Patents

Literature

121results about How to "To achieve the effect of heat insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous colored transparent heat insulation coating, and preparation method and use method thereof

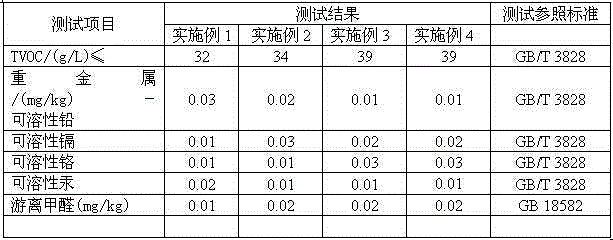

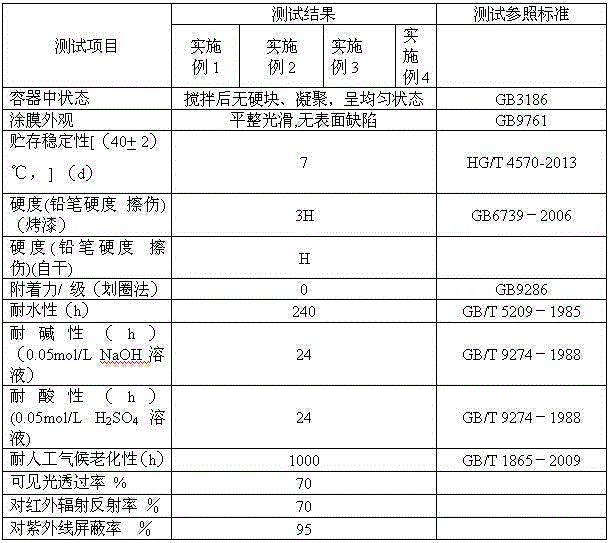

ActiveCN104151970AHigh hydroxyl contentImprove water resistanceReflecting/signal paintsMulticolor effect coatingsTin dioxidePolymer science

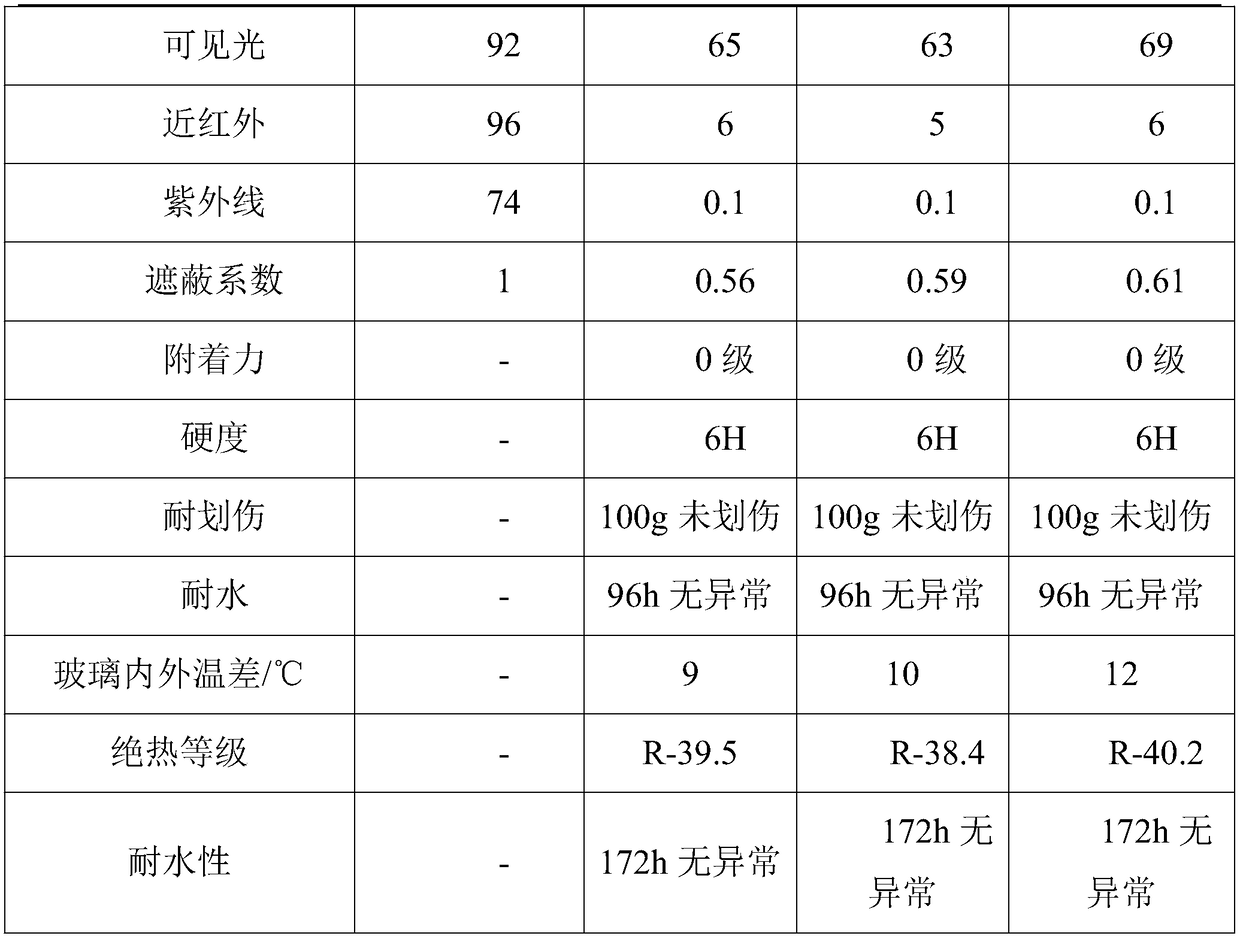

The invention discloses an aqueous colored transparent heat insulation coating, and a preparation method and a use method thereof. The aqueous colored transparent heat insulation coating is composed of a water-soluble hydroxy acrylic resin, an aqueous nanometer antimony-doped tin dioxide (ATO) slurry, an aqueous nanometer hydrotalcite slurry, an amino resin, an aqueous color paste, a film forming assistant, deionized water, a dispersant, a wetting agent, a pH adjusting agent, an antifoaming agent, an anti-settling slurry, a thickening agent, an adhesion accelerant and a leveling agent. The preparation method is characterized in that above substances are mixed under specific conditions to obtain the coating. The use method is characterized in that the addition amount of the amino resin is 4-8wt% when the coating is used as a single-component baking varnish; and the addition amount of the amino resin is 0 when the coating is used as a two-component air-dried paint. The coating has the advantages of very good adhesion, high hardness, excellent ageing resistance and good heat insulation effect on the surfaces of glass, plastic films and the like.

Owner:肇庆千江高新材料科技股份公司

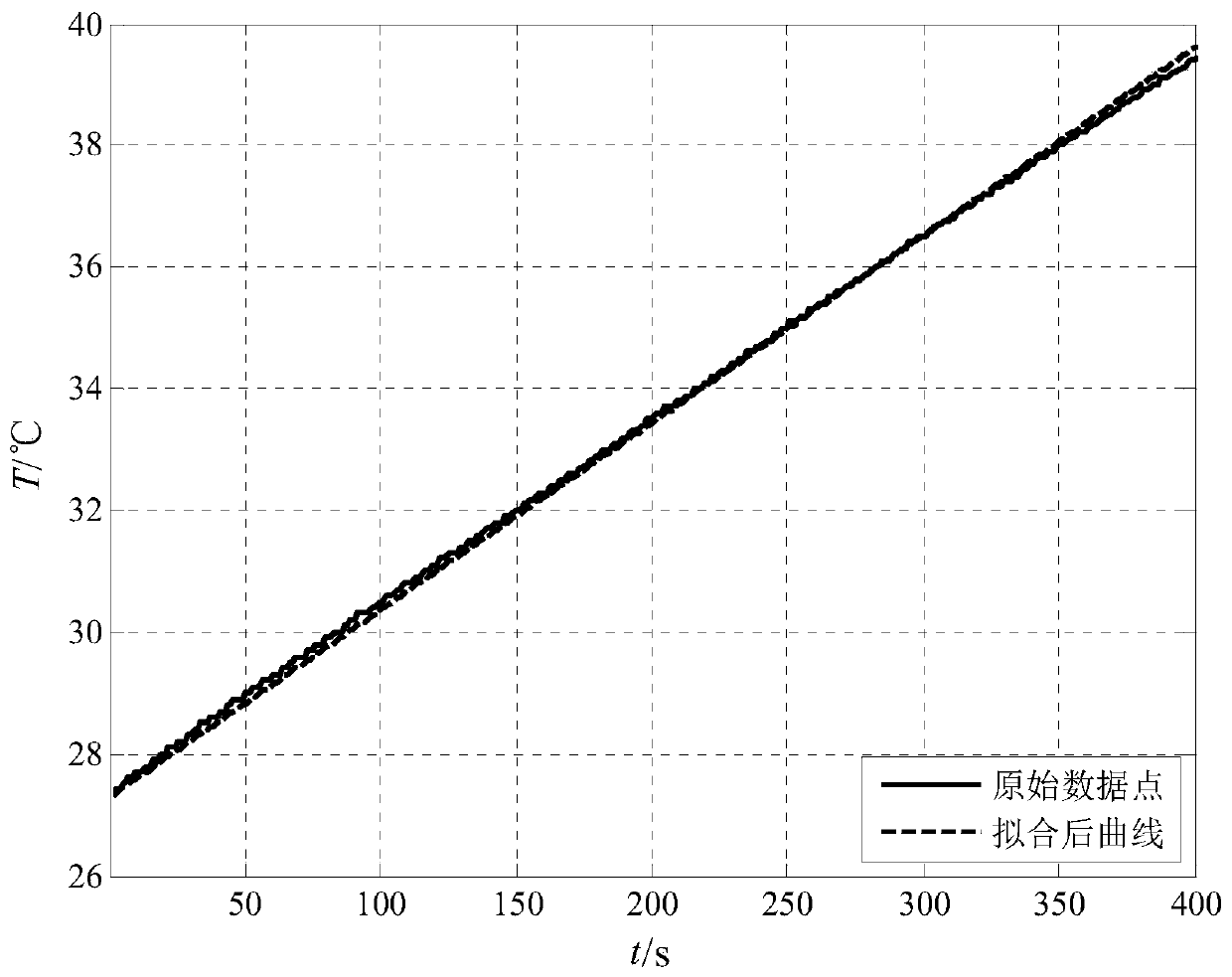

Square lithium ion battery internal thermophysical parameter identification method

ActiveCN109900734ARealize the establishmentAvoid errorsMaterial heat developmentSecondary cellsTwo temperatureEngineering

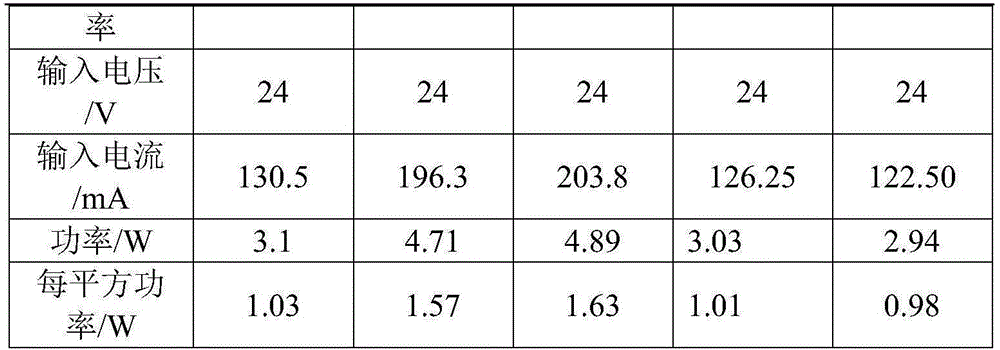

The invention relates to a square lithium ion battery internal thermophysical parameter identification method and belongs to the field of lithium ion batteries. According to methods for directly obtaining the analytical solutions of heat transfer model equations in existing battery thermophysical parameter identification methods, the overall parameters of batteries are identified, and the internalthermophysical properties of the batteries cannot be identified, while, with the square lithium ion battery internal thermophysical parameter identification method of the invention adopted, the problems in the existing methods can be solved. According to the square lithium ion battery internal thermophysical parameter identification method of the invention, the internal specific heat at constantpressure of a battery is obtained according to battery shell and internal mass, the specific heat at constant pressure of battery shells, heating power and the relation of the temperature of the battery varying with heating time; and the internal longitudinal thermal conductivity coefficient of the battery is obtained according to a heat transfer process, specific heat capacity and boundary conditions; two thermocouples on each battery shell are adopted to obtain two temperatures, and the temperatures of two temperature points at the inner sides of an equal thickness of the lithium ion batteryshells are obtained according to the longitudinal thermal conductivity coefficient and a heat transfer model; and on the basis of the two temperature points and the boundary conditions, the transverse thermal conductivity coefficient of the internal material of the battery is obtained according to the heat transfer model. The method is used to identify the internal thermophysical parameters of the battery.

Owner:HARBIN INST OF TECH

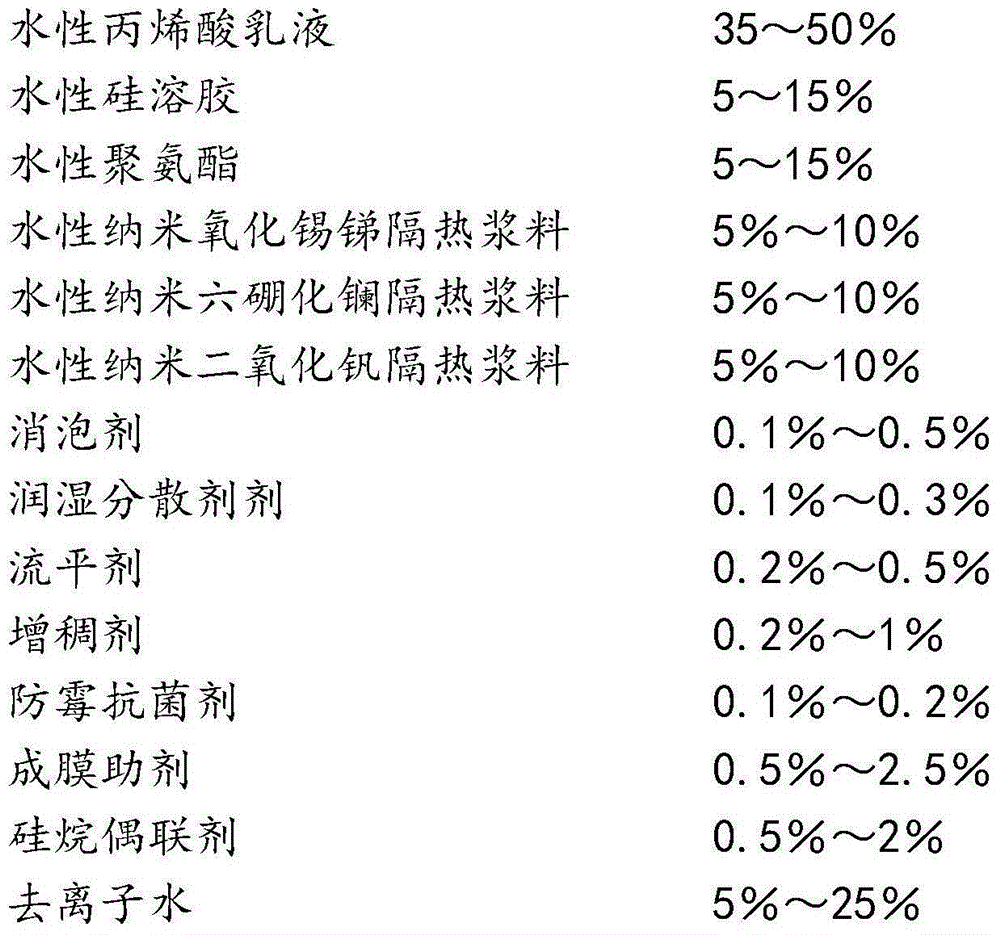

Water glass transparent reflecting heat-insulation coating material and preparation method thereof

InactiveCN106167657AAchieve a closed effectImprove lighting effectsPolyurea/polyurethane coatingsReflecting/signal paintsVanadium dioxideSlurry

The invention discloses a water glass transparent reflecting heat-insulation coating material and a preparation method thereof, wherein the water glass transparent reflecting heat-insulation coating material comprises, by mass, 35-50% of an aqueous acrylic emulsion, 5-15% of an aqueous silica sol, 5-15% of an aqueous polyurethane, 5-10% of an aqueous nanometer antimony tin oxide heat-insulation slurry, 5-10% of an aqueous nanometer lanthanum hexaboride heat-insulation slurry, 5-10% of an aqueous nanometer vanadium dioxide heat-insulation slurry, 0.1-0.5% of an anti-foaming agent, 0.1-0.3% of a wetting dispersing agent, 0.2-0.5% of a leveling agent, 0.2-1% of a thickening agent, 0.1-0.2% of an anti-mildew antibacterial agent, 0.5-2.5% of a film forming auxiliary agent, 0.5-2% of a silane coupling agent, and 5-25% of deionized water.

Owner:刘生金

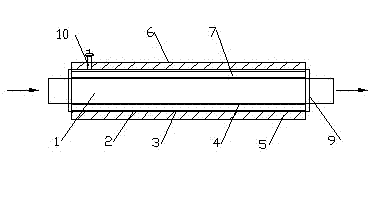

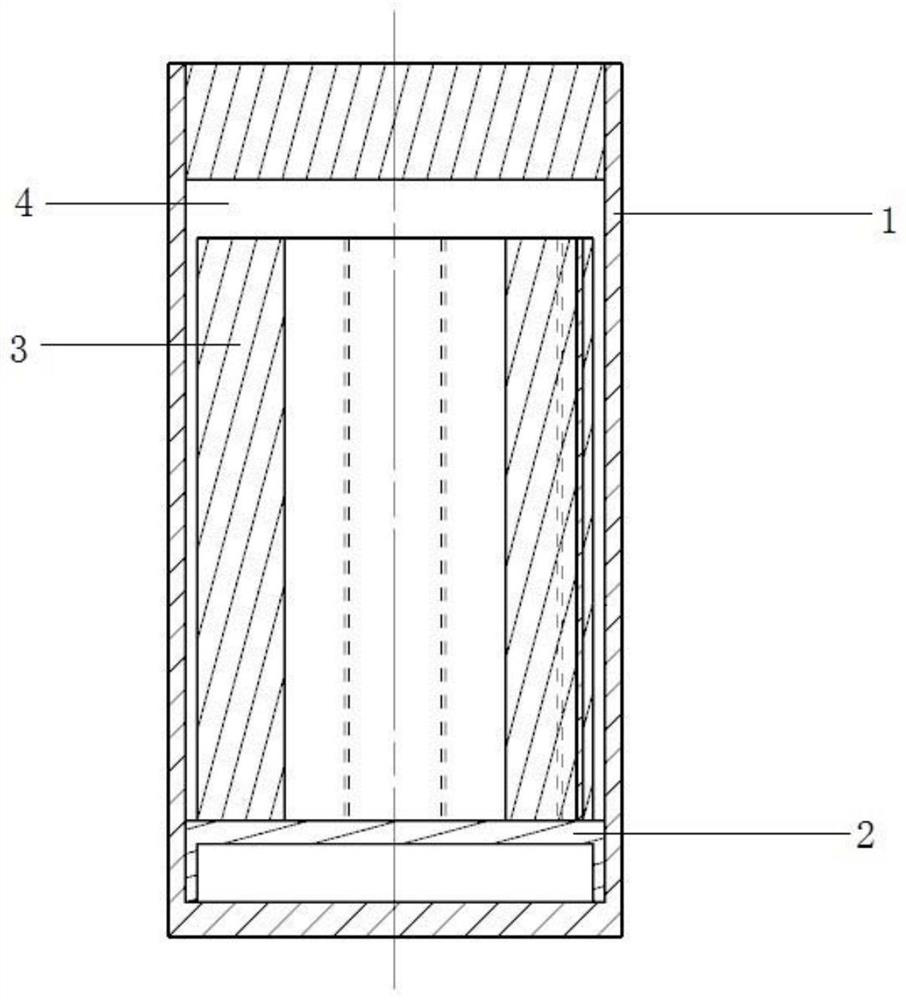

Vacuum heat insulation heat fluid energy-saving running pipeline

InactiveCN103090156AReduce maintenance costsReduce radiation lossThermal insulationPipe protection by thermal insulationSteel tubeFluid pipe

Provided is a vacuum heat insulation heat fluid energy-saving running pipeline. The vacuum heat insulation heat fluid energy-saving running pipeline comprises an inner fluid pipe and a shell steel pipe, the inner fluid pipe is arranged in the shell steel pipe in a sleeved mode, the two ends of the shell steel pipe is sealed by an end sealing plate and a vacuum heat insulation layer is formed between the two pipes, and the vacuum heat insulation layer is communicated with a sealed valve. By utilizing a triple heat insulation structure, heat energy radiation loss and cold coagulation in a steam, hot water transportation process are reduced, and the problems of relatively large single (double) way heat loss, high heat loss rate and low heat utilization efficiency of an existing running pipeline are reduced.

Owner:沈双喜 +1

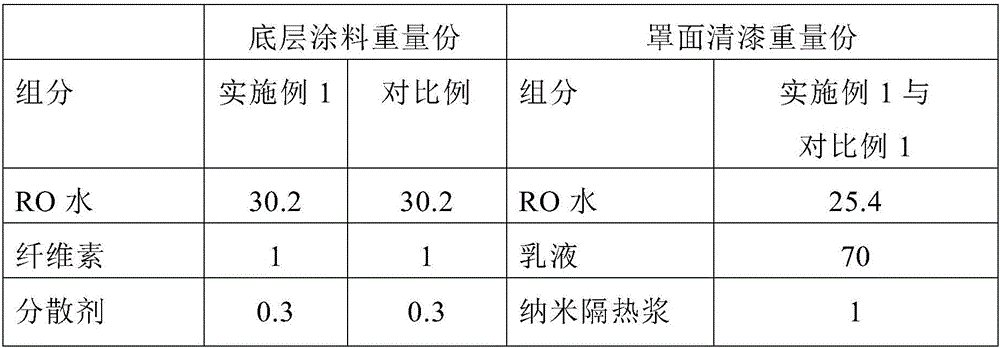

Colorful multi-layer paint with thermal insulation function and preparation method thereof

ActiveCN106380972ATo achieve the effect of heat insulationExtended service lifePolyurea/polyurethane coatingsReflecting/signal paintsInsulation layerCrack resistance

The invention relates to a colorful multi-layer paint with thermal insulation function and a preparation method thereof. The multi-layer paint comprises a prime paint, a main coating paint and finishing varnish from the inside out. By adding functional fillers to the prime paint and main coating paint, and adding nano thermal insulation slurry into the finishing varnish, the thermal insulation paint with barrier and reflection effects can be prepared. Compared with the prior art, according to the invention, through introduction of the overall functional fillers, the colorful multi-layer paint film can reach thermal insulation effect, thus reducing introduction of external heat to the inside and saving energy; the product has strong crack resistance, through the thermal insulation effect of the external thermal insulation finishing layer, the temperature change range of the external insulation layer can be reduced, and the crack resistance of the external insulation layer can be effectively improved. Through introduction of the functional material, the degradation rate of the coating film can be slowed, and the service life of the coating can be improved.

