Negative-pressure hollow glass, manufacturing method and application

A production method and glass technology, which are applied in the installation of window glass, parallel glass structure, climate change adaptation, etc., can solve the problems of shortening the service life of insulating glass, affecting the thermal insulation and thermal insulation performance, affecting the appearance of the glass, etc. Mechanization, beautiful appearance, the effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

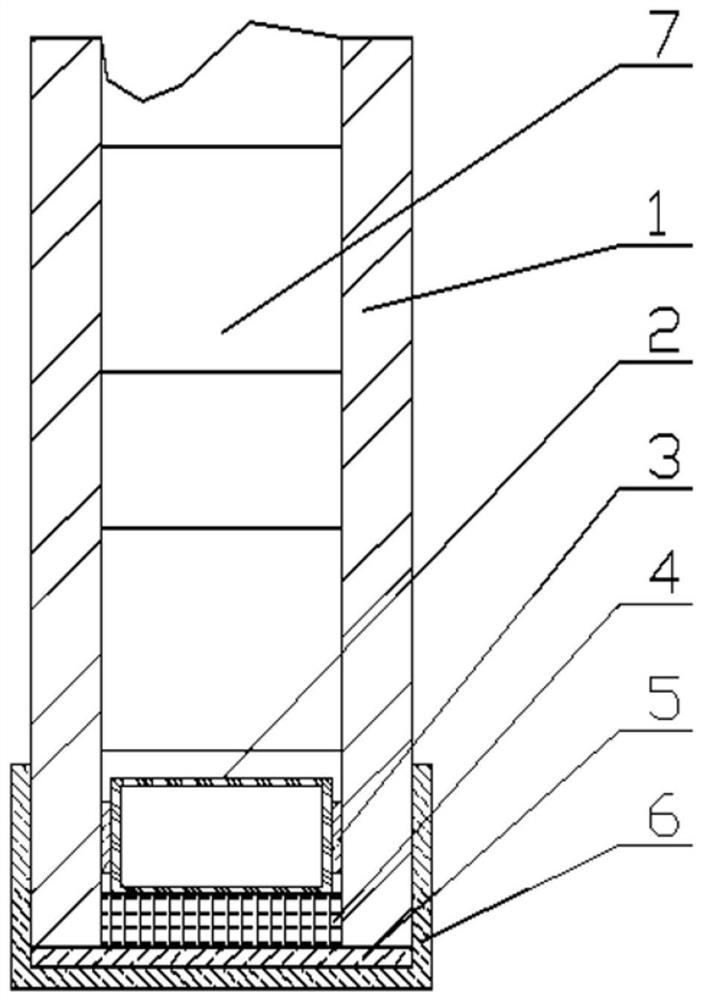

[0069] like Figure 13 As shown, the preparation method of the negative pressure insulating glass provided by the embodiment of the present invention includes:

[0070] S101: Make glass: Cut two pieces of glass of the same size according to the shape and size of the hollow glass to be produced, and then grind, clean and dry, and if tempered glass is required, it must be tempered;

[0071] S102: Cut spacers or make spacer frames, and make supports: select spacer bars of appropriate material and size, cut into spacer bars of corresponding lengths or make spacer frames of corresponding sizes according to the size of the glass; make supports of corresponding shapes and heights ;

[0072] S103: Fix the spacer or spacer frame: apply sealant or structural glue or double-sided tape on the bonding surface of the spacer or glass, and bond the spacer to the glass to form a closed frame; or Apply sealant or structural adhesive or double-sided tape on the bonding surface of the spacer fr...

