Buzzer placing mechanism

A buzzer, automatic feeding technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of no production line, save labor, improve work efficiency and product quality, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

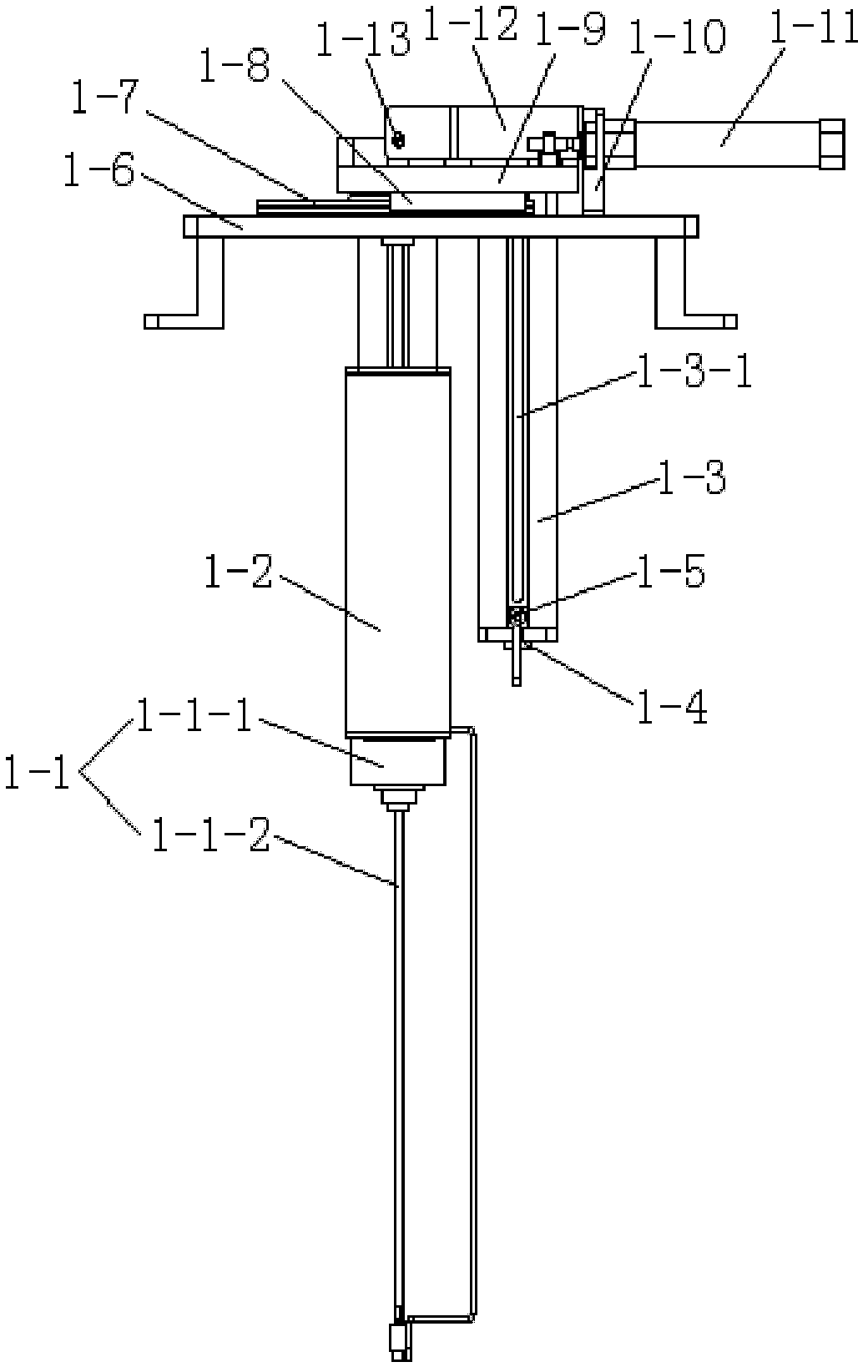

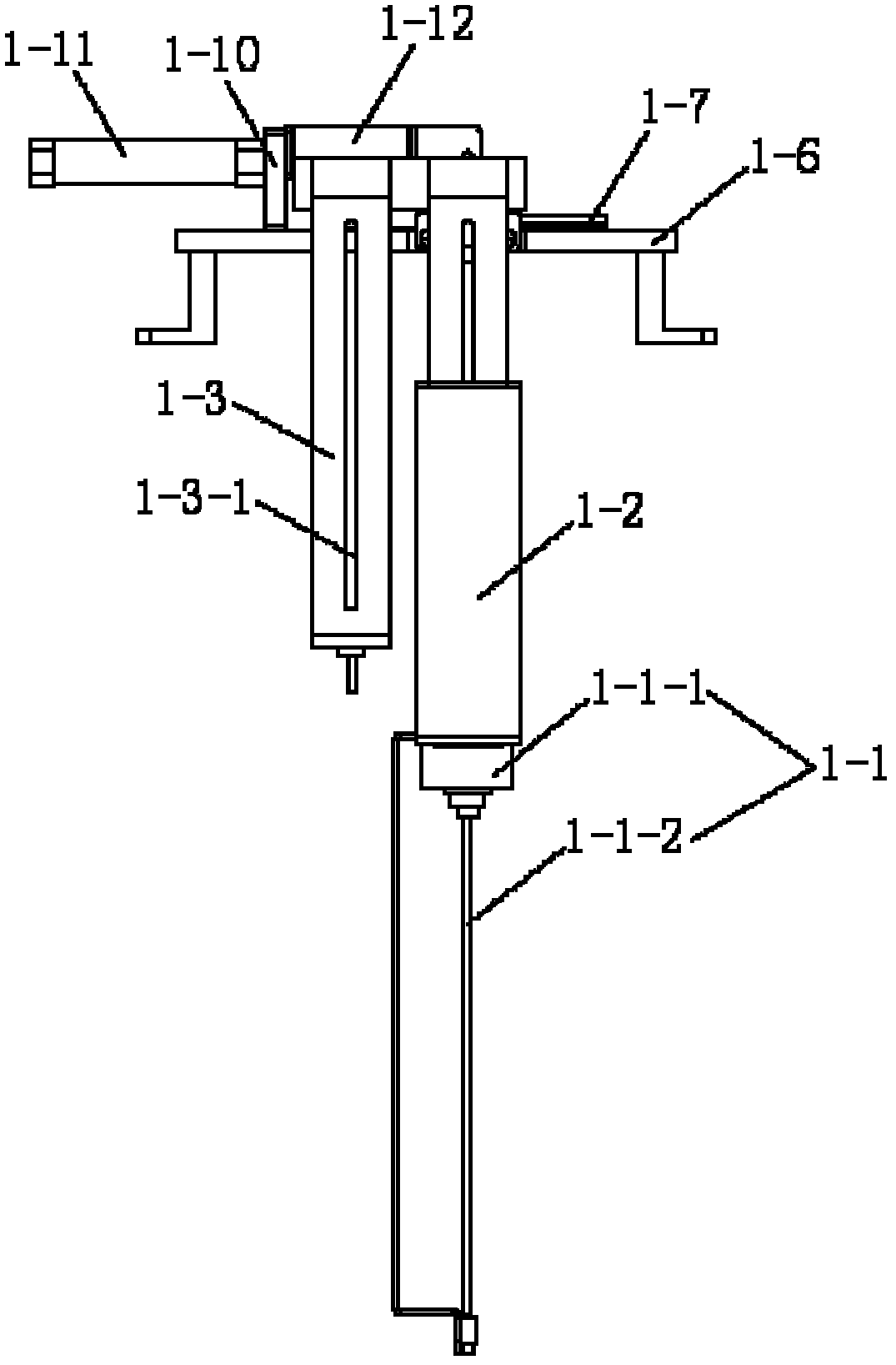

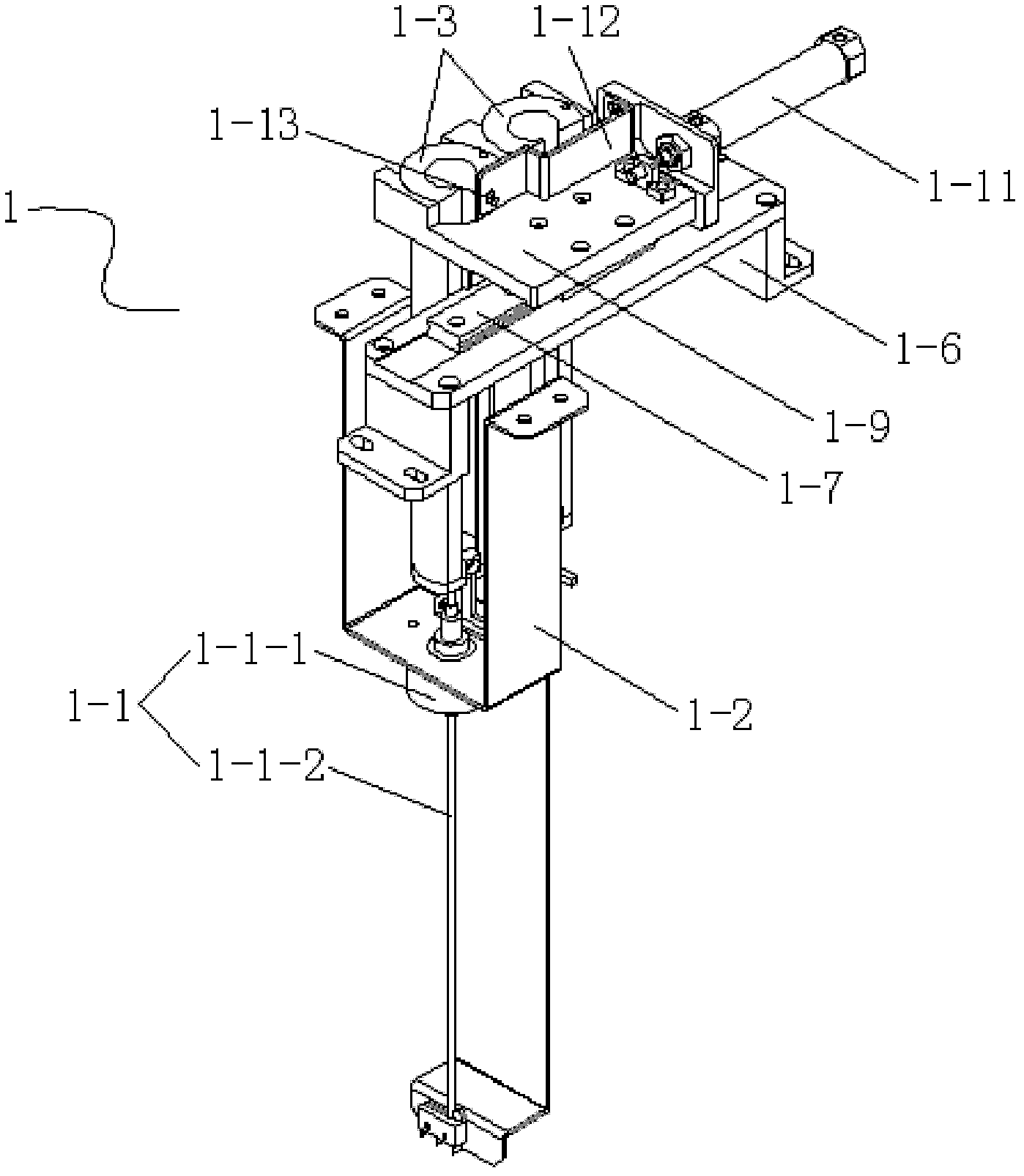

[0021] This embodiment includes an automatic feeding device 1 and a handling device 2 fixed on the workbench.

[0022] See Figure 1 to Figure 3 , the automatic feeding device 1 includes a linear stepper motor 1-1, a motor bracket 1-2, a barrel 1-3, a tray 1-4, a light sensor 1-5, a slide rail bracket 1-6, and a slide rail 1- 7. Slider 1-8, slider connecting plate 1-9, cylinder supporting plate 1-10, horizontal transposition cylinder 1-11, optical fiber sensor supporting plate 1-12 and reflective optical fiber sensor 1-13. The linear stepping motor 1-1 comprises a motor body 1-1-1 and a motor screw mandrel 1-1-2, the motor body 1-1-1 is fixed on the motor bracket 1-2, and the motor body 1-1-1 drives the motor The screw mandrel 1-1-2 moves up and down. The motor support 1-2 and the slide rail support 1-6 are respectively fixed on the lower end surface and the upper end surface of the workbench. The slide rail 1-7 is fixed on the slide rail support 1-6, the slide block 1-8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com