Owner:上海磐彩环保科技股份有限公司

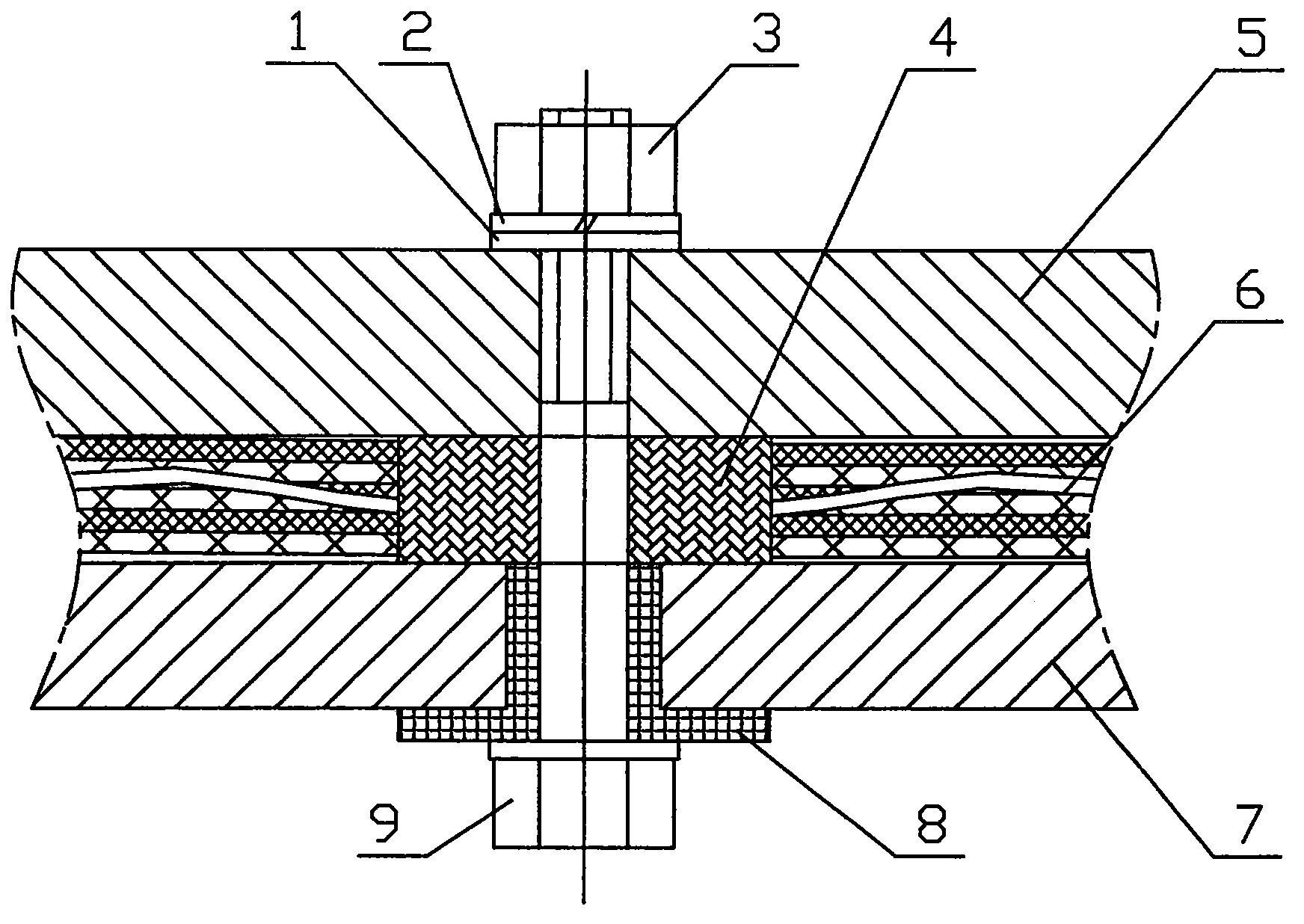

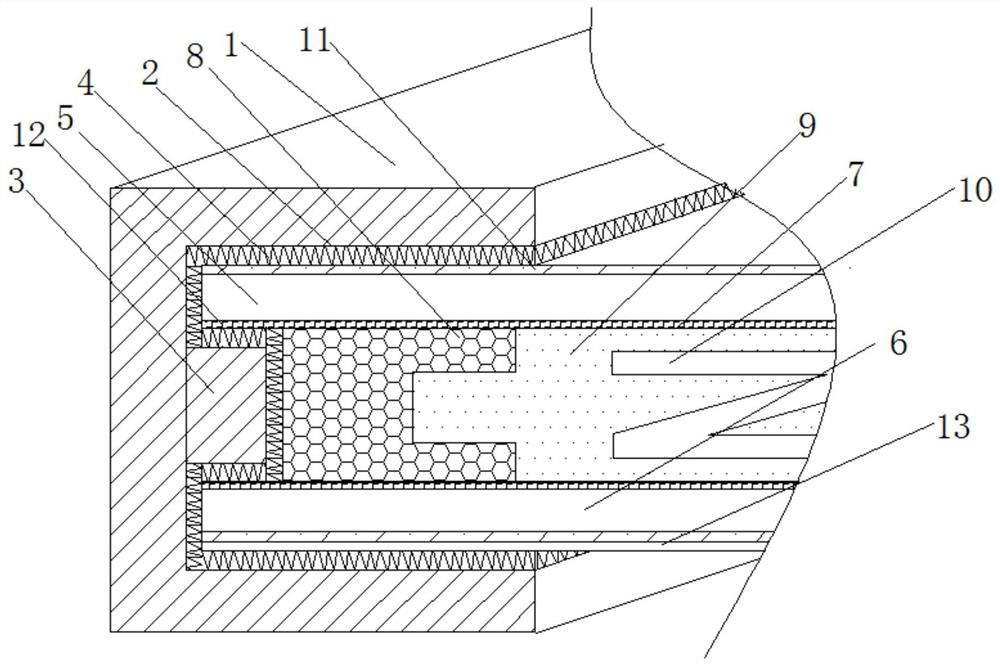

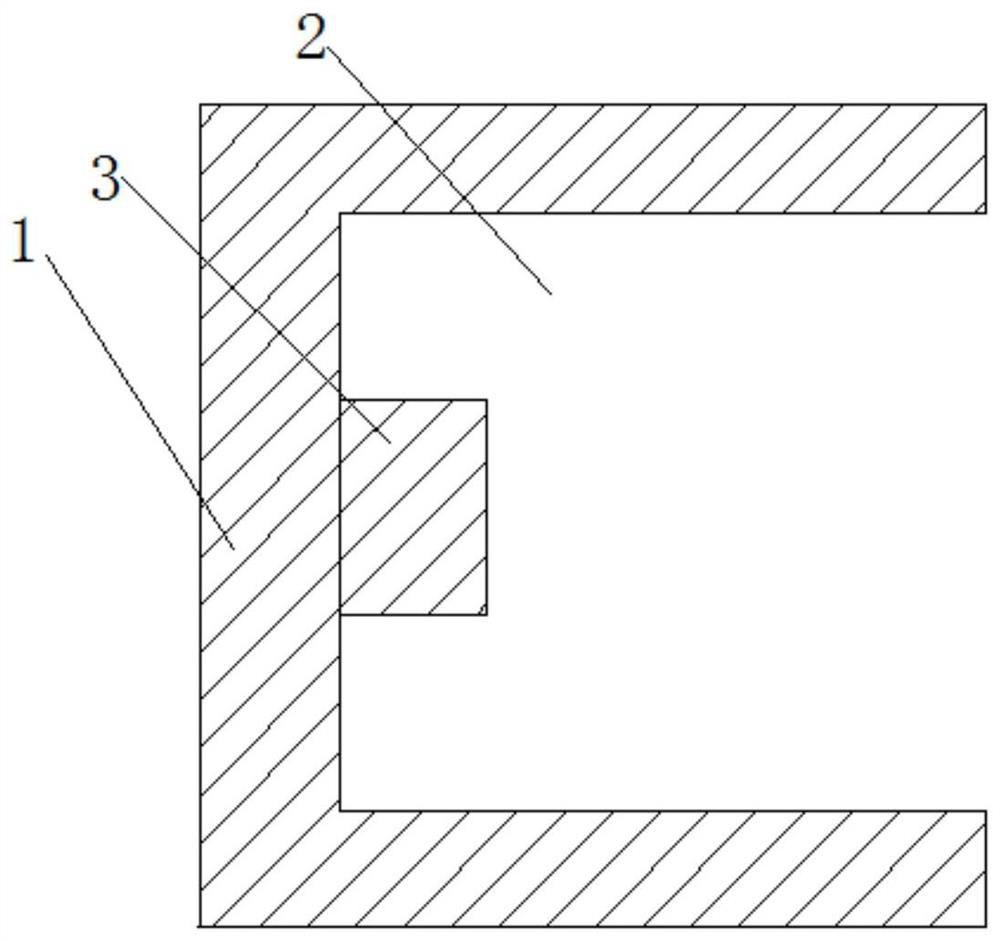

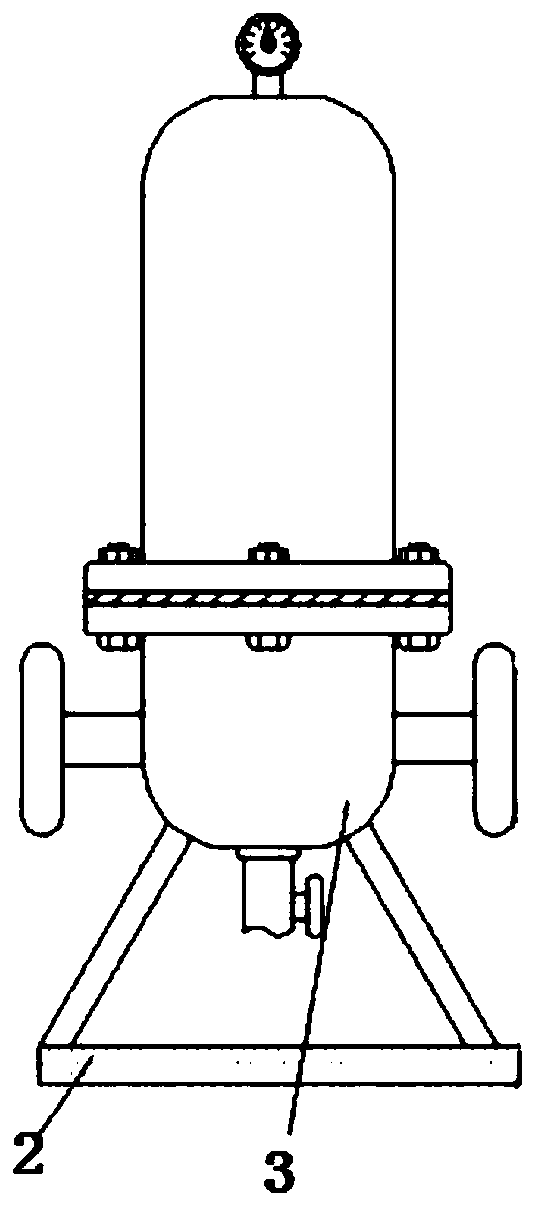

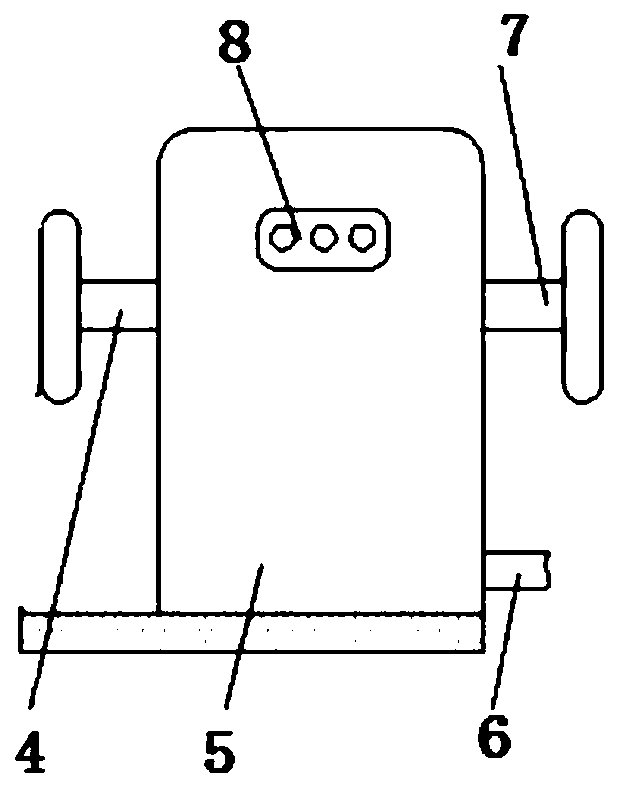

Thermal insulation connection device for space metal surfaces

ActiveCN105122966BLow costTo achieve the effect of heat insulationNutsCosmonautic thermal protectionThermal isolationMetal

The invention discloses a heat-insulating connection device for metal surfaces in space. The upper metal surface [5] and the lower metal surface [7] are connected by bolts [9] and nuts [3]. The upper metal surface [5] and the lower metal surface [7] are connected by bolts [9] and nuts [3]. The joints between the bolts [9] between the lower metal surfaces [7] are partially padded with glass fiber reinforced plastic pads [4], and the rest of the area is filled with multi-layer heat insulation components [6]. The imide heat-insulating bushing [8], the nut [3] and the upper metal surface [5] are sheathed with a fiberglass washer [1] and a spring washer [2]. The invention solves the problem of heat isolation between space metal surfaces, and achieves beneficial effects such as low cost, high reliability, and good heat insulation effect.

Owner:SHANGHAI SATELLITE ENG INST

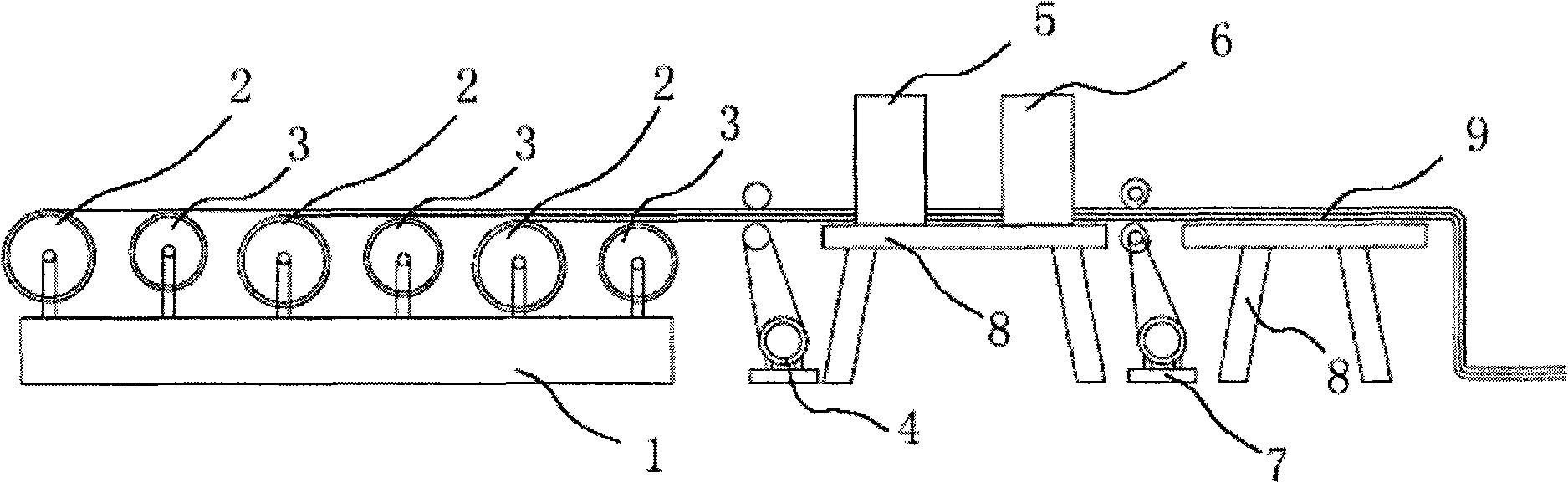

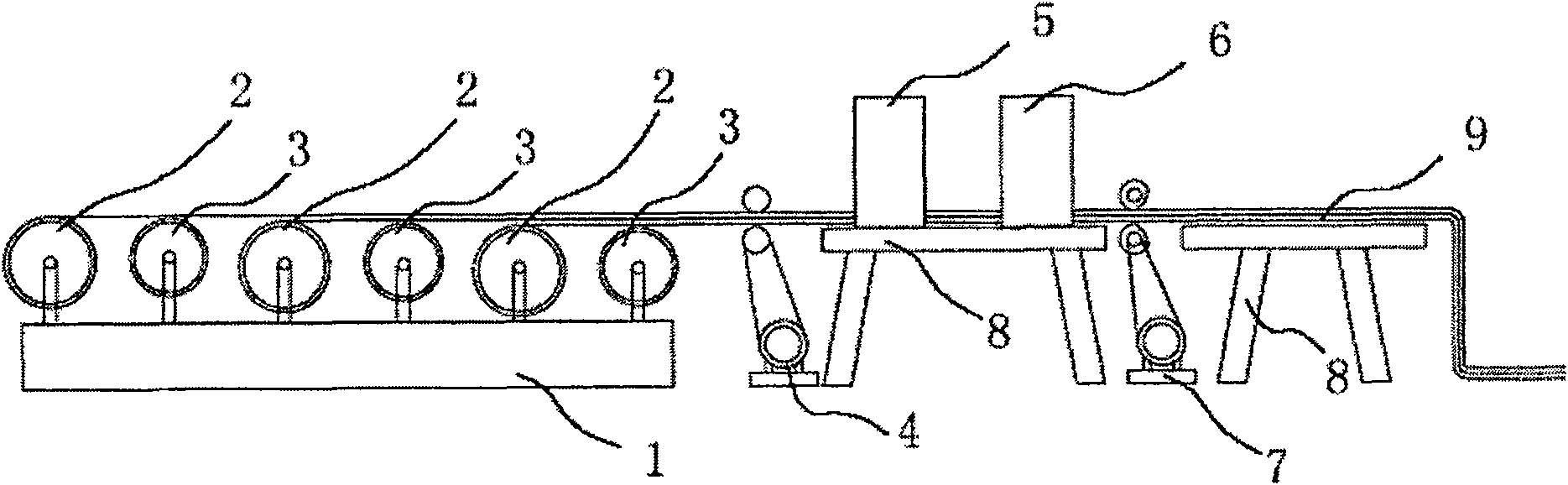

High vacuum multiple layer heat insulation quilt manufacture method

InactiveCN101285548AReduce workloadSave dressing timeThermal insulationPipe protection by thermal insulationProcess engineeringCryogenic engineering

The invention provides a method for making a microvacuum multilayer heat-insulating quilt, belonging to cryogenic engineering and cryogenic technical field. The method comprises the following steps of: preparing a mechanized production line; a plurality of reflecting layers and heat insulating layers is sewed into a quilt by seams after the plurality of reflecting layers and heat insulating layers are alternately combined on the production line according to certain requirements; and the quilt is evenly penetrated to make holes. The microvacuum multilayer heat-insulating quilt made by using the method reduces workloads for winding heat-insulating materials, shortens binding period, guarantees that the heat insulation quilt can not loose during using, and even can improve vacuumizing efficiency and maintain high vacuum degree between interlayer on the premise of a guarantee of excellent and stable heat insulation performance, thereby the method has more advantages of lot manufacturing and producing of cryogenic storage and transportation equipment, and prominent economic benefit and social benefit in cryogenic engineering.

Owner:SHANGHAI JIAO TONG UNIV

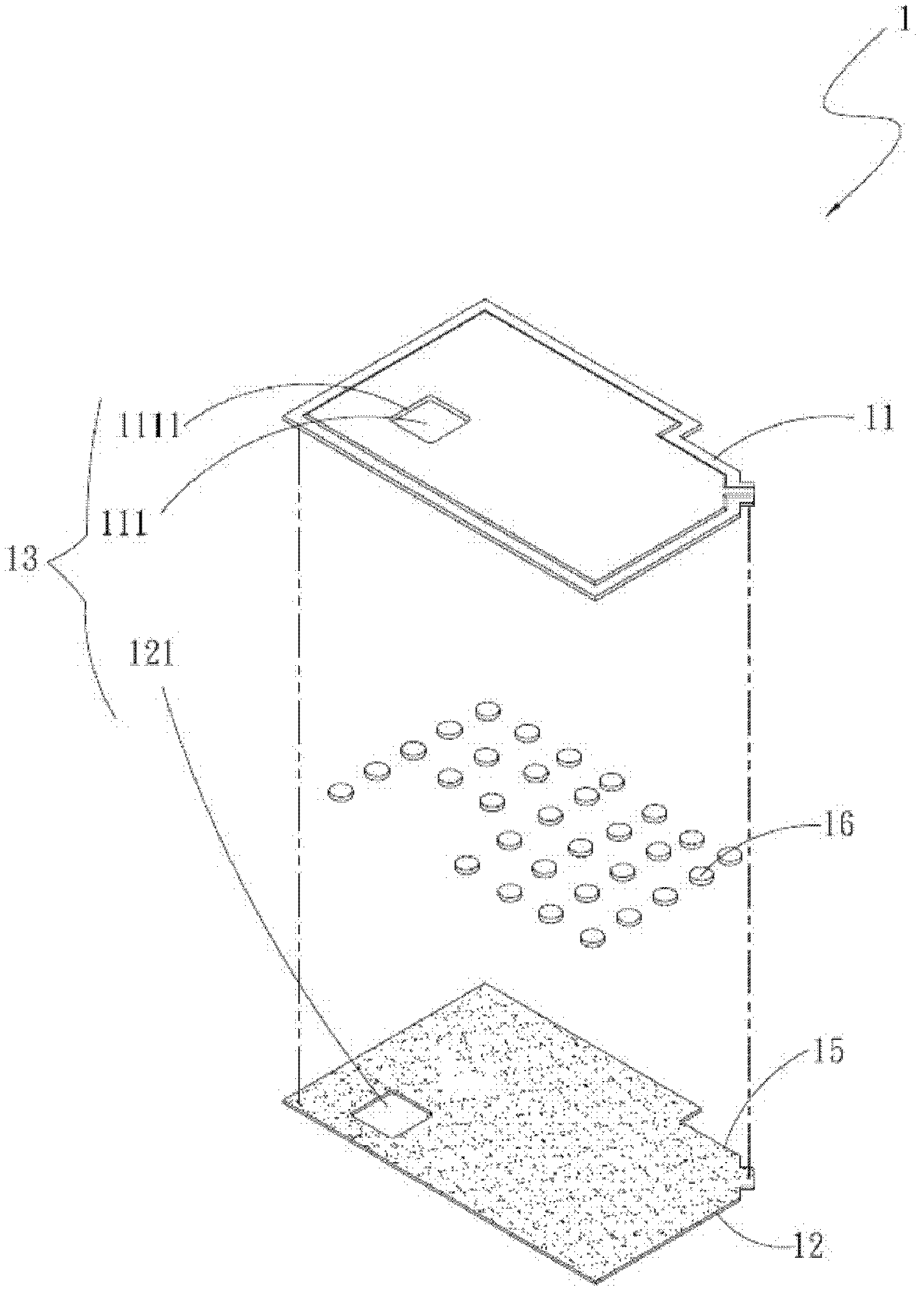

Uniform temperature plate structure and manufacturing method thereof

ActiveCN103021975AIncrease elasticityTo achieve the effect of heat insulationSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

