Mechanism for grabbing and placing massive objects

An object and block technology, which is applied in the field of grasping and placing mechanisms of block objects, can solve the problems of wasting manpower and time, and achieve the effect of improving efficiency and saving manpower and time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

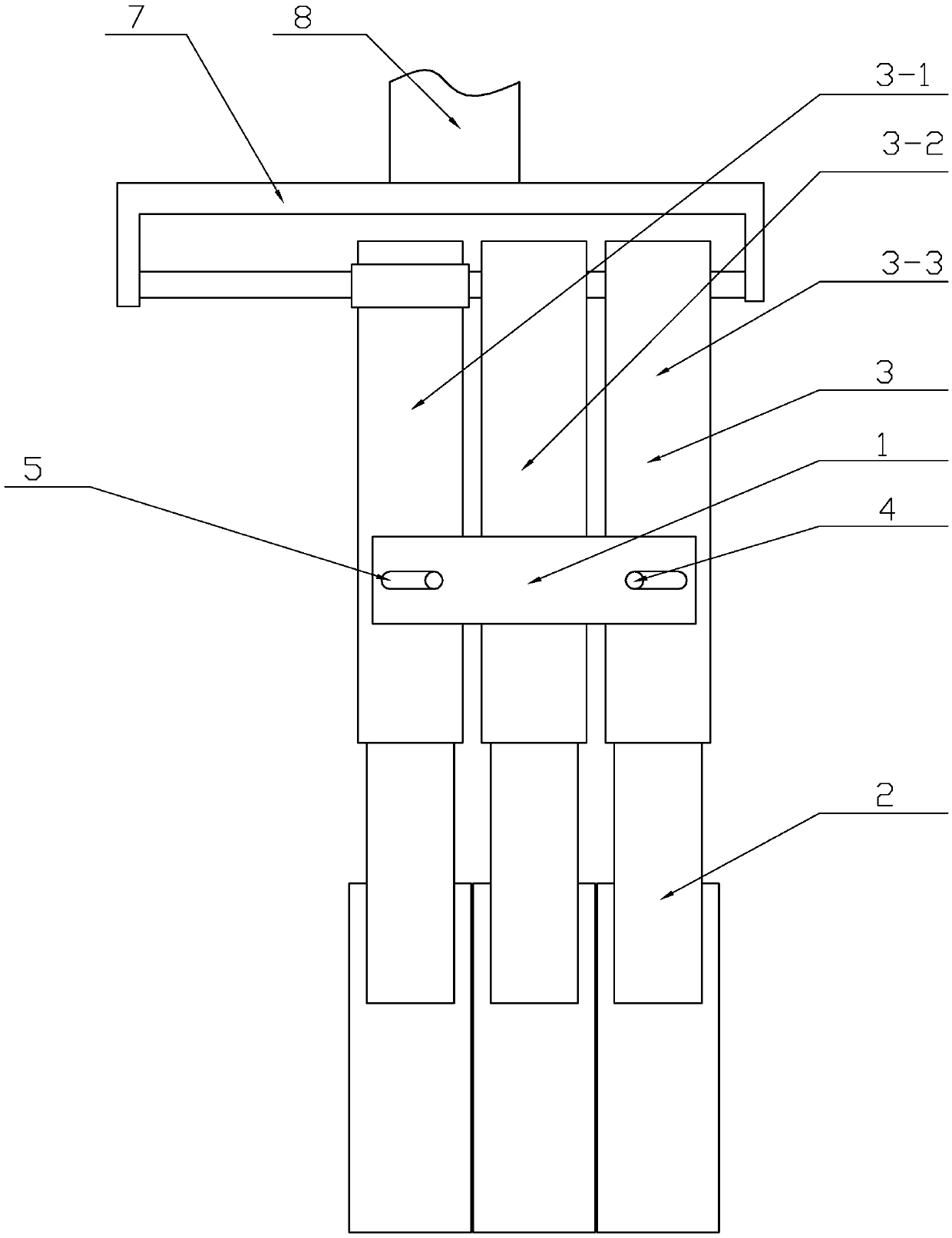

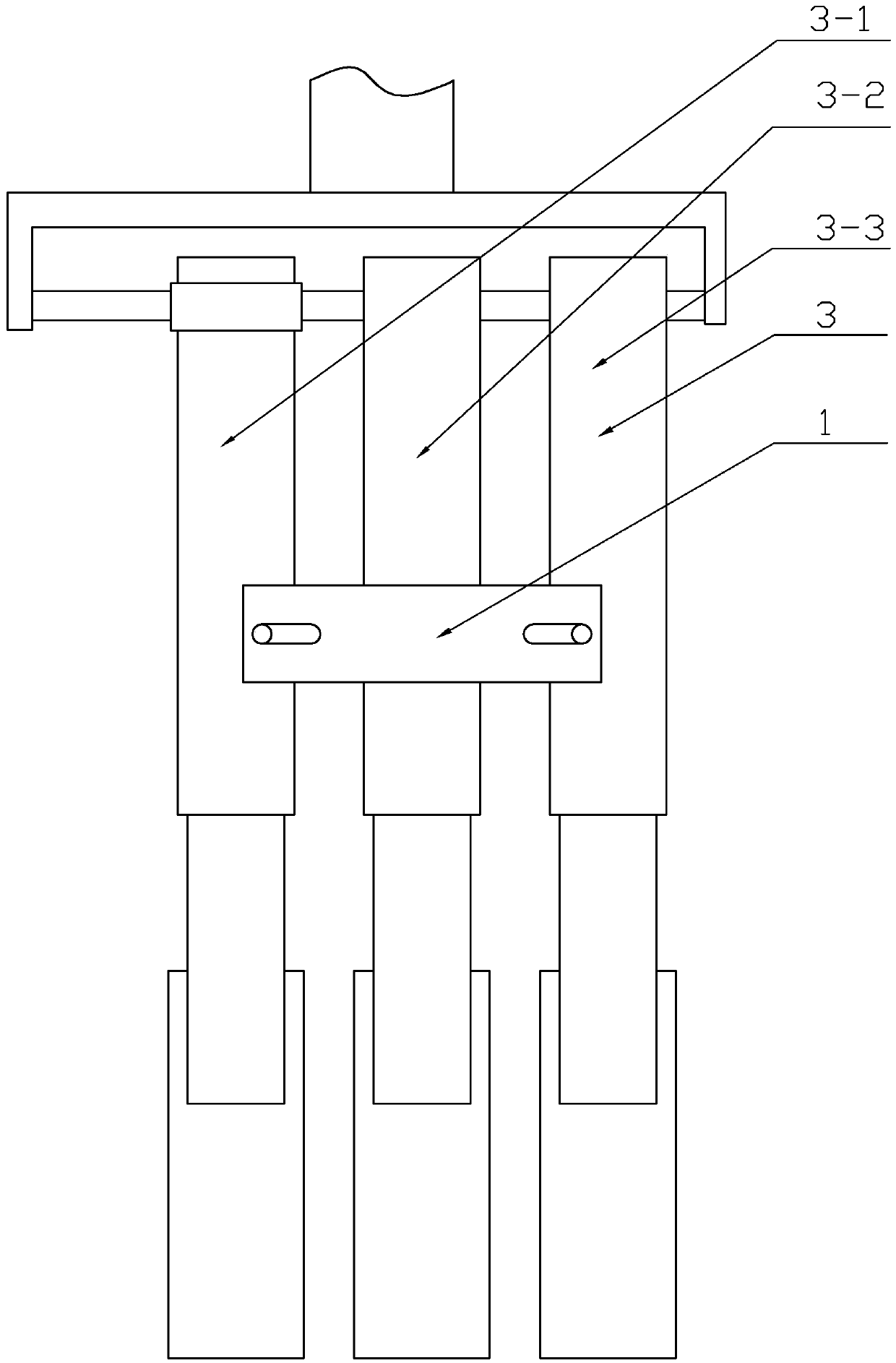

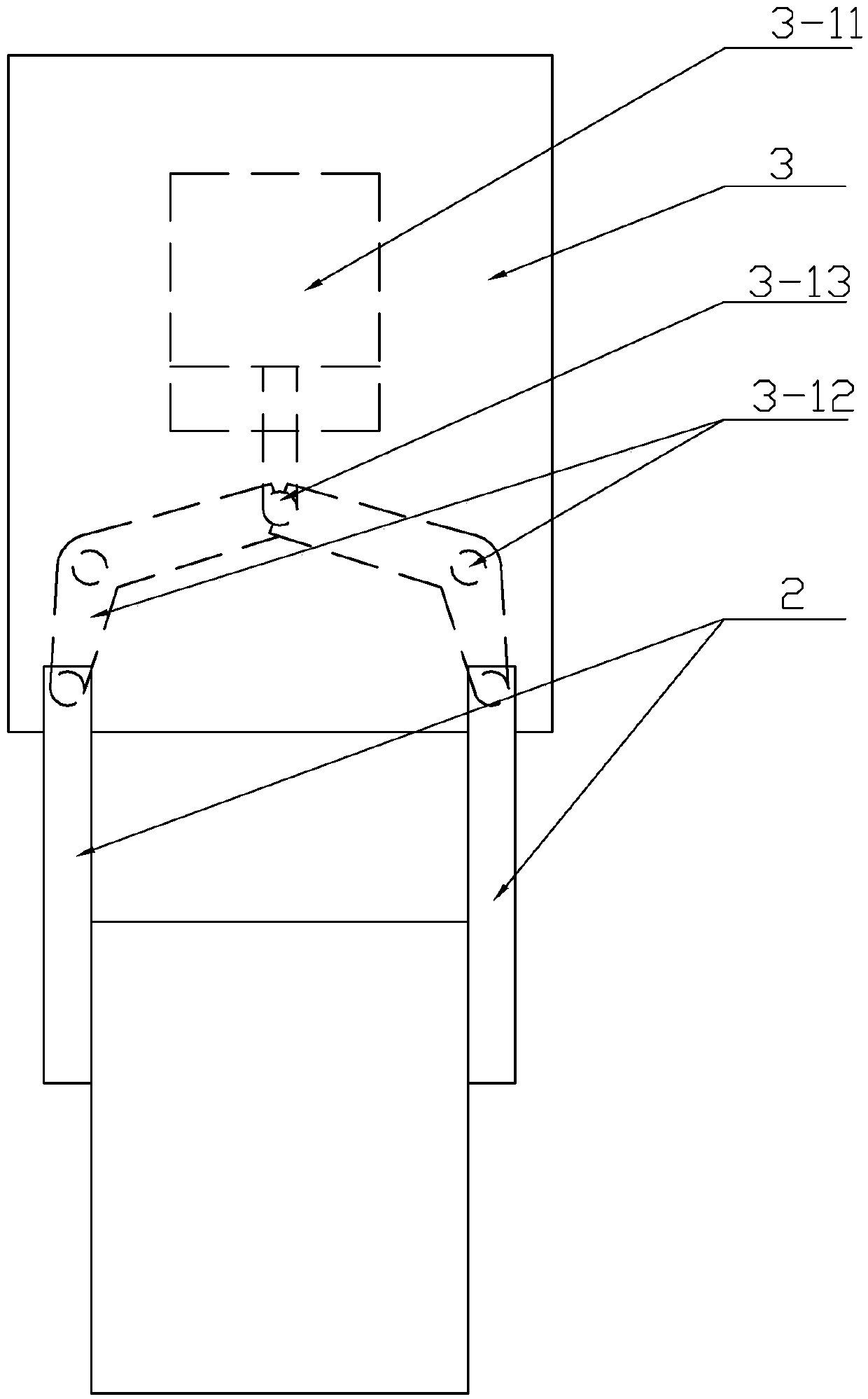

[0018] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, a mechanism for grabbing and placing massive objects in this embodiment, which is characterized in that it includes two connecting pieces 1, three sets of grabbing pieces 2 and three control grabbing sheets The grabbing piece driving mechanism 3 with combined action, a set of grabbing pieces 2 is fixedly connected to the lower end of each grabbing piece driving mechanism 3, and the three grabbing piece driving mechanisms 3 are arranged side by side in sequence and are movably connected by the pin 4 and the connecting piece 1 .

