Hollow glass with edge sealed by PUR glue and manufacturing method thereof

A glass and hollow technology, which is applied in the field of PUR glue-sealed hollow glass and its production, can solve the problems of low degree of mechanization and automation, shortened life, difficult to reconcile moisture absorption, etc., and achieve high degree of mechanization and automation, minus irrigation Installation process and equipment, good air tightness and water tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

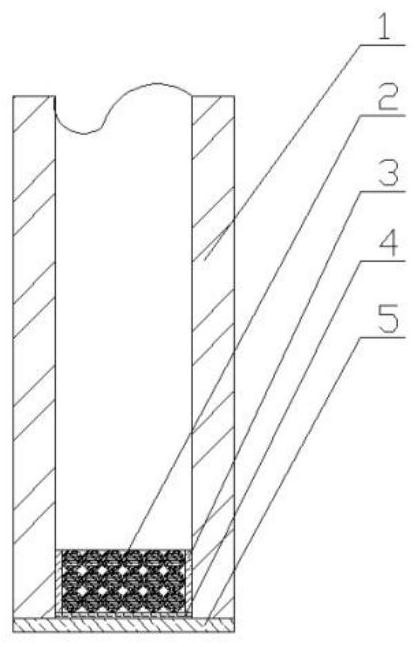

[0173] refer to figure 1 and Figure 10 , a kind of hollow glass edge-sealed with PUR glue, including glass 1, spacer bar 2, seal one 3, seal two 4 and seal three 5, cut two pieces of glass 1 of the same size according to the size of the hollow glass made, and carry out Edge grinding and cleaning; when tempered glass is required, enter the tempering furnace for tempering treatment; spacers made of molecular sieves, including molecular sieves and adhesives, 3A molecular sieves with a particle size of 1.4-2.0mm for molecular screening, adhesive selection Commonly used plastics such as PE, PP, PA, PS, PVC, ABS, PU, TPS, etc. can also choose hot melt adhesives such as EVA, TPR, PA, PES, PEA, TPE, PUR, TPU, etc., and can also choose hot melt adhesives Pressure-sensitive adhesive or hot-melt butyl adhesive makes the spacer self-adhesive, and there is no need to glue it when it is bonded to the glass; since the adhesive is mainly used for bonding, conventional raw materials with w...

Embodiment 2

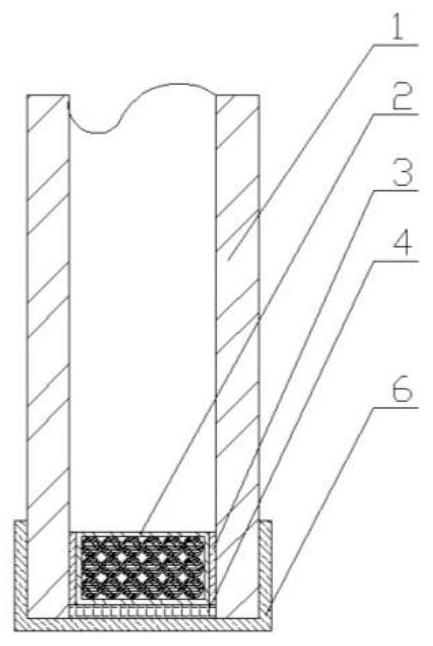

[0175] refer to figure 2 and Figure 11 , a kind of hollow glass edge-sealed with PUR glue, including glass 1, spacer 2, seal 3, seal 2 4 and seal 4 6, basically the same as embodiment 1, the difference is that spacer 2 adopts existing hollow glass Cavity spacer, such as aluminum spacer, stainless steel composite spacer, plastic fiberglass warm edge, etc. Spacer 2 has a bending gap and is filled with molecular sieve with slow suction function, such as Figure 11 As shown, there is a bending gap, and the placement and bending of the spacer bar 2 are also simpler and easier; the difference is that the seal 4 6 is used to replace the seal 3 5, and the seal 4 6 is a sealing tape (applied on the sealing tape on site. Apply PUR glue), seal 4 6 is the periphery of U-shaped sealed hollow glass, compared with embodiment 1, not only sealing effect is good, sealing time is long, and two pieces of glass 1 have better clamping and fixing and protection effect, In addition, it also has a...

Embodiment 3

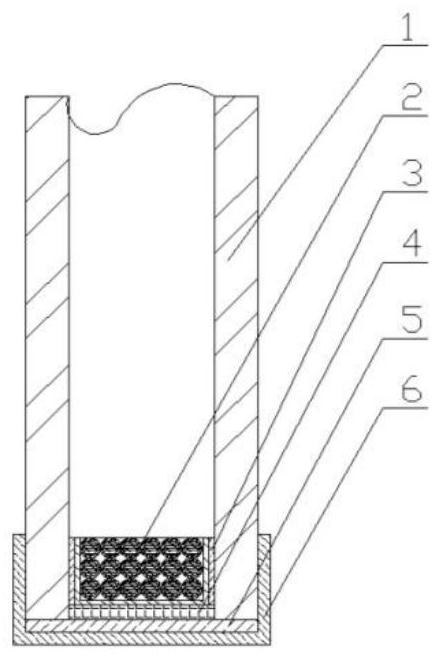

[0177] refer to image 3 and Figure 12 , a kind of hollow glass edge-sealed with PUR glue, including glass 1, spacer 2, seal 1 3, seal 2 4, seal 3 5 and seal 4 6, basically the same as embodiment 1, the difference is that spacer 2 uses Molecular sieve spacers with U-shaped dense layers, such as Figure 12 As shown, the spacer 2 adopts the method of prefabricating the bending gap, that is, the gap is pre-made at the bend, and the gap can be pressed with a mold or cut with a knife. With the gap, the bending of the spacer can become very simple and convenient. Accurate; in addition, the winding, placement and positioning are relatively simple; the difference is that there are four seals at the same time: seal 1 3, seal 2 4, seal 3 5 and seal 4 6, so the sealing performance is better and the glass is fixed and stronger protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com