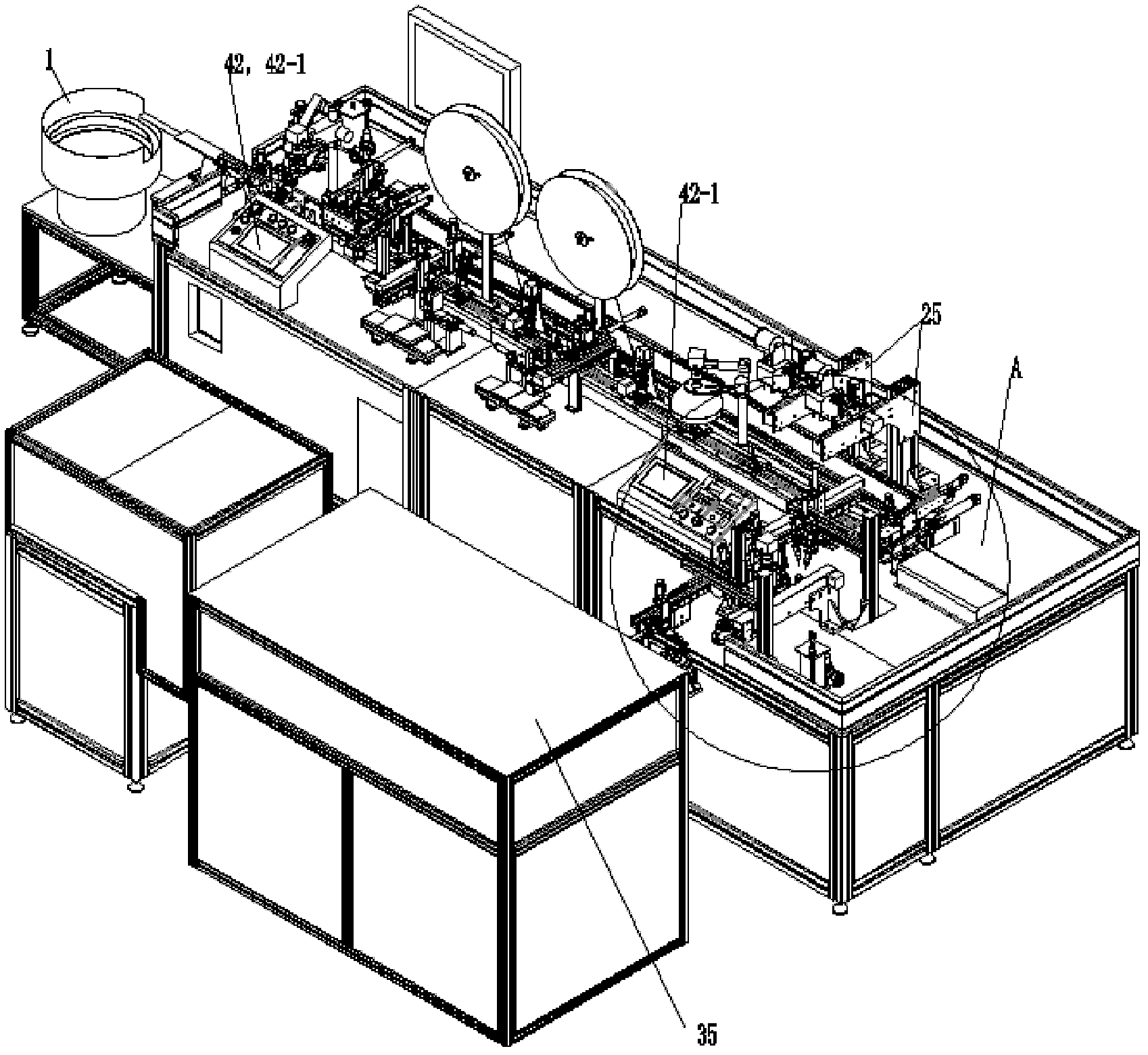

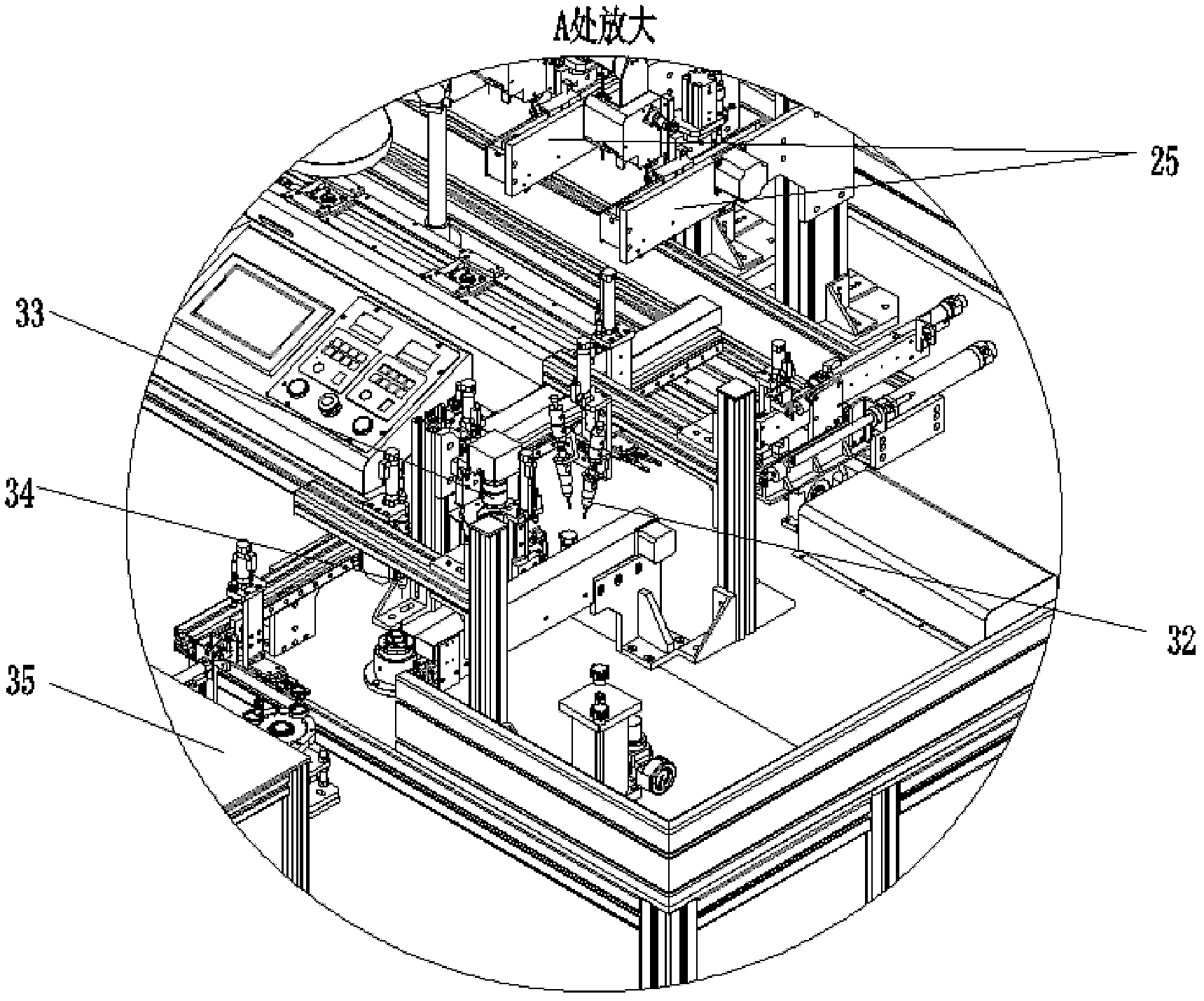

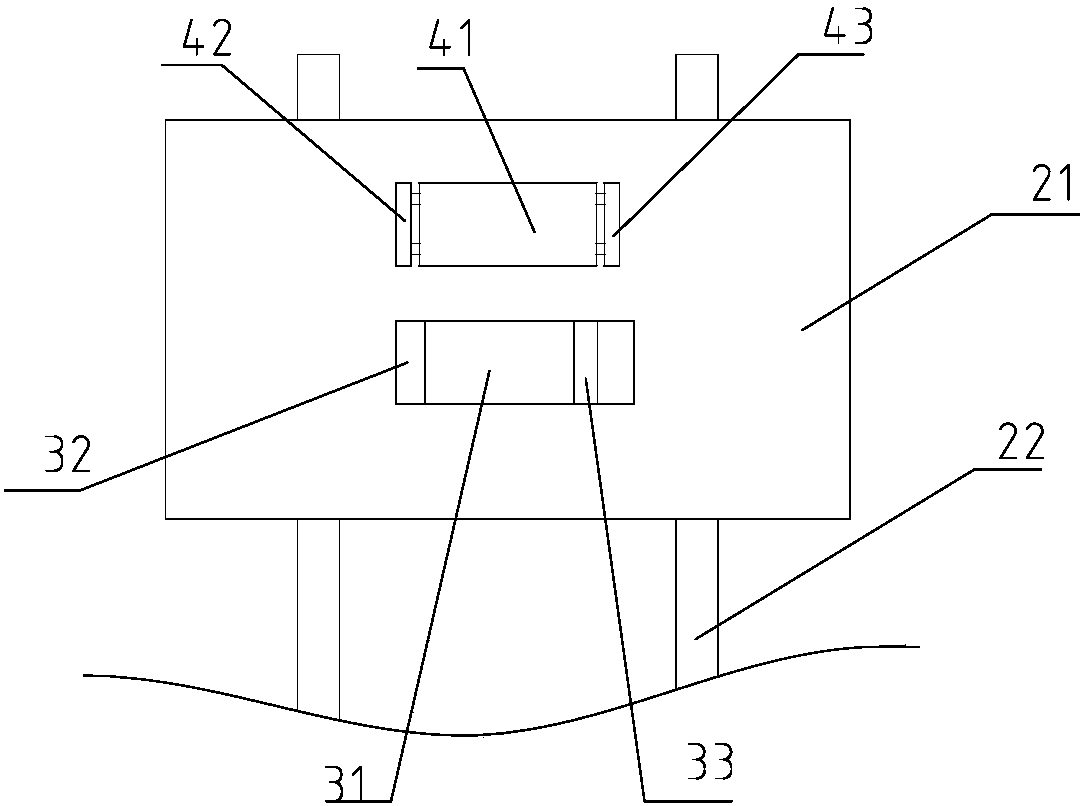

Automatic assembly production line of buzzers

ActiveCN102848187AGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

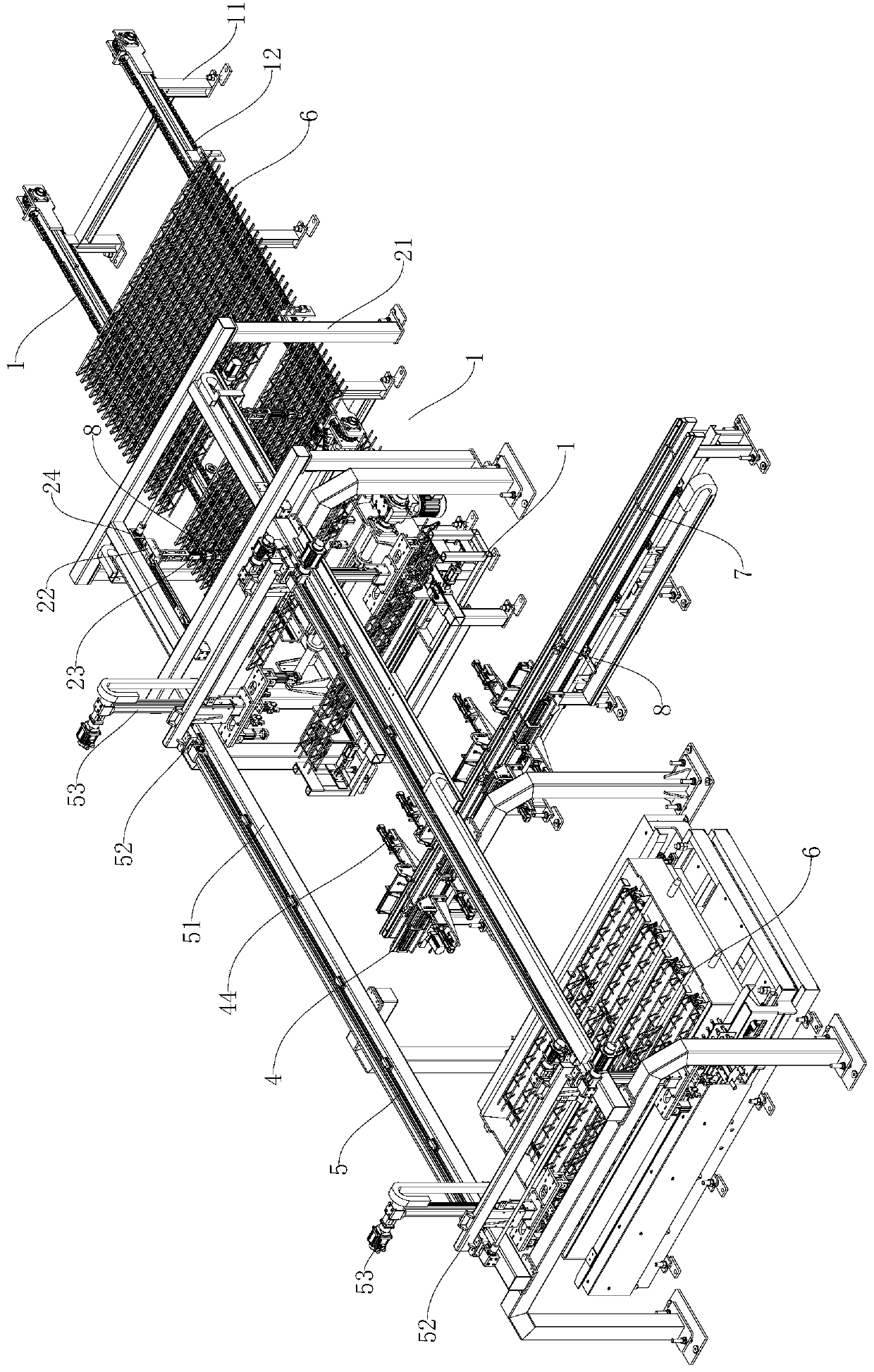

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

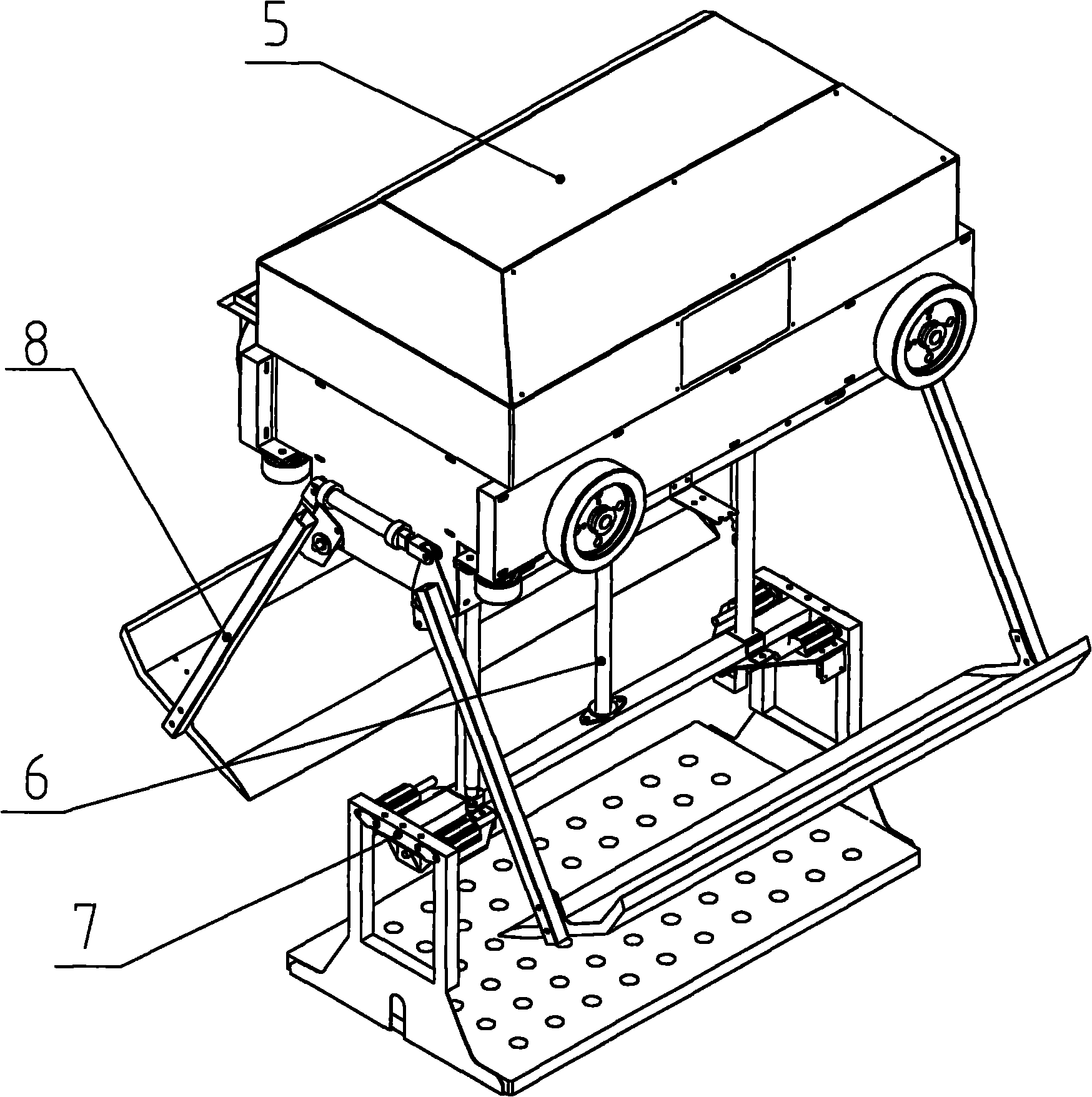

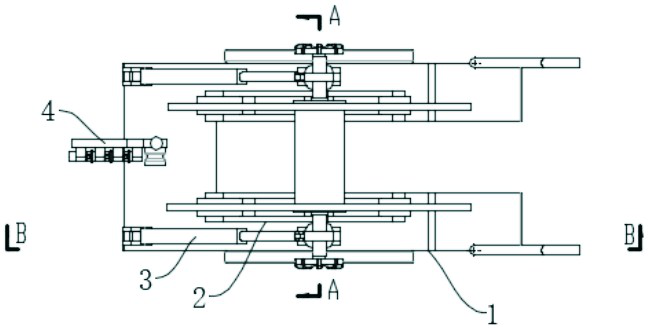

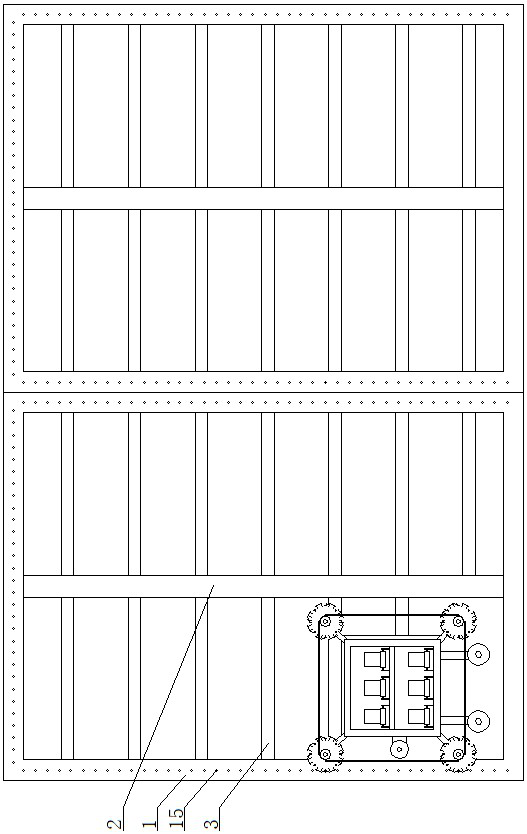

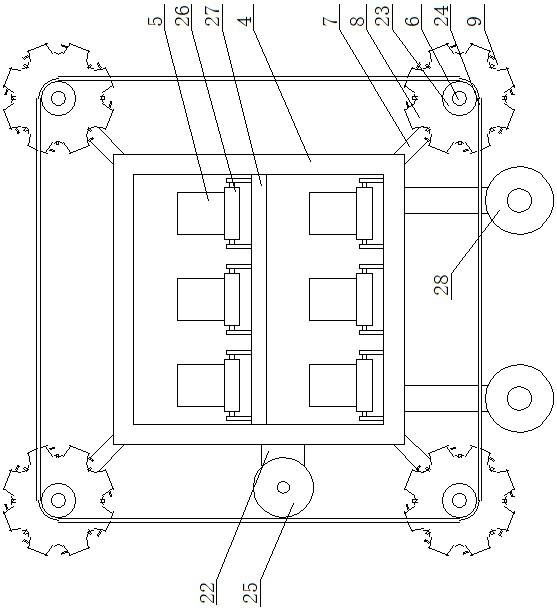

Conveying device for plug transplantation

ActiveCN101792064AIncrease the effective use areaIncrease profitCultivating equipmentsConveyor partsWheel driveSprocket

The invention relates to a conveying device for plug transplantation, which comprises stationary rails, two movable rails and a mobile car device, wherein the stationary rail is respectively erected at the two sides of a whole seedling bed in a greenhouse, and the two movable rails bestride the two stationary rails; the movable rail consists of two sprocket wheel driving devices, and the same sides of the two movable rails are respectively fixed on a pair of movable rail moving devices; the movable rail moving devices are erected on the stationary rails and can move along the stationary rails, and the mobile car device is arranged on sprocket wheels of the two movable rails; the lower part of the mobile car device is connected with a pneumatic lifting device, and the output end of the pneumatic lifting device is connected with a pneumatic gripping device; a pneumatic protecting device is arranged below the mobile car device, and at least one of a movable rail movement detecting deviceand a mobile car detecting device is assembled; and sensors for detecting and positioning are assembled on the pneumatic lifting device, the pneumatic gripping device and the pneumatic protecting device. The invention aims to reduce the labor intensity of workers, reduce the number of the workers, improve the utilization rate of greenhouse space, and increase the number of plugs in the existing greenhouse area to increase yield.

Owner:BEIJING KINGPENG INT HI TECH CORP

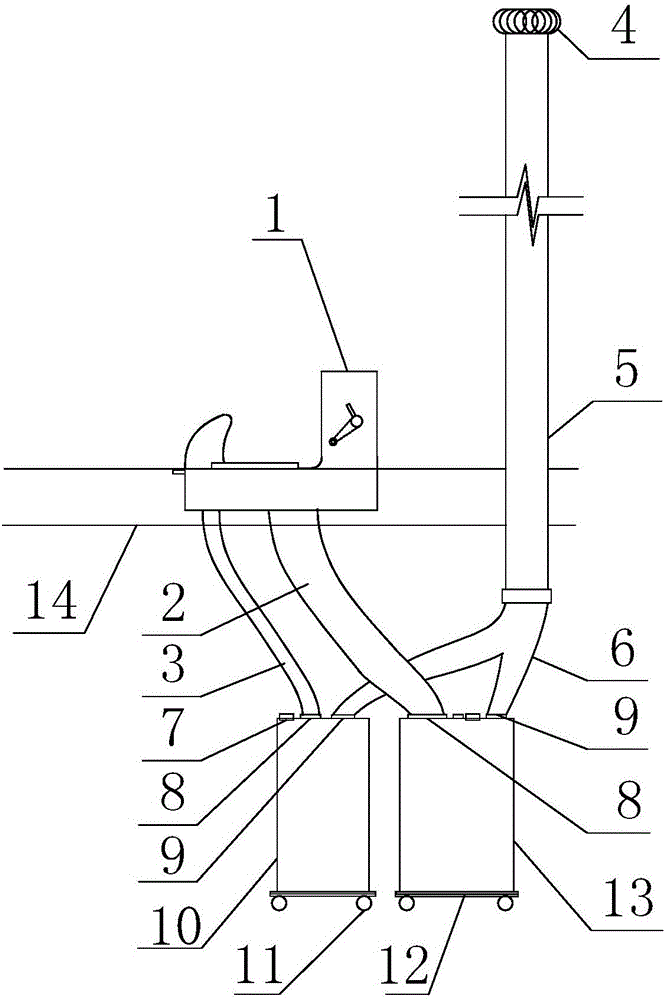

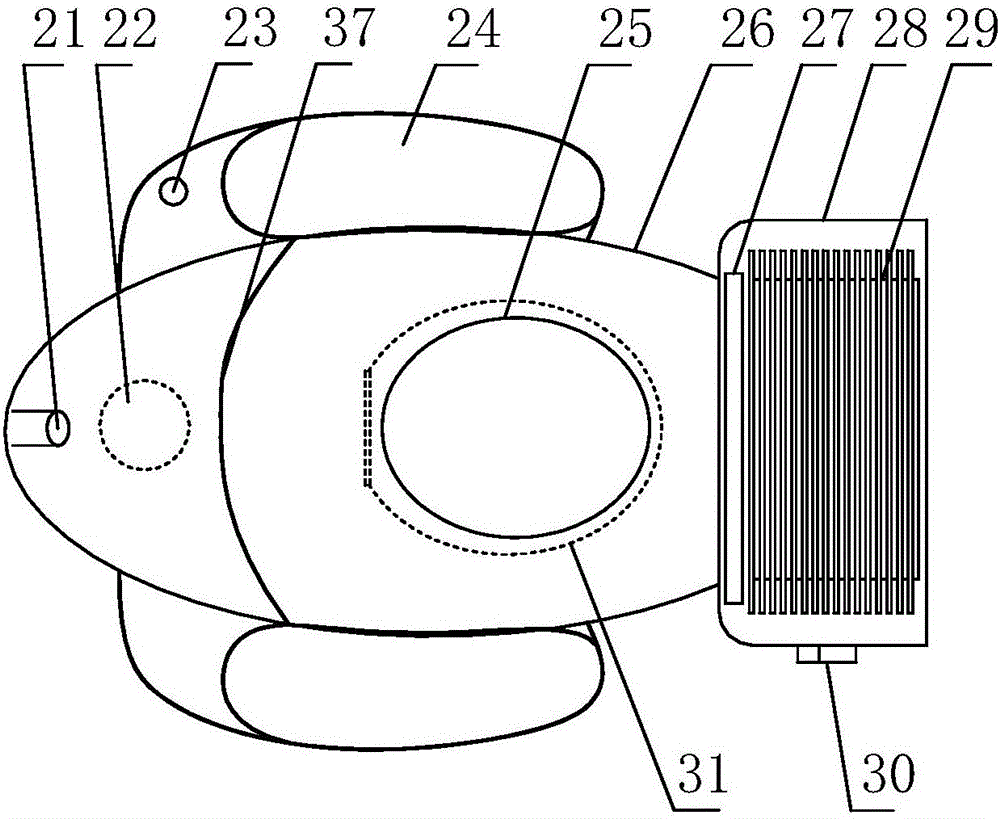

Flushing-free excrement and urine separating collecting and treatment system of public washroom

ActiveCN106214046AImprove processing efficiencyImprove utilization efficiencyBathroom accessoriesWater resourcesContamination

Provided is a flushing-free excrement and urine separating collecting and treatment system of a public washroom. A urine drainage pipe and an excrement discharge pipe separated from the urine drainage pipe are arranged in the public washroom and communicated with a urine collecting container and an excrement collecting container, the tops of the containers are communicated with an air drainage pipe, and an excrement-urine separation toilet stool comprises a bag storage box, a bag containing mechanism and an odor separating plate opening mechanism. Stacked excrement bags are stored in the bag storage box, the side wall of an inlet of an excrement channel is provided with a transversely-arranged bag hanging groove, the excrement bag on the innermost side is provided with the bag containing mechanism, and the excrement bag on the innermost side falls off through a chute and is arranged in the bag hanging groove. An odor separating plate controlled by a bag falling switch is arranged at the bottom of the excrement channel, and the bag falling switch is controlled to enable the excrement bags to slide into the collecting container after defecating. According to the system, water resources are saved, environmental friendliness is achieved, the problems of toilet deodorization and excrement falling opening contamination are solved, the treatment and utilization efficiency of excrement and urine organic fertilizer resources is greatly improved, and wide application prospects are achieved.