[0019] Each grab piece driving mechanism 3 can be screw drive, also can be cylinder expansion and contraction, by grabbing the reciprocating motion of piece driving mechanism 3, drive every group of grabbing pieces 2 pieces to close, finish the grab action of distiller's yeast piece, successively One of the three grasping piece driving mechanisms 3 arranged...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination Figure 1 ~ Figure 3 To illustrate this embodiment, the three grabbing piece driving mechanisms 3 are respectively the first grabbing piece driving mechanism 3-1, the second grabbing piece driving mechanism 3-2 and the third grabbing piece driving mechanism 3-3, two The connecting piece 1 is relatively fixedly connected to both sides of the second grabbing piece driving mechanism 3-2, and each connecting piece 1 is provided with two long holes 5, and the first grabbing piece driving mechanism 3-1 and the third grabbing piece driving mechanism 3-1 The driving mechanism 3-3 for taking the piece is all movably connected with the second grabbing piece driving mechanism 3-2 through the pin 4 and the long hole 5 on the connecting piece 1 . In such a design, the pins 4 are all located in the long holes 5, and the original positions of the pins 4 are all on the side close to the second grabbing piece driving mechanism, and the first...

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 To illustrate this embodiment, each group of grasping sheets 2 is two oppositely disposed grasping sheets. With such a design, the structure of the grasping piece is simple, because its own sheet structure makes the force of the blocky object more uniform when grasping, and avoids destroying the structure and shape of the blocky object, especially the distiller's yeast block. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com