Colorful multi-layer paint with thermal insulation function and preparation method thereof

A technology of thermal insulation and multi-layer coating, which is applied in the field of coatings, can solve the problems of lack of thermal insulation function, poor stability, single color, etc., and achieve the effects of shortening the temperature range, improving durability and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

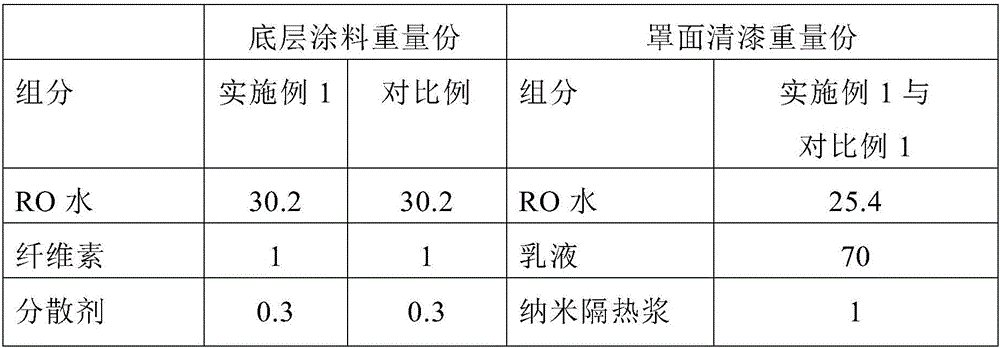

[0038] Embodiment 1 and comparative example 1

[0039]Table 1-3 is the batching of each component in embodiment 1 and comparative example 1, wherein, cellulose is ethyl cellulose ether, dispersant is hydrophobic copolymer sodium salt dispersant, antifreeze is propylene glycol, film-forming aid It is dodecyl alcohol ester, and the nano-aging anti-aging agent is nano-sized TiO 2 Slurry, nano heat insulation slurry is nano-arsenic trioxide or nano-alumina, inorganic protective colloid solution is magnesium lithium silicate aqueous solution, organic protective colloid solution is hydroxyethyl cellulose, rheological agent is silicon dioxide, coupling agent is titanium Ester coupling agent, PH regulator is 2-amino-2-methyl-1-propanol, fungicide is nitrogen-sulfur heterocyclic compound without organic volatiles, pigment and filler is calcined high-strength, heavy calcium , one or more of mica powder, talc powder or rutile titanium dioxide, the emulsion is water-based elastic pure ac...

Embodiment 2-4

[0067] Examples 2-4 adopt the same preparation method as Example 1, and the specific formulations are shown in Table 5-9.

[0068] Table 5 embodiment 2-4 primer formula

[0069]

[0070] Table 6 embodiment 2-4 main coating paint pigment component formula

[0071]

[0072]

[0073] Table 7 embodiment 2-4 main coat paint dispersion medium formula

[0074]

[0075] Table 8 embodiment 2-4 main coat paint varnish formula

[0076]

[0077]

[0078] Table 9 embodiment 2-4 finish varnish formula

[0079]

[0080] As mentioned above, the cellulose is ethyl cellulose ether, the dispersant is a hydrophobic copolymer sodium salt dispersant, the antifreeze is propylene glycol, the film-forming aid is dodecyl alcohol ester, and the nano-aging anti-aging agent is nano-scale TiO 2 Slurry, nano heat insulation slurry is nano silicon oxide or nano zinc oxide, inorganic protective colloid solution is magnesium lithium silicate aqueous solution, organic protective colloid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com