Owner:云南八卫科技有限公司

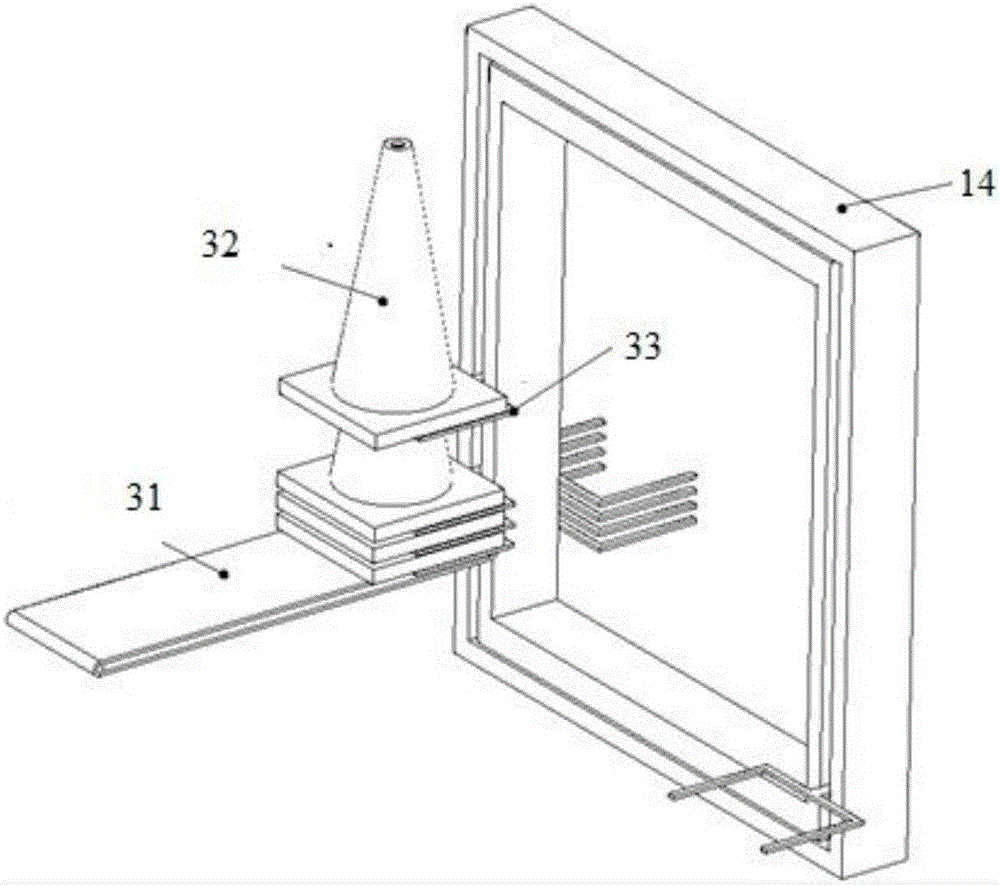

Automatic road cone placing and recycling device

InactiveCN102877423ARealize automatic placementRealize automatic recyclingTraffic signalsRoad signsUltimate tensile strengthAutomotive engineering

Owner:SHANDONG HI SPEED GRP CO LTD

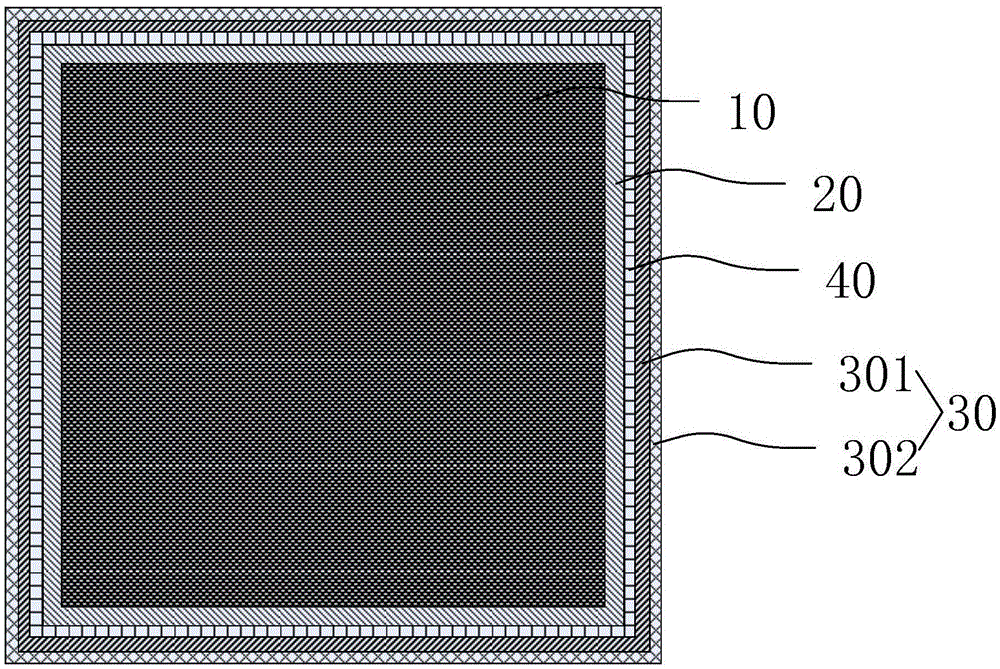

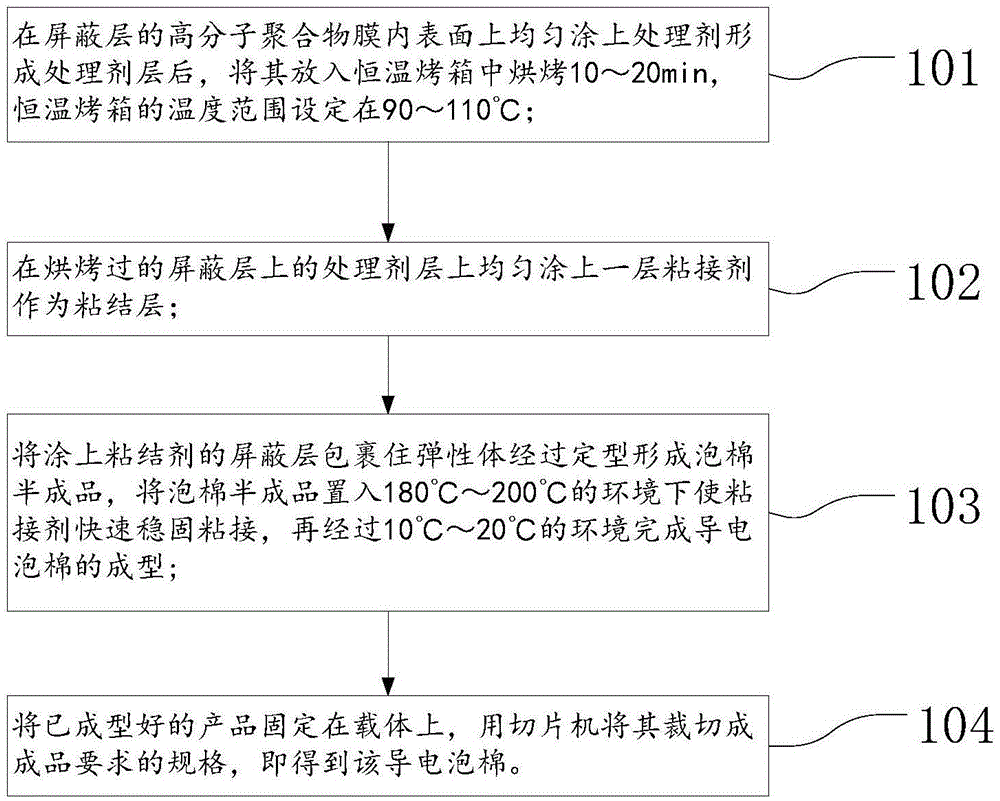

Conductive foam and fabrication method thereof

ActiveCN105555116AImprove surface activityTight and firm bondNon-macromolecular adhesive additivesMagnetic/electric field screeningPolymer chemistryPolymer

The invention discloses conductive foam and a fabrication method thereof. The conductive foam comprises an elastic body, a bonding layer and a shielding layer, wherein the bonding layer wraps the outer surface of the elastic body, the elastic body, the bonding layer and the shielding layer are sequentially arranged from inside to outside, the shielding layer is provided with a high-molecular polymer film and a metal layer from inside to outside, and a processing agent layer is arranged between the high-molecular polymer film and the bonding layer and used for improving the surface activity of the high-molecular polymer film. With a mode of additionally arranging the processing agent layer, the surface activity of the high-molecular polymer film is improved, the high-molecular polymer film is more tightly and firmly bonded with the elastic body by the bonding layer, a permeating bonding effect is formed between the bonding layer and the high-molecular polymer film, a tiny gap is eliminated, and the high-molecular polymer film is difficult to pop from the elastic body in a high-temperature environment.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

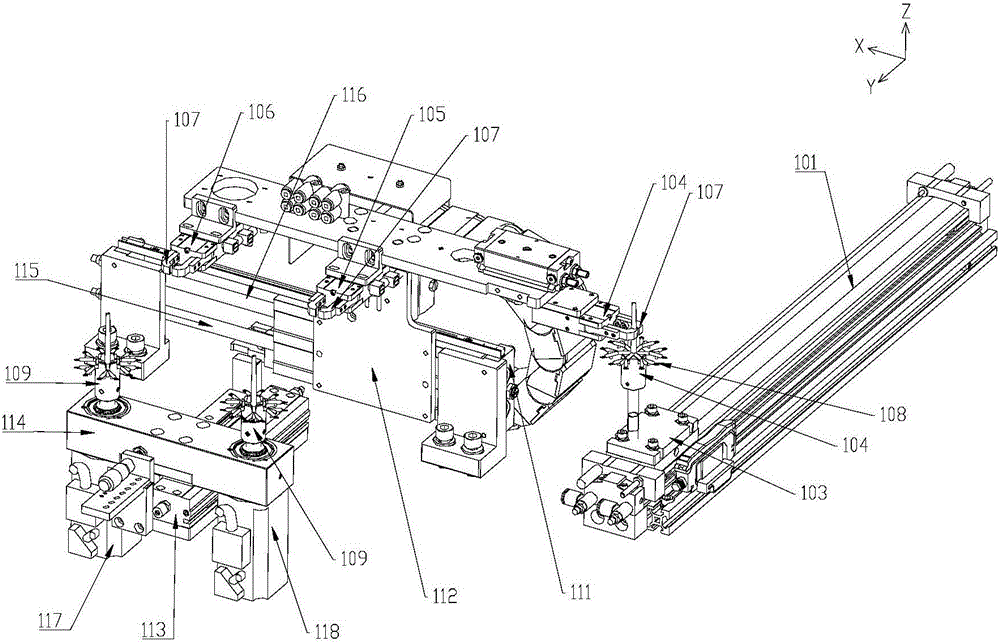

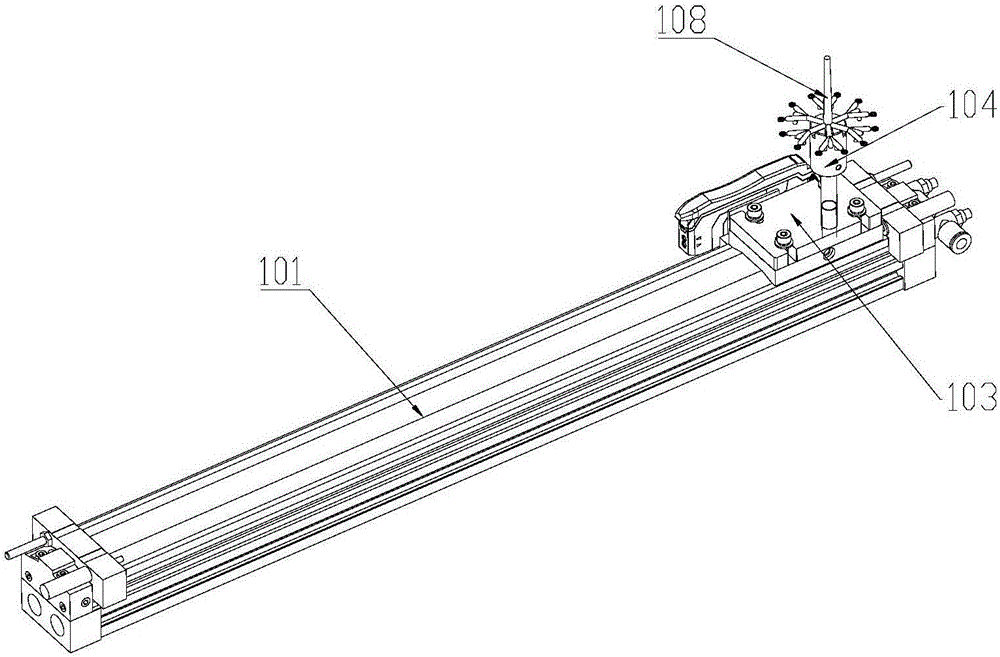

Shearing machine for injection molding lenses

InactiveCN106393217AImprove cutting efficiencyStable job qualityMetal working apparatusInjection molding machineMechanical engineering

The invention relates to a shearing machine for injection molding lenses. The shearing machine is characterized in that a feeding device comprises a positioning mechanism and a conveying device, and the conveying device comprises first swinging devices; each first swinging device comprises a clamping part for clamping injection molding parts, the multiple first swinging devices are configured to be capable of conveying the injection molding parts, and the positioning mechanism is configured to receive the injection molding parts conveyed from the conveying device for shearing; a shearing device comprises a first cutter, a second cutter and a drive device for driving the first cutter and the second cutter to do opposite or contrary motion, wherein the first cutter is opposite to the second cutter; a discharging device comprises a suction device for sucking and arranging the injection molding lens; and a warehousing device comprises a warehousing frame provided with an open end and capable of moving in the Z axis direction, the warehousing frame is provided with a supporting portion for supporting trays, and the supporting portion is of a multi-layer structure.

