Conveying device for plug transplantation

A conveying device and plug-in tray transplanting technology, which is applied in the field of agricultural engineering, can solve the problems of reducing the effective use area of greenhouses, lagging behind the development of agricultural automation, and low manual work efficiency, so as to increase the effective use area, arrange neatly, and improve automation horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

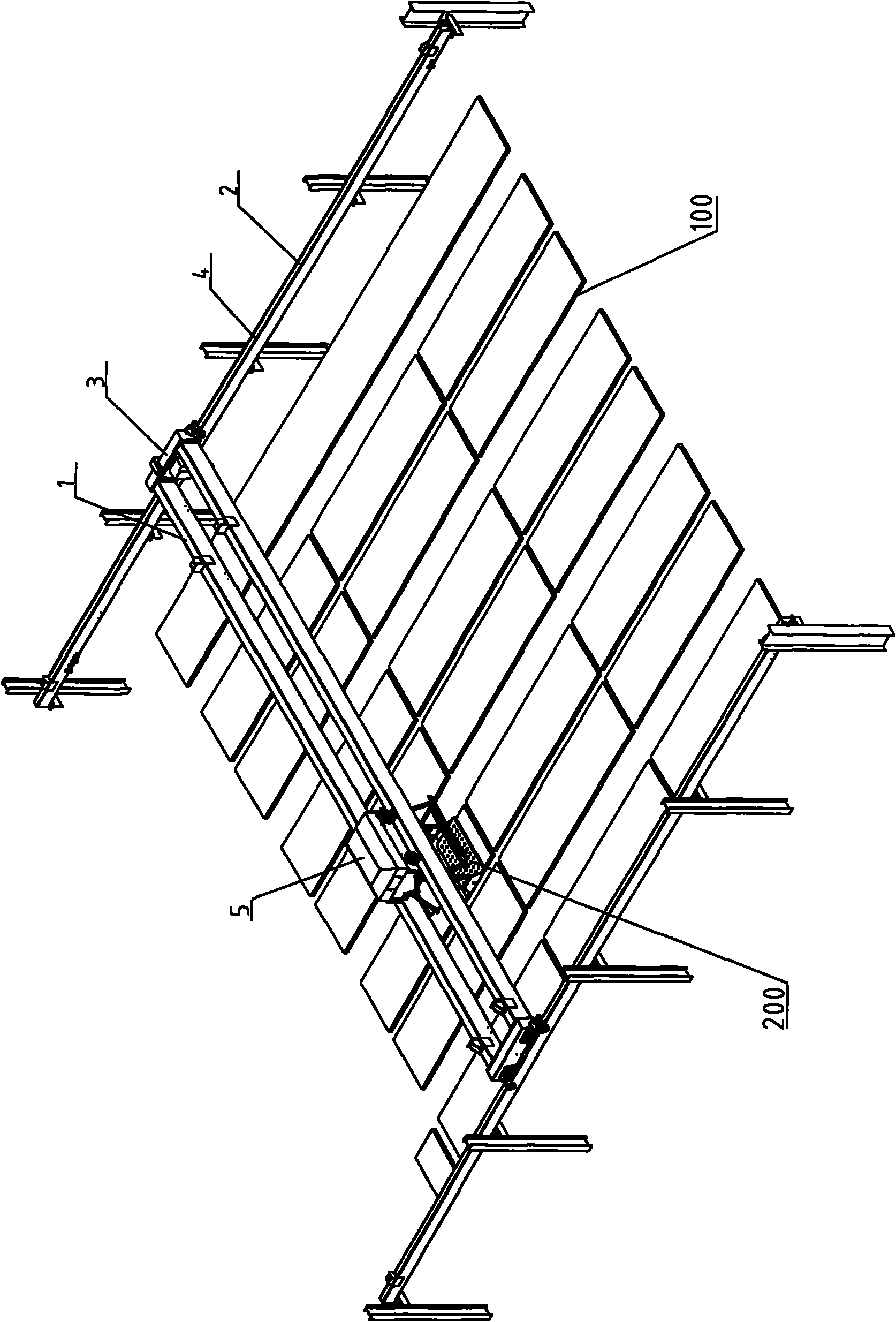

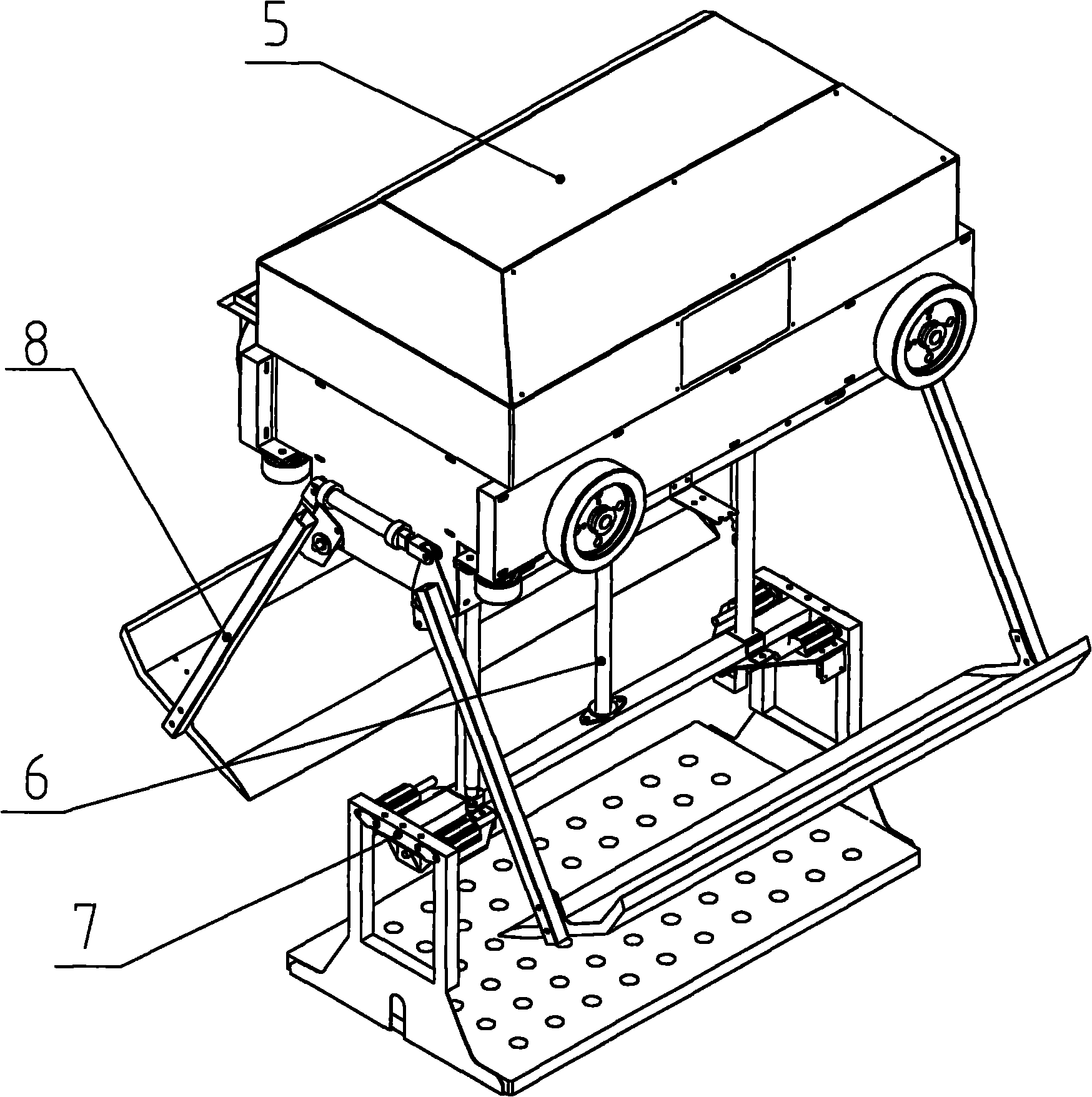

