Self-insulating brick

A technology of self-insulation bricks and insulation holes, which is used in climate change adaptation, building materials, etc., can solve the problems of heavy weight, low strength and low drying shrinkage value of cement bricks, and achieve the effect of light bulk density and good waterproofing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

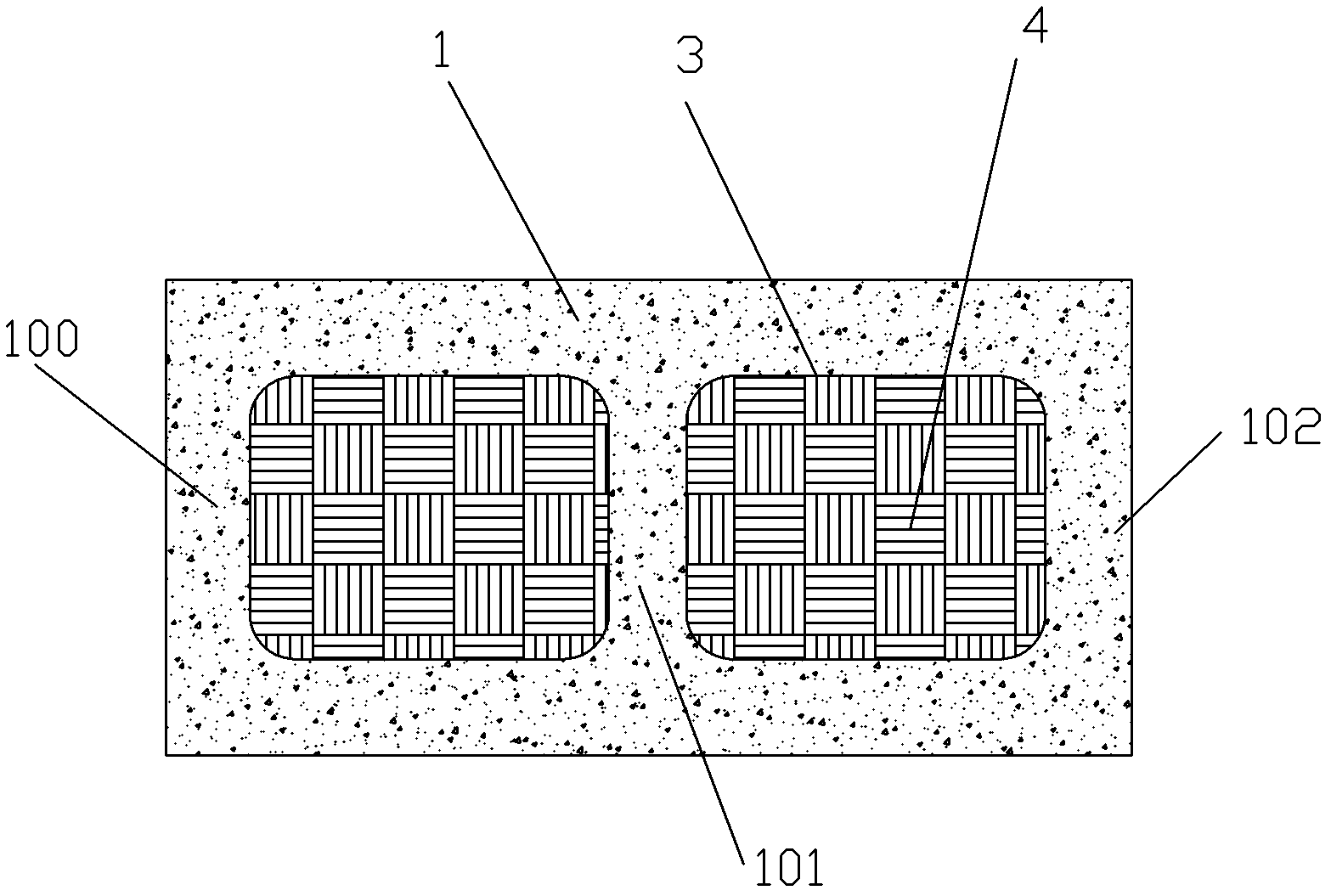

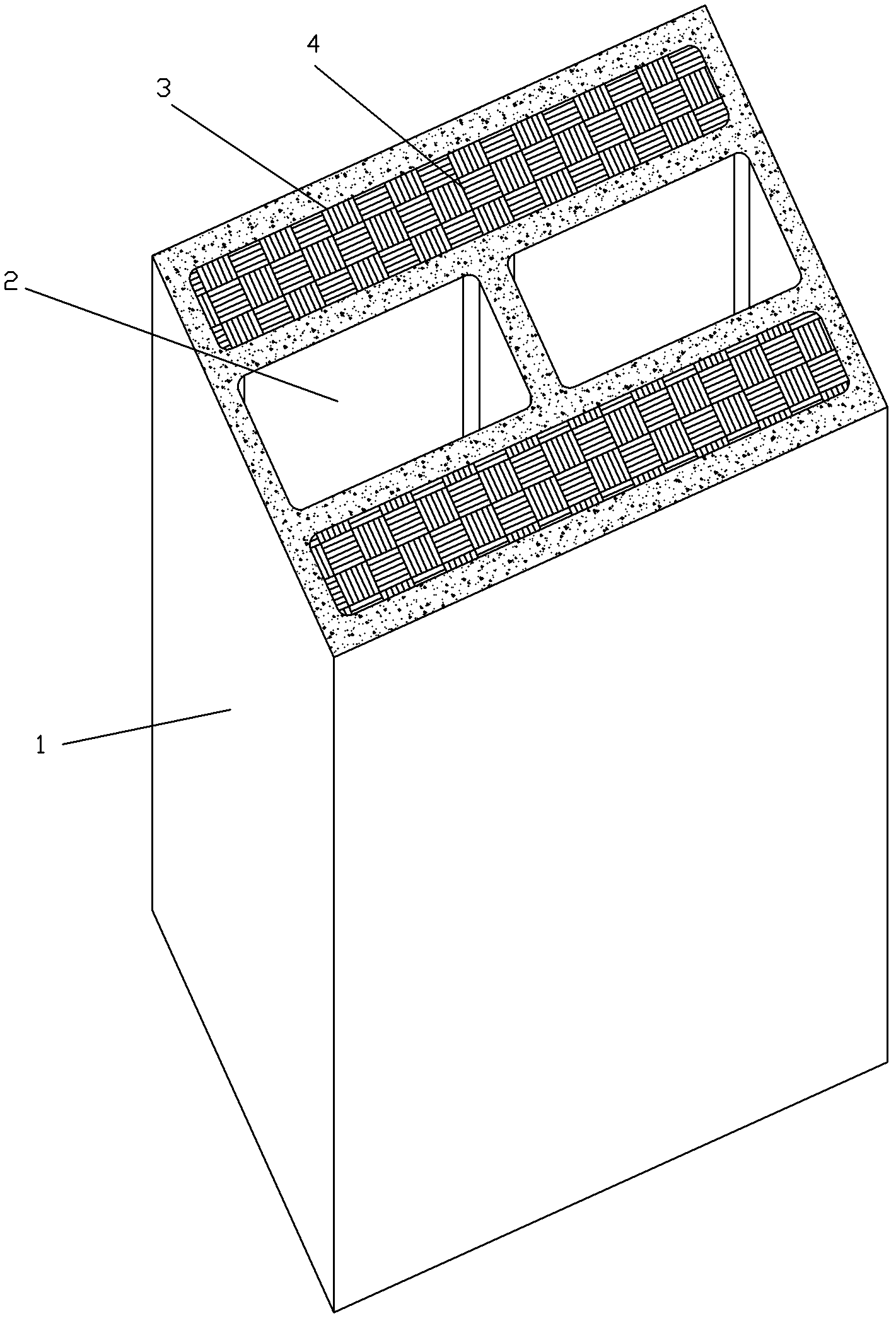

[0029] Self-insulation brick, it comprises brick body 1, and brick body 1 can be the same as the volume of existing brick body, is a cuboid shape, is provided with insulation hole 3 along height direction in brick body 1, is provided with insulation layer in insulation hole 3 4. Such as figure 1 As shown, the insulation hole 3 divides the wall into an inner layer 100, an intermediate layer 101 and an outer layer 102, and the insulation layer 4 is arranged in the insulation hole 3, and the insulation layer 4 is arranged between the inner layer 100 and the middle layer 101 and between the middle layer 101 and the middle layer 101. Between the outer layers 102.