Owner:GOERTEK INC

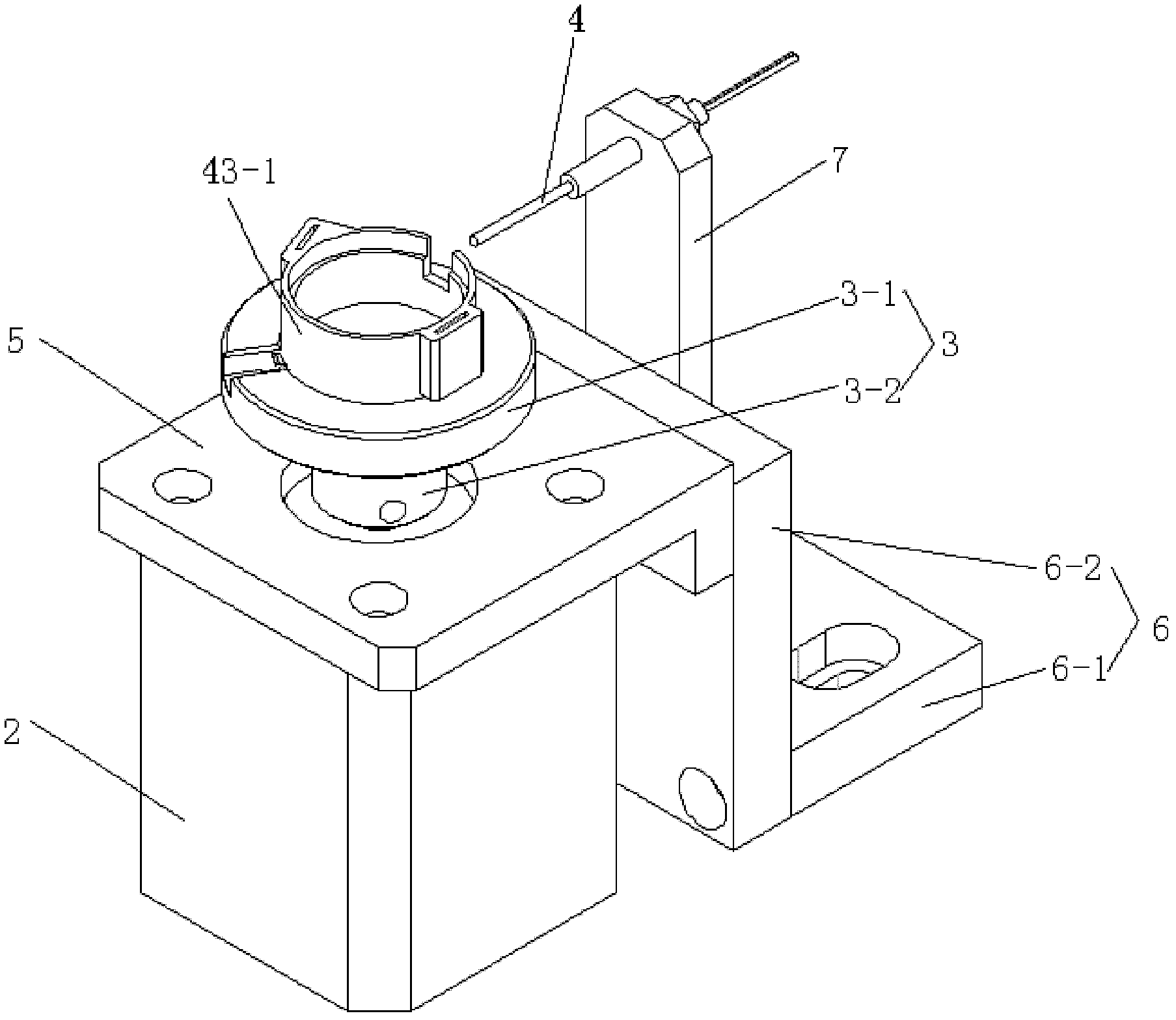

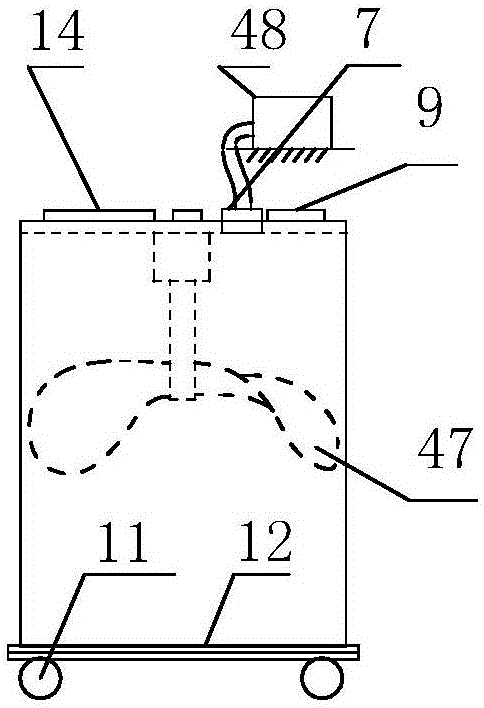

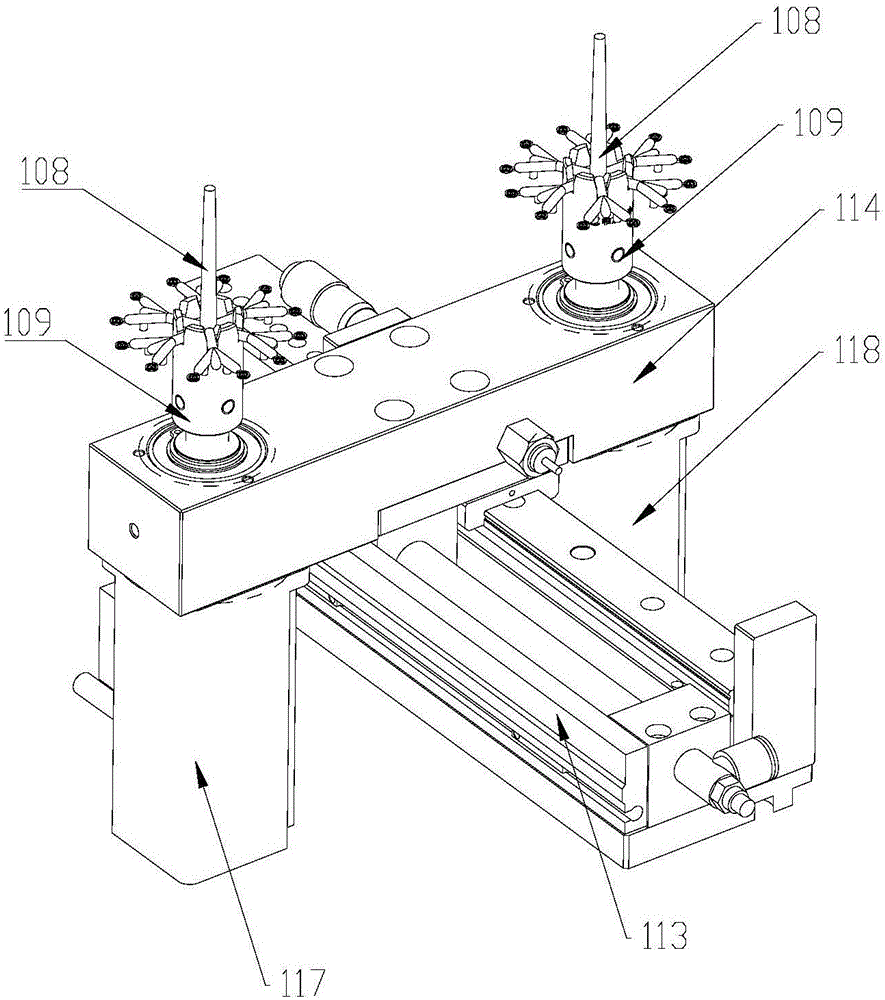

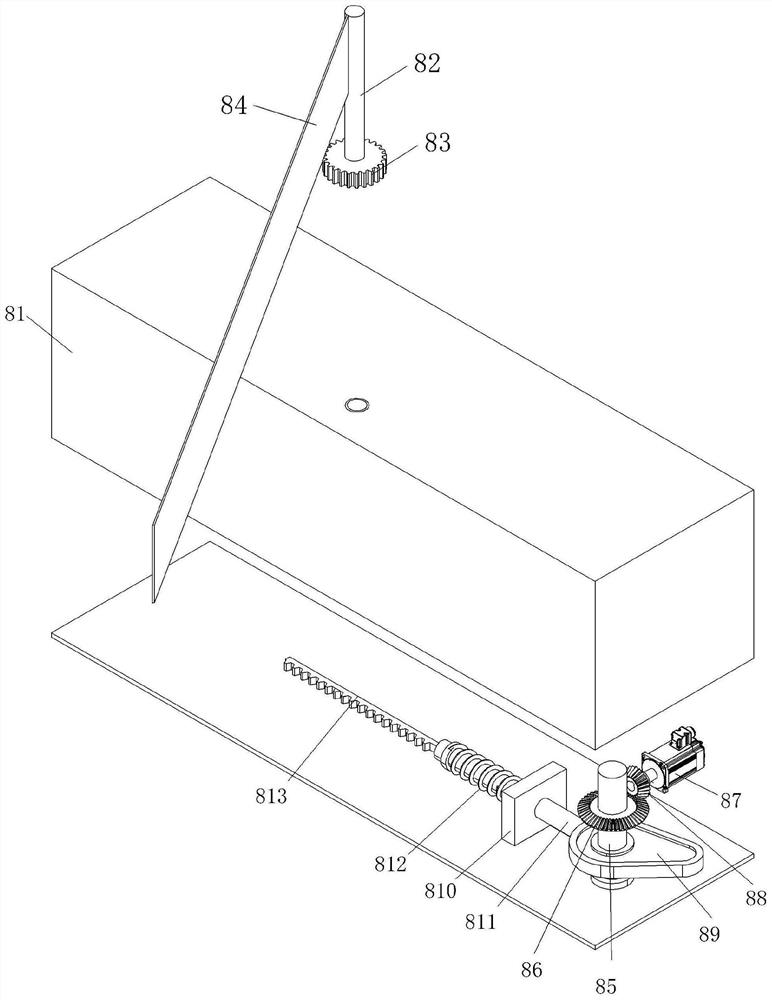

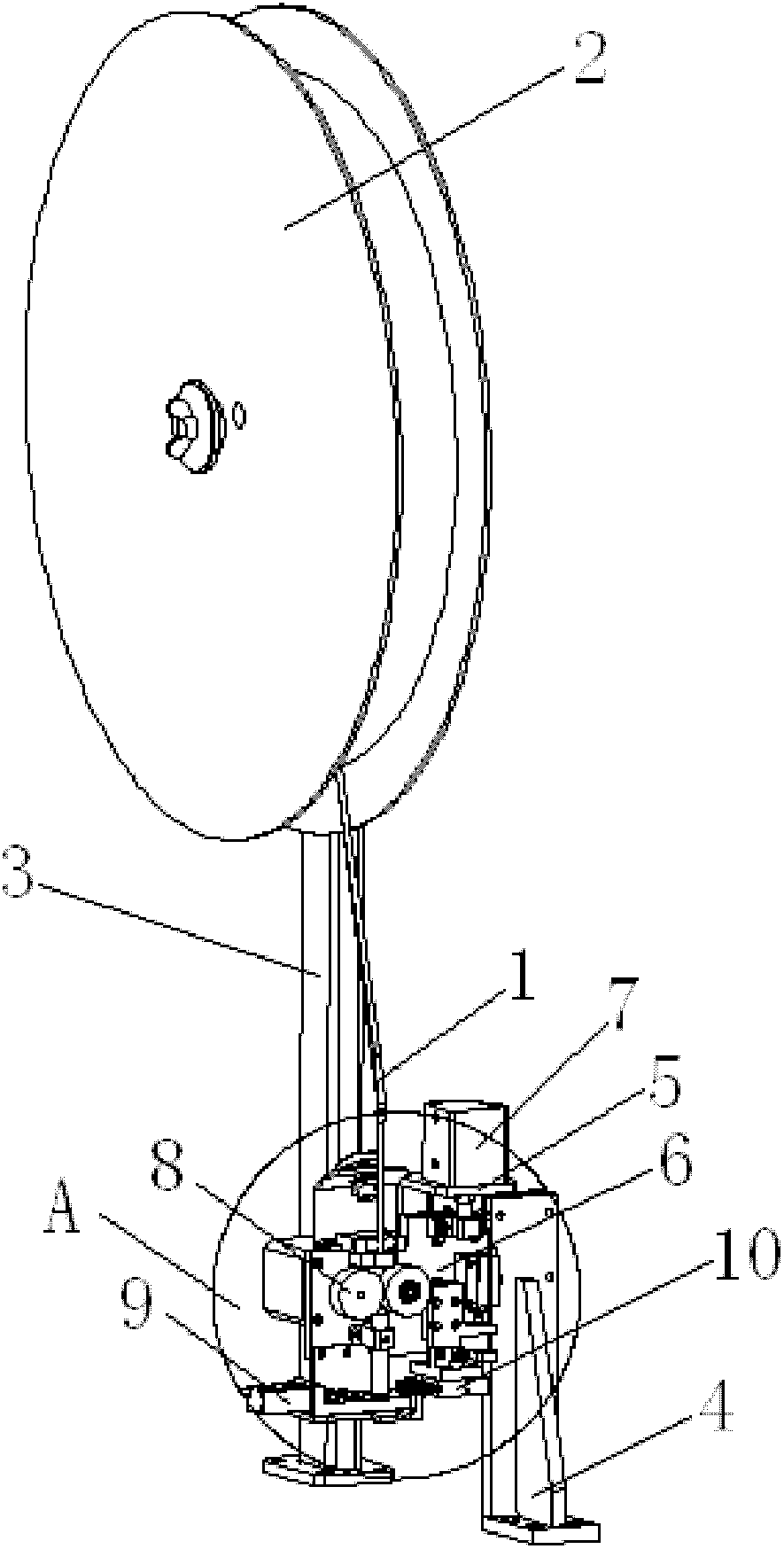

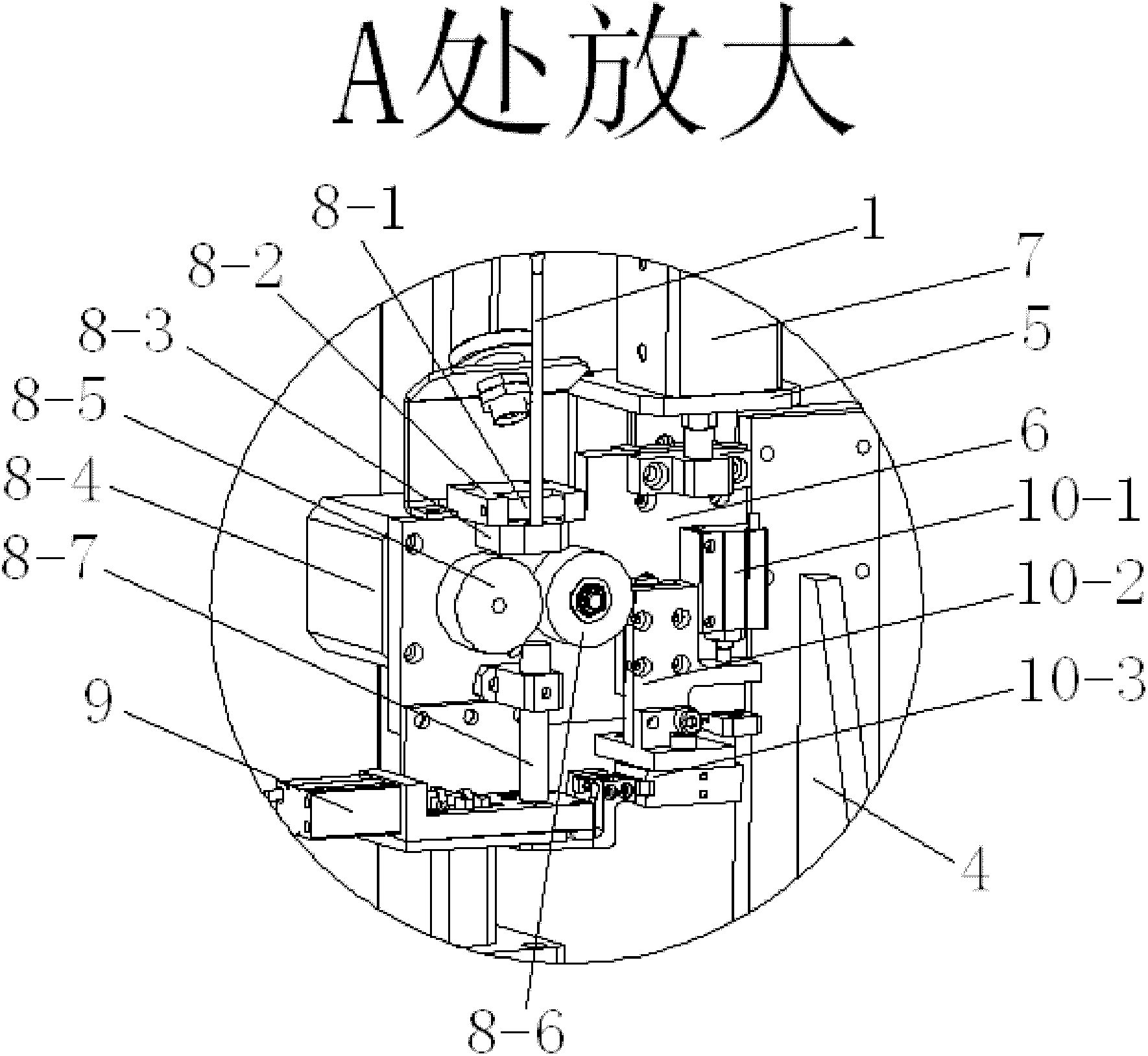

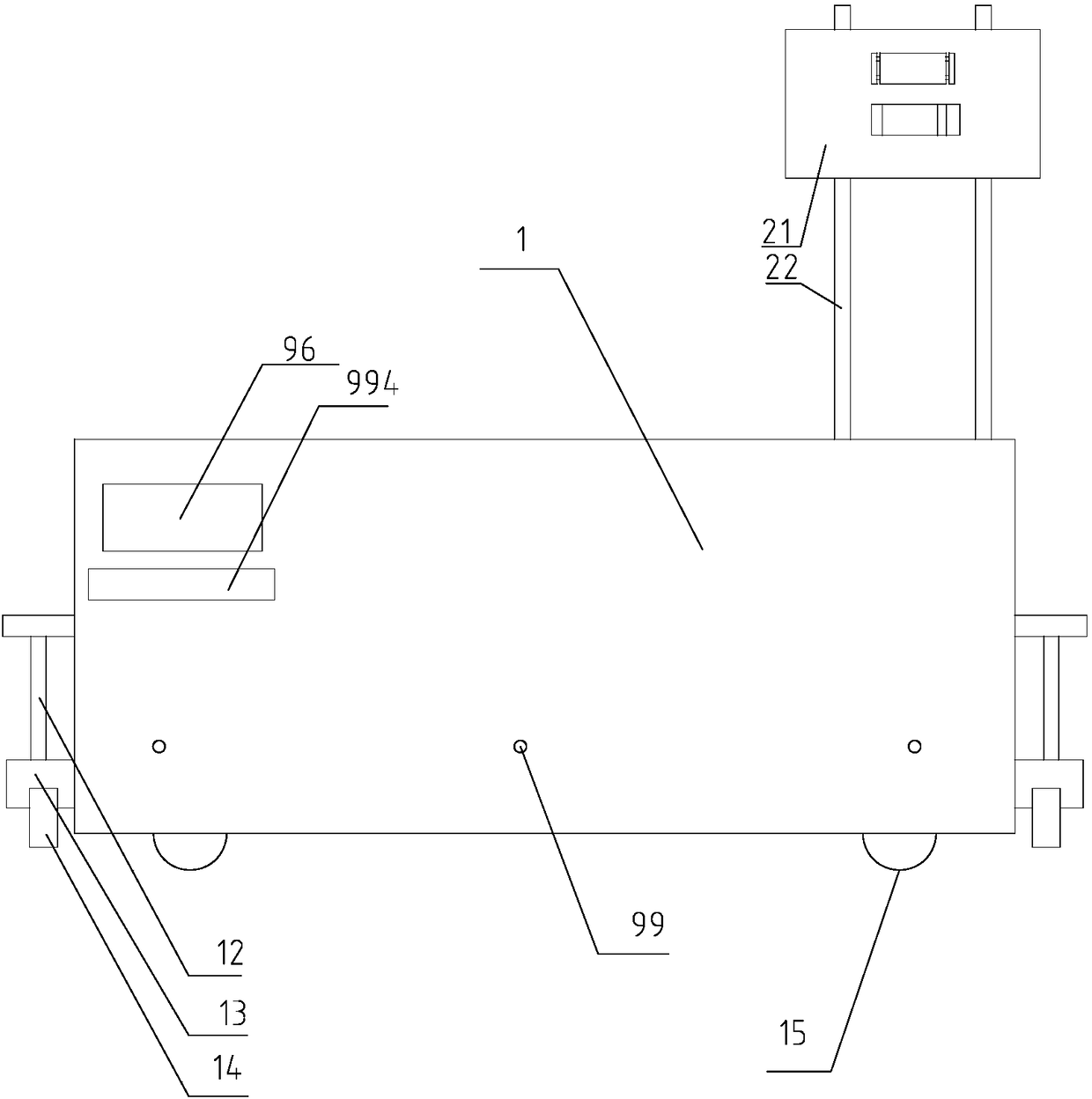

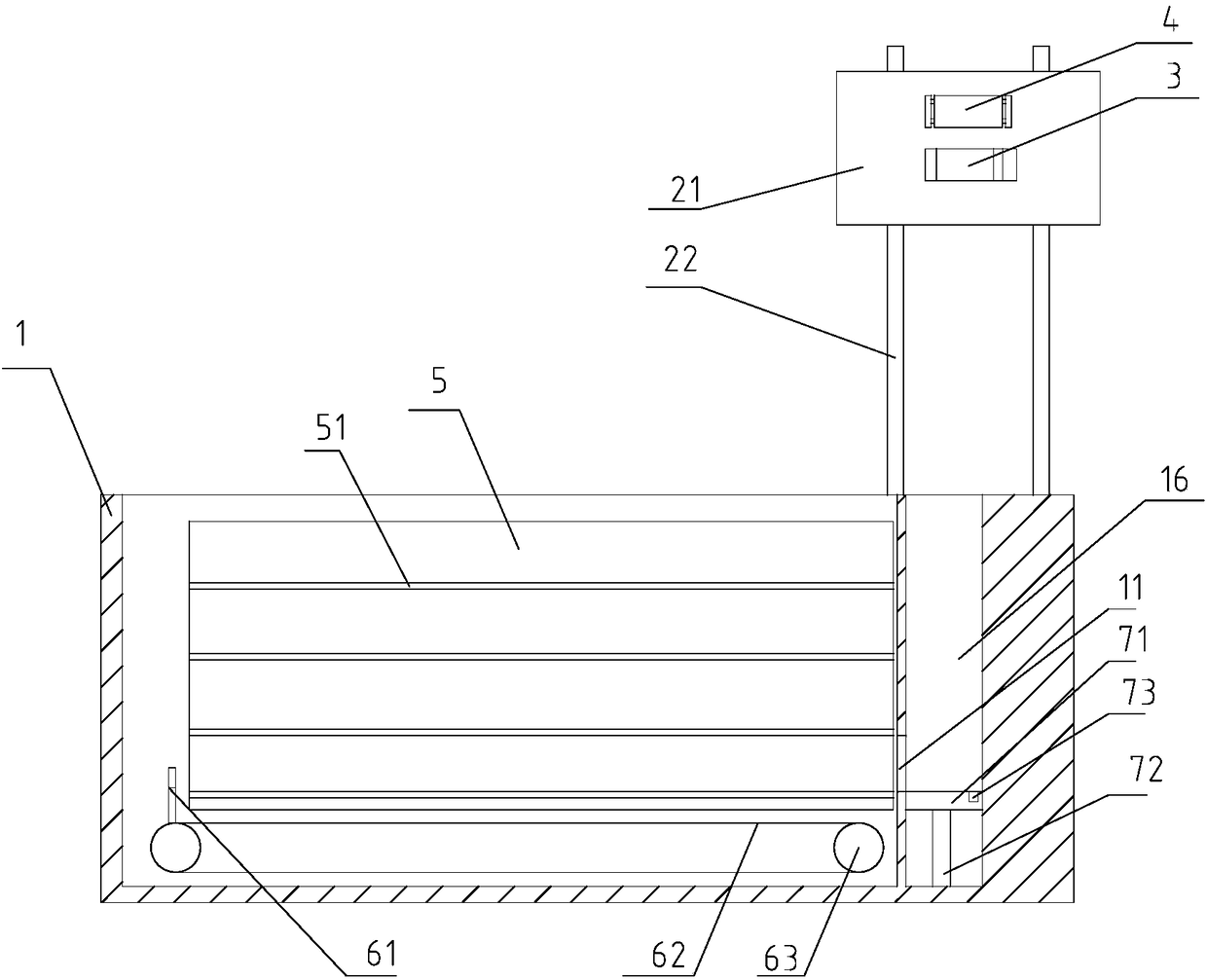

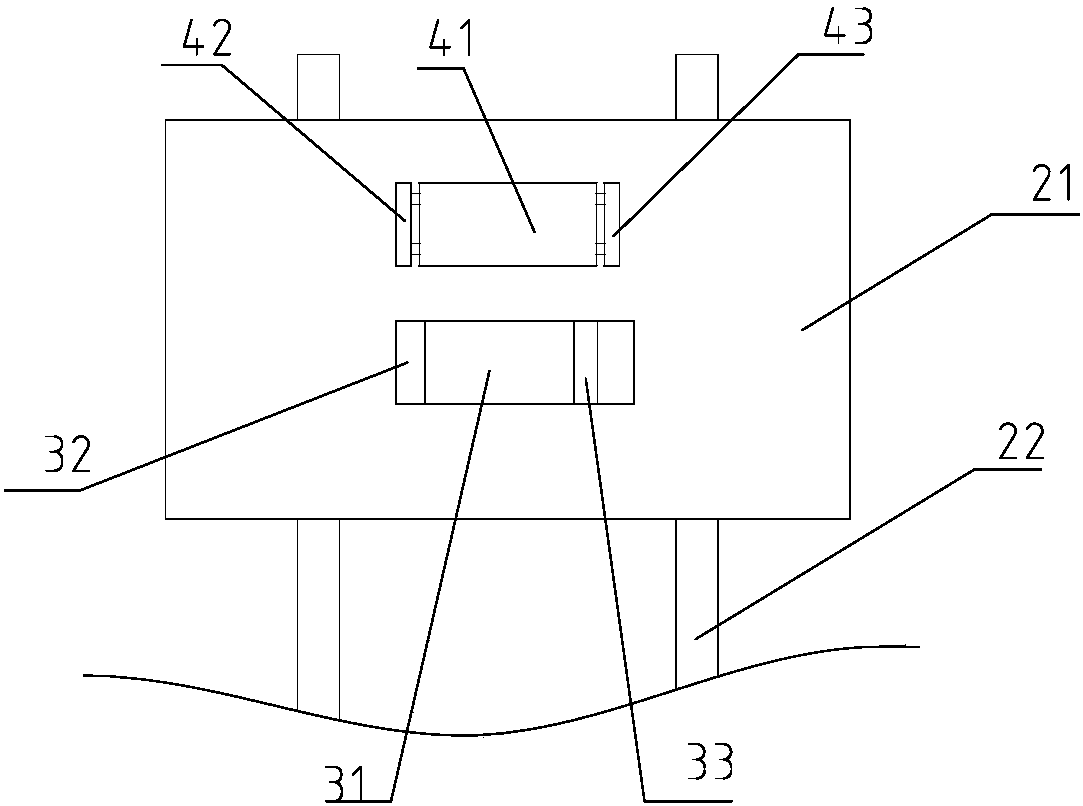

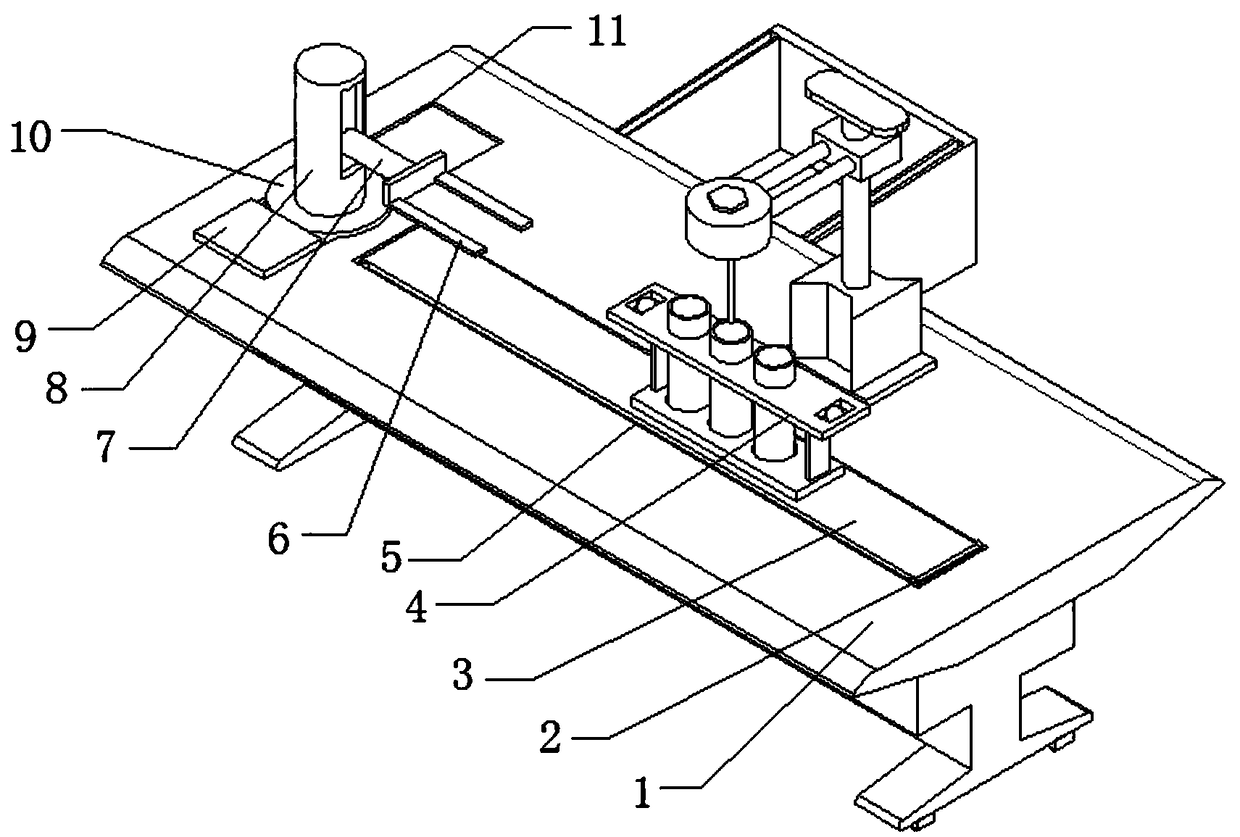

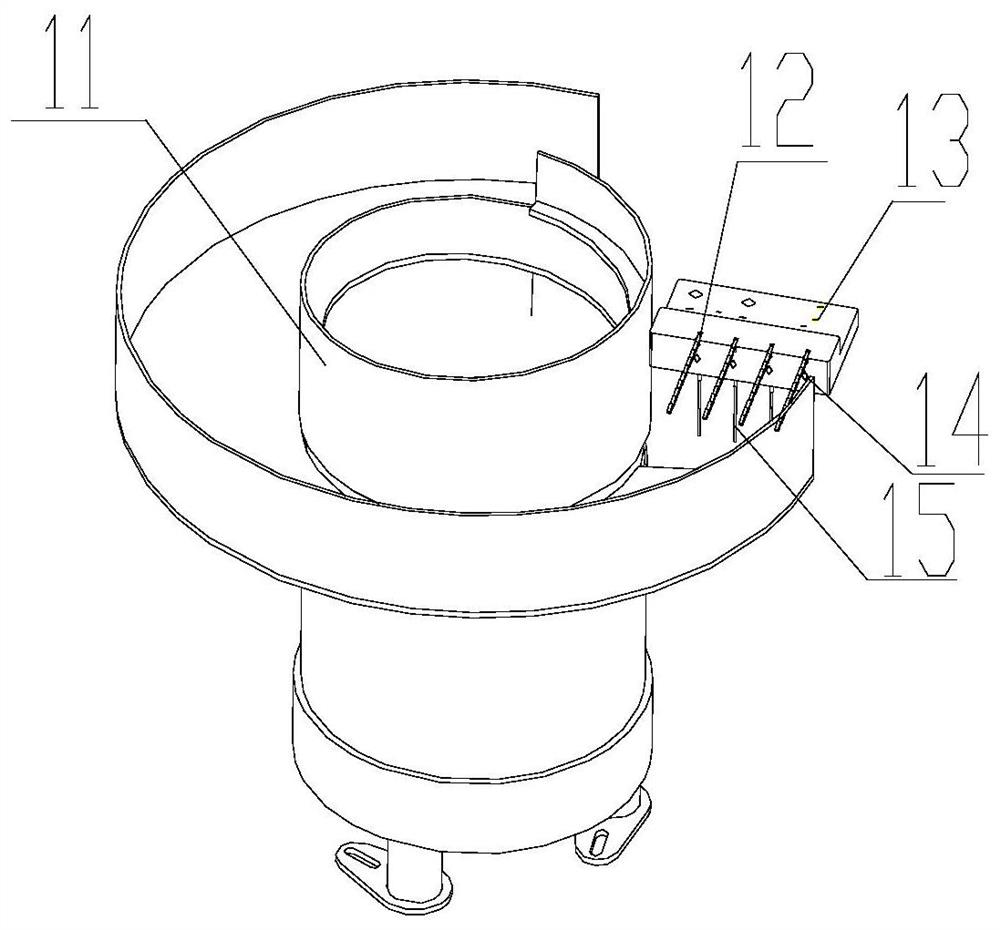

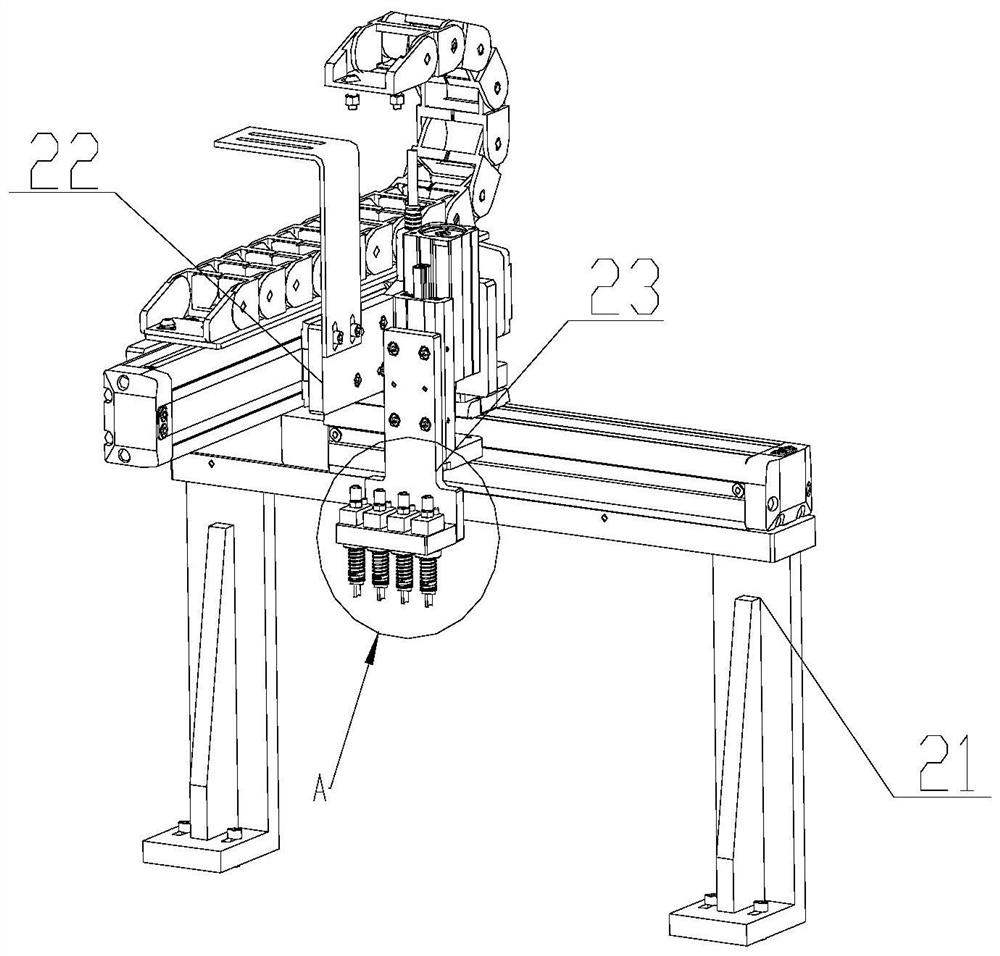

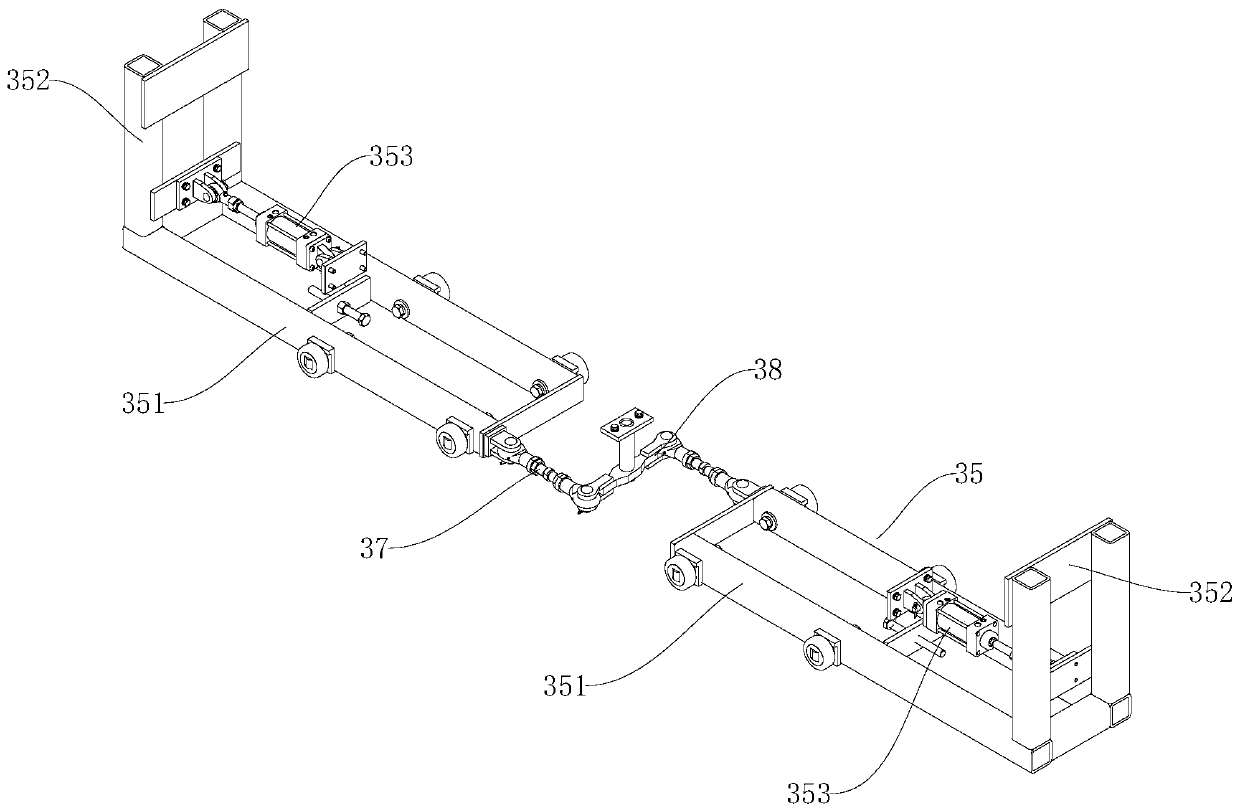

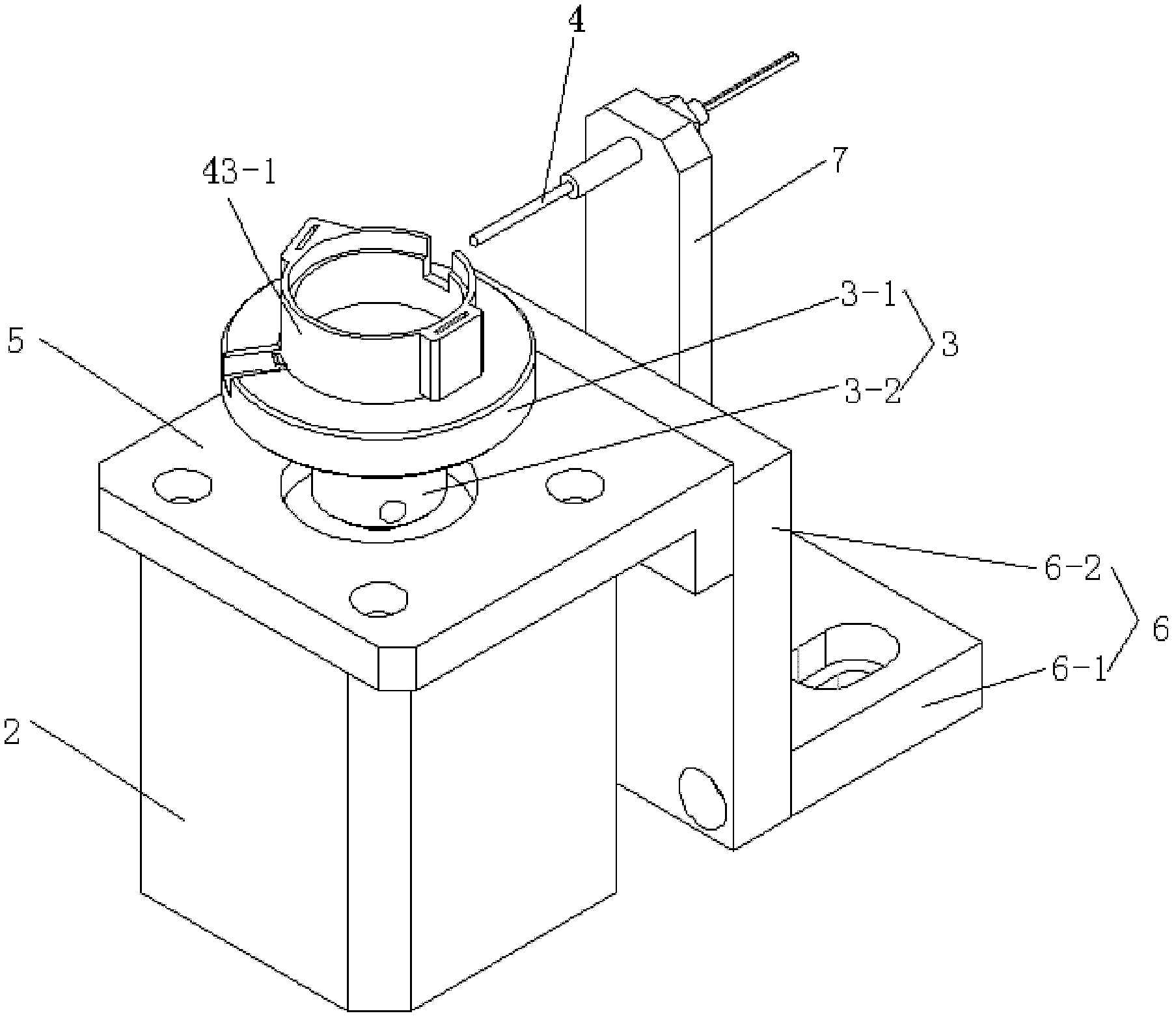

Buzzer placing mechanism

ActiveCN102848179ARealize automatic feeding processRealize automatic placementMetal working apparatusProduction lineIndustrial engineering

The invention discloses a buzzer placing mechanism. The buzzer placing mechanism comprises an automatic feeding device and a carrying device which are fixed on a working table; a buzzer is placed on the automatic feeding device; and the carrying device absorbs the buzzer and places the buzzer in a buzzer housing. The buzzer is placed on the automatic feeding device, and the carrying device absorbs the buzzer and places the buzzer in the buzzer housing, so that the buzzer is automatically fed and placed; and the buzzer placing mechanism can be a part of an automatic buzzer assembly production line, thereby saving labor and improving working efficiency and product quality.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

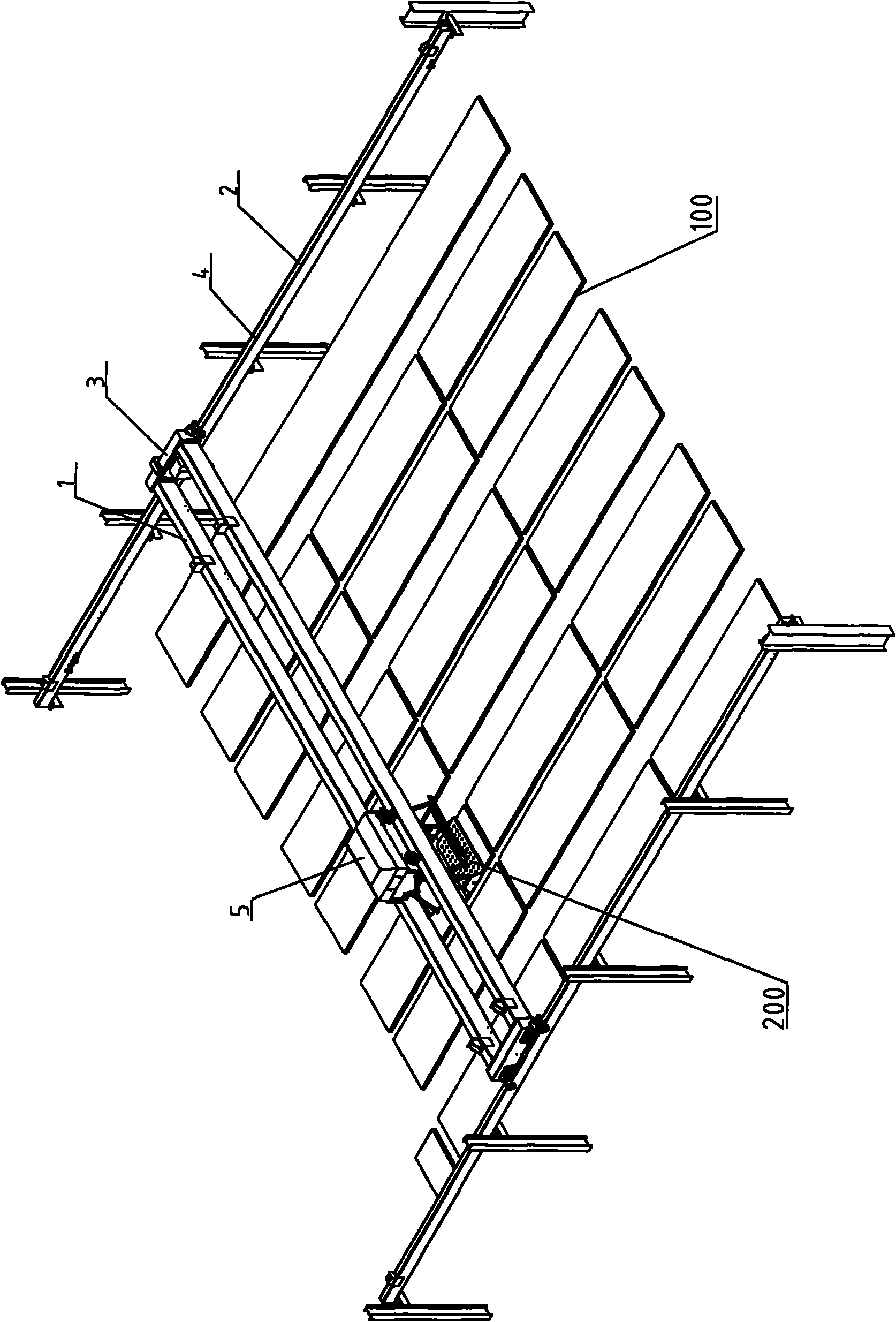

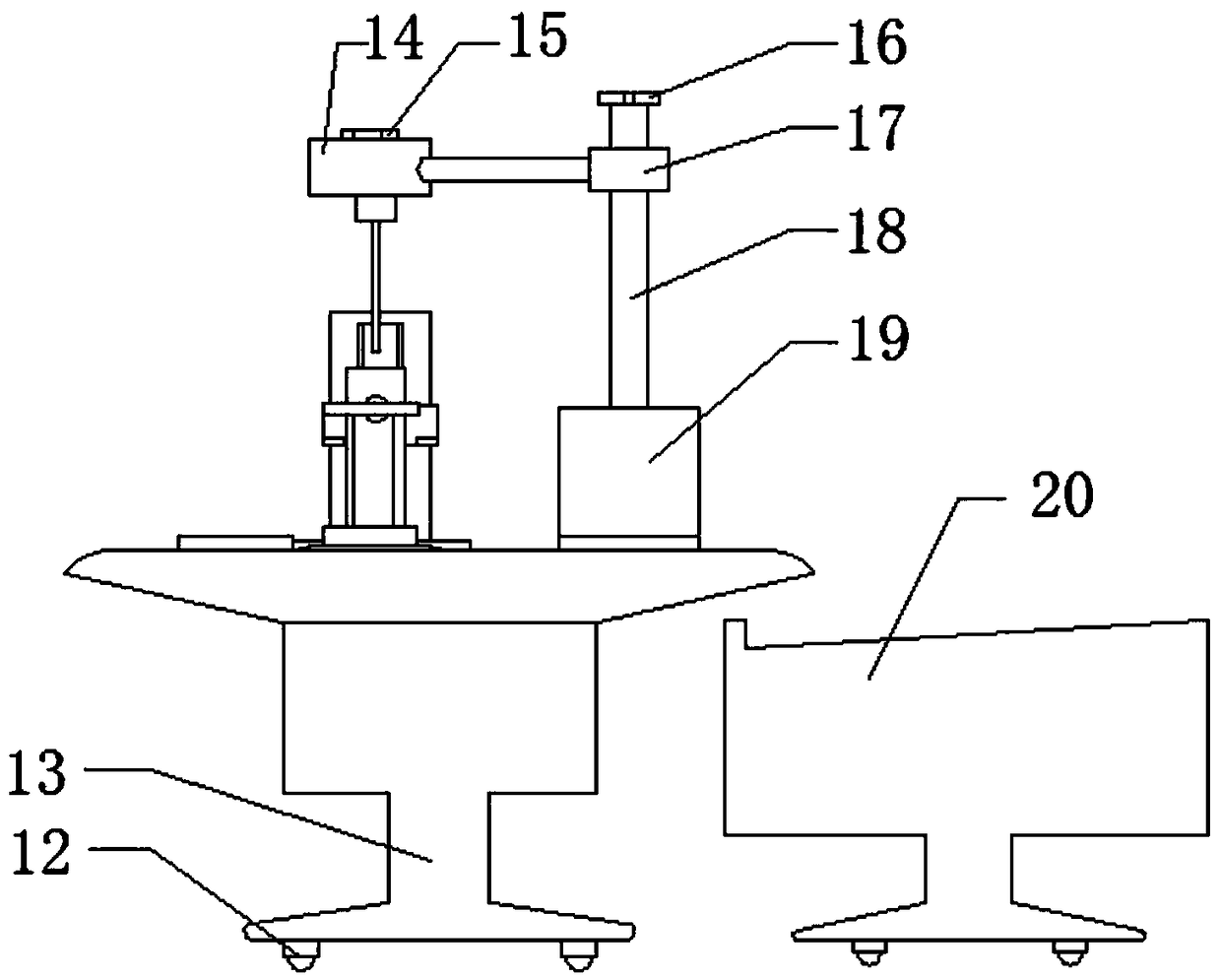

Method and device of automatically paving wall body mosaic pattern by utilizing small tiles

InactiveCN106760436AGuaranteed placement quality standardsImprove placement efficiencyOrnamental structuresBuilding constructionsCement slurryControl mode

The invention discloses a method and device of automatically paving wall body mosaic pattern by utilizing small tiles. The device comprises a moving roller, a base plate, a laser distance measuring positioning indicator, an eccentric vibration pneumatic sucking disc, an X-axis motion platform, a large power stepping motor, a cement slurry sprayer, a tooth form synchronous belt, an upright, a beam slide table, a tile sorting feeder, a hand-hold box controller, a human-computer interface, a Z-axis motion platform, a mechanical arm, a double-shaft air cylinder and a clamp; a mechanical arm base is installed on the Z-axis motion platform, the mechanical arm is installed on the mechanical arm base, and the clamp is installed on the double-shaft air cylinder; the laser distance measuring positioning indicator, the eccentric vibration pneumatic sucking disc, the tile sorting feeder and the cement slurry sprayer are stored on the base plate side by side, and option keys of a manual control mode and a procedure control mode are installed on the hand-hold box controller. Compared with traditional manual tile paving, the method and device of automatically paving the wall body mosaic pattern by utilizing the small tiles has the effects that paving efficiency is high, the labor intensity is reduced, and labor cost is remarkably reduced.