The invention relates to a uniform temperature plate structure and a manufacturing method thereof. The uniform temperature plate structure comprises a body, wherein the body is provided with a first plate body and a second plate body; the first plate body and the second plate body are correspondingly buckled and define a hollow area and a cavity together; the cavity is provided with at least one capillary structure, a support structure and a working fluid; and the hollow area correspondingly penetrates through the first and second plate bodies and the cavity. The uniform temperature plate structure disclosed by the invention can elastically avoid other electronic elements and even achieve the heat insulation effect by arranging the hollow area on the body.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

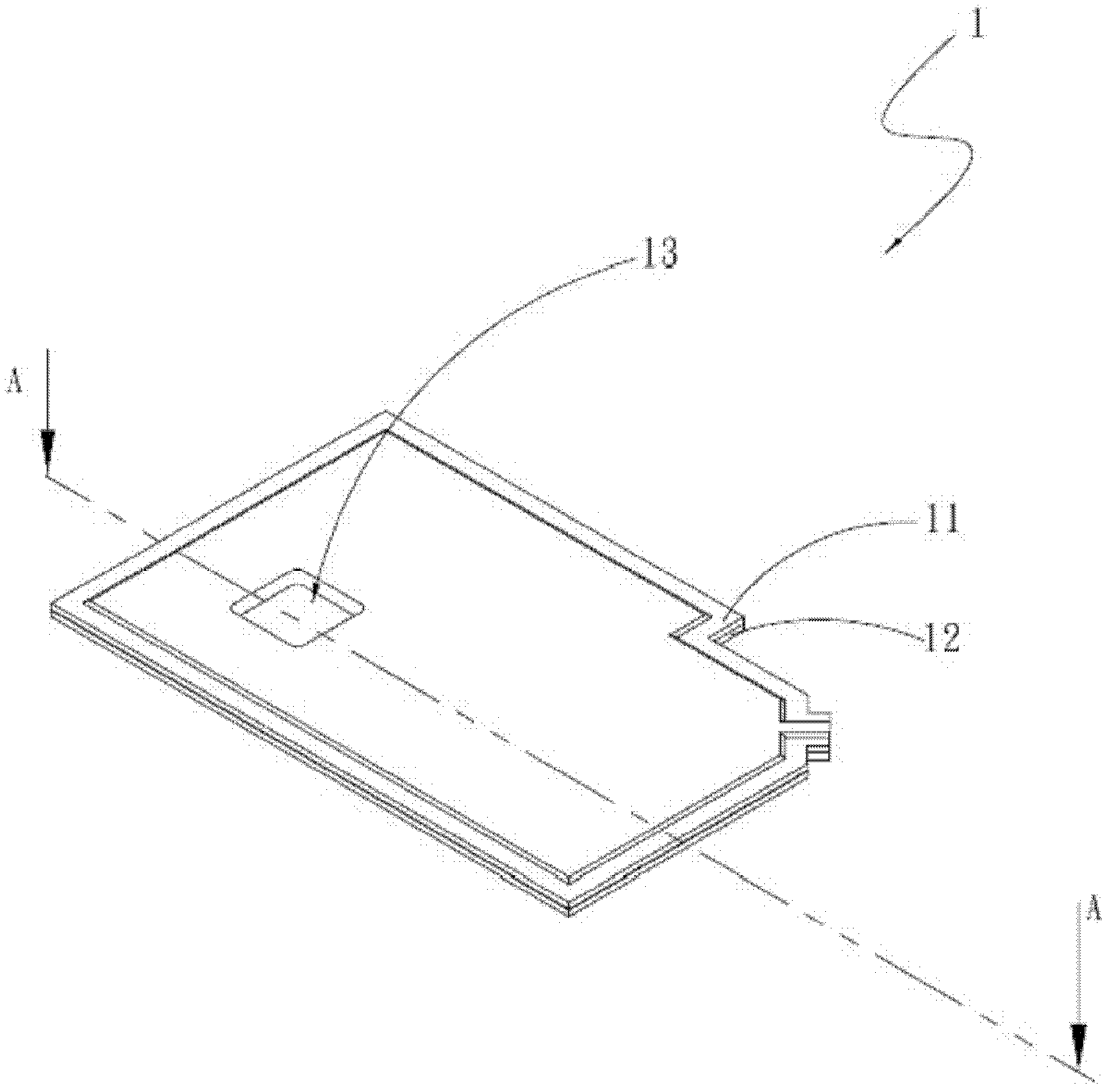

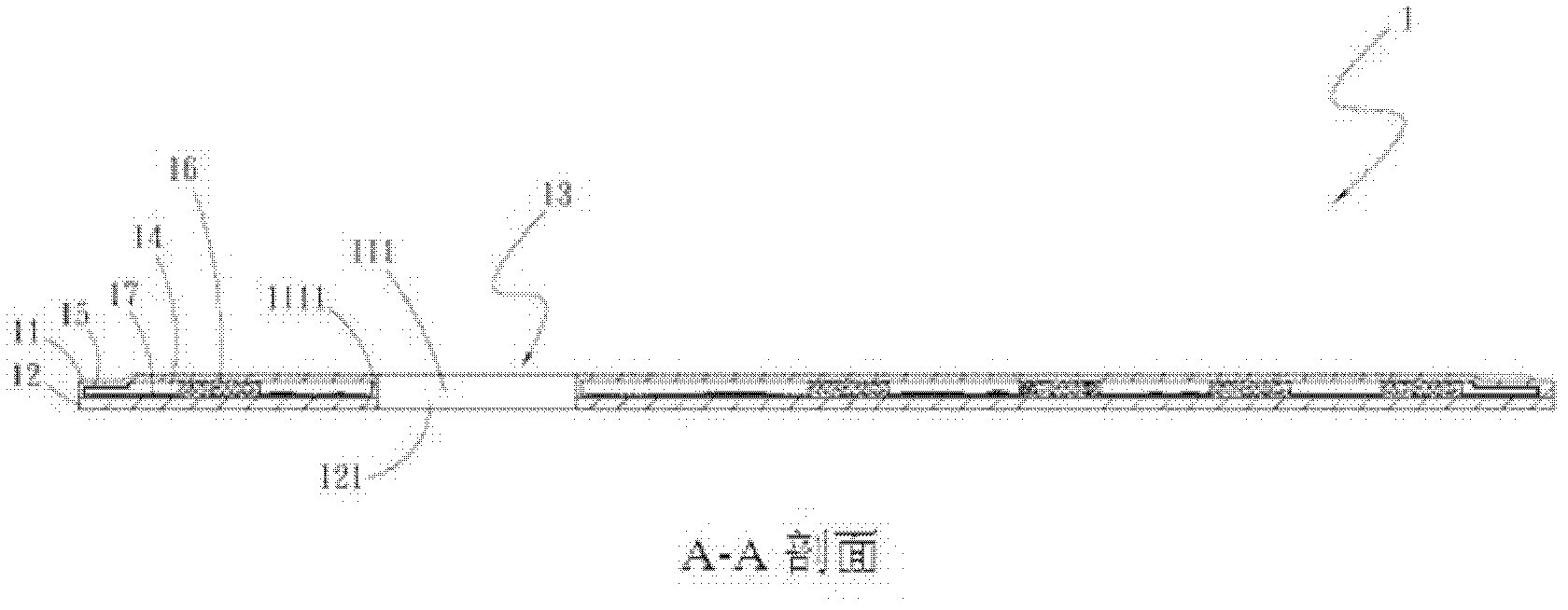

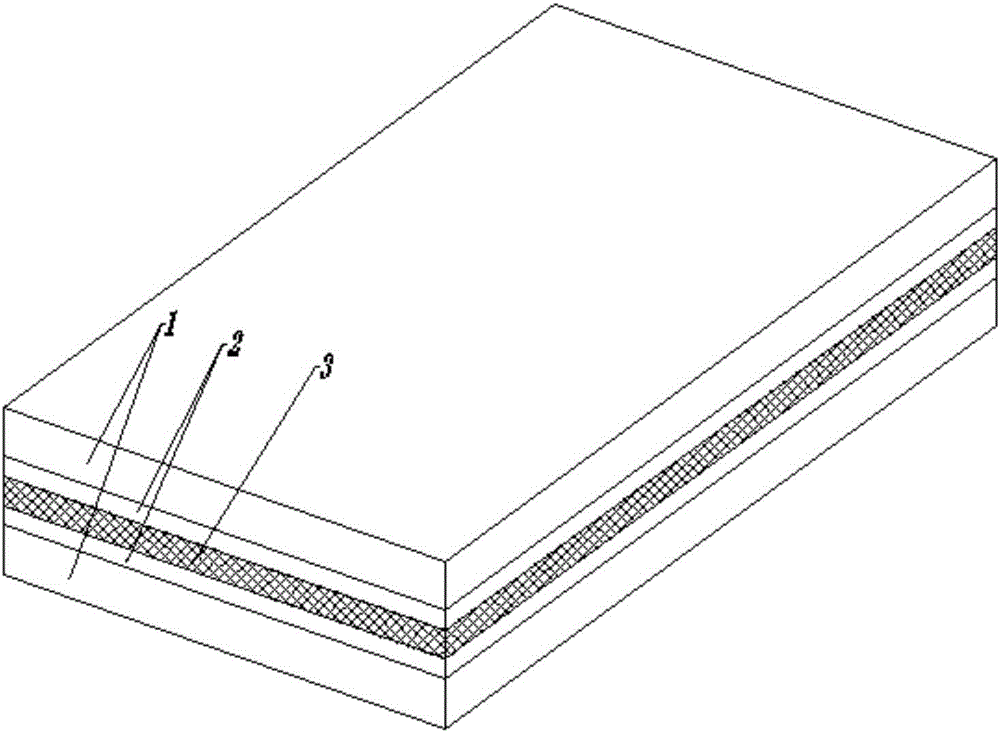

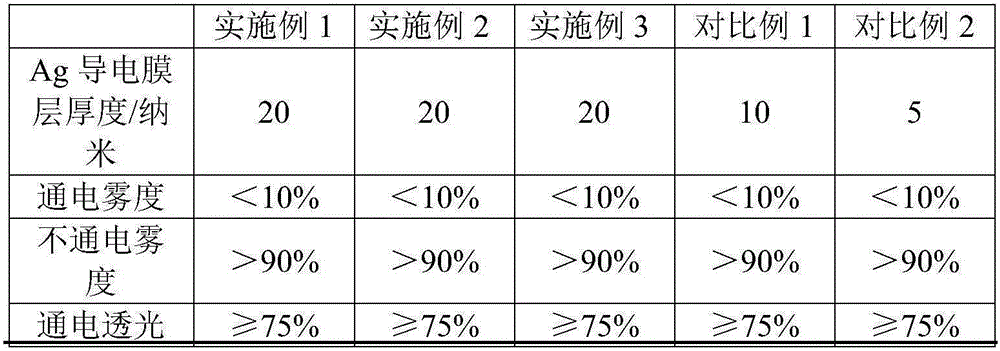

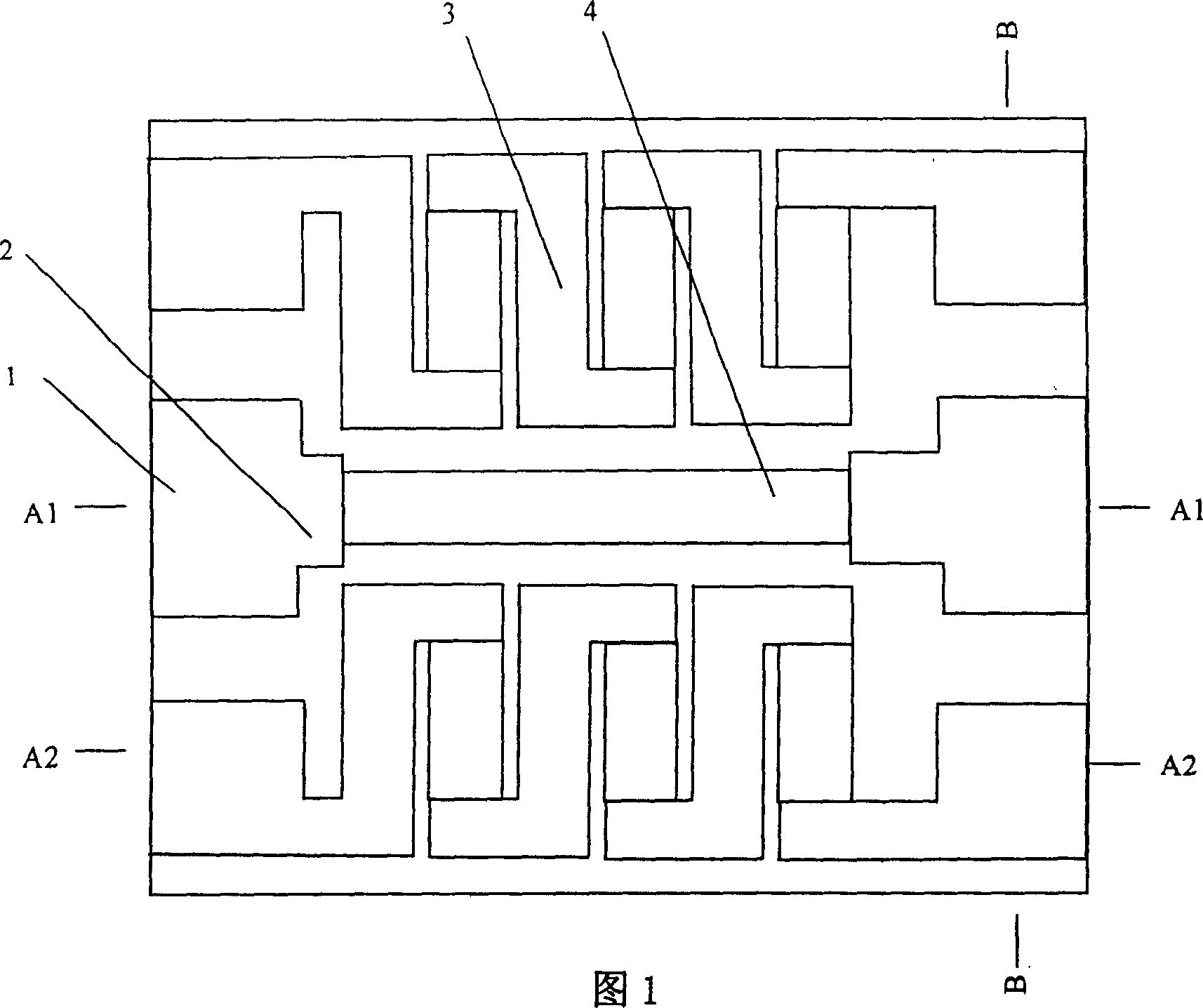

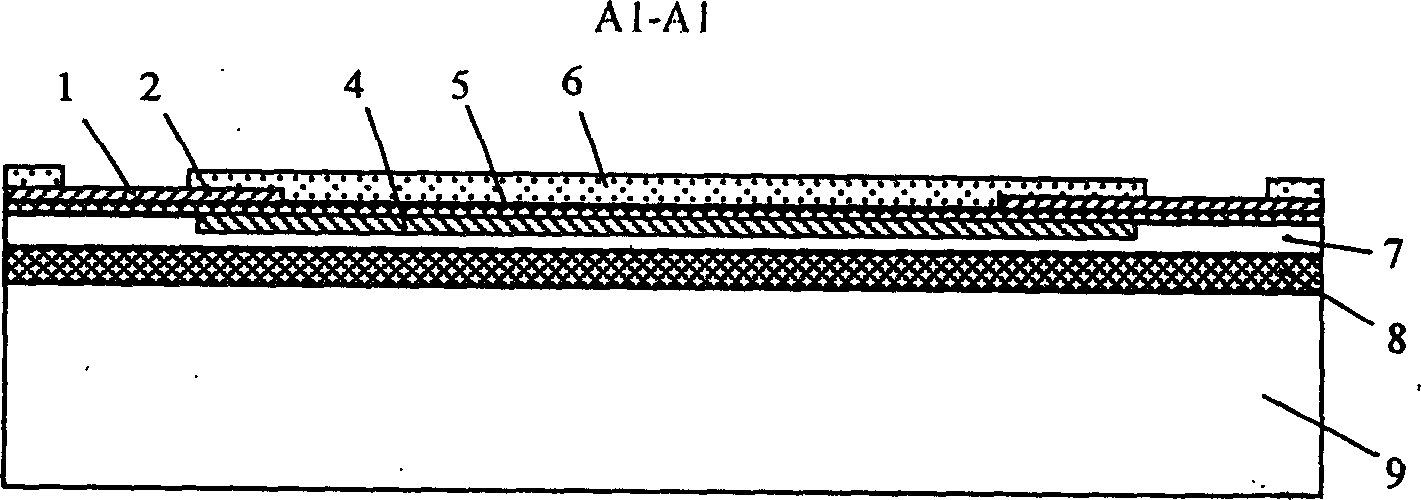

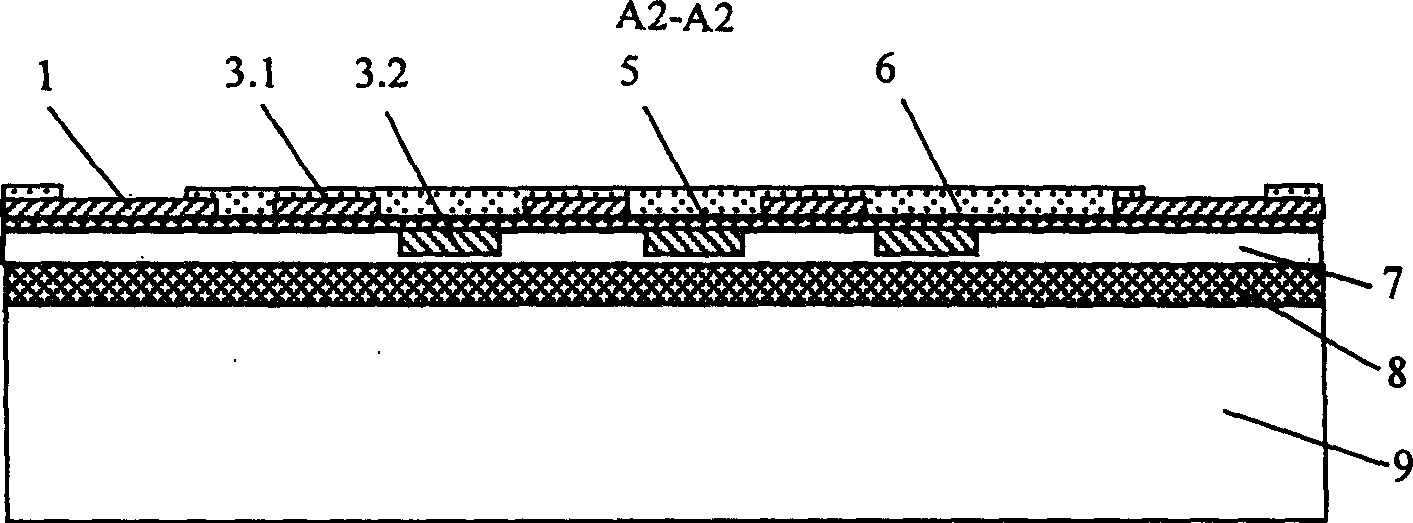

Light dimming film and manufacturing method thereof

PendingCN106773235ALower resistanceReduce energy consumptionNon-linear opticsElectrically conductiveLiquid crystal

The invention relates to a light dimming film and a manufacturing method thereof, in particular to a light dimming film manufactured from a transparent conductive film and a manufacturing method of the light dimming film. The light dimming film comprises a polymer dispersed liquid crystal layer, a first conductive film layer including a first Ag conductive layer and a first PET layer, and a second conductive film layer including a second Ag conductive layer and a second PET layer, wherein the first Ag conductive film layer is arranged on the upper surface of the polymer dispersed liquid crystal layer, and the second Ag conductive film layer is arranged on the lower surface of the polymer dispersed liquid crystal layer; the first PET layer is arranged on the upper surface of the first Ag conductive film layer, and the second Ag conductive film layer is provided with the second PET layer. The light dimming film is low in consumption voltage, low in energy consumption and capable of saving energy and achieving heat insulation.

Owner:广州汇驰实业发展有限公司

Centrifugal casting process for main pipeline of million kilowatt-grade nuclear power plant

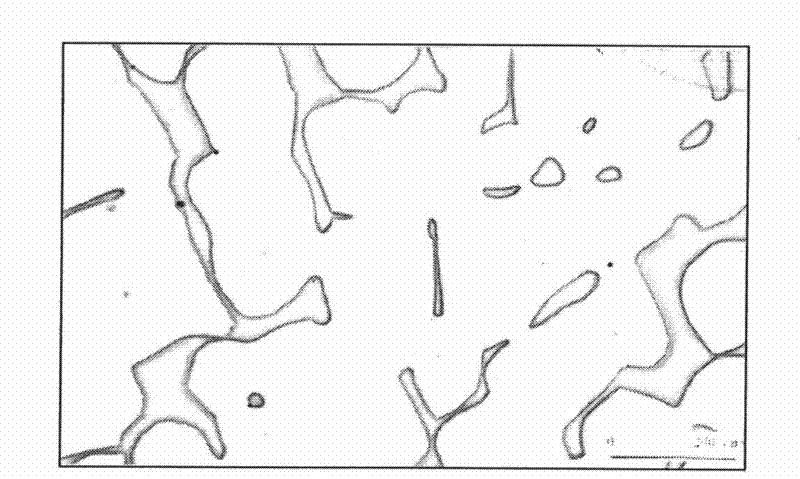

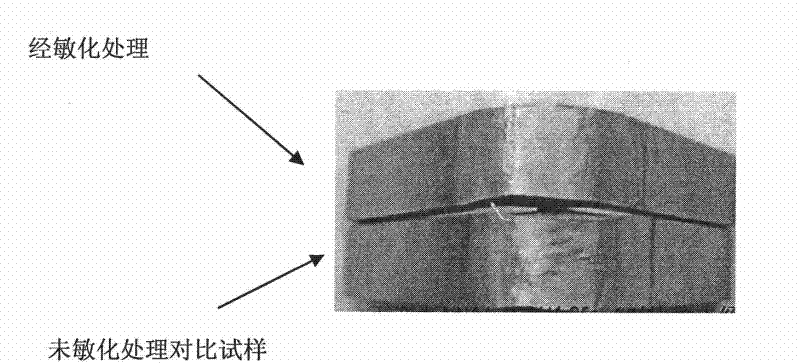

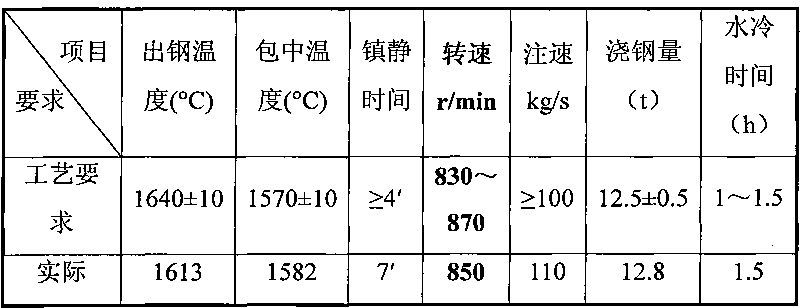

ActiveCN102233417ATo achieve the effect of heat insulationAdjust the setting characteristicsFoundry mouldsFurnace typesMolten steelSubmarine pipeline

The invention relates to a centrifugal casting process for a main pipeline of a million kilowatt-grade nuclear power plant. The centrifugal casting process comprises the main steps of smelting, cylinder coating, centrifugal casting, heat treatment and the like, wherein the tapping temperature of pressure molten steel is 1,640+ / -10 DEG C; after a cylinder is coated, the cylinder is roasted to the temperature of more than or equal to 280 DEG C and heat is preserved for 1 to 2 hours; the temperature of pouring steel is 1,570+ / -10 DEG C; the calming time is not less than 4 minutes; the rotating speed of the cylinder is controlled to be 800 to 870 r / min; and the casting speed is more than or equal to 100 kg / s. In the centrifugal casting process, process parameters and the process are controlled strictly, so the main pipeline capable of meeting the requirements of the million kilowatt-grade nuclear power plant can be manufactured.

