Method and device of automatically paving wall body mosaic pattern by utilizing small tiles

A mosaic and tile technology, applied in the field of architectural decoration, can solve the problems of pasting quality differences, heavy workload, complicated procedures, etc., achieve high placement efficiency, reduce labor costs, and ensure placement quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

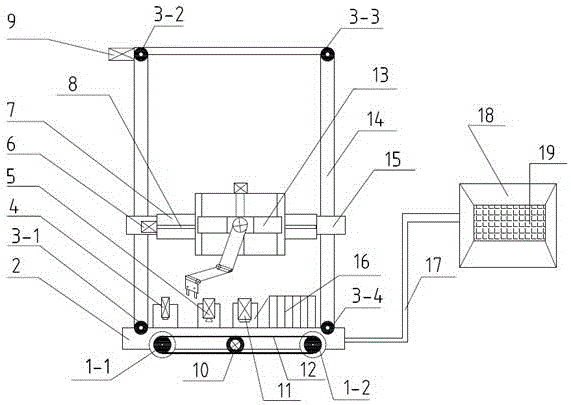

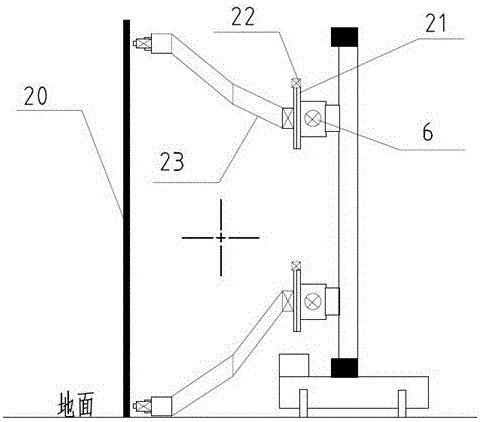

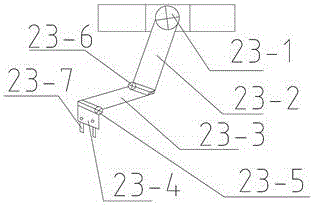

[0060] Example 1: Wall tile grid mosaic pattern placement

[0061] Turn on the hand-held box controller 18 and set it to manual control mode, perform servo power-on debugging on all motors, and move the chassis 2 to be parallel to the mounting wall through the button on the hand-held box controller 18 and keep it at At a distance of 40-60cm, move the beam slide 15 to a distance of 1 meter from the upper surface of the chassis 2; control the spatial posture of the mechanical arm 23 and the on-off of the biaxial cylinder 23-4, so that the clamp 23-7 is clamped Take out the laser rangefinder 4 and take it out; open the laser rangefinder 4, use the laser rangefinder 4 to measure the data information on the wall surface, and put the laser rangefinder 4 back to the original place after completion; open Man-machine interface 19, input the designed wall tile grid mosaic pattern text information, and according to the measured mounting wall data information, select small tiles with a si...

Embodiment 2

[0062] Example 2: Mounting of bird mosaic patterns on wall tiles

[0063]Turn on the hand-held box controller 18 and set it to manual control mode, perform servo power-on debugging on all motors, and move the chassis 2 to be parallel to the mounting wall through the button on the hand-held box controller 18 and keep it at At a distance of 40-60cm, move the beam slide 15 to a distance of 1 meter from the upper surface of the chassis 2; control the spatial posture of the mechanical arm 23 and the on-off of the biaxial cylinder 23-4, so that the clamp 23-7 is clamped Take out the laser rangefinder 4 and take it out; open the laser rangefinder 4, use the laser rangefinder 4 to measure the data information on the wall surface, and put the laser rangefinder 4 back to the original place after completion; open Man-machine interface 19, input the text information of the designed wall tile bird mosaic pattern, and according to the measured wall surface data information, select the size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com