Owner:XUCHANG UNIV

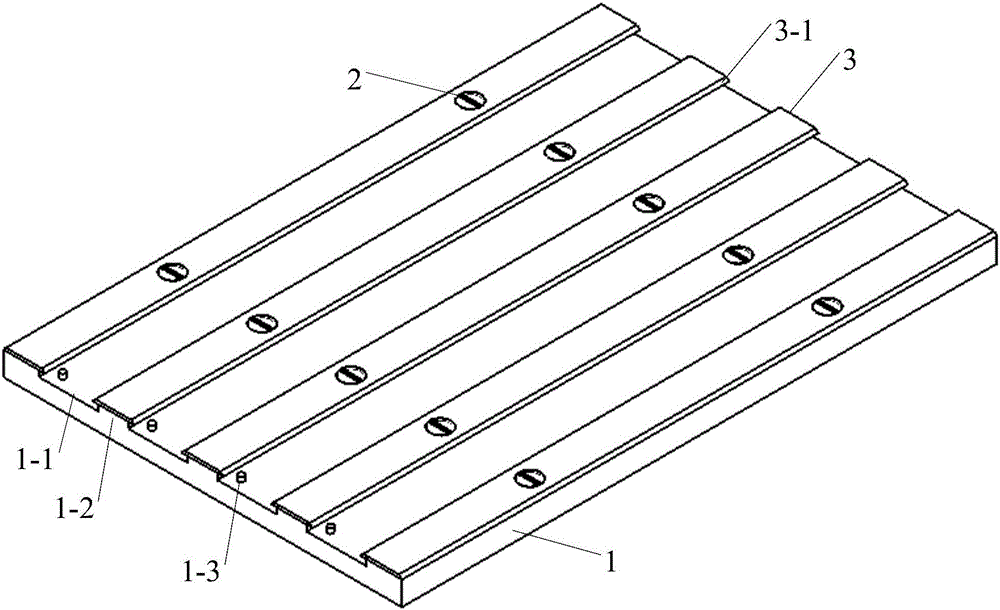

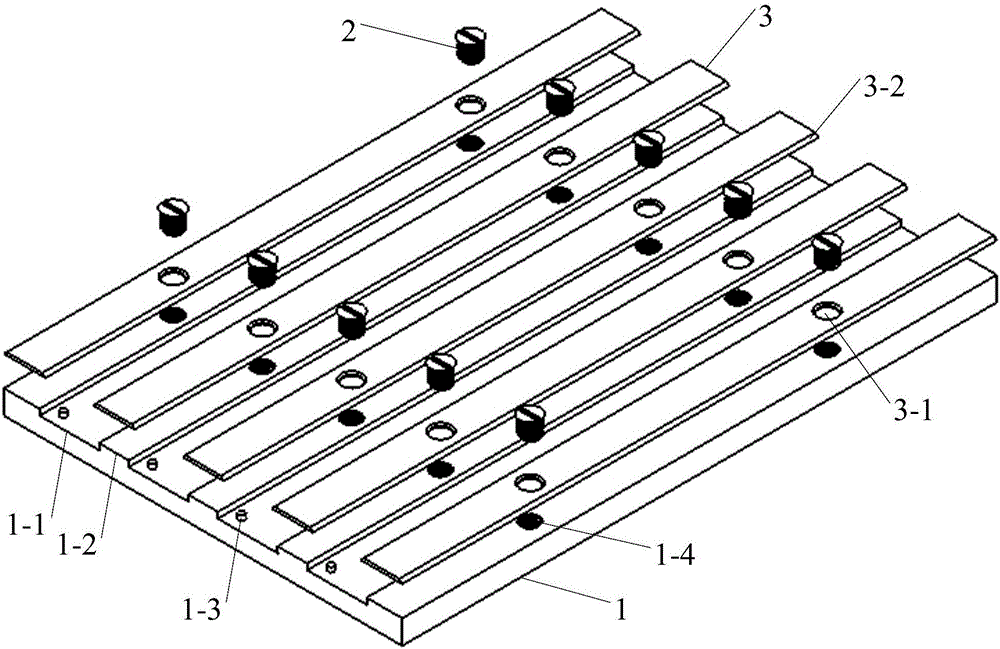

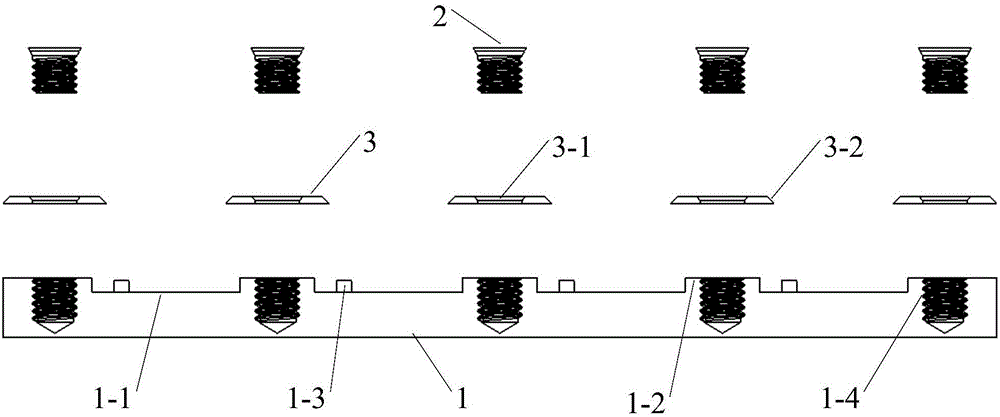

Auto-mounting tray for scattered or short-taped devices

InactiveCN106304829AAutomatic placement high speedPick up stableElectrical componentsSurface mountingEngineering

An auto-mounting tray for scattered or short-taped devices relates to the field of electronic assembly and solves the problems that re-taping for existing electronic device screening is time-consuming and labor-consuming with high production cost, post-taping length is too small due to part of the devices using little taping such that mounting requirements of a surface-mounting machine cannot be met, and manual mounting leads to poor mounting precision; the auto-mounting tray comprises a bottom table and an upper press plate, the bottom table is of equally-spaced groove array structure and comprises tape receiving grooves, terraces and tape positioning pins, the tape receiving grooves are used for holding device tapes, the tape positioning pins are used for positioning the device tapes, and the upper press plate is fixed to positioning holes of the terraces through fastening screws so as to fix the device tapes. The bottom table and the upper press plate enable device tapes to be reused, the scattered devices are arrayed, quick and stable pickup of suction nozzles is guaranteed, auxiliary cost is reduced, and assembly accuracy is improved; the auto-mounting tray is simple in structure, easy to operate and convenient for an operator to use.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

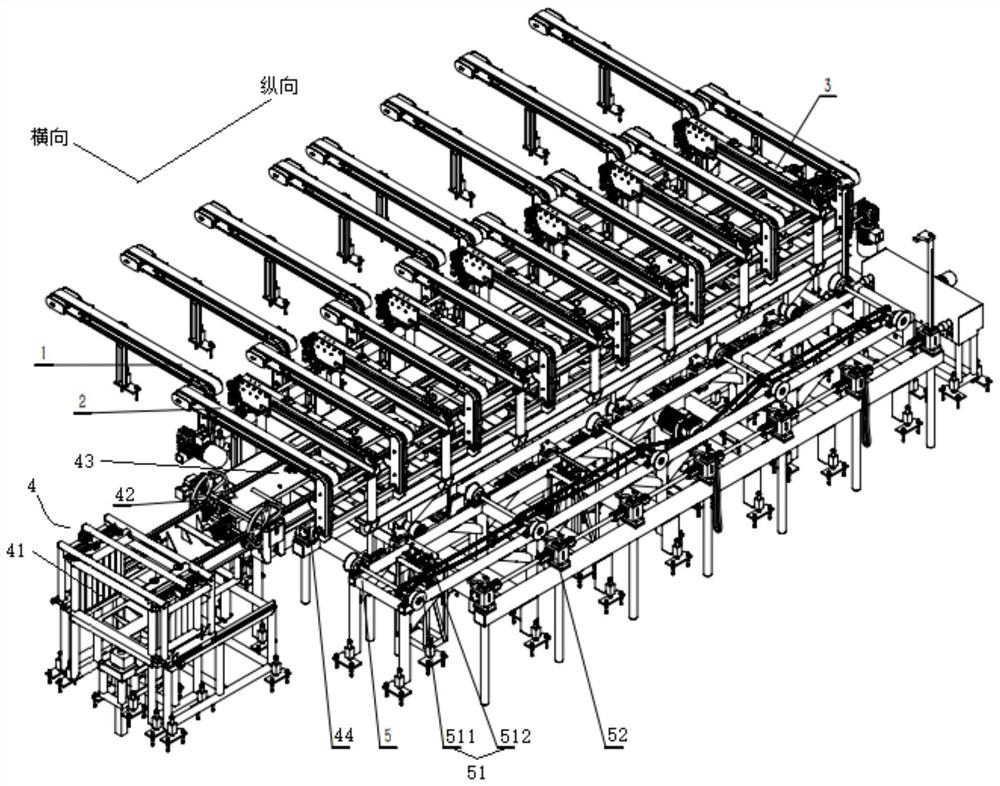

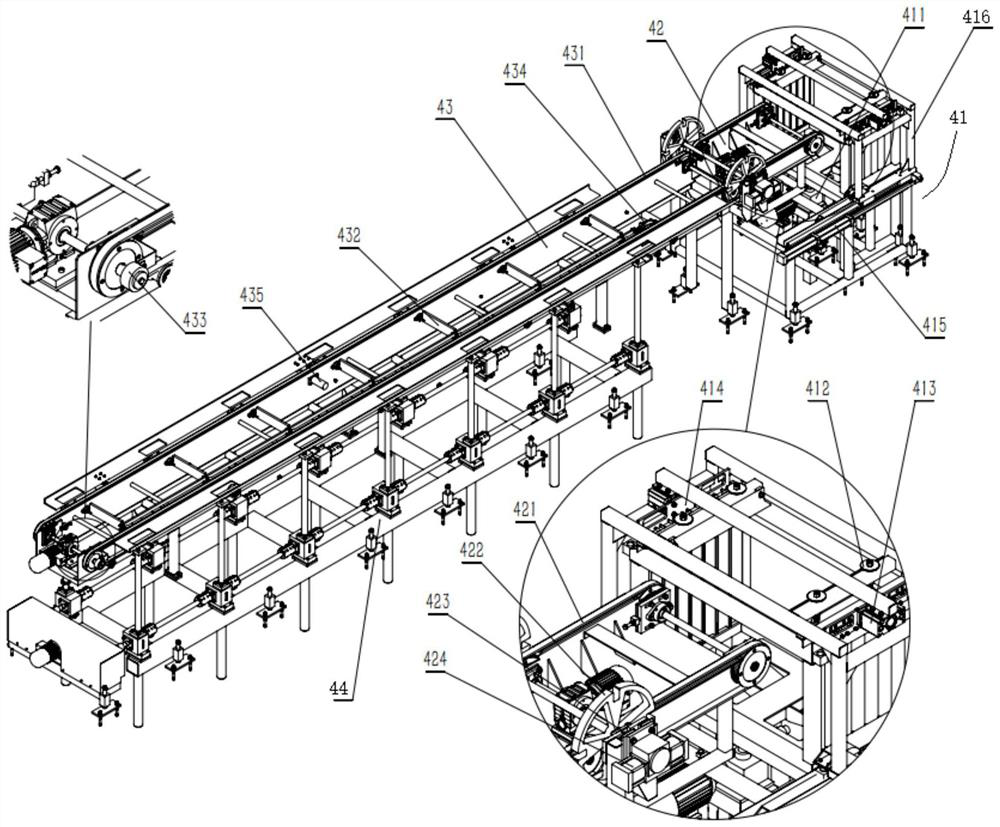

Automatic framing machine for aluminum profiles

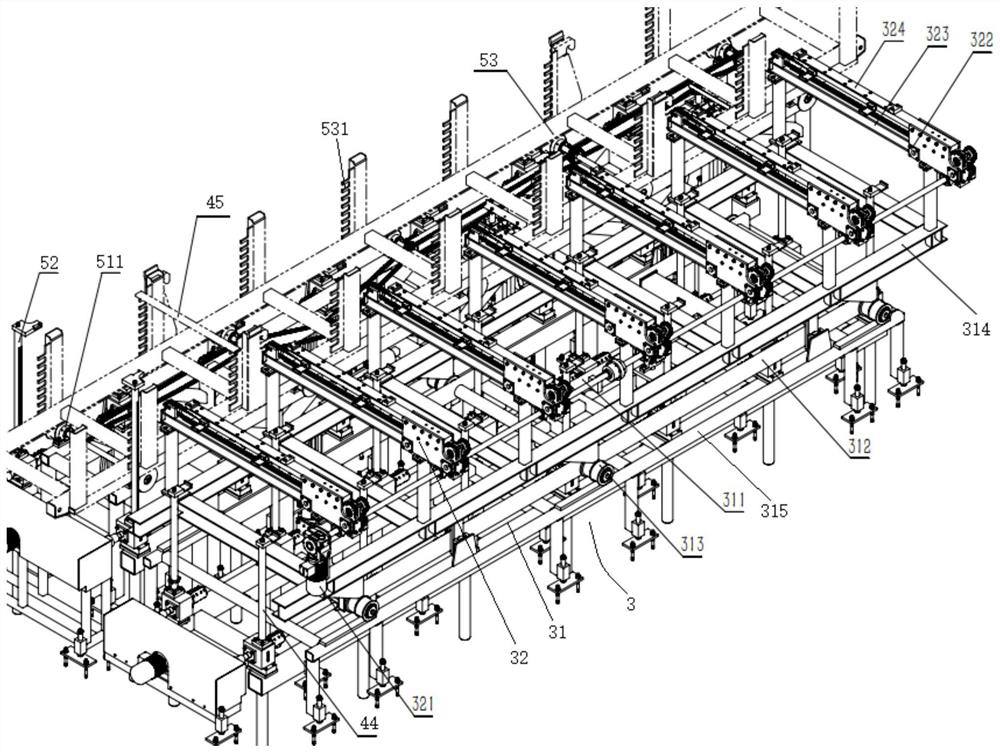

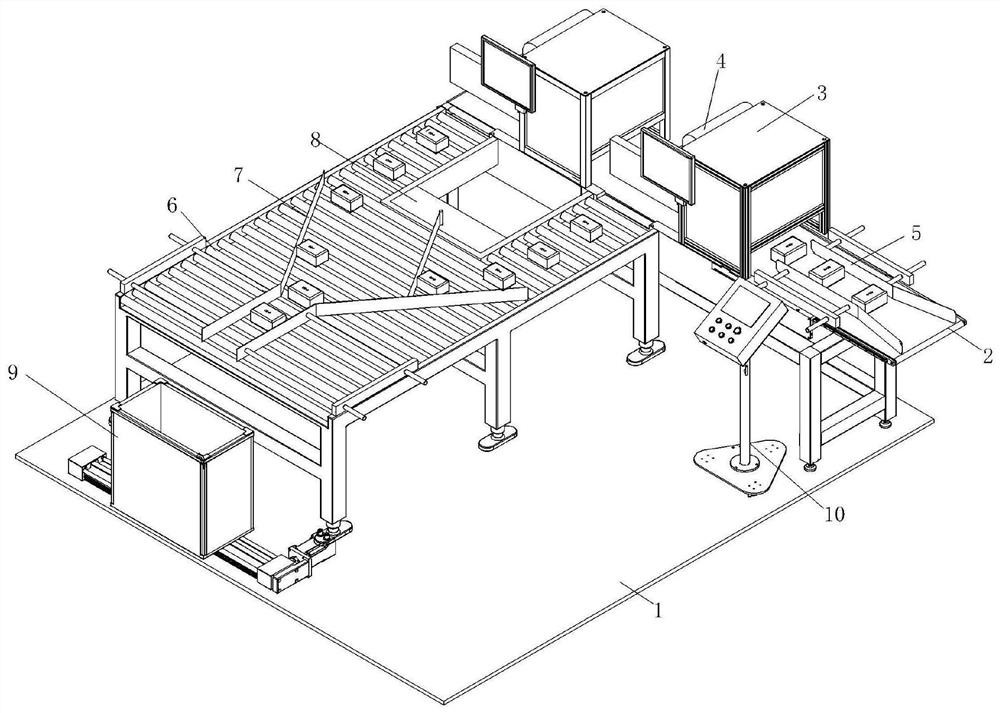

ActiveCN112520378ARealize automatic allocationAchieve positioningConveyor partsEngineeringMechanical engineering

The invention relates to an automatic framing machine for aluminum profiles, and belongs to the field of automatic equipment. The machine comprises a profile conveying device, a carrying device arranged below the profile conveying device, a parting stop conveying device arranged below the carrying device, and a material frame conveying device arranged on one side in the transverse direction of thecarrying device. The parting stop conveying device comprises a parting stop picking mechanism, a parting stop distribution mechanism, a parting stop positioning and conveying mechanism and first lifters which are sequentially arranged in the longitudinal direction, wherein the parting stop positioning and conveying mechanism is divided into a plurality of positioning points distributed at intervals in the longitudinal direction, and the first lifters correspond to the positioning points and are arranged on two sides in the transverse direction of the parting stop positioning and conveying mechanism. A plurality of parting stops conveyed by the parting stop picking mechanism are correspondingly conveyed to the positioning points of the parting stop positioning and conveying mechanism through the parting stop distribution mechanism, and automatic distribution and positioning of the parting stops are achieved. The parting stops at the positioning points are supported and conveyed to thecarrying device through the first lifters to be stacked with the aluminum profiles, conveyed by the profile conveying device, on the carrying device, automatic placement of the parting stops is achieved, the efficiency is improved, and the labor cost is reduced.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

Outer package detection device for pharmaceutical production line

The invention discloses an outer package detection device for a pharmaceutical production line. The outer package detection device comprises a base, an electric conveying belt, appearance detection devices, a sorting mechanism, a first limiting blocking groove, a Y-shaped electric conveying belt, a second limiting blocking groove, an intermittent discharging mechanism, a storage mechanism and a controller; the two appearance detection devices are arranged on the left side and the right side of the top end of the electric conveying belt; the storage mechanism is arranged at the top end of the base in the left-right direction and is located on the front side of the Y-shaped electric conveying belt; and the controller is installed at the top end of the base through a support in the vertical direction and is located in front of the right part of the electric conveying belt. According to the outer package detection device for the pharmaceutical production line, secondary appearance detection can be performed on outer packages of medicines, the phenomenon of false detection is avoided for product appearance detection, the workload and the processing cost of subsequent detection personnelare reduced, automatic placement of detected products can be realized, manual operation items of workers are reduced, and time and labor are saved.

Owner:钱万顺

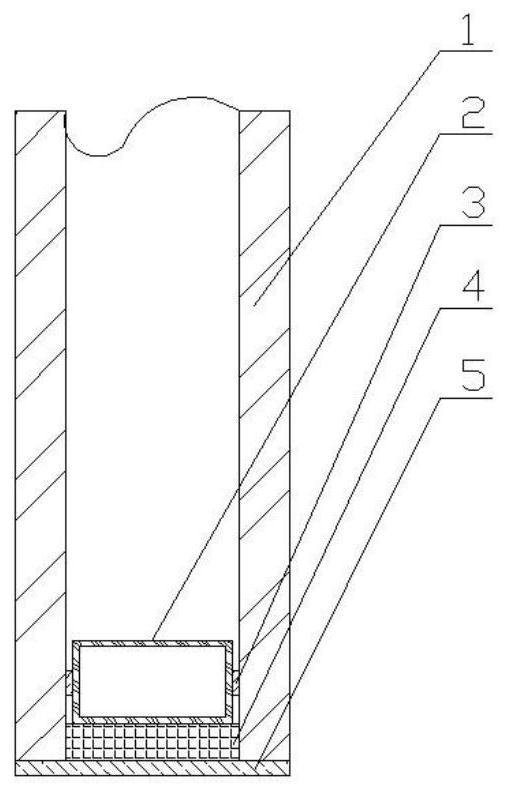

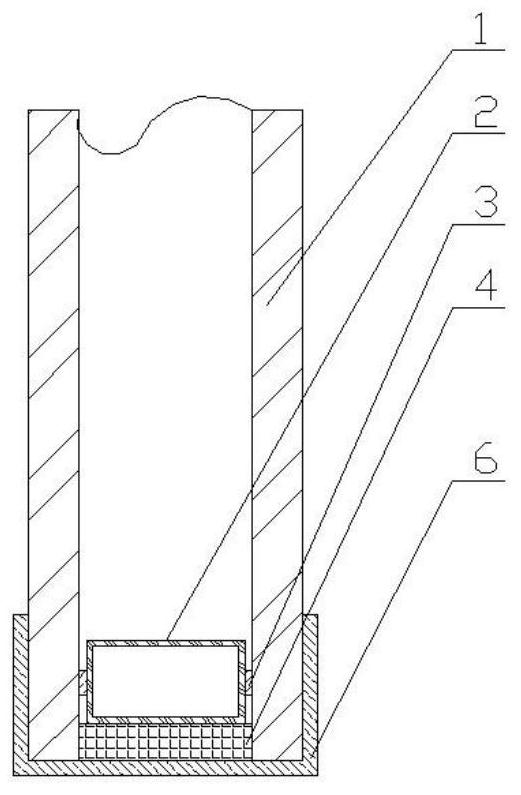

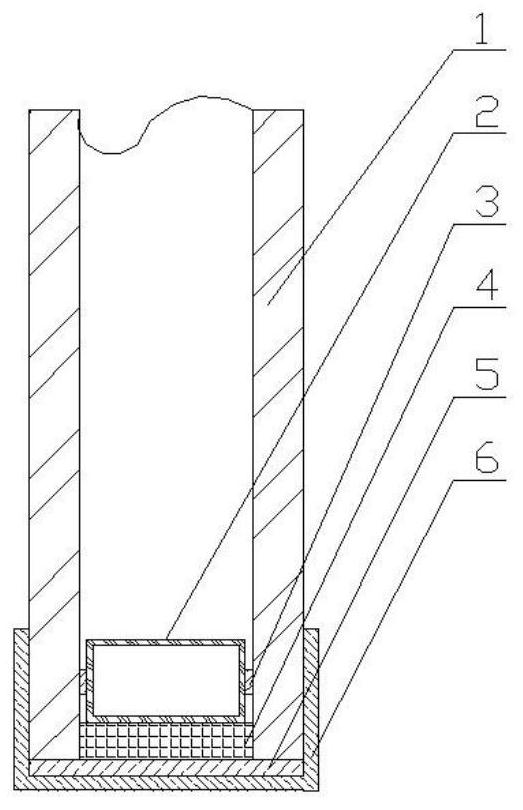

Negative-pressure hollow glass, manufacturing method and application

PendingCN112431519AEliminate respirationExtended service lifeConstruction materialWallsMolecular sievePumping vacuum

The invention belongs to the technical field of hollow glass production, and discloses negative-pressure hollow glass, a manufacturing method and application. The negative-pressure hollow glass comprises glass, spacing bars, molecular sieves, supporting materials, sealing layers bonded between the glass and the spacing bars, and sealing layers bonded between the glass and the peripheries of the spacing bars. A hollow layer is vacuumized to be in a negative pressure state, the air pressure of the hollow layer is smaller than the external pressure all the time in the use process of the hollow glass, the breathing phenomenon of the hollow glass is eliminated, an edge sealing structure is not subjected to repeated acting force generated by the breathing phenomenon, and the service life of theedge sealing structure and the service life of the hollow glass can be remarkably prolonged; due to the fact that the supporting materials are arranged in the hollow layer, the glass cannot deform, agood mirror surface effect can be kept all the time, and the appearance of a building is more attractive; and the spacing bars are adopted to replace spacing frames to be directly bonded on the glass,the technological process of manufacturing the spacing frames is omitted, mechanical and automatic production is facilitated, the placement speed is high, and the installation precision is high.