Owner:烟台台海玛努尔核电设备有限公司

Heat measuring type micro flow sensor

InactiveCN1786674ATo achieve the effect of heat insulationIncrease lateral thermal resistanceVolume/mass flow by thermal effectsThermopileSilica gel

The invention discloses heat measuring type micro flow sensor. It is set silicon dioxide adiabatic membrane, single crystal silicon film formed by heating element and thermoelectric pile semiconductor electrode, silicon dioxide insulating layer, thermoelectric pile metal electrode, metal tie-line and soldered dot, and silicon nitride film from down to up at single crystal silicon substrate. Or it is filled silica gel filler, or set thermoelectric pile semiconductor electrode and heating element at the middle. The thermoelectric pile semiconductor electrode is set silicon dioxide insulating layer, thermoelectric pile semiconductor electrode, metal tie-line and soldered dot, and silicon nitride film from down to up. The sensor is set at the flow passage. The heating element is supplied power to generate heat quantity. The thermoelectric pile is outputted the pressure signal to realize heat measuring type flow measurement.

Owner:ZHEJIANG UNIV

Textured stone-like heat-insulating reflective composite coating for buildings and preparation method thereof

PendingCN112143312AEasy to prepareWith synergistic heat insulation reflection effectAntifouling/underwater paintsPaints with biocidesWeather resistanceEmulsion

The invention provides a textured stone-like heat-insulating reflective composite coating for buildings and a preparation method thereof, and the textured stone-like heat-insulating reflective composite coating comprises the following components in percentage by mass: 11-20% of reflective heat-insulating emulsion, 3-20% of composite hollow glass bead powder, 0.1-0.24% of a bactericide, 0.05-0.10%of a preservative, 2-5% of a coalescing agent, 1-4% of a composite additive, 1-6% of ultrafine heat-insulating powder, 0.5-7% of a mica filler powder, 0.5-5% of nano titanium dioxide, 12-60% of whitesand, 4-20% of color sand, and 5-15% of water. The stone-like coating has the functions of heat insulation, weather resistance and stone-like texture, also has a flame-retardant effect, is low in production cost, is comprehensive in weather resistance and heat insulation, is good in texture effect, and is environment-friendly and pollution-free.

Owner:江西景新漆业股份有限公司

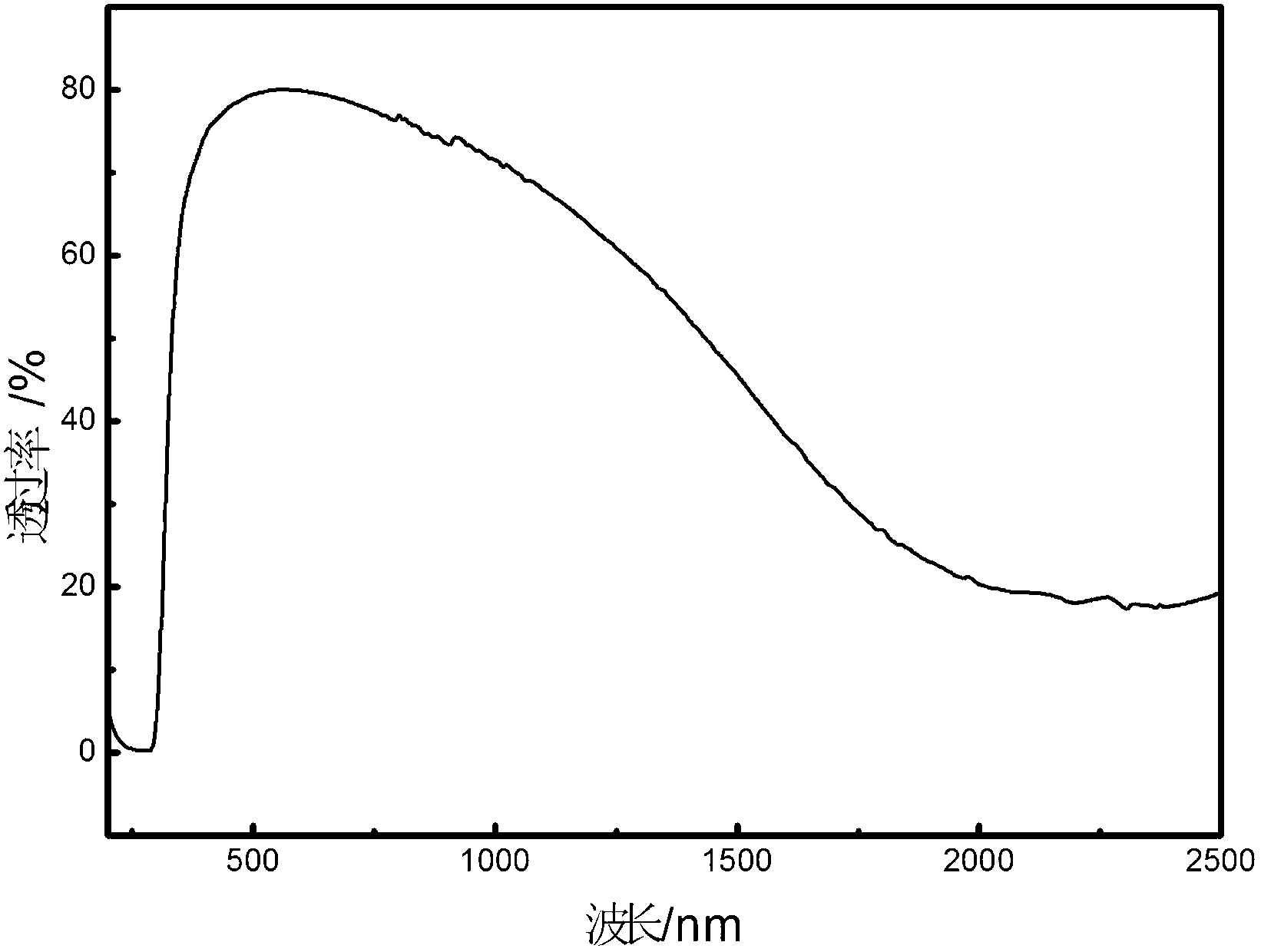

Preparation method and application of spherical thermal insulating nanometer material

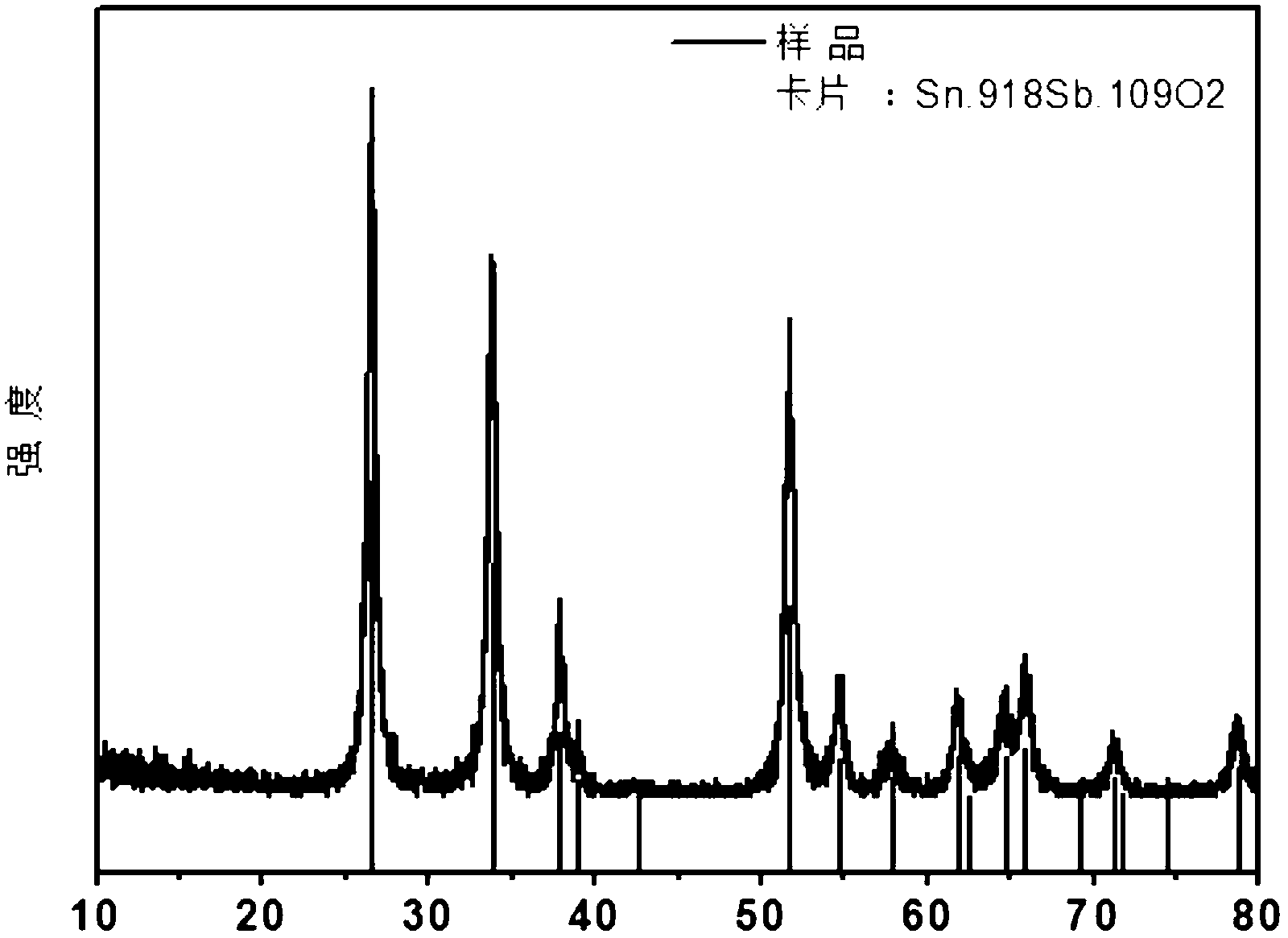

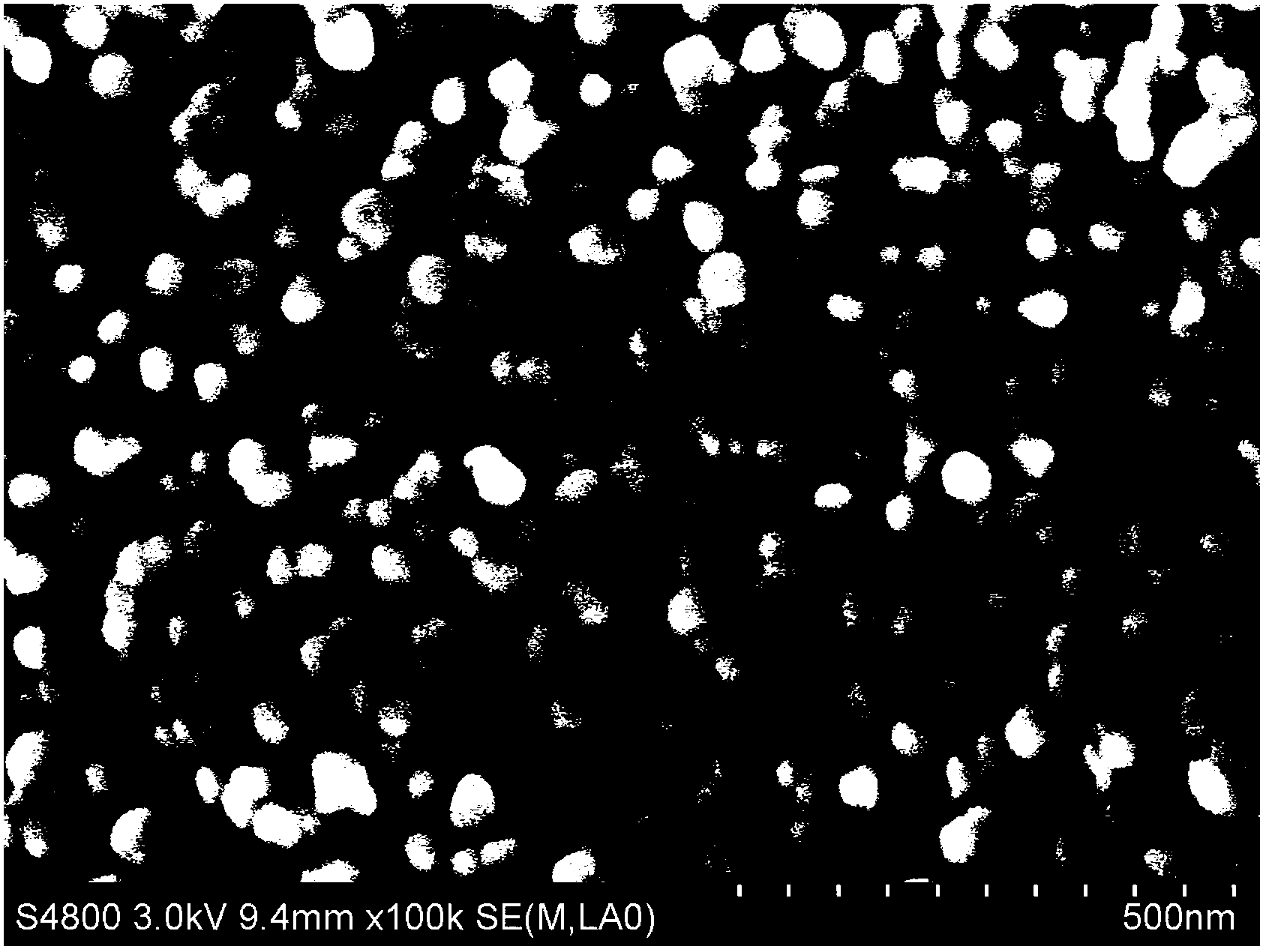

InactiveCN103172110AImprove transmittanceReduce transmittanceMaterial nanotechnologyAntimony compoundsEpoxyAcrylic resin

The invention discloses a preparation method and application of a spherical thermal insulating nanometer material. The preparation method comprises the following steps of: preparing a heat reflection spherical nanometer material ATO (Arsenic Trioxide)by adding a morphology control agent by means of a co-precipitation method; carrying out mixing and ball milling on film forming agents and the well dispersed heat reflection spherical nanometer material ATO to obtain a paint, wherein the film forming agents comprise polyurethane, acrylic resin and epoxy resin; and coating the paint on a glass and transparent resin material. The prepared film coating has good thermal insulation and transparent conductivity effects, light transmissivity of the transparent conductive film coating in a visible light region is more than 80%, light transmissivity of the transparent conductive film coating in an infrared light region is less than 20%; compared with blank glass, the temperature of the glass coated with the thermal insulating transparent conductive paint can be reduced by 5-10 DEG C, and the thermal insulating transparent conductive paint has excellent thermal insulation and transparent conductivity effect; and compared with the prior art, the product has the effects of stable chemical property, high transmissivity in the visible light region, low transmissivity in a near / far infrared light region, excellent thermal insulation performance and the like, and is easy to store for a long term.

Owner:SHANGHAI NORMAL UNIVERSITY

Paint for main pipe centrifugal casting mould pipe in million kilowatt grade nuclear power plant and coating method thereof

ActiveCN102310160AReduce cooling ratePrevent inclusionsMoulding toolsFoundry mouldsPressure rangeNuclear power plant

The invention relates to a paint for main pipe centrifugal casting mould pipes in a million kilowatt grade nuclear power plant and a coating method thereof. Mould pipes are preheated to 225+ / -25DEG C before spraying and stay at constant temperature for 1-3 hours. The spraying pressure ranges from 0.5Mpa to 1.0Mpa, and the temperature of the mould pipes maintains from 200DEG C to 250DEG C during the spraying process; spraying is performed for 5-10 times, and the coating thickness needs to be 4+ / -0.3mm; the temperature of the mould pipes which are roasted after coating is greater than or equal to 280DEG C and the mould pipes are insulated for 1-2 hours. The paint layer, which is a high temperature resistant light material with specific thickness, can effectively protect the mould pipes and alleviate the cooling speed of molten steel as well, and can meet technical requirements of main pipe blank centrifugal casting in a million kilowatt grade nuclear power plant.

Owner:烟台台海玛努尔核电设备有限公司

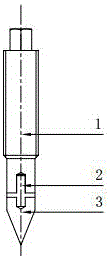

Insulating and adiabatic gamma knife stereotactic positioning frame head nail

InactiveCN106621074AGuaranteed accuracyLow costX-ray/gamma-ray/particle-irradiation therapyInterference fitEddy current

The invention discloses an insulating and adiabatic gamma knife stereotactic positioning frame head nail. The head nail comprises a titanium tail, an insulating and adiabatic body, and a titanium tip. The insulating and adiabatic body is of a cross structure composed of a disk and a central axis. The insulating and adiabatic body is clamped onto the lower end of the titanium tail and the top end of the titanium tip. The central axis of the insulating and adiabatic body extends into the titanium tail and the titanium tip. The head nail has the characteristics of simple structure, low cost, and good heat insulation effect. An interference fit structure is adopted. The product precision is high. A magnetic wire ring does not form eddy current during treatment. Heat or high temperature is not easy to produce. The problem of heat transfer is solved. The precision of products is improved. Effective guarantee is provided for measurement. Thus, the effect of radiotherapy is improved.

Owner:WUHAN RUIXIANGAN PRECISION MFG

Dual-state temperature change type cold-proof anti-freezing cable

ActiveCN111816355AImprove high temperature resistanceExtended service lifeInsulated cablesInsulated conductorsSoft layerLiquid state

The invention discloses a dual-state temperature change type cold-proof anti-freezing cable and belongs to the cable field. The dual-state temperature change type cold-proof anti-freezing cable includes a core layer, the outer end of the core layer is wrapped with an insulating layer. The outer end of the insulating layer is coated with a sheath; and the outer surface of the sheath is coated witha semi-transparent soft layer. At high temperature, a gas-controlled oil part is partially gasified to generate gas, an outer air bulge bulges outwards and is filled with air, and compared with an entity, the gas conduction speed is lower, the external temperature can be effectively isolated, the overall high temperature resistance of the cable is effectively improved and the service life is prolonged; and at low temperature, light oil returns to liquid, animal oil is cured, the gas-controlled oil part is integrally in a solid state with certain viscosity under the adjustment of the liquid light oil, so that the defect that the outer layer of the cable is hardened and embrittled at low temperature can be effectively overcome, and compared with the prior art, the brittleness resistance of the cable in winter is remarkably improved, and the service life of the cable is further prolonged.

