Stockpot

A soup pot and pot lid technology, which is applied to special materials of cooking utensils, lids of cooking utensils, cooking utensils, etc., can solve the problems of large heat loss, unfavorable energy saving, etc., and achieve the effect of fast heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

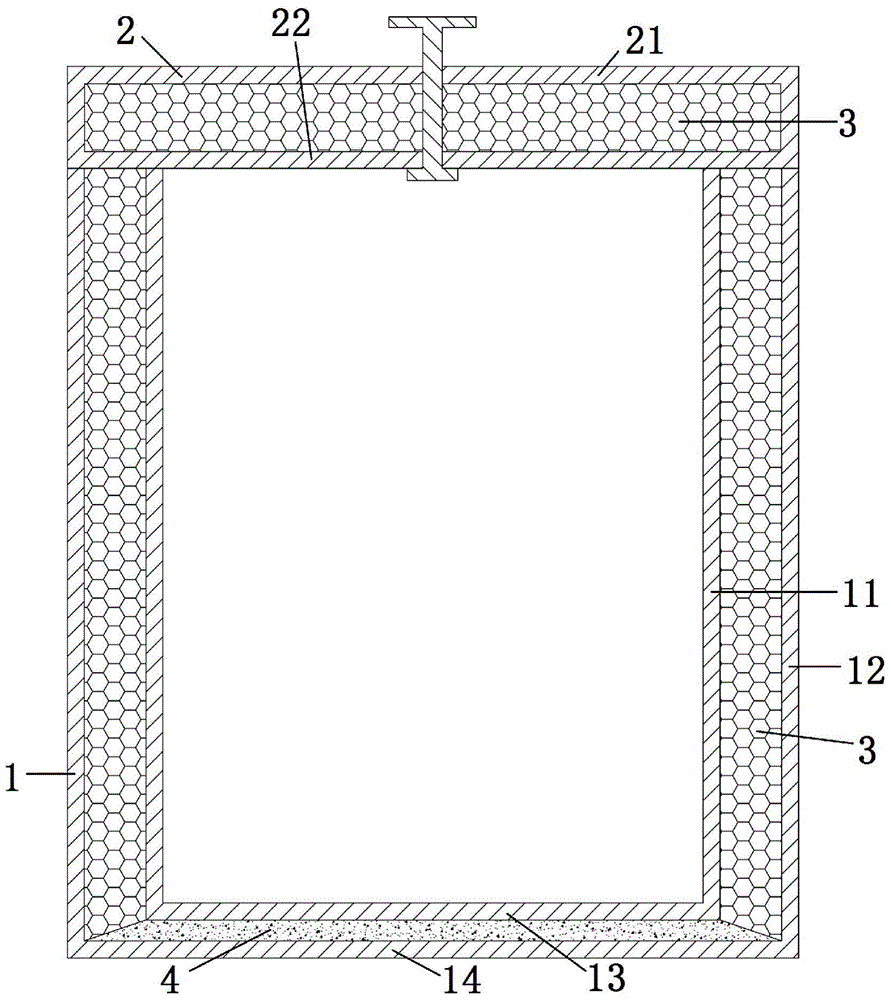

[0016] Such as figure 1 As shown, a soup pot, the soup pot includes a pot body 1 and a pot cover 2, the pot body 1 and the pot cover 2 are three-layer structure, the pot body 1 includes a pot wall and a pot bottom, wherein the pot wall Including inner layer pot wall 11 and outer layer pot wall 12, described pot bottom comprises inner layer pot bottom 13 and outer layer pot bottom 14, and described pot cover 2 comprises inner layer pot cover 22 and outer layer pot cover 21, described Between the inner pot wall 11 and the outer pot wall 12 is an expanded perlite filling layer 3, between the inner pot cover 22 and the outer pot cover 21 is an expanded perlite filling layer 3, and the inner layer Between the bottom of the pot 13 and the bottom of the outer layer of the pot 14 is a heat-conducting metal layer 4, the thickness of the heat-conducting metal layer 4 is between 0.3mm and 1.5mm; Expanded perlite filling layer 3 is added between the outer layers, so that the effect of he...

Embodiment 2

[0019] Such as figure 1 As shown, a soup pot, the soup pot includes a pot body 1 and a pot cover 2, the pot body 1 and the pot cover 2 are three-layer structure, the pot body 1 includes a pot wall and a pot bottom, wherein the pot wall Including inner layer pot wall 11 and outer layer pot wall 12, described pot bottom comprises inner layer pot bottom 13 and outer layer pot bottom 14, and described pot cover 2 comprises inner layer pot cover 22 and outer layer pot cover 21, described Between the inner pot wall 11 and the outer pot wall 12 is an expanded perlite filling layer 3, between the inner pot cover 22 and the outer pot cover 21 is an expanded perlite filling layer 3, and the inner layer Between the bottom of the pot 13 and the bottom of the outer layer of the pot 14 is a heat-conducting metal layer 4, the thickness of the heat-conducting metal layer 4 is between 0.3mm and 1.5mm; Expanded perlite filling layer 3 is added between the outer layers, so that the effect of he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com