Owner:WEIHAI RUNFENG GLASS

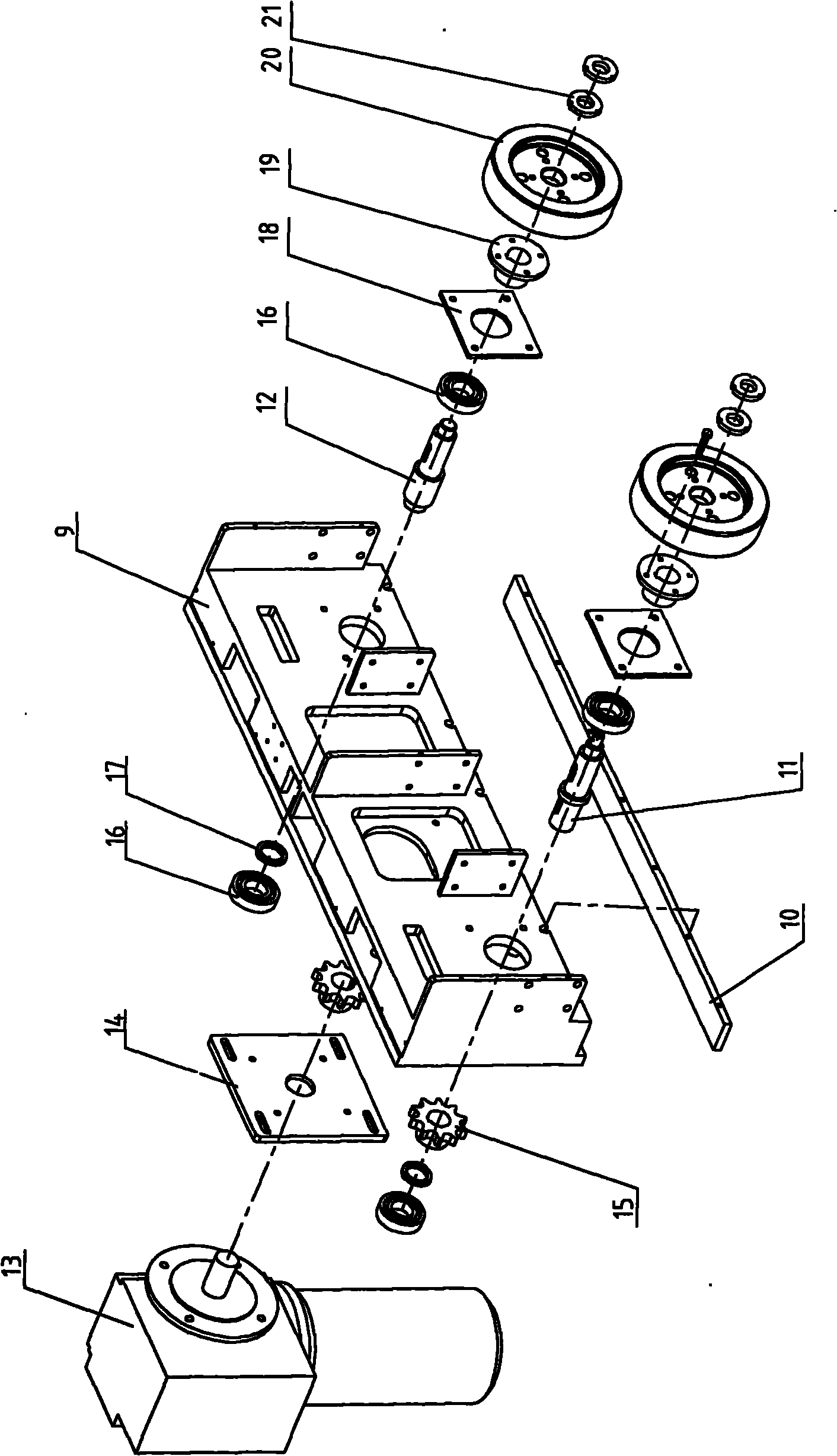

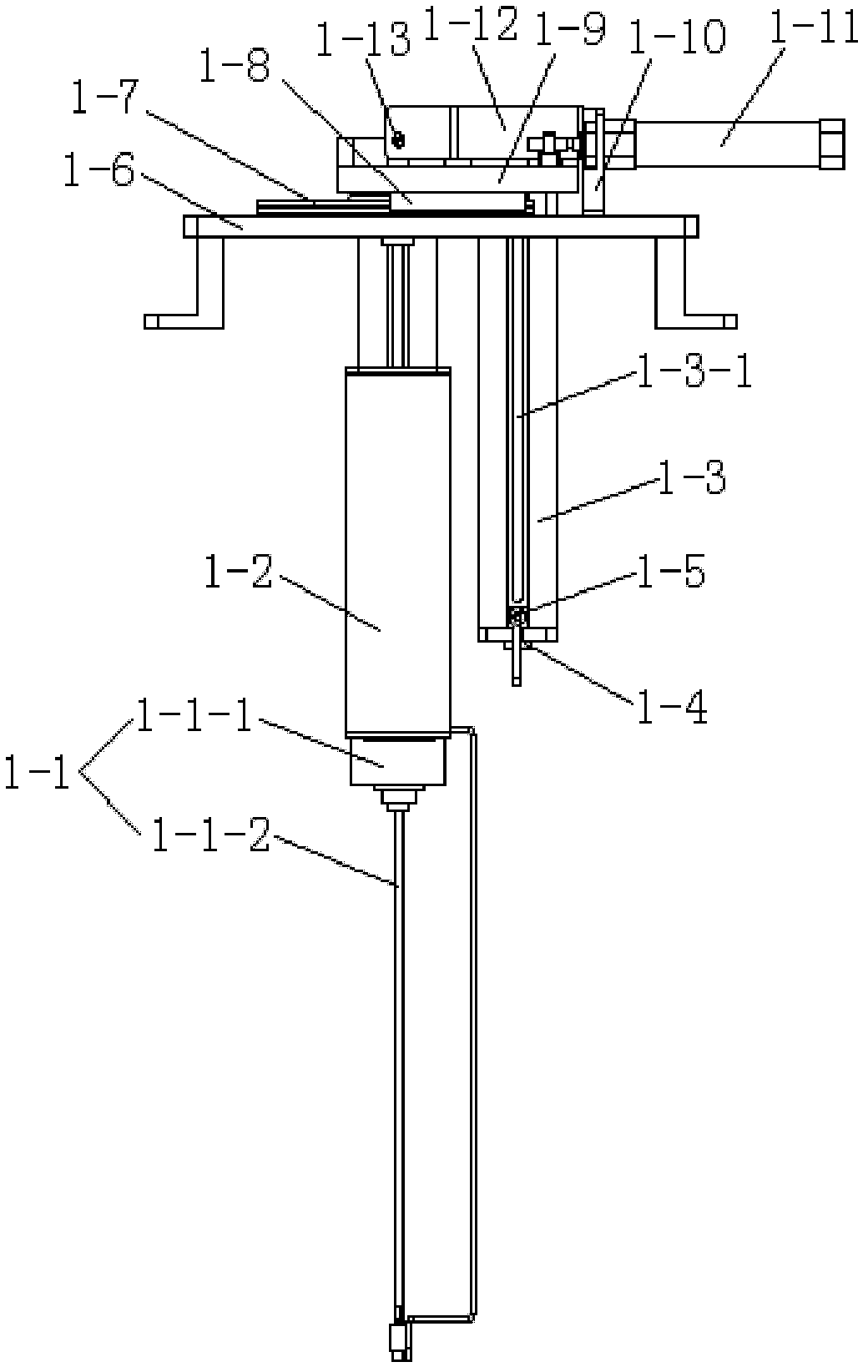

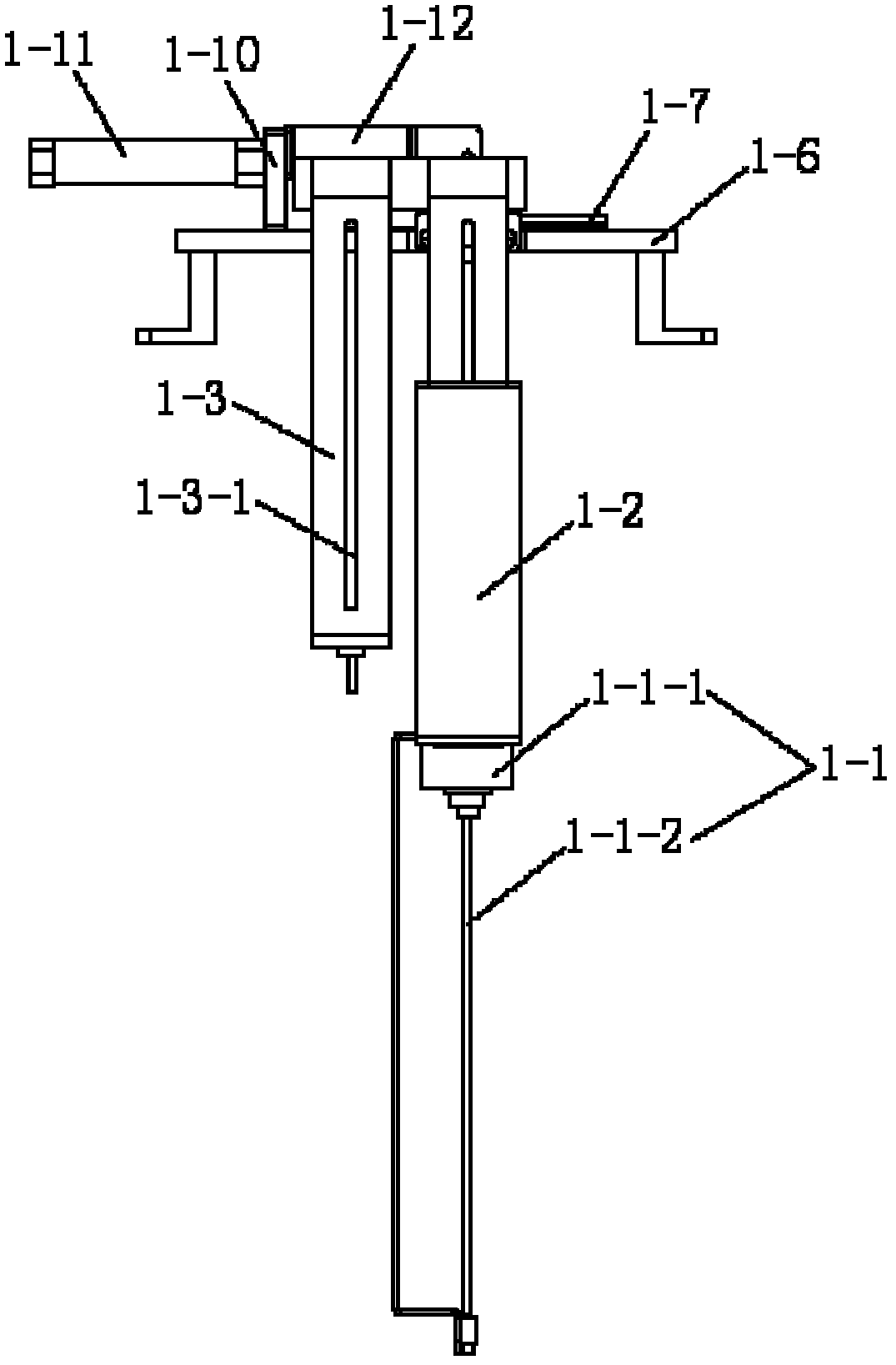

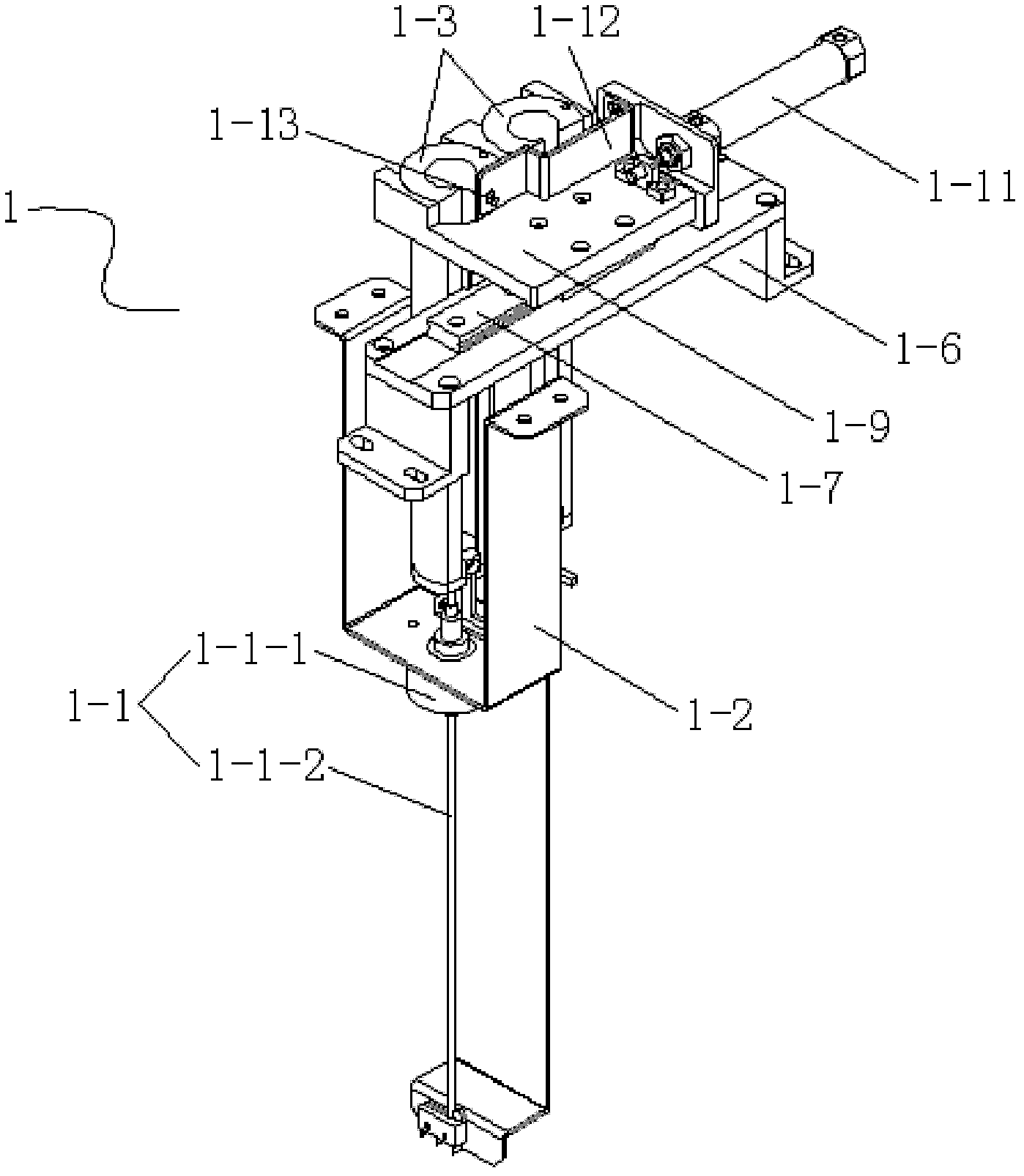

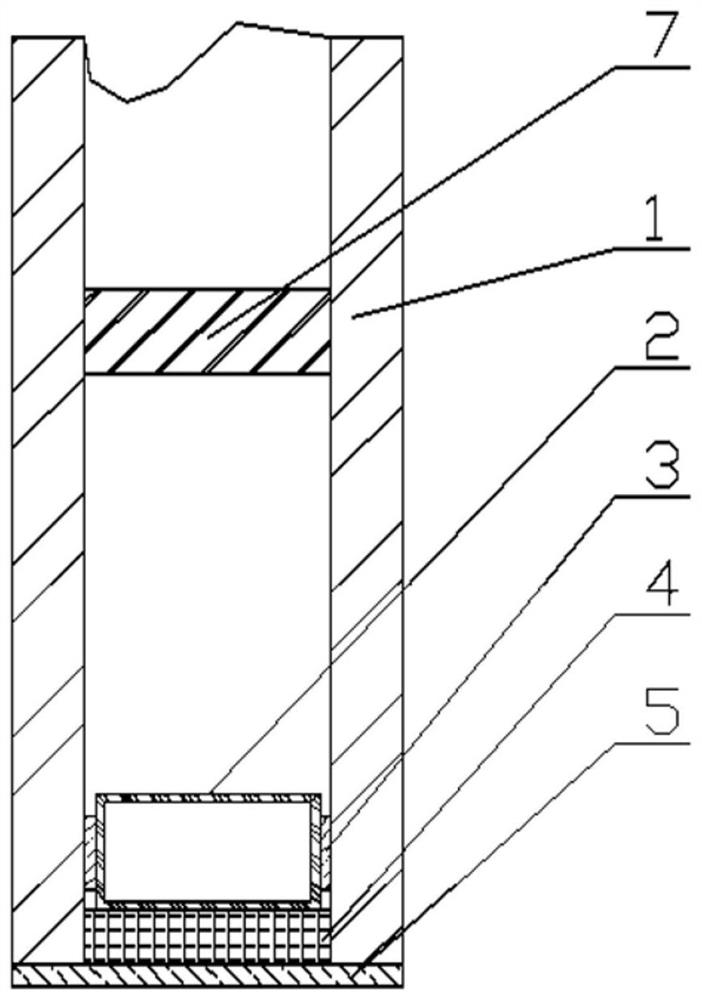

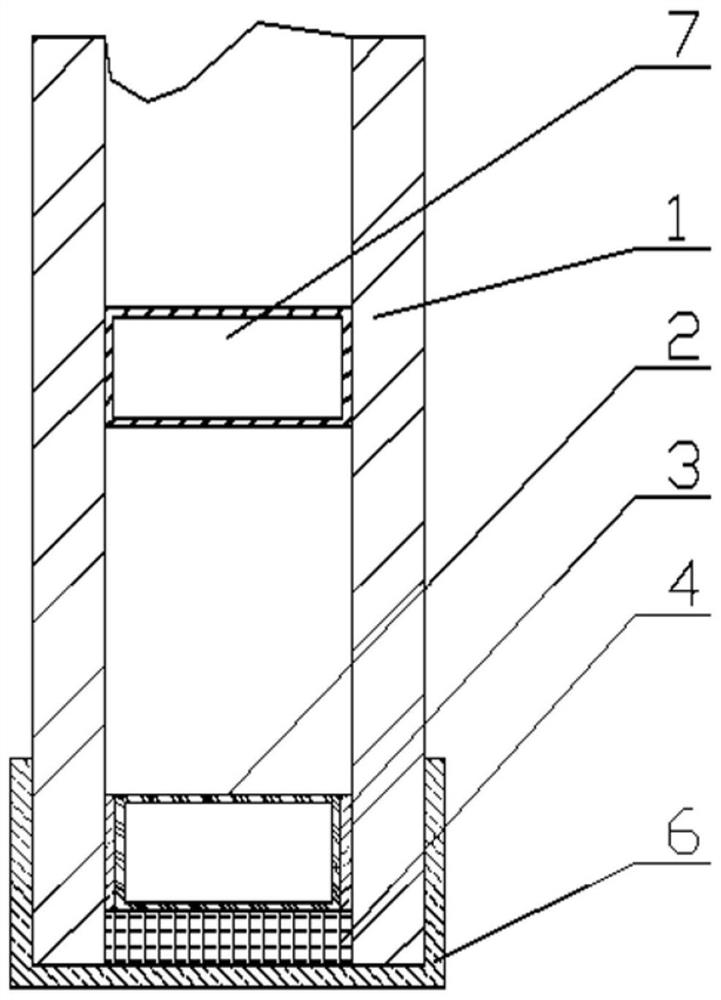

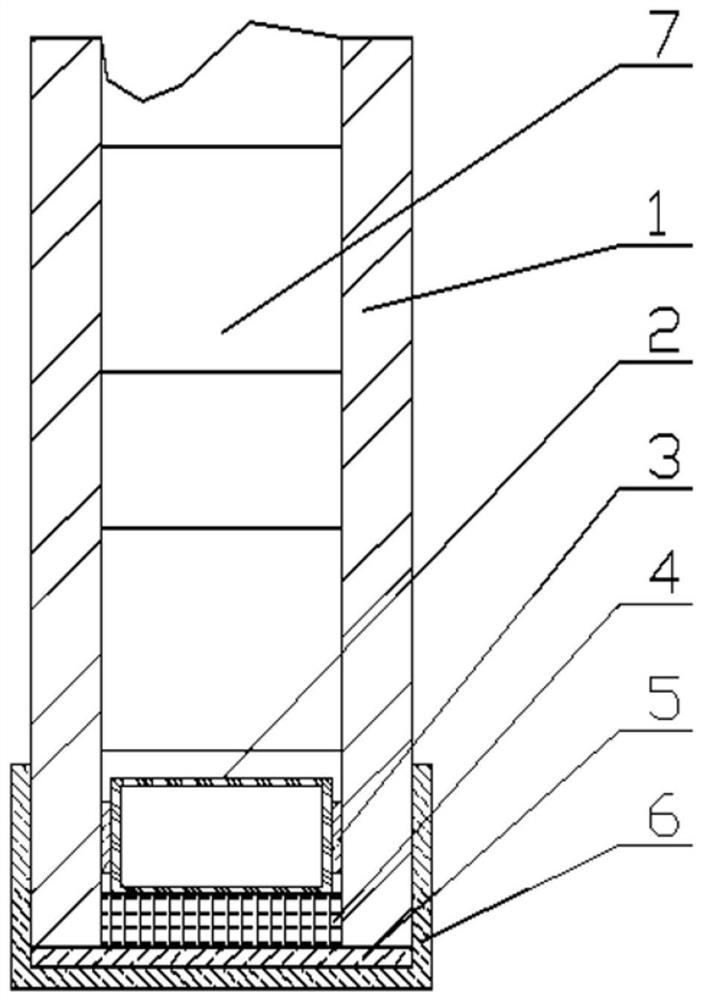

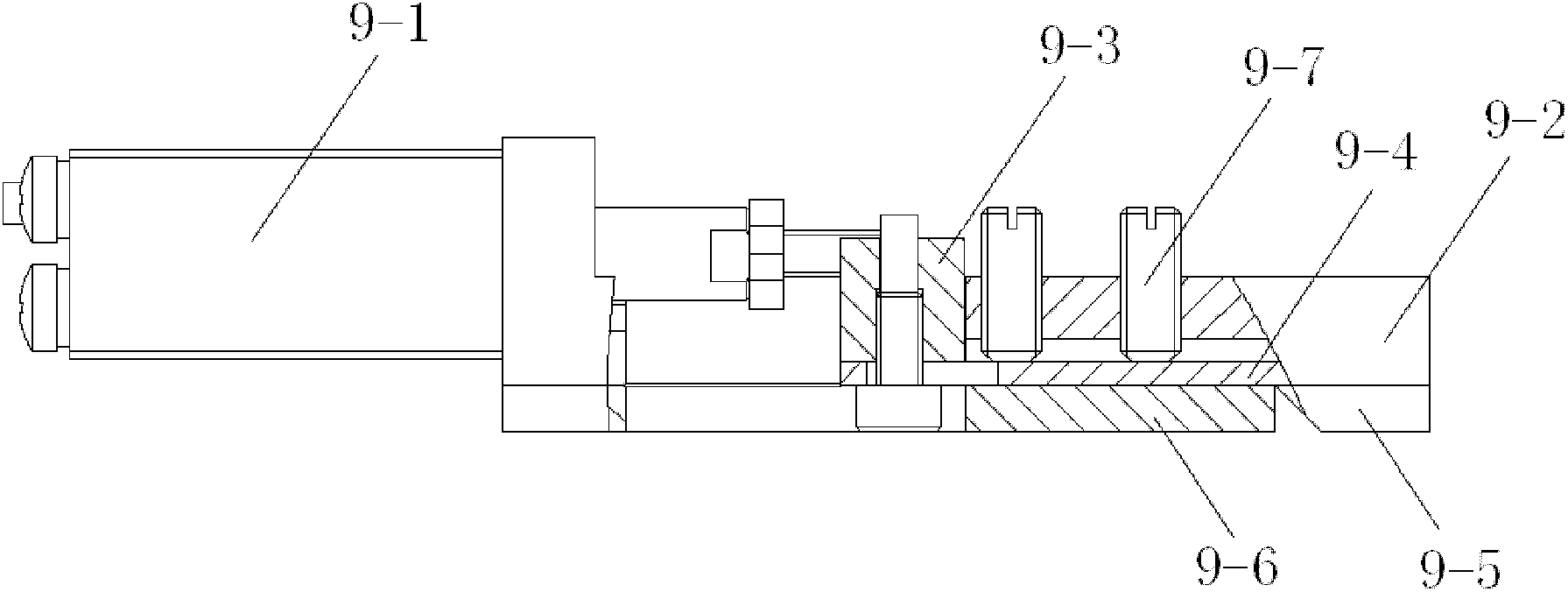

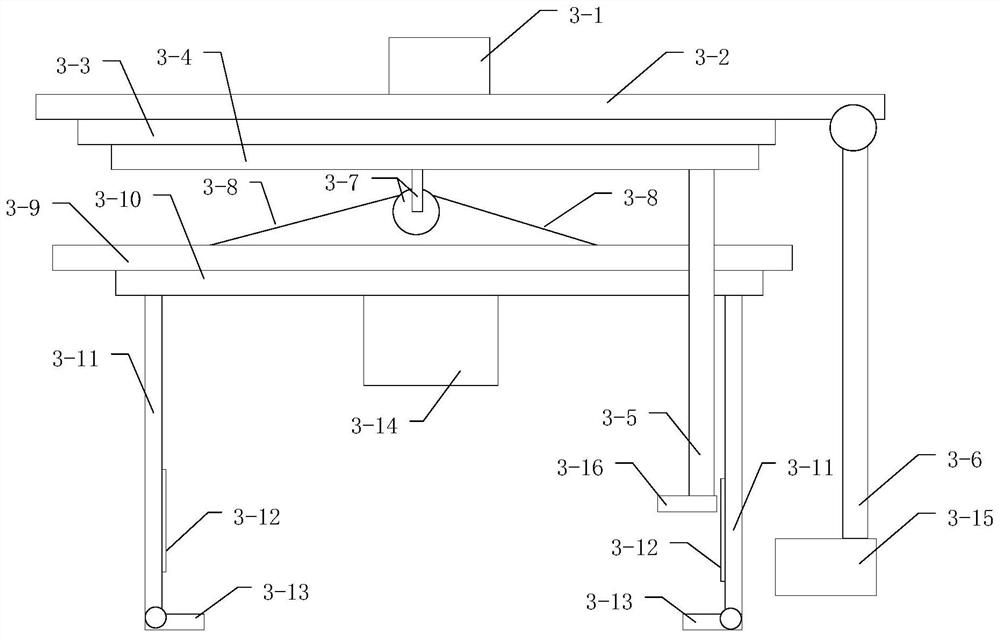

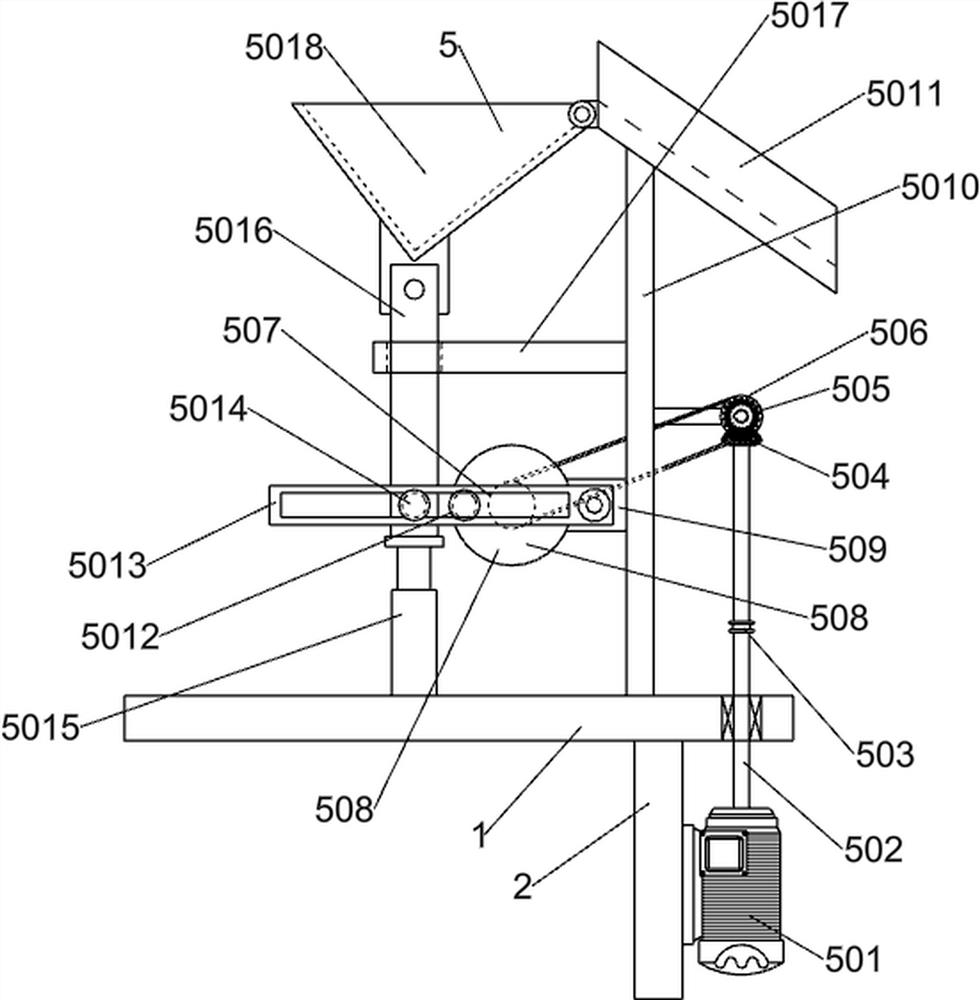

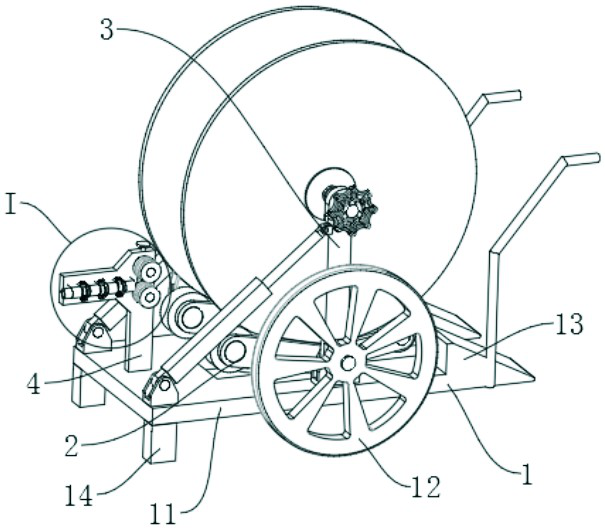

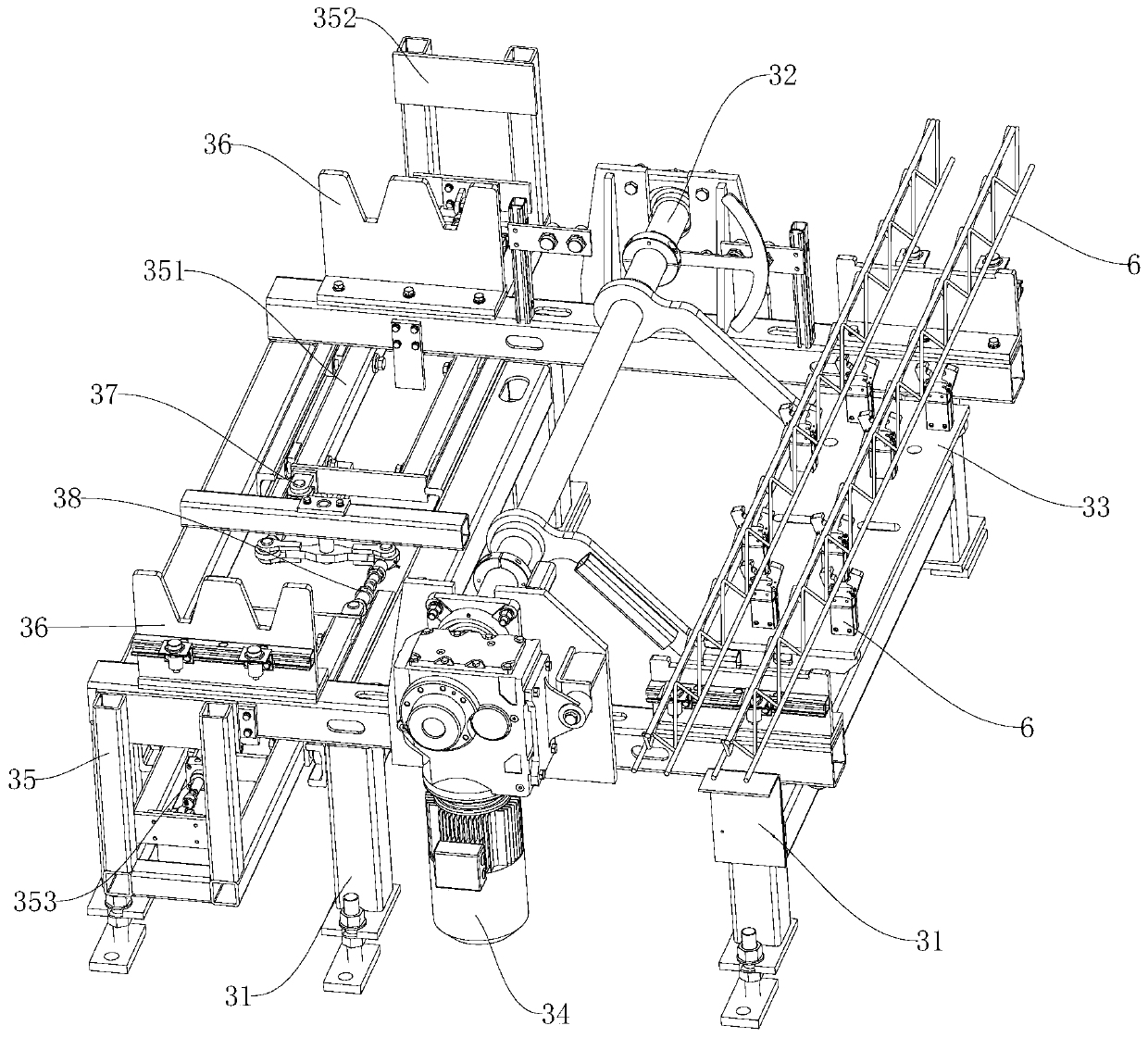

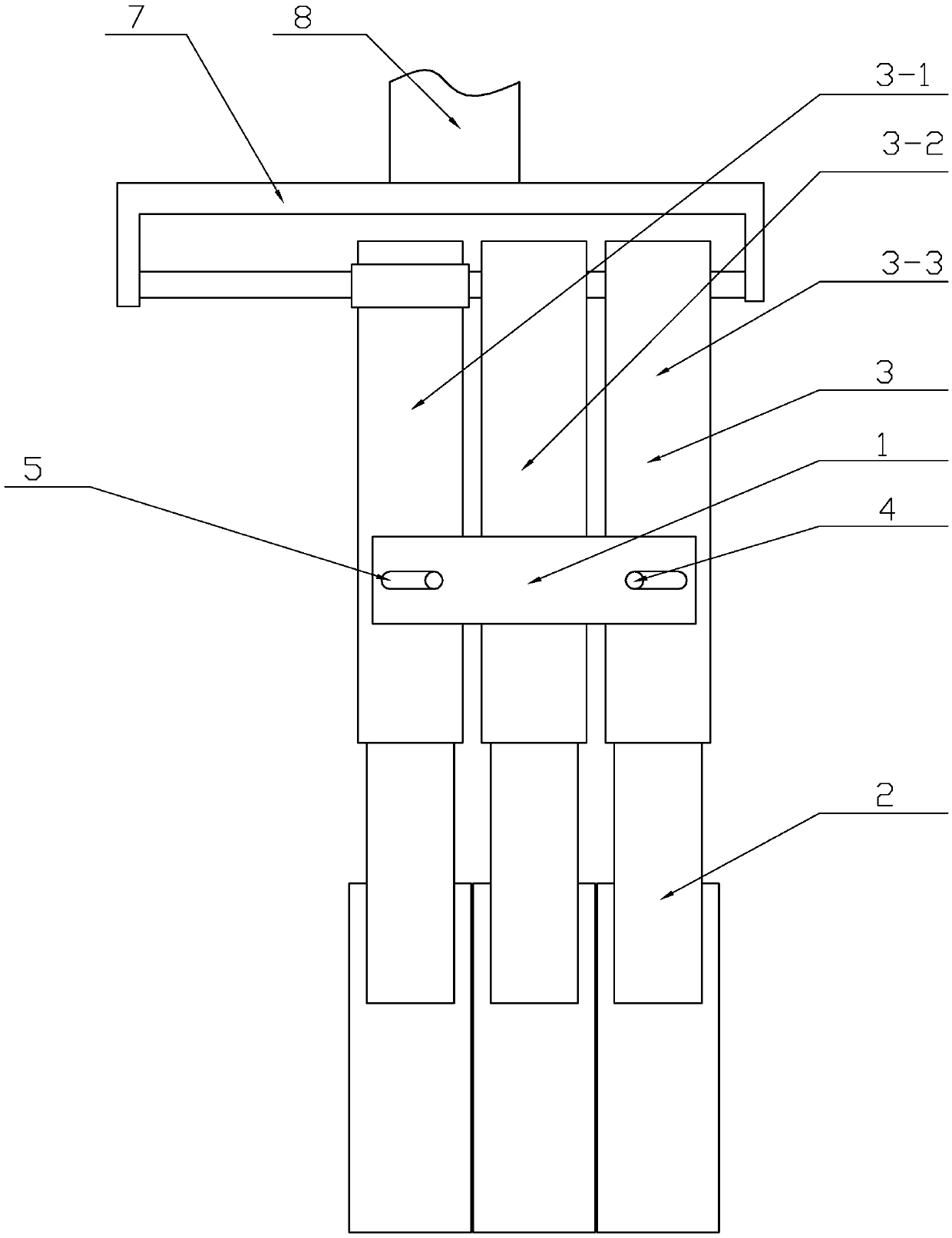

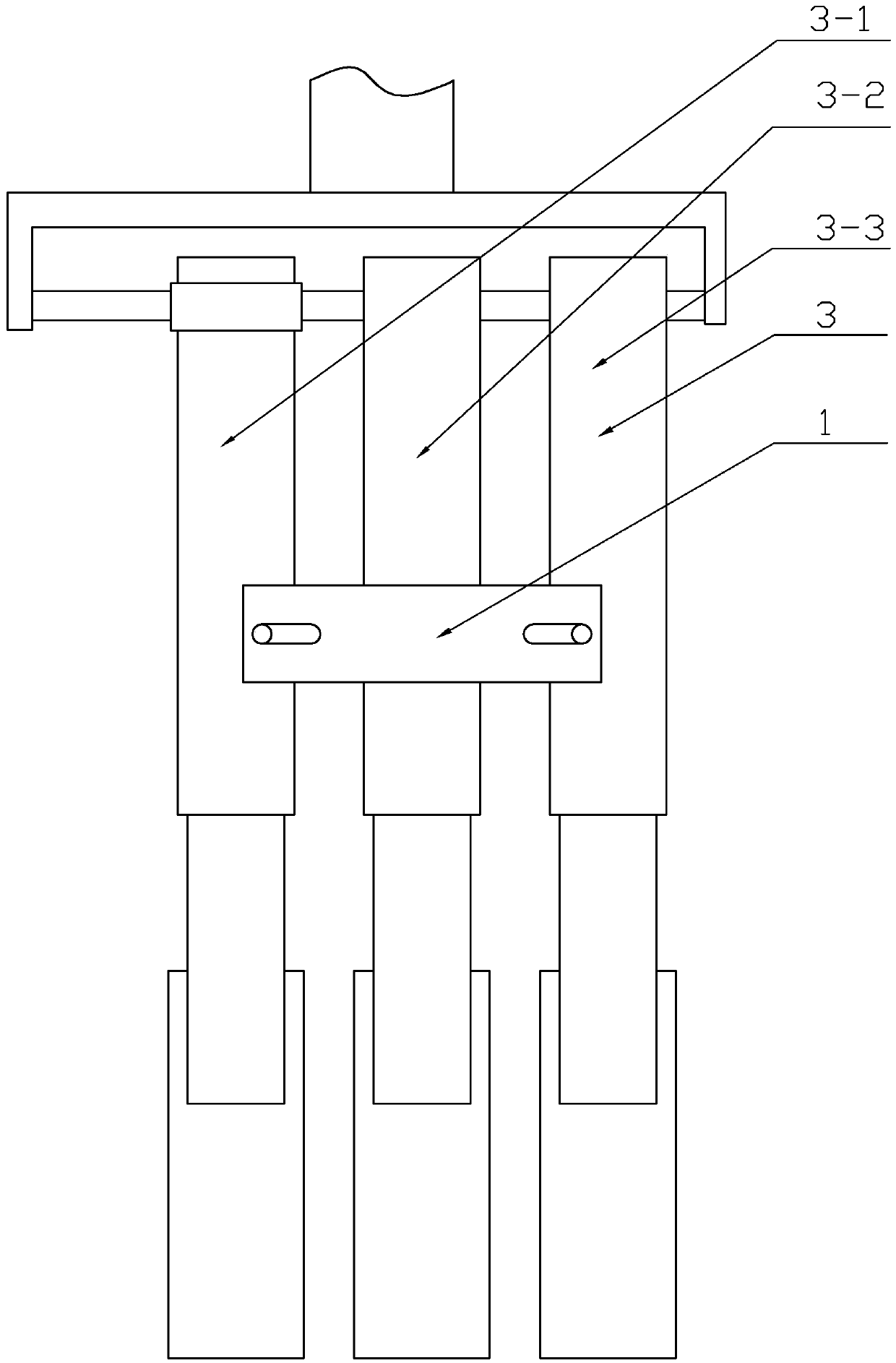

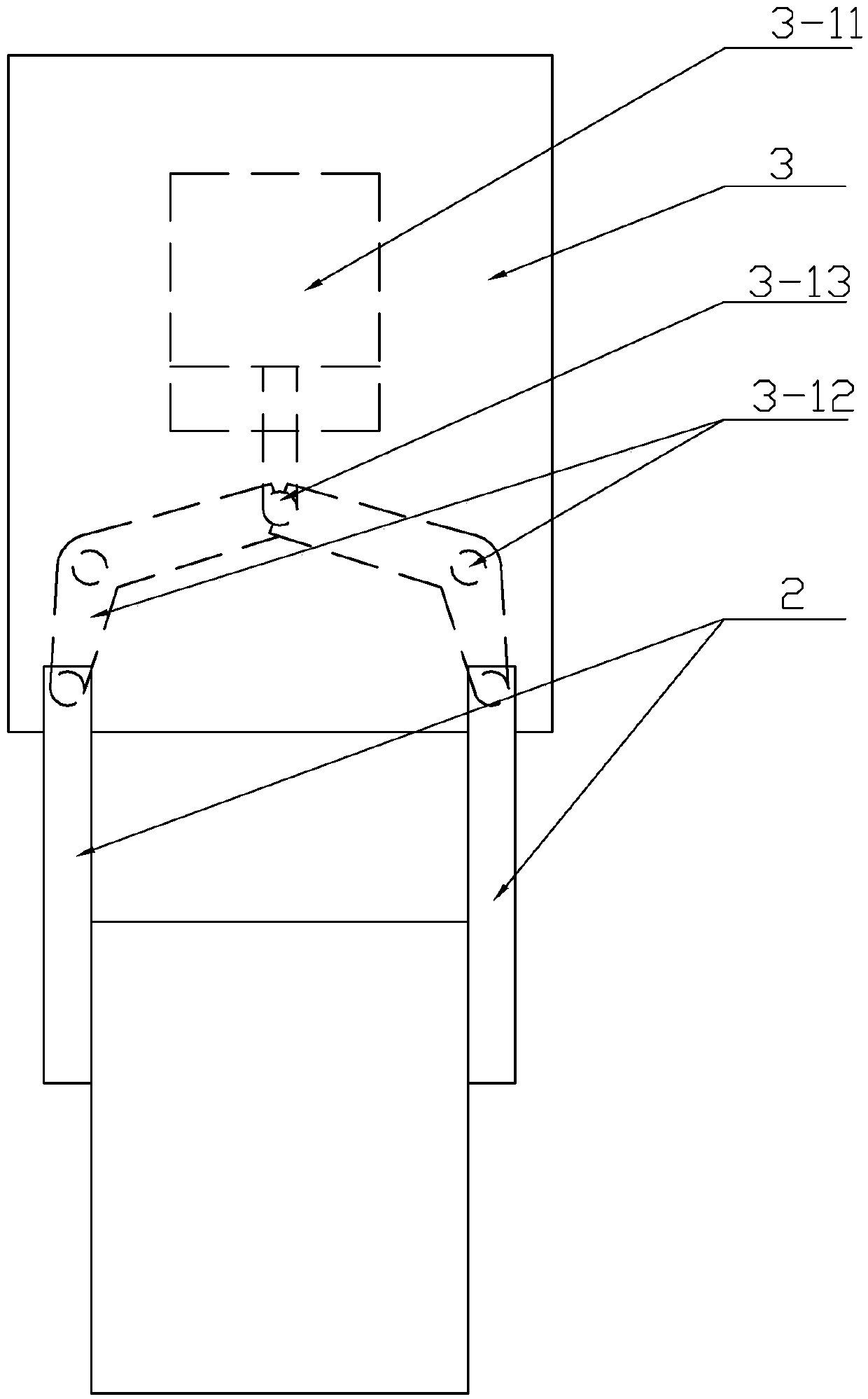

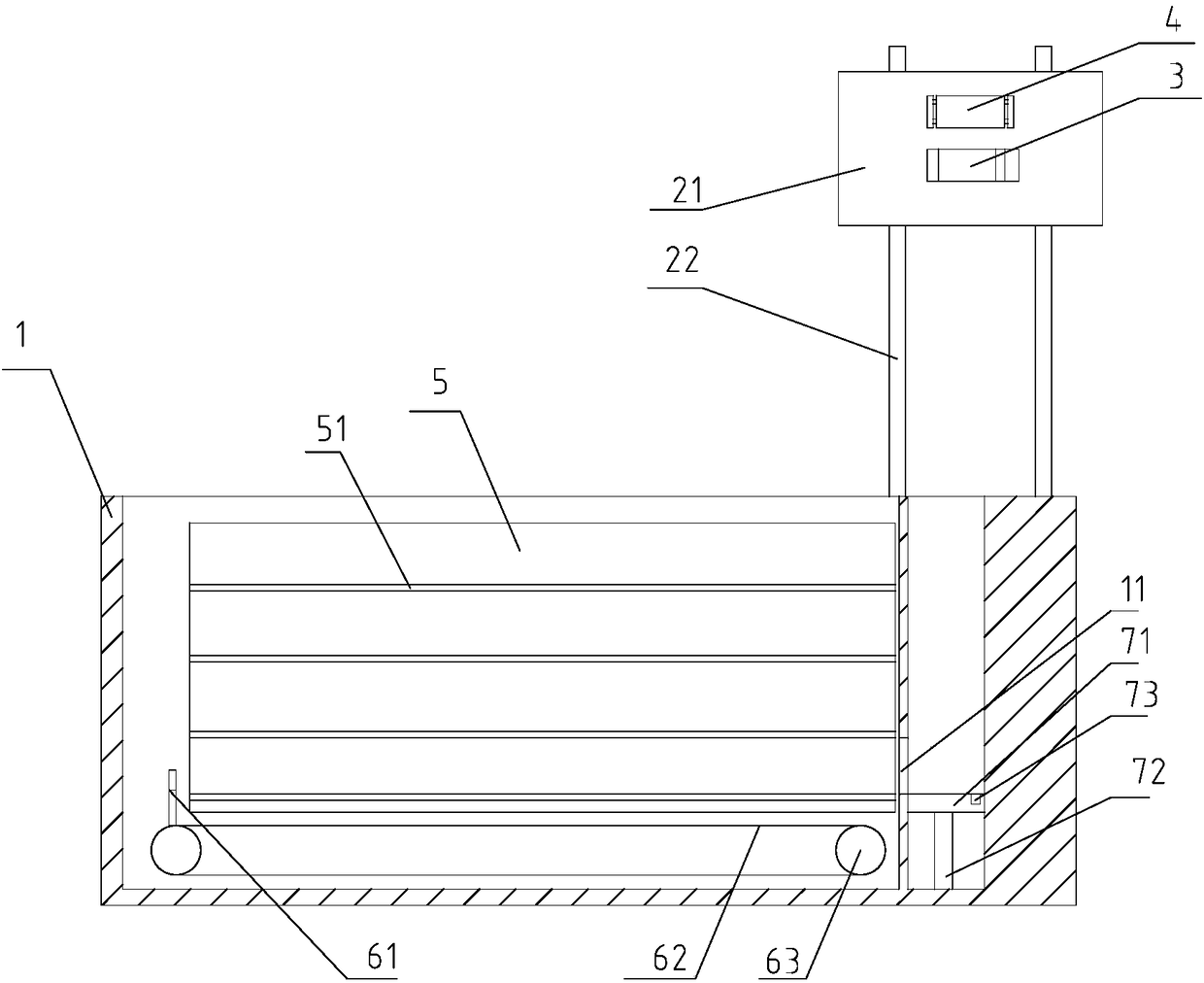

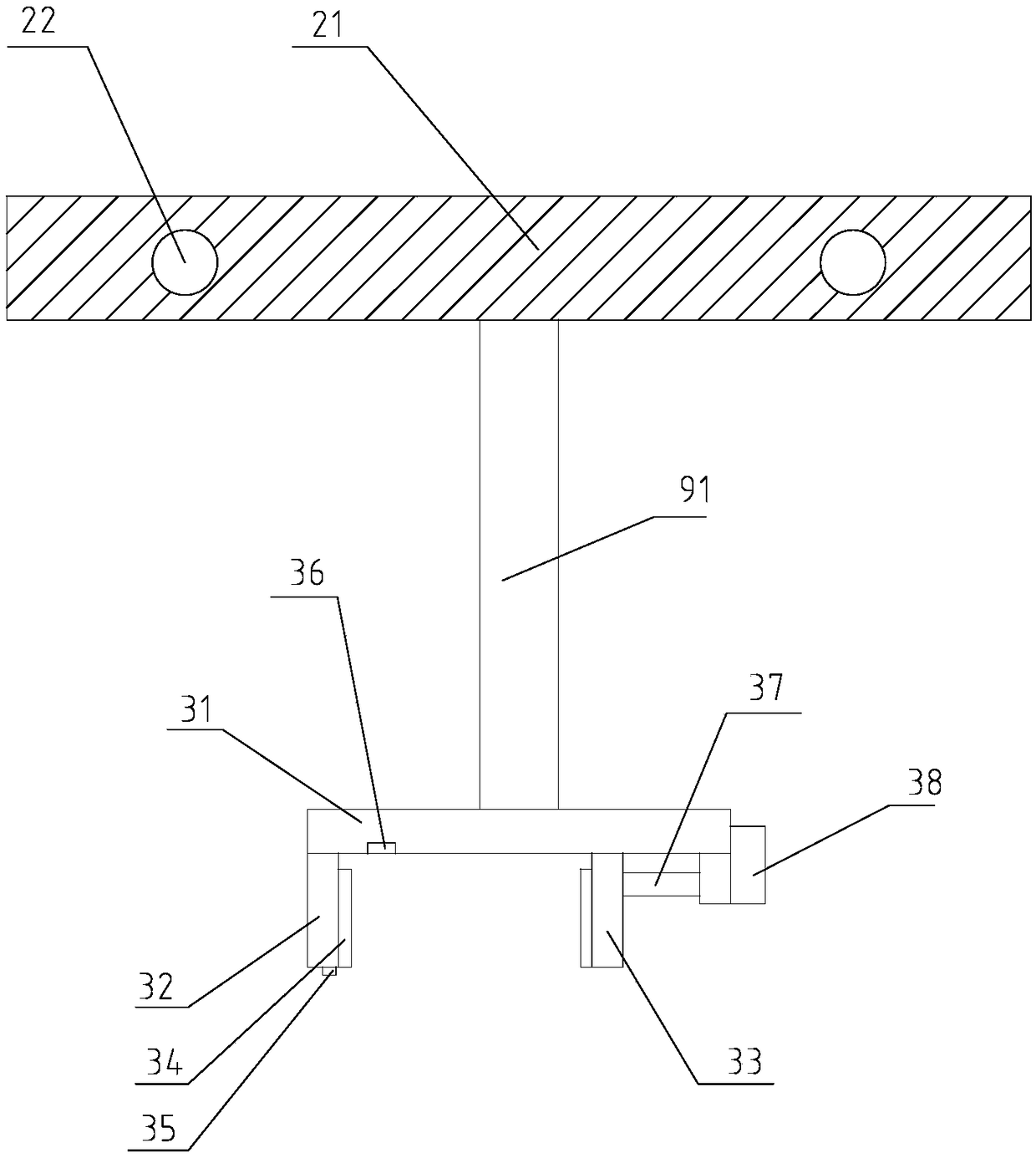

Thermoplastic tube mounting mechanism for automatic buzzer assembly line

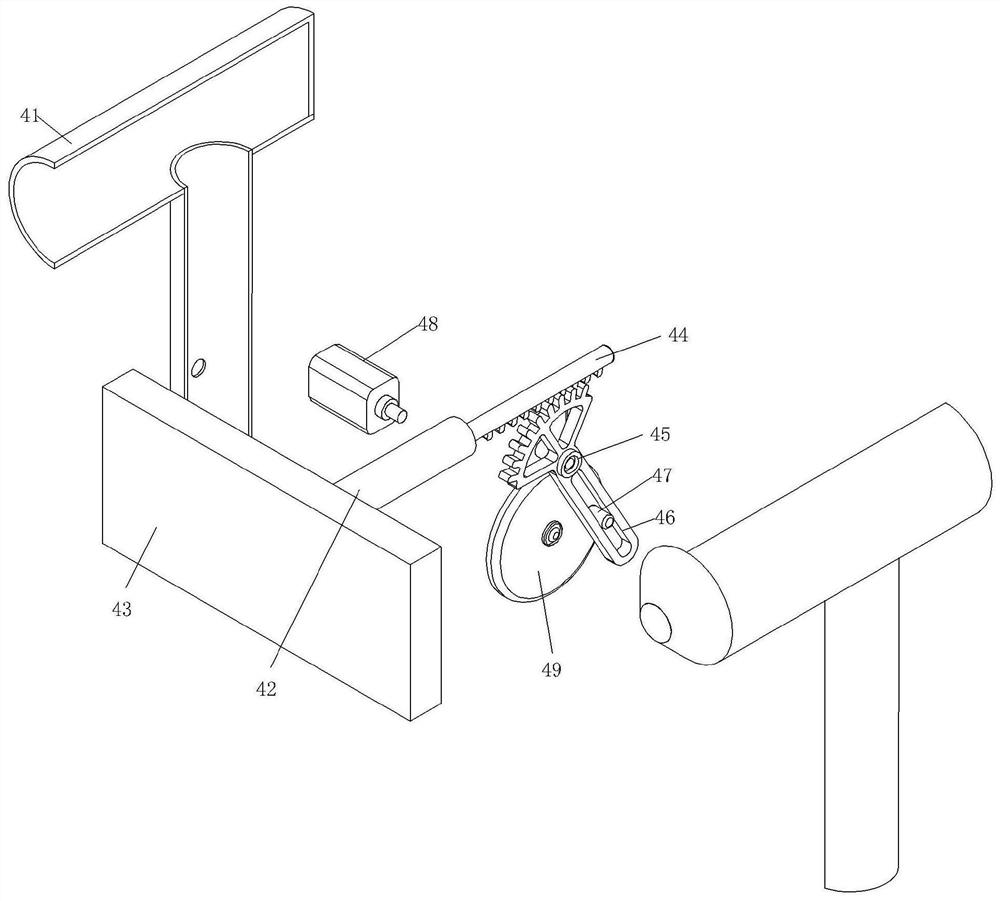

ActiveCN102848177ARealize automatic placementSave labor resourcesMetal working apparatusAssembly lineEngineering

The invention discloses a thermoplastic tube mounting mechanism for an automatic buzzer assembly line. The thermoplastic tube mounting mechanism for the automatic buzzer assembly line comprises a thermoplastic tube, a reel, a reel carrier, a support, a vertical plate, a slide plate, a lifting cylinder, a thermoplastic tube guide device and a heat shrinkable tube shearing device. The thermoplastic tube is wound on the reel which is rotatably connected with the top of the reel carrier. Both the reel carrier and the support are fixed on a bench. The vertical plate is fixed on the support. The slide plate is perpendicularly and slidably connected with the vertical plate. A cylinder block of the lifting cylinder is fixed on the vertical plate. A piston rod of the lifting cylinder is fixed on the slide plate. Both the thermoplastic tube guide device and the heat shrinkable tube shearing device are fixed on the slide plate. The heat shrinkable tube shearing device is located below the thermoplastic tube guide device. The thermoplastic tube mounting mechanism allows for automatic mounting of buzzer DIP (dual in-line package) thermoplastic tubes, labor resources are saved greatly, and work efficiency is improved.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