Owner:山东青江线缆有限公司

High-thermal-conductivity isothermal body temperature control irradiation device

PendingCN112393967AIncrease temperatureMake up for the defect that high temperature radiation assessment cannot be carried outPreparing sample for investigationTemperature controlNuclear power

The invention discloses a high-conductivity isothermal body temperature control irradiation device. The device comprises an irradiation capsule, a cushion block, an isothermal body and an inert gas layer. The irradiation capsule is an outer protective shell of the irradiation device and provides support for each component and a to-be-irradiated sample; the isothermal body provides temperature compensation for the to-be-measured sample by utilizing the nuclear irradiation heating characteristic of the isothermal body, so that the to-be-measured sample is in a uniform and stable temperature environment; the inert gas layer is arranged in a gap between the inner surface of the irradiation capsule shell and the outer surface of the isothermal body so as to perform heat preservation; the cushion block is arranged between the contact surfaces of the isothermal body and the irradiation capsule so as to perform heat insulation. The irradiation device disclosed by the invention provides a uniform and stable irradiation temperature environment for irradiation examination of a nuclear power material, is simple and reliable in structure and low in cost, and provides support for a reliable nuclear power material irradiation test.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

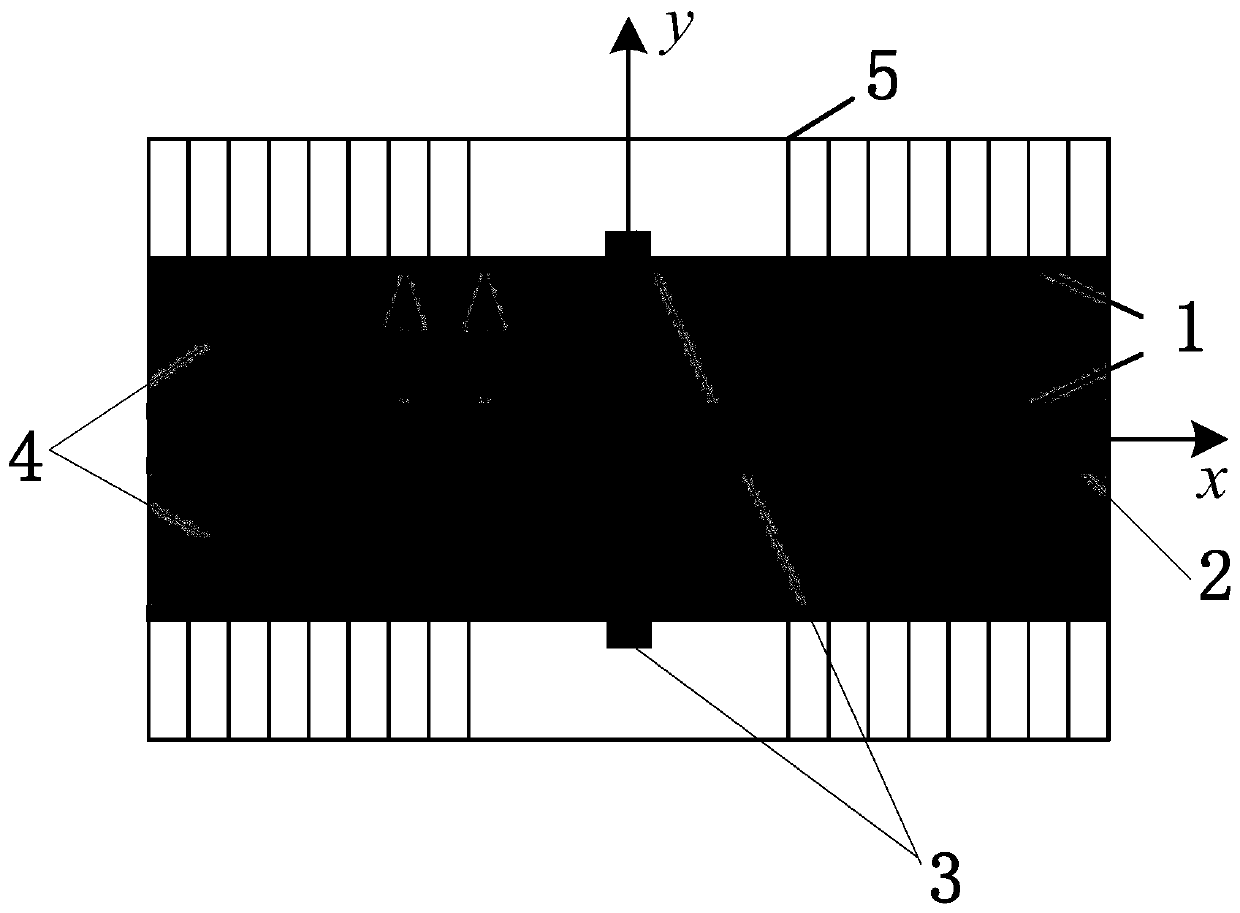

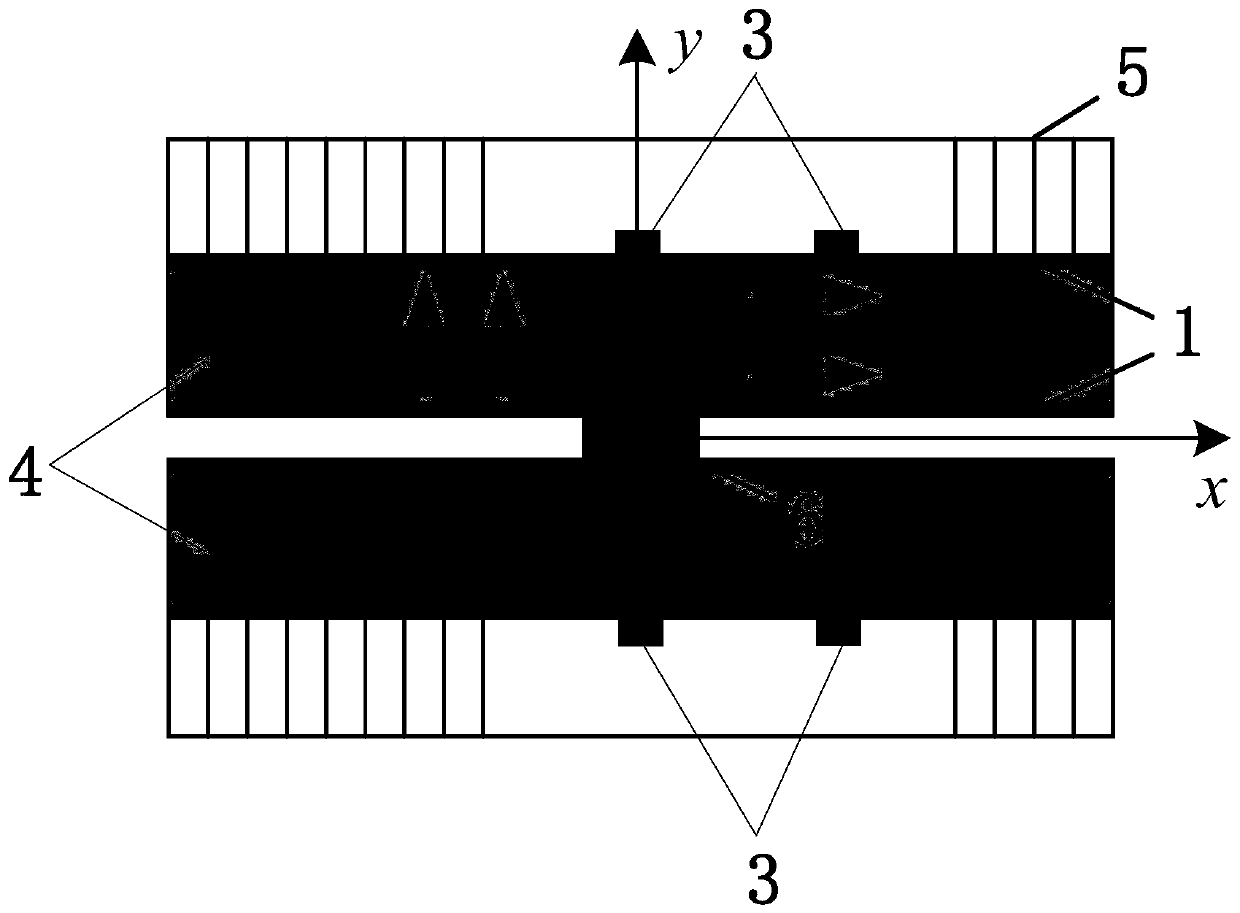

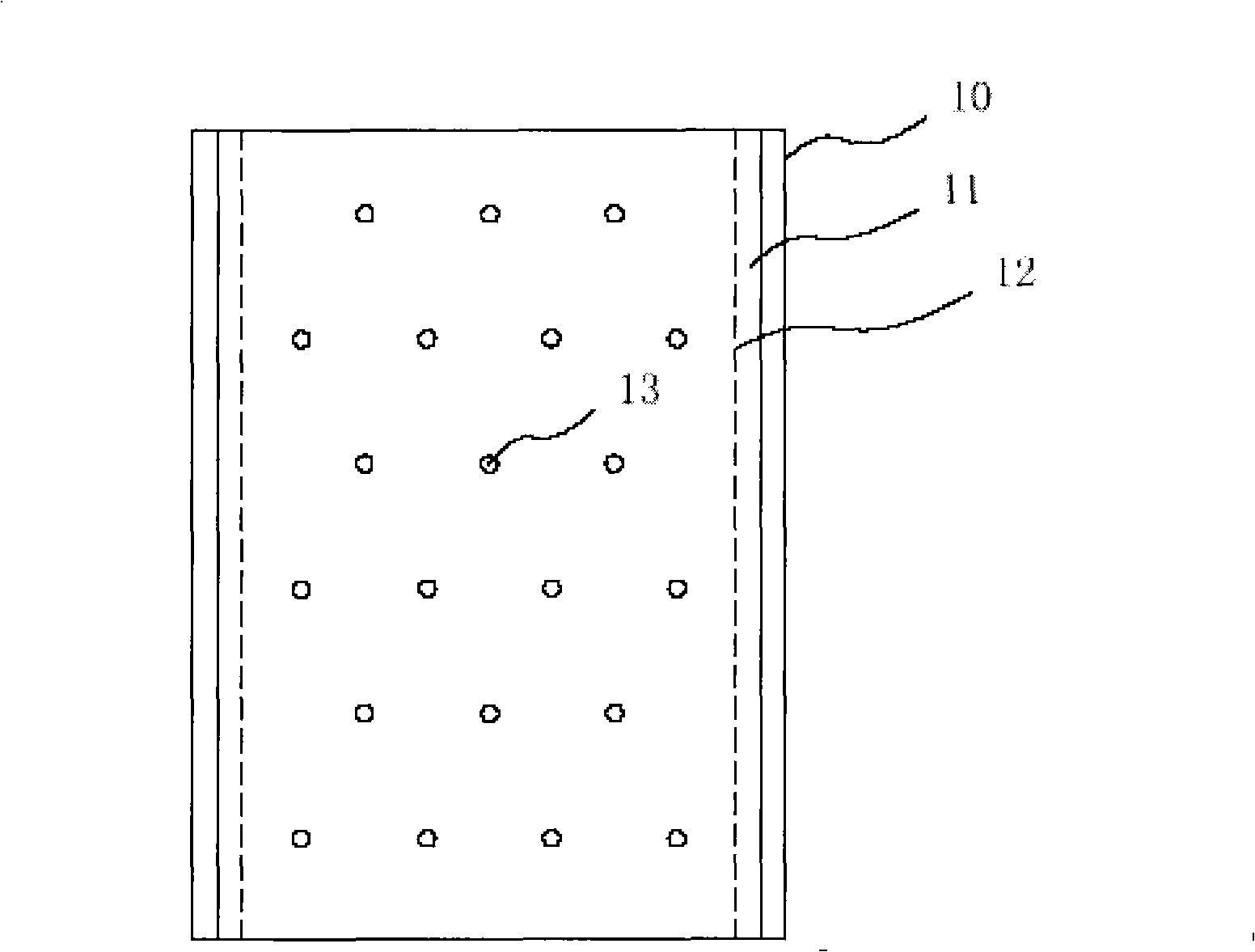

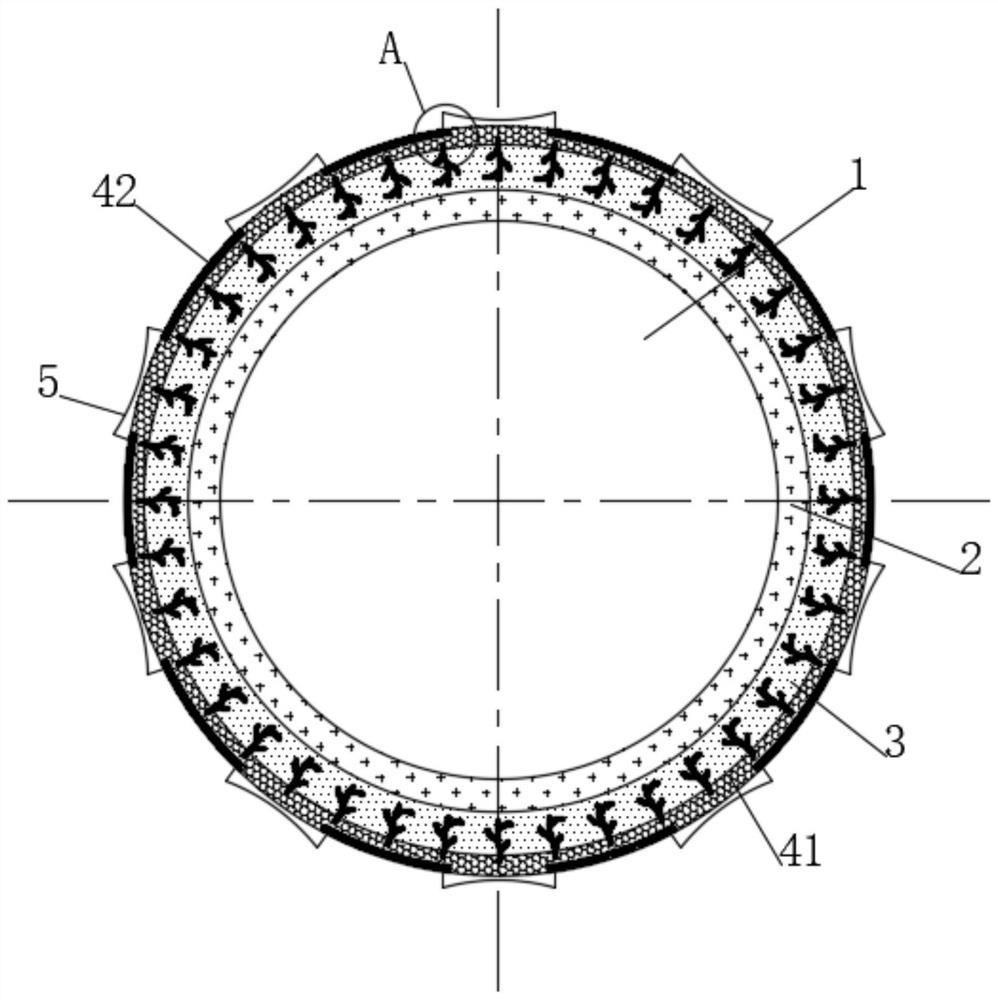

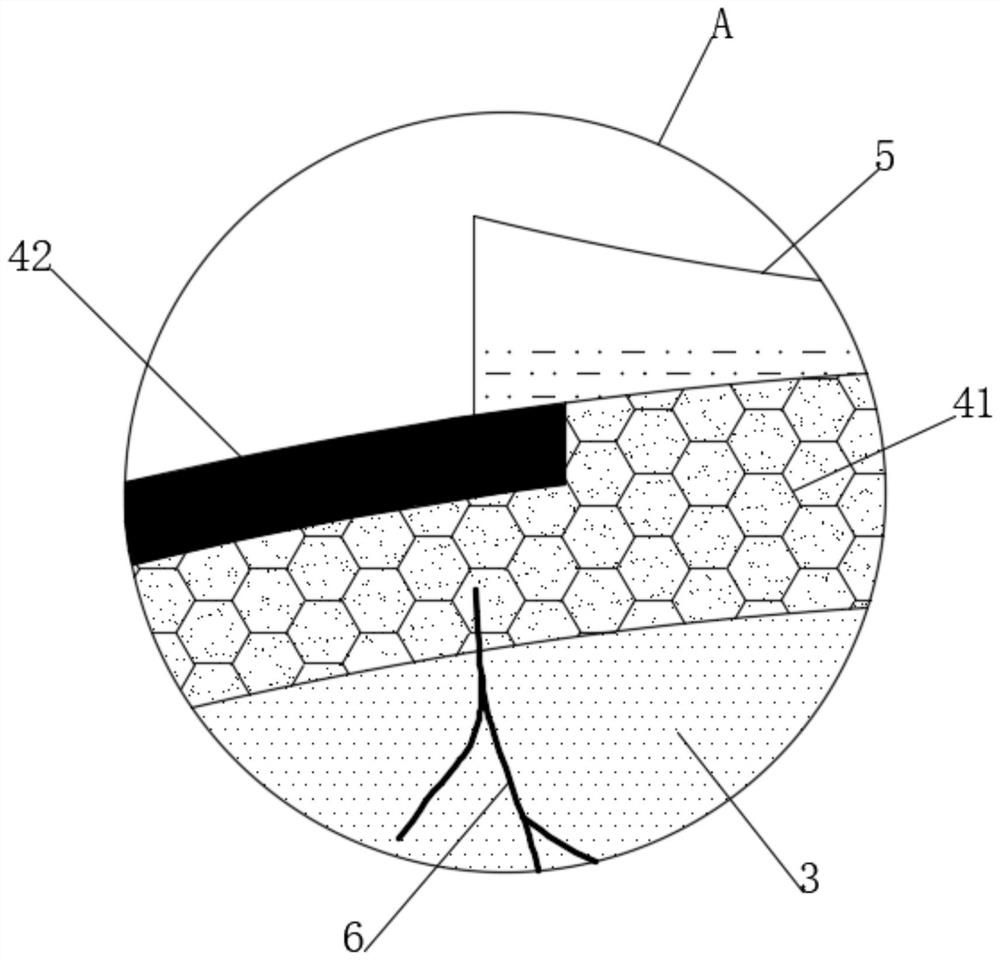

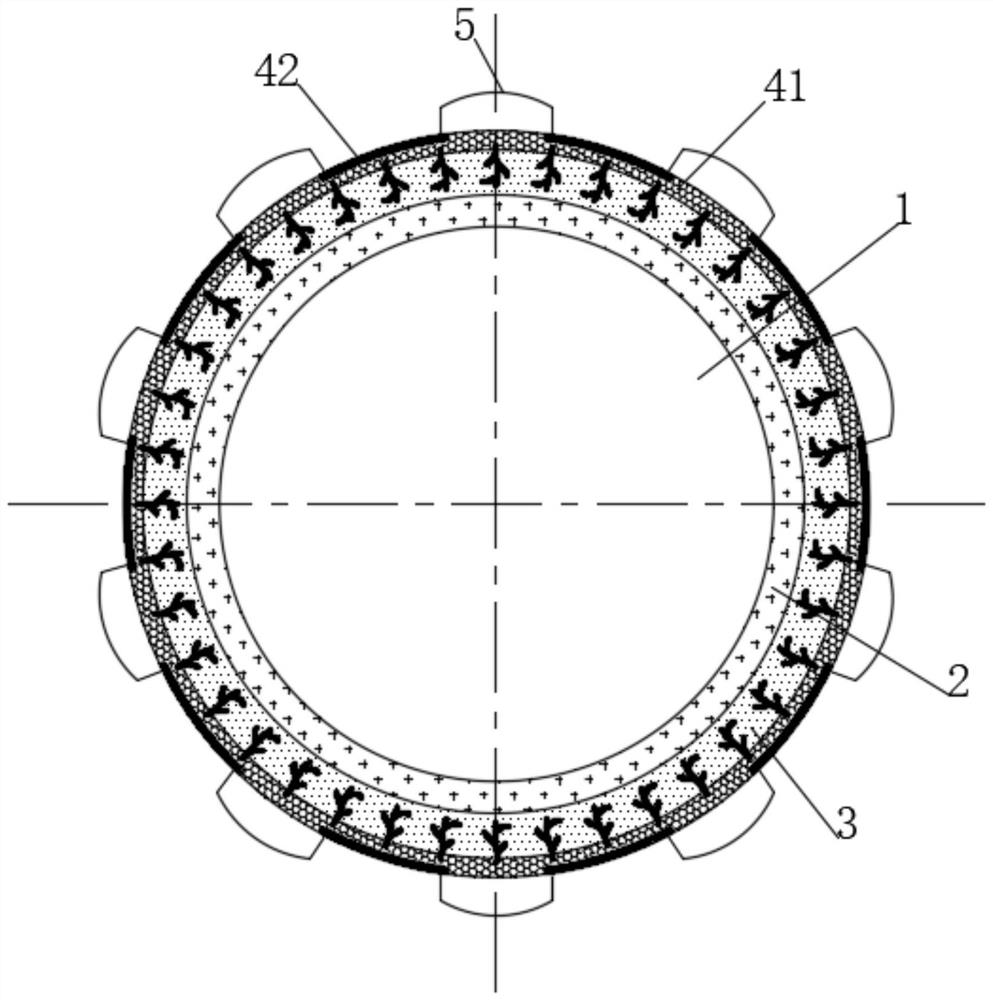

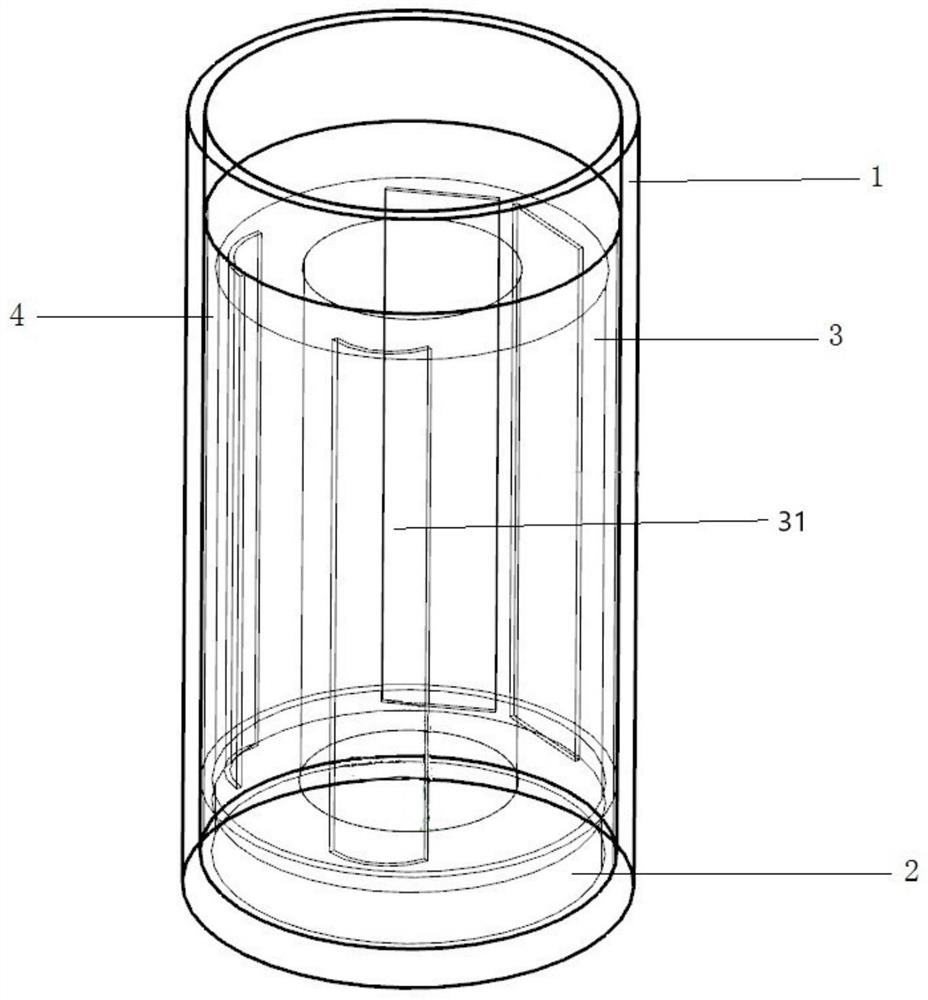

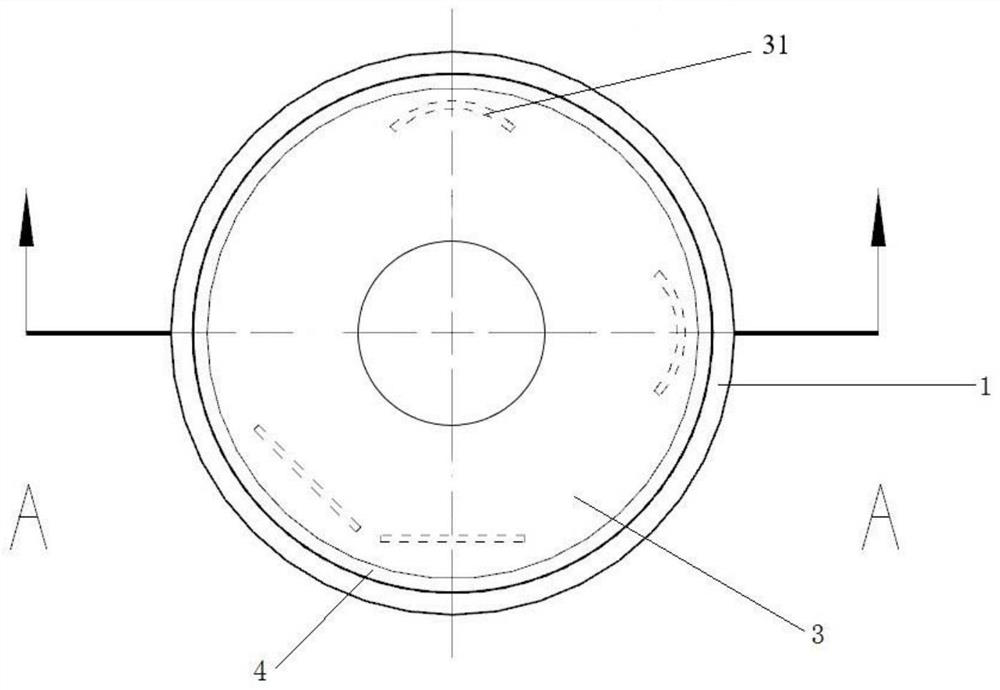

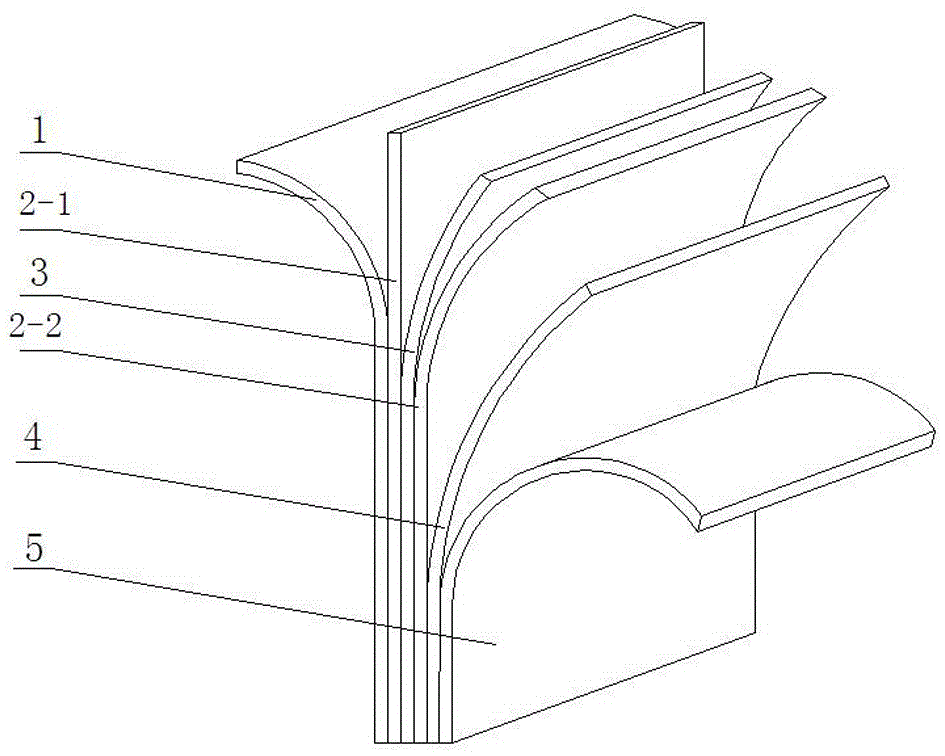

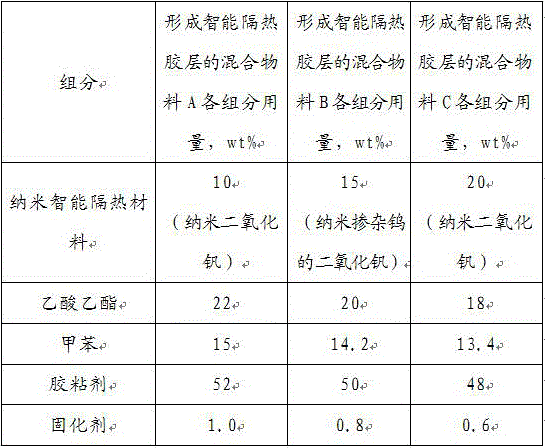

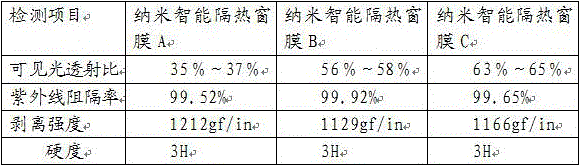

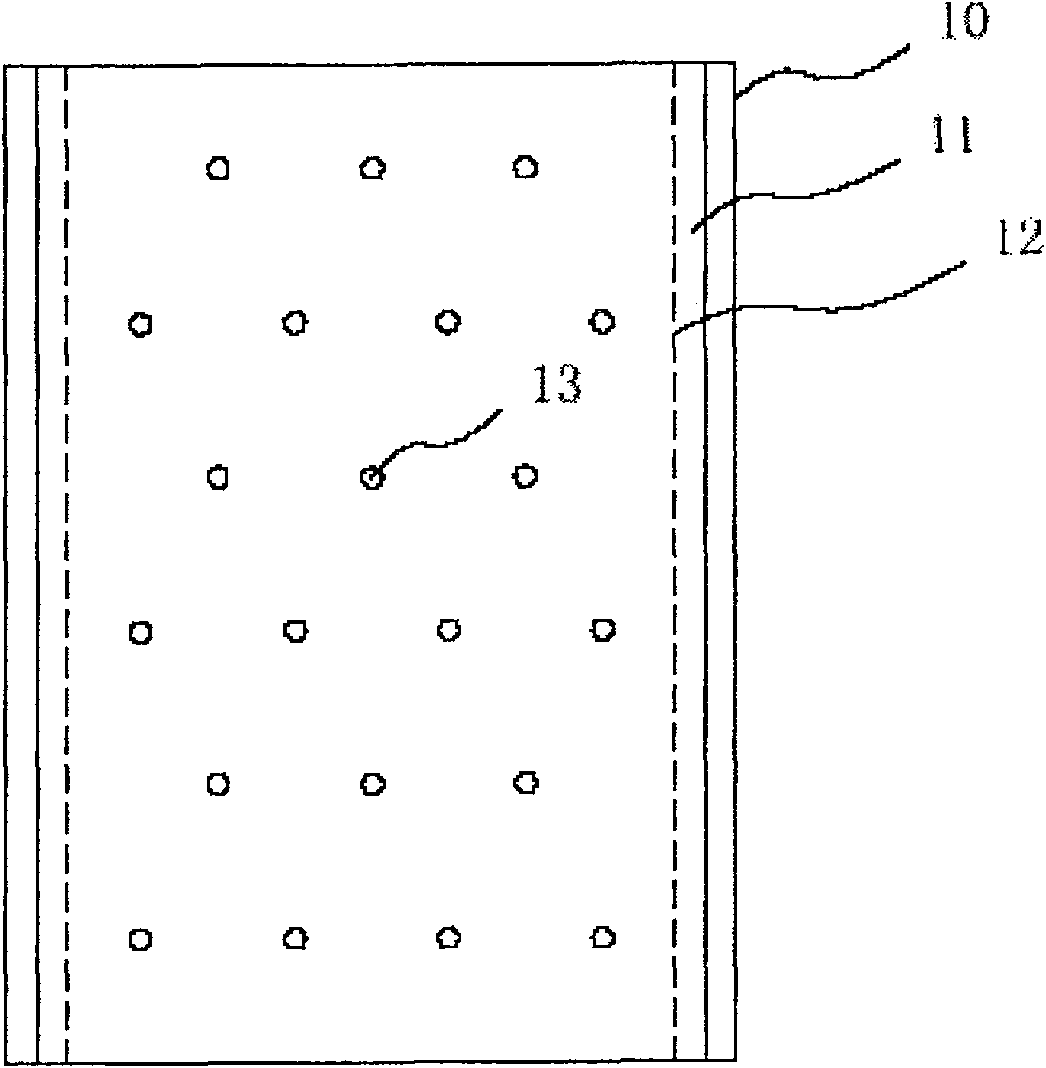

Nanometer intelligent thermal insulating window film

ActiveCN106183271AEasy to prepareEasy to operateSynthetic resin layered productsCoatingsPolyesterMetal coating

