Multifunctional cable pay-off device applied to municipal power construction

A technology of electric power construction and pay-off device, which is applied in the direction of cable installation device, cable installation, cutting/split cable equipment, etc., and can solve problems such as low stability and shaking of the reel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

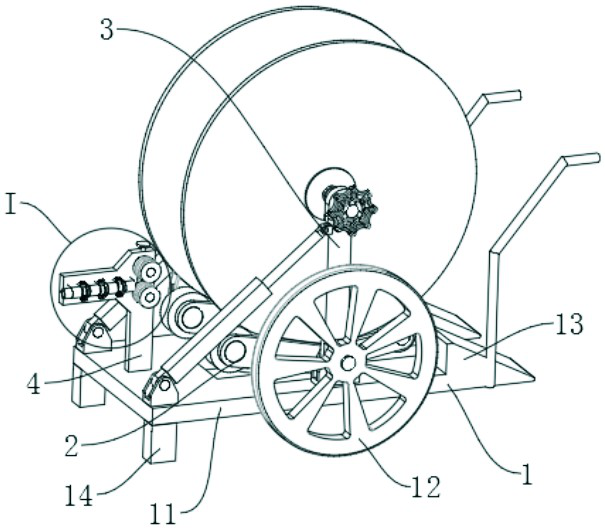

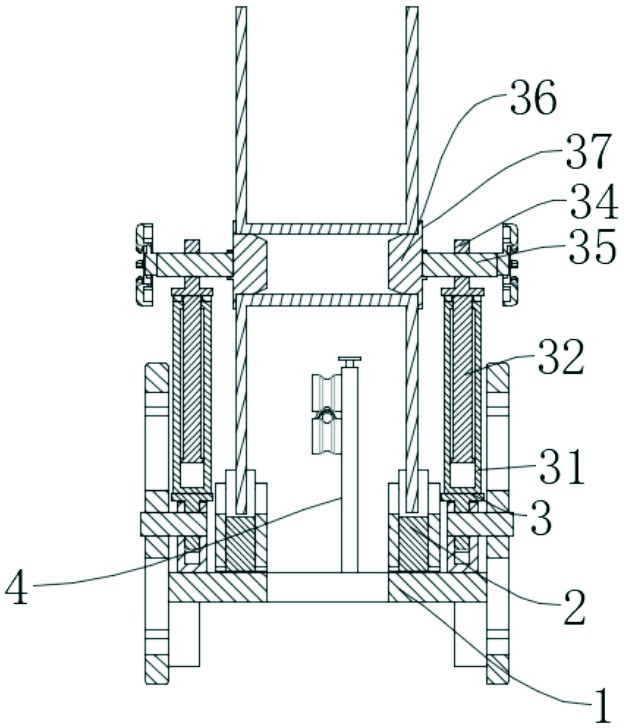

[0034] Embodiment one, such as Figure 1-7As shown, a multifunctional cable pay-off device applied to municipal electric power construction includes a mobile trolley 1, a supporting wheel mechanism 2, and an auxiliary mechanism 3. The middle part of the upper surface of the mobile trolley 1 is provided with a coil for supporting the wire to be unwound. The supporting wheel mechanism 2 of the wire reel, the upper plate surface of the mobile cart 1 located on both sides of the supporting wheel mechanism 2 is equipped with a wire reel to be placed on the supporting wheel mechanism 2, and the auxiliary supporting wheel mechanism 2 is stable. Auxiliary mechanism 3 of the wire reel for unwinding; auxiliary mechanism 3 includes sleeve pipe 31, inner rod 32, electric telescopic rod 33, mounting block 34, first lead screw 35, support shaft 36, annular baffle plate 37, sleeve pipe 31 The lower end is hinged with the upper surface of the mobile trolley 1, the inner cavity of the casing 3...

Embodiment 2

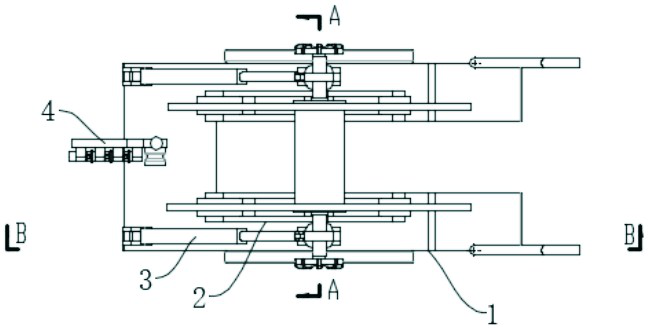

[0036] Embodiment two, on the basis of embodiment one, such as Figure 1-5 As shown, the supporting wheel mechanism 2 includes a fixed seat 21, a mounting seat 22, a first supporting wheel 23, a second supporting wheel 24, and a first wedge block 26. The mounting seat 22 is a V-shaped structure, and the tip is installed on the mobile cart 1. The fixed seat 21 on the upper plate surface is hinged, and the ends on both sides of the opening of the mounting seat 22 are respectively rotated and connected to the first supporting wheel 23 and the second supporting wheel 24 for supporting the surface of the reel to be unwound, and the mobile trolley 1 The upper plate surface is provided with the first wedge-shaped block 26 corresponding to the opening side of the mounting seat 22, and the mounting seat 22 can also be a T-shaped structure or other structures, as long as it can ensure that the first support roller 23 and the second support roller 24 are compatible with the The surface o...

Embodiment 3

[0039] Embodiment three, on the basis of embodiment one, such as figure 1 As shown, the mobile trolley 1 includes a base plate 11, wheels 12, and support legs 14. Push handles are provided on both sides of one end of the base plate 11, wheels 12 are provided at the middle position on both sides of the base plate 11, and a support for supporting the base plate 11 is provided at the other end of the base plate 11. Support leg 14, and the height of support leg 14 is lower than wheel 12 and is positioned at the height of base plate 11 lower part, arranges like this when support leg 14 touches the ground, base plate 11 is in the state of inclination, and rear end is inclined downward, can pass support leg like this 14 is on the ground so that the mobile trolley 1 will not move autonomously. Therefore, when unwinding, there is no need for a staff to hold the mobile trolley 1. Since the wheels are located on both sides of the base plate 11, and the wheel axles of the wheels are locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com