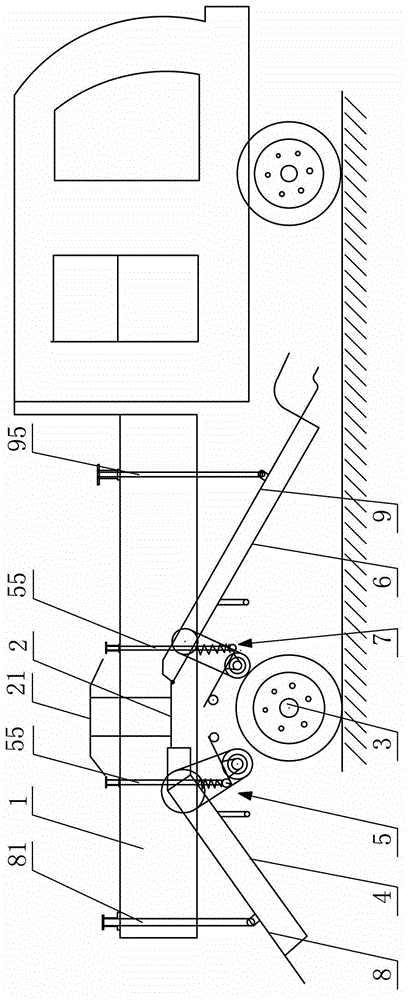

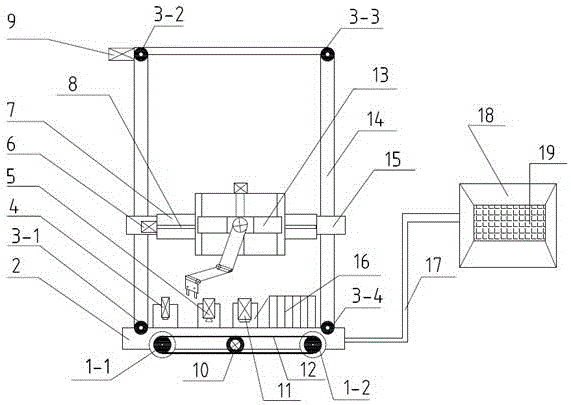

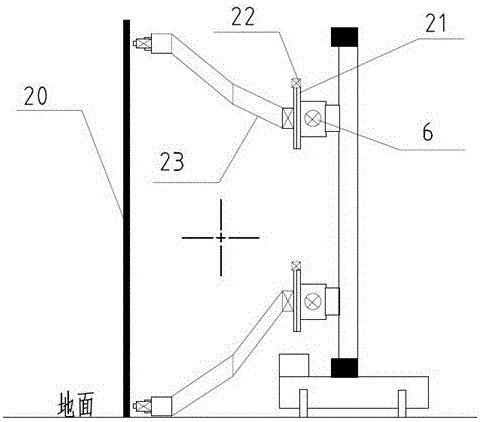

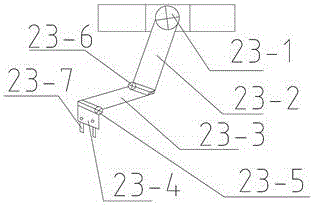

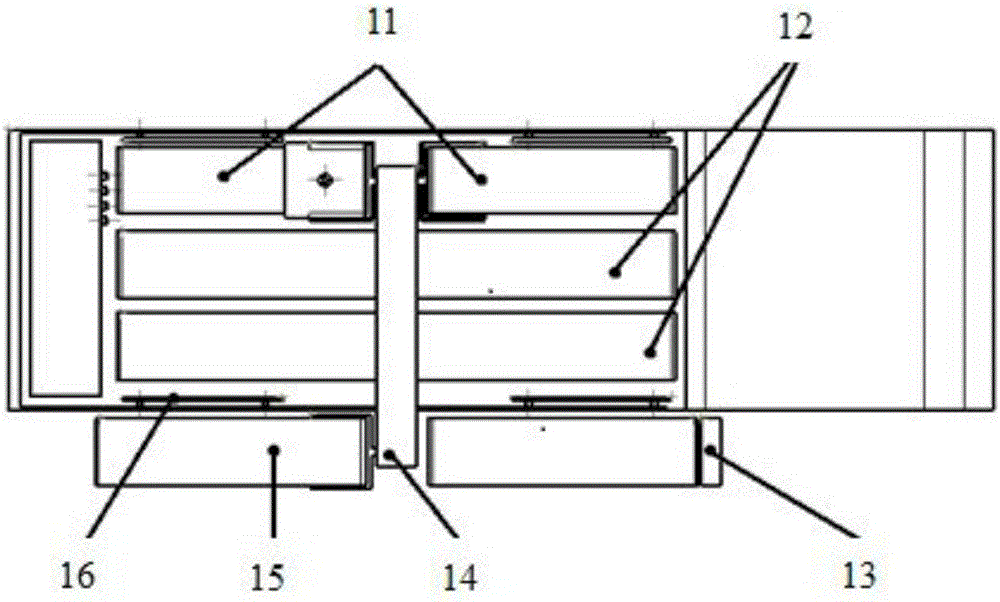

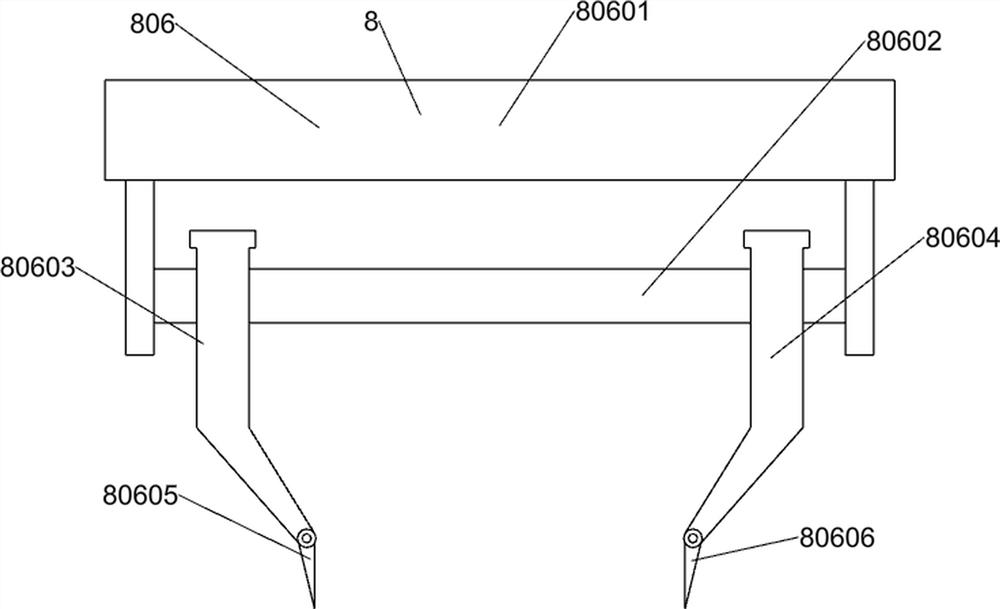

Gantry-type road cone automatically deploying and retracting device

The present invention relates to a gantry-type road cone automatically deploying and retracting device. The gantry-type road cone automatically deploying and retracting device comprises a conveying device, a transporting device and a ground-connected conveying and placing device, wherein the transporting device also comprises push plates and a conveying crawler belt, and the push plates are installed on side baffles of a vehicle body while the conveying crawler belt is installed on a flat board of the vehicle body; the transporting device also comprises a track and support forks, and the support forks can move along the track; and the ground-connected conveying and placing device comprises a road cone deploying and retracting crawler belt forming a certain angle with the ground, and a micro poking and shoveling component. Manual replacement and recycling of the road cones during road maintenance is replaced, and full automation of road cone placement and recycling is realized. Risks of road operation are reduced, and personal safety of workers during working is raised. The road working efficiency is raised, and time is saved. Through constant-speed advancement of the vehicle and constant-speed movements of the device, equal-distance placement of the road cones is realized, and the aim of controlling distance among the road cones can be achieved by changing travelling speed of the vehicle.