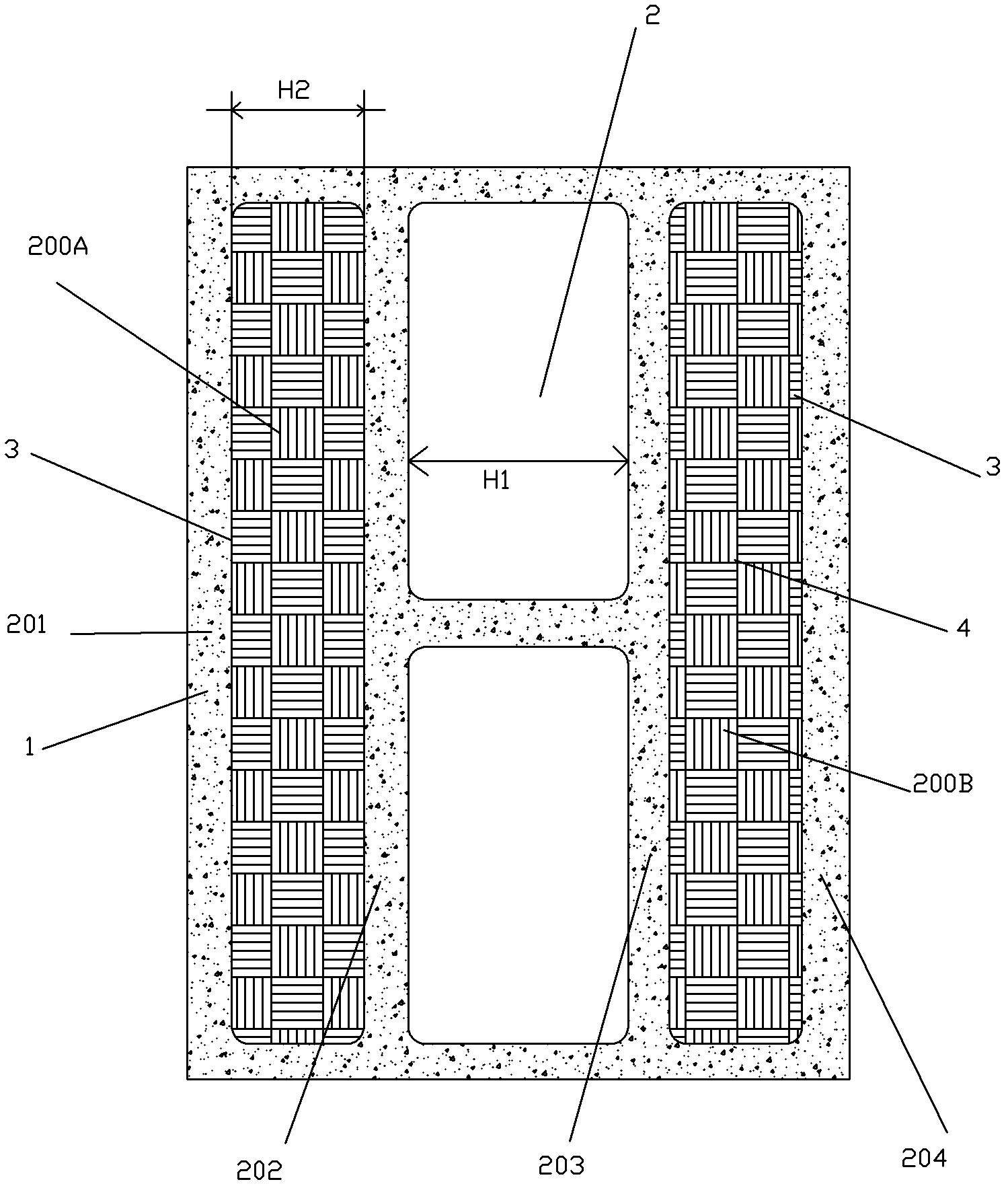

[0030] Such as figure 2 , image 3 As shown, the quantity of the heat preservation holes 3 can be two, and a vertical through hole 2 is also provided between the two heat preservation holes 3, the number of the vertical through holes 2 is 1-3, and a plurality of vertical through holes The holes are arranged laterall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com