Embodiment 1

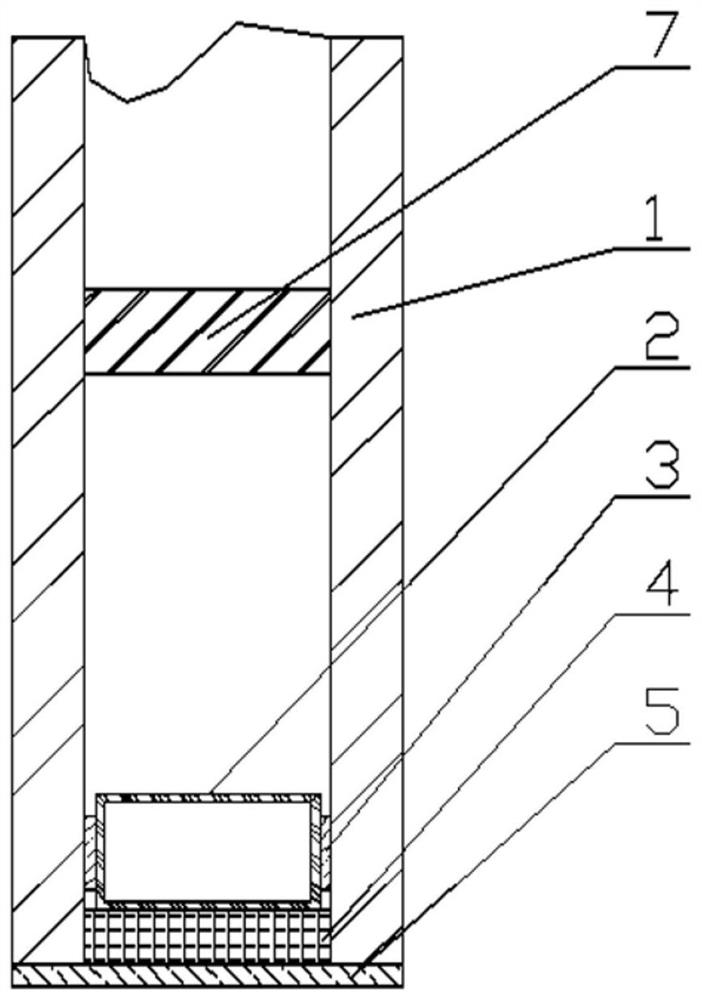

[0080] Embodiment 1: as figure 1 and Figure 10 As shown, a kind of negative pressure insulating glass comprises glass 1, spacer bar 2, first sealing layer 3, second sealing layer 4, third sealing layer 5 and support 7, cut two according to the size of the hollow glass made Glass 1 of the same size, and carry out edging and cleaning; when tempered glass is needed, enter the tempering furnace for tempering treatment; adopt existing insulating glass spacers, preferably warm edge strips, according to the size and shape of glass 1 and the first The glue thickness of the structural glue used in the sealing layer 4 is according to Figure 10 The length of each spacer 2 is determined by the placement method, the rectangular insulating glass uses 4 spacer 2, and the special-shaped insulating glass determines the number of spacer 2 according to the shape and size of the glass; Figure 10 The two ends of the four spacer bars 2 in the center are respectively cut into 45 degree angles s...

Embodiment 2

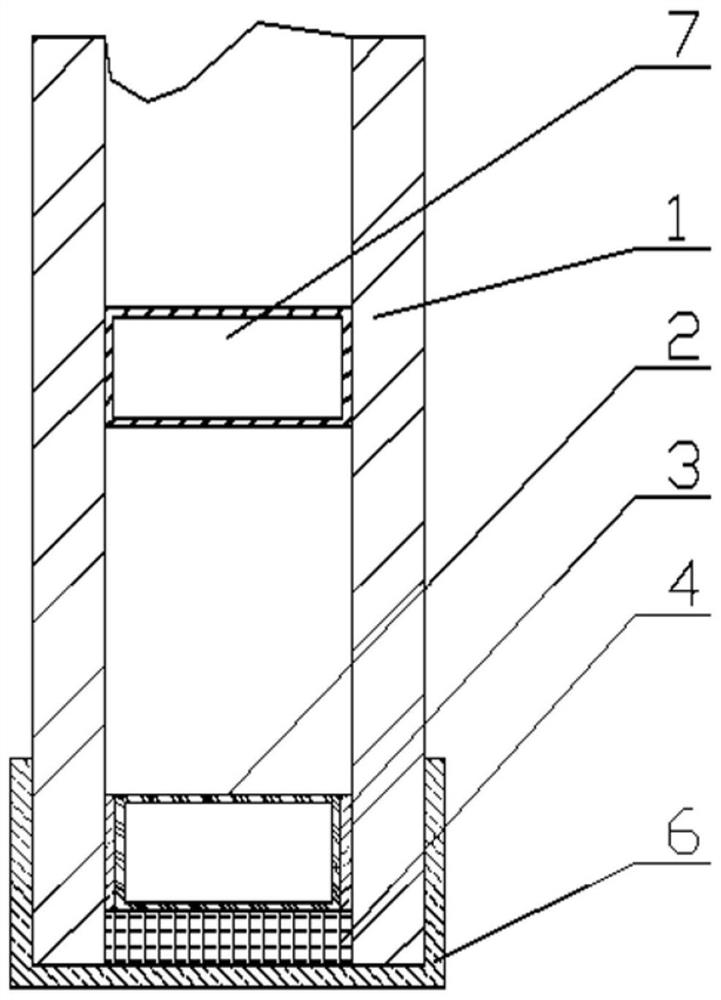

[0081] Embodiment 2: as figure 2 and Figure 11 As shown, a negative pressure insulating glass, including glass 1, spacer 2, first sealing layer 3, second sealing layer 4, fourth sealing layer 6 and support 7, is basically the same as embodiment 1, the difference The placement of the spacer bar 2 is as follows: Figure 11 As shown, the upper openings of the spacers 2 vertically placed on the left and right sides are exposed (the size of the exposure can be adjusted by the size of the cut corner), which facilitates the perfusion of molecular sieves and saves the process of punching holes on the spacers 2 , which saves equipment investment and processing time; the support 7 adopts a strip support, such as a spacer, and is bonded and fixed with a sealant; the first sealing layer 3 adopts a continuous bonding method, and continuous bonding has better Sealing effect; the difference is also that the fourth sealing layer 6 is used to replace the third sealing layer 5, the fourth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com