Owner:SHANGHAI DIANJI UNIV

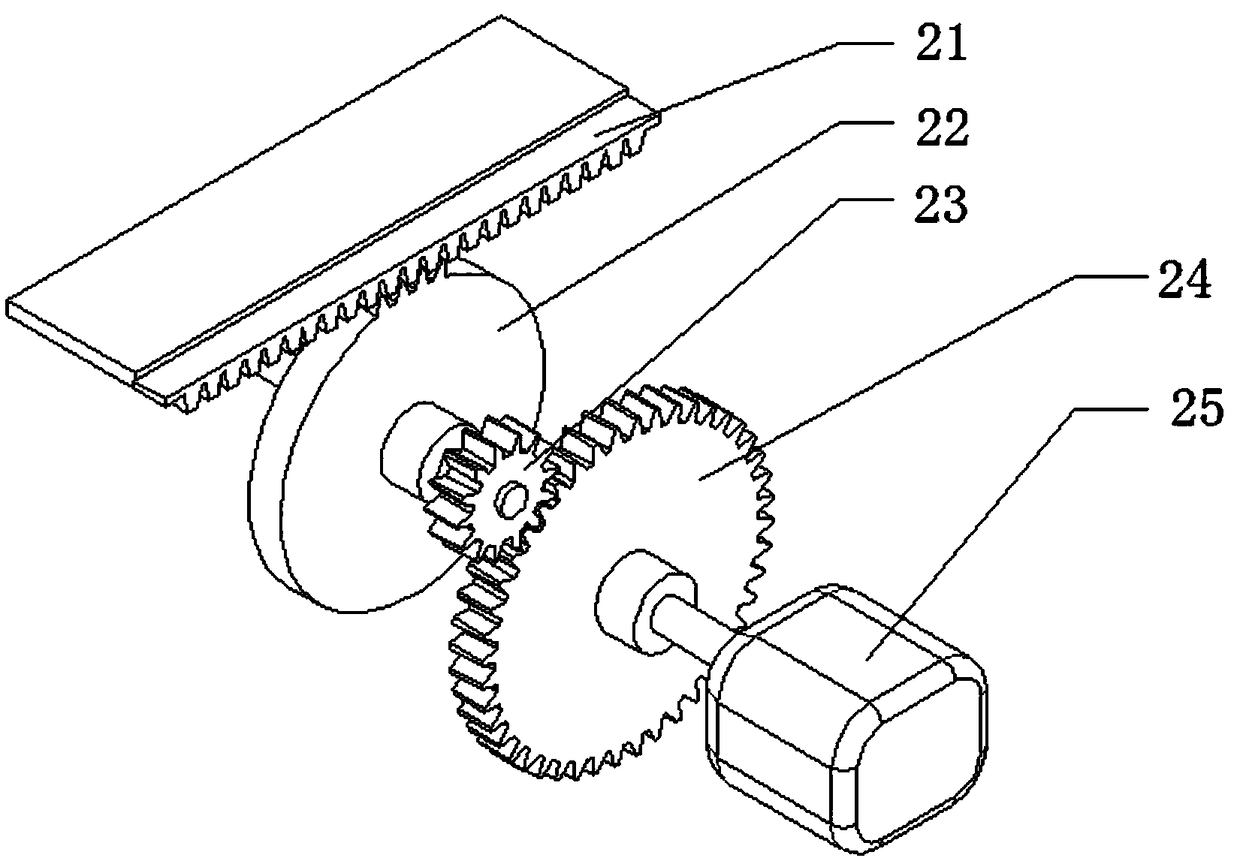

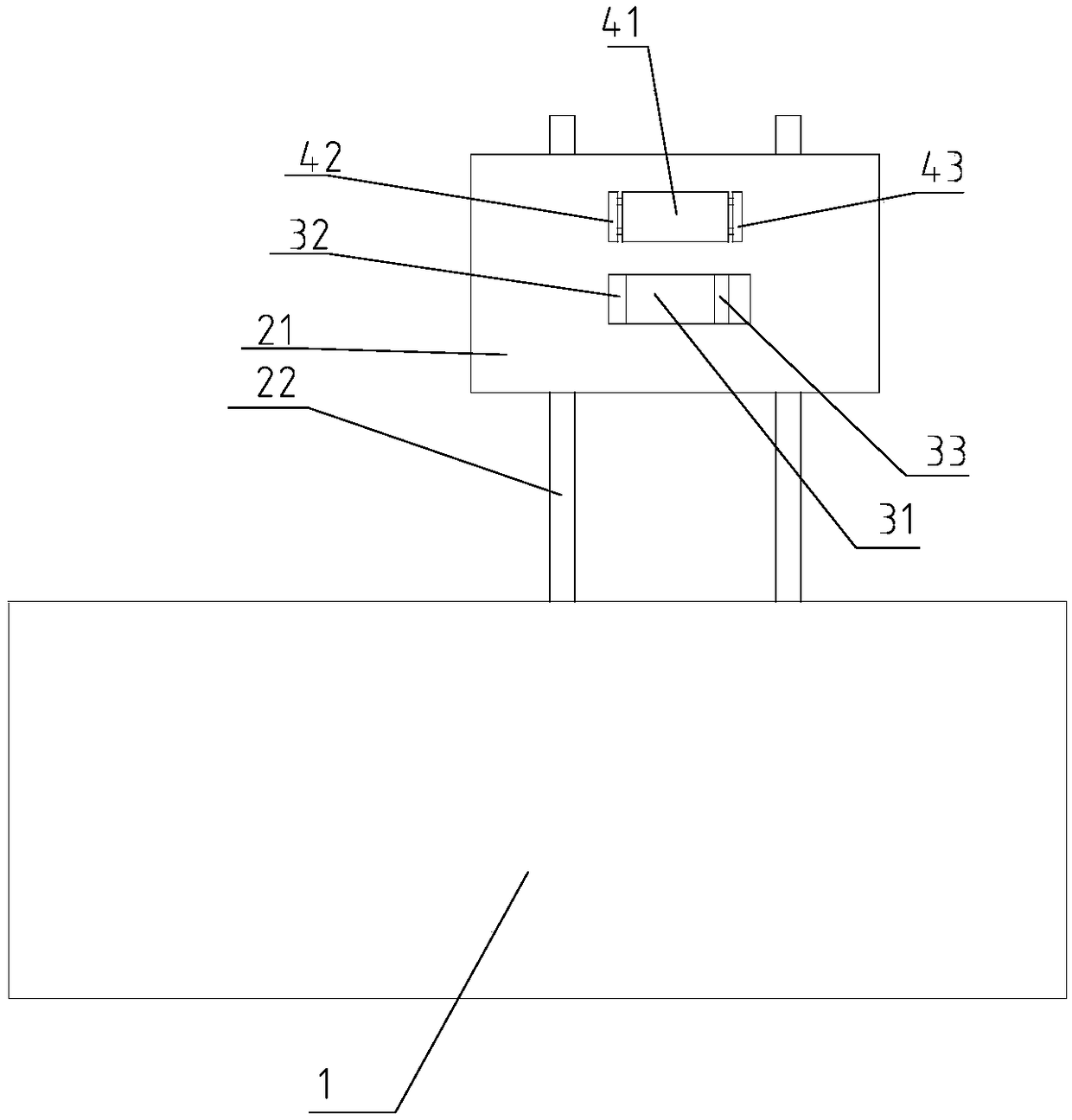

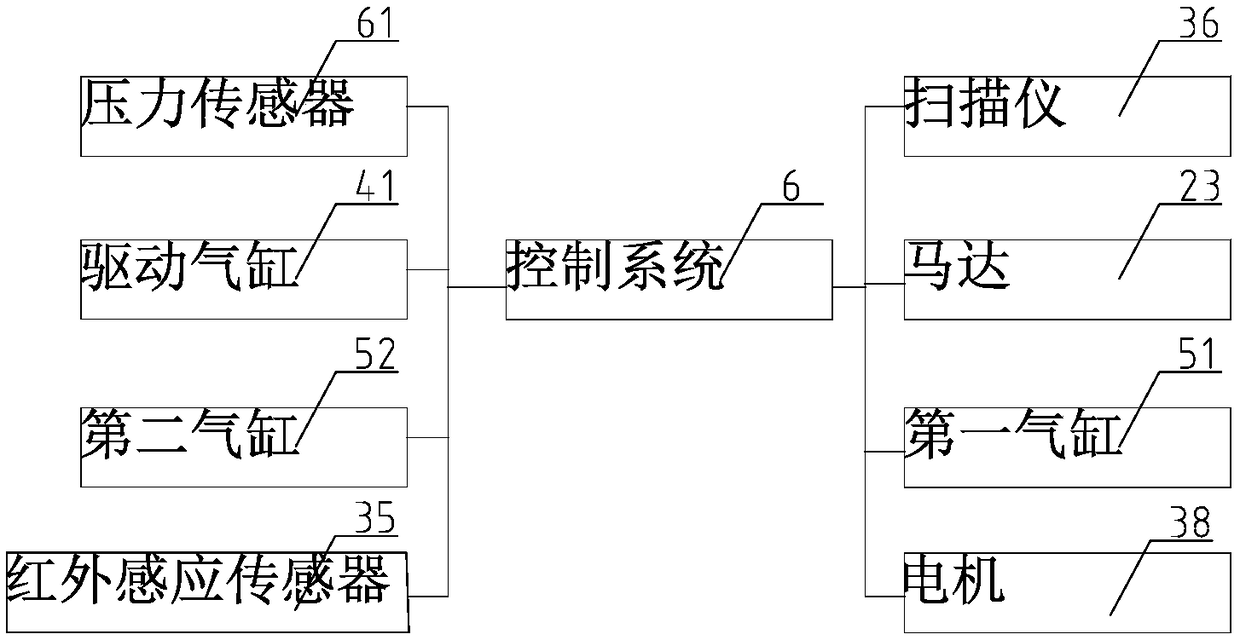

Bookshelf finishing machine

InactiveCN108373004ARealize automatic placementServing tablesStorage devicesControl systemDrive wheel

The invention discloses a bookshelf finishing machine which comprises a machine body, a scanner arranged on a bookshelf, a box arranged on the machine body and a control system; a conveying bin with the open top is arranged on the side wall of the box, the side wall of the box is provided with an outlet communicated with the conveying bin, a book support connected with the outlet is arranged inside the box, a pushing mechanism is arranged on the inner wall, opposite to the outlet, of the box, a supporting plate and a lifting device driving the lifting plate to ascend and descend are arranged in the conveying bin, a clamping arm located above the conveying bin is arranged on the machine body, a lifting mechanism for driving the clamping arm to ascend and descend is arranged on the machine body, a transverse motion mechanism for driving the clamping arm to move transversely is arranged on the machine body, a frame and a transverse motion wheel set for moving transversely are arranged atthe bottom of the machine body, the transverse motion wheel set is located in the frame, a longitudinal motion wheel set for moving longitudinally is arranged on the frame, a lifting cylinder for driving the frame to ascend and descend is arranged on the machine body, and the transverse motion wheel set and the longitudinal motion wheel set comprise guide wheels, driving wheels and power motors for driving the driving wheels to walk.

Owner:HANGZHOU SIWENKE TECH CO LTD

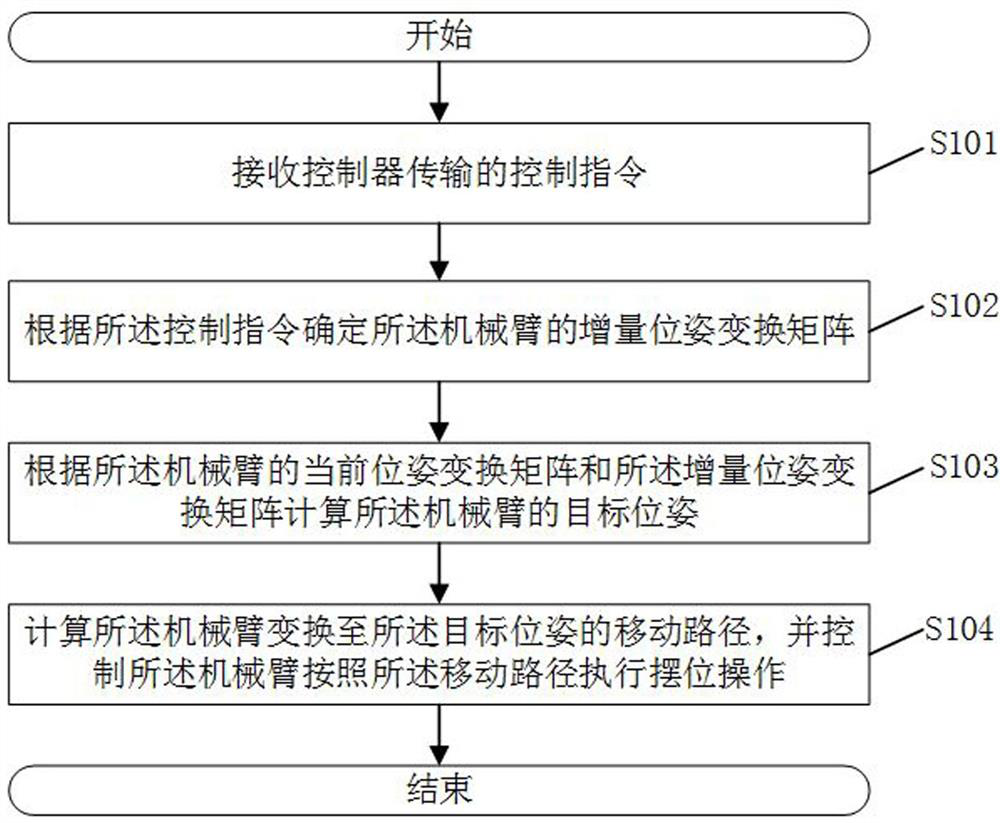

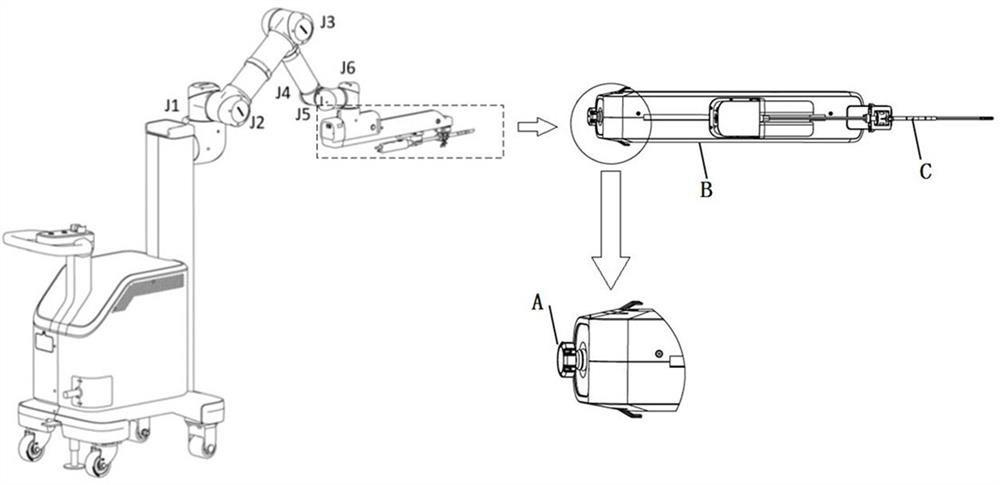

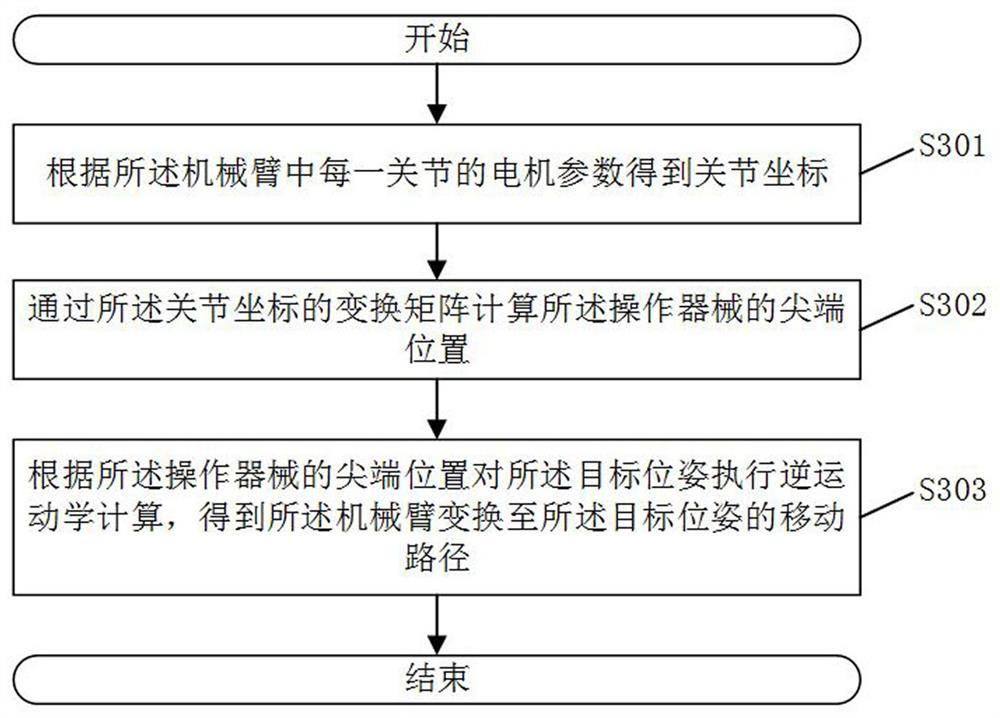

Mechanical arm positioning control method and system, robot and storage medium

ActiveCN113334391ARealize automatic placementHigh precisionProgramme-controlled manipulatorControl systemEngineering

The invention discloses a mechanical arm positioning control method and system, a robot and a storage medium. The mechanical arm positioning control method comprises the steps that a control instruction transmitted by a controller is received, wherein the control instruction is used for controlling the mechanical arm to move in the three-axis direction; an increment pose transformation matrix of the mechanical arm is determined according to the control instruction; the target pose of the mechanical arm is calculated according to the current pose transformation matrix and the increment pose transformation matrix of the mechanical arm; and the moving path of the mechanical arm converted to the target pose is calculated, and the mechanical arm is controlled to execute positioning operation according to the moving path. According to the mechanical arm positioning control method, automatic positioning of the mechanical arm can be achieved, and the positioning accuracy of the mechanical arm is improved. The disclosed mechanical arm positioning control system, the robot and the storage medium also have the above beneficial effects.

Owner:CHENGDU BORNS MEDICAL ROBOTICS INC

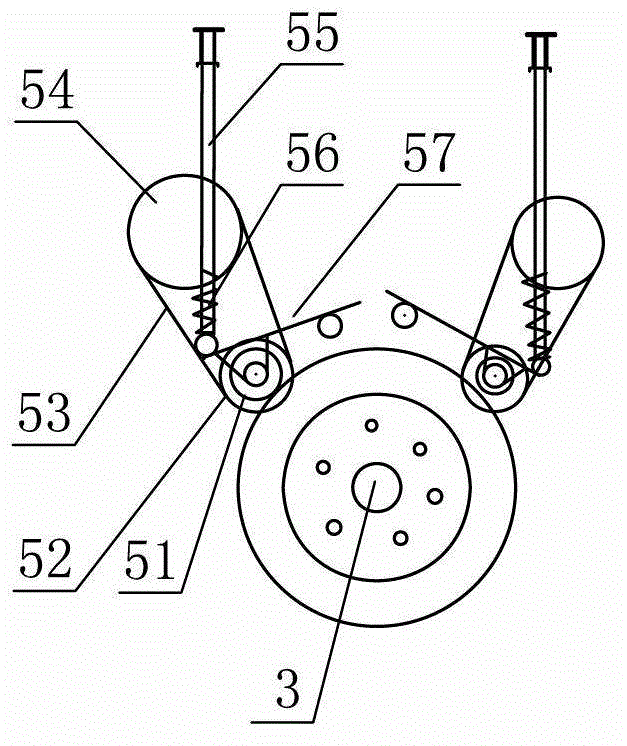

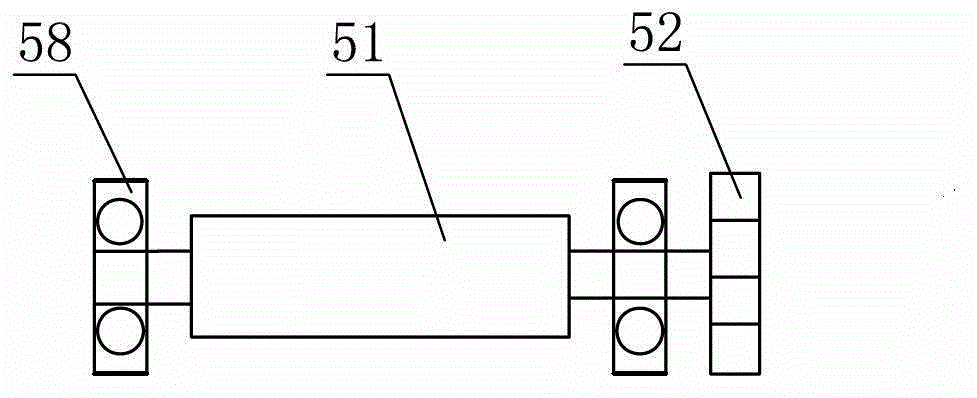

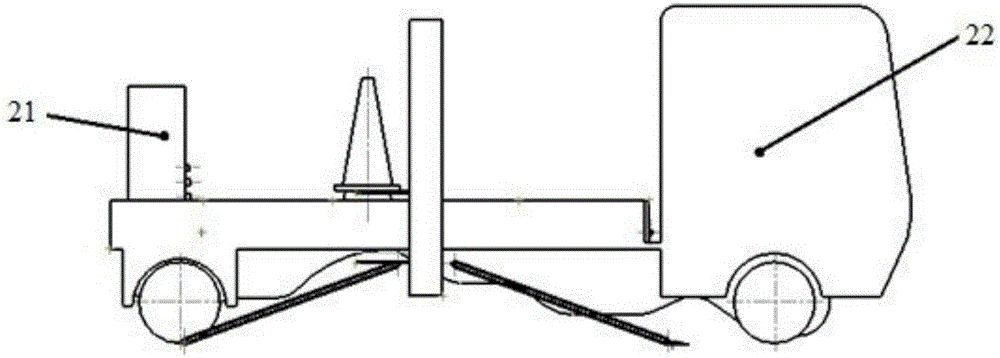

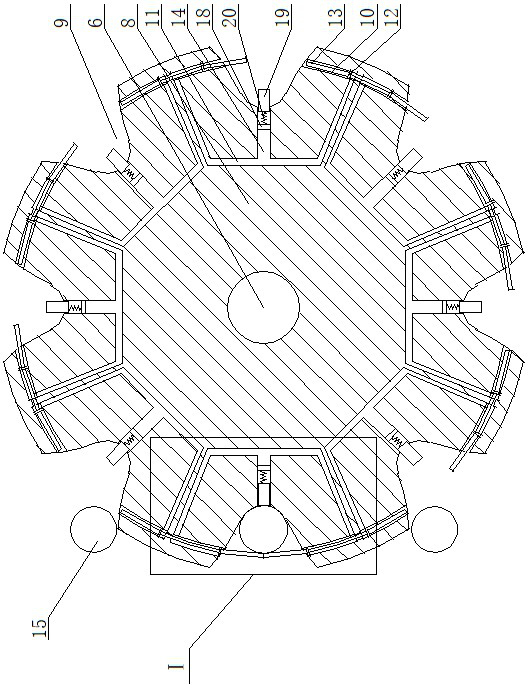

Rotary vehicle for automatically placing and withdrawing traffic cones, and method for automatically placing and withdrawing traffic cones

InactiveCN104805779AFully automatedImprove the manual placement of road conesTraffic signalsRoad signsSimulationConstant speed

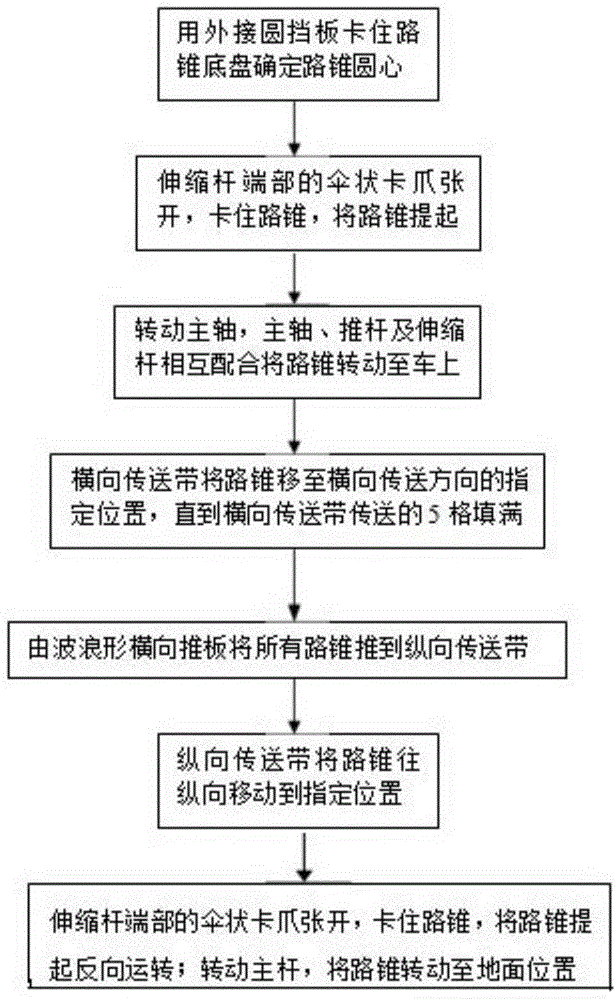

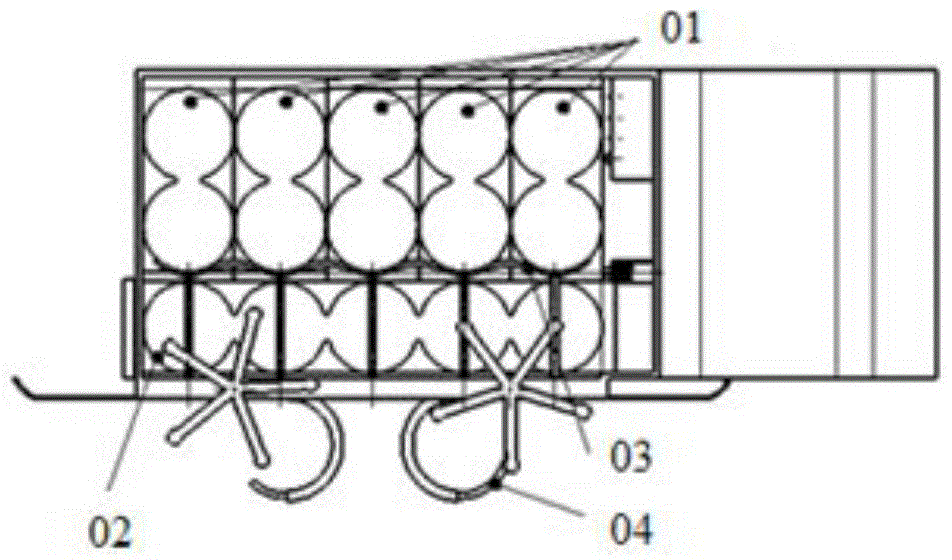

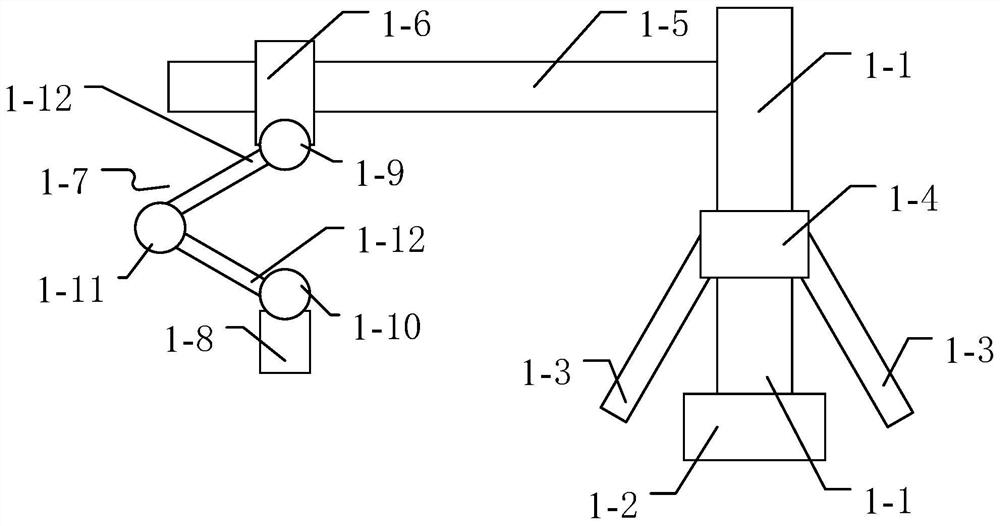

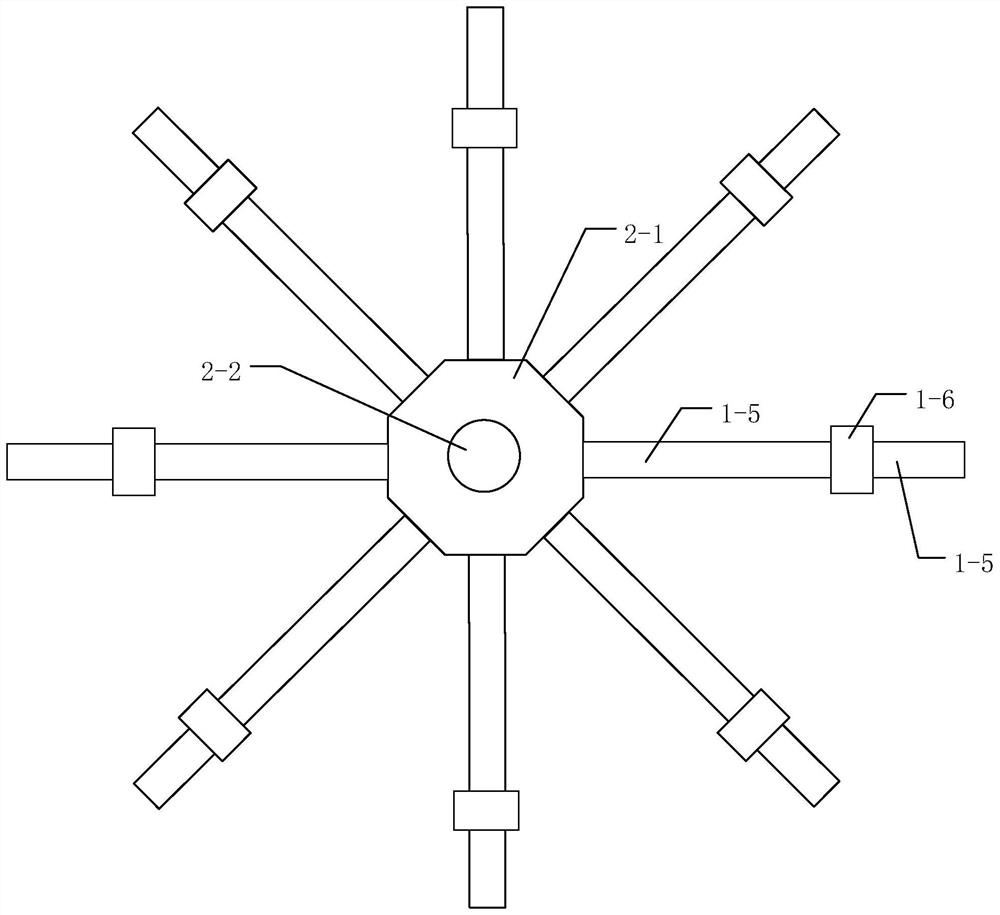

The invention relates to a method and device for placing and withdrawing inner-support traffic cones. The method comprises the following steps: step 1, the chassis of a traffic cone is clamped by a circumcircle baffle so as to confirm the circle center of the traffic cone; step 2, an umbrella-shaped claw positioned at the end of a telescopic rod is spread, clamped on the traffic cone and used for lifting the traffic cone upwards; step 3, a main shaft is rotated so as to drive the traffic cone to rotate onto a vehicle; step 4, a transverse conveying belt moves the traffic cone to a designated position in the transverse conveying direction, and the five positions of the transverse conveying belt are filled; step 5, a corrugated transverse push board pushes all the traffic cones to a longitudinal conveying belt; step 6, the longitudinal conveying belt longitudinally moves the traffic cones to the designated positions. The device disclosed by the invention can realize the functions of automatically placing and withdrawing the traffic cones. Through the constant-speed running of the vehicle and the constant-speed operation of the device, the withdrawal and the equal-distance arrangement of batches of traffic cones are realized, and the purpose of controlling the distance between adjacent traffic cones can be achieved through changing the running speed of the vehicle.

