High-efficiency surface mounting method and device

A placement machine and placement technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of large structure, low placement efficiency, and large area occupation, and achieve small footprint, improved placement efficiency, and land occupation. change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, specific implementations of the high-efficiency placement machine of the present invention will be introduced in conjunction with the accompanying drawings.

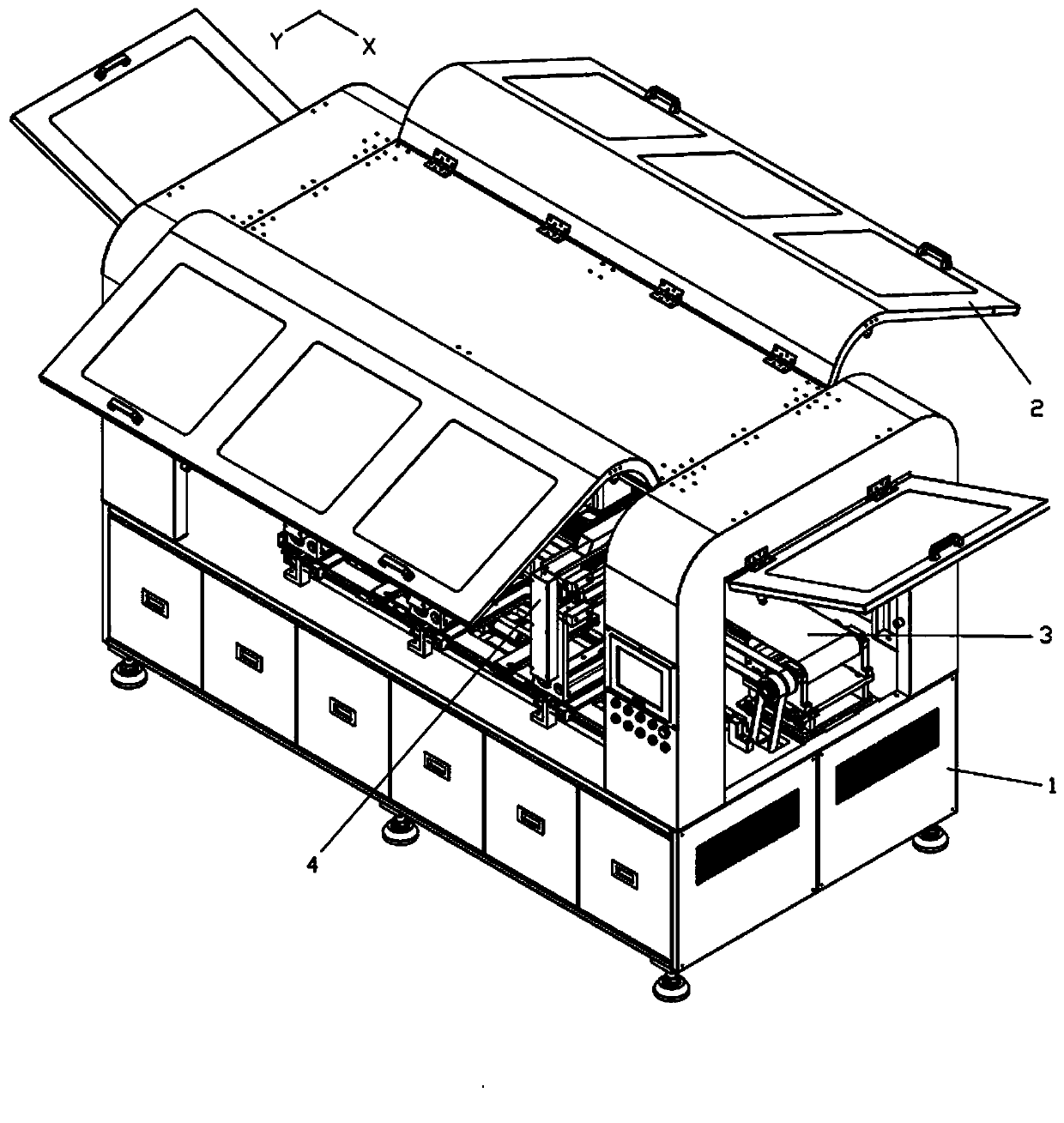

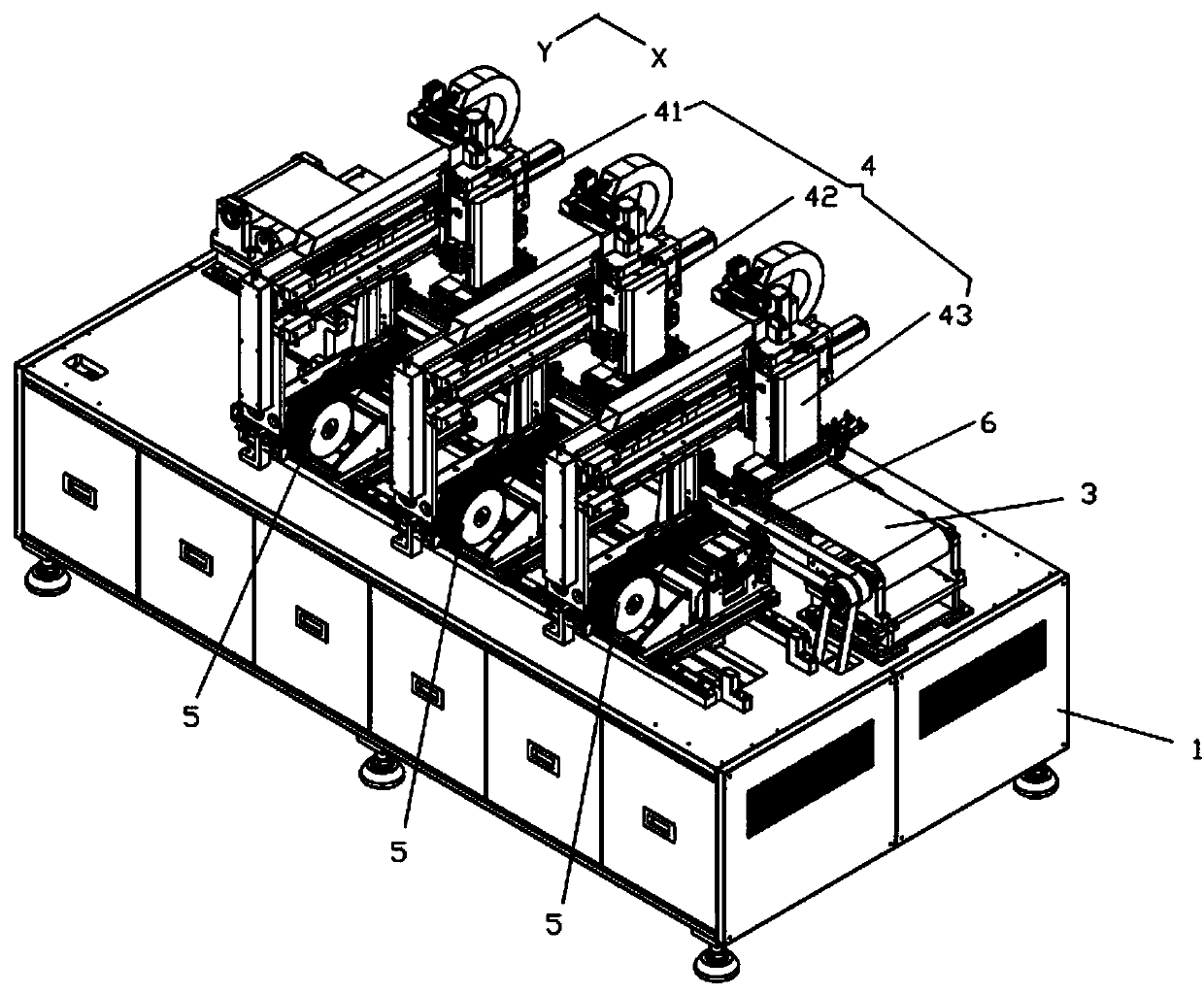

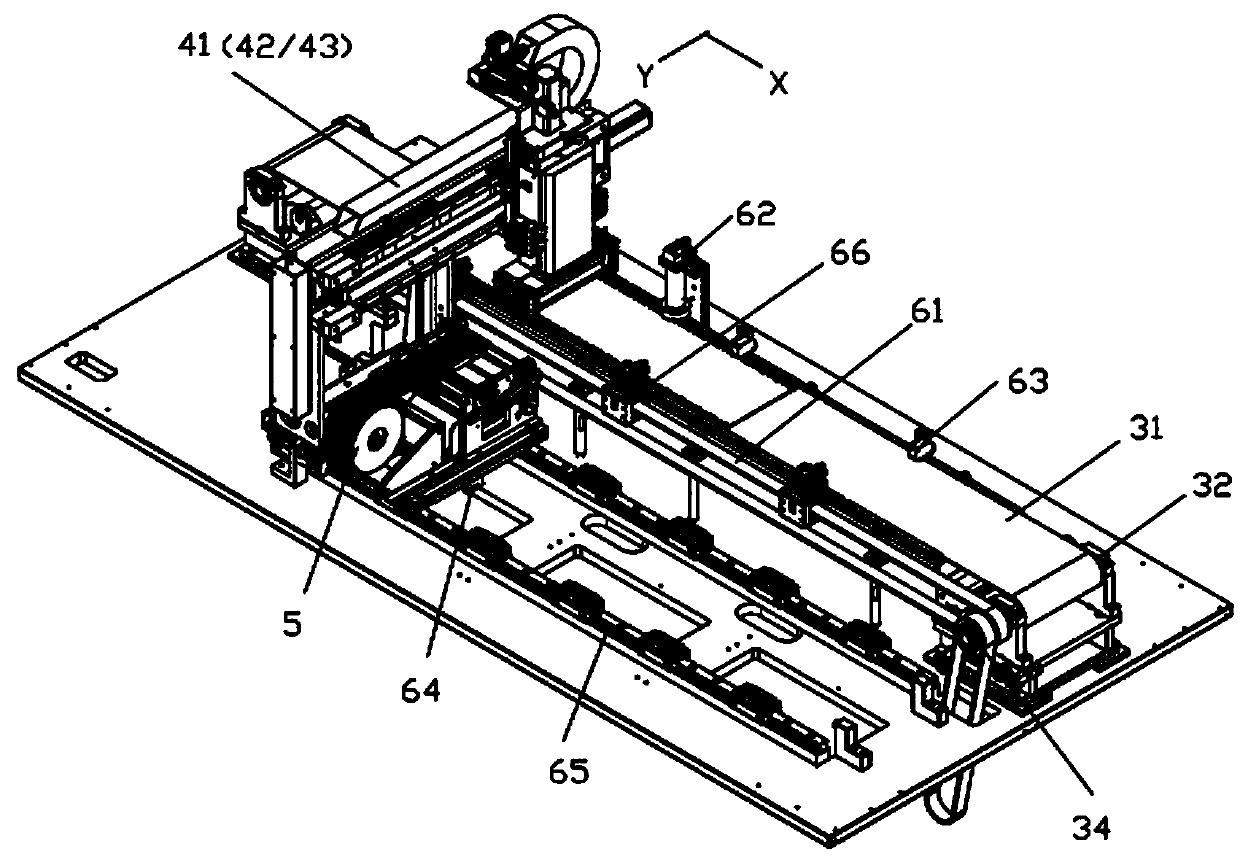

[0037] Such as figure 1 As shown, the high-efficiency placement machine includes a board feeding mechanism 3 for conveying circuit boards along the X direction, and a placement mechanism 4 for at least two groups of mounting components (in this embodiment, the first group of placement mechanisms 41, the second group of placement mechanisms chip mechanism 42 and the third group of chip placement mechanism 43), the conveying component mechanism 5, and the synchronous follower mechanism 6 that the chip placement mechanism and the circuit board run synchronously and at a constant speed when the chip placement mechanism mounts components.

[0038] Such as Figure 4 As shown, each group of patch mechanism 4 includes a moving beam device 44, a lifting slide device 45 and a suction element device 46. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com