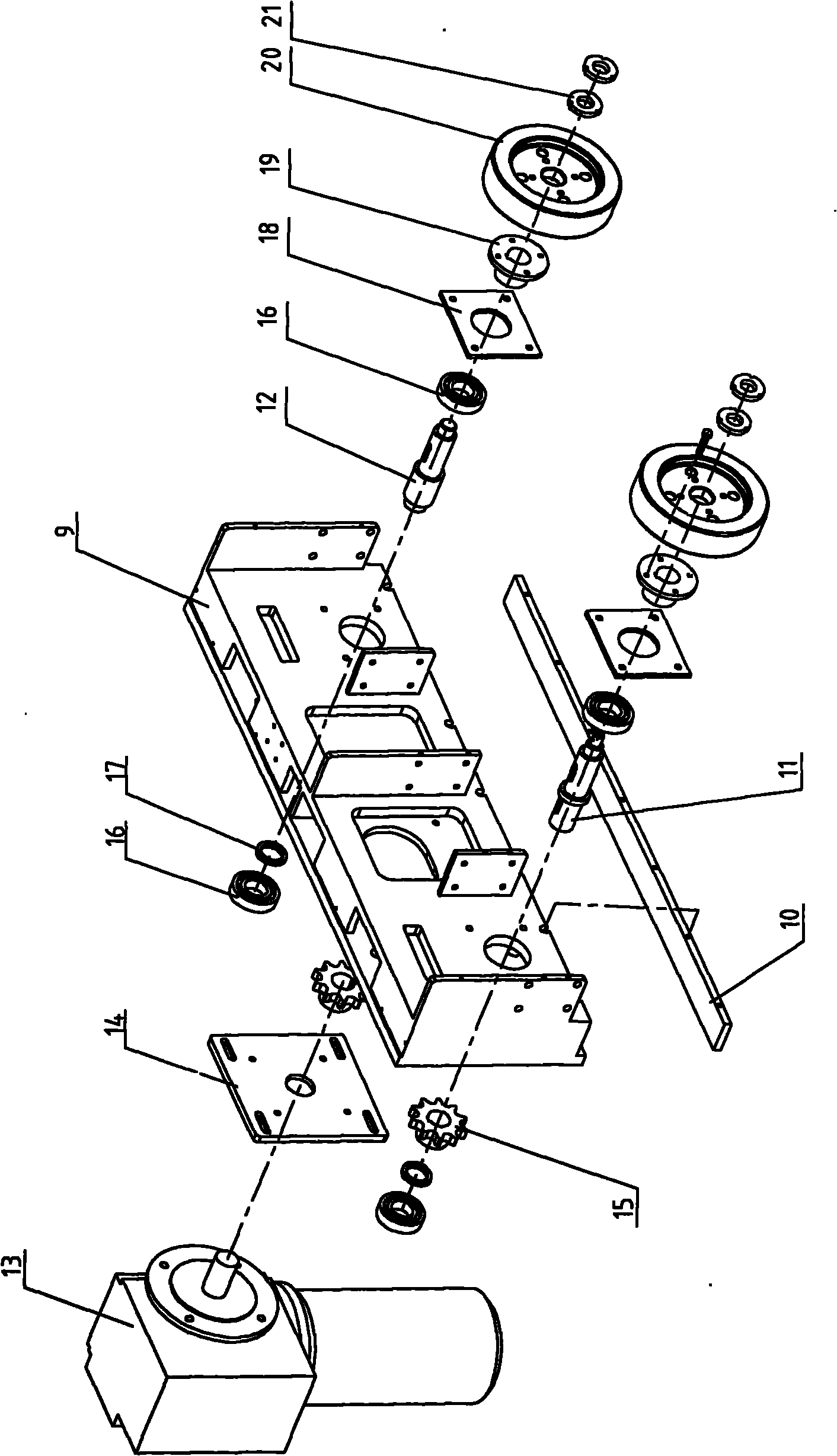

[0038] refer to figure 1 As shown, the tray transplanting and conveying device of the present invention includes: a static rail 2 is placed in parallel on both sides of the integral seedbed 100 in the greenhouse. Two parallel moving rails 1 spanning between two static rails 2, the moving rail 1 is composed of two hot-dip galvanized rectangular tubes, the two ends of the two moving rails are respectively fixed on a moving rail moving device 3, the The moving rail moving device 3 is erected on the static rail and can move along the static rail track; a moving trolley device 5 is mounted on the two moving rails 1 through wheels. see also figure 2 A pneumatic lifting device 6 is connected to the bottom of the moving trolley device 5, and a pneumatic gripping device 7 is connected to the output end of the pneumatic lifting device. A pneumatic protection device 8 can be established on both sides of the pneumatic lifting device 6 below the moving trolley device 5 . It can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com