Uniform temperature plate structure and manufacturing method thereof

A manufacturing method and technology of a temperature equalizing plate, which can be applied in lighting and heating equipment, electrical components, electric solid devices, etc., and can solve the problems of different heat and different power of electronic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described based on the preferred embodiments of the accompanying drawings.

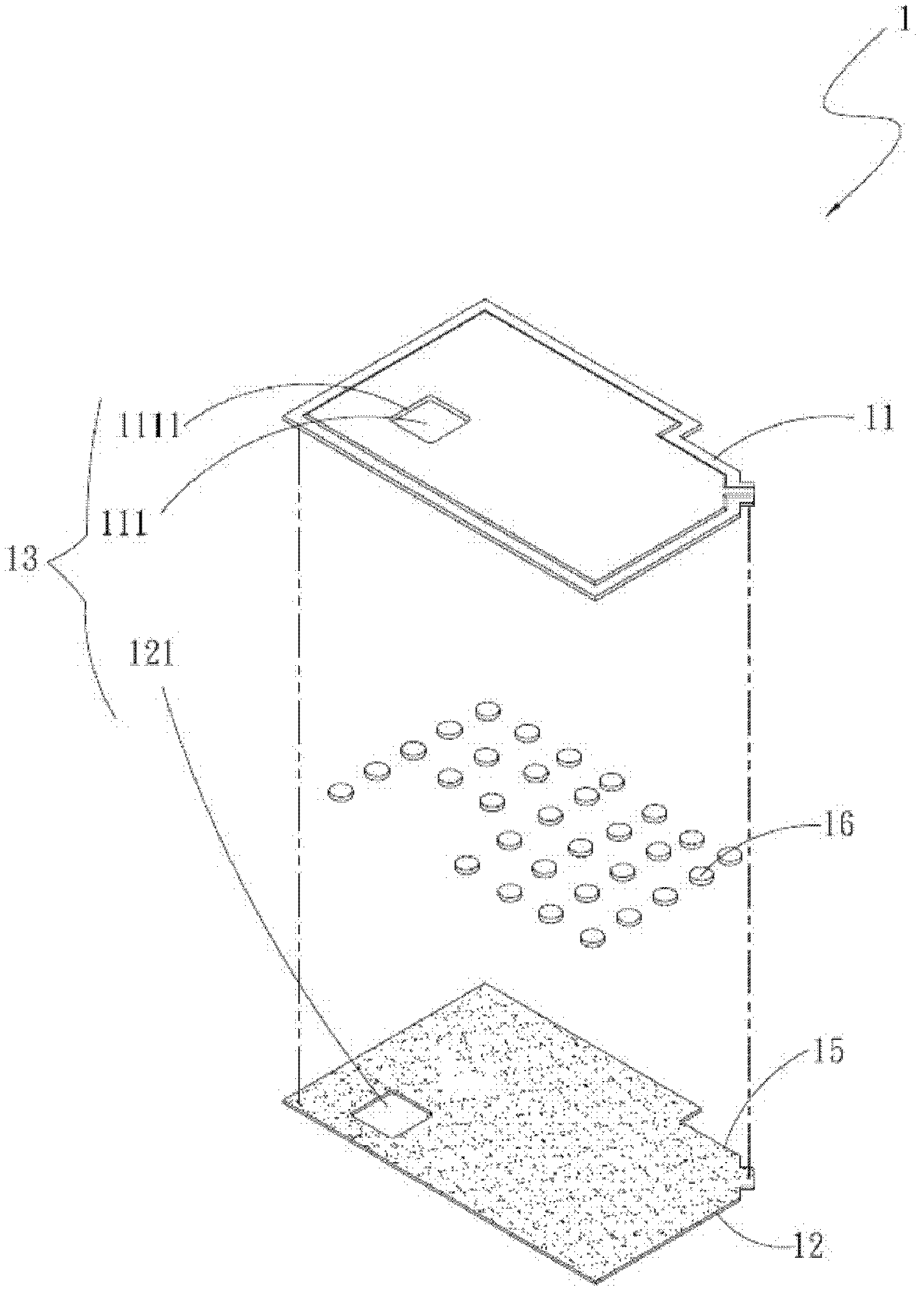

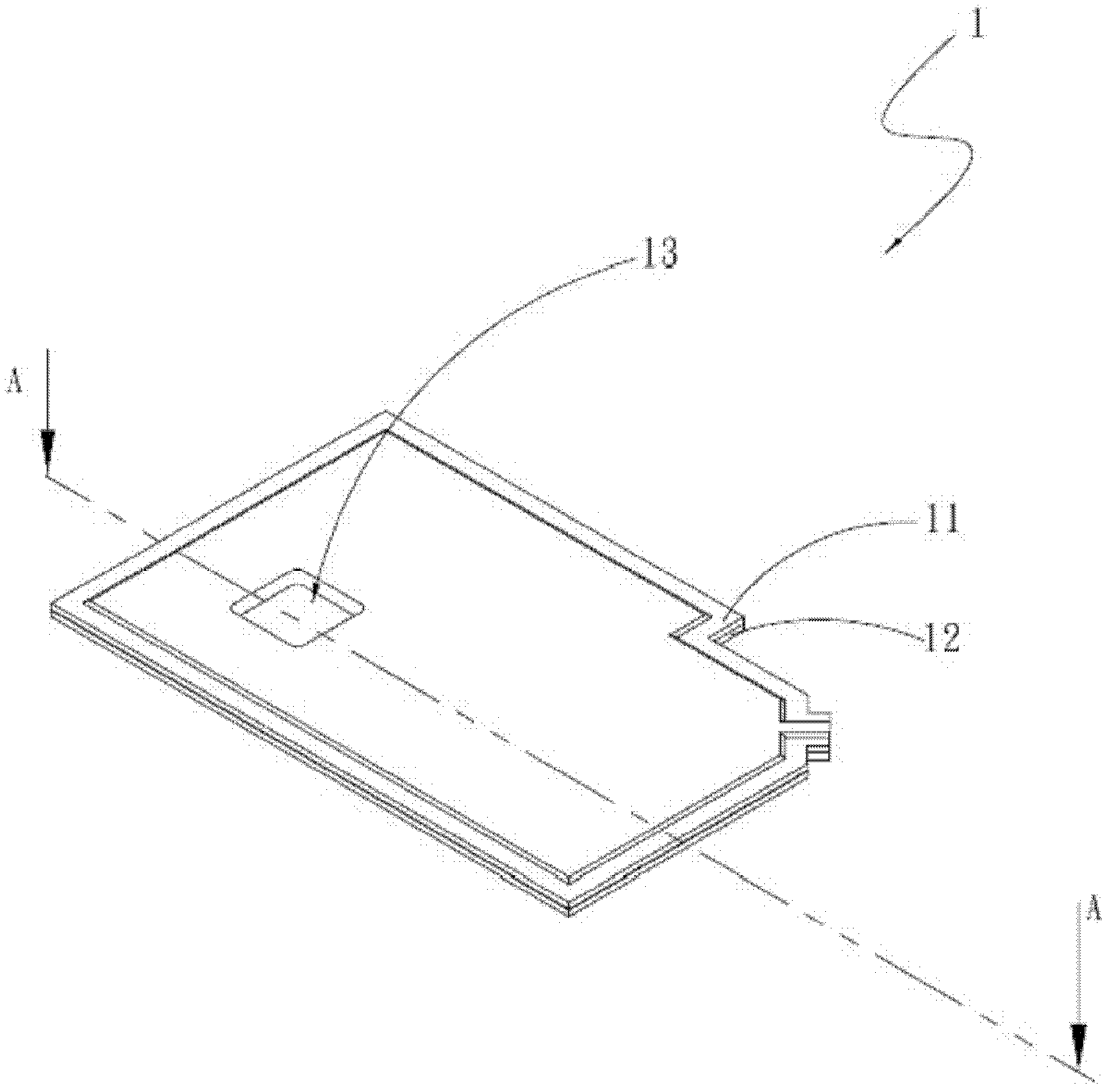

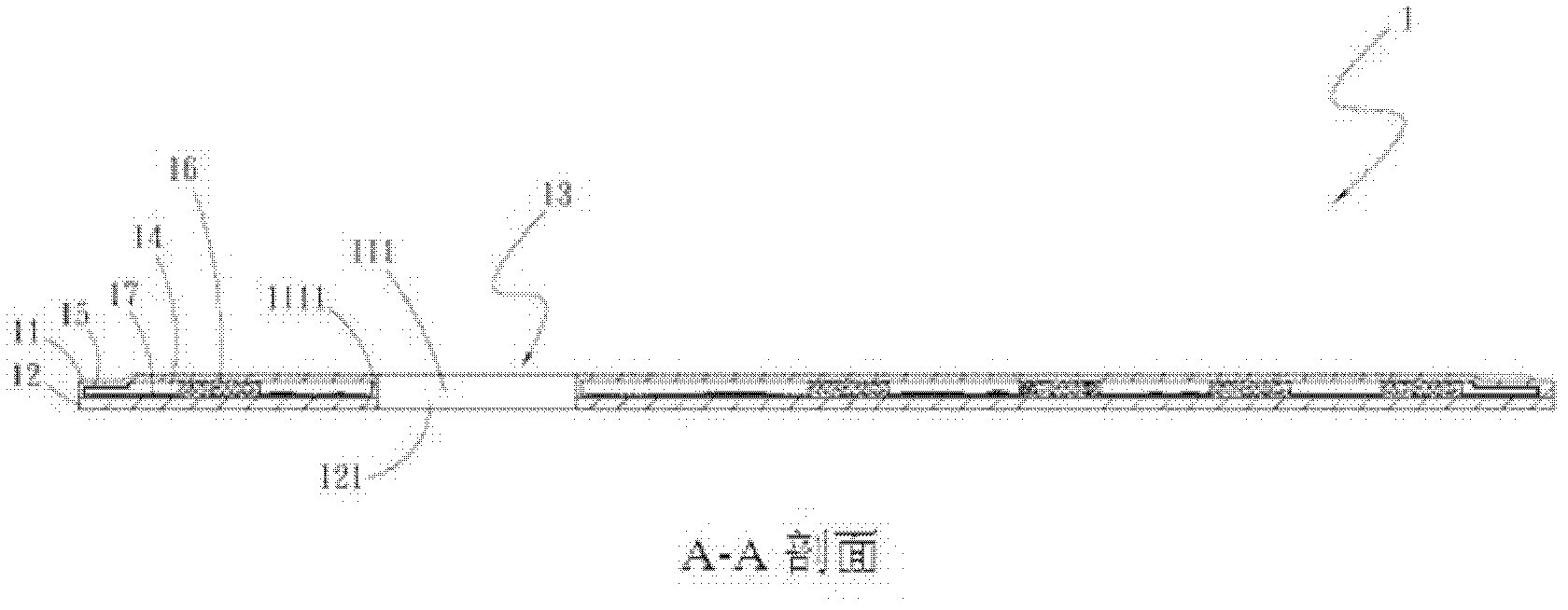

[0046] see figure 1 , figure 2 , image 3 , is the three-dimensional decomposition and assembly and the A-A sectional view of the first embodiment of the chamber structure of the present invention. The chamber structure includes: a body 1;

[0047] The main body 1 has a first plate body 11 and a second plate body 12, the first and second plate bodies 11, 12 are correspondingly covered, and jointly define at least one empty area 13 and a chamber 14, said The chamber 14 has at least one capillary structure 15, a supporting structure 16, and a working fluid 17. The hollow area 13 runs through the first and second plate bodies 11, 12 and the chamber 14 correspondingly. The chamber 14 is independent It is sealed between the first and second plate bodies 11, 12 and the hollow area 13.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com