The invention relates to a nanometer intelligent thermal insulating window film which is composed of an anti-scratch layer (1), a polyester film or polycarbonate film base material (2-1), an intelligent thermal insulating glue layer (3), a polyester film or polycarbonate film base material (2-2) with a metal coating, an ultraviolet blocking pressure-sensitive glue layer (4) and a release film (5). The anti-scratch layer (1) is combined with one surface of the polyester film or polycarbonate film base material (2-1), the intelligent thermal insulating glue layer (3) is combined with the other surface of the polyester film or polycarbonate film base material (2-1), the surface of the metal coating of the polyester film or polycarbonate film base material (2-2) with the metal coating is located on the outer surface of the intelligent thermal insulating glue layer (3), the ultraviolet blocking pressure-sensitive glue layer (4) is combined with the other surface of the polyester film or polycarbonate film base material (2-2) with the metal coating, and the release film (5) is located on the outer surface of the ultraviolet blocking pressure-sensitive glue layer (4). The nanometer intelligent thermal insulating window film has a low radiation rate and high visible light transmittance.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

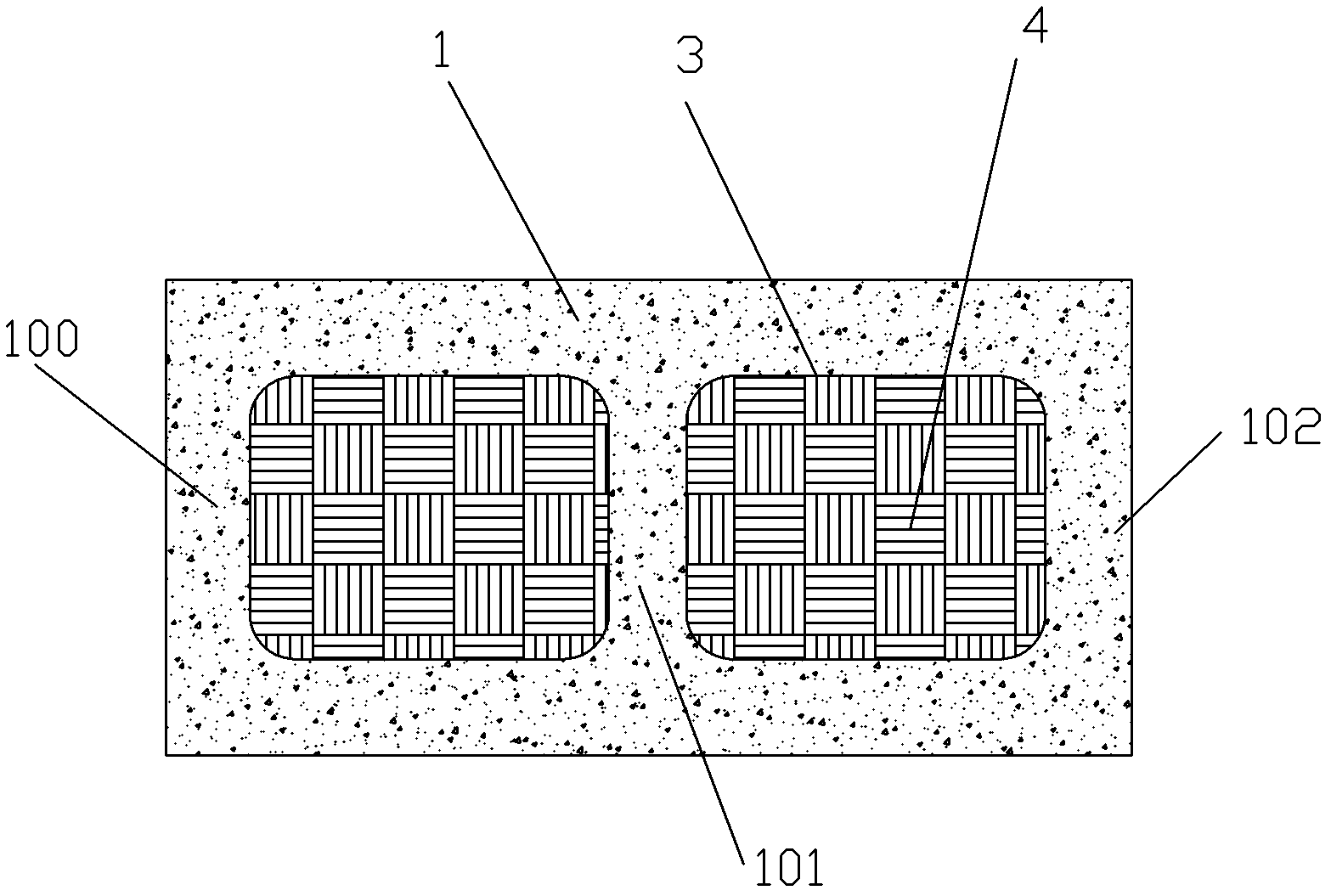

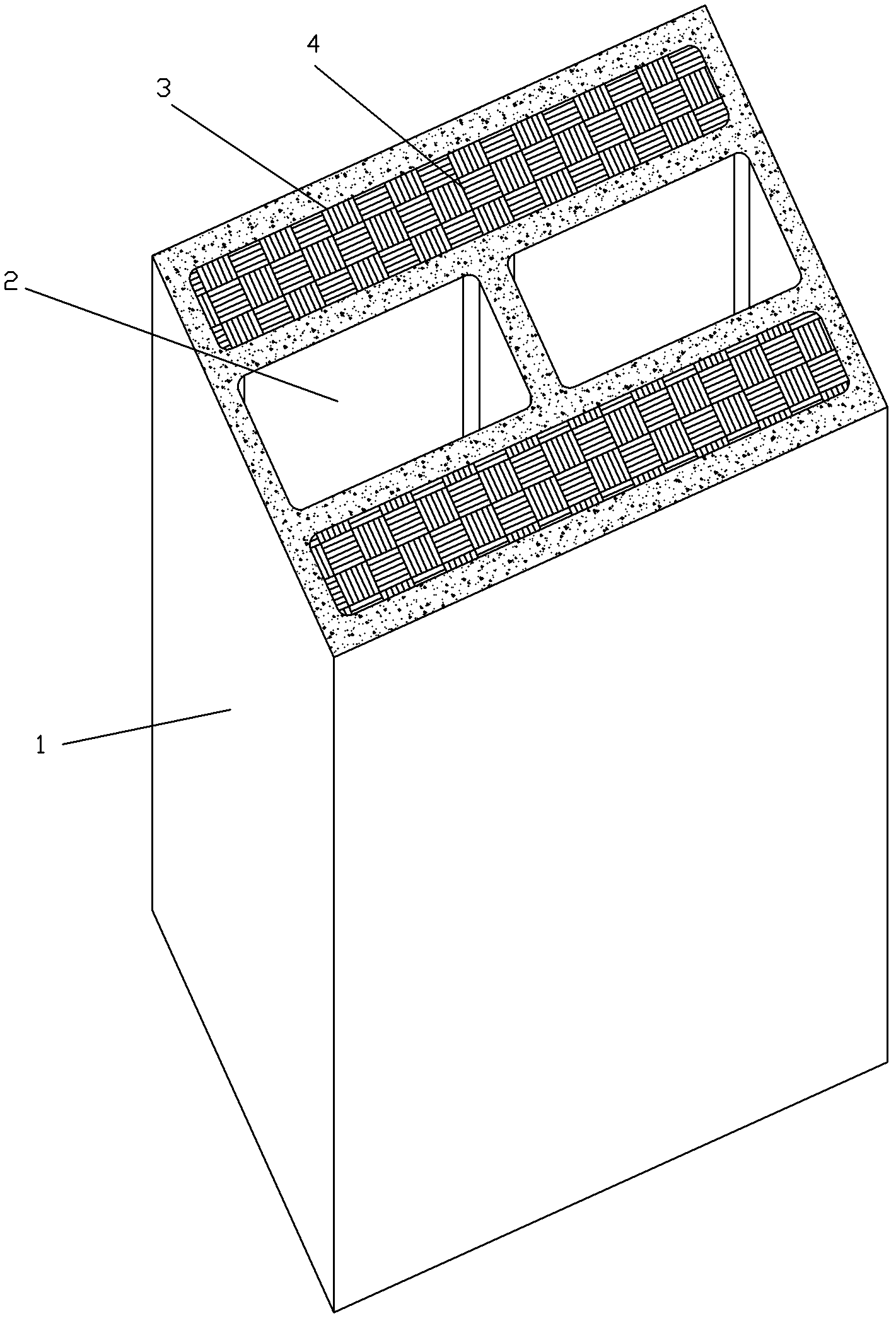

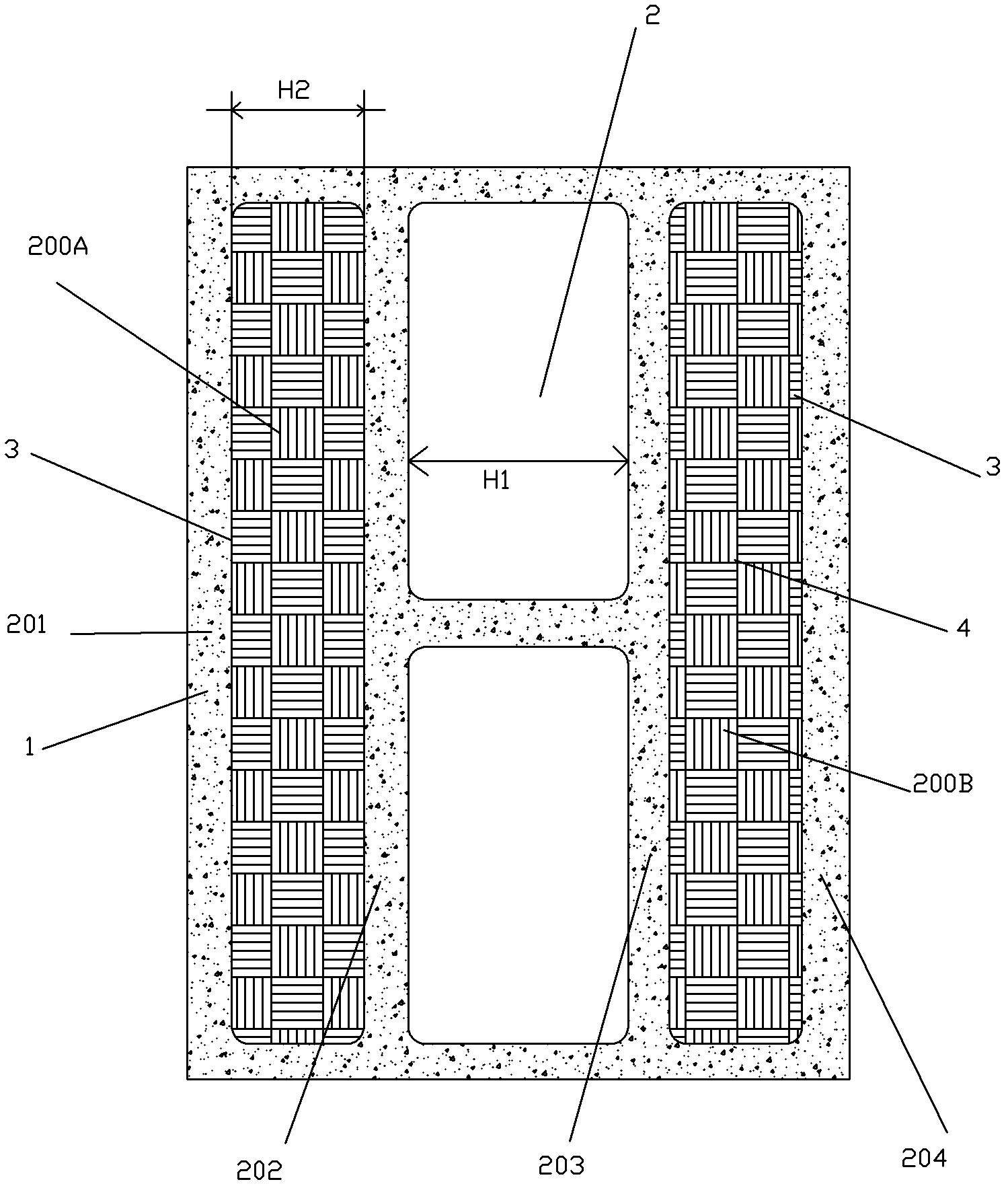

Self-insulating brick

InactiveCN102409798AExtension of timeInsulation up toConstruction materialClimate change adaptationState of artBrick

The invention discloses a self-insulating brick, which comprises a rectangular brick body. The self-insulating brick is characterized in that the brick body is provided with insulating holes along the height direction; the insulating holes are provided with insulating layers; two insulating holes are provided; vertical through holes are further arranged between the two insulating holes; the quantity of the vertical through holes is 1-3; and a plurality of vertical through holes are transversely arranged between the two insulating holes. Compared with the prior art, the self-insulating brick provided by the invention has the advantages of: energy conservation, thermal insulation, heat insulation, sound insulation, light volume weight, waterproofness, fire proofing, simple technology, convenient production, environment friendliness, convenient material drawing, soil conservation, low carbon, clay free, national land resource conversation, long product durability and capability of lowering construction cost.

