Floor building glass

A floor building and glass technology, applied in the direction of buildings, building components, building components, etc., can solve the problems of self-explosion of glass, hidden dangers, poor sound insulation effect, etc., to prevent the self-explosion of glass, prevent the problem of explosion, and improve the experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

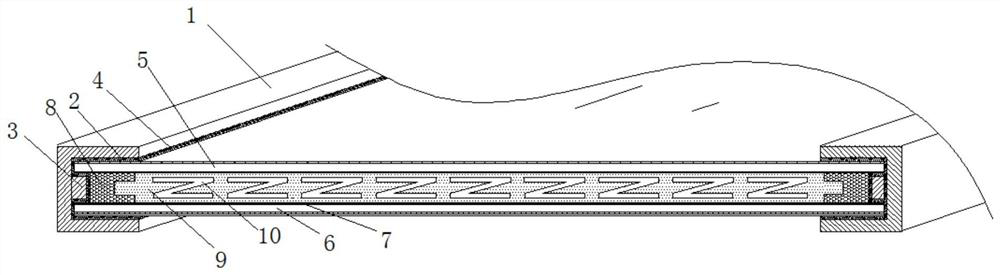

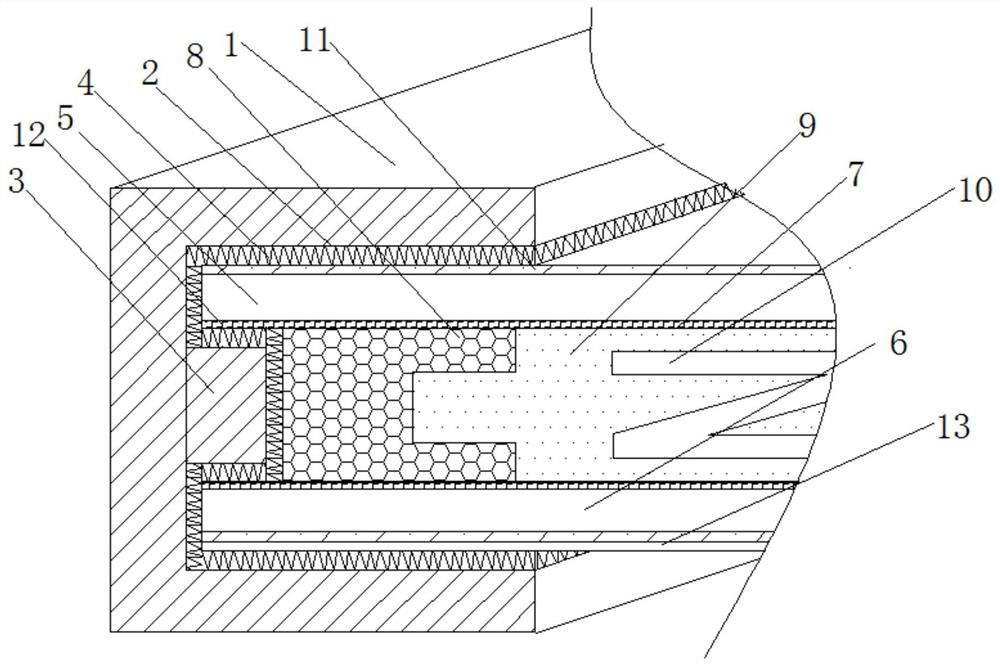

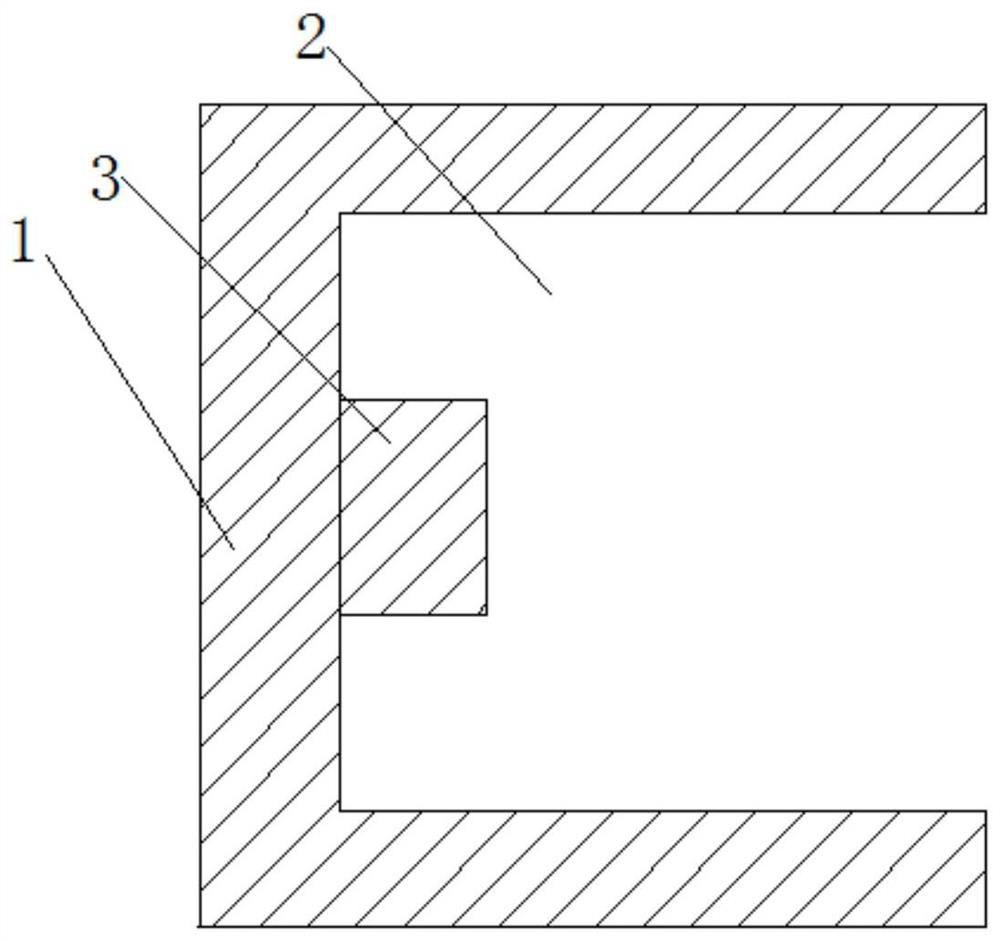

[0024] A storey architectural glass such as Figure 1-Figure 4 As shown, including the window frame body 1, the inside right side of the window frame body 1 is provided with an installation groove 2, the inside of the installation groove 2 is welded with a warm edge spacer 3, and the inside of the installation groove 2 is bonded with a hot melt adhesive layer 4, The inside of the hot melt adhesive layer 4 is respectively bonded with a glass inner plate 5 and a glass outer plate 6, the glass inner plate 5 is located above the glass outer plate 6, and a cavity 7 is opened between the glass inner plate 5 and the glass outer plate 6 , the interior of the cavity 7 is respectively bonded with a soundproof cotton 8 and a transparent silicone panel 9, the soundproof cotton 8 is located on both sides of the transparent silicone panel 9, and the inside of the transparent silicone panel 9 is provided with a soundproof layer 10.

[0025] In this embodiment, the model of the transparent si...

Embodiment 2

[0029] Such as figure 2 As shown, the top of the glass inner panel 5 and the bottom of the glass outer panel 6 are bonded with an explosion-proof membrane 11, and the bottom of the glass inner panel 5 and the top of the glass outer panel 6 are bonded with glass fiber filaments 12, and the explosion-proof membrane 11 The bottom is bonded with a thermal insulation film 13, and the explosion-proof film 11 has good safety and explosion-proof performance. When the glass breaks, it can be bonded to the shattered glass to avoid glass splashing and falling, and to ensure the safety of indoor and outdoor personnel. The glass fiber filament 12 has the effects of high elasticity, good rigidity, heat resistance, and light transmission, which can avoid the effect of glass self-explosion to a certain extent. Effect of too high indoor temperature.

[0030] In the present embodiment, the thickness of the explosion-proof film 11 is set to 3mil, and the model of the explosion-proof film 11 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com