Auto-mounting tray for scattered or short-taped devices

A component and scattered technology, applied in the field of trays carrying scattered or short-braided electronic components, can solve problems such as the inability to meet the placement requirements of the placement machine, the small amount of components used, and the lack of placement accuracy. Fast and stable picking, easy operation, and improved assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

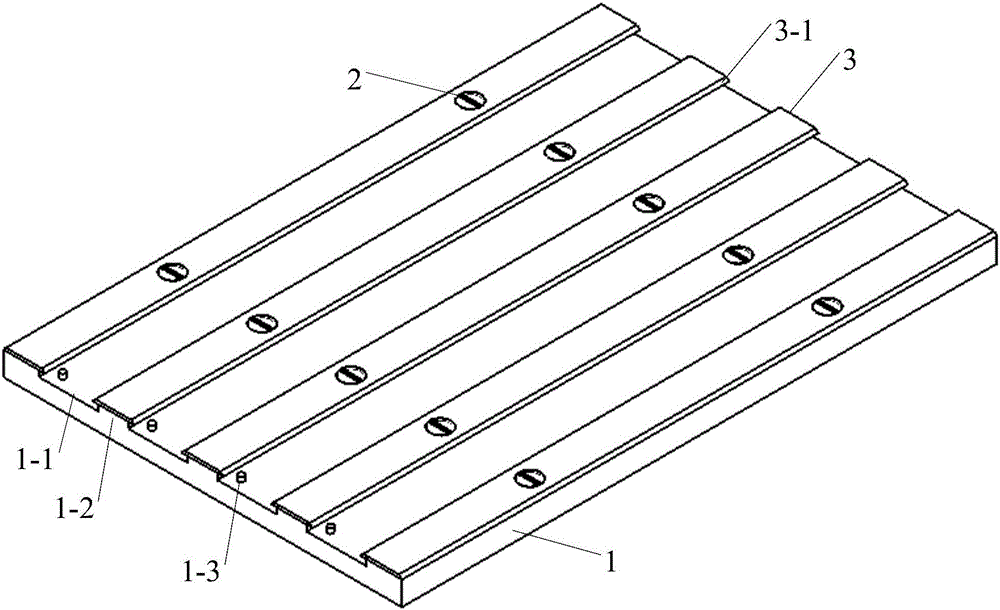

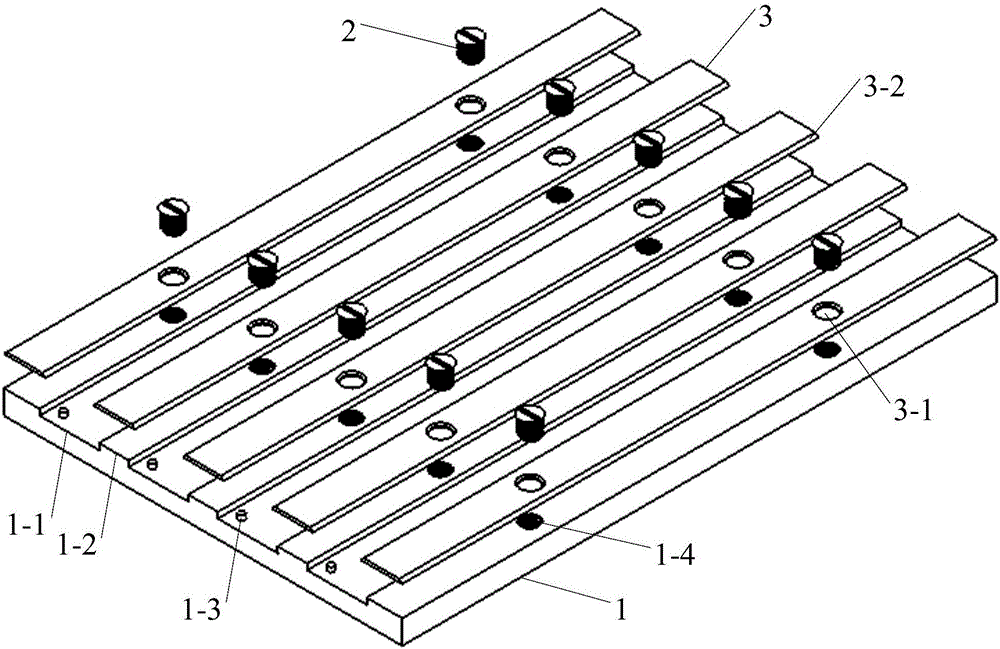

[0015] Specific implementation mode one, combination Figure 1 to Figure 5 To illustrate this embodiment, an automatic mounting tray for scattered or short braided components includes a bottom table 1, a fastening screw 2 and an upper pressure plate 3;

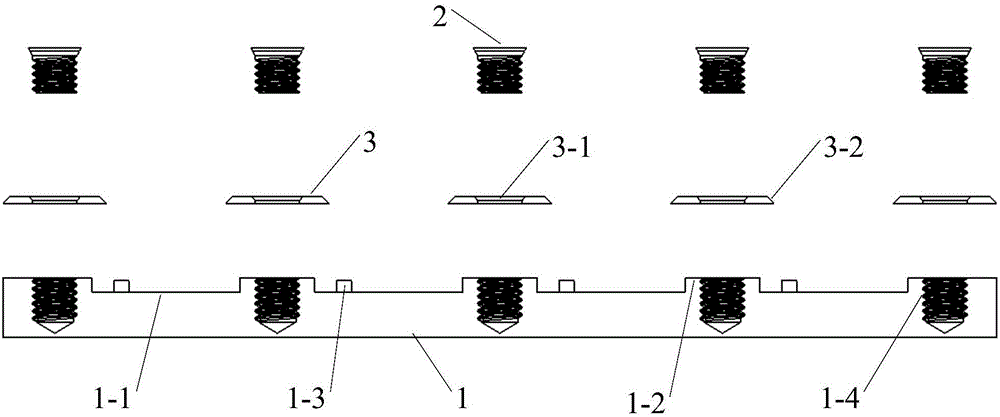

[0016] The bottom platform 1 is an equidistant array structure of grooves, and includes three parts: a carrier tape inlay groove 1-1, a boss 1-2, and a carrier tape positioning pin 1-3. The stages 1-2 are arranged at equal intervals, the carrier tape inlay grooves 1-1 are used to place the component carrier tape, the carrier tape positioning pins 1-3 are used to complete the precise positioning of the component carrier tape, the boss 1-2 The upper surface is designed with two positioning holes 1-4 with dual functions of size positioning and mechanical fixing;

[0017] The fastening screw 2 is a slotted countersunk head screw. After fastening, the fastening screw 2 needs to be completely sunk into the countersunk locating hole 3-1 ...

specific Embodiment approach 2

