Preparation method and application of spherical thermal insulating nanometer material

A nanomaterial and spherical technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low transmittance of visible light, poor heat insulation effect, complex process conditions, etc., and achieve energy-saving use and heat insulation Good effect and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the spherical heat-insulating nanomaterial provided in this example, the specific steps are as follows:

[0044] a) Weigh 0.3g SnCl 4 , dissolved in 80mL deionized water;

[0045] b) Stirring with magnetic force at room temperature for 10 minutes to obtain a light blue transparent solution 1;

[0046] c) Weigh 2.6058g SnCl 4 (10mmol) and 0.1141g SbCl 3 (0.5mmol), so that the molar ratio of Sb:Sn is (1:20), the two are dissolved in an appropriate amount of 2mol / L hydrochloric acid solution to obtain a colorless and transparent solution 2;

[0047] d) Dilute the ammonia solution to 1:1 for later use to obtain solution 3;

[0048] e) At 60°C, add 0.1g of cetyltrimethylammonium bromide, and use the double drop method to slowly and uniformly drop solutions 2 and 3 into solution 1 while stirring, so that the doping element antimony is in the system The concentration is 0.005mol / L, and the pH of the control solution system is less than 3;

[004...

Embodiment 2

[0062] The preparation method of this example is the same as that described in Example 1, except that in step c) the Sb doping molar ratio is 8%.