Owner:樊杰俊

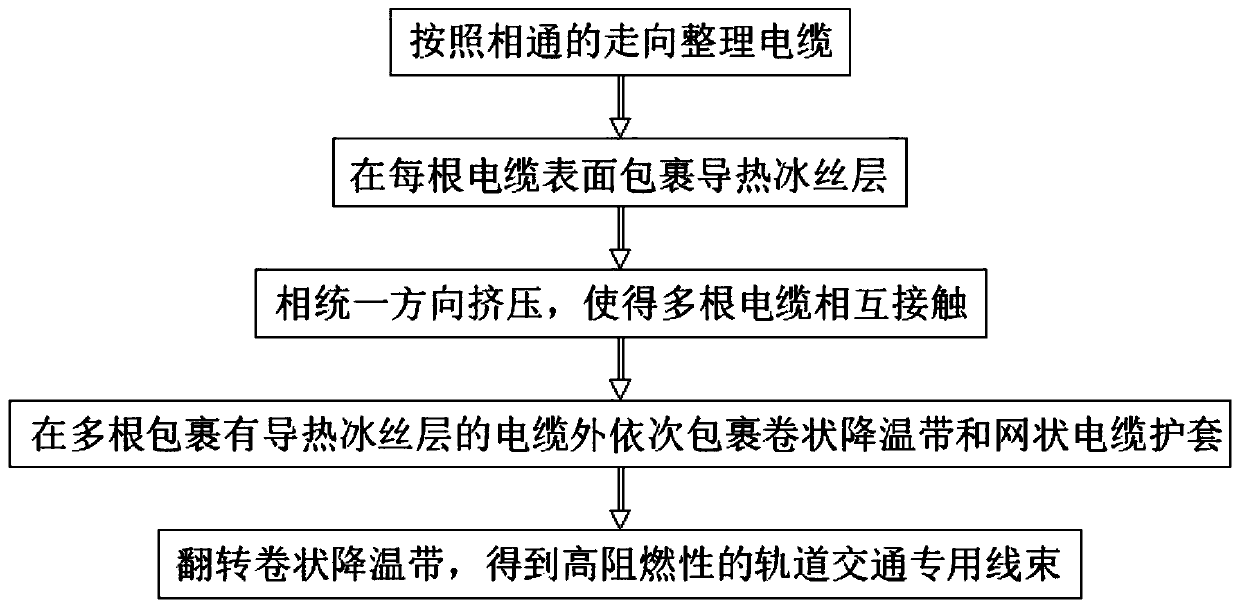

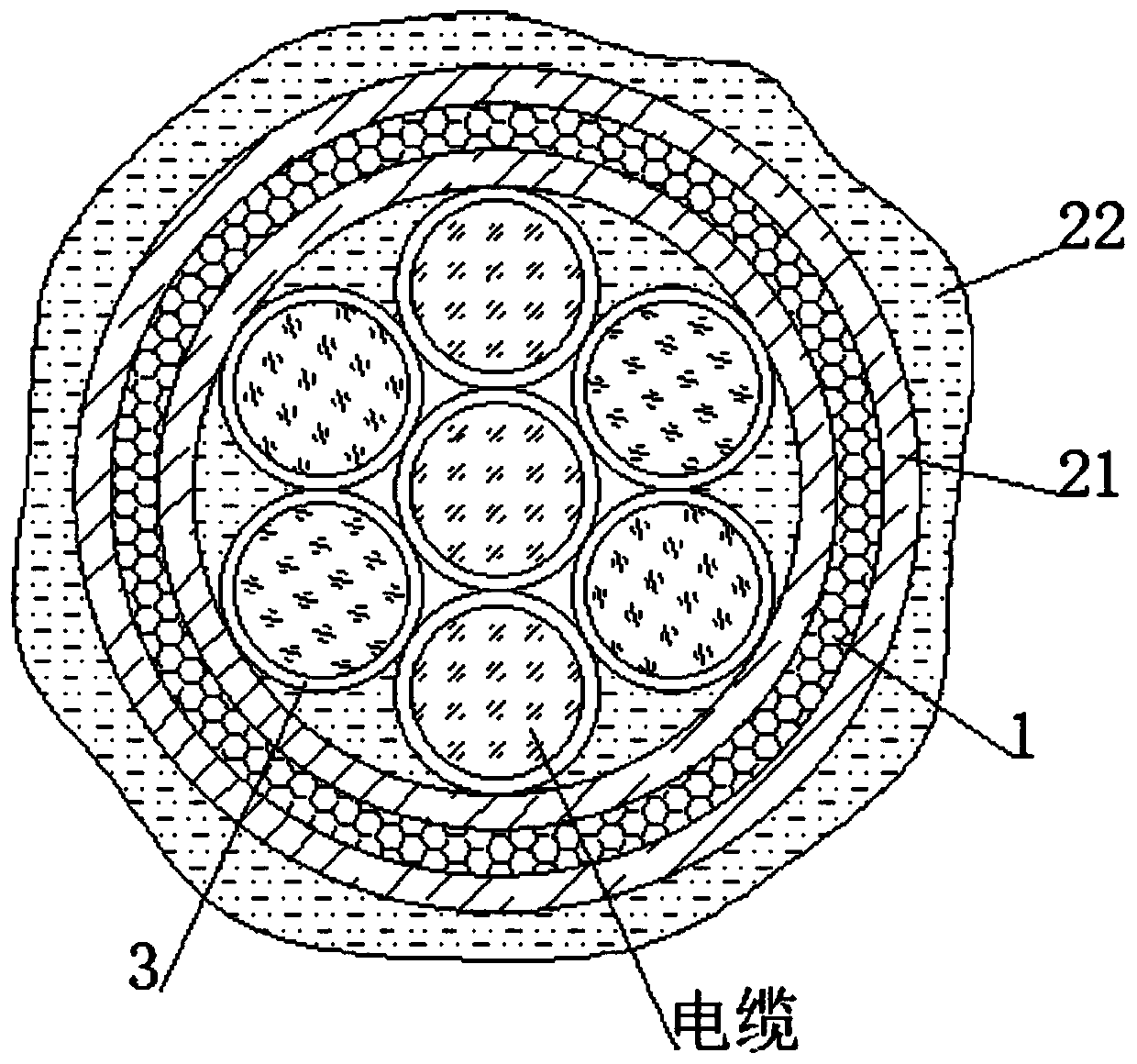

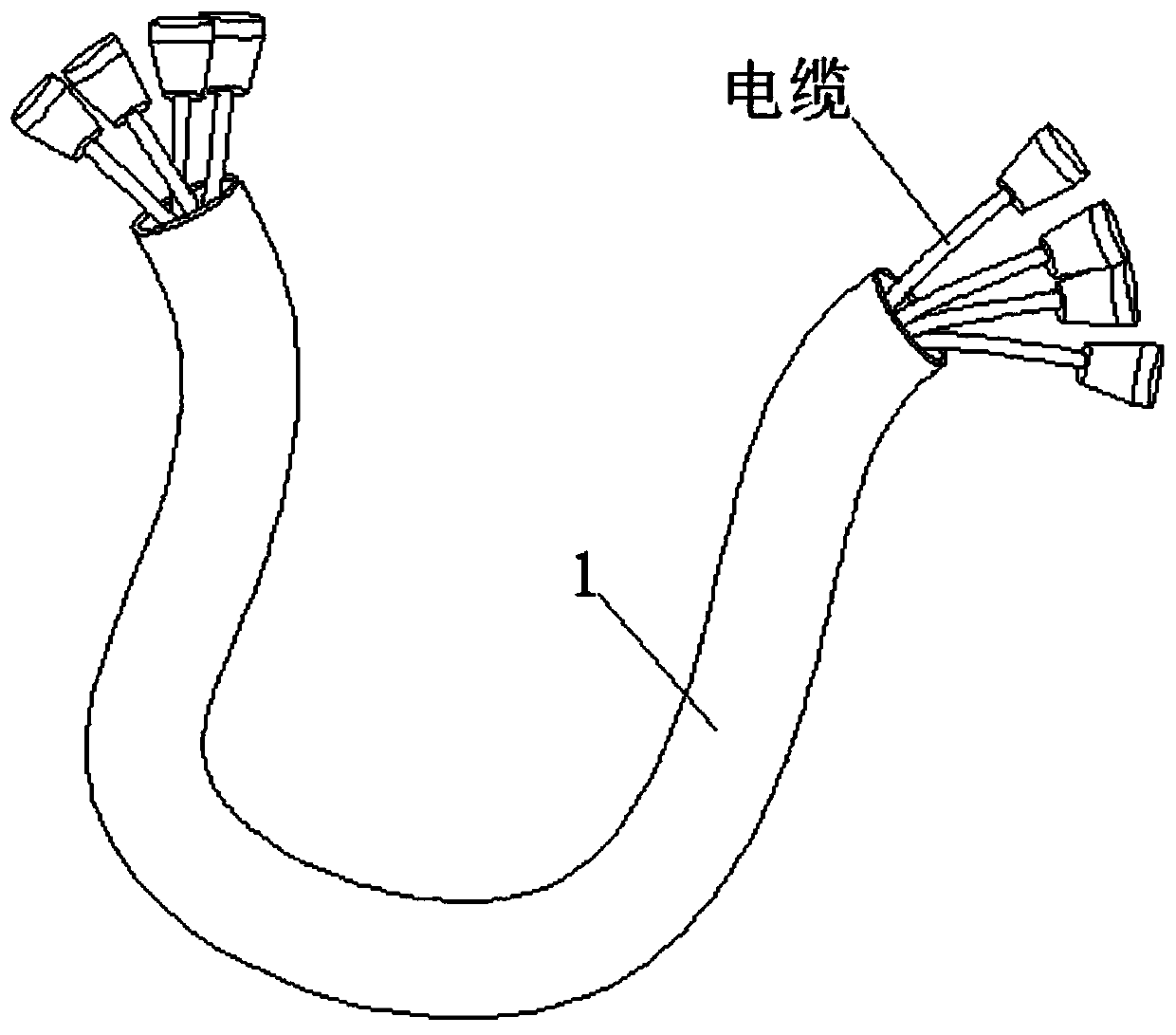

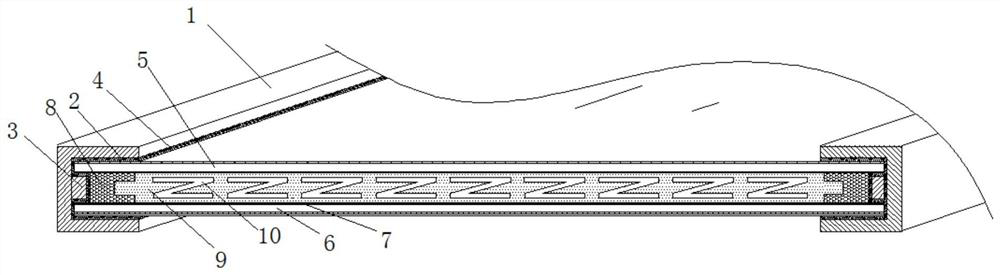

Production process of special highly-flame-retardant wire harness for rail transit

ActiveCN110610786AImprove adsorption capacityFast conductionClimate change adaptationInsulated cablesEngineeringMechanical engineering

The invention relates to a production process of a special highly-flame-retardant wire harness for rail transit. Each cable in a wire harness is coated with a heat conduction ice wire layer, in orderto improve the heat conduction and heat dissipation capabilities of the wire harness. Through the arrangement of a coiled cooling belt and a net-shaped cable sheath, inner-outer double-layer heat conduction and heat dissipation effects can be achieved, the wire harness can be rapidly cooled, the temperature near the wire harness can be lower than the temperature of an electrical system of the whole rail transit, the situation in which a cable can be easily ignited due to excessive temperature is avoided, and the safety is improved. The coiled cooling belt located on the outer side after beingturned over can achieve a heat insulation effect and avoid the influence on normal use of the wire harness due to the too high or too low external environment temperature. Because of the use of a dual-state heat conductor in the coiled cooling belt, heat conduction and heat dissipation effects can be achieved, and the effects of reminding a worker of leakage of the dual-state heat conductor and guiding the worker to a leakage point can be achieved to a certain extent.

Owner:汇铂斯电子技术(苏州)有限公司

Floor building glass

InactiveCN112049548APrevent burstTo achieve the effect of heat preservation and noise reductionConstructions elementsGlass/slag layered productsArchitectural glassInsulation layer

The invention relates to the technical field of glass, in particular to floor building glass. The floor building glass comprises a window frame body, wherein a mounting groove is formed in the right side of the interior of the window frame body, a warm edge spacing strip is welded to the interior of the mounting groove, a hot melt adhesive layer is bonded to the interior of the mounting groove, aglass inner plate and a glass outer plate are bonded to the interior of the hot melt adhesive layer, sound insulation cotton and a transparent silica gel panel are bonded to the interior of a cavity,and a sound insulation layer is arranged in the transparent silica gel panel. According to the floor building glass, the mounting groove is formed in the window frame body to achieve the effect of mounting the glass, the warm edge spacing strip is arranged to achieve the effects of heat preservation and noise reduction, the hot melt adhesive layer is arranged to achieve the effect of bonding and fixing the glass inner plate and the glass outer plate, when the glass is impacted by collision, the transparent silica gel panel can achieve the effect of shock absorption, the problem of glass burstis prevented to a certain extent, and the sound insulation cotton and the sound insulation layer can achieve the sound insulation effect.

Owner:恩平市鸿玻建材有限公司

High vacuum multiple layer heat insulation quilt manufacture method

InactiveCN100564986CTo achieve the effect of heat insulationReduce workloadThermal insulationPipe protection by thermal insulationSocial benefitsProduction line

The invention provides a method for making a microvacuum multilayer heat-insulating quilt, belonging to cryogenic engineering and cryogenic technical field. The method comprises the following steps of: preparing a mechanized production line; a plurality of reflecting layers and heat insulating layers is sewed into a quilt by seams after the plurality of reflecting layers and heat insulating layers are alternately combined on the production line according to certain requirements; and the quilt is evenly penetrated to make holes. The microvacuum multilayer heat-insulating quilt made by using the method reduces workloads for winding heat-insulating materials, shortens binding period, guarantees that the heat insulation quilt can not loose during using, and even can improve vacuumizing efficiency and maintain high vacuum degree between interlayer on the premise of a guarantee of excellent and stable heat insulation performance, thereby the method has more advantages of lot manufacturing and producing of cryogenic storage and transportation equipment, and prominent economic benefit and social benefit in cryogenic engineering.

Owner:SHANGHAI JIAOTONG UNIV

High-strength flue cover board brick and preparation method thereof

The invention particularly relates to a high-strength flue cover board brick and a preparation method thereof. The technical scheme comprises steps as follows: 50wt%-80wt% of bauxite, 5wt%-20wt% of clay, 5wt%-20wt% of mullite and 5wt%-15wt% of one of kyanite, andalusite and sillimanite are taken as raw materials, a sintering aid accounting for 0.1wt%-1wt% of the raw materials, a plasticizer accounting for 0.1wt%-5wt% of the raw materials and a binding agent accounting for 1wt%-10wt% of the raw materials are added, all components are mixed uniformly, aged for 12 h and subjected to extrusion molding, and a green body of the flue cover board brick is prepared accordingly; the green body of the flue cover board brick is dried for 24 h at the temperature of 110 DEG C and sintered for 3-7 h at the temperature of 1,100-1,500 DEG C, and the high-strength flue cover board brick is prepared. The high-strength flue cover board brick and the preparation method thereof have the characteristics as follows: the process is simple, controllability is high, and the prepared high-strength flue cover board brick is high in strength, good in thermal insulation effect, high in acidic and alkaline gas scouring resistance and good in thermal shock resistance stability.

Owner:YIXING MORGAN THERMAL CERAMICS CO LTD

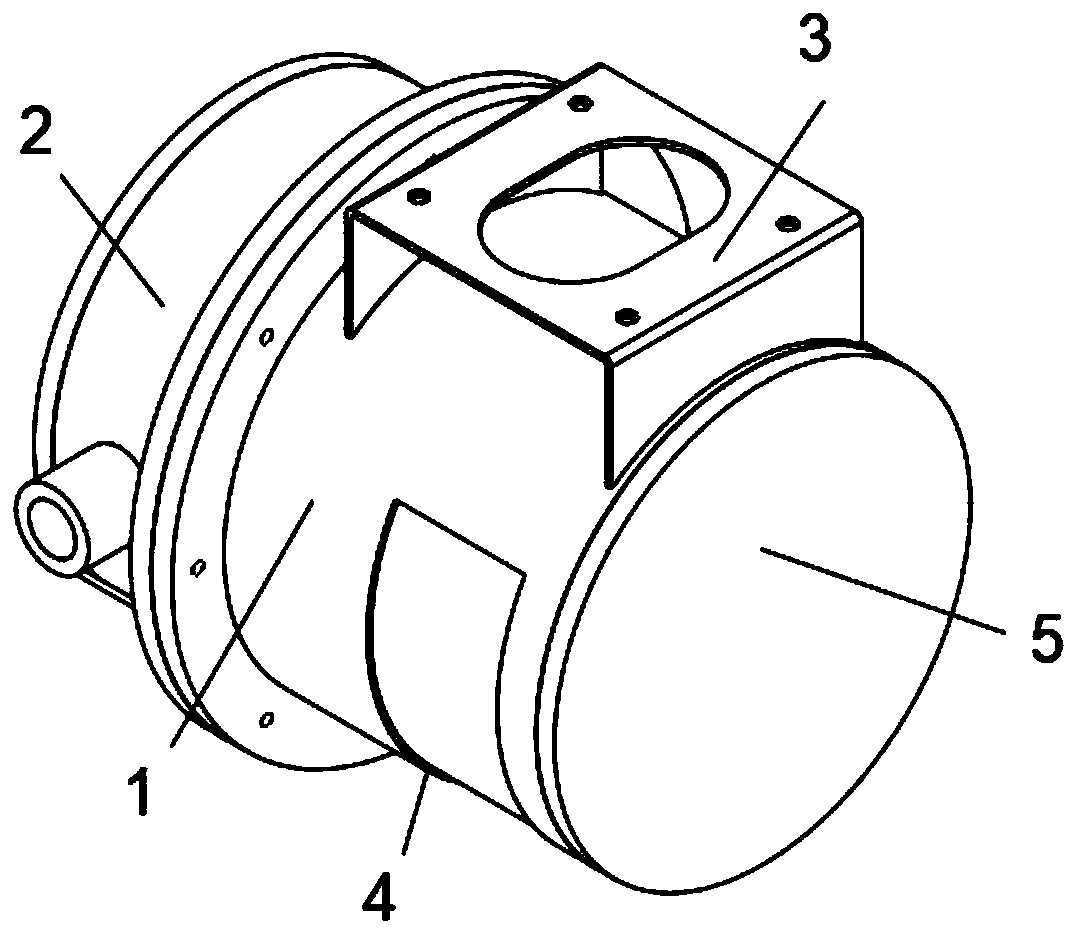

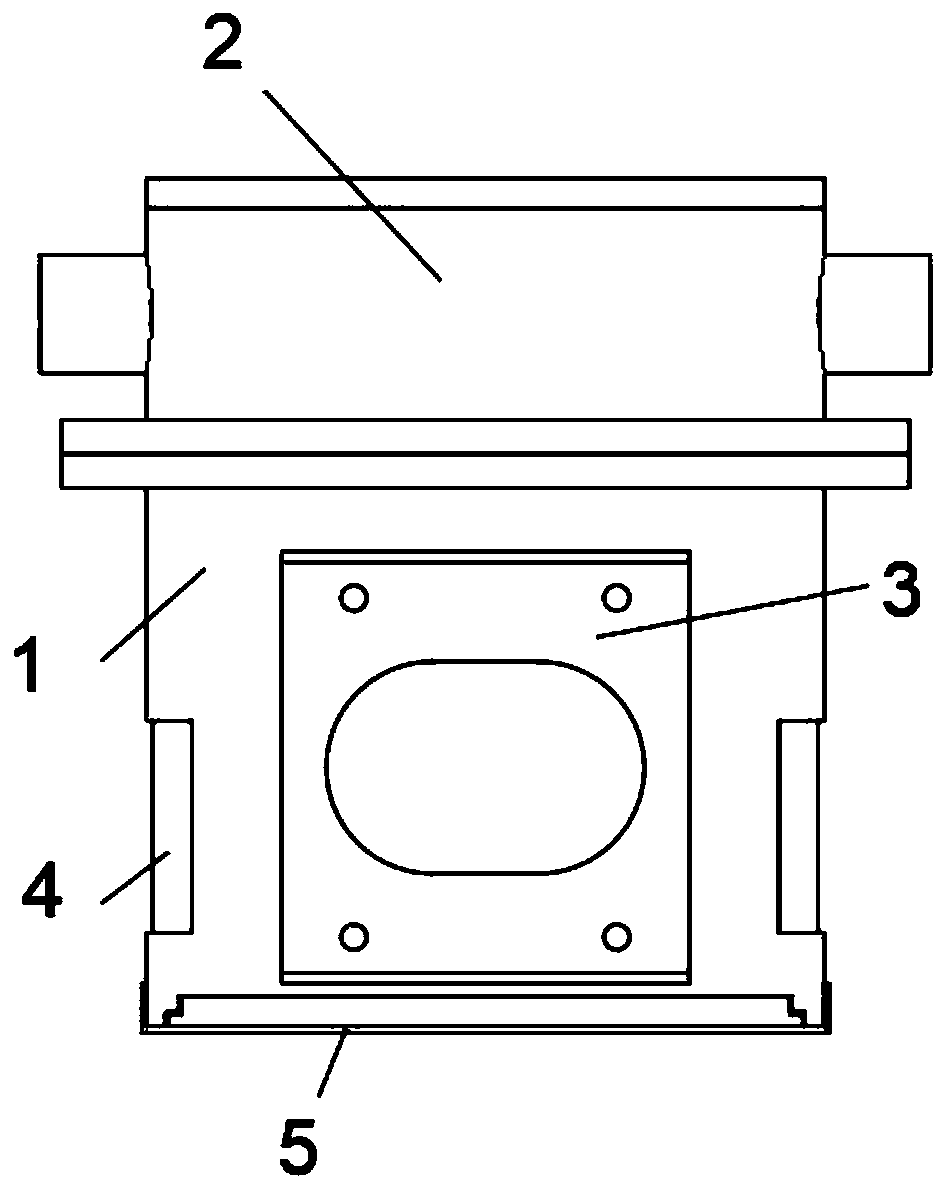

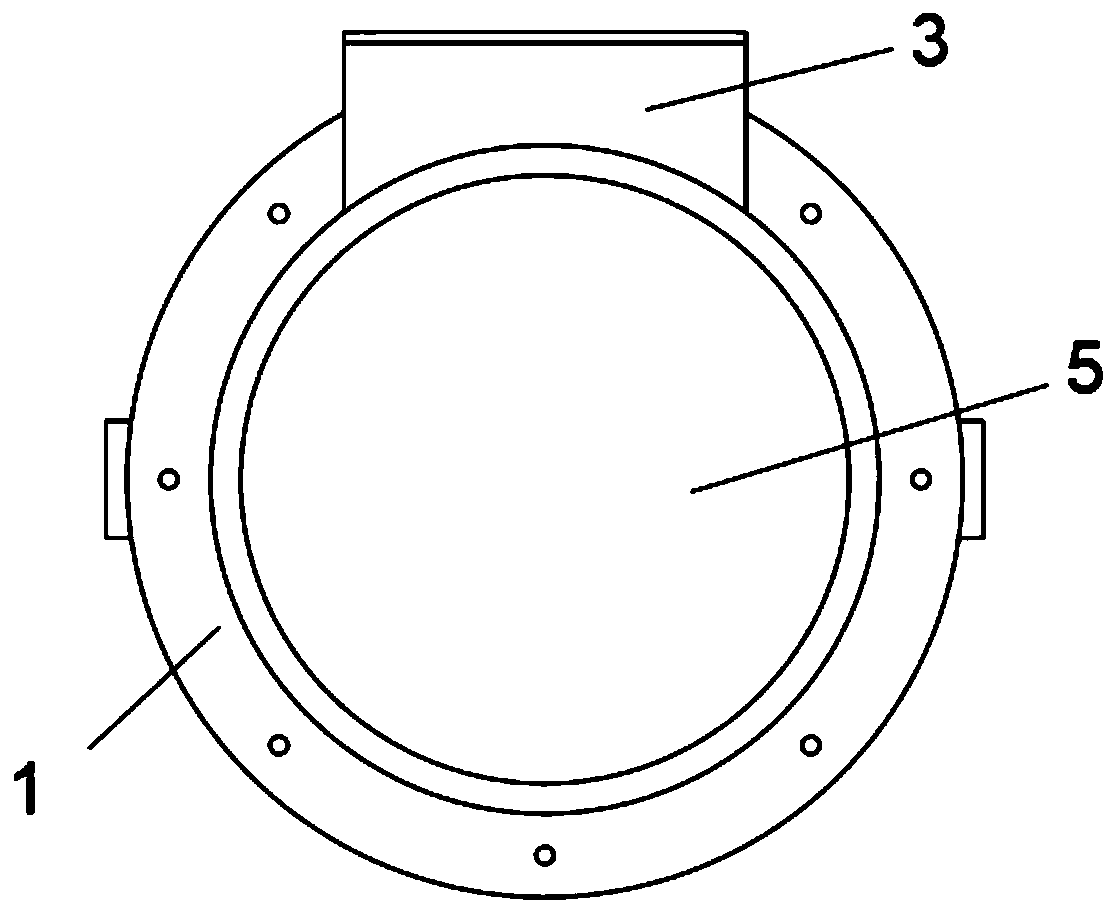

Explosion-proof protection structure for dangerous gas environment of laser radar

InactiveCN111273258AStable positionEnsure safetyWave based measurement systemsStructural engineeringLidar

An explosion-proof protection structure for a dangerous gas environment of a laser radar comprises a first outer cover and a second outer cover, the first outer cover and the second outer cover are fixedly connected through bolts, an installation frame is welded to the outer surface of the first outer cover, and notches are formed in the positions, located on the two sides of the installation frame, of the outer surface of the first outer cover. The technical key point is that the outer surface of the laser radar is provided with a radar shell and is combined with a first outer cover for use,so that multi-layer protection of the laser radar is realized; the rubber inner sleeve in the radar shell is tightly attached to the outer surface of the laser radar and buffers impact force from theoutside, and the explosive-proof protection effect is achieved. The glass cover, the glass inner plate and the glass pressing plate are used in a combined mode and are all made of explosion-proof glass materials, so that the explosion-proof effect can be achieved while normal use of the laser radar is prevented from being affected. And meanwhile, the glass cover is spirally mounted, so that the position of the glass inner plate is fixed, and subsequent replacement operation is facilitated.