[0022] Specific embodiment two, this embodiment is an example of using a scattered or short braided component automatic placement tray described in specific embodiment one to position and fix short braided components:

[0023] Put the short braid into the carrier tape inlay slot 1-1, and at the same time insert the positioning pins 1-3 into the positioning hole of the carrier tape, place the upper plate 3 on the surface of the boss 1-2, and ensure the sinking of the upper plate 3 The head positioning hole 3-1 is accurately aligned with the positioning hole 1-4 on the boss 1-2. At the same time, the upper pressure plate 3 will further press the carrier tape straight into the carrier tape mounting groove 1-1, and tighten the screws 2 Screw the countersunk positioning hole 3-1 into the positioning hole 1-4, keep the fastening screw 2 lower than the upper surface of the upper plate 3, and finally peel off the heat-sealed cover tape on the surface of the short braid. Through the above...

specific Embodiment approach 3

[0024] Specific embodiment three. This embodiment is an example of using an automatic placement tray for scattered or short braided components described in the first embodiment to locate and fix scattered components:

[0025] First determine the type of carrier tape (reusable twice) that is suitable for the scattered components, and complete the unloaded tape fixing process according to the above-mentioned short tape component fixing process, and finally put the scattered components on the carrier tape one by one for use Place the electronic components in the holes to complete the precise fixation of the scattered components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com