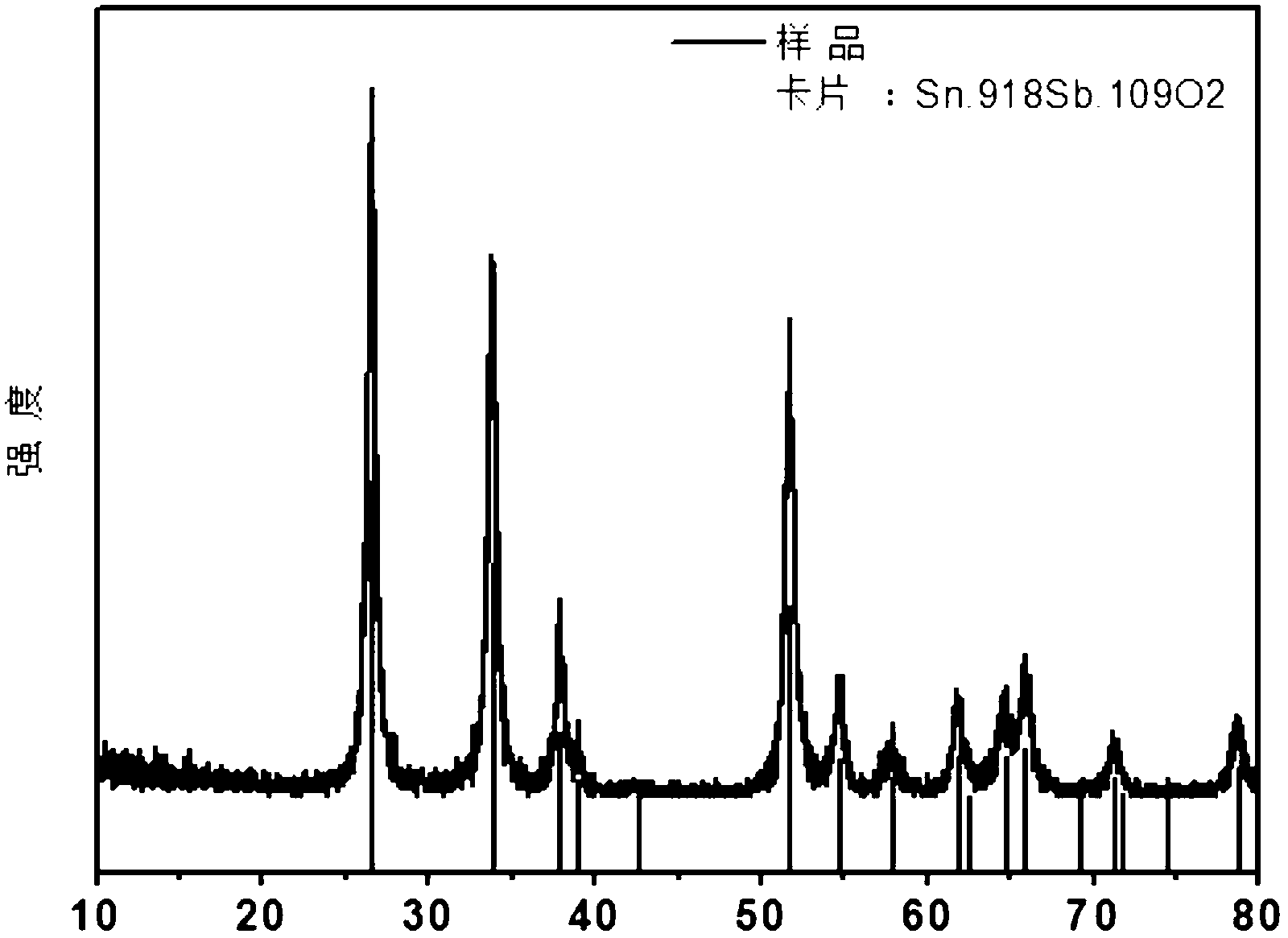

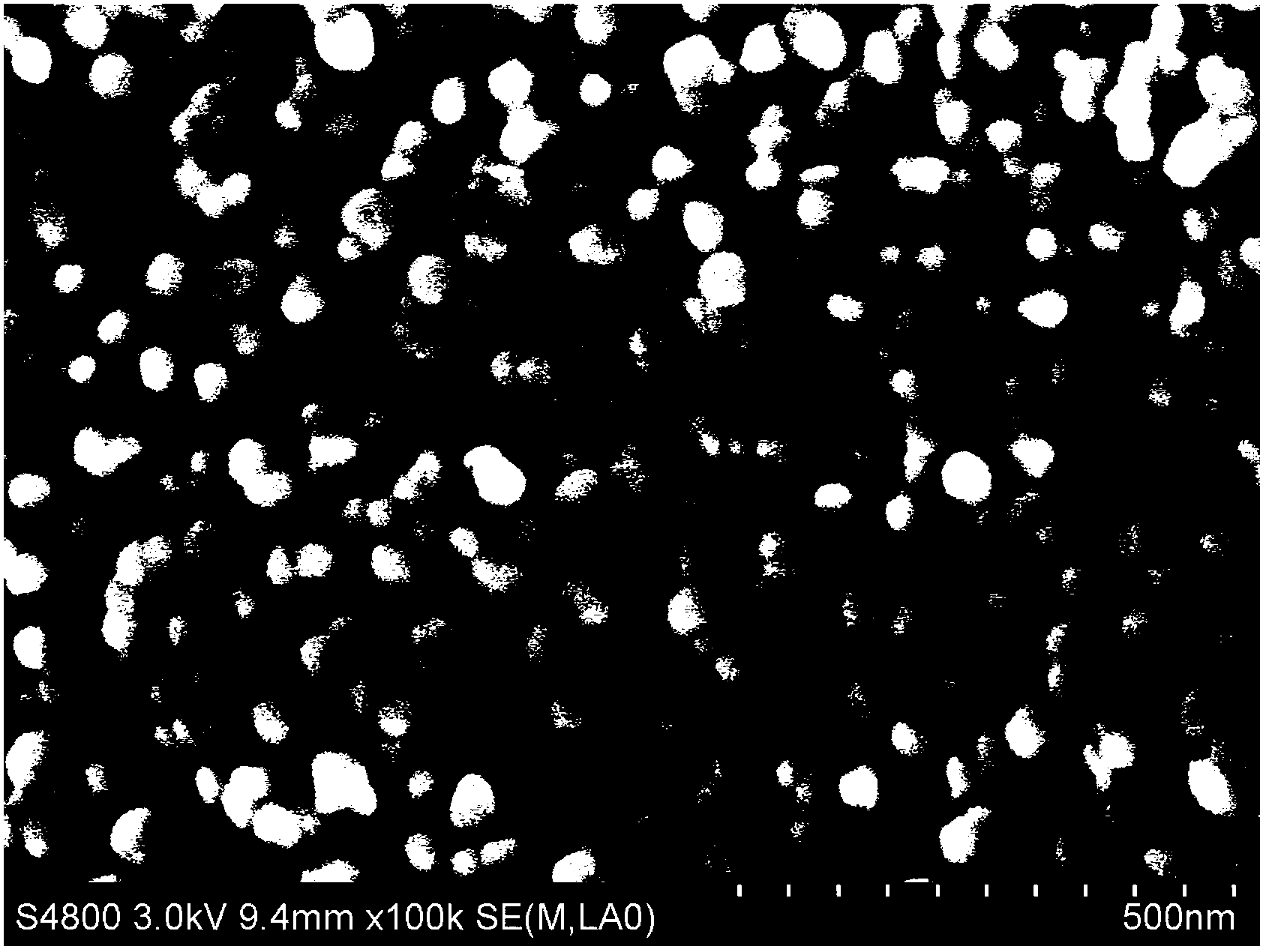

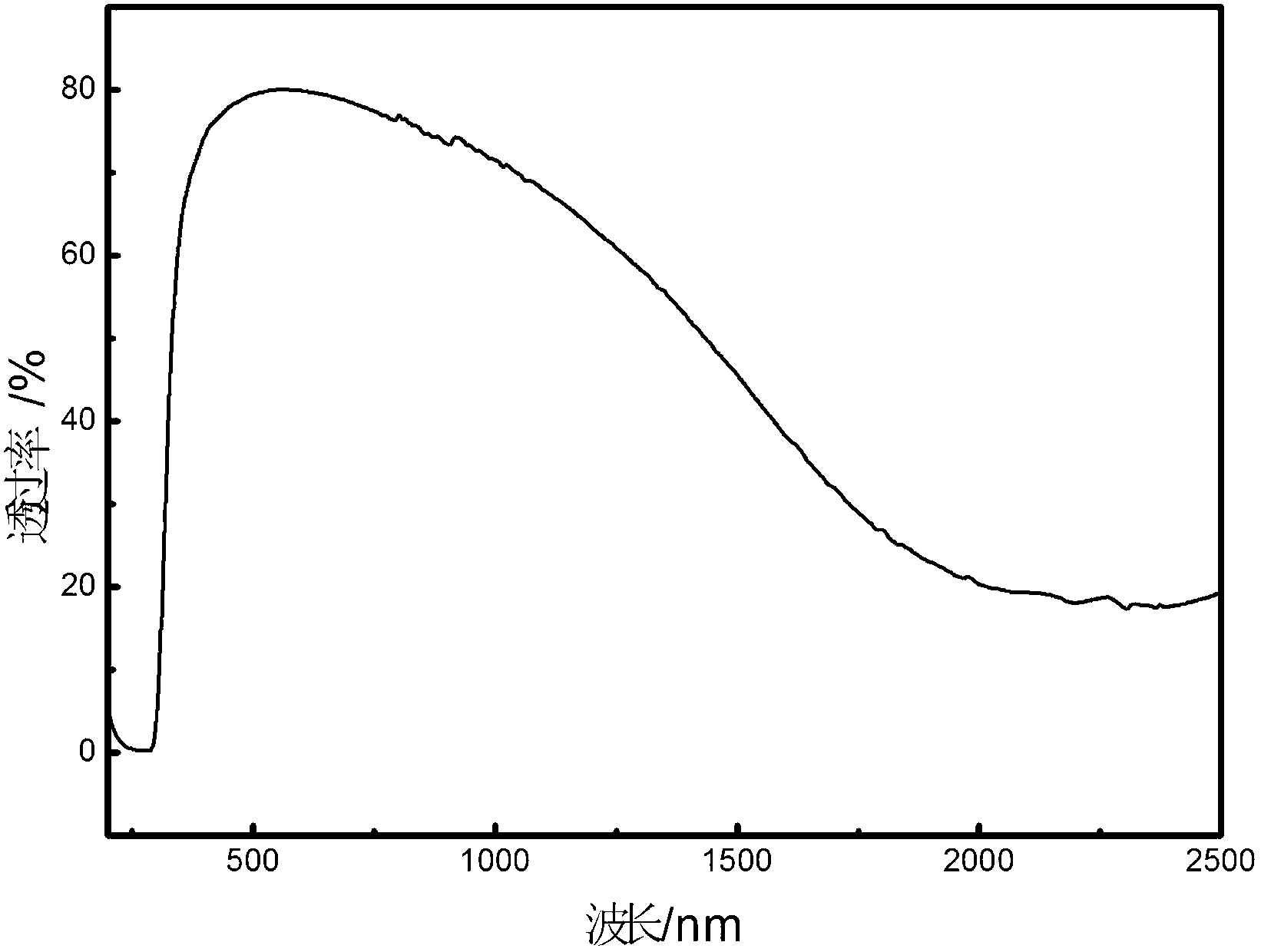

[0063] The analysis results of the X-ray diffraction pattern and the scanning electron microscope image of the heat-reflecting spherical nanomaterial prepared in this example are the same as those described in Example 1, and the analysis results of the ultraviolet-visible-near-infrared spectrum image of the heat-insulating transparent conductive film are the same as those of Example 1. It is basically the same as described in Example 1.

Embodiment 3

[0065] The preparation method of this example is the same as that described in Example 1, except that in step c) the Sb doping amount is 10%.

[0066] The analysis results of the X-ray diffraction pattern and the scanning electron microscope image of the heat-reflecting spherical nanomaterial prepared in this example are the same as those described in Example 1, and the analysis results of the ultraviolet-visible-near-infrared spectrum image of the heat-insulating transparent conductive film are the same as those of Example 1. It is basically the same as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com