Nanometer intelligent thermal insulating window film

An intelligent thermal insulation and nano technology, applied in coatings, layered products, synthetic resin layered products, etc., can solve the problems of coating adhesion, unguaranteed weather resistance, poor wear resistance and scratch resistance, etc. , to achieve the effects of simple and easy operation, high visible light transmittance, and good thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

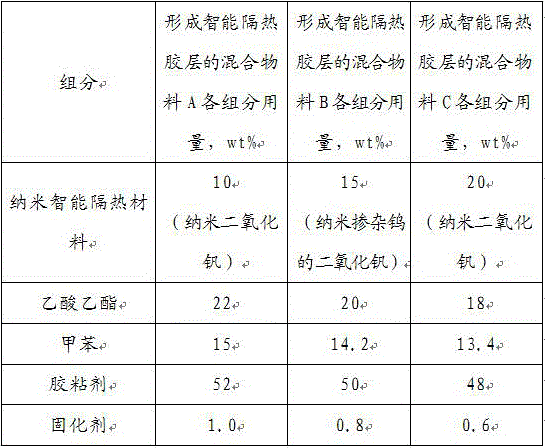

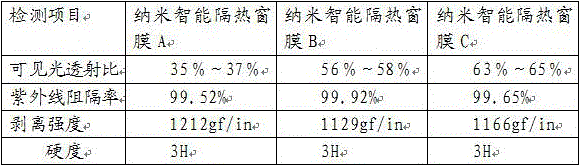

[0034] Embodiment 1~3 prepares nano intelligent thermal insulation window film A~C

[0035] The specific operation is as follows:

[0036] (A) Prepare raw materials

[0037] ① Prepare the base material

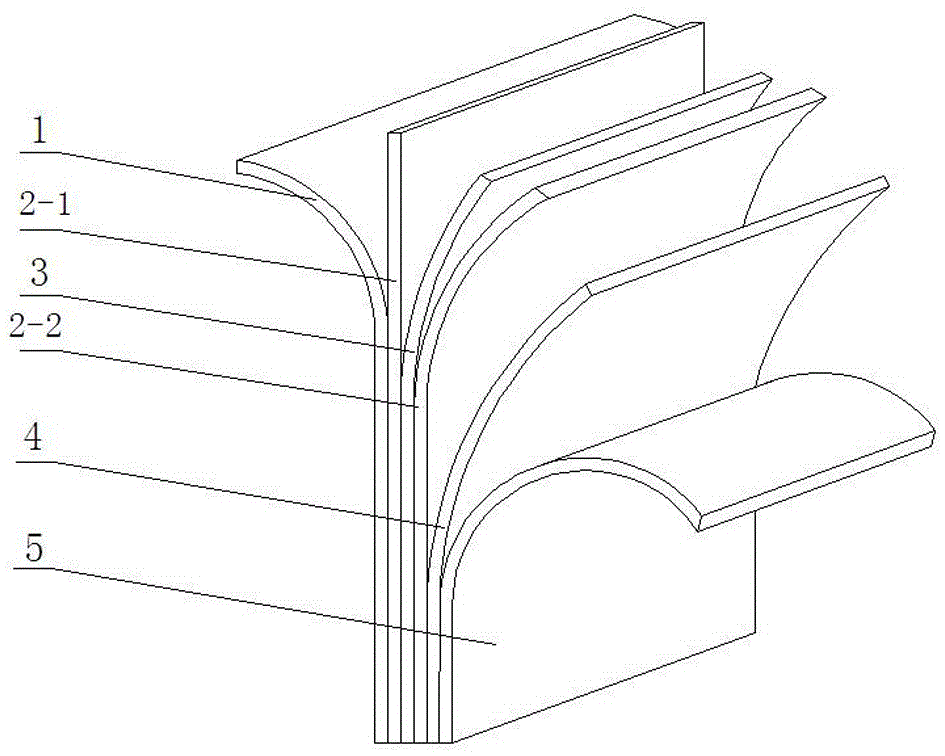

[0038] A transparent polyester film substrate 2-1 with a thickness of 23 μm; prepare a polyester film substrate 2-2 with a metal coating with a thickness of 23 μm, one surface of which has a silver metal layer of magnetron sputtering; prepare a thickness of 23 μm The release film 5;

[0039] ②Prepare the mixed material to form the anti-scratch layer 1

[0040] Prepare the anti-scratch agent and solvent ethyl acetate at a mass ratio of 1:1, mix the two evenly to obtain a mixture that forms a wear-resistant layer, and save it for later use. Among them, the anti-scratch agent is polyurethane produced by Danyang Zhongshun Chemical Co., Ltd. Acrylic paint BW1001; ethyl acetate from Changzhou Yuanxing Chemical Co., Ltd.;

[0041] ③Prepare the mixed materials A~C to form the int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com