Owner:张梅

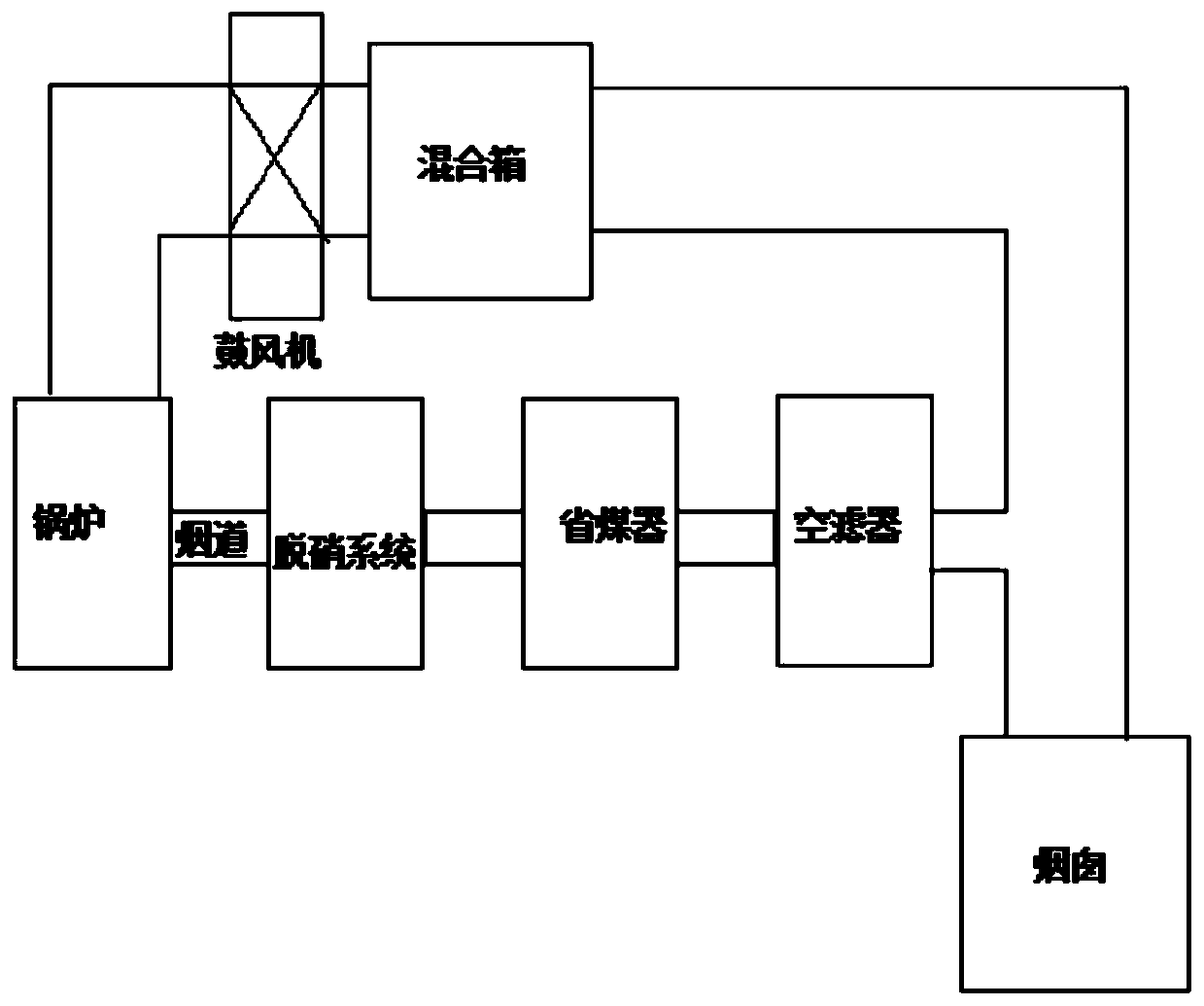

In-furnace denitration system and in-furnace denitration process

InactiveCN110975599AAvoid wasteful pitfallsImprove reliabilityGas treatmentDispersed particle filtrationThermodynamicsFlue gas

The invention relates to an in-furnace denitration system and an in-furnace denitration process. The system comprises a boiler, a boiler flue channel, a denitration system body, an economizer, an airfilter, a mixing box and a reflux channel, wherein the flue gas outlet of the boiler is communicated with one end of the boiler flue channel, the boiler flue channel is used for discharging flue gas,flowing out of the flue gas outlet, of the boiler, the denitration system, the economizer and the air filter are sequentially communicated with the boiler flue channel in the direction away from the boiler, the other end of the boiler flue channel is communicated with a chimney, the flue channel between the air filter and the chimney is further communicated with one end of the reflux channel, andthe other end of the reflux channel is communicated with the boiler. According to the invention, by combining with other structures or methods, the defects that flue gas discharged by a boiler is completely and directly discharged to a chimney after passing through a denitration system so as not to efficiently use the flue gas with high temperature, and incompletely-combusted coal powder particlesin the flue gas are completely and directly discharged to the chimney so as to completely waste the coal powder particles are effectively overcome.

Owner:江苏天莱环保工程有限公司

Heat insulation paper for decorating and preparation method thereof

InactiveCN108677596AGood insulation performanceThermal insulation performanceCovering/liningsWater-repelling agents additionEmulsionPolypropylene

The invention provides heat insulation paper for decorating and a preparation method thereof. The heat insulation paper is prepared from the following raw materials: inorganic fibers, wood pulp, waterborne acrylic emulsion, polypropylene oxide glycol, hexamine, octadecyl trimethyl ammonium chloride, polyvinyl alcohol, nano-silica aerogel and ethyl silicate hydrolysate. The heat insulation paper has the advantages of being resistant to high temperature, outstanding in heat insulation performance and heat insulated; in addition, the hydrophobicity is high, and the heat conductivity is low; and the temperature preserving and heat insulating effects are outstanding.

Owner:合肥谦尧建筑装饰工程有限公司

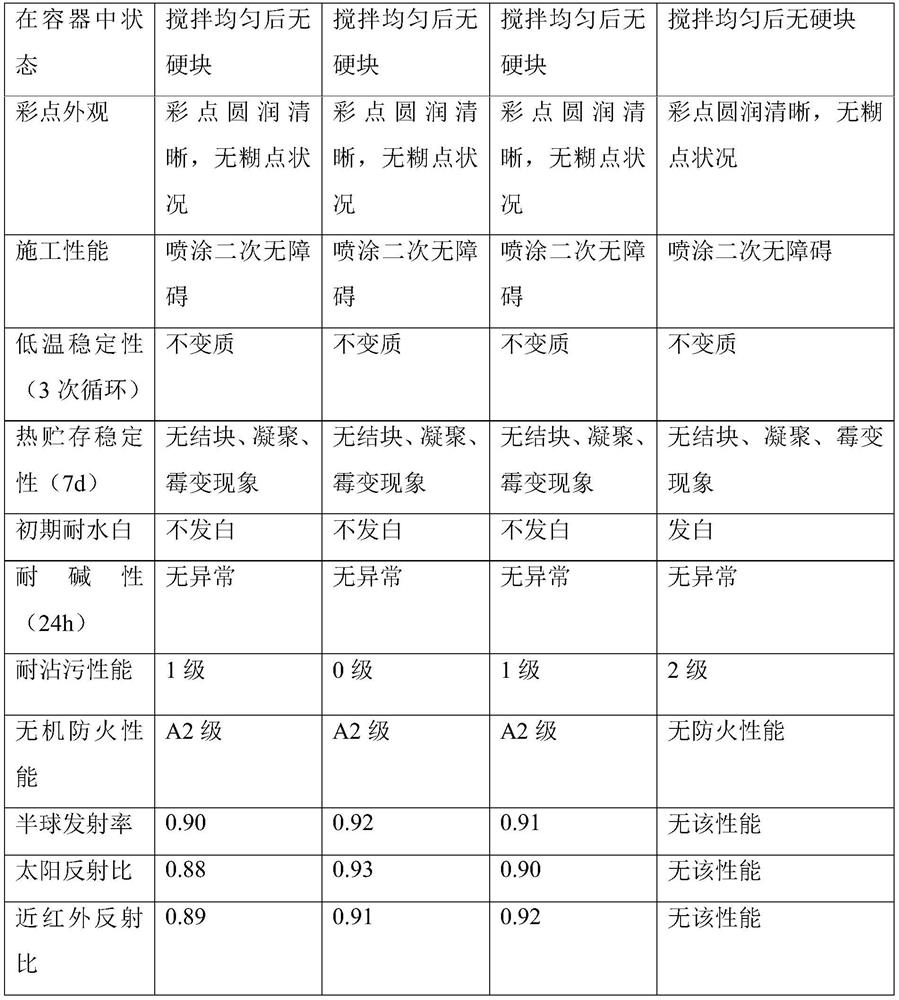

Marble-imitated reflective heat-insulating inorganic multicolor paint and preparation method thereof

InactiveCN113150686AStrong color renderingGuaranteed not to be brokenFireproof paintsReflecting/signal paintsCellulosePolymer science

The invention discloses marble-imitated reflective heat-insulating inorganic multi-color paint and a preparation method thereof. The multi-color paint comprises the following components in parts by weight: 20-30 parts of a continuous phase, 20-30 parts of a granulation protection glue liquid and 40-60 parts of base paint, wherein the basic paint is mainly prepared from the following components in parts by weight: 25 to 35 parts of water, 0.1 to 0.3 part of cellulose, 0.1 to 0.2 part of a de-foaming agent, 0.3 to 0.8 part of a dispersing agent, 12 to 20 parts of reflective thermal insulation titanium dioxide, 5 to 10 parts of heavy calcium powder, 5 to 10 parts of talcum powder, 5 to 10 parts of barium sulfate, 12 to 20 parts of inorganic silicon resin, 5 to 10 parts of reflective thermal insulation emulsion, 0.1 to 0.5 part of a thickening agent and 0.1 to 0.5 part of a sterilizing agent. The decoration effect is achieved, and the heat insulation effect is achieved by reflecting light; the inorganic silicon resin and the reflective heat-insulation emulsion are compounded, so that the reflective heat-insulation titanium dioxide does not become white at the initial stage, and the reflective heat-insulation titanium dioxide has good tinting ability.

Owner:四川嘉宝莉涂料有限公司

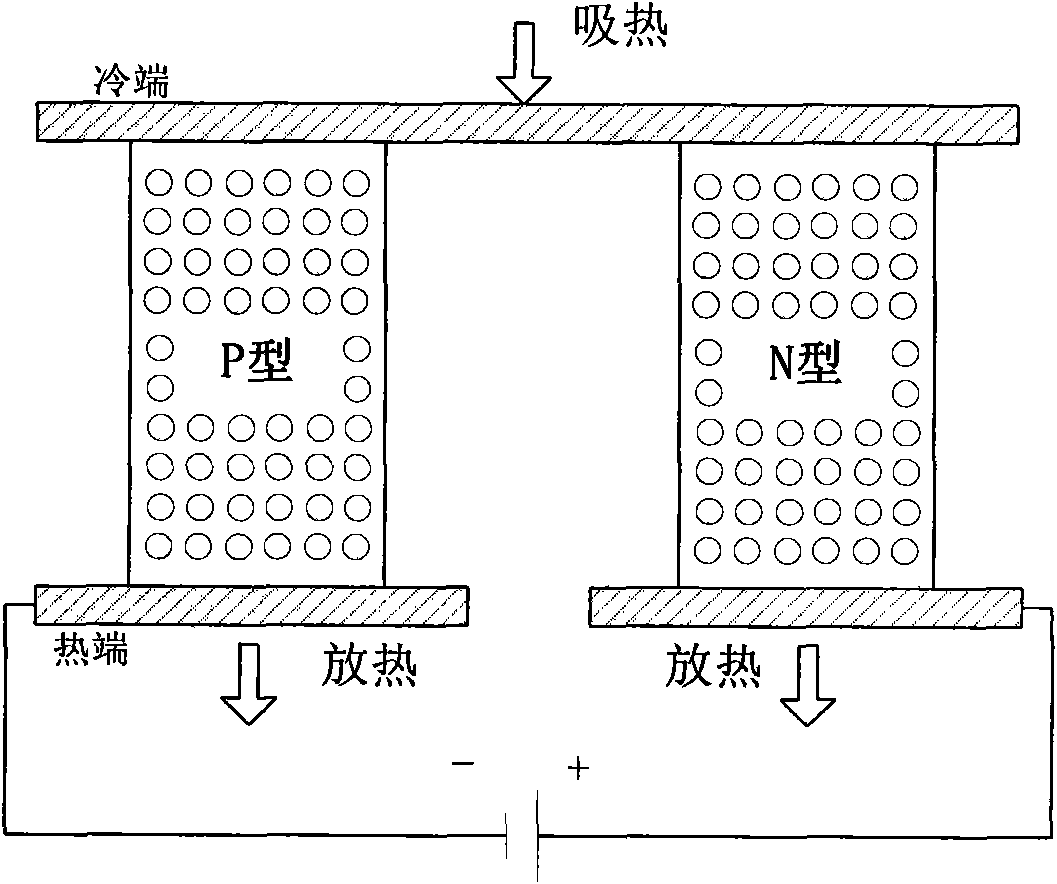

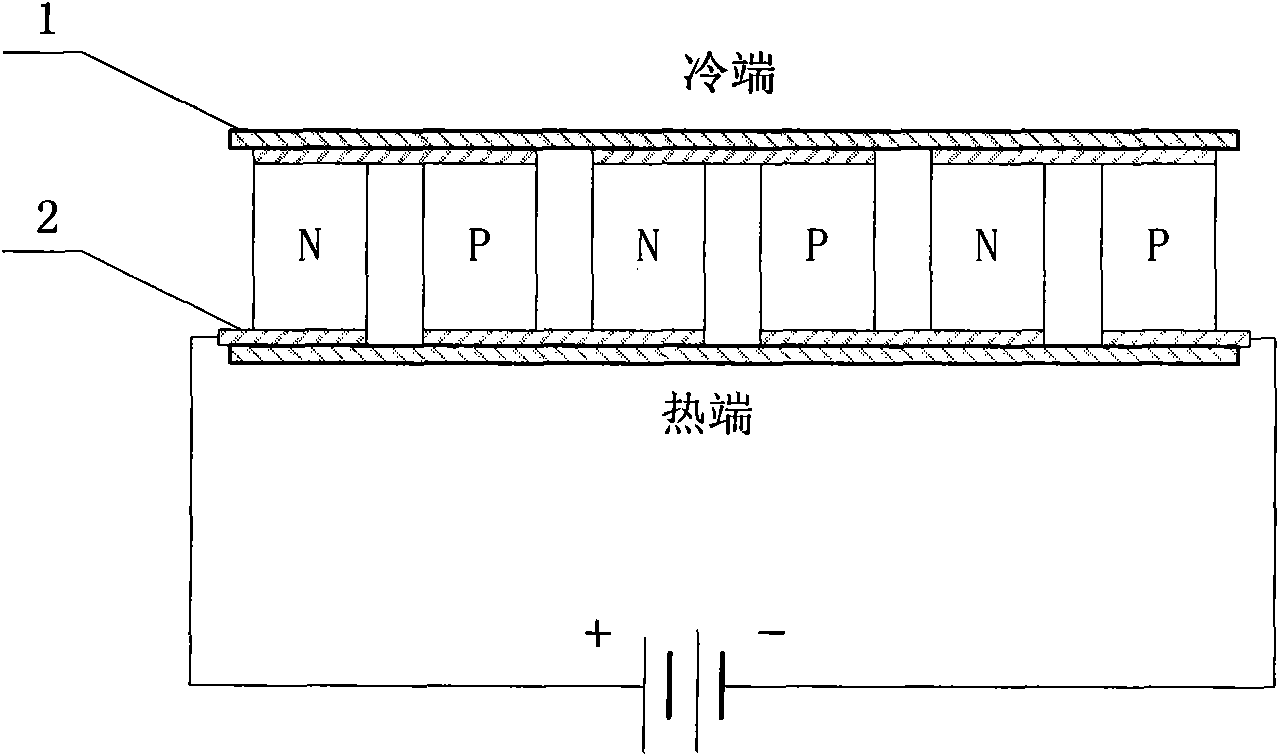

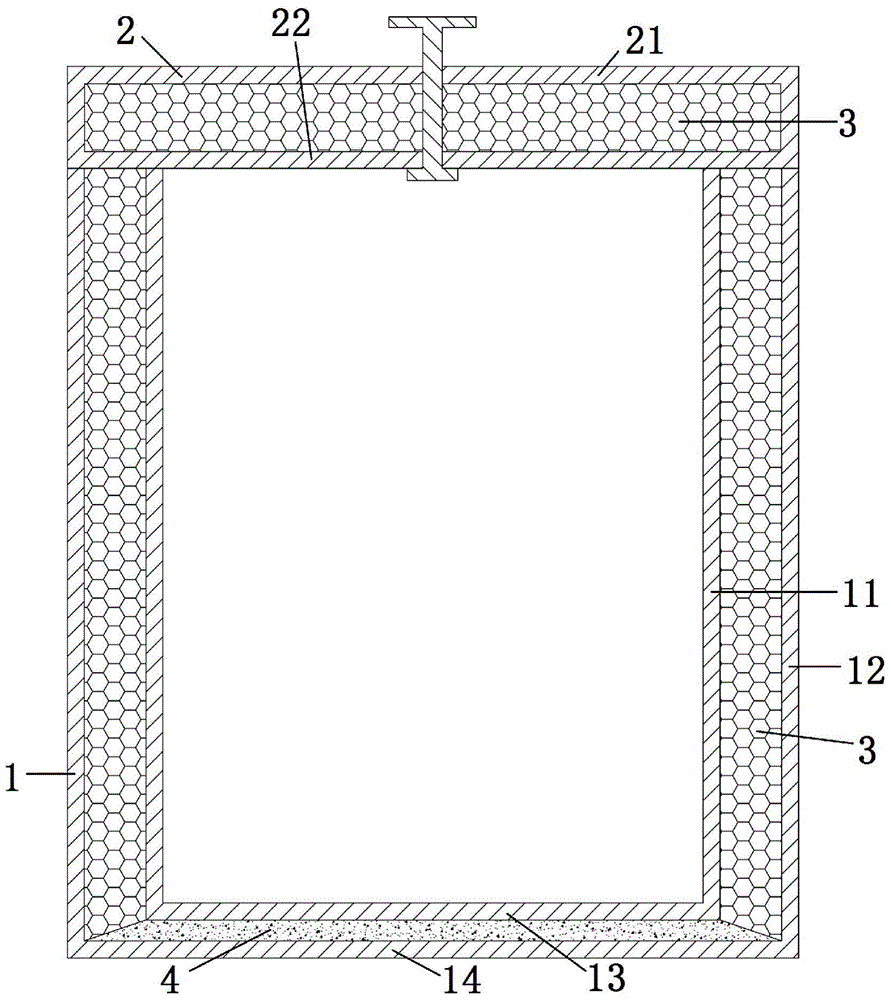

High-temperature resistant energy-saving environment-friendly low-voltage switch cabinet

ActiveCN102035143AWith double heat insulation effectFlexible layoutTemperatue controlEnergy efficient heating/coolingControl systemLow voltage

The invention discloses a high-temperature low-voltage switch cabinet, consisting of an internal-external two-compartment type box body part and a high-temperature resistant control system part, wherein the internal-external two-compartment type box body part mainly comprises an external compartment and a plurality of internal compartments; the external compartment is connected with the internal compartments through dual structures of a suspension ring and a supporting plate; the high-temperature resistant control system part is formed by sequentially connecting a temperature measurement module, a control module and a refrigeration module; by adopting the internal-external two-compartment type box body structure, the low-voltage switch cabinet has effect of dual heat insulation; the internal compartments and the external compartment are connected detachably, so that the internal compartments and the external compartment are manufactured by adopting a simple process, are flexible in layout, easy to separate and detach and benefit the check and replacement of internal electrical components; the high-temperature resistant control system monitors the internal temperature and intelligently reduces the temperature so as to achieve the effect of resisting high temperature; and by using a solar panel, the heat-insulating effect can be achieved, the auxiliary energy can be provided for the high-temperature resistant control system and the functions for saving energy and protecting environment can be achieved.

Owner:ZHEJIANG UNIV

Stockpot

InactiveCN105078203AGuaranteed minimum emissionImprove thermal conductivityCooking-vessel materialsCooking-vessel lids/coversEngineeringCopper

The invention discloses a stockpot which comprises a pot body and pot covers, wherein the pot body and the pot covers are in three-layer structures, the pot body comprises pot walls and pot bottoms, an expanded perlite filling layer is arranged between the inner-layer pot wall and the outer-layer pot wall, another expanded perlite filling layer is arranged between the inner-layer pot cover and the outer-layer pot cover, and a heat conduction metal layer is arranged between the inner-layer pot bottom and the outer-layer pot bottom, and has the thickness of 0.3mm-1-5mm. According to the stockpot, the three-layer structures are adopted, the expanded perlite filling layers are arranged between the inner layer and the outer layer of the pot wall, and between the inner layer and the outer layer of the pot cover, respectively, thus the heat insulation effect is achieved through the expanded perlite filling layers with the thickness of 1cm-2cm, and the minimum dissipation of heat is guaranteed; by arranging the heat conduction metal layer made of red copper but not limited to red copper between the inner layer and the outer layer of the pot bottom, the heat conduction of the pot bottom is rapid.

Owner:于洋

Waterproof thermal insulation coating

InactiveCN108587424AUV shieldingShield near infraredFireproof paintsAntifouling/underwater paintsIndium TrichloridePotassium persulfate

The invention provides a waterproof thermal insulation coating. The coating is prepared from, by weight, 80-100 parts of alkyd resin, 40-60 parts of acrylic emulsion, 20-30 parts of modified expandedperlite, 6-12 parts of dispersing agent, 4-8 parts of wetting agent, 8-16 parts of curing agent, 4-8 parts of thickener and 10-30 parts of water; modified expanded perlite is mainly prepared from expanded perlite, indium trichloride and tin tetrachloride, and polyacrylic emulsion is mainly prepared from methyl hydroxymethyl methacrylate, styrene, ammonium acrylate, silica sol, ethyl hexyl acrylate, alha-ethylhexyl acrylate, hydroxyethyl acrylate, water, potassium persulfate, a pH adjuster and sodium dodecylbenzene sulfonate. The thermal insulation coating has better thermal insulation effect and excellent water resistance.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com