Owner:SHANGHAI DIANJI UNIV

Automatic sorting equipment and control method thereof

ActiveCN112676171ARealize simulated manual operationRealize automatic placementSortingSensing by electromagnetic radiationLogistics managementProcess engineering

The invention discloses automatic sorting equipment and a control method thereof, and relates to the technical field of warehouse logistics. In one specific implementation mode of the equipment, a goods recognition and pickup device rotating on a rotatable suspension device can push target goods to be in an inclined state through a telescopic pushing support, mechanical arms are adjusted to be in an inclined state, so that clamping jaws of the mechanical arms are used for supporting the bottoms of the target goods, and after the target goods are successfully picked up, the target goods are recovered to be horizontal so as to complete picking up of the target goods. A transmission device drives the rotatable suspension device to rotate, and therefore the target goods picked up by the goods recognition and pickup device are sorted to specified sorting positions. Manual operation can be simulated to reduce manual intervention, unmanned sorting is achieved, many-to-many automatic sorting can be achieved, goods flow at multiple starting point positions can be transferred to multiple ending points, the sorting starting and stopping positions are dynamically and flexibly set, manual adjustment of goods placement is not needed, and automatic goods placement is achieved.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

Point-bonding sealed hollow glass and manufacturing method thereof

PendingCN112412275AReduce contact areaImprove insulation performanceConstruction materialClimate change adaptationMolecular sieveAdhesive

The invention discloses point-bonding sealed hollow glass. The hollow glass comprises a plurality of pieces of glass, a plurality of spacing bars, a first sealing adhesive, a molecular sieve, and at least one of a second sealing adhesive, a third sealing adhesive and a fourth sealing adhesive; the spacing bars are arranged between the adjacent pieces of glass; the spacing bars are arranged on theperiphery of the glass in a segmented mode to form a closed spacing frame; the molecular sieve is filled in the spacing frame; the first sealing adhesive is arranged between the glass and the spacingbars; the second sealing adhesive is arranged between the adjacent pieces of glass and is positioned on the outer side edges of the spacing bars; or the third sealing adhesive is arranged between theadjacent pieces of glass and located on the outer side edges of the spacing bars; or the third sealing adhesive is arranged between the adjacent pieces of glass and located on the outer side edge of the second sealing adhesive; or the fourth sealing adhesive is arranged at the edge parts of the side surface and the outer surface of the adjacent glass. The point-bonding sealed hollow glass is simple in technological process, high in mechanization and automation degree, short in production period, high in production efficiency and good in product quality, and the service life of the hollow glasscan be greatly prolonged.

Owner:WEIHAI RUNFENG GLASS

Book record scanning management device

PendingCN109327642ARealize scanningAchieve placementPictoral communicationSoftware engineeringSprocket

The invention discloses a book record scanning management device, comprising a box body, wherein a first servo motor is fixed to the top end of the box body, the output shaft of the first servo motoris fixed with a first sprocket, left and right sides of the first sprocket are in transmission connection with a second sprocket and a third sprocket, a first screw and a second screw are fixed on thesecond sprocket, the first screw and second screw are both in transmission connection with first sliding blocks by threads, the front sides of the first sliding blocks are fixed with connecting blocks, a pushing mechanism is fixed between the two connecting blocks, the lower end of the pushing mechanism is provided with a scanning mechanism, a storage rack is fixed in the middle of the box body,and support adjustment mechanisms are disposed at four corners of the lower end of the box body. Through the above structure, files such as books or records are automatically placed on the bookshelf,and the information is automatically scanned and input, thereby improving work efficiency and accuracy, and saving manpower.

Owner:BAOJI UNIV OF ARTS & SCI

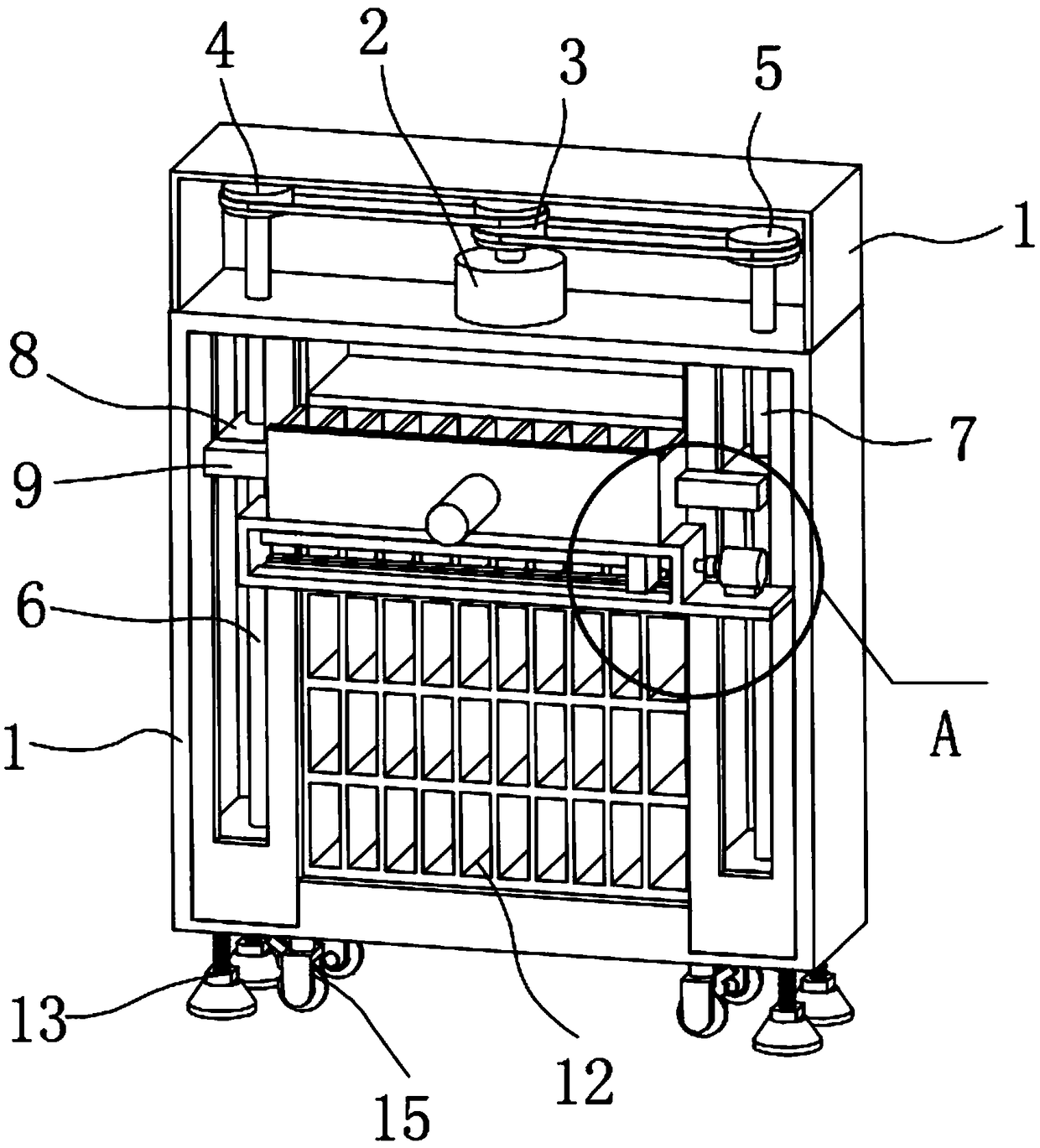

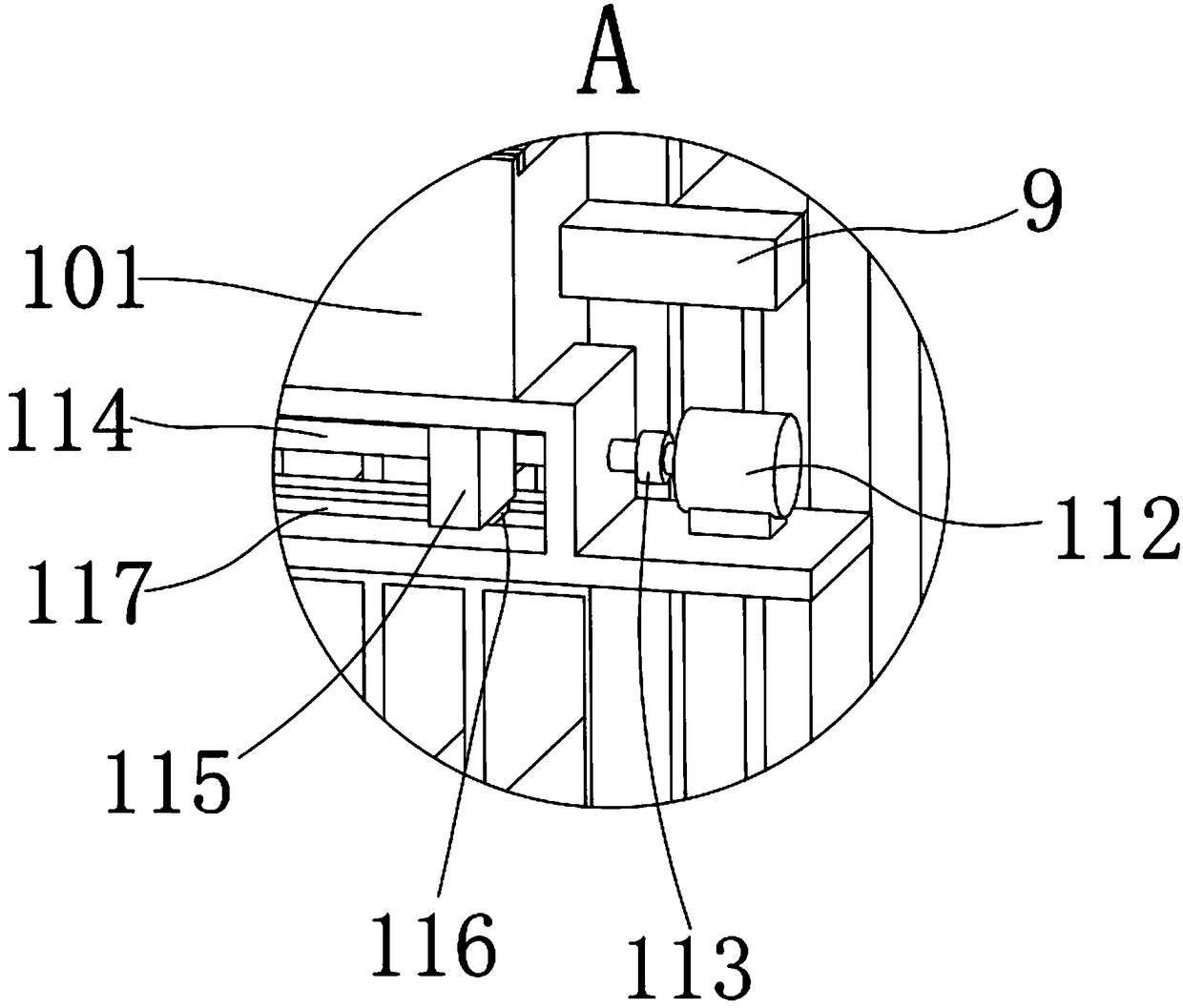

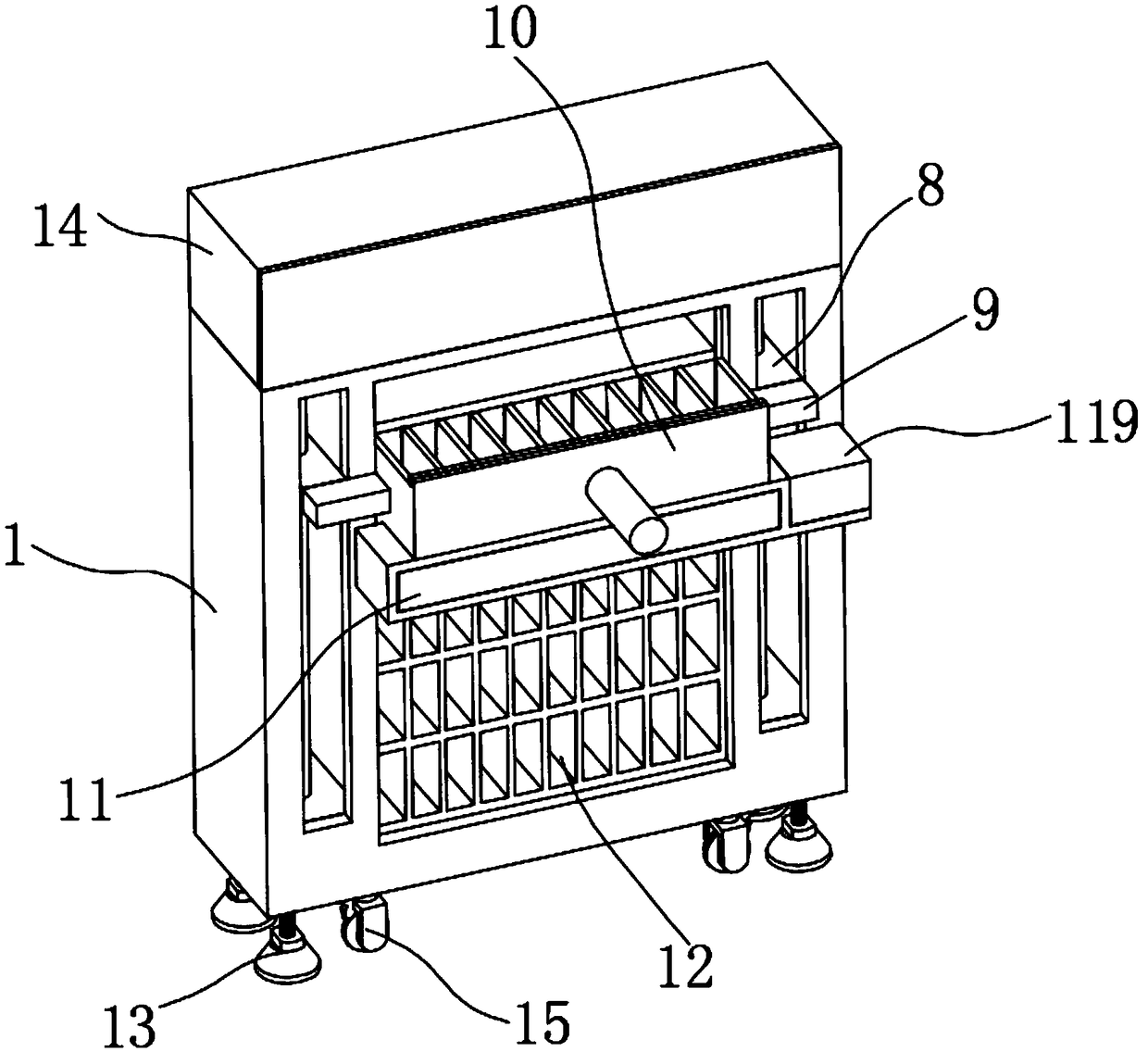

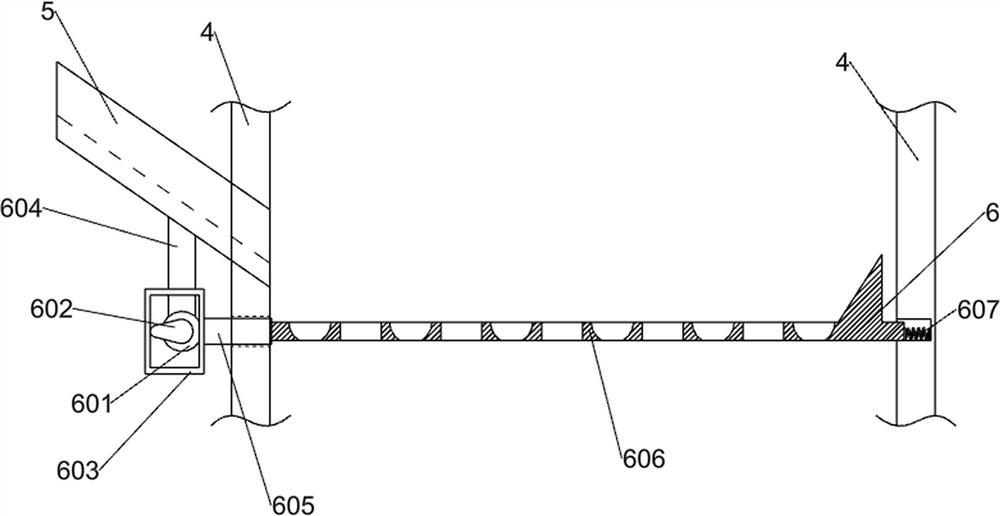

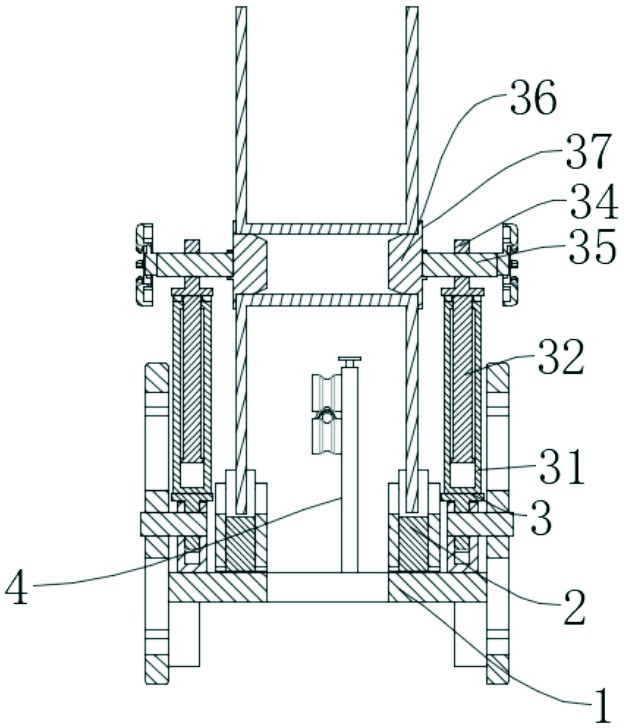

Breaking type single-seam camellia oleifera fruit shelling device

ActiveCN112586756ARealize automatic feeding processRealize automatic placementHuskingHullingEngineeringMechanical engineering

The invention relates to the field of tea oil, in particular to a breaking type single-seam camellia oleifera fruit shelling device. A technical problem to be solved is to provide the breaking type single-seam camellia oleifera fruit shelling device. A technical scheme is as follows: the breaking type single-seam camellia oleifera fruit shelling device comprises a first mounting machine tool plate, a supporting foot stand, an operation control screen, a fixed frame, a feeding system and the like; an upper part of the supporting foot stand is welded with the first mounting machine tool plate; the operation control screen is connected with the first machine tool mounting plate; and the fixed frame is connected with the first mounting machine tool plate. Automatic feeding and automatic placing of single-seam camellia oleifera fruits are realized, a friction rotation is conducted on the camellia oleifera fruits with openings not facing upwards after an automatic placing, the camellia oleifera fruits are made to rotate till the openings face upwards, and finally camellia oleifera fruit shells are automatically opened and shelled through the single-seam openings of the camellia oleiferafruit shells.

Owner:衡山善泊生态农业有限公司

Environment-friendly type medical test tube stirring device

InactiveCN108993290ARealize automatic stirringRealize automatic placementTransportation and packagingMixersEngineeringTransfer mechanism

The invention relates to an environment-friendly type medical test tube stirring device, which belongs to the field of experiment equipment. The medical test tube stirring device is composed of a workbench, a transmission mechanism, a stirring mechanism, a test tube rack, a transfer mechanism, and a test tube collection box, specifically, the stirring of the test tube is completed by the cooperation of the transmission mechanism having intermittence and an agitator, and the test tube is stirred and stored by placing the test tube rack into the test tube collection box through the transfer mechanism. The environment-friendly type medical test tube stirring device has the advantages of environmental protection, high precision during work, obvious stirring effect, and high efficiency during working.

Owner:滨州医学院烟台附属医院

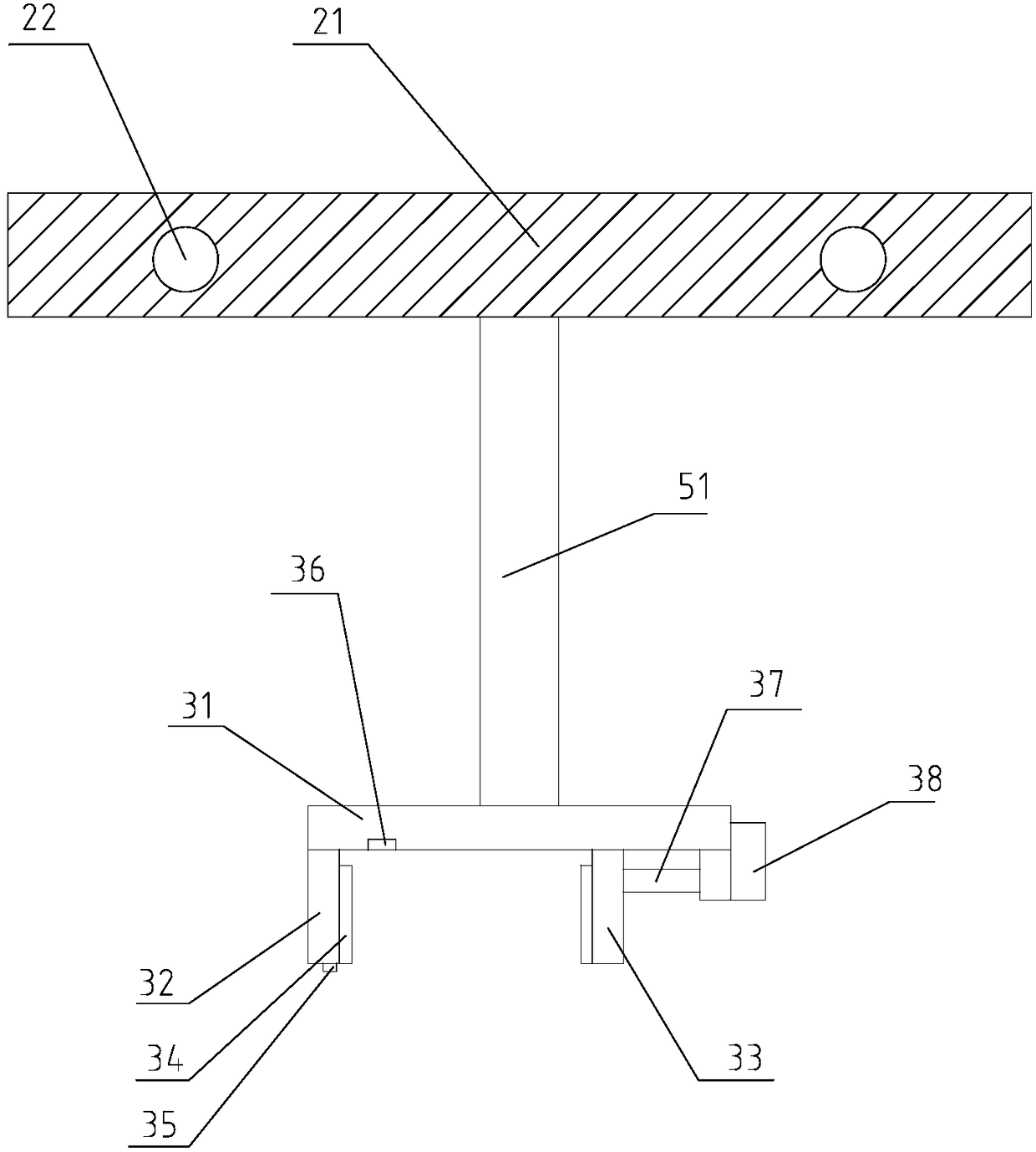

Clamping mechanism of bookrack arranging machine

InactiveCN108438873ARealize automatic placementConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a clamping mechanism of a bookrack arranging machine, belongs to the field of intelligent devices, and solves the technical problem of manual storage books in bookracks in theprior art. The clamping mechanism of the bookrack arranging machine comprises a machine body and a control system; a clamping arm is arranged on the machine body; the clamping arm comprises a bracket,a left clamping arm, a right clamping arm, and a driving mechanism for driving the left clamping arm and the right clamping arm to relatively act; a scanner, connected with the control system, is arranged on the side, towards the left clamping arm and the right clamping arm, of the bracket; the machine body is provided with a lifting mechanism for driving the clamping arm to lift; and the machinebody is additionally provided with a transverse moving mechanism for driving the clamping arm to transversely move.

Owner:HANGZHOU SIWENKE TECH CO LTD

Multifunctional cable pay-off device applied to municipal power construction

ActiveCN113968514ARealize automatic placementAvoid shaking from side to sideApparatus for cutting/splicing cablesFilament handlingStructural engineeringArchitectural engineering

The invention relates to the technical field of cable pay-off, in particular to a multifunctional cable pay-off device applied to municipal electric power construction. The device comprises a movable plate trailer, a riding wheel mechanism and auxiliary mechanisms, wherein the riding wheel mechanism for supporting a winding roll to be paid off is arranged in the middle of the upper plate surface of the movable plate trailer; and the upper plate faces, located on the two sides of the riding wheel mechanism, of the movable plate trailer are each provided with an auxiliary mechanism used for placing the winding roll to be paid off on the riding wheel mechanism and assisting the riding wheel mechanism to stabilize the winding roll to be paid off. Through the arrangement of the auxiliary mechanisms, the function of automatically placing the winding roll on the riding wheel mechanism is achieved, and the function of preventing the winding roll from swinging left and right in the pay-off process is achieved; and due to the arrangement of the riding wheel mechanism, the winding roll can be conveniently moved to the riding wheel mechanism, and a second riding wheel is prevented from being impacted by the winding roll.

Owner:STATE GRID CORP OF CHINA +1

Magnet magnetizing device

PendingCN112885558ARealize automatic placementNo reverse material phenomenonMagnetic bodiesMagnetic rotationCondensed matter physics

The invention provides a magnet magnetizing device which comprises a magnet feeding and positioning device, a material taking device and a magnetizing rotating device, and the magnet feeding and positioning device is used for feeding and locating a magnet to be magnetized; the material taking device is used for sucking the magnets in the magnet feeding and positioning device and placing the magnets on the magnetizing rotating device; and the magnetizing rotating device is used for magnetizing the magnet to be magnetized. By means of the magnetizing device, the problems that in existing manual magnetizing, the magnetizing direction is likely to be reverse, and the magnetizing material rate is low can be solved.

Owner:GOERTEK INC

Truss stirrup mounting equipment and mounting method

ActiveCN111515675ARealize automatic placementLow costAssembly machinesCeramic shaping apparatusStirrupControl theory

The invention provides truss stirrup mounting equipment and mounting method, and belongs to the technical field of sleeper production equipment. The truss stirrup mounting equipment comprises a conveying device used for conveying trusses, an overturning device arranged on one side of an input end of the conveying device, a stirrup mounting device used for mounting stirrups on the overturned trusses, and a lifting conveying device. The trusses are sequentially placed on the conveying device side by side, then the trusses are conveyed to the overturning device through the conveying device, the two trusses as a group are turned over by 180 degrees through the overturning device, then the overturned trusses are conveyed to the mounting device through the lifting conveying device, the overturned trusses and the stirrups are mounted, and finally the assembled trusses are conveyed to a die through the lifting conveying device for pouring. According to the truss stirrup mounting equipment andmounting method provided by the invention, the automatic installation of the sleeper trusses, the stirrups and a fixing frame is realized, the cost of personnel is reduced, and the influence of uncertain factors of installation by personnel on the quality of sleepers is avoided.

Owner:LANGFANG HESS BUILDING MATERIALS MACHINERY CO LTD

Mechanism for grabbing and placing massive objects

InactiveCN105523378AAchieve crawlingRealize automatic placementConveyor partsEngineeringMechanical engineering

The invention discloses a mechanism for grabbing and placing massive objects, relates to a grabbing and placing mechanism, and solves the problems of labor and time wastes in traditional grabbing and placement of wine ball blocks by manual operation. The mechanism for grabbing and placing the massive objects is characterized by comprising two connecting pieces, three sets of grabbing pieces and three grabbing piece driving mechanisms for controlling opening and closing actions of the grabbing pieces; the lower ends of the three grabbing piece driving mechanisms are fixedly connected with three sets of grabbing pieces; and the three grabbing piece driving mechanisms are arranged side by side in sequence, and are movably connected with the connecting pieces through pins. The mechanism for grabbing and placing the massive objects is used for grabbing and placing the wine ball blocks.

Owner:HARBIN XINZHIDA AUTOMATION COMPLETE EQUIP CO LTD

Novel intelligent storage shelf device for logistics storage

ActiveCN112758576AEffective placementQuick placementStorage devicesLogistics managementAgricultural engineering

Owner:JIUJIANG VOCATIONAL & TECHN COLLEGE

Automatic assembly production line of buzzers

ActiveCN102848187BGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Arrangement device of bookshelf arranging machine

The invention discloses an arrangement device of a bookshelf arranging machine, and belongs to the field of intelligent equipment. According to the arrangement device, the technical problem of high labor intensity of book arranging in the prior art is solved. The book arrangement device comprises a machine body, a box body and a control system, wherein the box body and the control system are arranged on the machine body; a conveying bin with an opening in the top is arranged on the side wall of the box body, an outlet communicating with the conveying bin is formed in the side wall of the box body, and a book support connected with the outlet is arranged in the box body; a pushing mechanism is arranged on the inner wall, opposite to the outlet, of the box body, a supporting plate and a lifting device for driving the supporting plate to ascend and descend are arranged in the conveying bin, and a clamping arm positioned above the conveying bin is arranged on the machine body; the clampingarm comprises a support, a left clamp arm body, a right clamp arm body and a driving mechanism, wherein the driving mechanism drives the left clamping arm body to move relative to the right clamp armbody; and a scanner connected to the control system is arranged on the side, facing the left clamping arm body and the right clamping arm body, of the support, a lifting mechanism used for driving the clamping arm to ascend and descend is arranged on the machine body, and a transverse moving mechanism used for driving the clamping arm to transversely move is further arranged on the machine body.

Owner:HANGZHOU SIWENKE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com